Towards Optimization of Energy Consumption of Tello Quad-Rotor with Mpc Model Implementation

Abstract

1. Introduction

- Sensors for measuring attitude, such as gyroscopes to measure angular position and angular velocity, accelerometers to measure acceleration, and magnetometers to measure the direction of the magnetic field and scan the area and detect metals in space;

- Sensors for measuring the velocity and position of the drone, such as an altimeter, GPS, and camera;

- Sensors for detecting obstacles around the drone, such as ultrasonic sensors and telemeter lasers.

- Minimization of errors: indeed, this is the classic approach; the fewer the errors committed in the pursuit of the desired trajectory, the less energy spent [24];

- Fuzzy logic applied to altitude control: climbing or descending consumes double or even more energy because this movement causes the rotation of the four engines simultaneously, so one possibility is establishing fuzzy logic between the flight height and the battery state of charge [25];

- The search for an optimal trajectory: energy consumption can be reduced by using or avoiding air currents and thus by finding the flight path that is least costly in terms of energy compared to a direct flight to the destination [25].

2. Materials and Methods

- The conditions are taken into consideration to identify the dynamic mathematical model;

- The parameters of the Tello EDU quad-rotor are identified;

- Linear and nonlinear model predictive control is used;

- An in-depth comparison is made to show the effectiveness of a nonlinear controller and how the optimization of energy consumption can be achieved for the control part.

2.1. Tello Quad-Rotor Model

2.2. Quad-Rotor Mathematical Model

- The structure of the quad-rotor is assumed to be rigid and symmetrical, which means that the matrix of inertia is assumed to be diagonal;

- The propellers are assumed to be rigid in order to be able to neglect the effect of their deformation during rotation;

- The center of mass and the origin of the frame linked to the structure coincide;

- The lift and drag forces are proportional to the square of the rotors’ rotation speed, which is a very close approximation of the aerodynamic behavior;

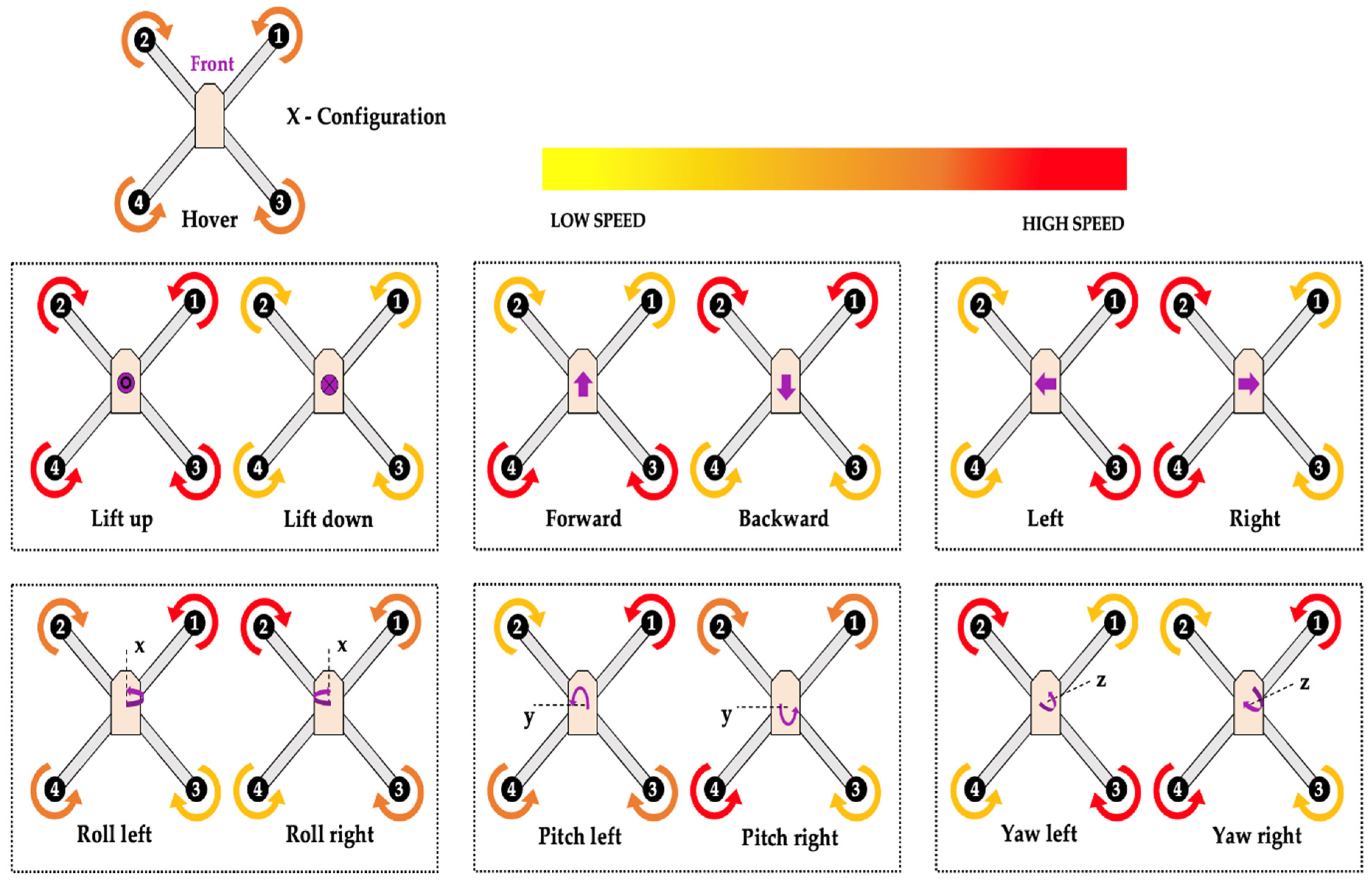

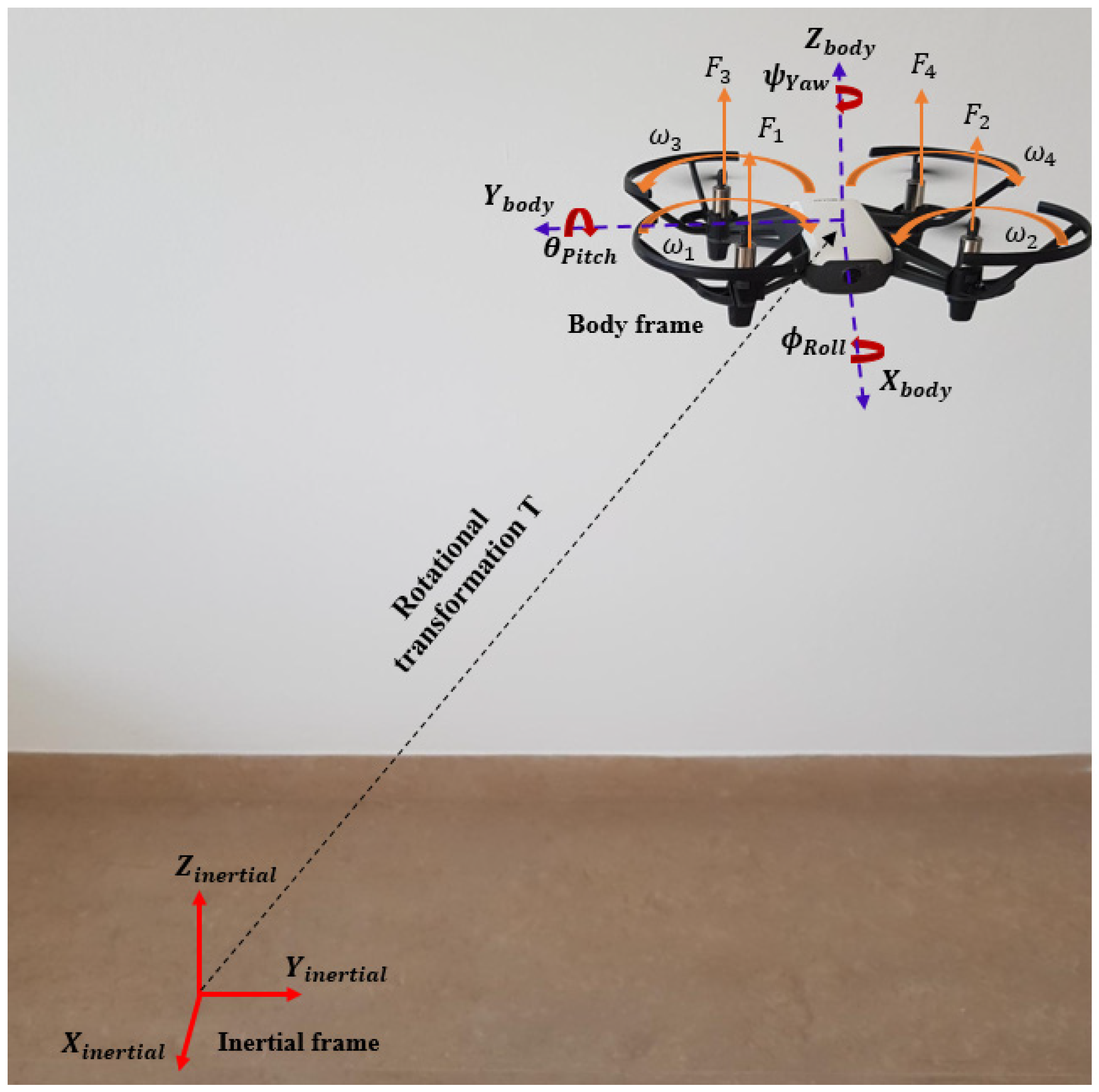

- To evaluate the quad-rotor’s mathematical model, two frames were used: a fixed inertial frame to the Earth and a second mobile frame fixed in the quad-rotor . The transformation matrix gives the passage between the body frame and the inertial frame, which contains the orientation and the mobile position reference relative to the fixed reference.

- The weight force of the quad-rotor is given by:

- The thrust forces created by the four rotors are perpendicular to the plane of the propellers and are proportional to the square of the rotational speed of the motors. The thrust forces are given by:

- The drag force is the coupling between the pressure force and the viscous frictional force.

- The inertial moments due to the thrust force: The rotation around the X- and Y-axes is due to the inertial moment created by the difference between the thrust forces of Rotors 2 and 4 and 1 and 3, respectively:

- The inertial moment due to drag forces: The rotation around the z-axis is due to the reactive torque caused by the drag torques in each propeller:

- The inertial moment resulting from aerodynamic friction is given by:

- Gyroscopic effect: This effect is defined as the difficulty of modifying the position or the orientation of the plane of rotation of a rotating mass. In this case, there are two gyroscopic moments. The gyroscopic moment of the helices is given by the expression:

- Dynamic equation of translation motion

- Dynamic equation of rotation motion

- The matrix that shows the relationship between forces/inertial moments and angular velocities of four motors

Identification of Parameters of the Tello EDU Drone

2.3. Control Strategy of Quad-Rotor System

- Linear Control Strategy: Linear control techniques were the first to be used for UAV flight control. Linear controllers are applied to a linearized model of the quad-rotor; linearization is applied around an equilibrium point using a Taylor-series expansion and the Jacobean method, which will be presented later [33,34,35,36].

- Nonlinear Control Strategy: Nonlinear controllers perform better because they are applied to the accurate quad-rotor model, which presents all of the critical nonlinearities of the dynamics [20]. The following presents the most frequently used method in UAV flight control. Usually, the application of a nonlinear controller can achieve higher performance with a nonlinear model of the UAV plant, but the main disadvantage is that it needs higher computational power [20,37,38,39].

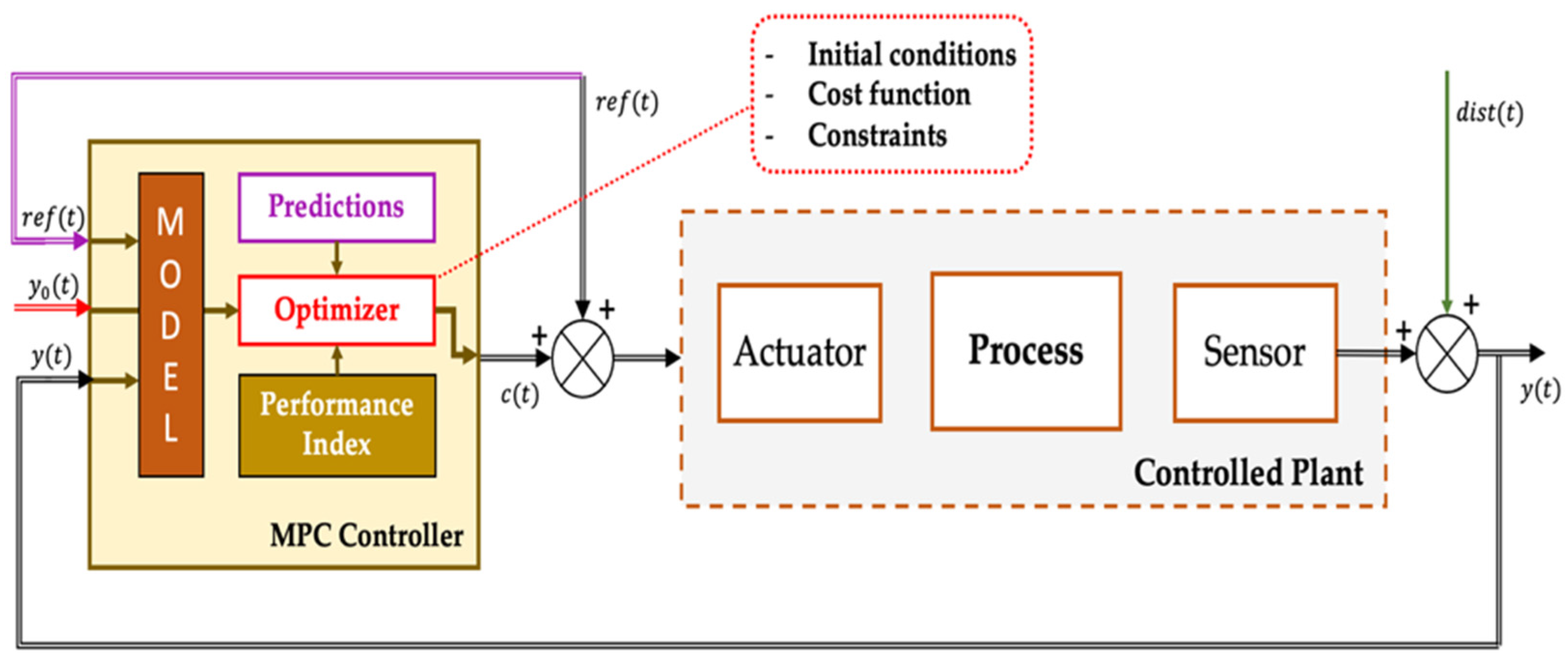

- The first scenario assumes that the dynamic model is linear, so MPC is also linear; this is very familiar in science when a dynamic model should be linearized around a defined point, called the equilibrium point.

- The second scenario entails taking the nonlinear model as it is and then, according to the constraints, building an efficient nonlinear MPC controller. The second method presents different complications and requires much more computational power.

| Controller Type | Linearity Type | Stability and Time Response | Computation Time |

|---|---|---|---|

| PID controller [36] | Linear | Low stability in higher disturbances, acceptable response time | Low |

| Linear quadratic regulator [21] | Linear | Good stability with slow response time | Very low |

| H-infinity optimal control [35] | Linear | High stability, medium response time | Medium |

| Backstepping control [24,40,41] | Nonlinear | Not robust when uncertainties are present in the model of the plant | Medium |

| Sliding mode control [42,43] | Nonlinear | Robust, even in the presence of uncertainties and disturbances | High |

| Adaptive control [18,44,45] | Nonlinear | Good stability in the presence of uncertainties | High |

| Model predictive control (MPC) [27,28,31,46] | Linear or nonlinear | Stability is not guaranteed, high optimization for different constraints | High |

2.3.1. Model Predictive Control Concept

- : Cost function for output reference tracking;

- : Cost function for manipulated variable tracking;

- : Cost function for manipulated variable movement suppression;

- : Cost function for constraint violation;

- : The quadratic program.

- , which represents the dynamic of the system;

- , which represents the outputs of the system;

- ;

- ;

- , , which represents state variables.

2.3.2. Linear Model Predictive Control

- Linearization of the quad-rotor system

- Design of Linear MPC for the Tello Quad-rotor System

- -

- mo: 6 measured outputs that represent the state vector ;

- -

- md: 0 measured disturbances, where all disturbances applied to the quad-rotor are neglected.

- -

- mv: 4 manipulated variables , which represent the input control variables.

2.3.3. Nonlinear Model Predictive Control

- The prediction model can be nonlinear and include time-varying parameters.

- The equality and inequality constraints can be nonlinear.

- The scalar cost function to be minimized can be a nonquadratic (linear or nonlinear) function of the decision variables.

- Design of Nonlinear MPC for the Tello quad-rotor system

3. Results and Discussion

- Error position tracking;

- Velocity tracking;

- Control input tracking.

3.1. Straight Curvature Reference Trajectory

3.2. Circular Reference Trajectory

3.3. Helical Reference Trajectory

3.4. Performance measurements and ExTime

4. Summary and Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| UAV | Unmanned aerial vehicles |

| GPS | Global Positioning System |

| MPC | Model predictive control |

| LMPC | Linear model predictive control |

| NLMPC | Nonlinear model predictive control |

| LQ | Linear quadratic controller |

| MV | Manipulated variables |

| MD | Measured disturbances |

| MO | Measured outputs |

| PID | Proportional–Integral–Derivative Controller |

| QP | Quadratic program |

References

- Barnhart, R.K.; Hottman, S.B.; Marshall, D.M.; Shappee, E. Introduction to Unmanned Aircraft Systems, 1st ed.; CRC Press: Boca Raton, FL, USA, 2016. [Google Scholar] [CrossRef]

- Nonami, K.; Kendoul, F.; Suzuki, S.; Wang, W.; Nakazawa, D. Autonomous Flying Robots: Unmanned Aerial Vehicles and Micro Aerial Vehicles; Springer: Tokyo, Japan, 2010. [Google Scholar] [CrossRef]

- Padfield, G.D.; Kluever, C.A.; Young, T.M.; Keane, A.J.; Sóbester, A.; Scanlan, J.P. Design of Unmanned Aerial Systems. In Design of Unmanned Aerial Systems; Wiley: New York, NY, USA, 2020. [Google Scholar] [CrossRef]

- Dalamagkidis, K. Classification of Uavs; Springer: Dordrecht, The Netherlands, 2014. [Google Scholar] [CrossRef]

- Idrissi, M.; Salami, M.; Annaz, F. A Review of Quadrotor Unmanned Aerial Vehicles: Applications, Architectural Design and Control Algorithms. J. Intell. Robot. Syst. 2022, 104, 22. [Google Scholar] [CrossRef]

- Jacewicz, M.; Żugaj, M.; Głębocki, R.; Bibik, P. Quadrotor Model for Energy Consumption Analysis. Energies 2022, 15, 7136. [Google Scholar] [CrossRef]

- Zhang, X.; Li, X.; Wang, K.; Lu, Y. A Survey of Modelling and Identification of Quadrotor Robot. Abstr. Appl. Anal. 2014, 2014, 320526. [Google Scholar] [CrossRef]

- Ye, J.; Wang, J.; Lv, P. Mutual Aerodynamic Interference Mechanism Analysis of an “X” Configuration Quadcopter. Aerospace 2021, 8, 349. [Google Scholar] [CrossRef]

- Balestrieri, E.; Daponte, P.; De Vito, L.; Lamonaca, F. Sensors and Measurements for Unmanned Systems: An Overview. Sensors 2021, 21, 1518. [Google Scholar] [CrossRef]

- Guan, S.; Zhu, Z.; Wang, G. A Review on UAV-Based Remote Sensing Technologies for Construction and Civil Applications. Drones 2022, 6, 117. [Google Scholar] [CrossRef]

- Barbaraci, G. Modeling and control of a quadrotor with variable geometry arms. J. Unmanned Veh. Syst. 2015, 3, 35–57. [Google Scholar] [CrossRef]

- Tahir, Z.; Jamil, M.; Liaqat, S.A.; Mubarak, L.; Tahir, W.; Gilani, S.O. State Space System Modeling of a Quad Copter UAV. Indian J. Sci. Technol. 2016, 9. [Google Scholar] [CrossRef]

- Chovancová, A.; Fico, T.; Chovanec, Ľ.; Hubinsk, P. Mathematical Modelling and Parameter Identification of Quadrotor (a survey). Procedia Eng. 2014, 96, 172–181. [Google Scholar] [CrossRef]

- Mokhtari, M.R.; Cherki, B. A new robust control for minirotorcraft unmanned aerial vehicles. ISA Trans. 2015, 56, 86–101. [Google Scholar] [CrossRef]

- Bodó, Z.; Lantos, B. Modeling and Control of Outdoor Quadrotor UAVs. In Proceedings of the SISY 2018—IEEE 16th International Symposium on Intelligent Systems and Informatics, Subotica, Serbia, 13–15 September 2018; pp. 111–116. [Google Scholar] [CrossRef]

- Ducard, G.J.; Allenspach, M. Review of designs and flight control techniques of hybrid and convertible VTOL UAVs. Aerosp. Sci. Technol. 2021, 118, 107035. [Google Scholar] [CrossRef]

- Chand, A.N.; Kawanishi, M.; Narikiyo, T. Adaptive pole placement pitch angle control of a flapping-wing flying robot. Adv. Robot. 2016, 30, 1039–1049. [Google Scholar] [CrossRef]

- Chen, N.; Song, F.; Li, G.; Sun, X.; Ai, C. An adaptive sliding mode backstepping control for the mobile manipulator with nonholonomic constraints. Commun. Nonlinear Sci. Numer. Simul. 2013, 18, 2885–2899. [Google Scholar] [CrossRef]

- Bogdanov, A.; Carlsson, M.; Harvey, G.; Hunt, J.; Kieburtz, D.; van der Merwe, R.; Wan, E. State-dependent riccati equation control of a small unmanned helicopter. In Proceedings of the AIAA Guidance, Navigation, and Control Conference and Exhibit, Austin, TX, USA, 11–14 August 2003. [Google Scholar] [CrossRef]

- Raffo, G.V.; Ortega, M.G.; Rubio, F.R. Robust Nonlinear Control for Path Tracking of a Quad-Rotor Helicopter. Asian J. Control. 2015, 17, 142–156. [Google Scholar] [CrossRef]

- How, J.P.; Frazzoli, E.; Chowdhary, G.V. Linear Flight Control Techniques for Unmanned Aerial Vehicles; Springer: Dordrecht, The Netherlands, 2015. [Google Scholar] [CrossRef]

- Khan, N.; Ullah, F.U.M.; Afnan; Ullah, A.; Lee, M.Y.; Baik, S.W. Batteries State of Health Estimation via Efficient Neural Networks With Multiple Channel Charging Profiles. IEEE Access 2020, 9, 7797–7813. [Google Scholar] [CrossRef]

- Kim, J.; Baek, S.; Jeon, S.; Cha, H. DynLiB: Maximizing Energy Availability of Hybrid Li-Ion Battery Systems. IEEE Trans. Comput. Des. Integr. Circuits Syst. 2022, 41, 3850–3861. [Google Scholar] [CrossRef]

- Bodó, Z.; Lantos, B. Integrating Backstepping Control of Outdoor Quadrotor UAVs. Period. Polytech. Electr. Eng. Comput. Sci. 2019, 63, 122–132. [Google Scholar] [CrossRef]

- Gao, F.; Wang, L.; Wang, K.; Wu, W.; Zhou, B.; Han, L.; Shen, S. Optimal Trajectory Generation for Quadrotor Teach-and-Repeat. IEEE Robot. Autom. Lett. 2019, 4, 1493–1500. [Google Scholar] [CrossRef]

- Ryzerobotics. User Manual 2018.09; Ryze Robotics: Shenzhen, China, 2018; 22p. [Google Scholar]

- Ru, P.; Subbarao, K. Nonlinear Model Predictive Control for Unmanned Aerial Vehicles. Aerospace 2017, 4, 31. [Google Scholar] [CrossRef]

- Ławryńczuk, M.; Nebeluk, R. Computationally Efficient Nonlinear Model Predictive Control Using the L1 Cost-Function. Sensors 2021, 21, 5835. [Google Scholar] [CrossRef]

- Rubio, A.A.; Seuret, A.; Mannisi, A.; Ariba, Y.; Arce, A. Optimal control strategies for load carrying drones. In Delays and Networked Control Systems; Springer: Cham, Switzerland, 2016; Volume 6, pp. 183–197. [Google Scholar] [CrossRef]

- Al Younes, Y.; Barczyk, M. Nonlinear Model Predictive Horizon for Optimal Trajectory Generation. Robotics 2021, 10, 90. [Google Scholar] [CrossRef]

- Benotsmane, R.; Reda, A.; Vasarhelyi, J. Model Predictive Control for Autonomous Quadrotor Trajectory Tracking. In Proceedings of the 2022 23rd International Carpathian Control Conference (ICCC 2022), Bolzano, Italy, 27 June–1 July 2022; pp. 215–220. [Google Scholar] [CrossRef]

- Roy, R.; Islam, M.; Sadman, N.; Mahmud, M.; Gupta, K.; Ahsan, M. A Review on Comparative Remarks, Performance Evaluation and Improvement Strategies of Quadrotor Controllers. Technologies 2021, 9, 37. [Google Scholar] [CrossRef]

- Hongwei, M.; Ali, S.M.; Liwei, Q.; Farid, G. A Review on Linear and Nonlinear Control Techniques for Position and Attitude Control of a Quadrotor. Control. Intell. Syst. 2017, 45, 43–57. [Google Scholar] [CrossRef]

- Emran, B.J.; Najjaran, H. A review of quadrotor: An underactuated mechanical system. Annu. Rev. Control. 2018, 46, 165–180. [Google Scholar] [CrossRef]

- Araar, O.; Aouf, N. Full linear control of a quadrotor UAV, LQ vs H∞. In Proceedings of the 2014 UKACC International Conference on Control (CONTROL 2014), Loughborough, UK, 9–11 July 2014; pp. 133–138. [Google Scholar] [CrossRef]

- Koszewnik, A. The Parrot UAV Controlled by PID Controllers. Acta Mech. Autom. 2014, 8, 65–69. [Google Scholar] [CrossRef]

- Rawlings, J.B.; Meadows, E.S.; Muske, A.D.K.R. Nonlinear Model Predictive Control: A Tutorial and Survey. IFAC Proc. Vol. 1994, 27, 185–197. [Google Scholar] [CrossRef]

- Isidori, A.; Marconi, L.; Serrani, A. Robust nonlinear motion control of a helicopter. IEEE Trans. Autom. Control 2003, 48, 413–426. [Google Scholar] [CrossRef]

- Qin, S.J.; Badgwell, T.A. An Overview of Nonlinear Model Predictive Control Applications. In Nonlinear Model Predictive Control; Birkhäuser: Basel, Switzerland, 2000; pp. 369–392. [Google Scholar] [CrossRef]

- Bentarzi, H.; Dekhandji, F.Z.; Saibi, A.; Boushaki, R.; Belaidi, H. Backstepping Control of Drone. Eng. Proc. 2022, 14, 4. [Google Scholar] [CrossRef]

- Lee, K.U.; Choi, Y.H.; Park, J.B. Backstepping Based Formation Control of Quadrotors with the State Transformation Technique. Appl. Sci. 2017, 7, 1170. [Google Scholar] [CrossRef]

- Herrera, M.; Chamorro, W.; Gómez, A.P.; Camacho, O. Sliding Mode Control: An Approach to Control a Quadrotor. In Proceedings of the 2015 Asia-Pacific Conference on Computer-Aided System Engineering (APCASE 2015), Quito, Ecuador, 14–16 July 2015; pp. 314–319. [Google Scholar] [CrossRef]

- Doan, Q.V.; Vo, A.T.; Le, T.D.; Kang, H.-J.; Nguyen, N.H.A. A Novel Fast Terminal Sliding Mode Tracking Control Methodology for Robot Manipulators. Appl. Sci. 2020, 10, 3010. [Google Scholar] [CrossRef]

- Lungu, M.; Lungu, R. Adaptive backstepping flight control for a mini-UAV. Int. J. Adapt. Control Signal Process. 2012, 27, 635–650. [Google Scholar] [CrossRef]

- Deng, Z.; Zhu, H.; Lin, S. Adaptive Sliding Mode Control Method for Reconfigurable Modular Robots under Dynamic Constraints. Acad. J. Manuf. Eng. 2020, 18, 16–20. [Google Scholar]

- Camacho, C.B.E.F. Model Predictive Control; Springer: London, UK, 2000. [Google Scholar] [CrossRef]

- Mądziel, M.; Jaworski, A.; Kuszewski, H.; Woś, P.; Campisi, T.; Lew, K. The Development of CO2 Instantaneous Emission Model of Full Hybrid Vehicle with the Use of Machine Learning Techniques. Energies 2022, 15, 142. [Google Scholar] [CrossRef]

- Kamel, M.; Burri, M.; Siegwart, R. Linear vs Nonlinear MPC for Trajectory Tracking Applied to Rotary Wing Micro Aerial Vehicles. IFAC-PapersOnLine 2017, 50, 3463–3469. [Google Scholar] [CrossRef]

- Domański, P.D. Performance Assessment of Predictive Control—A Survey. Algorithms 2020, 13, 97. [Google Scholar] [CrossRef]

- Benotsmane, R.; Vásárhelyi, J. Nonlinear Model Predictive Control for Autonomous Quadrotor Trajectory Tracking. In Lecture Notes in Mechanical Engineering, 4th ed.; Jármai, K., Cservenák, Á., Eds.; Springer: Cham, Switzerland, 2022; pp. 24–34. [Google Scholar] [CrossRef]

| Parameters | Values |

|---|---|

| Mass | 0.8 [kg] |

| 0.0097 | |

| 0.0097 | |

| 0.017 | |

| b | 1 |

| d | 0.08 |

| l | 0.06 [m] |

| g | 9.81 [m/s2] |

| MPC Parameters | |

|---|---|

| Sample time () | 0.1 s |

| Prediction horizon (P) | 20 s |

| Control horizon (M) | 3 s |

| MPC Constraints | |

| Boundaries of | [−10–12] Nm |

| Boundaries of | [−10–12] Nm |

| Boundaries of | [−10–12] Nm |

| Boundaries of | [−10–12] Nm |

| MPC Weights | |

| Translation motion along | 1 |

| Translation motion along | 1 |

| Translation motion along | 1 |

| Pitch motion along | 0.1 |

| Roll motion along | 0.1 |

| Yaw motion along | 0.1 |

| Nonlinear MPC Parameters | |

|---|---|

| Sample time () | 0.1 s |

| Prediction Horizon (P) | 18 s |

| Control Horizon (M) | 3 s |

| Nonlinear MPC Constraints | |

| Boundaries of | [0–12] Nm |

| Boundaries of | [0–10] Nm |

| Boundaries of | [0–10] Nm |

| Boundaries of | [0–10] Nm |

| Nonlinear MPC Weights | |

| Translation motion along | 1 |

| Translation motion along | 1 |

| Translation motion along | 1 |

| Pitch motion along | 1 |

| Roll motion along | 1 |

| Yaw motion along | 1 |

| Trajectory/Controller | 1st Trajectory | 2nd Trajectory | 3rd Trajectory | |||

|---|---|---|---|---|---|---|

| Δu [Nm]/ ExTime [ms] | Δu | ExTime | Δu | ExTime | Δu | ExTime |

| LMPC | 3.1678 | 64 | 2.7054 | 63 | 1.4229 | 62 |

| NLMPC | 5.9188 | 6.8 | 5.2379 | 6 | 4.8955 | 5.7 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Benotsmane, R.; Vásárhelyi, J. Towards Optimization of Energy Consumption of Tello Quad-Rotor with Mpc Model Implementation. Energies 2022, 15, 9207. https://doi.org/10.3390/en15239207

Benotsmane R, Vásárhelyi J. Towards Optimization of Energy Consumption of Tello Quad-Rotor with Mpc Model Implementation. Energies. 2022; 15(23):9207. https://doi.org/10.3390/en15239207

Chicago/Turabian StyleBenotsmane, Rabab, and József Vásárhelyi. 2022. "Towards Optimization of Energy Consumption of Tello Quad-Rotor with Mpc Model Implementation" Energies 15, no. 23: 9207. https://doi.org/10.3390/en15239207

APA StyleBenotsmane, R., & Vásárhelyi, J. (2022). Towards Optimization of Energy Consumption of Tello Quad-Rotor with Mpc Model Implementation. Energies, 15(23), 9207. https://doi.org/10.3390/en15239207