Interactions between Package Design, Airflow, Heat and Mass Transfer, and Logistics in Cold Chain Facilities for Horticultural Products

Abstract

1. Introduction

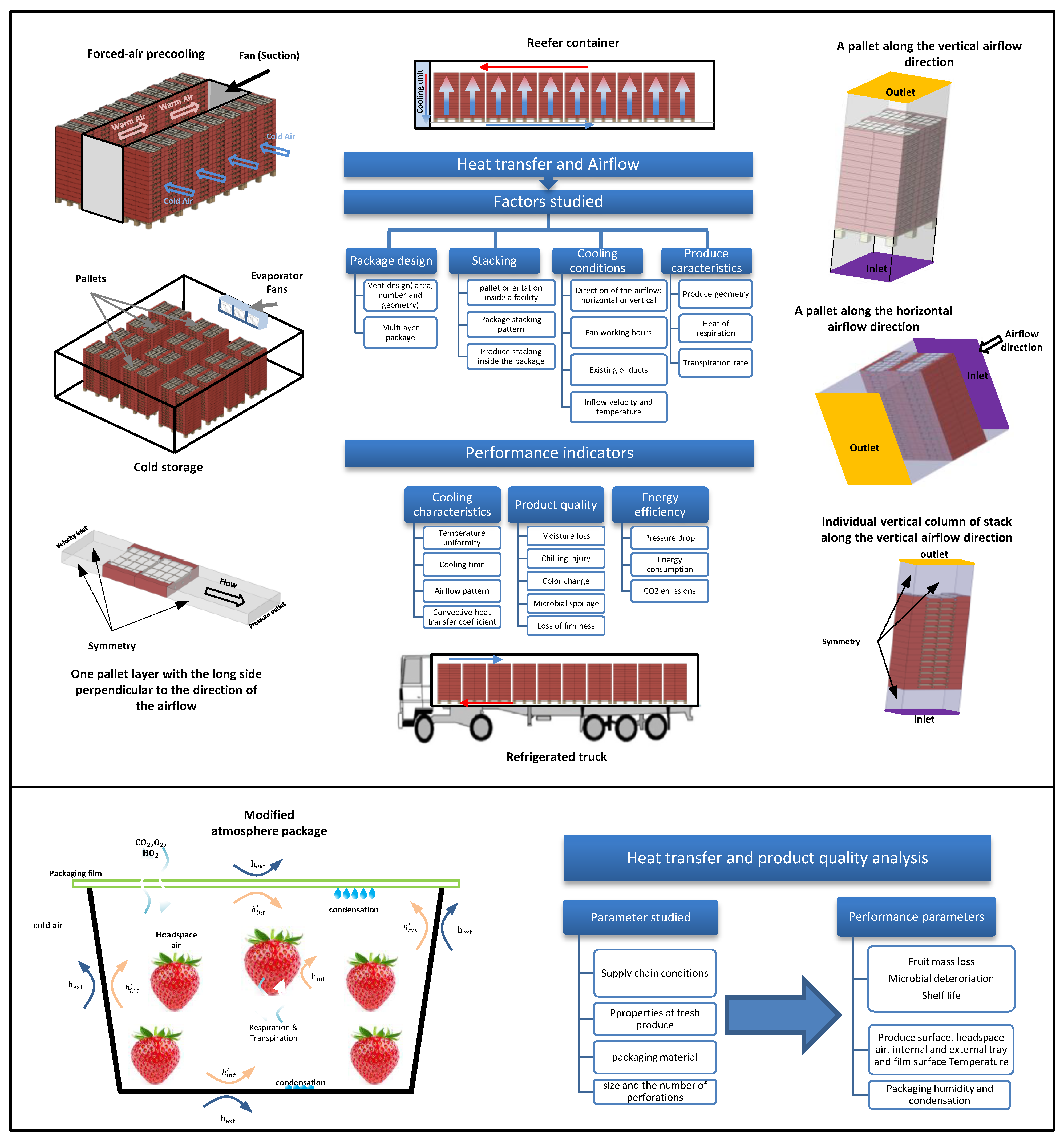

2. Numerical, Experimental, or Both Methods for the Analysis of the Cold Chain

2.1. Experimental Approach

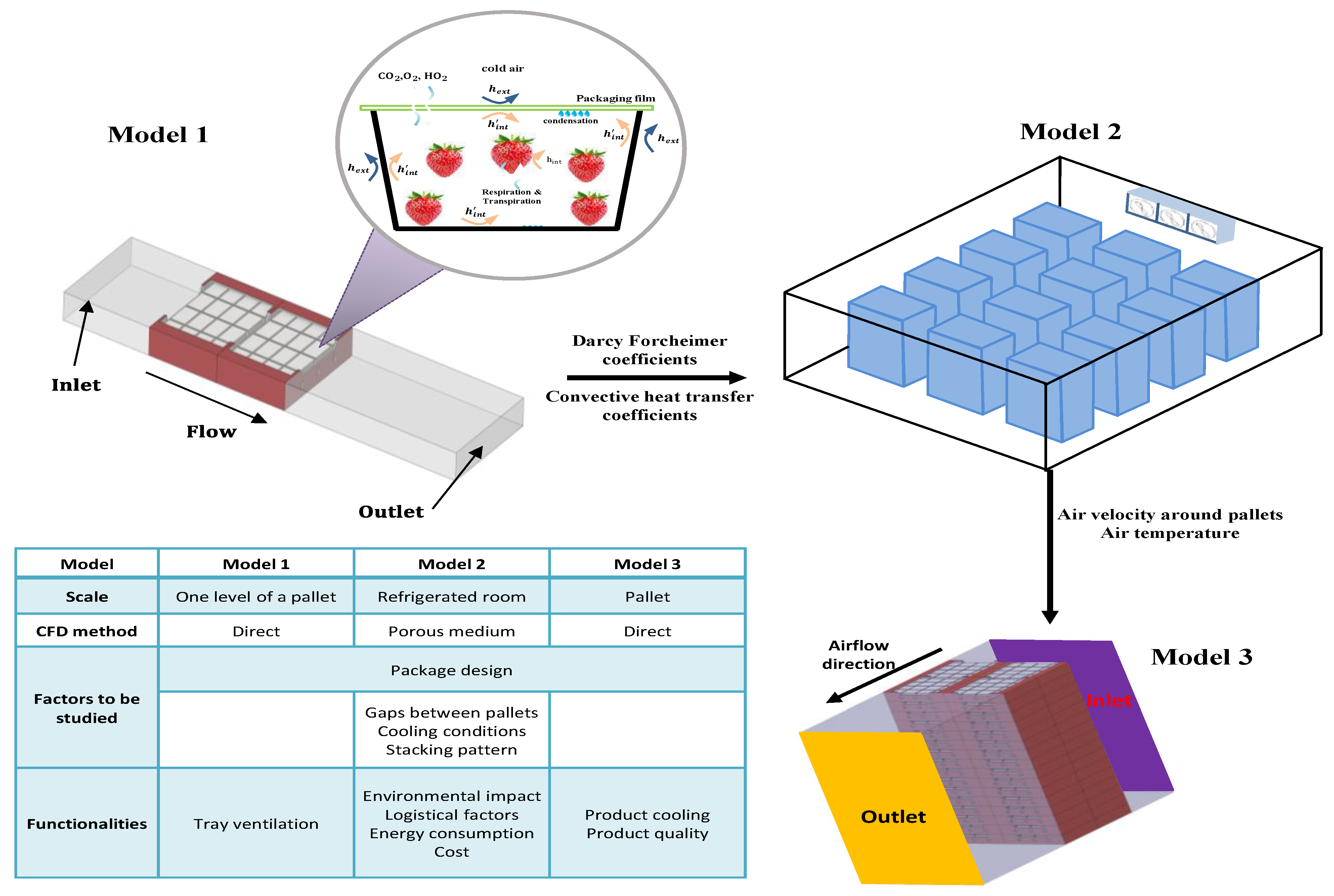

2.2. Numerical Approach

2.3. Turbulence Models

| Reference | Software | Turbulence Model | Mesh Type and Size | Numerical Approach |

|---|---|---|---|---|

| [74] | ANSYS Fluent 13 | SST k-ω | Hybrid grids (hexahedral and tetrahedral cells) base model: 4.1 × 106 cells model 2: 4.9 × 106 model 3: 5.9 × 106 model 4: 7.2 × 106 cells | Direct CFD simulation |

| [52] | ANSYS Fluent | SST k-ω | Tetrahedral hybrid mesh 4.62 × 106 cells | Porous medium |

| [40] | ANSYS | K-ε | Tetraedrique 7.4 × 106 cells | Direct CFD simulation |

| [75] | Fluent v.6.1.18 | RNG K-ε | A non-uniform quadrilateral mesh 74,430 cells | Porous |

| [29] | Fluent 6.3.26 | SST k-ω | Tetrahedral hybrid mesh | Direct CFD simulation |

| [32] | Fluent | RSM | 624,000 cells for the empty configuration 419,000 cells for the loaded configuration as the load is not part of the modeled domain | Direct CFD simulation |

2.4. Validation of the Predicted Values

3. Facility Conditions, Logistic Aspects, Pallets, and Package Impacts

3.1. Global Airflow Characteristics within Refrigerating Facilities

3.1.1. Pre-Cooling Facility

3.1.2. Transport Vehicles

3.1.3. Cold Storage Facility

3.2. Produce Packaging Design: The Impact on Produce Cooling

3.2.1. Cooling Facility Scale

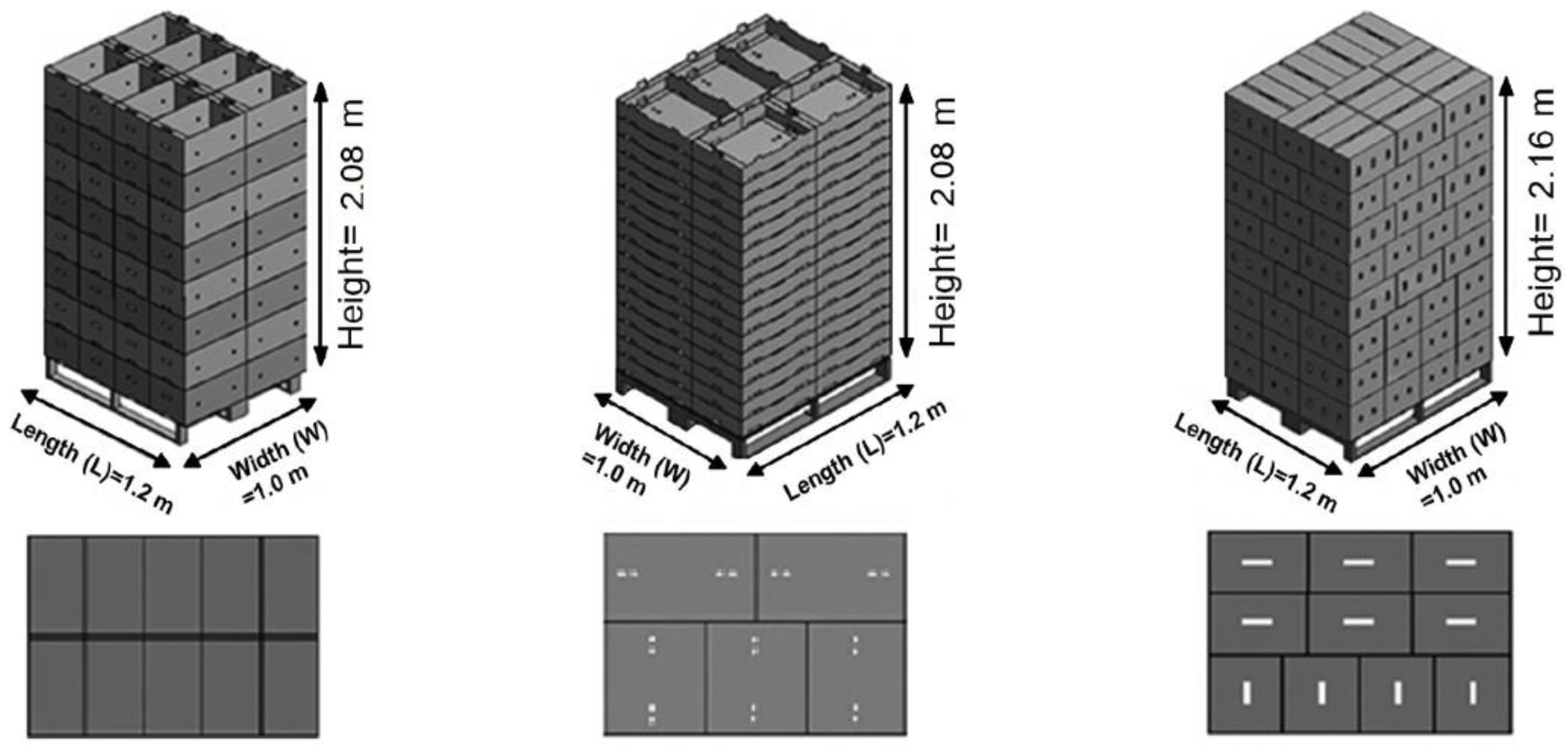

3.2.2. Pallet Scale

Cooling Heterogeneity

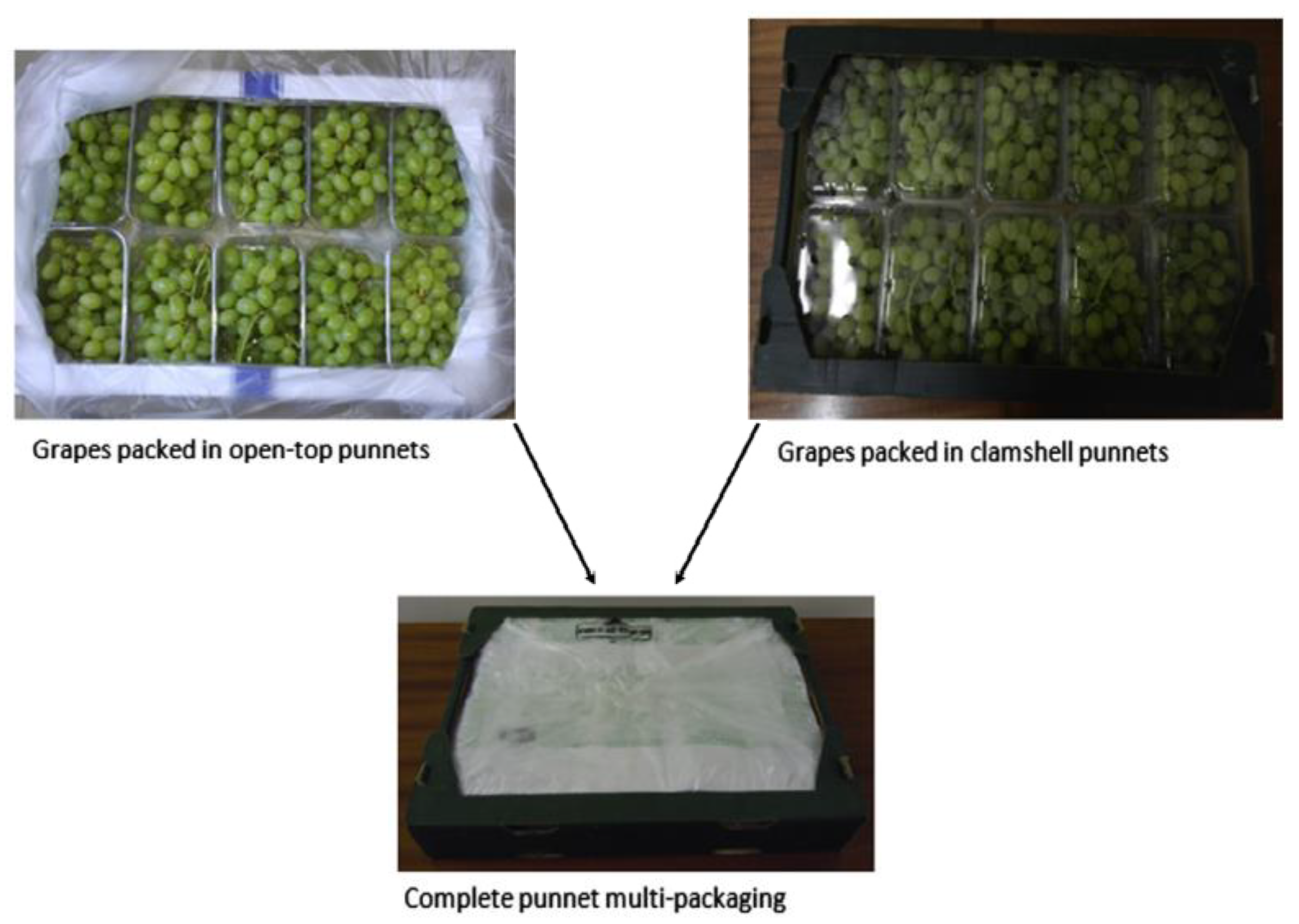

Multi-Layer Packaging

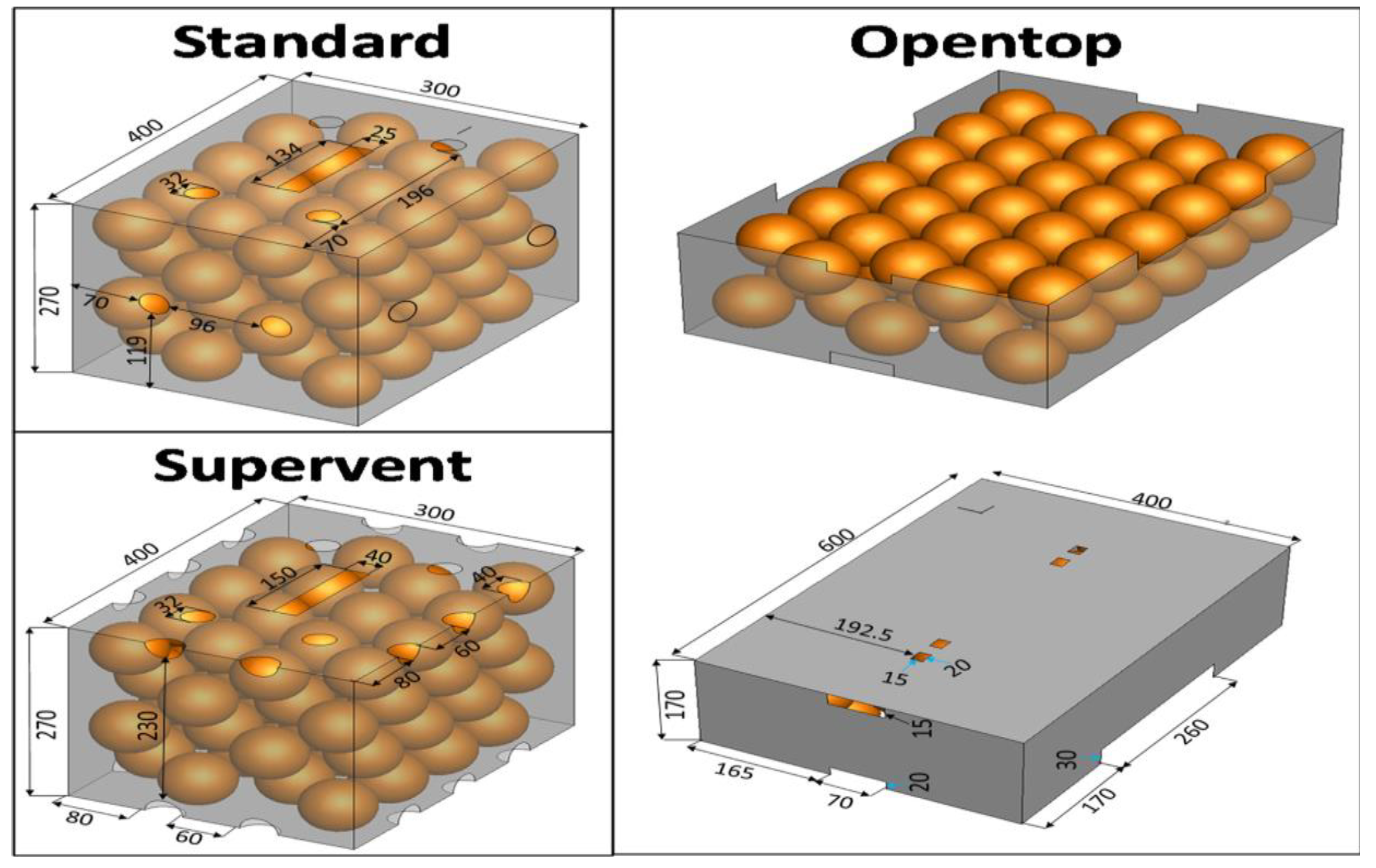

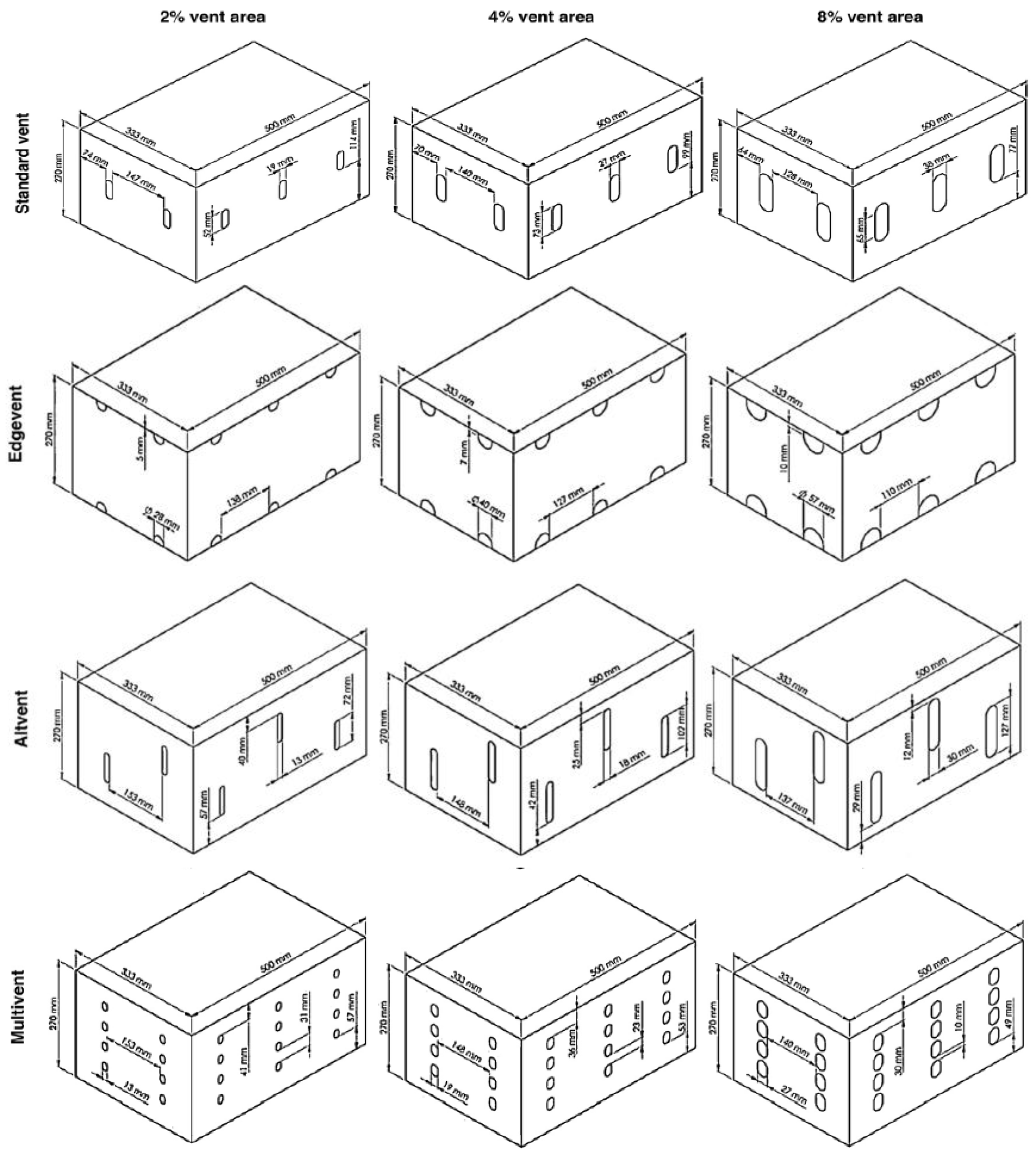

Alternative Designs

- -

- Faster cooling and better thermal homogeneity for the Supervent package. This is due to the alignment of the side holes, which improves the distribution of the flow in the boxes. For the transport link (vertical flow), the superiority of the Supervent is explained by the presence of a large central orifice associated with orifices close to the side walls, which together promote the emergence of a uniform flow within the box and greatly reduces the thermal heterogeneities of the products.

- -

- The poor thermal performance of the Opentop package, which is open on its upper part and whose configuration is close to that of cheese packages, can be explained in particular by:

- The big difference in the opening between the two faces of the cardboard favors the establishment of a short circuit and, thus a transfer of the flow towards the cartons having the big opening surface compared with the cartons of the weak opening section. This is because on the same level of the pallet, we find boxes with a small and a large perforated section facing the flow.

- The strong disproportionality between the relatively large openings in the upper part of the package above the products and those in the lower part facing the products. This configuration strongly reduces the accessibility of the cold caused by the flow from the top openings to the products located in the lower part of the box. This results in an increase in temperature heterogeneities and an increase in the cooling time of the products.

- -

- The palletization mode (regular or irregular) considerably affects the cooling time and the temperature heterogeneities. This phenomenon concerns, in particular, the downstream cartons whose openings do not communicate with the upstream cartons.

3.2.3. Box Scale

4. Other Aspects of Evaluation

5. Discussion

6. Conclusions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Nomenclature

| WHO | World health organization |

| CFD | Computational fluid dynamics |

| CSD | Computational structural dynamics |

| LDV | Laser-Doppler Velocitymeter |

| PIV | Particle Image Velocimetry |

| ASL | Air speed logger |

| RANS | Reynolds Averaged Navier-Stokes |

| NS | Navier-Stokes |

| HCT | Half cooling Time |

| SECT | Seven-eighths Cooling Time |

| CHTC | Convective heat transfer coefficient |

| FAC | Forced air cooling |

| MAP | Modified Atmosphere Packaging |

| TVA | Total vent area |

| CHT | Computational heat transfer |

| VCC | Virtual Cold Chain |

| RH | Relative humidity |

| ) | |

| ) | |

| t | time (s) |

| ) | |

| ) | |

| ) | |

| mean pressure (Pa) | |

| turbulent Prandtl number | |

| ) | |

| mean fluid temperature (K) | |

| k | turbulence kinetic energy |

| ) | |

| K | Darcy permeability |

| F | Forchheimer coefficient |

| ) | |

| ) | |

| package hydraulic diameter (m) | |

| effective product diameter (m) | |

| Pr | Prandtl number |

| Re | Reynold number |

| Nu | Nusselt number |

| Turbulent Reynolds number | |

| Turbulence intensity |

References

- WHO. WHO European Action Plan for Food and Nutrition Policy 2007–2012; WHO: Geneva, Switzerland, 2008.

- Petrescu, D.C.; Vermeir, I.; Petrescu-Mag, R.M. Consumer Understanding of Food Quality, Healthiness, and Environmental Impact: A Cross-National Perspective. Int. J. Environ. Res. Public Health 2019, 17, 169. [Google Scholar] [CrossRef] [PubMed]

- James, S.J.; James, C. The food cold-chain and climate change. Food Res. Int. 2010, 43, 1944–1956. [Google Scholar] [CrossRef]

- Laguerre, O.; Hoang, H.M.; Flick, D. Experimental investigation and modelling in the food cold chain: Thermal and quality evolution. Trends Food Sci. Technol. 2013, 29, 87–97. [Google Scholar]

- IIF. Nouvelle Note d’Information de l’IIF: Le Rôle du Froid Dans L’alimentation Mondiale; IIF: Paris, France, 2020. [Google Scholar]

- Loisel, J.; Duret, S.; Cornuéjols, A.; Cagnon, D.; Tardet, M.; Derens-Bertheau, E.; Laguerre, O. Cold chain break detection and analysis: Can machine learning help? Trends Food Sci. Technol. 2021, 112, 391–399. [Google Scholar] [CrossRef]

- Sajadiye, S.M.; Zolfaghari, M. Simulation of in-line versus staggered arrays of vented pallet boxes for assessing cooling performance of orange in cool storage. Appl. Ther. Eng. 2017, 115, 337–349. [Google Scholar] [CrossRef]

- Wu, W.; Cronjé, P.; Verboven, P.; Defraeye, T. Unveiling how ventilated packaging design and cold chain scenarios affect the cooling kinetics and fruit quality for each single citrus fruit in an entire pallet. Food Packag. Shelf Life 2019, 21, 100369. [Google Scholar] [CrossRef]

- Yahia, E.M.; Fonseca, J.M.; Kitinoja, L. Postharvest Technology of Perishable Horticultural Commodities; Woodhead Publishing: Duxford, UK, 2019; pp. 43–69. [Google Scholar]

- Gustavsson, J.; Cederberg, C.; Sonesson, U.; Van Otterdijk, R.; Meybeck, A. Global Food Losses and Food Wastes Extent, Causes and Prevention; FAO: Rome, Italy, 2011. [Google Scholar]

- Ademe. Pertes et Gaspillages Alimentaires: L’etat des Lieux et Leur Gestion par Etapes de la Chaine Alimentaire; Ademe: Angers, France, 2016. [Google Scholar]

- FAO. Energy-Smart Food for People and Climate—Issue Paper; FAO: Rome, Italy, 2011; p. 78. [Google Scholar]

- Mercier, S.; Brecht, J.K.; Uysal, I. Commercial forced-air precooling of strawberries: A temperature distribution and correlation study. J. Food Eng. 2019, 242, 47–54. [Google Scholar] [CrossRef]

- Mukama, M.; Ambaw, A.; Opara, U.L. Advances in design and performance evaluation of fresh fruit ventilated distribution packaging: A review. Food Packag. Shelf Life 2020, 24, 100472. [Google Scholar] [CrossRef]

- Dehghannya, J.; Ngadi, M.; Vigneault, C. Mathematical Modeling Procedures for Airflow, Heat and Mass Transfer During Forced Convection Cooling of Produce: A Review. Food Eng. Rev. 2010, 2, 227–243. [Google Scholar]

- Pathare, P.B.; Opara, U.L.; Vigneault, C.; Delele, M.A.; Al-Said, F.A.-J. Design of Packaging Vents for Cooling Fresh Horticultural Produce. Food Bioprocess Technol. 2012, 5, 2031–2045. [Google Scholar] [CrossRef]

- Defraeye, T.; Cronje, P.; Berry, T.; Opara, U.L.; East, A.; Hertog, M.; Verboven, P.; Nicolai, B. Towards integrated performance evaluation of future packaging for fresh produce in the cold chain. Trends Food Sci. Technol. 2015, 44, 201–225. [Google Scholar]

- Ambaw, A.; Fadiji, T.; Opara, U.L. Thermo-Mechanical Analysis in the Fresh Fruit Cold Chain: A Review on Recent Advances. Foods 2021, 10, 1357. [Google Scholar] [CrossRef] [PubMed]

- Derens, E.; Palagos, B.; Guilpart, J. The cold chain of chilled products under supervision in France. In Proceedings of the 13th World Congress of Food Science & Technology, Nante, France, 17–21 September 2006; IUFoSt: Nante, France, 2006; p. 823. [Google Scholar]

- Derens-Bertheau, E.; Osswald, V.; Laguerre, O.; Alvarez, G. Cold chain of chilled food in France. Int. J. Refrig. 2015, 52, 161–167. [Google Scholar] [CrossRef]

- Ndraha, N.; Hsiao, H.-I.; Vlajic, J.; Yang, M.-F.; Lin, H.-T.V. Time-temperature abuse in the food cold chain: Review of issues, challenges, and recommendations. Food Control 2018, 89, 12–21. [Google Scholar] [CrossRef]

- Mercier, S.; Villeneuve, S.; Mondor, M.; Uysal, I. Time-Temperature Management Along the Food Cold Chain: A Review of Recent Developments. Compr. Rev. Food Sci. Food Saf. 2017, 16, 647–667. [Google Scholar] [CrossRef]

- Wu, W.; Häller, P.; Cronjé, P.; Defraeye, T. Full-scale experiments in forced-air precoolers for citrus fruit: Impact of packaging design and fruit size on cooling rate and heterogeneity. Biosyst. Eng. 2018, 169, 115–125. [Google Scholar] [CrossRef]

- Hoang, H.-M.; Duret, S.; Flick, D.; Laguerre, O. Preliminary study of airflow and heat transfer in a cold room filled with apple pallets: Comparison between two modelling approaches and experimental results. Appl. Ther. Eng. 2015, 76, 367–381. [Google Scholar] [CrossRef]

- Han, J.-W.; Zhao, C.-J.; Qian, J.-P.; Ruiz-Garcia, L.; Zhang, X. Numerical modeling of forced-air cooling of palletized apple: Integral evaluation of cooling efficiency. Int. J. Refrig. 2018, 89, 131–141. [Google Scholar]

- Han, J.-W.; Qian, J.-P.; Zhao, C.-J.; Yang, X.-T.; Fan, B.-L. Mathematical modelling of cooling efficiency of ventilated packaging: Integral performance evaluation. Int. J. Heat Mass Transf. 2017, 111, 386–397. [Google Scholar] [CrossRef]

- Vigneault, C.; Goyette, B.; de Castro, L.R. Maximum slat width for cooling efficiency of horticultural produce in wooden crates. Postharvest Biol. Technol. 2006, 40, 308–313. [Google Scholar] [CrossRef]

- Moureh, J.; Tapsoba, M.; Flick, D. Airflow in a slot-ventilated enclosure partially filled with porous boxes: Part II—Measurements and simulations within porous boxes. Comput. Fluids 2009, 38, 206–220. [Google Scholar] [CrossRef]

- Delele, M.A.; Tijskens, E.; Atalay, Y.T.; Ho, Q.T.; Ramon, H.; Nicolaï, B.M.; Verboven, P. Combined discrete element and CFD modelling of airflow through random stacking of horticultural products in vented boxes. J. Food Eng. 2008, 89, 33–41. [Google Scholar] [CrossRef]

- Delele, M.A.; Ngcobo, M.E.K.; Getahun, S.T.; Chen, L.; Mellmann, J.; Opara, U.L. Studying airflow and heat transfer characteristics of a horticultural produce packaging system using a 3-D CFD model. Part I: Model development and validation. Postharvest Biol. Technol. 2013, 86, 536–545. [Google Scholar] [CrossRef]

- Alvarez, G.; Bournet, P.-E.; Flick, D. Two-dimensional simulation of turbulent flow and transfer through stacked spheres. Int. J. Heat Mass Transf. 2003, 46, 2459–2469. [Google Scholar] [CrossRef]

- Moureh, J.; Flick, D. Airflow pattern and temperature distribution in a typical refrigerated truck configuration loaded with pallets. Int. J. Refrig. 2004, 27, 464–474. [Google Scholar] [CrossRef]

- Moureh, J.; Tapsoba, M.; Flick, D. Airflow in a slot-ventilated enclosure partially filled with porous boxes: Part I—Measurements and simulations in the clear region. Comput. Fluids 2009, 38, 194–205. [Google Scholar] [CrossRef]

- Ferrua, M.J.; Singh, R.P. Modeling the forced-air cooling process of fresh strawberry packages, Part II: Experimental validation of the flow model. Int. J. Refrig. 2009, 32, 349–358. [Google Scholar] [CrossRef]

- Laguerre, O.; Ben Amara, S.; Charrier-Mojtabi, M.C.; Lartigue, B.; Flick, D. Experimental study of air flow by natural convection in a closed cavity: Application in a domestic refrigerator. J. Food Eng. 2008, 85, 547–560. [Google Scholar] [CrossRef]

- Laguerre, O.; Benamara, S.; Flick, D. Numerical simulation of simultaneous heat and moisture transfer in a domestic refrigerator. Int. J. Refrig. 2010, 33, 1425–1433. [Google Scholar] [CrossRef]

- Ferrua, M.J.; Singh, R.P. Improved airflow method and packaging system for forced-air cooling of strawberries. Int. J. Refrig. 2011, 34, 1162–1173. [Google Scholar] [CrossRef]

- Praeger, U.; Jedermann, R.; Sellwig, M.; Neuwald, D.A.; Hartgenbusch, N.; Borysov, M.; Truppel, I.; Scaar, H.; Geyer, M. Airflow distribution in an apple storage room. J. Food Eng. 2020, 269, 109746. [Google Scholar] [CrossRef]

- Ferrua, M.J.; Singh, R.P. Modeling the forced-air cooling process of fresh strawberry packages, Part III: Experimental validation of the energy model. Int. J. Refrig. 2009, 32, 359–368. [Google Scholar] [CrossRef]

- O’Sullivan, J.; Ferrua, M.J.; Love, R.; Verboven, P.; Nicolaï, B.; East, A. Modelling the forced-air cooling mechanisms and performance of polylined horticultural produce. Postharvest Biol. Technol. 2016, 120, 23–35. [Google Scholar] [CrossRef]

- Defraeye, T.; Lambrecht, R.; Tsige, A.A.; Delele, M.A.; Opara, U.L.; Cronjé, P.; Verboven, P.; Nicolai, B. Forced-convective cooling of citrus fruit: Package design. J. Food Eng. 2013, 118, 8–18. [Google Scholar] [CrossRef]

- Hoang, M.H.; Laguerre, O.; Moureh, J.; Flick, D. Heat transfer modelling in a ventilated cavity loaded with food product: Application to a refrigerated vehicle. J. Food Eng. 2012, 113, 389–398. [Google Scholar] [CrossRef]

- Ngcobo, M.E.K.; Delele, M.A.; Opara, U.L.; Zietsman, C.J.; Meyer, C.J. Resistance to airflow and cooling patterns through multi-scale packaging of table grapes. Int. J. Refrig. 2012, 35, 445–452. [Google Scholar] [CrossRef]

- Zou, Q.; Opara, L.U.; McKibbin, R. A CFD modeling system for airflow and heat transfer in ventilated packaging for fresh foods: I. Initial analysis and development of mathematical models. J. Food Eng. 2006, 77, 1037–1047. [Google Scholar] [CrossRef]

- Zhao, C.-J.; Han, J.-W.; Yang, X.-T.; Qian, J.-P.; Fan, B.-L. A review of computational fluid dynamics for forced-air cooling process. Appl. Energy 2016, 168, 314–331. [Google Scholar] [CrossRef]

- Ambaw, A.; Bessemans, N.; Gruyters, W.; Gwanpua, S.G.; Schenk, A.; De Roeck, A.; Delele, M.A.; Verboven, P.; Nicolai, B.M. Analysis of the spatiotemporal temperature fluctuations inside an apple cool store in response to energy use concerns. Int. J. Refrig. 2016, 66, 156–168. [Google Scholar] [CrossRef]

- Ergun, S. Fluid flow through packed columns. Chem. Eng. Progress 1952, 48, 89–94. [Google Scholar]

- Ambaw, A.; Verboven, P.; Defraeye, T.; Tijskens, E.; Schenk, A.; Opara, U.L.; Nicolai, B.M. Porous medium modeling and parameter sensitivity analysis of 1-MCP distribution in boxes with apple fruit. J. Food Eng. 2013, 119, 13–21. [Google Scholar] [CrossRef]

- Delele, M.A.; Schenk, A.; Tijskens, E.; Ramon, H.; Nicolaï, B.M.; Verboven, P. Optimization of the humidification of cold stores by pressurized water atomizers based on a multiscale CFD model. J. Food Eng. 2009, 91, 228–239. [Google Scholar] [CrossRef]

- Sajadiye, S.M.; Ahmadi, H.; Zolfaghari, M.; Mohtasebi, S.S.; Mostofi, Y.; Raja, A. A Multi-Scale Three-Dimensional CFD Model of a Full Loaded Cool Storage. Int. J. Food Eng. 2013, 9, 163–178. [Google Scholar] [CrossRef]

- Getahun, S.; Ambaw, A.; Delele, M.; Meyer, C.J.; Opara, U.L. Analysis of airflow and heat transfer inside fruit packed refrigerated shipping container: Part I—Model development and validation. J. Food Eng. 2017, 203, 58–68. [Google Scholar] [CrossRef]

- Delele, M.A.; Ngcobo, M.E.K.; Opara, U.L.; Meyer, C.J. Investigating the Effects of Table Grape Package Components and Stacking on Airflow, Heat and Mass Transfer Using 3-D CFD Modelling. Food Bioprocess Technol. 2012, 6, 2571–2585. [Google Scholar]

- Chau, K.V.; Gaffney, J.J.; Baird, C.D.; Church, G.A., II. Resistance to Air Flow of Oranges in Bulk and in Cartons. Trans. ASAE 1985, 28, 2083–2088. [Google Scholar] [CrossRef]

- Diop, M.; Flick, D.; Alvarez, G.; Moureh, J. Experimental and Numerical Investigation of the Diffusion of a Confined Wall Jet through a Perforated Plate. Open J. Fluid Dyn. 2022, 12, 168–212. [Google Scholar] [CrossRef]

- Laguerre, O.; Duret, S.; Hoang, H.M.; Guillier, L.; Flick, D. Simplified heat transfer modeling in a cold room filled with food products. J. Food Eng. 2015, 149, 78–86. [Google Scholar] [CrossRef]

- O’Sullivan, J. Significant Factors Affecting the Forced-Air Cooling Process of Polylined Horticultural Produce: A Thesis Presented in Partial Fulfilment of the Requirements for the Degree of Doctor of Philosophy in Food Technology at Massey University, Palmerston North, New Zealand. Ph.D. Thesis, Massey University, Palmerston North, New Zealand, 2016. [Google Scholar]

- Moureh, J.; Pham, A.T.; Flick, D. Simplified model of airflow and heat transfer in a pallet of food product generating heat. J. Food Process Eng. 2022, 45, e13953. [Google Scholar] [CrossRef]

- Duret, S.; Hoang, H.M.; Derens-Bertheau, E.; Delahaye, A.; Laguerre, O.; Guillier, L. Combining Quantitative Risk Assessment of Human Health, Food Waste, and Energy Consumption: The Next Step in the Development of the Food Cold Chain? Risk Anal. 2019, 39, 906–925. [Google Scholar] [CrossRef]

- Duret, S.; Hoang, H.-M.; Guillier, L.; Derens-Bertheau, E.; Dargaignaratz, C.; Oriol, S.; Delahaye, A.; Laguerre, O.; Nguyen-the, C. Interactions between refrigeration temperatures, energy consumption in a food plant and microbiological quality of the food product: Application to refrigerated stuffed pasta. Food Control 2021, 126, 108076. [Google Scholar] [CrossRef]

- Malalasekera, H.K.V.W. An Introduction to Computational Fluid Dynamics: The Finite Volume Method; Longman Scientific & Technical: Essex, UK, 1995. [Google Scholar]

- Defraeye, T.; Verboven, P.; Nicolai, B. CFD modelling of flow and scalar exchange of spherical food products: Turbulence and boundary-layer modelling. J. Food Eng. 2013, 114, 495–504. [Google Scholar] [CrossRef]

- Moureh, J.; Menia, N.; Flick, D. Numerical and experimental study of airflow in a typical refrigerated truck configuration loaded with pallets. Comput. Electron. Agric. 2002, 34, 25–42. [Google Scholar] [CrossRef]

- Ambaw, A.; Mukama, M.; Opara, U.L. Analysis of the effects of package design on the rate and uniformity of cooling of stacked pomegranates: Numerical and experimental studies. Comput. Electron. Agric. 2017, 136, 13–24. [Google Scholar] [CrossRef]

- Berry, T.M.; Defraeye, T.; Nicolai, B.M.; Opara, U.L. Multiparameter Analysis of Cooling Efficiency of Ventilated Fruit Cartons using CFD: Impact of Vent Hole Design and Internal Packaging. Food Bioprocess Technol. 2016, 9, 1481–1493. [Google Scholar] [CrossRef]

- Launder, B.E.; Spalding, D.B. The numerical computation of turbulent flows. Comput. Methods Appl. Mech. Eng. 1974, 3, 269–289. [Google Scholar] [CrossRef]

- Wilcox, D.C. Turbulence modeling for C.F.D. DCW Industries. Inc. J. Fluid Mech. 2006, 289, 406–407. [Google Scholar]

- Menter, F.R. Eddy Viscosity Transport Equations and Their Relation to the k-ε Model. J. Fluids Eng. 1997, 119, 876–884. [Google Scholar] [CrossRef]

- Park, T.S.; Sung, H.J. A nonlinear low-Reynolds-number κ-ε model for turbulent separated and reattaching flows—I. Flow field computations. Int. J. Heat Mass Transf. 1995, 38, 2657–2666. [Google Scholar] [CrossRef]

- Leschziner, M.A. Modelling turbulent separated flow in the context of aerodynamic applications. Fluid Dyn. Res. 2006, 38, 174–210. [Google Scholar] [CrossRef]

- Moureh, J.; Flick, D. Airflow characteristics within a slot-ventilated enclosure. Int. J. Heat Fluid Flow 2005, 26, 12–24. [Google Scholar] [CrossRef]

- Moureh, J.; Tapsoba, S.; Derens, E.; Flick, D. Air velocity characteristics within vented pallets loaded in a refrigerated vehicle with and without air ducts. Int. J. Refrig. 2009, 32, 220–234. [Google Scholar] [CrossRef]

- Tapsoba, M.; Moureh, J.; Flick, D. Airflow patterns inside slotted obstacles in a ventilated enclosure. Comput. Fluids 2007, 36, 935–948. [Google Scholar] [CrossRef]

- Hoang, M.L.; Verboven, P.; De Baerdemaeker, J.; Nicolaï, B.M. Analysis of the air flow in a cold store by means of computational fluid dynamics. Int. J. Refrig. 2000, 23, 127–140. [Google Scholar] [CrossRef]

- Defraeye, T.; Cronjé, P.; Verboven, P.; Opara, U.L.; Nicolai, B. Exploring ambient loading of citrus fruit into reefer containers for cooling during marine transport using computational fluid dynamics. Postharvest Biol. Technol. 2015, 108, 91–101. [Google Scholar] [CrossRef]

- Chourasia, M.K.; Goswami, T.K. Steady state CFD modeling of airflow, heat transfer and moisture loss in a commercial potato cold store. Int. J. Refrig. 2007, 30, 672–689. [Google Scholar] [CrossRef]

- Brosnan, T.; Sun, D.-W. Precooling techniques and applications for horticultural products—A review. Int. J. Refrig. 2001, 24, 154–170. [Google Scholar] [CrossRef]

- Han, J.-W.; Zhao, C.-J.; Yang, X.-T.; Qian, J.-P.; Fan, B.-L. Computational modeling of airflow and heat transfer in a vented box during cooling: Optimal package design. Appl. Ther. Eng. 2015, 91, 883–893. [Google Scholar] [CrossRef]

- Getahun, S.; Ambaw, A.; Delele, M.; Meyer, C.J.; Opara, U.L. Experimental and Numerical Investigation of Airflow Inside Refrigerated Shipping Containers. Food Bioprocess Technol. 2018, 11, 1164–1176. [Google Scholar] [CrossRef]

- Duret, S.; Hoang, H.M.; Flick, D.; Laguerre, O. Experimental characterization of airflow, heat and mass transfer in a cold room filled with food products. Int. J. Refrig. 2014, 46, 17–25. [Google Scholar] [CrossRef]

- Praeger, U.; Jedermann, R.; Sellwig, M.; Neuwald, D.A.; Truppel, I.; Scaar, H.; Hartgenbusch, N.; Geyer, M. Influence of room layout on airflow distribution in an industrial fruit store. Int. J. Refrig. 2021, 131, 714–722. [Google Scholar] [CrossRef]

- Defraeye, T.; Nicolai, B.; Kirkman, W.; Moore, S.; Niekerk, S.V.; Verboven, P.; Cronjé, P. Integral performance evaluation of the fresh-produce cold chain: A case study for ambient loading of citrus in refrigerated containers. Postharvest Biol. Technol. 2016, 112, 1–13. [Google Scholar] [CrossRef]

- Vigneault, C.; Thompson, J.; Wu, S.; Hui, K.P.C.; LeBlanc, D.I. Transportation of fresh horticultural produce Postharvest Technol. Hortic. Crops 2009, 2, 1–24. [Google Scholar]

- O’Sullivan, J.; Ferrua, M.; Love, R.; Verboven, P.; Nicolaï, B.; East, A. Airflow measurement techniques for the improvement of forced-air cooling, refrigeration and drying operations. J. Food Eng. 2014, 143, 90–101. [Google Scholar] [CrossRef]

- Sousa-Gallagher, M.J.; Mahajan, P.V. Integrative mathematical modelling for MAP design of fresh-produce: Theoretical analysis and experimental validation. Food Control 2013, 29, 444–450. [Google Scholar] [CrossRef]

- Ferrua, M.J.; Singh, R.P. Modeling the forced-air cooling process of fresh strawberry packages, Part I: Numerical model. Int. J. Refrig. 2009, 32, 335–348. [Google Scholar] [CrossRef]

- Berry, T.M.; Fadiji, T.S.; Defraeye, T.; Opara, U.L. The role of horticultural carton vent hole design on cooling efficiency and compression strength: A multi-parameter approach. Postharvest Biol. Technol. 2017, 124, 62–74. [Google Scholar] [CrossRef]

- Wang, D.; Lai, Y.H.; Zhao, H.X.; Jia, B.G.; Wang, Q.; Yang, X.Z. Numerical and Experimental Investigation on Forced-Air Cooling of Commercial Packaged Strawberries. Int. J. Food Eng. 2019, 15, 20180384. [Google Scholar] [CrossRef]

- Dehghannya, J.; Ngadi, M.; Vigneault, C. Mathematical modeling of airflow and heat transfer during forced convection cooling of produce considering various package vent areas. Food Control 2011, 22, 1393–1399. [Google Scholar] [CrossRef]

- Anderson, B.A.; Sarkar, A.; Thompson, J.F.; Singh, R.P. Commercial-Scale Forced-Air Cooling of Packaged Strawberries. Trans. ASAE 2004, 47, 183–190. [Google Scholar] [CrossRef]

- Getahun, S.; Ambaw, A.; Delele, M.; Meyer, C.J.; Opara, U.L. Analysis of airflow and heat transfer inside fruit packed refrigerated shipping container: Part II—Evaluation of apple packaging design and vertical flow resistance. J. Food Eng. 2017, 203, 83–94. [Google Scholar] [CrossRef]

- Berry, T.M.; Defraeye, T.; Wu, W.; Sibiya, M.G.; North, J.; Cronje, P.J.R. Cooling of ambient-loaded citrus in refrigerated containers: What impacts do packaging and loading temperature have? Biosyst. Eng. 2021, 201, 11–22. [Google Scholar] [CrossRef]

- Derens-Bertheau, E.; Pham, A.T.; Flick, D.; Moureh, J. Impact de la Palettisation et des Vitesses D’air sur la Température des Produits. In Revue Général du Froid et du Conditionnement de L’air; Renadoc: Renadoc, France, 2019. [Google Scholar]

- Alvarez, G.; Flick, D. Analysis of heterogeneous cooling of agricultural products inside bins Part I: Aerodynamic study. J. Food Eng. 1999, 39, 227–237. [Google Scholar] [CrossRef]

- Alvarez, G.; Flick, D. Analysis of heterogeneous cooling of agricultural products inside bins Part II: Thermal study. J. Food Eng. 1999, 39, 239–245. [Google Scholar] [CrossRef]

- Defraeye, T.; Lambrecht, R.; Delele, M.A.; Tsige, A.A.; Opara, U.L.; Cronjé, P.; Verboven, P.; Nicolai, B. Forced-convective cooling of citrus fruit: Cooling conditions and energy consumption in relation to package design. J. Food Eng. 2014, 121, 118–127. [Google Scholar] [CrossRef]

- Ngcobo, M.E.K.; Delele, M.A.; Opara, U.L.; Meyer, C.J. Performance of multi-packaging for table grapes based on airflow, cooling rates and fruit quality. J. Food Eng. 2013, 116, 613–621. [Google Scholar] [CrossRef]

- O’Sullivan, J.L.; Ferrua, M.J.; Love, R.; Verboven, P.; Nicolaï, B.; East, A. Forced-air cooling of polylined horticultural produce: Optimal cooling conditions and package design. Postharvest Biol. Technol. 2017, 126, 67–75. [Google Scholar] [CrossRef]

- Ferrua, M.J.; Singh, R.P. Design guidelines for the forced-air cooling process of strawberries. Int. J. Refrig. 2009, 32, 1932–1943. [Google Scholar] [CrossRef]

- Nalbandi, H.; Seiiedlou, S.; Ghasemzadeh, H.R.; Rangbar, F. Innovative Parallel Airflow System for forced-air cooling of strawberries. Food Bioprod. Process. 2016, 100, 440–449. [Google Scholar] [CrossRef]

- Wu, W.; Defraeye, T. Identifying heterogeneities in cooling and quality evolution for a pallet of packed fresh fruit by using virtual cold chains. Appl. Ther. Eng. 2018, 133, 407–417. [Google Scholar] [CrossRef]

- Nalbandi, H.; Seiiedlou, S. Sensitivity analysis of the precooling process of strawberry: Effect of package designing parameters and the moisture loss. Food Sci. Nutr. 2020, 8, 2458–2471. [Google Scholar] [CrossRef] [PubMed]

- Pham, A.T.; Moureh, J.; Belaidi, M.; Flick, D. CFD modelling of a pallet of heat-generating product applied to a cheese product. Int. J. Refrig. 2021, 128, 163–176. [Google Scholar] [CrossRef]

- Pham, A.T. Characterization of Heat Transfer and Airflow within a Pallet of Heat-Generating Product: Applied to Cheese Pallets. Ph.D. Thesis, AgroParisTech—INRAE, Antony, France, 2019. [Google Scholar]

- Kumar, R.; Kumar, A.; Narayana Murthy, U. Heat transfer during forced air precooling of perishable food products. Biosyst. Eng. 2008, 99, 228–233. [Google Scholar] [CrossRef]

- Dincer, I. Development of new effective Nusselt-Reynolds correlations for air-cooling of spherical and cylindrical products. Int. J. Heat Mass Transf. 1994, 37, 2781–2787. [Google Scholar] [CrossRef]

- Tanner, D.J.; Cleland, A.C.; Opara, L.U. A generalised mathematical modelling methodology for the design of horticultural food packages exposed to refrigerated conditions Part 2. Heat transfer modelling and testing. Int. J. Refrig. 2002, 25, 43–53. [Google Scholar] [CrossRef]

- Ferrua, M.J.; Singh, R.P. A nonintrusive flow measurement technique to validate the simulated laminar fluid flow in a packed container with vented walls. Int. J. Refrig. 2008, 31, 242–255. [Google Scholar] [CrossRef]

- Le Page, J.-F.; Chevarin, C.; Kondjoyan, A.; Daudin, J.-D.; Mirade, P.-S. Development of an approximate empirical-CFD model estimating coupled heat and water transfers of stacked food products placed in airflow. J. Food Eng. 2009, 92, 208–216. [Google Scholar] [CrossRef]

- Poskas, P.; Poskas, R.; Sirvydas, A.; Smaizys, A. Experimental investigation of opposing mixed convection hear transfer in the vertical flat channel in a laminar–turbulent transition region. Int. J. Heat Mass Transf. 2011, 54, 662–668. [Google Scholar] [CrossRef]

- Chourasia, M.K.; Goswami, T.K. CFD simulation of effects of operating parameters and product on heat transfer and moisture loss in the stack of bagged potatoes. J. Food Eng. 2007, 80, 947–960. [Google Scholar] [CrossRef]

- Gaffney, J.J.; Baird, C.D.; Chau, K.V. Influence of airflow rate, respiration, evaporative cooling, and other factors affecting weight loss calculations for fruits and vegetables. ASHRAE Trans. 1985, 91, 690–707. [Google Scholar]

- Pham, A.T.; Moureh, J.; Flick, D. Experimental characterization of airflow within a pallet of product generating heat: Application for cheese product. Int. J. Refrig. 2019, 106, 89–103. [Google Scholar] [CrossRef]

- Pham, A.T.; Moureh, J.; Flick, D. Experimental characterization of heat transfer within a pallet of product generating heat. J. Food Eng. 2019, 247, 115–125. [Google Scholar] [CrossRef]

- Delele, M.A.; Ngcobo, M.E.K.; Getahun, S.T.; Chen, L.; Mellmann, J.; Opara, U.L. Studying airflow and heat transfer characteristics of a horticultural produce packaging system using a 3-D CFD model. Part II: Effect of package design. Postharvest Biol. Technol. 2013, 86, 546–555. [Google Scholar] [CrossRef]

- Wu, W.; Cronjé, P.; Nicolai, B.; Verboven, P.; Linus Opara, U.; Defraeye, T. Virtual cold chain method to model the postharvest temperature history and quality evolution of fresh fruit—A case study for citrus fruit packed in a single carton. Comput. Electron. Agric. 2018, 144, 199–208. [Google Scholar] [CrossRef]

- Berry, T.M.; Defraeye, T.; Shrivastava, C.; Ambaw, A.; Coetzee, C.; Opara, U.L. Designing ventilated packaging for the fresh produce cold chain. Food Bioprod. Process. 2022, 134, 121–149. [Google Scholar] [CrossRef]

- Shoji, K.; Schudel, S.; Onwude, D.; Shrivastava, C.; Defraeye, T. Mapping the postharvest life of imported fruits from packhouse to retail stores using physics-based digital twins. Resour. Conserv. Recycl. 2022, 176, 105914. [Google Scholar] [CrossRef]

- Jalali, A.; Linke, M.; Geyer, M.; Mahajan, P. Integrative programming for simulation of packaging headspace and shelf life of fresh produce. MethodsX 2021, 8, 101514. [Google Scholar] [CrossRef]

- Mukama, M.; Ambaw, A.; Berry, T.M.; Opara, U.L. Energy usage of forced air precooling of pomegranate fruit inside ventilated cartons. J. Food Eng. 2017, 215, 126–133. [Google Scholar] [CrossRef]

- Ambaw, A.; Mukama, M.; Fadiji, T.; Opara, U.L. Fresh fruit packaging design verification through virtual prototyping technique. Food Packag. Shelf Life 2022, 32, 100858. [Google Scholar] [CrossRef]

- Fadiji, T.; Coetzee, C.; Chen, L.; Chukwu, O.; Opara, U.L. Susceptibility of apples to bruising inside ventilated corrugated paperboard packages during simulated transport damage. Postharvest Biol. Technol. 2016, 118, 111–119. [Google Scholar] [CrossRef]

- Wu, W.; Beretta, C.; Cronje, P.; Hellweg, S.; Defraeye, T. Environmental trade-offs in fresh-fruit cold chains by combining virtual cold chains with life cycle assessment. Appl. Energy 2019, 254, 113586. [Google Scholar] [CrossRef]

- Joshi, K.; Tiwari, B.; Cullen, P.J.; Frias, J.M. Predicting quality attributes of strawberry packed under modified atmosphere throughout the cold chain. Food Packag. Shelf Life 2019, 21, 100354. [Google Scholar] [CrossRef]

- Ajani, C.K.; Zhu, Z.; Sun, D.W. Recent advances in multiscale CFD modelling of cooling processes and systems for the agrifood industry. Crit. Rev. Food Sci. Nutr. 2021, 61, 2455–2470. [Google Scholar] [CrossRef] [PubMed]

| Reference | Method | Produce Type | Unit of Operation | Produce Phenomena | Type of Study | Performance Indicators |

|---|---|---|---|---|---|---|

| [71] | Exp & Num | Spheres | Transport | - | Thermal Aerodynamic | Airflow rate Velocity magnitude Nusselt number Air and core product temperature |

| [79] | Exp | Apples | Storage | Moisture | Thermal, Aerodynamic, Product quality | Air velocity Convective heat transfer coefficient (CHTC) HCT Temperature field in the cold room Weight loss |

| [46] | Exp & Num | Apples | Storage | Respiration | Thermal Aerodynamic | Airflow Temperature Natural convection Refrigeration load |

| [51] | Exp & Num | Apples | Transport | Respiration | Thermal Aerodynamic | Pallet pressure drop Airflow pattern Air velocity SECT HCT |

| [13] | Exp | Strawberries | Pre-cooling | - | Thermal | HCT Air and Produce temperature |

| [38] | Exp | Apples | Storage | - | Aerodynamic | Air speed Air velocity |

| [7] | Num | Oranges | Storage | Respiration, Transpiration | Thermal Aerodynamic | Air velocity Product temperature Surface heat transfer coefficient Absolute deviations of mean product temperature |

| [80] | Exp | Apples | Storage | - | Aerodynamic | Air velocity Air speed Air volume rate |

| [81] | Exp | Citrus | Transport | Thermal product quality energy consumption | Air temperature SECT Mass loss Chilling injury Decay incidence Energy consumption Power use of refrigeration unit |

| Reference | Method | Produce Type | Unit of Operation | Produce Phenomena | Type of Study | Performance Indicators |

|---|---|---|---|---|---|---|

| [89] | Exp | Strawberries | Pre-cooling | - | Thermal | SECT Produce temperature |

| [90] | Exp & Num | Apples | Transport | Respiration | Thermal, Aerodynamic | Pressure drop Vertical air velocity Produce temperature HCT SECT |

| [23] | Exp | Citrus | Pre-cooling | - | Thermal | HCT |

| [91] | Exp & Num | Oranges | Transport | Thermal Aerodynamic Product quality | Product temperature Cooling time Quality parameter |

| Reference | Method | Produce Type | Unit of Operation | Produce Phenomena | Type of Study | Performance Indicators |

|---|---|---|---|---|---|---|

| [93] | Exp | PVC spheres | Pre-cooling | - | Aerodynamic | Air velocity Turbulence intensity |

| [94] | Exp | PVC spheres | Pre-cooling | - | Thermal | CHTC |

| [85] | Num | Strawberries | Pre-cooling | Moisture | Thermal Aerodynamic | Air velocity Fruit temperature |

| [39] | Exp | Strawberries | Pre-cooling | Moisture | Thermal | Fruit temperature Air temperature Moisture loss SECT |

| [98] | Num | Strawberries | Pre-cooling | Moisture | Thermal Aerodynamic | Airflow rate Fruit temperature Air temperature Cooling time Moisture loss |

| [37] | Num & Exp | Strawberries | Pre-cooling | Moisture | Thermal Aerodynamic | Fruit temperature SECT Energy consumed Airflow rate |

| [30] | Num & Exp | Oranges | Pre-cooling | Heat of Respiration | Thermal Aerodynamic | Airflow velocity Pressure drop Turbulence Produce temperature |

| [41] | Num & Exp | Oranges | Pre-cooling | - | Thermal | SECT CHTC |

| [95] | Num & Exp | Oranges | Pre-cooling | - | Thermal | SECT CHTC |

| [40] | Num & Exp | Kiwifruit | Pre-cooling | - | Thermal Aerodynamic | Air velocity Flowrate % HCT Air temperature Produce temperature SECT |

| [99] | Num & Exp | Strawberries | Pre-cooling | - | Thermal Aerodynamic | Air velocity Airflow HCT air temperature Produce temperature |

| [63] | Num & Exp | Pomegranates | Pre-cooling | - | Thermal Aerodynamic | Pressure drop SECT Produce temperature Air velocity Heat transfer coefficient |

| [97] | Num & Exp | Kiwifruit | Pre-cooling | - | Thermal Aerodynamic | HCT Air velocity Fruit temperature net energy requirement |

| [100] | Num | Citrus | Pre-cooling, Storage, Transport | - | Thermal Aerodynamic Product quality | Air velocity SECT Fruit temperature Overall fruit quality |

| [25] | Num & Exp | Apples | Pre-cooling | Transpiration | Thermal Aerodynamic Product quality | SECT Airflow rate Fruit temperature Energy consumption Fan power Transpiration coefficient Chilling injury Mass loss |

| [8] | Num | Orange | Pre-cooling, Storage, Transport | - | Thermal Aerodynamic Product quality | Kinetic rate-law quality model SECT Air velocity Fruit temperature |

| [101] | Num & Exp | Strawberries | Pre-cooling | Moisture | Thermal Aerodynamic | Fruit temperature Air temperature Air velocity Airflow % SECT |

| Reference | Product | Correlation | Range of Value |

|---|---|---|---|

| [104] | Orange | 25,000 | |

| Tomato | |||

| [94] | Sphere in a stack | 4000 , | |

| [105] | Spherical product | - | |

| Cylindrical product |

| Reference | Product | Heat of Respiration (W·Kg−1) |

|---|---|---|

| [77] | Apple | |

| [110] | Potato | , , |

| [111] | - | a et b depend on fruit type |

| Reference | Method | Produce Type | Unit of Operation | Produce Phenomena | Type of Study | Performance Indicators |

|---|---|---|---|---|---|---|

| [88] | Num | 2 D circles | Pre-cooling | - | Thermal | Heterogeneity index Produce surface temperature |

| [114] | Exp & Num | Oranges | Pre-cooling | - | Thermal Aerodynamic | Airflow velocity Pressure drop Produce temperature HCT SECT |

| [77] | Exp & Num | Apples | Pre-cooling | Respiration, transpiration & moisture | Thermal Aerodynamic | Airflow velocity Turbulent kinetic energy Produce temperature HCT |

| [64] | Num | Apples | Pre-cooling | - | Thermal Aerodynamic | SECT CHTC Pressure drop Pressure loss coefficient Ventilation power usage |

| [26] | Exp & Num | Apples | Pre-cooling | - | Thermal Aerodynamic Product quality | Airflow velocity Produce temperature HCT SECT Fan energy consumption Chilling injury Mass loss |

| [86] | Num, Exp | Apples | Pre-cooling | - | Thermal Aerodynamic mechanical resistance | SECT CHTC Total fan energy consumption |

| [115] | Num | Citrus | Pre-cooling, storage & transport | - | Thermal Aerodynamic Product quality | Air velocity SECT CHTC Fruit temperature Overall fruit quality |

| [87] | Exp & Num | Strawberries | Pre-cooling | - | Thermal | Produce quality Airflow velocity SECT |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nasser Eddine, A.; Duret, S.; Moureh, J. Interactions between Package Design, Airflow, Heat and Mass Transfer, and Logistics in Cold Chain Facilities for Horticultural Products. Energies 2022, 15, 8659. https://doi.org/10.3390/en15228659

Nasser Eddine A, Duret S, Moureh J. Interactions between Package Design, Airflow, Heat and Mass Transfer, and Logistics in Cold Chain Facilities for Horticultural Products. Energies. 2022; 15(22):8659. https://doi.org/10.3390/en15228659

Chicago/Turabian StyleNasser Eddine, Ahmad, Steven Duret, and Jean Moureh. 2022. "Interactions between Package Design, Airflow, Heat and Mass Transfer, and Logistics in Cold Chain Facilities for Horticultural Products" Energies 15, no. 22: 8659. https://doi.org/10.3390/en15228659

APA StyleNasser Eddine, A., Duret, S., & Moureh, J. (2022). Interactions between Package Design, Airflow, Heat and Mass Transfer, and Logistics in Cold Chain Facilities for Horticultural Products. Energies, 15(22), 8659. https://doi.org/10.3390/en15228659