Experimental Assessment of the Performance and Fine Particulate Matter Emissions of a LPG-Diesel Dual-Fuel Compression Ignition Engine

Abstract

1. Introduction

- Determine the maximum diesel substitution by LPG until the knock phenomenon at different engine loads without any engine modification.

- Evaluate the impact of LPG substitution on emissions PM2.5 and the performance of the engine.

- Measure the diesel saved when the engine runs in dual-fuel mode.

2. Experimental Setup

2.1. Test Cell

2.2. LPG Substitution

2.3. Experimental Procedure

3. Results and Discussion

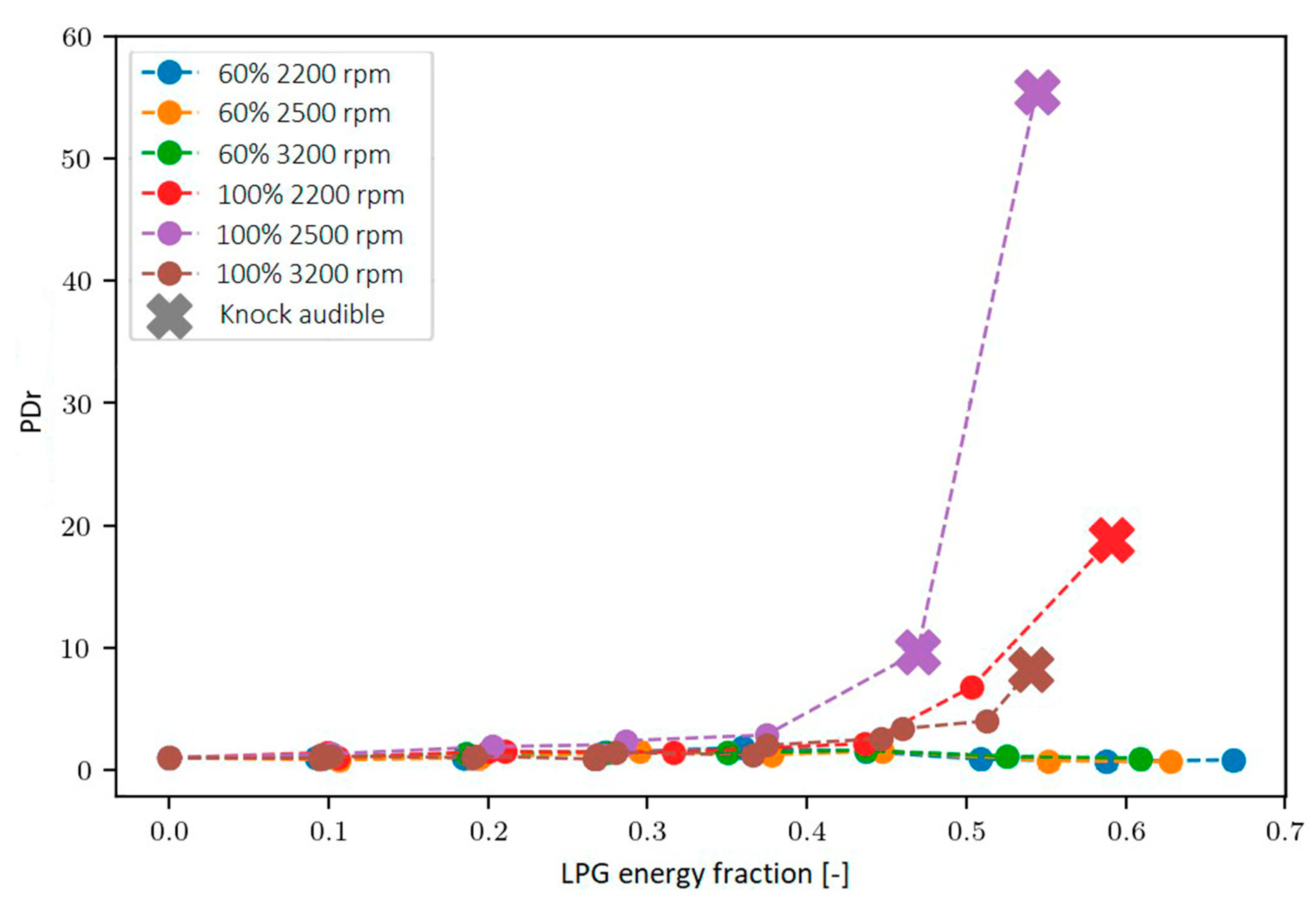

3.1. Dual Operation Limits

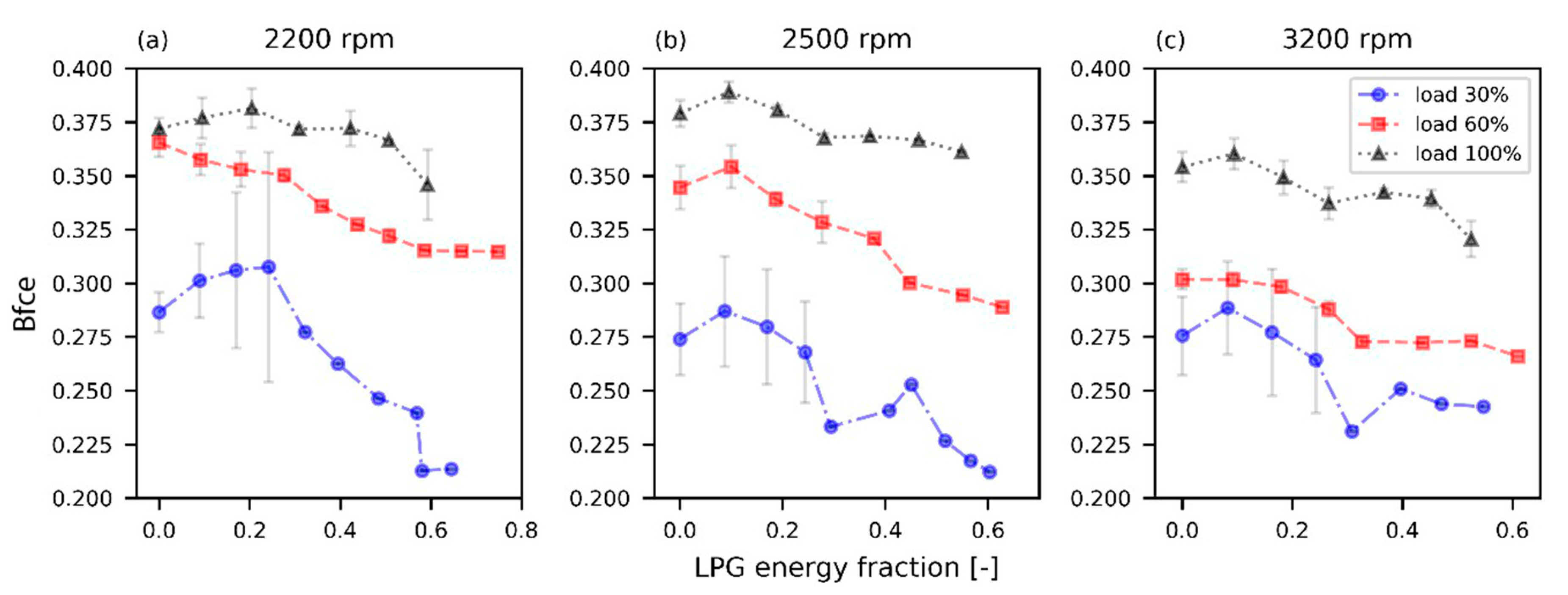

3.2. Engine Performance

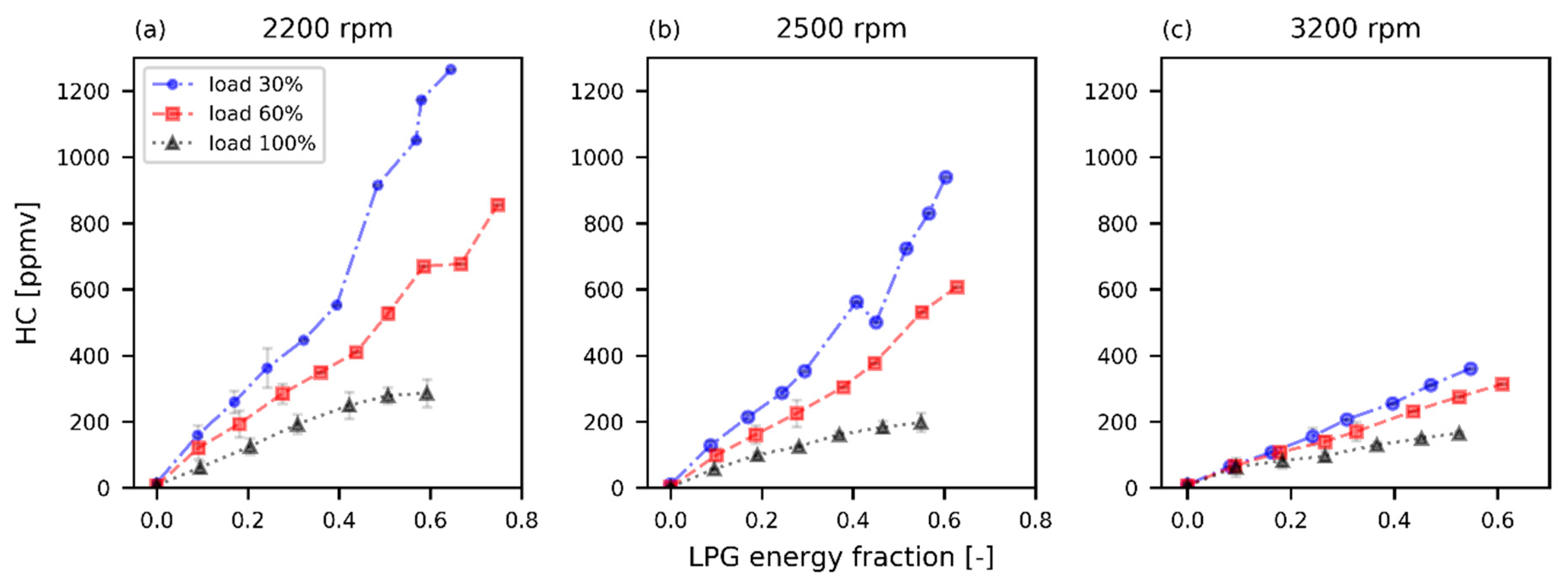

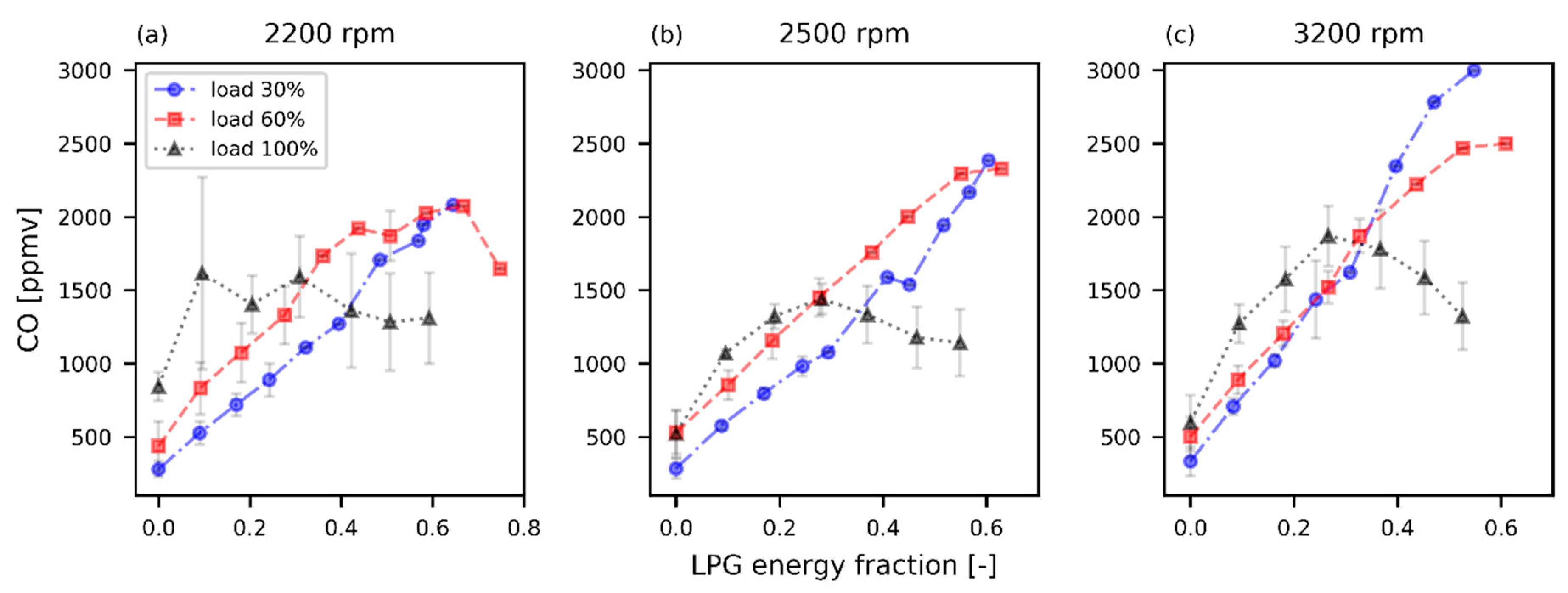

3.3. Emissions

4. Conclusions

- -

- LPG diesel dual-fuel mode operation was possible without knocking in operations at low and medium loads. However, knock occurred at full load, both for a rotation regime of 2200 rpm, 2500 rpm and 3200 rpm, with an LPG energy fraction of 59%, 55% and 53%, respectively. The high knock tendency is caused by the low cetane number of the LPG and a high compression ratio of the engine, which induce high temperature in the combustion chamber during the compression stage.

- -

- A small increase in engine brake fuel conversion efficiency was obtained, especially at full load, but it decreases as the LPG energy fraction increases. This is explained by the fact that for larger fractions of LPG, the amount of pilot fuel decreases, and the greater the amount of diesel, the better and stronger the ignition, which leads to better combustion. If the fuel savings obtained for the maximum fractions of LPG are considered, a saving of 54.3% of specific fuel consumption is achieved.

- -

- The emissions of HC and CO increased as a larger fraction of LPG was injected into the engine. The rate of formation of HC emissions increases while the load level is lower and similarly increases if the engine speed is lower. CO emissions have a dependence on the level of engine load; at full load, these emissions can decrease. These emissions are due to incomplete combustion (low combustion temperature). In addition, an increase in the ignition delay occurs as the amount of LPG injected increases, which influences the combustion of the mixture.

- -

- NOx emissions can be reduced depending on the engine operating conditions. At low loads, these emissions decrease while the exhaust gas temperature decreases. However, at full load operation, they could increase while the exhaust gas temperature decreases. That is explained by the equivalence ratio used, considering that it is greater (less air) than the low and medium load.

- -

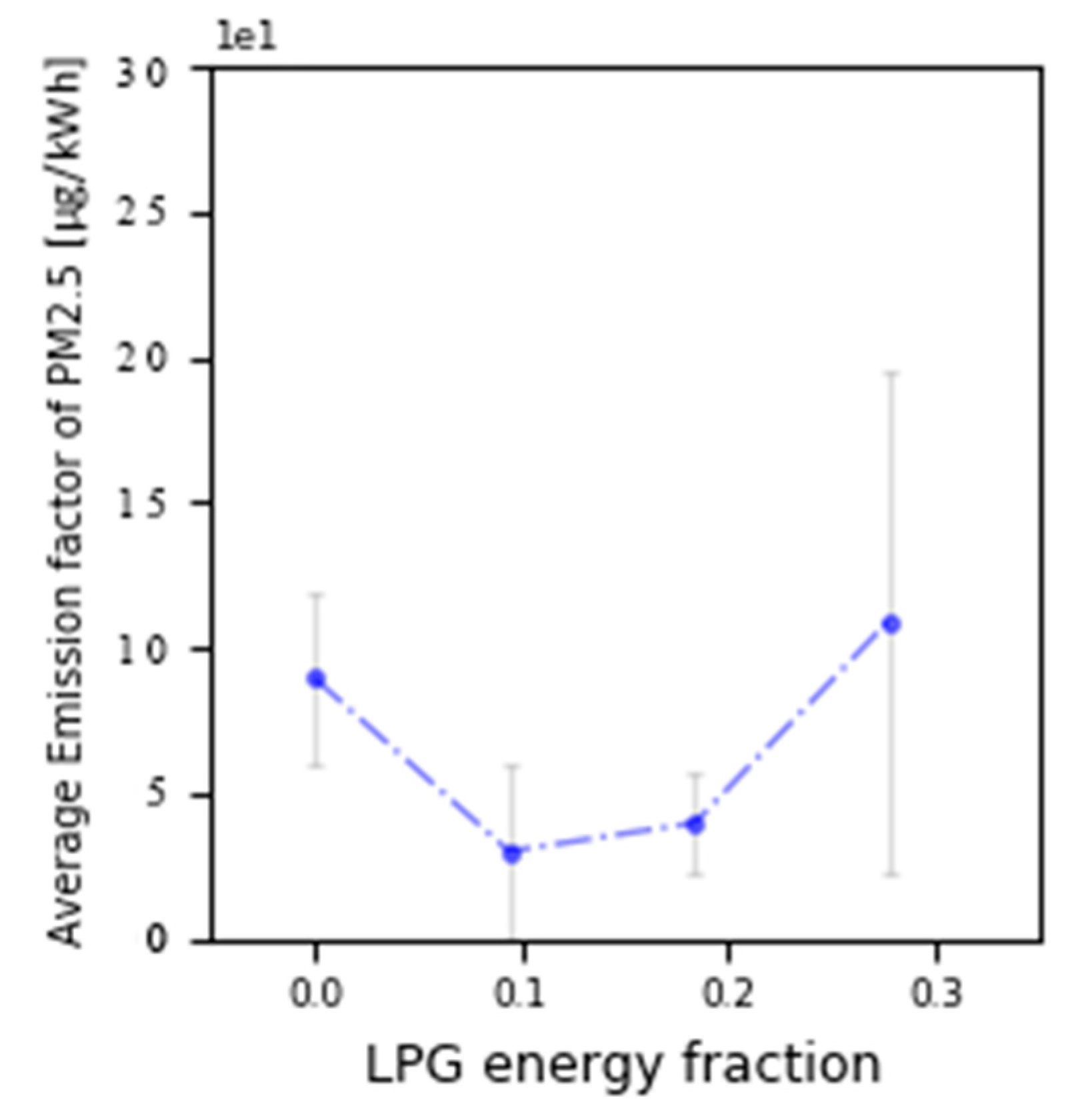

- PM2.5 tends to decrease as the fraction of LPG entering the engine increases.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Nomenclature

| Bsfc | Brake specific diesel fuel consumption |

| Bfce | Brake fuel conversion efficiency |

| CO | Carbon monoxide |

| CO2 | Carbon dioxide |

| CI | Compression ignition |

| EGR | Exhaust gas recirculation |

| HC | Hydrocarbon |

| IC | Internal combustion |

| LHV | Low heating value |

| LPG | Liquified petroleum gas |

| Mass flow rate | |

| NOx | Nitrogen oxide |

| Pbrake | Power brake |

| PDr | Pondered deviation from reference index |

| PM2.5 | Fine particulate matter |

| rpm | Revolutions per minute |

| SD | Standard deviation |

| VC | Variation coefficient |

References

- Jian, D.; Xiaohong, G.; Gesheng, L.; Xintang, Z. Study on Diesel–LPG Dual-fuel Engines. SAE 2001. [Google Scholar] [CrossRef]

- Ashok, B.; Ashok, S.D.; Kumar, C.R. LPG diesel dual-fuel engine—A critical review. Alex. Eng. J. 2015, 54, 105–126. [Google Scholar] [CrossRef]

- Waldie, A.; Jay, G.; Holland, D. The risk posed to vehicle occupants and rescue personnel by dual-fuelled vehicles fitted with liquid petroleum gas (LPG) tanks. SAE 2001. [Google Scholar] [CrossRef]

- Poonia, M.P.; Bhardwaj, A.; Jethoo, A.S.; Pandel, U. Experimental investigations on engine performance and exhaust emissions in an LPG diesel dual-fuel engine. Int. J. Environ. Sci. Dev. 2011, 2, 418–422. Available online: http://www.ijesd.org/papers/162-D557.pdf (accessed on 18 August 2022). [CrossRef]

- Negurescu, N.; Pana, C.; Cernat, A. Theoretical and experimental investigations on the LPG fuelled diesel engine. In Proceedings of FISITA 2012 World Automotive Congress; Springer: Berlin/Heidelberg, Germany, 2013; Volume 191, pp. 37–49. [Google Scholar] [CrossRef]

- Tiwari, D.R.; Sinha, G.P. Performance and emission study of LPG diesel dual-fuel engine. Int. J. Eng. Adv. Technol. 2014, 3, 2249–8958. [Google Scholar]

- Rao, G.A.; Raju, A.V.S.; Rao, C.V.M.; Rajulu, K.G. Effect of LPG content on the performance and emissions of a diesel–LPG dual-fuel engine. Bangladesh J. Sci. Ind. Res. 2011, 46, 195–200. [Google Scholar] [CrossRef]

- Rao, G.A.; Raju, A.V.S.; Rajulu, K.G.; Rao, C.V.M. Performance evaluation of a dual-fuel engine (diesel + LPG). Indian J. Sci. Technol. 2010, 3, 235–238. [Google Scholar] [CrossRef]

- Ayhan, V.; Parlak, A.; Cesur, I.; Boru, B.; Kolip, A. Performance and exhaust emission characteristics of a diesel engine running with LPG. Int. J. Phys. Sci. 2011, 6, 1905–1914. [Google Scholar] [CrossRef]

- Kumaraswamy, A.; Prasad, B.D. Use of LPG in A dual-fuel engine. Int. J. Mod. Eng. Res. 2012, 2. Available online: https://www.semanticscholar.org/paper/Use-of-LPG-in-A-Dual-Fuel-Engine-Kumaraswamy-Prasad/09087e2e262b058b9908a56dfa5c6da3a04cf346 (accessed on 18 August 2022).

- Mirgal, N.; Kumbhar, S.; Ibrahim, M.M.; Chellapachetty, B. Experimental investigations on LPG–Diesel dual fuel engine. J. Chem. Pharm. Sci. 2017, 10, 211–214. Available online: https://www.semanticscholar.org/paper/Experimental-investigations-on-LPG-diesel-dual-fuel-Mirgal-Kumbhar/3c0541ec935d0706a09e3b7bd4f9cd519e867f1e (accessed on 18 August 2022).

- Qi, D.H.; Bian, Y.Z.H.; Ma, Z.H.Y.; Zhang, C.H.H.; Liu, S.H.Q. Combustion and exhaust emission characteristics of a compression ignition engine using liquefied petroleum gas–diesel blended fuel. Energy Convers. Manag. 2007, 48, 500–509. [Google Scholar] [CrossRef]

- Sudhir, C.V.; Desai, V.; Kumar, S.Y.; Mohanan, P. Performance and Emission Studies on the effect of Injection Timing and Diesel Replacement on a 4-S LPG–Diesel Dual-Fuel Engine. SAE 2003. [Google Scholar] [CrossRef]

- Le, T.A.; Nguyen, T.T. Experimental Study on Performance, Emissions and Combustion Characteristics of a Single Cylinder Dual-fuel LPG/Diesel Engine. Appl. Energy 2011, 88, 3959–3968. [Google Scholar] [CrossRef]

- Van Dzung, D.; Tung, T.T.H. Study on the Effect of the Fuel Supply Mode in Dual-Fuel Engine (LPG-Diesel). Ph.D. Thesis, Da Nang University, Da Nang, Vietnam, 2018. [Google Scholar]

- Poonia, M.P.; Ramesh, A.; Gaur, R.R. Experimental Investigation of the Factors Affecting the Performance of a LPG-Diesel Dual-fuel Engine. SAE 1999, 108, 499–508. [Google Scholar] [CrossRef]

- Mohanan, P.; Kumar, Y.S. Effect of LPG Intake Temperature, Pilot Fuel and Injection Timing on the Combustion Characteristics & Emission of a LPG Diesel Dual-fuel Engine. SAE 2001. [Google Scholar] [CrossRef]

- Poonia, M.P.; Ramesh, A.; Gaur, R.R.; Joshi, A. Effect of pilot fuel quantity, injector needle lift pressure and load on combustion characteristics of a LPG diesel dual-fuel engine. Int. J. Eng. Innov. Technol. 2012, 2, 26–31. Available online: https://www.semanticscholar.org/paper/Effect-of-Pilot-Fuel-Quantity-%2C-Injector-Needle-and-Ramesh-Gaur/7771d67308d4478b5648aaef505ffefc92c47fe6 (accessed on 18 August 2022).

- Selim, M.Y.E. Combustion Noise Measurements and Control from Small Diesel and Dual-fuel Engines. SAE 2004. [Google Scholar] [CrossRef]

- Selim, M.Y.E. Sensitivity of dual-fuel engine combustion and knocking limits to gaseous fuel composition. Energy Convers. Manag. 2004, 45, 411–425. [Google Scholar] [CrossRef]

- Luf, S. Analysis of combustion process in a dual-fuel compression ignition engine fuelled with LPG in liquid phase. J. KONES Power Train Transp. 2007, 14, 355–362. Available online: https://www.semanticscholar.org/paper/Analysis-of-combustion-process-in-a-dual-fuel-with-Luft/08326b6a3e5151789985f16662e05be5223800c6 (accessed on 18 August 2022).

- Ogawa, H.; Miyamoto, N.; Li, C.; Nakazawa, S.; Akao, K. Low Emission and Knock-Free Combustion with Rich and Lean Biform Mixture in a Dual-Fuel CI Engine with Induced LPG as the Main Fuel Low Emission and Knock-Free Combustion with Rich and Lean Biform Mixture in a Dual-Fuel CI Engine with Induced LPG as the Main Fuel. SAE 2001. [Google Scholar] [CrossRef]

- Ergenc, A.T.; Koca, D.O. PLC controlled single cylinder diesel–LPG engine. Fuel 2014, 130, 273–278. [Google Scholar] [CrossRef]

- Elnajjar, E.; Selim, M.Y.E.; Hamdan, M.O. Experimental study of dual-fuel engine performance using variable LPG composition and engine parameters. Energy Convers. Manag. 2013, 76, 32–42. [Google Scholar] [CrossRef]

- Rosas, M.; Amador, G. Knock Detection Method for Dual-Fuel Compression Ignition Engines Based on Block Vibration Analysis. SAE Int. J. Engines 2021, 14, 199–209. [Google Scholar] [CrossRef]

- Castro, N.; Toledo, M.; Amador, G. An experimental investigation of the performance and emissions of a hydrogen-diesel dual fuel compression ignition internal combustion engine. Appl. Therm. Eng. 2019, 156, 660–667. [Google Scholar] [CrossRef]

| Engine Model | Perkins Prima M80T Turbocharged |

|---|---|

| Cycle | 4 stroke |

| Cylinders configuration | 4 in line |

| Bore × Stroke | 84.5 mm × 88.9 mm |

| Displacement | 1994 cm3 |

| Compression ratio | 17.2:1 |

| Power rating | 58 kW at 4500 rpm |

| Torque rating | 145 N-m at 2350 rpm |

| Injection system | Direct injection system, Bosch VE pump with cold start compensation and electric stop. |

| Injection timing | 18° before TDC |

| Inlet valve opening | 7° after TDC |

| Inlet valve closing | 36° after TDC |

| Exhaust valve opening | 36° before BDC |

| Exhaust valve closing | 10° before TDC |

| Item | Uncertainty |

|---|---|

| Torque | ±0.7 N-M |

| Engine Speed | ±1 Rpm |

| LPG Volume Flow Rate | ±3 L/Min |

| CO | ±1 Ppm Vol |

| NOx HC | ±1 Ppm Vol ±1 Ppm Vol |

| CO2 O2 SNOWREX | ±1 Ppm Vol ±1 Ppm Vol ±0.001 Gr |

| Speed (rpm) | Load Level (%) | LPG Energy Fraction (%) | PDr (-) | Bfce (%) | Diesel Reduction Consumption (%) |

|---|---|---|---|---|---|

| 2200 | 30 | 20 | 38.1 | 16.9 | |

| 60 | 40.1 | ||||

| 60 | 60 | 44.1 | |||

| 100 | 59 | knock | |||

| 60 | 56.1 | ||||

| 2500 | 30 | 10 | 38.9 | ||

| 60 | 40.6 | ||||

| 60 | 60 | 47.5 | |||

| 100 | 55 | knock | |||

| 60 | 52.6 | ||||

| 3200 | 30 | 10 | 36.0 | ||

| 60 | 67.8 | ||||

| 60 | 60 | 47.5 | |||

| 100 | 53 | knock | |||

| 60 | 47.5 |

| Speed (rpm) | Load Level (%) | LPG Energy Fraction (%) | Equation Ratio (-) | CO (ppmv) | NOx (ppmv) | HC (ppmv) | Exhaust Gas Temperature (°C) |

|---|---|---|---|---|---|---|---|

| 2200 | 30 | 20 | 0.27 | 719 | 315 | 260 | 166.3 |

| 60 | 0.18 | 1708 | 161 | 915 | 160.2 | ||

| 60 | 60 | 0.26 | 1872 | 597 | 528 | 234.1 | |

| 100 | 59 | knock | |||||

| 60 | 0.62 | 1310 | 1320 | 287 | 315.4 | ||

| 2500 | 30 | 10 | 0.26 | 577 | 432 | 128 | 179.8 |

| 60 | 0.2 | 1539 | 364 | 501 | 182.9 | ||

| 60 | 60 | 0.22 | 2297 | 534 | 532 | 218.0 | |

| 100 | 55 | knock | |||||

| 60 | 0.54 | 1144 | 1171 | 199 | 314.8 | ||

| 3200 | 30 | 10 | 0.29 | 707 | 571 | 65 | 221.4 |

| 60 | 0.2 | 2784 | 489 | 311 | 213.0 | ||

| 60 | 60 | 0.2 | 2470 | 574 | 275 | 223.8 | |

| 100 | 53 | knock | |||||

| 60 | 0.45 | 1324 | 762 | 165 | 298.6 | ||

| Speed (rpm) | LPG Energy Fraction | Emission Factors (µg/kWh) | SD (-) | VC (-) | Average of Emission Factors (µg/kWh) |

|---|---|---|---|---|---|

| 2500 | 0 | 119.0 | 0.1431 | 2.96 × 10−5 | 89.5 |

| 0 | 89.7 | 0.1427 | 2.96 × 10−5 | ||

| 0 | 59.8 | 0.1441 | 2.96 × 10−5 | ||

| 0.1 | 59.8 | 0.1445 | 2.99 × 10−5 | 44.7 | |

| 0.1 | 0.0 | 0.1438 | 2.99 × 10−5 | ||

| 0.1 | 29.6 | 0.1391 | 2.99 × 10−5 | ||

| 0.2 | 59.5 | 0.1388 | 1.72 × 10−5 | 39.6 | |

| 0.2 | 29.7 | 0.1424 | 1.72 × 10−5 | ||

| 0.2 | 29.7 | 0.1369 | 1.72 × 10−5 | ||

| 0.3 | 59.5 | 0.1436 | 8.66 × 10−5 | 109.2 | |

| 0.3 | 209.0 | 0.1412 | 8.66 × 10−5 | ||

| 0.3 | 59.1 | 0.1447 | 8.66 × 10−5 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Toledo, E.; Guerrero, F.; Amador, G.; Toledo, M. Experimental Assessment of the Performance and Fine Particulate Matter Emissions of a LPG-Diesel Dual-Fuel Compression Ignition Engine. Energies 2022, 15, 9035. https://doi.org/10.3390/en15239035

Toledo E, Guerrero F, Amador G, Toledo M. Experimental Assessment of the Performance and Fine Particulate Matter Emissions of a LPG-Diesel Dual-Fuel Compression Ignition Engine. Energies. 2022; 15(23):9035. https://doi.org/10.3390/en15239035

Chicago/Turabian StyleToledo, Eliezer, Fabián Guerrero, German Amador, and Mario Toledo. 2022. "Experimental Assessment of the Performance and Fine Particulate Matter Emissions of a LPG-Diesel Dual-Fuel Compression Ignition Engine" Energies 15, no. 23: 9035. https://doi.org/10.3390/en15239035

APA StyleToledo, E., Guerrero, F., Amador, G., & Toledo, M. (2022). Experimental Assessment of the Performance and Fine Particulate Matter Emissions of a LPG-Diesel Dual-Fuel Compression Ignition Engine. Energies, 15(23), 9035. https://doi.org/10.3390/en15239035