Evaluation of OKRA (Abelmoschus esculentus) Macromolecular Solution for Enhanced Oil Recovery in Kazakhstan Carbonate Reservoir

Abstract

1. Introduction

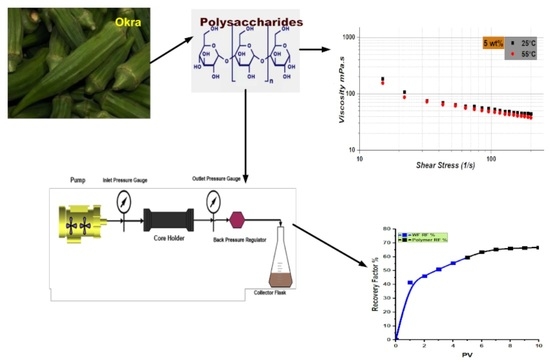

2. Materials and Methods

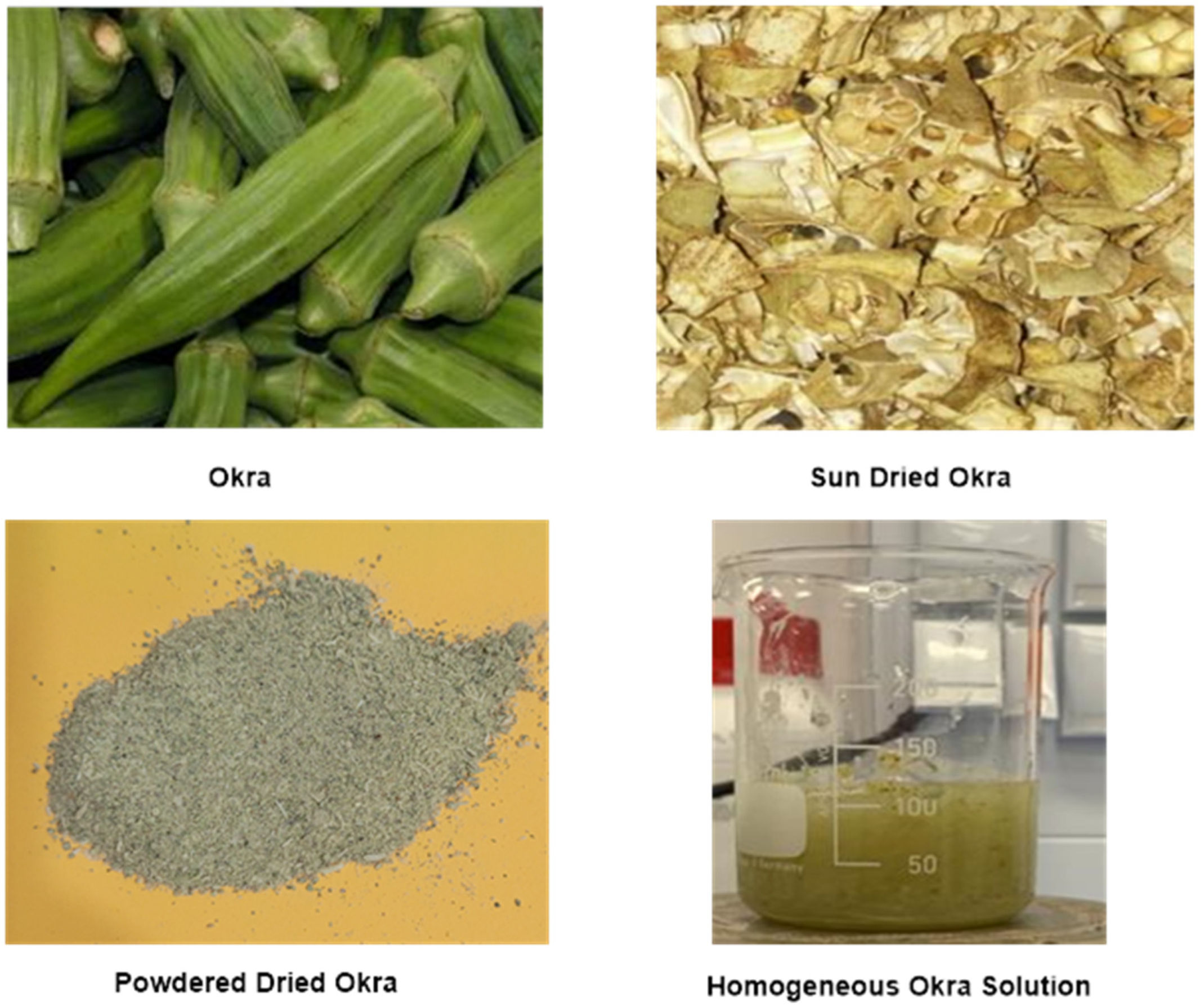

2.1. Preparation Method

2.2. Characterization

2.3. Rheology Test

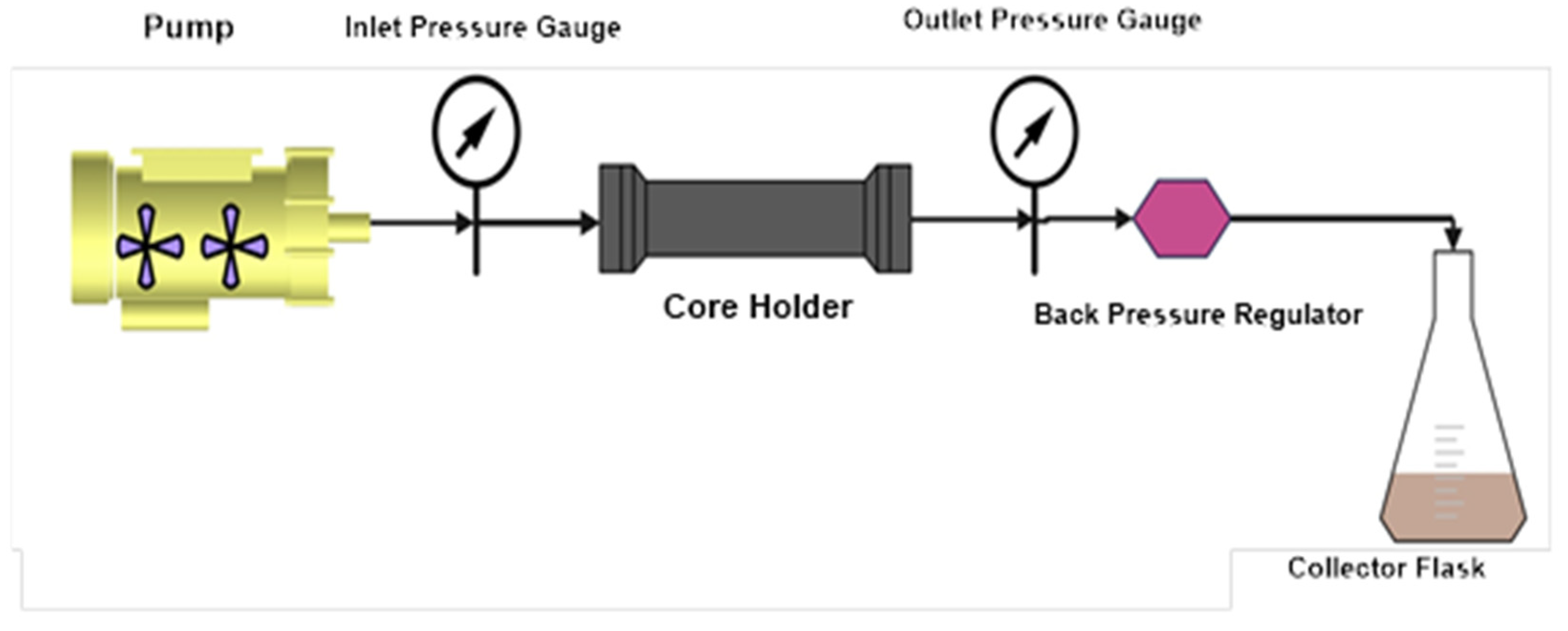

2.4. Core Flooding Experiment

3. Results and Discussion

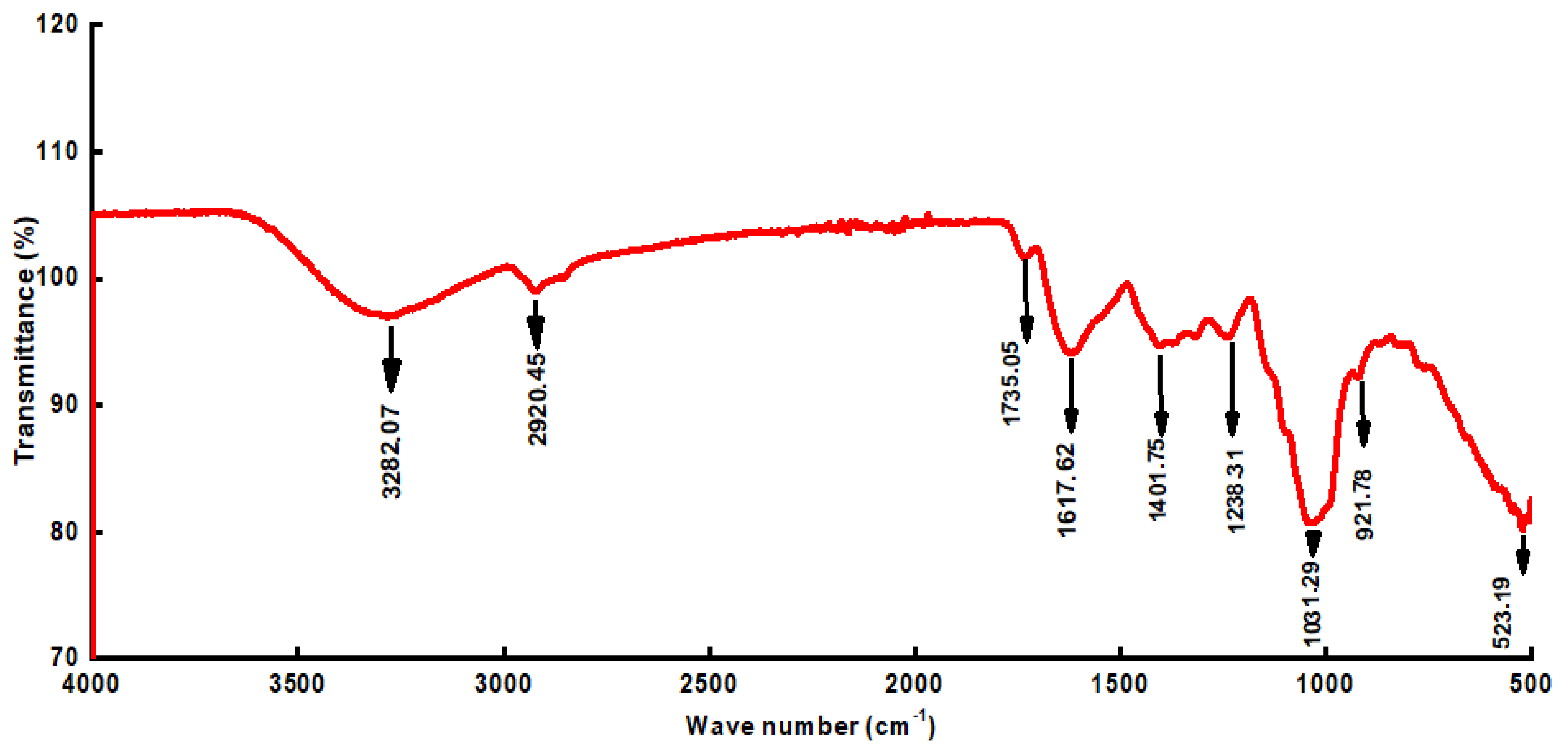

3.1. Characterization Results

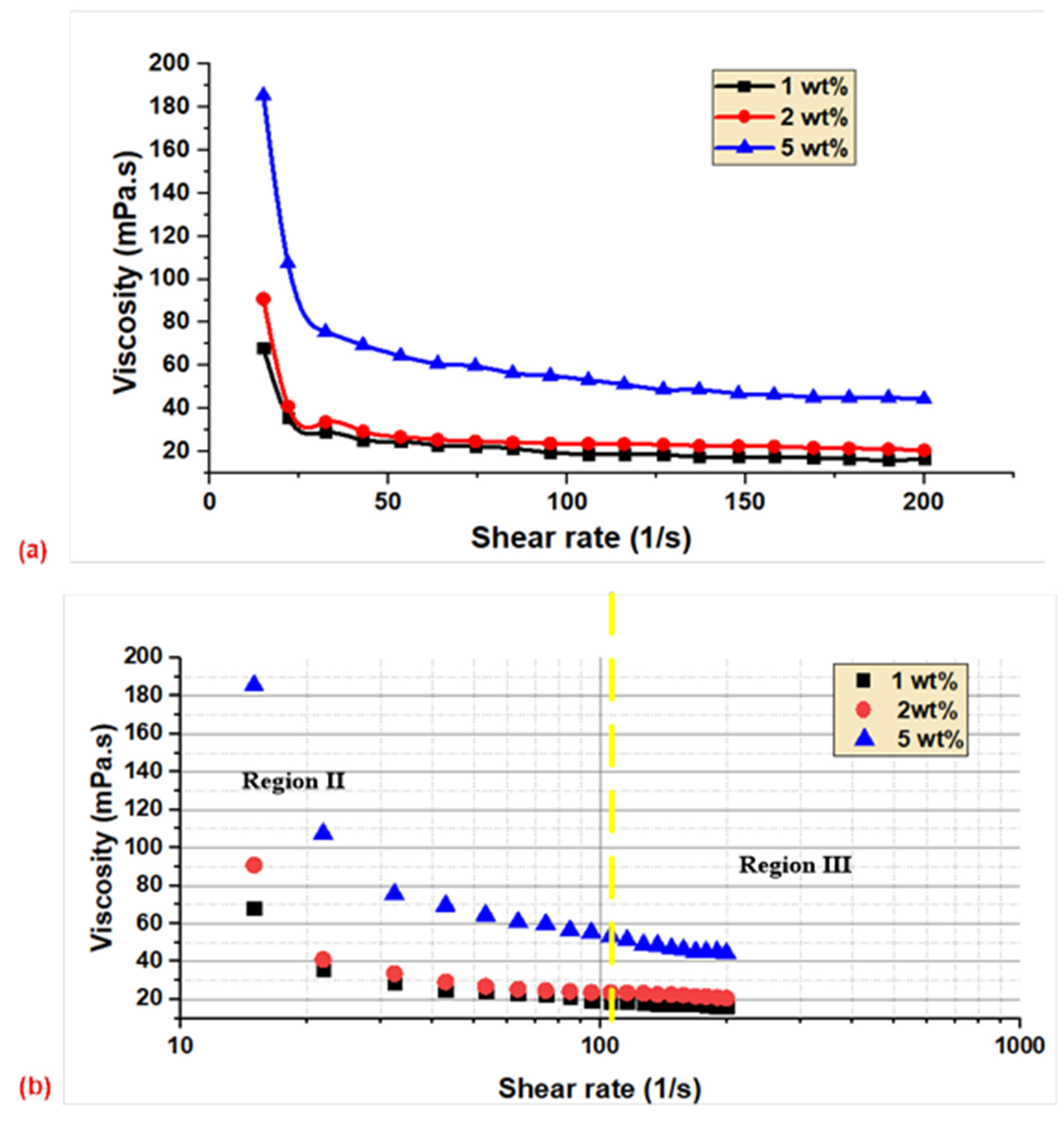

3.2. Effect of Concentration on Viscosity

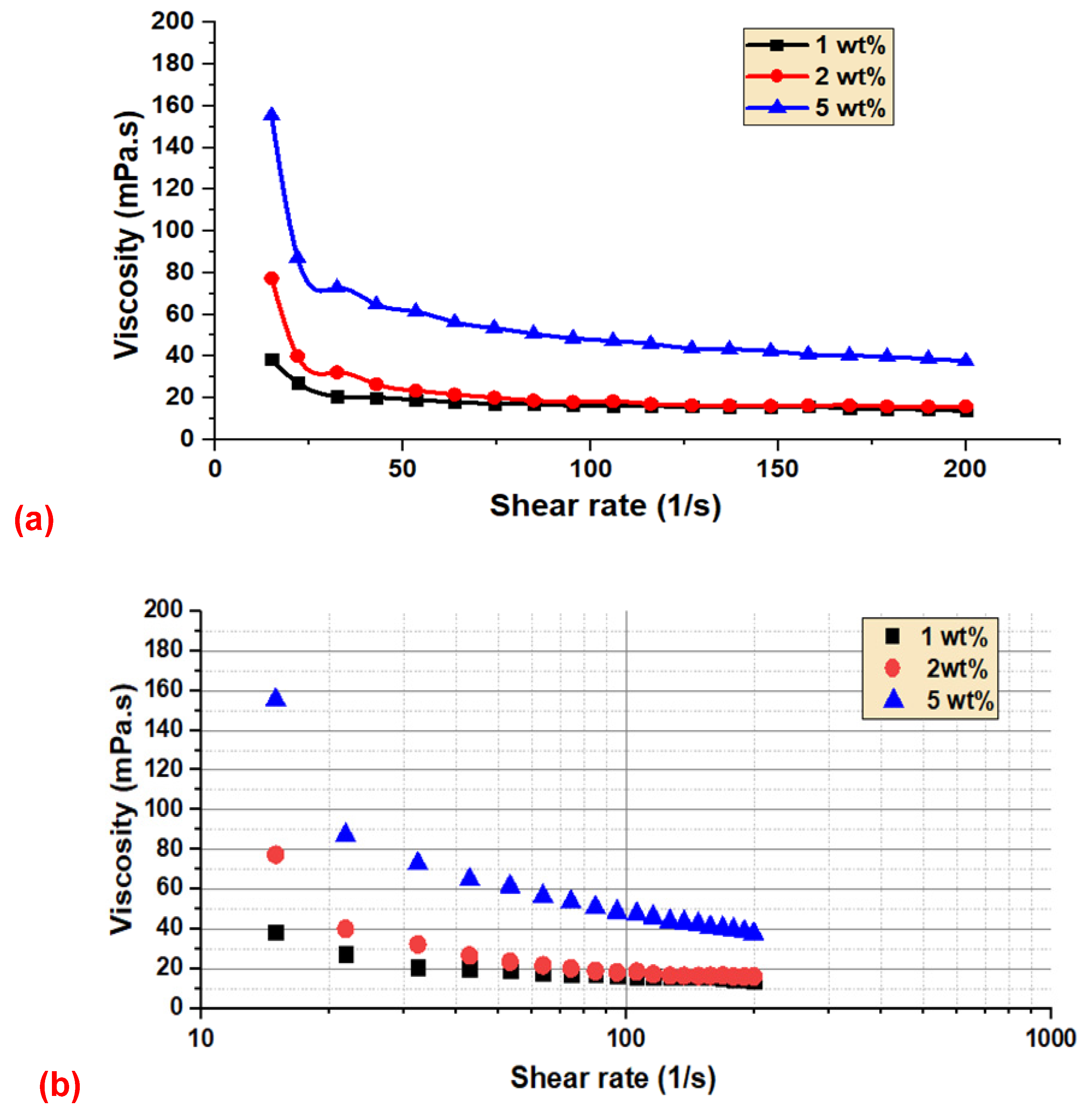

3.3. Effect of Concentration on Viscosity at Reservoir Temperature

3.4. Shear-Thinning Modelling

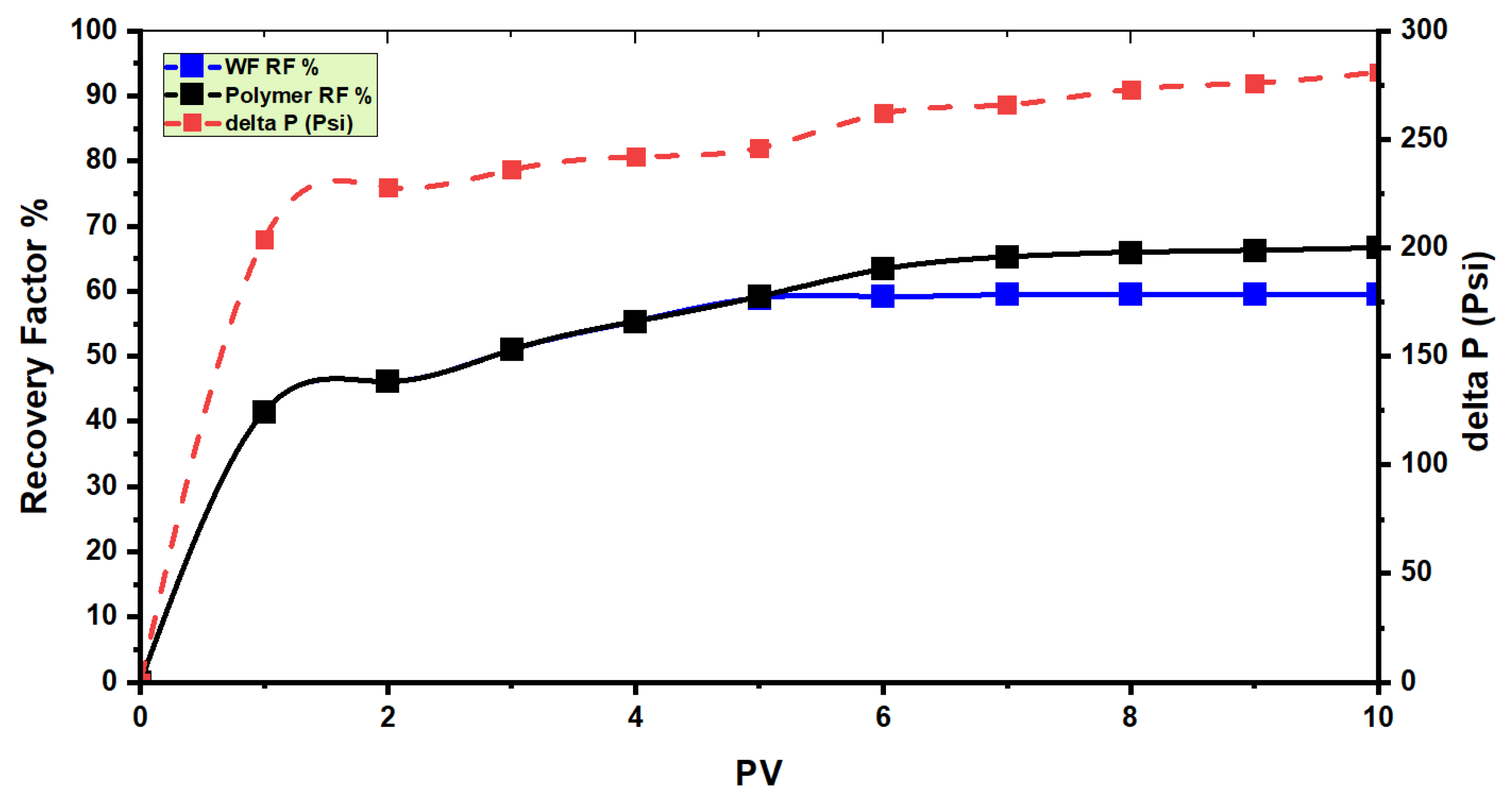

3.5. Core Flooding

4. Conclusions

- (1)

- Okra size is between 150–900 μm, which is slightly large. The morphology can be described by rod-like structures with pores and staking as sheet structures which affect the coordination of the molecules under shear rate;

- (2)

- Okra characterization confirmed the presence of polysaccharides and halo compounds, and the stretching of esters; this highlights the impact of the source’s natural origin;

- (3)

- The viscosity depends on the shear rate and increases by increasing the concentration. However, there is no significant viscosity reduction at the reservoir temperature;

- (4)

- The viscosity shear-rate relationship is shear-thinning and was described by the Ostwald–de Waele power-law model. The values of and vary with concentration and temperature, and indicate pseudo-plasticity intensity;

- (5)

- The incremental oil recovery is 7% and the flow is restricted by the mechanical entrapment due to the large molecules and the low porosity–permeability of the cores;

- (6)

- Okra’s effectiveness depends on its original source and polysaccharide characterization as well as the operating conditions;

- (7)

- Okra is considered a promising material to enhance heavy oil recovery in Kazakhstan field conditions.

Author Contributions

Funding

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Nia, A.R.; Awasthi, A.; Bhuiyan, N. Industry 4.0 and demand forecasting of the energy supply chain: A literature review. Comput. Ind. Eng. 2021, 154, 107128. [Google Scholar] [CrossRef]

- Raniolo, S.; Mancini, S.; Vimercati, S.; Gentil, P.; Simeone, D.; Buchanan, A. The Use of New Technologies to Maximize Oil Production in a Viscous Oil Field in Arctic Environment: The Nikaitchuq Experience. In Proceedings of the Abu Dhabi International Petroleum Exhibition and Conference, Abu Dhabi, United Arab Emirates, 10–13 November 2014. [Google Scholar] [CrossRef]

- Fleshman, R.; Lekic, H.O. Artificial lift for high-volume production. Oilfield Rev. 1999, 11, 49–63. [Google Scholar]

- Beckwith, R. Pumping Oil: 155 Years of Artificial Lift. J. Pet. Technol. 2014, 66, 101–107. [Google Scholar] [CrossRef]

- Babadagli, T. Philosophy of EOR. In Proceedings of the SPE/IATMI Asia Pacific Oil & Gas Conference and Exhibition, Bali, Indonesia, 29–31 October 2019. [Google Scholar] [CrossRef]

- Olajire, A.A. Review of ASP EOR (alkaline surfactant polymer enhanced oil recovery) technology in the petroleum industry: Prospects and challenges. Energy 2014, 77, 963–982. [Google Scholar] [CrossRef]

- Abbas, A.H.; Sulaiman, W.R.W.; Jaafar, M.Z.; Agi, A.A. Laboratory experiment based permeability reduction estimation for enhanced oil recovery. J. Eng. Sci. Technol. 2018, 13, 2464–2480. [Google Scholar]

- Khan, M.N.; Sulaiman, W.R.W.; Abbas, A.H. Study of Sulfosuccinate and Extended Sulfated Sodium Surfactants on the Malaysian Crude/Water Properties for ASP Application in Limestone. Arab. J. Sci. Eng. 2021, 46, 6915–6924. [Google Scholar] [CrossRef]

- Dong, H.; Fang, S.; Wang, D.; Wang, J.; Liu, Z.L.; Hou, W. Review of Practical Experience & Management by Polymer Flooding at Daqing. In Proceedings of the SPE Symposium on Improved Oil Recovery, Tulsa, OK, USA, 20–23 April 2008. [Google Scholar]

- Abidin, A.; Puspasari, T.; Nugroho, W. Polymers for Enhanced Oil Recovery Technology. Procedia Chem. 2012, 4, 11–16. [Google Scholar] [CrossRef]

- Bai, B.; Zhou, J.; Yin, M. A comprehensive review of polyacrylamide polymer gels for conformance control. Pet. Explor. Dev. 2015, 42, 525–532. [Google Scholar] [CrossRef]

- Zhu, D.; Hou, J.; Wei, Q.; Chen, Y. Development of a High-Temperature-Resistant Polymer-Gel System for Conformance Control in Jidong Oil Field. SPE Reserv. Eval. Eng. 2018, 22, 100–109. [Google Scholar] [CrossRef]

- Al-Hajri, S.; Mahmood, S.M.; Abdulelah, H.; Akbari, S. An Overview on Polymer Retention in Porous Media. Energies 2018, 11, 2751. [Google Scholar] [CrossRef]

- Kulawardana, E.U.; Koh, H.; Kim, D.H.; Liyanage, P.J.; Upamali, K.A.; Huh, C.; Weerasooriya, U.; Pope, G.A. Rheology and Transport of Improved EOR Polymers under Harsh Reservoir Conditions. In Proceedings of the SPE Improved Oil Recovery Symposium, Tulsa, OK, USA, 14–18 April 2012. [Google Scholar]

- Huh, C.; Lange, E.; Cannella, W. Polymer retention in porous media. In Proceedings of the SPE/DOE Enhanced Oil Recovery Symposium, Tulsa, OK, USA, 22–25 April 1990. [Google Scholar]

- Chen, Q.; Ye, Z.; Xu, H.; Wang, Y.; Lai, N. Study on the biodegradability of a chitosan-modified hyperbranched polymer for enhanced oil recovery. J. Appl. Polym. Sci. 2021, 139, 51425. [Google Scholar] [CrossRef]

- Alfazazi, U.; Thomas, N.C.; Alameri, W.; Al-Shalabi, E.W. Experimental investigation of polymer injectivity and retention under harsh carbonate reservoir conditions. J. Pet. Sci. Eng. 2020, 192, 107262. [Google Scholar] [CrossRef]

- Wang, L.; Lu, X.-G.; Deng, Q.-J.; Xiao, L. EOR technology after polymer flooding and it’s technical and economic evaluation. Oilfield Chem. 2010, 4, 6–9. [Google Scholar]

- Al-Murayri, M.T.; Al-Mayyan, H.E.; Moudi, K.; Al-Ajmi, F.; Pitts, D.; Wyatt, M.J.; French, K.; Surtek, J.; Dean, E. Chemical EOR Economic Evaluation in a Low Oil Price Environment: Sabriyah Lower Burgan Reservoir Case Study. In Proceedings of the SPE EOR Conference at Oil and Gas West Asia, Muscat, Oman, 26 March 2018. [Google Scholar] [CrossRef]

- Needham, R.B.; Doe, P.H. Polymer flooding review. J. Pet. Technol. 1987, 39, 1503–1507. [Google Scholar] [CrossRef]

- Abbas, A.H.; Abdullah, D.S.; Jaafar, M.Z.; Sulaiman, W.R.W.; Agi, A. Comparative numerical study for polymer alternating gas (PAG) flooding in high permeability condition. SN Appl. Sci. 2020, 2, 938. [Google Scholar] [CrossRef]

- Taylor, K.C.; Nasr-El-Din, H.A. Water-soluble hydrophobically associating polymers for improved oil recovery: A literature review. J. Pet. Sci. Eng. 1998, 19, 265–280. [Google Scholar] [CrossRef]

- Wever, D.; Picchioni, F.; Broekhuis, A. Polymers for enhanced oil recovery: A paradigm for structure–Property relationship in aqueous solution. Prog. Polym. Sci. 2011, 36, 1558–1628. [Google Scholar] [CrossRef]

- Kamal, M.S.; Sultan, A.; Al-Mubaiyedh, U.A.; Hussein, I.A. Review on Polymer Flooding: Rheology, Adsorption, Stability, and Field Applications of Various Polymer Systems. Polym. Rev. 2015, 55, 491–530. [Google Scholar] [CrossRef]

- Chaudhary, P.; Kumar, S.; Reddy, S. Polymer and its Role in EOR and Water shut-off Process. J. Basic Appl. Eng. Res. 2016, 3, 717–720. [Google Scholar]

- Zhang, X.; Li, B.; Pan, F.; Su, X.; Feng, Y. Enhancing Oil Recovery from Low-Permeability Reservoirs with a Ther-moviscosifying Water-Soluble Polymer. Molecules 2021, 26, 7468. [Google Scholar] [CrossRef] [PubMed]

- Kumar, S.; Tiwari, R.; Husein, M.; Kumar, N.; Yadav, U. Enhancing the Performance of HPAM Polymer Flooding Using Nano CuO/Nanoclay Blend. Processes 2020, 8, 907. [Google Scholar] [CrossRef]

- Bou-Hamdan, K.F. Applications of Nanomaterials in the Oil and Gas Industry. In Handbook of Research on Green Synthesis and Applications of Nanomaterials; IGI Global: Hershey, PA, USA, 2022; pp. 173–198. [Google Scholar]

- Ikeagwu, C.; Adetila, S. The study of local polymers on enhanced oil recovery. Arch. Appl. Sci. Res. 2015, 7, 48–55. [Google Scholar]

- Fakher, S.; Ahdaya, M.; Imqam, A. Hydrolyzed polyacrylamide—Fly ash reinforced polymer for chemical enhanced oil recovery: Part 1—Injectivity experiments. Fuel 2019, 260, 116310. [Google Scholar] [CrossRef]

- Xu, J.-L.; Zhang, J.-C.; Liu, Y.; Sun, H.-J.; Wang, J.-H. Rheological properties of a polysaccharide from floral mushrooms cultivated in Huangshan Mountain. Carbohydr. Polym. 2016, 139, 43–49. [Google Scholar] [CrossRef] [PubMed]

- Olawuyi, I.F.; Lee, W.Y. Structural characterization, functional properties and antioxidant activities of polysaccharide extract obtained from okra leaves (Abelmoschus esculentus). Food Chem. 2021, 354, 129437. [Google Scholar] [CrossRef]

- Zhao, C.; Li, X.; Miao, J.; Jing, S.; Li, X.; Huang, L.; Gao, W. The effect of different extraction techniques on property and bioactivity of polysaccharides from Dioscorea hemsleyi. Int. J. Biol. Macromol. 2017, 102, 847–856. [Google Scholar] [CrossRef]

- Savi, A.; Calegari, G.C.; Santos, V.A.Q.; Pereira, E.A.; Teixeira, S.D. Chemical characterization and antioxidant of polysaccharide extracted from Dioscorea bulbifera. J. King Saud Univ.-Sci. 2018, 32, 636–642. [Google Scholar] [CrossRef]

- Hua, D.; Zhang, D.; Huang, B.; Yi, P.; Yan, C. Structural characterization and DPPH· radical scavenging activity of a polysaccharide from Guara fruits. Carbohydr. Polym. 2014, 103, 143–147. [Google Scholar] [CrossRef]

- Agi, A.; Junin, R.; Arsad, A.; Abbas, A.; Gbadamosi, A.; Azli, N.B.; Oseh, J. Synergy of the flow behaviour and disperse phase of cellulose nanoparticles in enhancing oil recovery at reservoir condition. PLoS ONE 2019, 14, e0220778. [Google Scholar] [CrossRef]

- Hu, H.; Zhao, K.; Fernandes, N.; Boufflet, P.; Bannock, J.H.; Yu, L.; de Mello, J.C.; Stingelin, N.; Heeney, M.; Giannelis, E.P. Entanglements in marginal solutions: A means of tuning pre-aggregation of conjugated polymers with positive implications for charge transport. J. Mater. Chem. C 2015, 3, 7394–7404. [Google Scholar] [CrossRef]

- De Kort, G.W.; Leoné, N.; Stellamanns, E.; Auhl, D.; Wilsens, C.H.R.M.; Rastogi, S. Effect of Shear Rate on the Orientation and Relaxation of a Vanillic Acid Based Liquid Crystalline Polymer. Polymers 2018, 10, 935. [Google Scholar] [CrossRef] [PubMed]

- Lee, Y.; Jang, Y.; Lee, W.; Wang, J.; Sung, W. Effect of Acidity of Formation Water for Low-Salinity Polymer Injection Method in Carbonate Reservoirs. In Proceedings of the Offshore Technology Conference Asia, Kuala Lumpur, Malaysia, 3–6 November 2020. [Google Scholar] [CrossRef]

- Ma, J.; Yu, P.; Xia, B.; An, Y. Effect of salt and temperature on molecular aggregation behavior of acrylamide polymer. e-Polymers 2019, 19, 594–606. [Google Scholar] [CrossRef]

- De Rosa, I.M.; Kenny, J.M.; Puglia, D.; Santulli, C.; Sarasini, F. Morphological, thermal and mechanical characterization of okra (Abelmoschus esculentus) fibres as potential reinforcement in polymer composites. Compos. Sci. Technol. 2010, 70, 116–122. [Google Scholar] [CrossRef]

- Stawski, D.; Çalişkan, E.; Yilmaz, N.D.; Krucińska, I. Thermal and Mechanical Characteristics of Okra (Abelmoschus esculentus) Fibers Obtained via Water- and Dew-Retting. Appl. Sci. 2020, 10, 5113. [Google Scholar] [CrossRef]

- Toledo, R.T.; Singh, R.K.; Kong, F. Fundamentals of Food Process Engineering, 4th ed.; Springer Nature: Cham, Switzerland, 2018. [Google Scholar] [CrossRef]

- Xu, K.; Guo, M.; Du, J. Molecular characteristics and rheological properties of water-extractable polysaccharides de-rived from okra (Abelmoschus esculentus L.). Int. J. Food Prop. 2017, 20, S899–S909. [Google Scholar] [CrossRef]

| Temperature °C | Concentrations | Consistency Index K | Flow Behavior Index n | Stability Index R2 |

|---|---|---|---|---|

| 25 | 1 wt.% | 89.2 | 0.67 | 0.95 |

| 2 wt.% | 65.9 | 0.75 | 0.91 | |

| 5 wt.% | 208.6 | 0.71 | 0.99 | |

| 55 | 1 wt.% | 44.4 | 0.77 | 0.96 |

| 2 wt.% | 119.5 | 0.59 | 0.97 | |

| 5 wt.% | 248.6 | 0.64 | 0.99 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Abbas, A.H.; Ajunwa, O.M.; Mazhit, B.; Martyushev, D.A.; Bou-Hamdan, K.F.; Alsaheb, R.A.A. Evaluation of OKRA (Abelmoschus esculentus) Macromolecular Solution for Enhanced Oil Recovery in Kazakhstan Carbonate Reservoir. Energies 2022, 15, 6827. https://doi.org/10.3390/en15186827

Abbas AH, Ajunwa OM, Mazhit B, Martyushev DA, Bou-Hamdan KF, Alsaheb RAA. Evaluation of OKRA (Abelmoschus esculentus) Macromolecular Solution for Enhanced Oil Recovery in Kazakhstan Carbonate Reservoir. Energies. 2022; 15(18):6827. https://doi.org/10.3390/en15186827

Chicago/Turabian StyleAbbas, Azza Hashim, Obinna Markraphael Ajunwa, Birzhan Mazhit, Dmitriy A. Martyushev, Kamel Fahmi Bou-Hamdan, and Ramzi A. Abd Alsaheb. 2022. "Evaluation of OKRA (Abelmoschus esculentus) Macromolecular Solution for Enhanced Oil Recovery in Kazakhstan Carbonate Reservoir" Energies 15, no. 18: 6827. https://doi.org/10.3390/en15186827

APA StyleAbbas, A. H., Ajunwa, O. M., Mazhit, B., Martyushev, D. A., Bou-Hamdan, K. F., & Alsaheb, R. A. A. (2022). Evaluation of OKRA (Abelmoschus esculentus) Macromolecular Solution for Enhanced Oil Recovery in Kazakhstan Carbonate Reservoir. Energies, 15(18), 6827. https://doi.org/10.3390/en15186827