Performance Simulation of the Active Magnetic Regenerator under a Pulsed Magnetic Field

Abstract

:1. Introduction

2. Materials and Methods

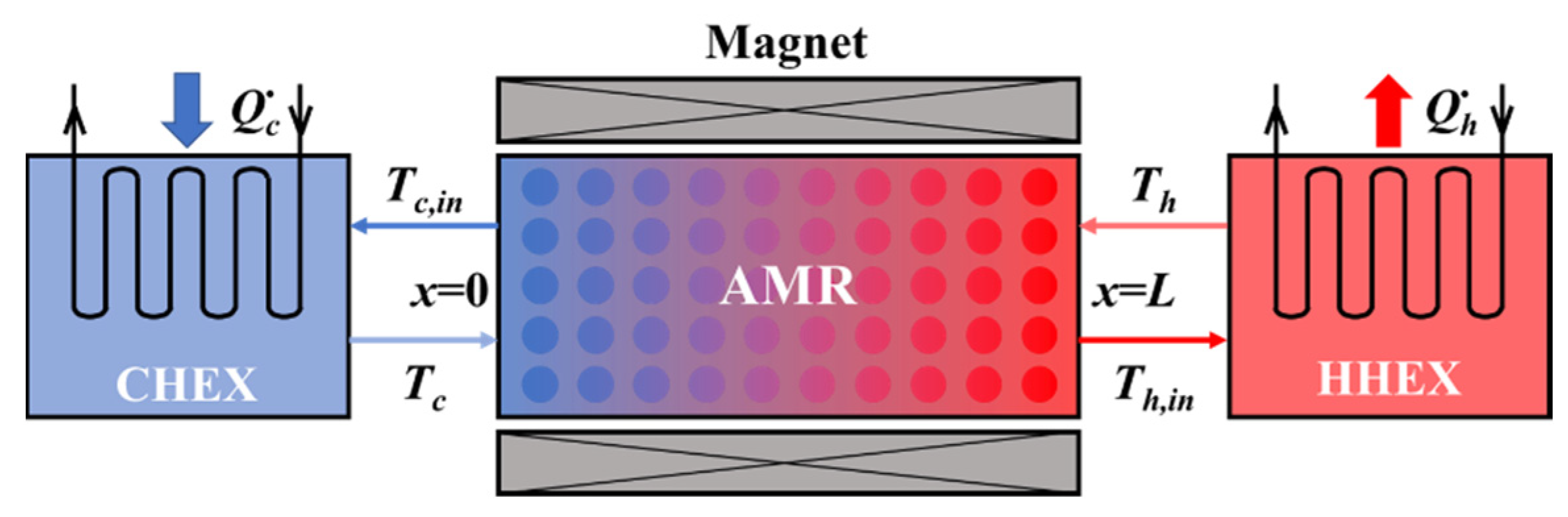

2.1. Numerical Model Description

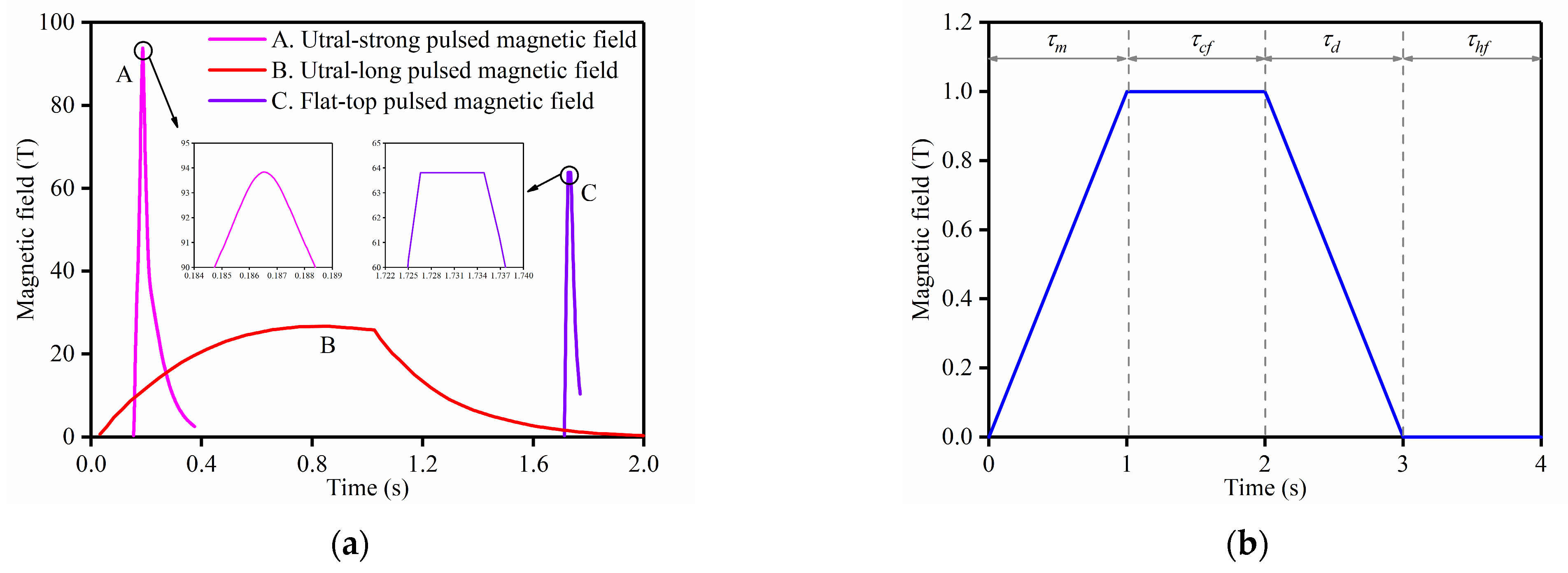

2.1.1. Pulsed Magnetic Field

2.1.2. Numerical Model

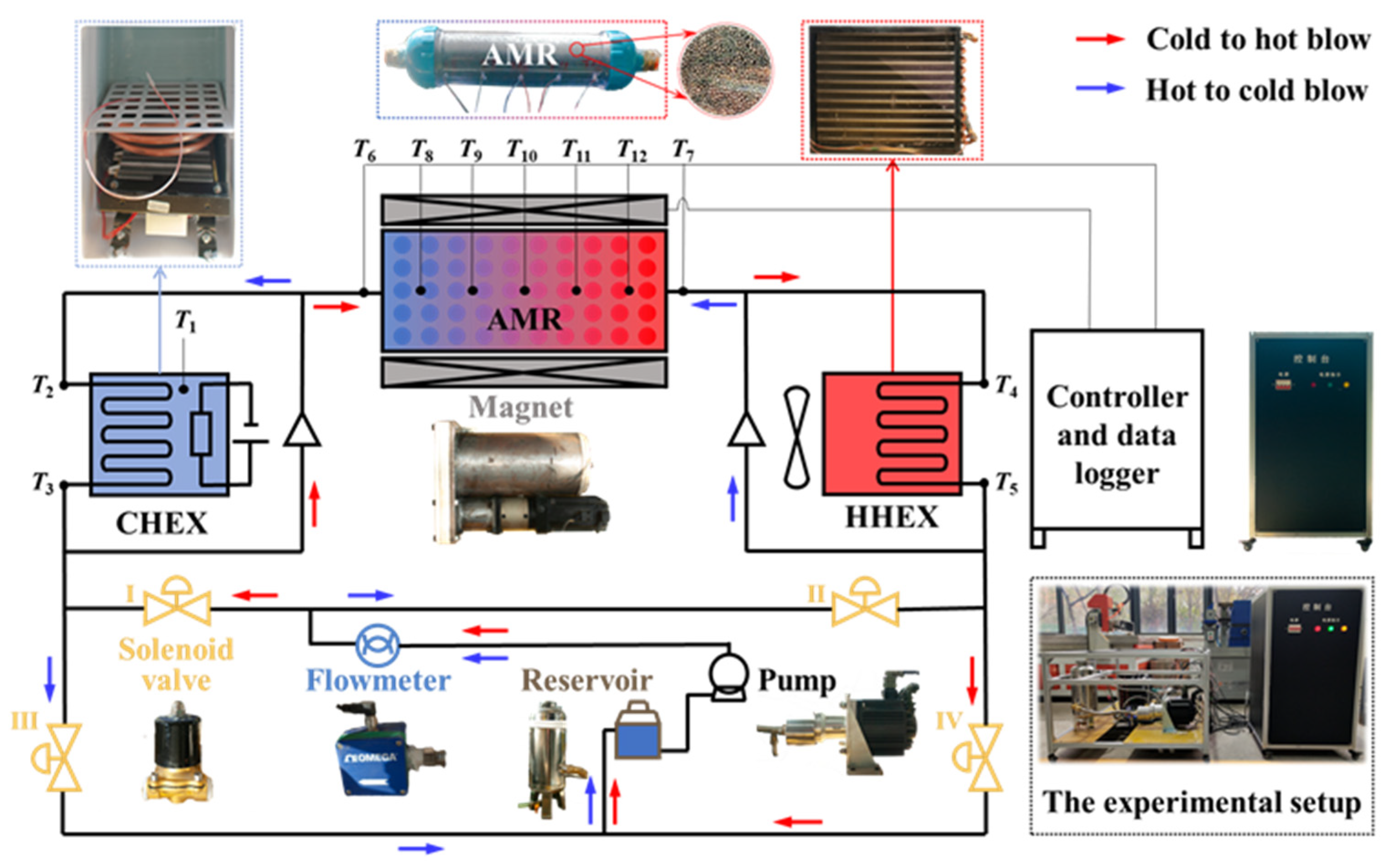

2.1.3. Model Validation

3. Results and Discussion

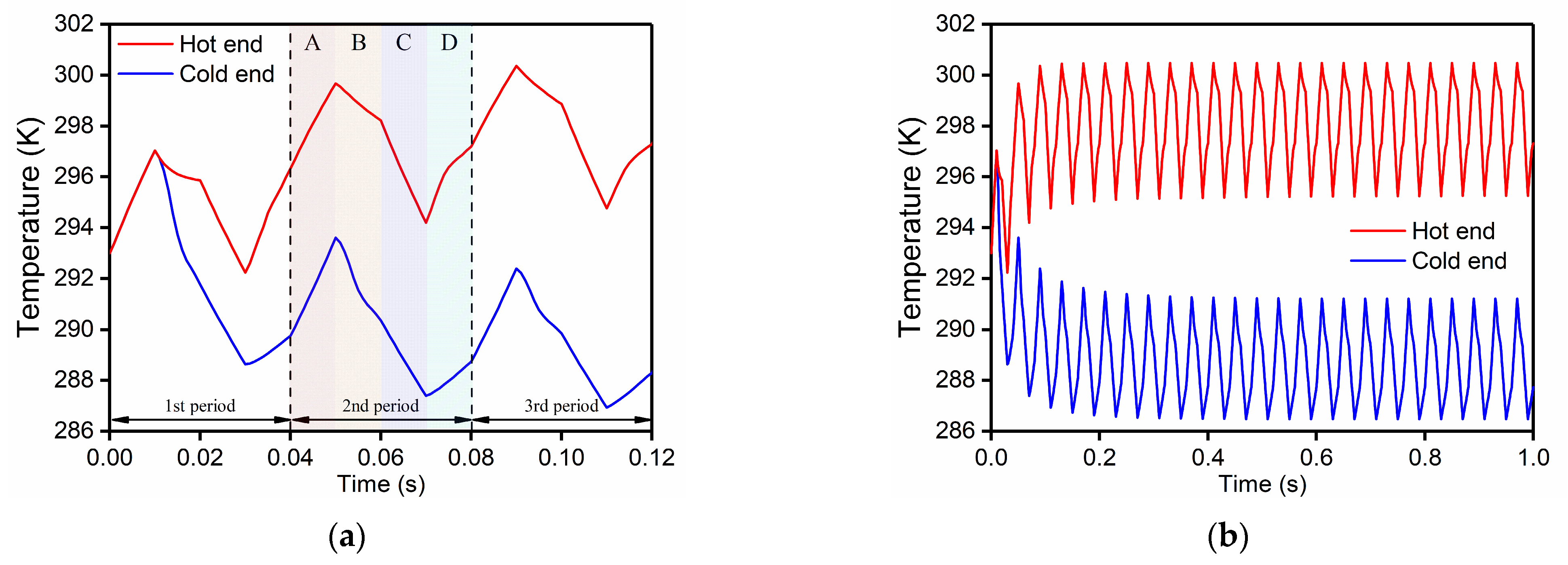

3.1. Thermodynamic Cycle

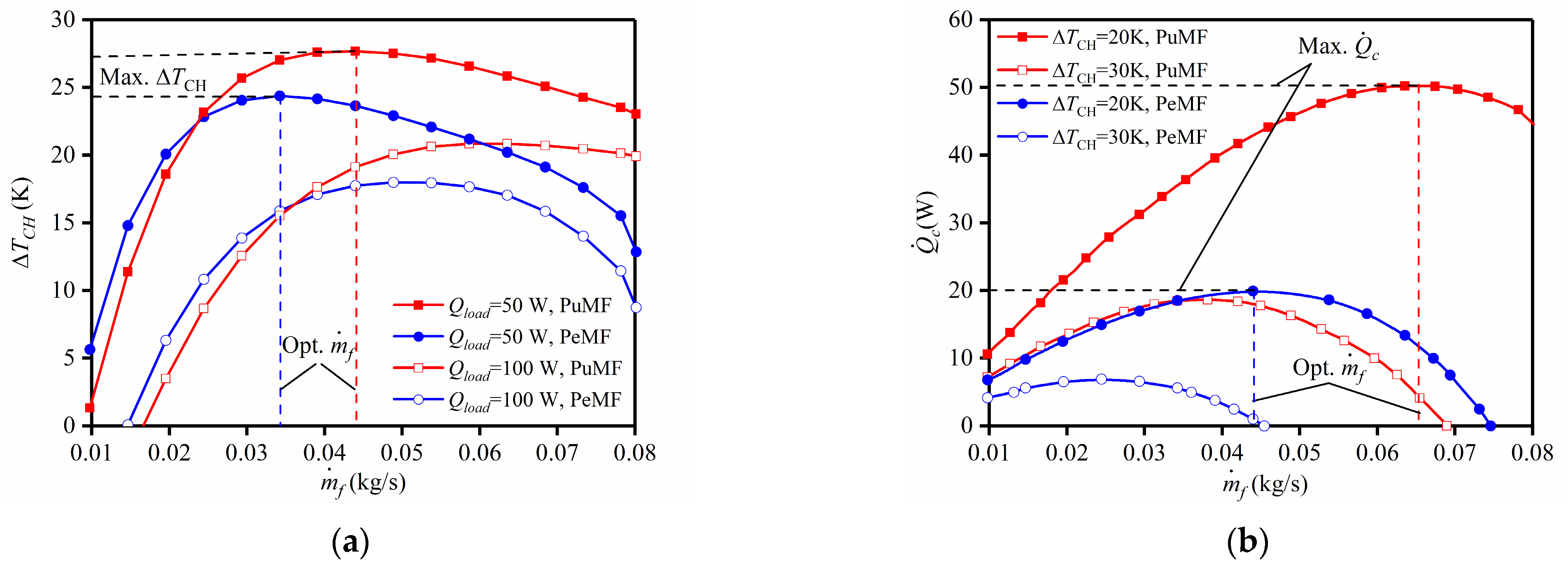

3.2. Comparison of AMR Performance in the Pulsed and Permanent Magnetic Fields

3.2.1. Transient-State Performance

3.2.2. Steady-State Performance

3.3. Effects of Key Parameters on the Performance of AMR

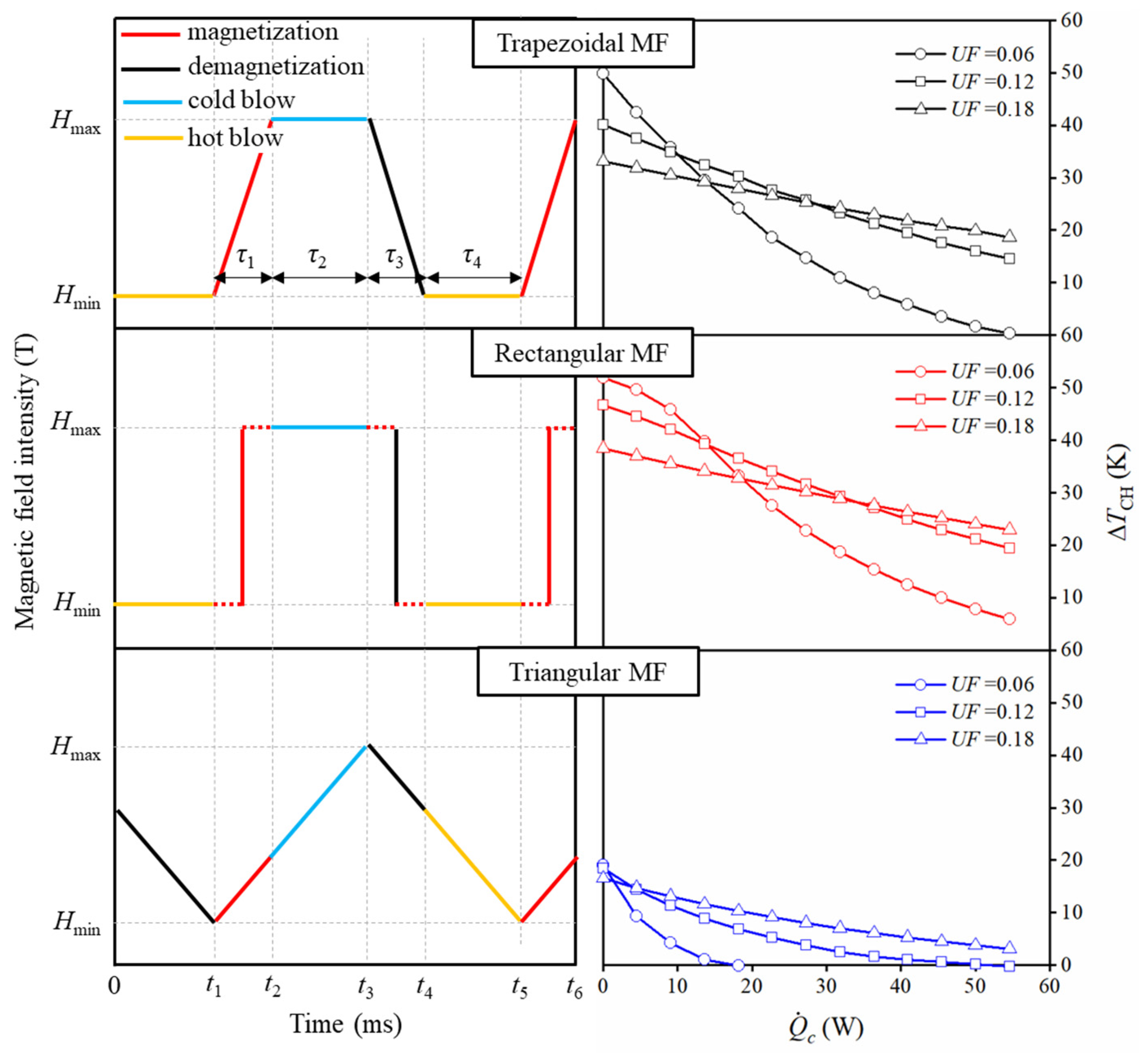

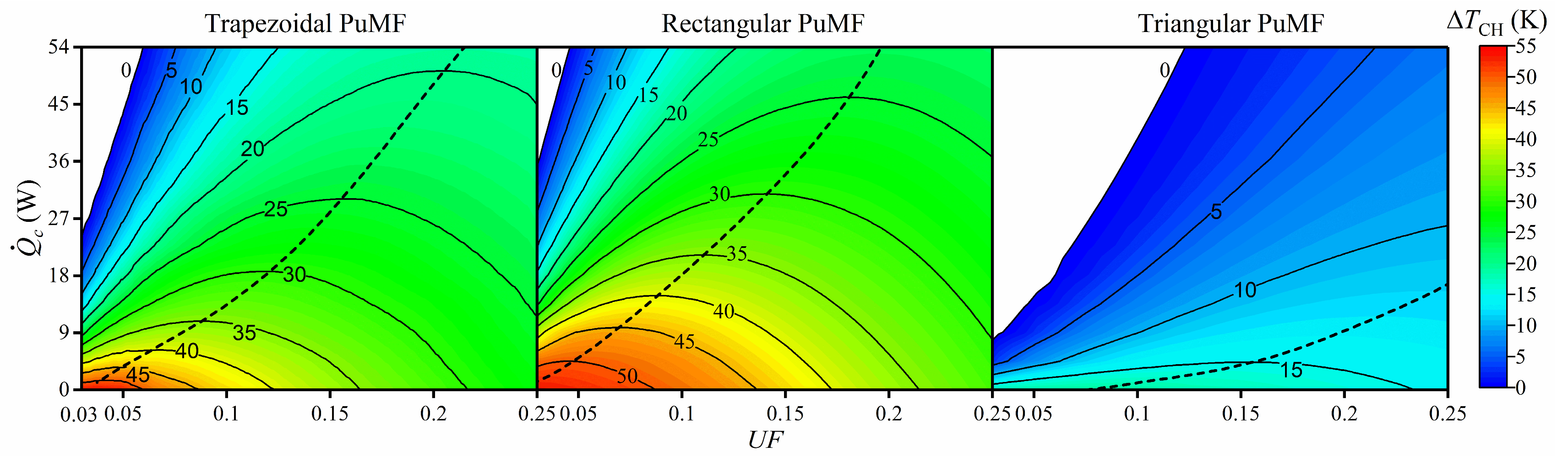

3.3.1. Effect of the Pulsed Magnetic Field Waveform

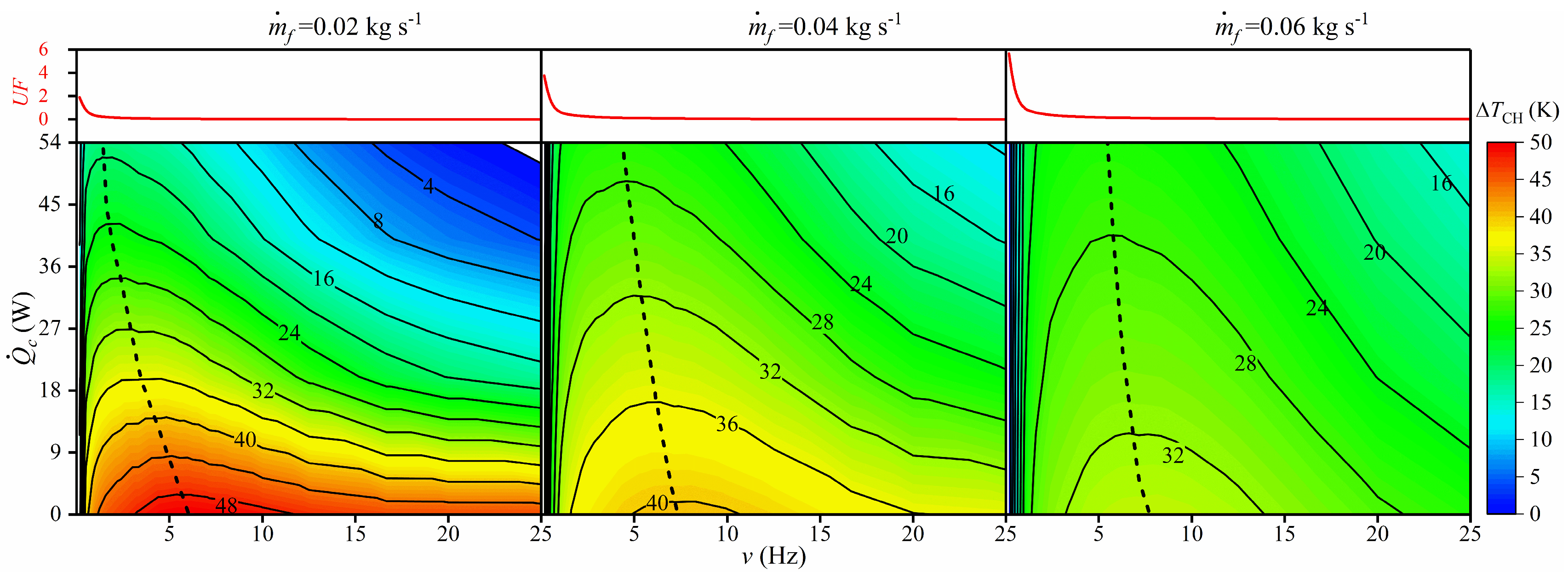

3.3.2. Effect of the Pulsed Magnetic Field Frequency

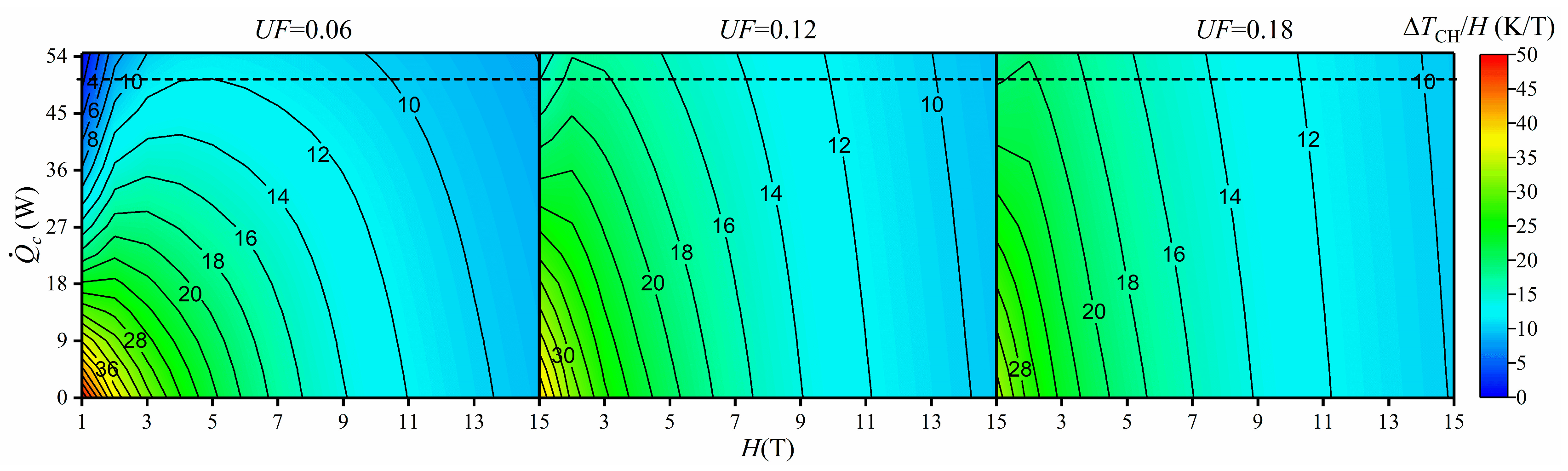

3.3.3. Effect of Pulsed Magnetic Field Intensity

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Krautz, M.; Beyer, L.; Funk, A.; Waske, A.; Weise, B.; Freudenberger, J.; Gottschall, T. Predicting the dominating factors during heat transfer in magnetocaloric composite wires. Mater. Des. 2020, 193, 108832. [Google Scholar] [CrossRef]

- Zhang, Y.; Wu, J.; He, J.; Wang, K.; Yu, G. Solutions to obstacles in the commercialization of room-temperature magnetic refrigeration. Renew. Sustain. Energy Rev. 2021, 143, 110933. [Google Scholar] [CrossRef]

- Benke, D.; Fries, M.; Gottschall, T.; Ohmer, D.; Taubel, A.; Skokov, K.; Gutfleisch, O. Maximum performance of an active magnetic regenerator. Appl. Phys. Lett. 2021, 119, 203901. [Google Scholar] [CrossRef]

- Kitanovski, A.; Tušek, J.; Tomc, U.; Plaznik, U.; Ožbolt, M.; Poredoš, A. Magnetocaloric Energy Conversion; Springer International Publishing: Berlin/Heidelberg, Germany, 2015. [Google Scholar]

- Brown, G.V. Magnetic heat pumping near room temperature. J. Appl. Phys. 1976, 47, 3673–3680. [Google Scholar] [CrossRef]

- Greco, A.; Aprea, C.; Maiorino, A.; Masselli, C. A review of the state of the art of solid-state caloric cooling processes at room-temperature before 2019. Int. J. Refrig. 2019, 106, 66–88. [Google Scholar] [CrossRef]

- Kitanovski, A.; Egolf, P.W. Innovative ideas for future research on magnetocaloric technologies. Int. J. Refrig. 2010, 33, 449–464. [Google Scholar] [CrossRef]

- Yang, Z.; Xu, Z.; Wang, J.; Li, Y.; Lin, G.; Chen, J. Thermoeconomic performance optimization of an irreversible Brayton refrigeration cycle using Gd, Gd0.95Dy0.05 or Gd0.95Er0.05 as the working substance. J. Magn. Magn. Mater. 2020, 499, 166189. [Google Scholar]

- Zhang, B.; Ding, H.; Wang, S.; Cao, Q.; Liu, M.; Wan, Q.; Xu, Y.; Li, L. Bidirectional repeating long pulse magnet system for magnetic refrigerator. IEEE Trans. Appl. Supercond. 2014, 24, 4900105. [Google Scholar] [CrossRef]

- Kihara, T.; Kohama, Y.; Hashimoto, Y.; Katsumoto, S.; Tokunaga, M. Adiabatic measurements of magneto-caloric effects in pulsed high magnetic fields up to 55 T. Rev. Sci. Instrum. 2013, 84, 74901. [Google Scholar] [CrossRef]

- Kihara, T.; Katakura, I.; Tokunaga, M.; Matsuo, A.; Kawaguchi, K.; Kondo, A.; Kindo, K.; Ito, W.; Xu, X.; Kainuma, R. Optical imaging and magnetocaloric effect measurements in pulsed high magnetic fields and their application to Ni-Co-Mn-In Heusler alloy. J. Alloys Compd. 2013, 577, S722–S725. [Google Scholar] [CrossRef]

- Kihara, T.; Xu, X.; Ito, W.; Kainuma, R.; Tokunaga, M. Direct measurements of inverse magnetocaloric effects in metamagnetic shape-memory alloy NiCoMnIn. Phys. Rev. B 2014, 90, 214409. [Google Scholar] [CrossRef]

- Kamantsev, A.P.; Koledov, V.V.; Mashirov, A.V.; Shavrov, V.G.; Yen, N.H.; Thanh, P.T.; Quang, V.M.; Dan, N.H.; Los, A.S.; Gilewski, A.; et al. Measurement of magnetocaloric effect in pulsed magnetic fields with the help of infrared fiber optical temperature sensor. J. Magn. Magn. Mater. 2017, 440, 70–73. [Google Scholar] [CrossRef]

- Gottschall, T.; Min MD, K.; Skokov, K.P. Magnetocaloric effect of gadolinium in high magnetic fields. Phys. Rev. 2019, 99, 134429. [Google Scholar] [CrossRef]

- Ghorbani Zavareh, M.; Salazar Mejía, C.; Nayak, A.K.; Skourski, Y.; Wosnitza, J.; Felser, C.; Nicklas, M. Direct measurements of the magnetocaloric effect in pulsed magnetic fields: The example of the Heusler alloy Ni50Mn35In15. Appl. Phys. Lett. 2015, 106, 71904. [Google Scholar] [CrossRef]

- Chiba, Y.; Smaili, A.; Sari, O. Enhancements of thermal performances of an active magnetic refrigeration device based on nanofluids. Mechanika. 2017, 23, 31–38. [Google Scholar] [CrossRef]

- Han, X.; Peng, T.; Ding, H.; Ding, T.; Zhu, Z.; Xia, Z.; Wang, J.; Han, J.; Ouyang, Z.; Wang, Z.; et al. The pulsed high magnetic field facility and scientific research at Wuhan National High Magnetic Field Center. Matter Radiat. Extrem. 2017, 2, 278–286. [Google Scholar] [CrossRef]

- Nakashima AT, D.; Dutra, S.L.; Trevizoli, P.V.; Barbosa, J.R. Influence of the flow rate waveform and mass imbalance on the performance of active magnetic regenerators. Part I: Experimental analysis. Int. J. Refrig. 2018, 93, 236–248. [Google Scholar] [CrossRef]

- Trevizoli, P.V.; Nakashima, A.T.; Peixer, G.F.; Barbosa, J.R. Performance evaluation of an active magnetic regenerator for cooling applications—Part I: Experimental analysis and thermodynamic performance. Int. J. Refrig. 2016, 72, 192–205. [Google Scholar] [CrossRef]

- Qian, S.; Yuan, L.; Yu, J.; Yan, G. Variable load control strategy for room-temperature magnetocaloric cooling applications. Energy 2018, 153, 763–775. [Google Scholar] [CrossRef]

- Aprea, C.; Greco, A.; Maiorino, A. The use of the first and of the second order phase magnetic transition alloys for an AMR refrigerator at room temperature: A numerical analysis of the energy performances. Energy Convers. Manag. 2013, 70, 40–55. [Google Scholar] [CrossRef]

- Balli, M.; Jandl, S.; Fournier, P.A. Kedous-Lebouc, Advanced materials for magnetic cooling: Fundamentals and practical aspects. Phys. Rev. Appl. 2017, 4, 21305. [Google Scholar] [CrossRef]

- Koshkid’Ko, Y.S.; Ćwik, J.; Ivanova, T.I.; Nikitin, S.A.; Miller, M.; Rogacki, K. Magnetocaloric properties of Gd in fields up to 14 T. J. Magn. Magn. Mater. 2017, 433, 234–238. [Google Scholar] [CrossRef]

| Parameter | Value or Range | Unit |

|---|---|---|

| AMR length (L) | 0.1 m | m |

| AMR diameter (D) | 0.03 m | m |

| Porosity (ε) | 0.35 | - |

| MCM particle diameter (d) | 0.7 mm | mm |

| Magnetic field intensity (H) | 1~15 | T |

| Magnetic field frequency (ν) | 0~25 | Hz |

| Initial temperature (Ti) | 293 | K |

| Parameter | Values |

|---|---|

| AMR sizes | L = 0.23 m, D = 0.03 m |

| ε | 0.35 |

| ds | 0.5~0.8 mm |

| H | 1.35 T |

| ṁf | 0.063 kg/s |

| ms | 0.85 kg |

| Qload | 50 W |

| Ti, Tamb | 293 K |

| Operating time | τm, τcf, τd, τhf = 1, 2, 1, 2 s |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shen, L.; Tong, X.; Li, L.; Lv, Y.; Liu, Z.; Xie, J. Performance Simulation of the Active Magnetic Regenerator under a Pulsed Magnetic Field. Energies 2022, 15, 6804. https://doi.org/10.3390/en15186804

Shen L, Tong X, Li L, Lv Y, Liu Z, Xie J. Performance Simulation of the Active Magnetic Regenerator under a Pulsed Magnetic Field. Energies. 2022; 15(18):6804. https://doi.org/10.3390/en15186804

Chicago/Turabian StyleShen, Limei, Xiao Tong, Liang Li, Yiliang Lv, Zeyu Liu, and Junlong Xie. 2022. "Performance Simulation of the Active Magnetic Regenerator under a Pulsed Magnetic Field" Energies 15, no. 18: 6804. https://doi.org/10.3390/en15186804

APA StyleShen, L., Tong, X., Li, L., Lv, Y., Liu, Z., & Xie, J. (2022). Performance Simulation of the Active Magnetic Regenerator under a Pulsed Magnetic Field. Energies, 15(18), 6804. https://doi.org/10.3390/en15186804