A Closed-Loop Water Management Methodology for PEM Fuel Cell System Based on Impedance Information Feedback

Abstract

1. Introduction

2. Fuel Cell System

2.1. System Structure

- A temperature control module.

- An air stoichiometry control module.

- A stack.

- An impedance measurement module.

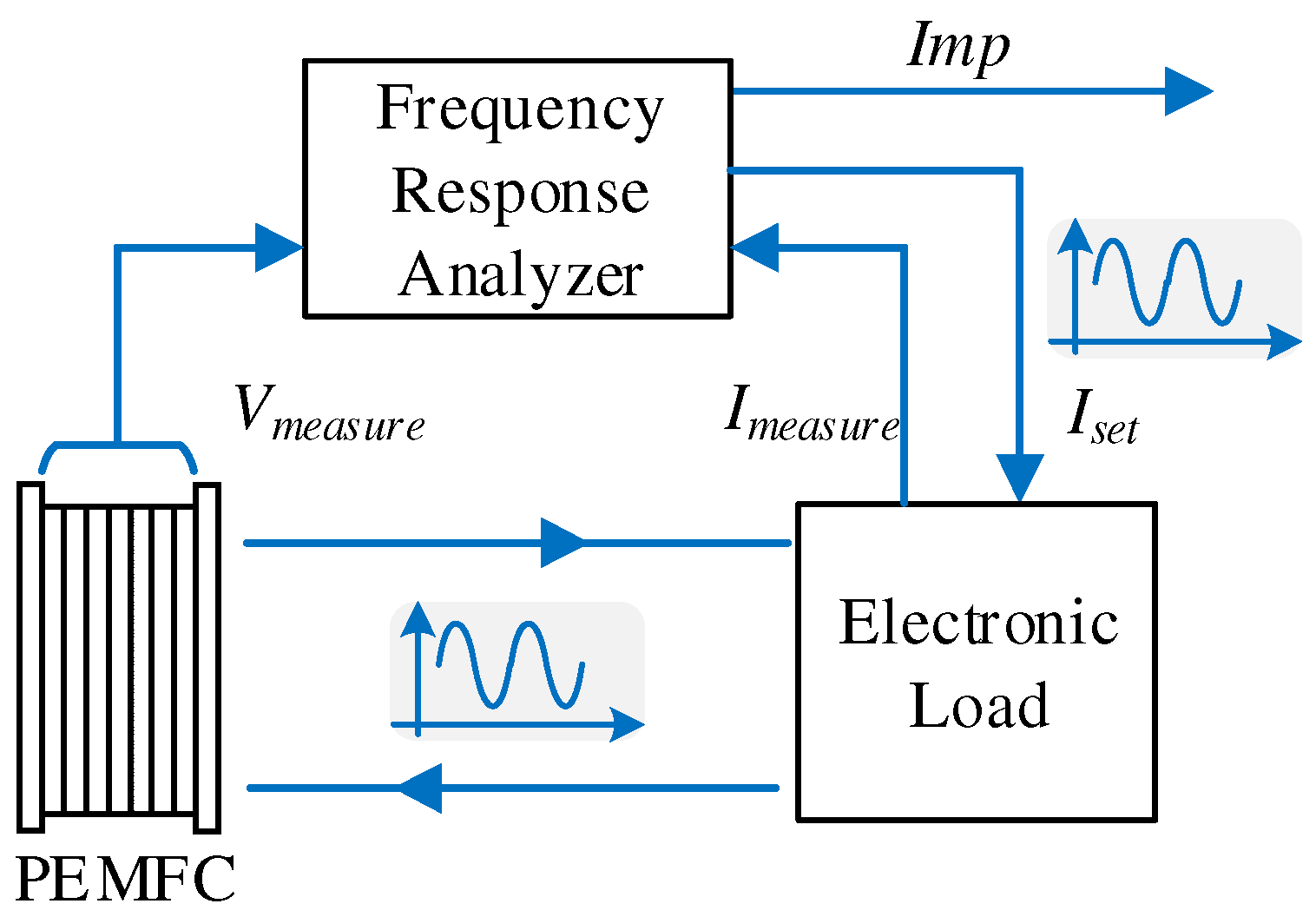

2.2. Impedance Measurement Module

3. Design of the Closed-Loop Water Management System

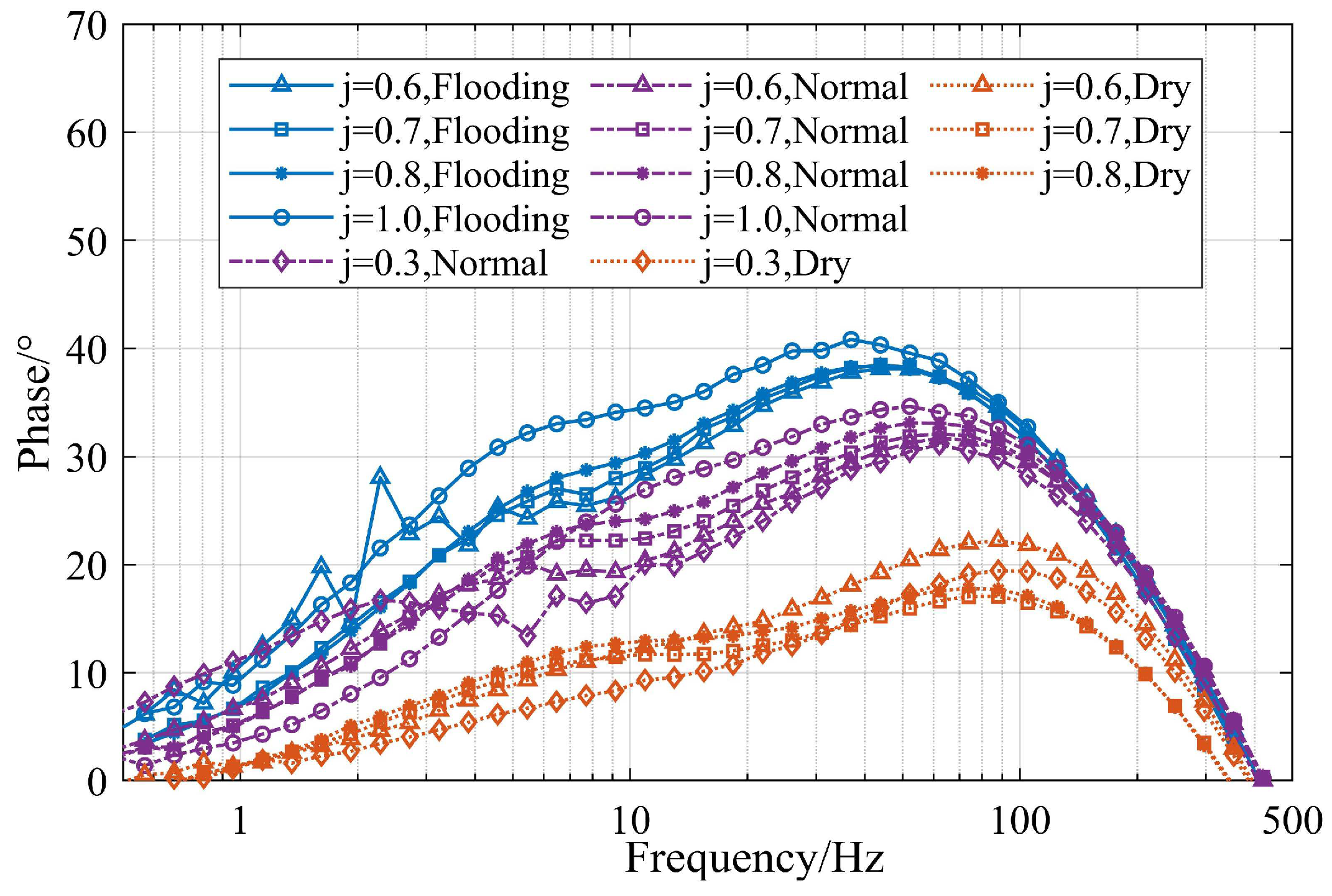

3.1. Design of the Impedance-Based Water Content Measurement Module

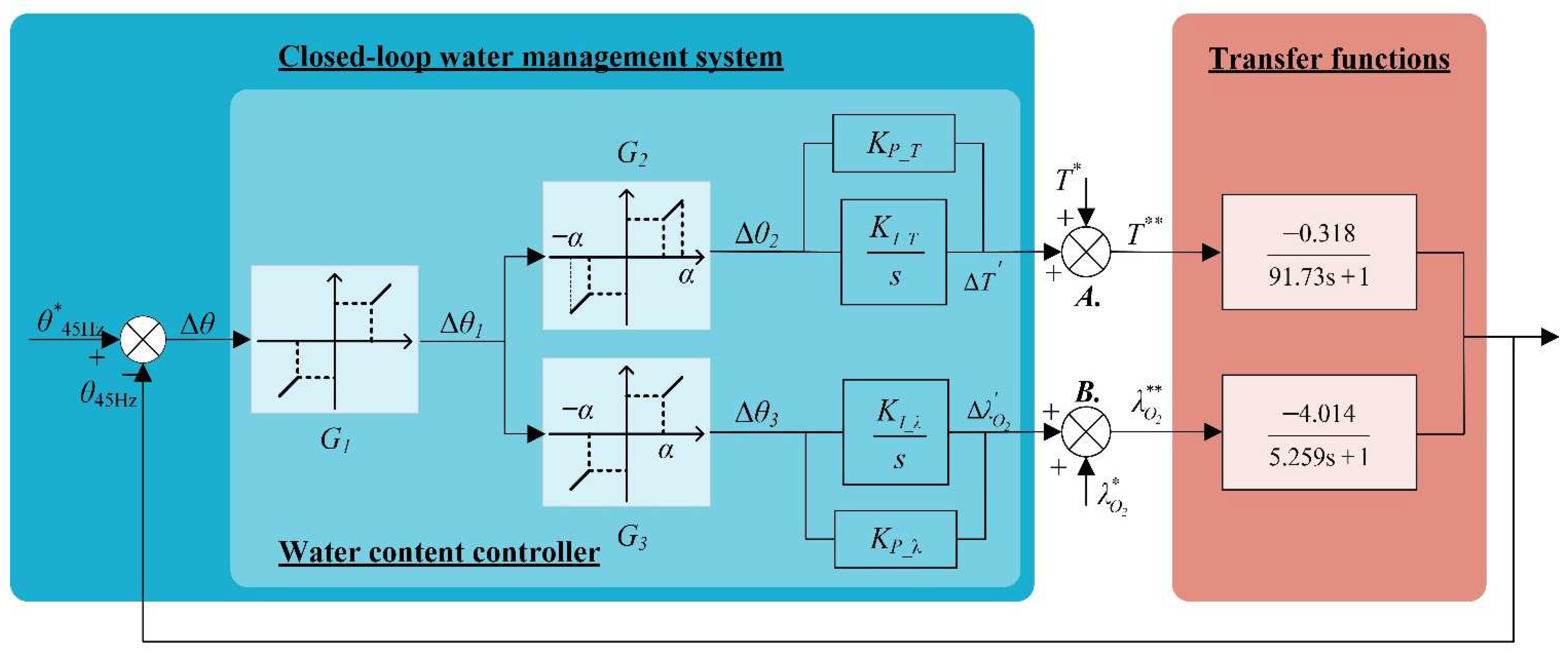

3.2. Design of the Water Content Controller

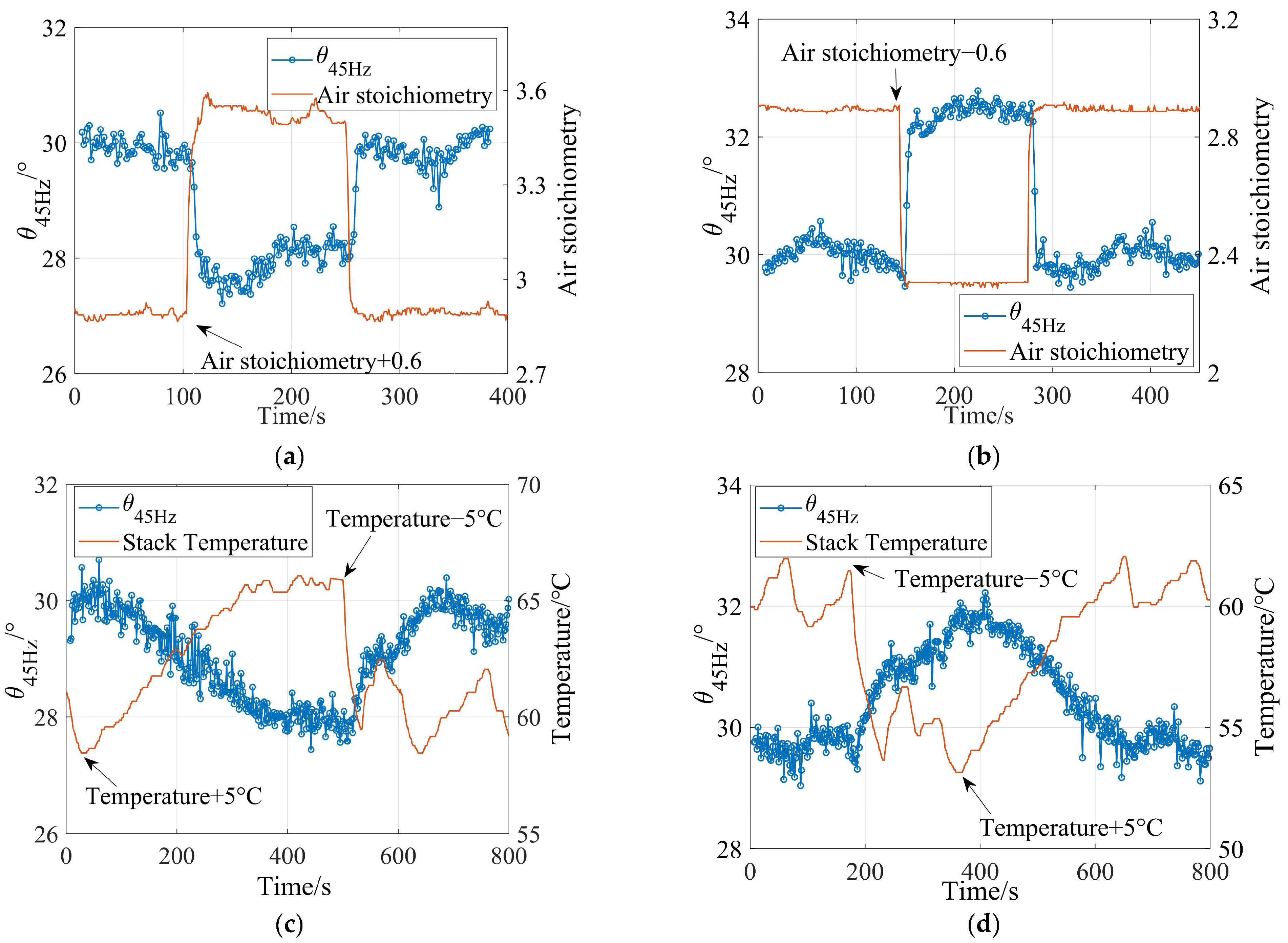

3.2.1. Research on the Open-Loop Characteristics of Water Content

3.2.2. Design of the Water Content Regulation Approaches

- Air stoichiometry is applied to meet conditions where the water content needs to be significantly regulated.

- Stack temperature is used to meet the low demanding case of water content regulation.

- The water management system regulates the water content by changing stack temperature when |Δθ1| is larger than 1° but smaller than 3°.

- The water management system regulates the water content by changing air stoichiometry when |Δθ1|is larger than 3°.

4. Experimental Validation of the Control Strategy

4.1. Results of Constant-Load Experiments

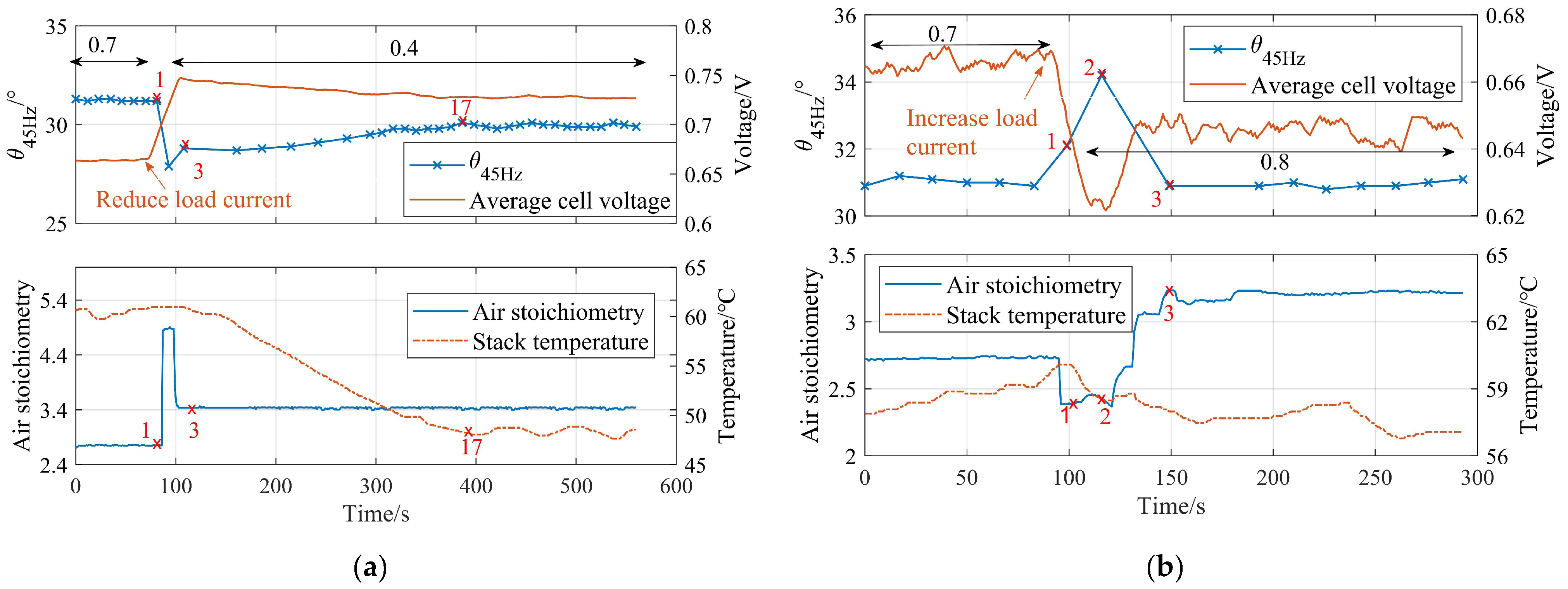

4.2. Results of Variable-Load Experiments

4.3. Discussion

5. Conclusions and Prospects

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Yin, C.; Cao, J.; Tang, Q.; Su, Y.; Wang, R.; Li, K.; Tang, H. Study of internal performance of commercial-size fuel cell stack with 3D multi-physical model and high resolution current mapping. Appl. Energy 2022, 323, 119567. [Google Scholar] [CrossRef]

- Barnoon, P.; Toghraie, D.; Mehmandoust, B.; Fazilati, M.A.; Eftekhari, S.A. Natural-forced cooling and Monte-Carlo multi-objective optimization of mechanical and thermal characteristics of a bipolar plate for use in a proton exchange membrane fuel cell. Energy Rep. 2022, 8, 2747–2761. [Google Scholar] [CrossRef]

- Su, Y.; Yin, C.; Hua, S.; Wang, R.; Tang, H. Study of cell voltage uniformity of proton exchange membrane fuel cell stack with an optimized artificial neural network model. Int. J. Hydrogen Energy 2022, 47, 29037–29052. [Google Scholar] [CrossRef]

- Schmittinger, W.; Vahidi, A. A review of the main parameters influencing long-term performance and durability of PEM fuel cells. J. Power Sources 2008, 180, 1–14. [Google Scholar] [CrossRef]

- Lebreton, C.; Benne, M.; Damour, C.; Yousfi-Steiner, N.; Grondin-Perez, B.; Hissel, D.; Chabriat, J.P. Fault Tolerant Control Strategy applied to PEMFC water management. Int. J. Hydrogen Energy 2015, 40, 10636–10646. [Google Scholar] [CrossRef]

- Ous, T.; Arcoumanis, C. Degradation aspects of water formation and transport in Proton Exchange Membrane Fuel Cell: A review. J. Power Sources 2013, 240, 558–582. [Google Scholar] [CrossRef]

- Ijaodola, O.S.; El-Hassan, Z.; Ogungbemi, E.; Khatib, F.N.; Wilberforce, T.; Thompson, J.; Olabi, A.G. Energy efficiency improvements by investigating the water flooding management on proton exchange membrane fuel cell (PEMFC). Energy 2019, 179, 246–267. [Google Scholar] [CrossRef]

- Moçotéguy, P.; Ludwig, B.; Beretta, D.; Pedersen, T. Study of the impact of water management on the performance of PEMFC commercial stacks by impedance spectroscopy. Int. J. Hydrogen Energy 2020, 45, 16724–16737. [Google Scholar] [CrossRef]

- Peng, Y.; Mahyari, H.M.; Moshfegh, A.; Javadzadegan, A.; Toghraie, D.; Shams, M.; Rostami, S. A transient heat and mass transfer CFD simulation for proton exchange membrane fuel cells (PEMFC) with a dead-ended anode channel. Int. Commun. Heat Mass Transf. 2020, 115, 104638. [Google Scholar] [CrossRef]

- Pei, P.; Chen, H. Main factors affecting the lifetime of Proton Exchange Membrane fuel cells in vehicle applications: A review. Appl. Energy 2014, 125, 60–75. [Google Scholar] [CrossRef]

- Yan, C.; Chen, J.; Liu, H.; Kumar, L.; Lu, H. Health Management for PEM Fuel Cells Based on an Active Fault Tolerant Control Strategy. IEEE Trans. Sustain. Energy 2020, 12, 1311–1320. [Google Scholar] [CrossRef]

- Debenjak, A.; Gašperin, M.; Pregelj, B.; Atanasijević-Kunc, M.; Petrovčič, J.; Jovan, V. Detection of Flooding and Drying inside a PEM Fuel Cell Stack. Stroj. Vest. 2013, 59, 56–64. [Google Scholar] [CrossRef]

- Yuan, X.Z.; Song, C.; Wang, H.; Zhang, J. Electrochemical Impedance Spectroscopy in PEM Fuel Cells: Fundamentals and Applications; Springer: London, UK, 2010; pp. 193–258. [Google Scholar]

- Fouquet, N.; Doulet, C.; Nouillant, C.; Dauphin-Tanguy, G.; Ould-Bouamama, B. Model based PEM fuel cell state-of-health monitoring via ac impedance measurements. J. Power Sources 2006, 159, 905–913. [Google Scholar] [CrossRef]

- Gebregergis, A.; Pillay, P.; Rengaswamy, R. PEMFC fault diagnosis, modeling, and mitigation. IEEE Trans. Ind. Appl. 2010, 46, 295–303. [Google Scholar] [CrossRef]

- Song, M.; Pei, P.; Zha, H.; Xu, H. Water management of proton exchange membrane fuel cell based on control of hydrogen pressure drop. J. Power Sources 2014, 267, 655–663. [Google Scholar] [CrossRef]

- Ous, T.; Arcoumanis, C. Visualisation of water accumulation in the flow channels of PEMFC under various operating conditions. J. Power Sources 2009, 187, 182–189. [Google Scholar] [CrossRef]

- Cadet, C.; Jemei, S.; Druart, F.; Hissel, D. Diagnostic tools for PEMFCs: From conception to implementation. Int. J. Hydrogen Energy 2014, 39, 10613–10626. [Google Scholar] [CrossRef]

- Kurz, T.; Hakenjos, A.; Krämer, J.; Zedda, M.; Agert, C. An impedance-based predictive control strategy for the state-of-health of PEM fuel cell stacks. J. Power Sources 2008, 180, 742–747. [Google Scholar] [CrossRef]

- Kitamura, N.; Manabe, K.; Nonobe, Y.; Kizaki, M. Development of Water Content Control System for Fuel Cell Hybrid Vehicles Based on AC Impedance; SAE Technical Paper; 2010-01-1088; SAE: New York, USA, 2010. [Google Scholar]

- Hong, P. Water Content Estimation and Control of PEM Fuel Cell Stack and the Individual Cell in Vehicle; Springer Nature: Berlin/Heidelberg, Germany, 2022; pp. 12–40. [Google Scholar]

- Le Canut, J.M.; Abouatallah, R.M.; Harrington, D.A. Detection of membrane drying, fuel cell flooding, and anode catalyst poisoning on PEMFC stacks by electrochemical impedance spectroscopy. J. Electrochem. Soc. 2006, 153, A857. [Google Scholar] [CrossRef]

- Zhang, L.; Pan, M.; Quan, S. Model predictive control of water management in PEMFC. J. Power Sources 2008, 180, 322–329. [Google Scholar] [CrossRef]

- Chen, X.; Xu, J.; Liu, Q.; Chen, Y.; Wang, X.; Li, W.; Ding, Y.; Wan, Z. Active disturbance rejection control strategy applied to cathode humidity control in PEMFC system. Energy Convers. Manag. 2020, 224, 113389. [Google Scholar] [CrossRef]

- Hosseini, M.; Afrouzi, H.H.; Arasteh, H.; Toghraie, D. Energy analysis of a proton exchange membrane fuel cell (PEMFC) with an open-ended anode using agglomerate model: A CFD study. Energy 2019, 188, 116090. [Google Scholar] [CrossRef]

- Santarelli, M.G.; Torchio, M.F.; Calı, M.; Giaretto, V. Experimental analysis of cathode flow stoichiometry on the electrical performance of a PEMFC stack. Int. J. Hydrogen Energy 2007, 32, 710–716. [Google Scholar] [CrossRef]

- Amirinejad, M.; Rowshanzamir, S.; Eikani, M.H. Effects of operating parameters on performance of a proton exchange membrane fuel cell. J. Power Sources 2006, 161, 872–875. [Google Scholar] [CrossRef]

- Yuan, H.; Dai, H.; Ming, P.; Wang, X.; Wei, X. Quantitative analysis of internal polarization dynamics for polymer electrolyte membrane fuel cell by distribution of relaxation times of impedance. Appl. Energy 2021, 303, 117640. [Google Scholar] [CrossRef]

- Lu, H.; Chen, J.; Yan, C.; Liu, H. On-line fault diagnosis for proton exchange membrane fuel cells based on a fast electrochemical impedance spectroscopy measurement. J. Power Sources 2019, 430, 233–243. [Google Scholar] [CrossRef]

- Mei, B.; Barnoon, P.; Toghraie, D.; Su, C.H.; Nguyen, H.C.; Khan, A. Energy, exergy, environmental and economic analyzes (4E) and multi-objective optimization of a PEM fuel cell equipped with coolant channels. Renew. Sustain. Energy Rev. 2022, 157, 112021. [Google Scholar] [CrossRef]

- Pukrushpan, J.T.; Stefanopoulou, A.G.; Peng, H. Control of Fuel Cell Power Systems: Principles, Modeling, Analysis and Feedback Design; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2004; pp. 31–36. [Google Scholar]

- Liao, Z. Research on Closed-Loop Water Management Technology of Proton Exchange Membrane Fuel Cell based on AC Impedance. Master’s Thesis, University of Electronic Science and Technology of China, Chengdu, China, 2022. [Google Scholar]

- Bao, C.; Ouyang, M.; Yi, B. Analysis of water management in proton exchange membrane fuel cells. Tsinghua Sci. Technol. 2006, 11, 54–64. [Google Scholar] [CrossRef]

| Parameters | Value |

|---|---|

| Current density (A·cm−2) | 0.7 |

| Initial stack temperature (°C) | 60 |

| Initial air stoichiometry | 2.9 |

| Initial θ45Hz (°) | 30 |

| Air Stoichiometry | K | T1 | Stack Temperature | K | T1 |

|---|---|---|---|---|---|

| +0.6 | −3.933 | 5.154 | +5 °C | −0.37 | 98.7 |

| −0.6 | −4.095 | 5.364 | −5 °C | −0.34 | 88.2 |

| Parameters | K | T1 |

|---|---|---|

| Air stoichiometry | −4.014 | 5.259 |

| Stack temperature | −0.318 | 91.73 |

| Parameters | tr | σ% 1 |

|---|---|---|

| Air stoichiometry | 11.57 s | 5.259 |

| Stack temperature | 201.806 s | 91.73 |

| Parameters | Value |

|---|---|

| Current density (A·cm−2) | 0.7 |

| Initial stack temperature (°C) | 60 |

| Initial air stoichiometry | 2.8 |

| Initial θ45Hz (°) | 30 |

| Control cycle (s) | 15 |

| Perturbed Parameters | Increased Temperature | Reduced Temperature | Increased Air Stoichiometry | Reduced Air Stoichiometry |

|---|---|---|---|---|

| θabn | 29.8° | 32.4° | 29.6° | 32.6° |

| |Δθ|max | 1.2° | 1.4° | 1.4° | 1.6° |

| Ctotal1 | 6 | 5 | 4 | 6 |

| Perturbed Parameters | Down-Loading | Loading |

|---|---|---|

| θabn | 27.9 | 34.2 |

| |Δθ|max | 3.1 | 3.2 |

| Ctotal | 15 | 2 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xu, X.; Li, K.; Liao, Z.; Cao, J.; Wang, R. A Closed-Loop Water Management Methodology for PEM Fuel Cell System Based on Impedance Information Feedback. Energies 2022, 15, 7561. https://doi.org/10.3390/en15207561

Xu X, Li K, Liao Z, Cao J, Wang R. A Closed-Loop Water Management Methodology for PEM Fuel Cell System Based on Impedance Information Feedback. Energies. 2022; 15(20):7561. https://doi.org/10.3390/en15207561

Chicago/Turabian StyleXu, Xinjie, Kai Li, Zhenjie Liao, Jishen Cao, and Renkang Wang. 2022. "A Closed-Loop Water Management Methodology for PEM Fuel Cell System Based on Impedance Information Feedback" Energies 15, no. 20: 7561. https://doi.org/10.3390/en15207561

APA StyleXu, X., Li, K., Liao, Z., Cao, J., & Wang, R. (2022). A Closed-Loop Water Management Methodology for PEM Fuel Cell System Based on Impedance Information Feedback. Energies, 15(20), 7561. https://doi.org/10.3390/en15207561