Abstract

Fertilization is an essential element in plant cultivation. Supplying the right amounts of nutrients allows plants to grow and develop. Due to the rising price of mineral fertilizers, other fertilizers and soil conditioners are growing in importance. One of these is the digestate produced in agricultural biogas plants. Due to its properties, the digestate can be used directly as a fertilizer. In this case, the effects of application can both change the soil environment and directly affect plant growth. Physical, biological, and thermal transformations can also produce products based on the digestate or its fractions, which can be successfully used for fertilizer purposes. Among other things, this paper discusses the production and use of composts, biocarbon, and/or fertilizer granules from the solid fraction of the digestate. Numerous scientific studies, including the authors’ own research in this article, indicate that digestate can be successfully used as fertilizer, both without processing and with selected methods of treatment. However, further research is needed—especially on the diversity of raw materials used for biogas production and their effects on the composition and performance of the digestate. In addition, research should continue on the processing of digestate into specific products, depending on the needs of soils and plants.

1. Introduction

Rational energy management is one of humanity’s greatest challenges in the 21st century. Regulations and climate change argue for reducing the use of fossil fuels for energy production [1]. Renewable energy sources (RESs) have been gaining prominence in the last two decades. Their numerous benefits are apparent from environmental, economic, and social perspectives [2]. One renewable energy source is the production of biogas, whether from biomass, waste, or byproducts [3,4]. This process takes place in industrial facilities called biogas plants, although in tropical countries it is also possible in small-scale backyard reactors. The main product of the anaerobic digestion process that occurs in the installations in question is biogas, which is a valuable fuel that, when purified into biomethane, can also replace natural gas, which is a fossil fuel [5]. However, it is also important to keep in mind the second product, i.e., digestate, which is a valuable fertilizer that acts comprehensively to accelerate plant growth.

Restrictions on the availability of mineral fertilizers can affect the food security of many countries worldwide. This is directly related to limited crop production. Digestate, which is an alternative to commonly used mineral, natural, and organic fertilizers, can be a partial solution to this problem [6]. The digestate, which is the other product of the decomposition of raw materials used for biogas production, is most often applied directly to fields as fertilizer in its unprocessed form. However, this product has not always been considered as important as biogas. Due to the recent rise I the prices of mineral fertilizers and problems with their availability and purchase, the numerous benefits of using digestate are increasingly being recognized. Raw materials that can be processed in biogas plants are found virtually everywhere in the world. Hence, biogas production should also be implemented globally on a large scale (since energy production in biogas plants is completely under the control of the operator). This would also enable the local production and management of the digestate. This activity can be directly related to sustainable development and a circular economy.

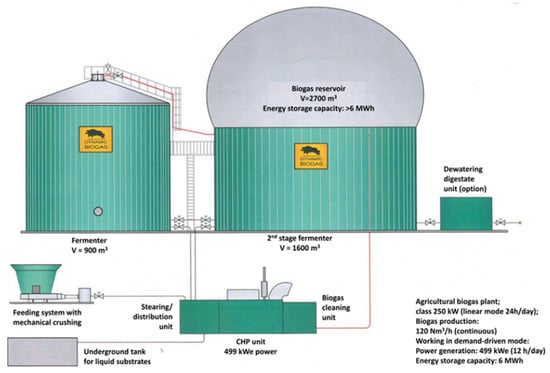

Agricultural biogas plants, which are renewable energy installations, perform many functions [7]. By far the most important and most frequently mentioned role is the production of renewable energy in the form of electricity and heat in cogeneration (as well as cooling in trigeneration), or of energy in chemical form, i.e., biomethane [8]. Another function is related to energy storage and energy stabilization in demand-driven biogas plants [9]. This is because the biogas produced may or may not be immediately injected into the grid or directed to a cogeneration engine to produce electricity and heat. It is possible to control this process and direct electricity and heat to the grid when it is most needed. These are topics that, until recently, have received little attention or emphasis. In view of the current energy market and the geopolitical situation in Europe, this solution is definitely gaining importance. In particular, it should be emphasized that biogas plants are RES installations that are completely independent of weather conditions, season, or precipitation. In addition, they are installations that can store energy in the form of biogas under the domes of digesters. As a result, they can operate as demand-driven power plants and supply energy to the grid at the times of the day when demand is greatest. Currently, biogas plants are being built in Poland with a continuous operation capacity of 250 kW, but with cogeneration (i.e., combined heat and power) units of 499 kW, which will operate for 12 h/day. A diagram of such an installation is shown in Figure 1.

Figure 1.

Diagram of operation of a 499 kW demand-driven biogas plant with energy storage (Dynamic Biogas Company).

In addition to functions related to energy production and transmission, other functions should be mentioned in the context of biogas plants. The plants are installations where biowaste can be managed [10]. The substitution of corn silage and other targeted crops for biowaste is gaining importance every year. The waste and byproducts from the agrifood industry are especially worth mentioning here [11,12]. Due to the fact that biogas plants can use the vast majority of biodegradable waste, their environmental role should be emphasized [13].

Another advantage of biogas plants is directly related to the use of the second product of the anaerobic digestion process besides biogas—namely, the digestate. The digestate, also known as digested pulp, is the product resulting from the anaerobic digestion process. It consists primarily of organic matter that is not decomposed in the process, as well as minerals, water, and microorganisms. Due to the richness and variety of compounds included in the substance in question, the preferred direction of its management should be direct use for fertilizer purposes.

Crop fertilization is the most popular raw digestate management method but, depending on the type of application, different processing methods may need to be used, including dehydration, solid–liquid separation, drying, evaporation, biological processes (e.g., composting, anaerobic digestion), and thermal processes (e.g., direct combustion, pyrolysis, or gasification). Regardless of the methods used and the resulting materials, both the raw digestate and the produced products can be used as fertilizers, among other things.

The aim of this study was to discuss the properties and possibilities of using digestate and its fractions as fertilizer, considering the latest innovative processes for its processing. Fertilization is the most popular raw digestate management method, but there are alternatives. For this reason, other directions for the use of digestate have been indicated and discussed. The authors conducted a literature search considering the topics presented in the main chapters and subsections. The results available in the literature were compared to the results obtained in the authors’ own research. This activity was based on the concept of the paper and the issues discussed by the authors. This is significant because, in many places around the world, digestate fertilization without treatment is the only method of its management.

2. Biogas Digestate—Production, Properties, and Processing

2.1. Production and Properties

Anaerobic digestion is a natural process that occurs during the storage of biodegradable waste, or in swampy areas, among other situations. The process in question produces methane, nitrous oxide, and carbon dioxide, among others, under uncontrolled conditions. The process can also be used under controlled conditions in biogas plants. If biodegradable raw materials are placed in a sealed reactor chamber, biogas production can occur, with methane as the main component, and carbon dioxide to a lesser extent. However, it is necessary to provide the appropriate groups of bacteria that carry out the process in question. However, only part of the fermented mass is decomposed under anaerobic conditions. The parts that do not decompose are pumped out of the digester and enter the digestate. The product produced should be managed periodically as fertilizer material or processed into other products.

As mentioned earlier in the Introduction, the number of substrates that can be used for biogas production is very large. Their availability is also very widespread, occurring virtually everywhere. Unlike other renewable energy sources, this is a major advantage. In contrast to solar energy or wind power, for example, biogas can be produced in a stable and fully controllable manner by the operator. For small-scale backyard biogas plants, locations where the temperature remains high throughout the year are particularly advantageous. This is because anaerobic digestion often occurs better under mesophilic and thermophilic conditions. In contrast, large industrial biogas plants that produce a lot of heat in cogeneration can be built and operated practically all over the globe.

It should be stated that the main influence on the properties of the digestate lies in the substrates used for biogas production. In many European countries, the dominant feedstocks for energy production are still corn silage, slurry, and manure [14,15]. Due to the possibility of waste management, all kinds of waste and byproducts from the agrifood industry are increasingly being used for biogas production [16]. Biogas production can reduce the amount of landfilled waste and reduce uncontrolled emissions of greenhouse gases and other pollutants into the air, soil, and water environments [17]. This direction is definitely proper; therefore, such a trend should be expected in the years to come.

The substrates used to produce biofuels, including biogas, include sugars, proteins, and fats, among others. Their degree and time of decomposition vary, as do the physical and chemical properties of the feedstocks. These parameters directly affect the properties of the produced digestate and the possibility of its use for fertilizer purposes.

In the context of the formation of the digestate, it is also important to mention its quantity. The mass of the formed digest is closely related to the amounts and types of substrates used for biogas production. The factors affecting it are primarily the types of raw materials, their susceptibility to decomposition, and the pretreatment and fermentation technologies used. Logistics in the supply of raw materials and the management of digestate undoubtedly represent a major challenge. This is due to the fact that a typical 1 MW agricultural biogas plant processes several dozen Mg of raw materials per day (between 30 and 80 Mg, depending on the energy value of the substrates). The amount of digestate produced, depending on several factors, usually accounts for 70–90% of the feedstock weight.

As a product of the decomposition of substrates containing organic matter under anaerobic conditions, digestate has specific properties. As mentioned earlier, the properties are mainly influenced by the types of raw materials used for biogas production. It should be unequivocally emphasized that adequate-quality raw materials form the basis of a high-quality product. This is assuming that the technological process of biogas production is carried out correctly and there is no breakdown of the process due to acidification, for example.

The total solids content is one of the basic properties of the digestate, and this parameter indicates how strongly the substrate is hydrated. Organic matter is decomposed under anaerobic conditions, but a certain part of it remains undecomposed. The size of the parameter in question is particularly important because of the possibility of enriching the soil with organic fractions at the time of fertilization. Equally important are the contents of selected elements—both those positively affecting the soil, such as nitrogen, phosphorus, and potassium, as well as those threatening the soil, i.e., heavy metals. A separate group consists of pathogens that may be present in the digestate [18]. Table 1 shows the properties of several different digestates, to illustrate the considerable variability in the parameters of digestates from different installations.

Table 1.

Properties of the digestates generated at biogas plants [19].

The contents of all analyzed parameters in the digestates from three Polish agricultural biogas plants varied (Table 1). For example, the dry matter content was in the range of 3.21–6.62%. The organic matter content also varied between the biogas plants, ranging from 60.96 to 76.47%. The pH for all analyzed samples was alkaline and ranged from 8.10 to 9.40 kg‧Mg−1 FM. The greatest variation was observed for NPK analysis—especially for potassium (1.30–16.30 kg‧Mg−1 FM). Given the possibility of considerable diversity in digestates, their effects on individual plants will also vary.

2.2. Processing

Suitable conditions do not always exist to allow the direct use of digestate for fertilizer purposes. These limitations may be due, among other things, to the lack of adequate agricultural land on which the digestate can be distributed. Other examples include legal restrictions on the use of the digestate, or unfavorable terrain near the biogas plant. There are more limitations and aspects in the field of fertilizer use—for example, those related to transport costs and the use of low-emission spreading techniques. The need to process the digestate may be due to the reasons given above. It may also be related to a deliberate effort to produce other products, of which the digestate would be the starting material. This may be associated with additional benefits—primarily those related to a wide management spectrum of the products according to specific needs.

Processing of the digestate brings many benefits. However, it should be borne in mind that each of the activities aimed at producing new products from the digestate is associated with additional costs. These include the purchase of additional equipment and machinery, the consumption of electricity, the involvement of staff, and the need to set aside a new site for investment. However, considering the value of products such as compost or biocarbon and the existence of a developed market for these products, this activity is often profitable. Nevertheless, the technical, technological, and economic aspects of processing the digestate should be considered and verified. Additional factors for deciding on the introduction of raw digestate processing methods include environmental and social aspects.

Separation is the simplest operation to increase the amount and variety of management directions of the digestate. This method results in a minimum of two fractions of the digestate, which significantly differ in terms of their physical and chemical properties [20]. Due to additional costs, separation into more than two fractions is unlikely to be used. Another solution is to dry the digestate. The heat generated in cogeneration can be used for this process. However, due to the high hydration of raw digestate, this solution is not often practiced. As an alternative, the solid fraction can be dried before further use in energy processes. Another interesting technology is the thickening of the digestate through the use of an evaporator powered by heat from cogeneration, where water is rapidly evaporated under reduced pressure at temperatures as low as 60–75 °C.

The liquid fraction is characterized by low dry matter content and reduced organic matter content. However, it should be emphasized that it is primarily fraction of the digestate that contains the dissolved minerals necessary for plants’ growth and development. Therefore, it can be used for fertilizer purposes [21]. In some respects, however, the fraction in question is similar to raw digestate. Therefore, the manner of its application and its effects on soil and plant life are similar to those of raw digestate. Another direction of its use is the dilution of the new portion of raw materials supplied to the reactor in the biogas plant. This action can not only save water—which could be used to reduce the dry weight of the feedstock mixture—but also provide beneficial microorganisms involved in anaerobic digestion.

The second fraction obtained by separating the raw digestate is the solid fraction. Its most important property is a higher proportion of dry matter—usually reaching 25–35%—and an increased proportion of organic matter compared to the liquid fraction. For this reason, the number of directions for its utilization is greater than for the liquid fraction. The main uses to be mentioned here include fertilizer applications as well as energy utilization. The solid fraction can be used directly as a loose fertilizer—both fresh and after drying. The advantages of such a solution include providing nutrients, creating humus, or retaining water in the soil. Another solution is to use it in the composting process. In addition to being a source of carbon, the raw material in question can also play the role of a structure-forming material. It is also worth mentioning the possibility of granulating the solid fraction, both with and without additives. The product of this process is an organic fertilizer in the form of granules. When discussing the energetic use of the solid fraction, it is worth mentioning such processes as the production of solid fuels (e.g., pellets and briquettes), followed by their combustion, pyrolysis, or even secondary use of the considered raw material in the process of anaerobic digestion [22].

3. Biogas Digestate as a Valuable Source of Nutrients

3.1. The Use of the Raw Digestate

The most common way to manage digestate is to use it directly for fertilizer purposes without prior processing. This is due to its physical and chemical properties, which strongly support its use in agriculture. Low dry mass, relatively high organic matter content, slightly acidic pH, and NPK abundance are just some of the parameters supporting the application of the product of the anaerobic digestion process as a fertilizer. As mentioned earlier, another advantage of the solution in question is the lack of need for further processing of the digestate, enabling biogas plant managers to reduce costs. However, before using the digestate, the contents of heavy metals and the presence of pathogens should be verified. Exceeding acceptable standards could result in the inability to fertilize with the digestate.

When using typical agricultural substrates (e.g., manure, slurry, byproducts of the agrifood industry) for biogas production, the digestate is a valuable product that can be successfully used for fertilizer purposes [23]. Managing biodegradable waste and manure in this way can contribute to increasing energy production from RESs, reducing the amount of waste that decomposes uncontrollably, reducing the carbon footprint, and introducing environmentally friendly fertilizers to the soil, among other things [24].

The effects of the use of waste—including digestate—on soil properties have been addressed by scientists for many years. For example, as early as 2011, a study by Odlare et al. [25] concluded that digestate can be an alternative to mineral fertilizers. However, it was noted that the fertilizing effect may be delayed. The reason for this is that organic waste contains less immediate plant-available nitrogen than mineral fertilizers. Based on the study, digestate had positive effects on a number of soil chemical characteristics.

In a study by Slepetiene et al. (2020) [26], the aim was to determine the potential for using of solid and liquid digestate as a biofertilizer and soil amendment. The paper highlighted the role of digestate as a source of organic matter and humic acids. A positive impact on the humification process was found. Thus, digestate can have beneficial effects on eroded soils and soils with lower productivity.

The use of digestate as fertilizer is the subject of numerous ongoing studies around the world. Selected scientific publications on the cultivation of specific crops are presented in Table 2.

Table 2.

Fertilizer use of digestate.

In the study of Lee et al. [27], the aim was to evaluate the nutritional value of digestate and digestate + biochar for switchgrass (Panicum virgatum) production. A greenhouse experiment was conducted to determine the effects of various nitrogen sources—including control, urea (nutrient control), sewage sludge digestate, and sewage sludge digestate + corn stover biochar—on switchgrass growth and feedstock composition. The results indicated that both digestate and digestate with added biochar can be potential substitutes for chemical fertilizers, resulting in increased biomass yield [27].

Doyeni et al. [28] compared the effects of chicken manure digestate, cow manure digestate, and pig manure digestate on spring wheat (Triticum aestivum) productivity, soil microbial activities, and greenhouse gas emissions in loam and sandy loam soils under controlled climate conditions. It was found that digestates had a similar effect on total biomass yield based on the experiment conducted. Higher biomass yield was observed in the digestate treatments compared with the control [28].

The analysis showed an increase in the yield depending on the dose of the digestate. Furthermore, an increase in the fat and protein contents was observed in winter rapeseed. This is important in terms of the possibility of using the plant for biofuel production. The authors also emphasized that the dose of the digestate affects the yield obtained and the mass of 1000 seeds [29].

3.2. The use of Products Based on Digestate

In recent years, increased use has been noted not only of raw digestate, but also of products derived from it [30]. This activity is due to a number of reasons, although the most important is the fulfillment of the fertilizer needs of plants, due to their specific requirements.

3.2.1. Compost Production Using Digestate

As mentioned earlier, digestate is a material with a relatively low dry matter content. Therefore, the preferred feedstock for the composting process is the solid fraction of the digestate. Our own research [31] showed that the solid fraction, even without the addition of other raw materials, can be a good substrate for compost production. This was confirmed by the temperature course, among other things. The solid fraction both plays the role of a carbon source and forms the structure of the composted mixture. Tambone et al., [32] performed a study on the characteristics of the solid fractions obtained by mechanical separation of digestate in terms of their compostability and compost quality. The separated solid fraction of digestate was obtained via anaerobic digestion of pig slurry, energy crops, and agro-industrial residues in five plants located in Northern Italy. As highlighted by the authors, the composts obtained fully adhered to the legal limits for high-quality compost.

3.2.2. Biochar Produced Using Digestate

Biochar created as a result of the pyrolysis process is a material with wide possibilities of use. Activities aimed at its application in environmental protection have a special role to play here. The possibility of using the solid fraction of digestate as a potential feedstock for preparing biochar was noted by Hung [33], among others. Liu et al. studied solid digestate generated via the anaerobic digestion of food wastes as a potential feedstock for biochar. The obtained results provide an alternative strategy for disposing of waste generated during the anaerobic digestion of food waste [34]. This is especially important given the growing amount of food waste in the world. Breunig et al., on the other hand, highlighted that digestate and biochar can be applied on land to sequester carbon and improve net primary productivity. However, they noted that the achievable scale is tied to expected growth in bioenergy production and the land available for application [35].

3.2.3. Fertilizer Granules Produced Using Digestate

Digestate can be successfully used as a component for the production of organic fertilizers, organic–mineral fertilizers, or soil conditioners. Due to their lower water content, the resulting granules will have a higher concentration of nutrients and organic matter than untreated digestate or the wet solid fraction. The solid fraction of the digestate can be pelletized both alone and with the addition of other components. In this case, it is possible to obtain smaller pellets as well as larger briquettes. This is confirmed both by our own research [36] and by that of other authors, such as Petrova et al. [37]. Cathcart et al. performed an economic analysis of anaerobic digestate fuel pellet production, considering mechanical separation to partition phosphorous. Thus, they proposed a solution to use the solid fraction of digestate for both fertilizer and fuel production [38].

3.2.4. Possible Development of a Digestate Market and Directions for Further Research

Fertilization is a key issue in any farm that produces crops. Due to the increasing prices of mineral fertilizers and current regulations concerning issues such as environmental protection, organic fertilizers are increasingly used. These fertilizers have a positive effect not only on the quantity and quality of crops, but also on the soil environment where they are applied [39]. Agricultural biogas plants processing maize silage and slurry produce digestate with a predominant share of unprocessed organic matter from maize [40]. The current trend is to use the waste from the agrifood industry for the production of biogas [41]. This trend has contributed not only to increasing the production and profitability of the conducted business activity, but also to increasing the contents of nutrients in digestate.

This is due to the variety in digestate’s micro- and macroelements. It should be expected that the interest in digestate from biogas plants—mainly processing waste from the agrifood industry—will increase [42]. The use of waste for energy production in biological processes is consistent with the principle of the circular economy [43]. This is a direction of research that is and will continue to be developed [44]. According to the information reviewed in this article, digestate can be used in many ways, including fertilization, biological processes, thermal processes, and reclamation. This was confirmed by the results of our own research [19,22,31,36] and by the results reported in other scientific papers [45,46,47]. According to the authors, further research should concern the costs of managing the discussed product, depending on the preferred method.

Analyzing an example, favorable conditions for fertilization may not always occur. For example, there may not be enough land nearby, or the land may be sloped, making it difficult to spread the fertilizer. Another such case would be when the ground is covered with snow. In this case, it would be necessary to store or process the product. Each action is associated with the need for additional devices, depending on the process. In addition, it will be necessary to assume costs related to electricity, for example. Due to the rapidly rising electricity prices, a situation may arise that will force the use of other solutions. Another research area could be the efficiency of digestate use with respect to alternative products, depending on the management strategy. For example, the macronutrients in a digestate are available in various forms. This may determine their availability after application to the soil.

The change in the structure of the substrates used for the production of biogas directly affects the properties of the digestate [48]. Being aware of this, one of the most important research directions should be the comparison of digestates from different biogas plants for plant growth. This would enable a more precise determination of the positive influence not only on the yield, but also on the soil environment. Due to the current geopolitical problems in Europe and the rising prices of electricity and natural gas, it should be concluded that both biogas and digestate are valuable products. To some extent, these products have a positive impact not only on the environment, but also in facilitating independence from external suppliers of the products in question—mainly fossil fuels. For this reason, further research on digestate should be carried out, not only in the fields of environmental, ecology, and agricultural sciences, but also in economics.

4. Conclusions

The role of agricultural biogas plants as RESs is gaining importance every year. This is supported not only by economic concerns, but also by environmental and social factors. In particular, the role of demand-driven biogas plants in stabilizing the electricity system by providing electricity in peak demand periods during the day deserves emphasis. In addition to the amount of biogas or the electricity produced from biogas, attention should be paid to the second product of the anaerobic digestion process, i.e., the digestate. Management of the digestate is a major challenge for plant owners. However, due to the possibility of its use in agriculture, it should also be welcomed as an opportunity. After all, the digestate itself may turn out to be an additional source of revenue for biogas plant owners.

Recently, a significant increase in the price of mineral fertilizers has been observed around the world, mainly due to the increase in the price of natural gas and the high prices of raw materials used to produce compound fertilizers. In addition, there are problems with their availability. Hence, it is necessary to look for alternative solutions to these problems. Due to the abundance and variety of nutrients necessary for plants’ growth and development, increased use of digestate should be expected.

Fertilization remains the most popular way to use raw digestate. Considering the properties of the product in question, this solution should be considered the preferred one. The roles of other directions of use of processed digestate should also be emphasized, representing certain alternatives that can prove extremely useful.

Regulations on both the production and use of all fertilizers are becoming increasingly stringent. This is expected to have a positive impact on the protection of the natural environment. The use of digestate as fertilizer can make it possible to obtain adequate crop yields while reducing the negative impact on the environment. Biogas production based on the use of waste and byproducts also fits in with activities related to sustainable development and the circular economy. Considering the increase in the price of mineral fertilizers observed since 2021, special attention should be paid to the discussed alternative fertilizer, which can be used in crop production.

Author Contributions

Conceptualization, W.C. and J.D.; methodology, W.C. and T.J.; software, W.C. and T.J.; validation, J.D. and T.J.; formal analysis, W.C.; investigation, W.C. and J.D.; resources, W.C. and K.W.; data curation, W.C. and T.J.; writing—original draft preparation, W.C., J.D., T.J., M.G. and T.J.; writing—review and editing, W.C., J.D., T.J., M.G. and T.J.; visualization, W.C.; supervision, J.D.; project administration, W.C. and J.D. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest. The funders had no role in the 308 design of the study; in the collection, analyses, or interpretation of data; in the writing of the manuscript; or in the decision to publish the results.

Abbreviations

| FM | Fresh matter |

| RESs | Renewable energy sources |

| TS | Total solids (% FM) |

| VS | Volatile solids (% TS) |

References

- Czajka, K.; Kawalec, W.; Król, R.; Sówka, I. Modelling and Calculation of Raw Material Industry. Energies 2022, 15, 5035. [Google Scholar] [CrossRef]

- Czekała, W.; Tarkowski, F.; Pochwatka, P. Social aspects of energy production from renewable sources, Społeczne aspekty produkcji energii ze źródeł odnawialnych. Probl. Ekorozw. 2021, 16, 61–66. [Google Scholar] [CrossRef]

- Sobczak, A.; Chomać-Pierzecka, E.; Kokiel, A.; Różycka, M.; Stasiak, J.; Soboń, D. Economic Conditions of Using Biodegradable Waste for Biogas Production, Using the Example of Poland and Germany. Energies 2022, 15, 5239. [Google Scholar] [CrossRef]

- Gao, X.; Tang, X.; Zhao, K.; Balan, V.; Zhu, Q. Biogas Production from Anaerobic Co-Digestion of Spent Mushroom Substrate with Different Livestock Manure. Energies 2021, 14, 570. [Google Scholar] [CrossRef]

- Al-Wahaibi, A.; Osman, A.I.; Al-Muhtaseb, A.H.; Alqaisi, O.; Baawain, M.; Fawzy, S.; Rooney, D.W. Techno-economic evaluation of biogas production from food waste via anaerobic digestion. Sci. Rep. 2020, 10, 15719. [Google Scholar] [CrossRef]

- Vázquez-Rowe, I.; Golkowska, K.; Lebuf, V.; Vaneeckhaute, C.; Michels, E.; Meers, E.; Benetto, E.; Koster, D. Environmental assessment of digestate treatment technologies using LCA methodology. Waste Manag. 2015, 43, 442–459. [Google Scholar] [CrossRef]

- Koryś, K.A.; Latawiec, A.E.; Grotkiewicz, K.; Kuboń, M. The Review of Biomass Potential for Agricultural Biogas Production in Poland. Sustainability 2019, 11, 6515. [Google Scholar] [CrossRef]

- Gustafsson, M.; Anderberg, S. Dimensions and characteristics of biogas policies—Modelling the European policy landscape. Renew. Sustain. Energy Rev. 2021, 135, 110200. [Google Scholar] [CrossRef]

- Aryal, N.; Kvist, T. Alternative of Biogas Injection into the Danish Gas Grid System—A Study from Demand Perspective. ChemEngineering 2018, 2, 43. [Google Scholar] [CrossRef]

- Paolini, V.; Petracchini, F.; Segreto, M.; Tomassetti, L.; Naja, N.; Cecinato, A. Environmental impact of biogas: A short review of current knowledge. J. Environ. Sci. Health. A Tox. Hazard. Subst. Environ. Eng. 2018, 53, 899–906. [Google Scholar] [CrossRef]

- Czekała, W.; Smurzyńska, A.; Cieślik, M.; Boniecki, P.; Kozłowski, K. Biogas efficiency of selected fresh fruit covered by the Russian embargo. In Proceedings of the Energy and Clean Technologies Conference Proceedings SGEM 2016, Albena Resort, Bulgaria, 28 June–7 July 2016; Volume III, pp. 227–233. [Google Scholar]

- Pochwatka, P.; Kowalczyk-Juśko, A.; Sołowiej, P.; Wawrzyniak, A.; Dach, J. Biogas Plant Exploitation in a Middle-Sized Dairy Farm in Poland: Energetic and Economic Aspects. Energies 2020, 13, 6058. [Google Scholar] [CrossRef]

- Czekała, W. Biogas as a Sustainable and Renewable Energy Source. In Clean Fuels for Mobility, Energy, Environment, and Sustainability; Di Blasio, G., Agarwal, A.K., Belgiorno, G., Shukla, P.C., Eds.; Springer: Singapore, 2022; pp. 201–214. [Google Scholar] [CrossRef]

- Kowalczyk-Juśko, A.; Pochwatka, P.; Zaborowicz, M.; Czekała, W.; Mazurkiewicz, J.; Mazur, A.; Janczak, D.; Marczuk, A.; Dach, J. Energy value estimation of silages for substrate in biogas plants using an artificial neural network. Energy 2020, 202, 117729. [Google Scholar] [CrossRef]

- Mazurkiewicz, J. Energy and Economic Balance between Manure Stored and Used as a Substrate for Biogas Production. Energies 2022, 15, 413. [Google Scholar] [CrossRef]

- Kozłowski, K.; Pietrzykowski, M.; Czekała, W.; Dach, J.; Kowalczyk-Juśko, A.; Jóźwiakowski, K.; Brzoski, M. Energetic and economic analysis of biogas plant with using the dairy industry waste. Energy 2019, 183, 1023–1031. [Google Scholar] [CrossRef]

- Pochwatka, P.; Kowalczyk-Jusko, A.; Mazur, A.; Janczak, D.; Pulka, J.; Dach, J.; Mazurkiewicz, J. Energetic and Economic Aspects of Biogas Plants Feed with Agriculture Biomass. In Proceedings of the 4th International Conference on Green Energy and Applications, ICGEA 2020, Singapore, 7–9 March 2020; pp. 130–133. [Google Scholar] [CrossRef]

- Seruga, P.; Krzywonos, M.; Paluszak, Z.; Urbanowska, A.; Pawlak-Kruczek, H.; Niedźwiecki, Ł.; Pińkowska, H. Pathogen reduction potential in anaerobic digestion of organic fraction of municipal solid waste and food waste. Molecules 2020, 25, 275. [Google Scholar] [CrossRef]

- Czekała, W.; Lewicki, A.; Pochwatka, P.; Czekała, A.; Wojcieszak, D.; Jóźwiakowski, K.; Waliszewska, H. Digestate management in Polish farms as an element of the nutrient cycle. J. Clean. Prod. 2020, 242, 118454. [Google Scholar] [CrossRef]

- Barampouti, E.M.; Mai, S.; Malamis, D.; Moustakas, K.; Loizidou, M. Exploring technological alternatives of nutrient recovery from digestate as a secondary resource. Renew. Sustain. Energy Rev. 2020, 134, 110379. [Google Scholar] [CrossRef]

- Reuland, G.; Sigurnjak, I.; Dekker, H.; Michels, E.; Meers, E. The Potential of Digestate and the Liquid Fraction of Digestate as Chemical Fertiliser Substitutes under the RENURE Criteria. Agronomy 2021, 11, 1374. [Google Scholar] [CrossRef]

- Czekała, W. Biogas Production from Raw Digestate and its Fraction. J. Ecol. Eng. 2019, 20, 97–102. [Google Scholar] [CrossRef]

- Czekała, W. Agricultural Biogas Plants as a Chance for the Development of the Agri-Food Sector. J. Ecol. Eng. 2018, 19, 179–183. [Google Scholar] [CrossRef]

- Jurgutis, L.; Šlepetienė, A.; Šlepetys, J.; Cesevičienė, J. Towards a Full Circular Economy in Biogas Plants: Sustainable Management of Digestate for Growing Biomass Feedstocks and Use as Biofertilizer. Energies 2021, 14, 4272. [Google Scholar] [CrossRef]

- Odlare, M.; Arthurson, V.; Pell, M.; Svensson, K.; Nehrenheim, E.; Abubaker, J. Land application of organic waste—Effects on the soil ecosystem. Appl. Energy 2011, 88, 2210–2218. [Google Scholar] [CrossRef]

- Slepetiene, A.; Volungevicius, J.; Jurgutis, L.; Liaudanskiene, I.; Amaleviciute-Volunge, K.; Slepetys, J.; Ceseviciene, J. The potential of digestate as a biofertilizer in eroded soils of Lithuania. Waste Manag. 2020, 102, 441–451. [Google Scholar] [CrossRef]

- Lee, M.-S.; Urgun-Demirtas, M.; Shen, Y.; Zumpf, C.; Anderson, K.E.; Rayburn, L.A.; Lee, D.K. Effect of digestate and digestate supplemented with biochar on switchgrass growth and chemical composition. Biomass Bioenergy 2021, 144, 105928. [Google Scholar] [CrossRef]

- Doyeni, M.O.; Baksinskaite, A.; Suproniene, S.; Tilvikiene, V. Effect of Animal Waste Based Digestate Fertilization on Soil Microbial Activities, Greenhouse Gas Emissions and Spring Wheat Productivity in Loam and Sandy Loam Soil. Agronomy 2021, 11, 1281. [Google Scholar] [CrossRef]

- Koszel, M.; Parafiniuk, S.; Szparaga, A.; Bochniak, A.; Kocira, S.; Atanasov, A.Z.; Kovalyshyn, S. Impact of Digestate Application as a Fertilizer on the Yield and Quality of Winter Rape Seed. Agronomy 2020, 10, 878. [Google Scholar] [CrossRef]

- Brienza, C.; Sigurnjak, I.; Meier, T.; Michels, E.; Adani, F.; Schoumans, O.; Vaneeckhaute, C.; Meers, E. Techno-economic assessment at full scale of a biogas refinery plant receiving nitrogen rich feedstock and producing renewable energy and biobased fertilisers. J. Clean. Prod. 2021, 308, 127408. [Google Scholar] [CrossRef]

- Czekała, W.; Dach, J.; Dong, R.; Janczak, D.; Malińska, K.; Jóźwiakowski, K.; Smurzyńska, A.; Cieślik, M. Composting potential of the solid fraction of digested pulp produced by a biogas plant. Biosyst. Eng. 2017, 160, 25–29. [Google Scholar] [CrossRef]

- Tambone, F.; Terruzzi, L.; Scaglia, B.; Adani, F. Composting of the solid fraction of digestate derived from pig slurry: Biological processes and compost properties. Waste Manag. 2015, 35, 55–61. [Google Scholar] [CrossRef]

- Hung, C.-Y.; Tsai, W.-T.; Chen, J.-W.; Lin, Y.-Q.; Chang, Y.-M. Characterization of biochar prepared from biogas digestate. Waste Manag. 2017, 66, 53–60. [Google Scholar] [CrossRef]

- Liu, J.; Huang, S.; Chen, K.; Wang, T.; Mei, M.; Li, J. Preparation of biochar from food waste digestate: Pyrolysis behavior and product properties. Bioresour. Technol. 2020, 302, 122841. [Google Scholar] [CrossRef]

- Breunig, H.M.; Amirebrahimi, J.; Smith, S.; Scown, C.D. Role of Digestate and Biochar in Carbon-Negative Bioenergy. Environ. Sci. Technol. 2019, 53, 12989–12998. [Google Scholar] [CrossRef]

- Czekała, W. Solid Fraction of Digestate from Biogas Plant as a Material for Pellets Production. Energies 2021, 14, 5034. [Google Scholar] [CrossRef]

- Petrova, I.P.; Ruser, R.; Guzman-Bustamante, I. Pellets from Biogas Digestates: A Substantial Source of N2O Emissions. Waste Biomass Valori. 2021, 12, 2433–2444. [Google Scholar] [CrossRef]

- Cathcart, A.; Smyth, B.M.; Lyons, G.; Murray, S.T.; Rooney, D.; Johnston, C.R. An economic analysis of anaerobic digestate fuel pellet production: Can digestate fuel pellets add value to existing operations? Clean. Eng. Technol. 2021, 3, 100098. [Google Scholar] [CrossRef]

- Velichkova, R.; Pushkarov, M.; Angelova, R.A.; Sandov, O.; Markov, D.; Simova, I.; Stankov, P. Exploring the Potential of Straw Biochar for Environmentally Friendly Fertilizers. Sustainability 2022, 14, 6323. [Google Scholar] [CrossRef]

- Witaszek, K.; Pilarski, K.; Niedbała, G.; Pilarska, A.A.; Herkowiak, M. Energy Efficiency of Comminution and Extrusion of Maize Substrates Subjected to Methane Fermentation. Energies 2020, 13, 1887. [Google Scholar] [CrossRef]

- Hanif, M.U.; Zwawi, M.; Algarni, M.; Bahadar, A.; Iqbal, H.; Capareda, S.C.; Hanif, M.A.; Waqas, A.; Hossain, N.; Siddiqui, M.T.H.; et al. The Effects of Using Pretreated Cotton Gin Trash on the Production of Biogas from Anaerobic Co-Digestion with Cow Manure and Sludge. Energies 2022, 15, 490. [Google Scholar] [CrossRef]

- Witaszek, K.; Herkowiak, M.; Pilarska, A.A.; Czekała, W. Methods of Handling the Cup Plant (Silphium perfoliatum L.) for Energy Production. Energies 2022, 15, 1897. [Google Scholar] [CrossRef]

- Pilarski, K.; Pilarska, A.A.; Boniecki, P.; Niedbała, G.; Witaszek, K.; Piekutowska, M.; Idzior-Haufa, M.; Wawrzyniak, A. Degree of Biomass Conversion in the Integrated Production of Bioethanol and Biogas. Energies 2021, 14, 7763. [Google Scholar] [CrossRef]

- Soleymani Angili, T.; Grzesik, K.; Salimi, E.; Loizidou, M. Life Cycle Analysis of Food Waste Valorization in Laboratory-Scale. Energies 2022, 15, 7000. [Google Scholar] [CrossRef]

- Głowacka, A.; Szostak, B.; Klebaniuk, R. Effect of Biogas Digestate and Mineral Fertilisation on the Soil Properties and Yield and Nutritional Value of Switchgrass Forage. Agronomy 2020, 10, 490. [Google Scholar] [CrossRef]

- Baryga, A.; Połeć, B.; Klasa, A. The Effects of Soil Application of Digestate Enriched with P, K, Mg and B on Yield and Processing Value of Sugar Beets. Fermentation 2021, 7, 241. [Google Scholar] [CrossRef]

- Slepetiene, A.; Kochiieru, M.; Jurgutis, L.; Mankeviciene, A.; Skersiene, A.; Belova, O. The Effect of Anaerobic Digestate on the Soil Organic Carbon and Humified Carbon Fractions in Different Land-Use Systems in Lithuania. Land 2022, 11, 133. [Google Scholar] [CrossRef]

- Horta, C.; Riaño, B.; Anjos, O.; García-González, M.C. Fertiliser Effect of Ammonia Recovered from Anaerobically Digested Orange Peel Using Gas-Permeable Membranes. Sustainability 2022, 14, 7832. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).