Research and Design of LC Series Resonant Wireless Power Transfer System with Modulation Control Method for Supercapacitor Charging in Linear Motion Systems

Abstract

1. Introduction

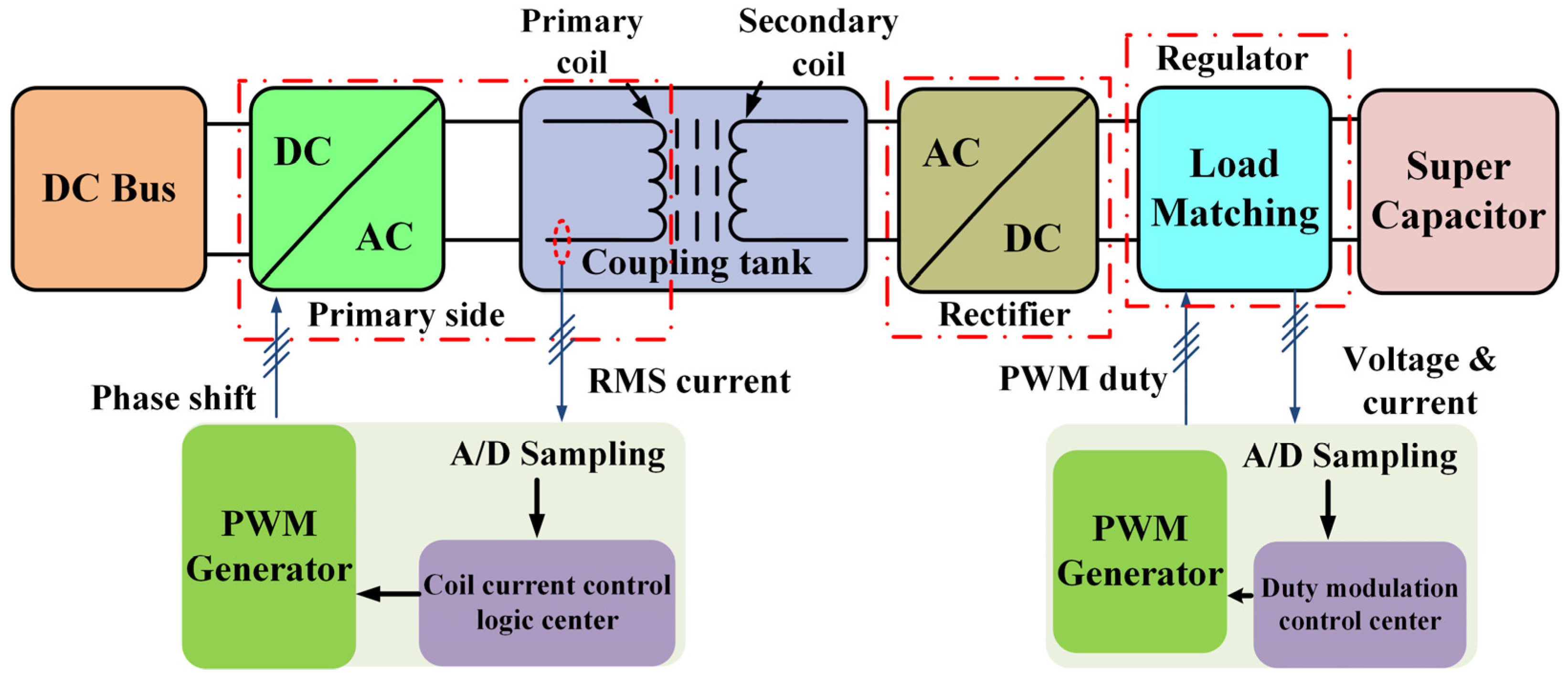

2. Configuration of the Proposed WPT Charging System

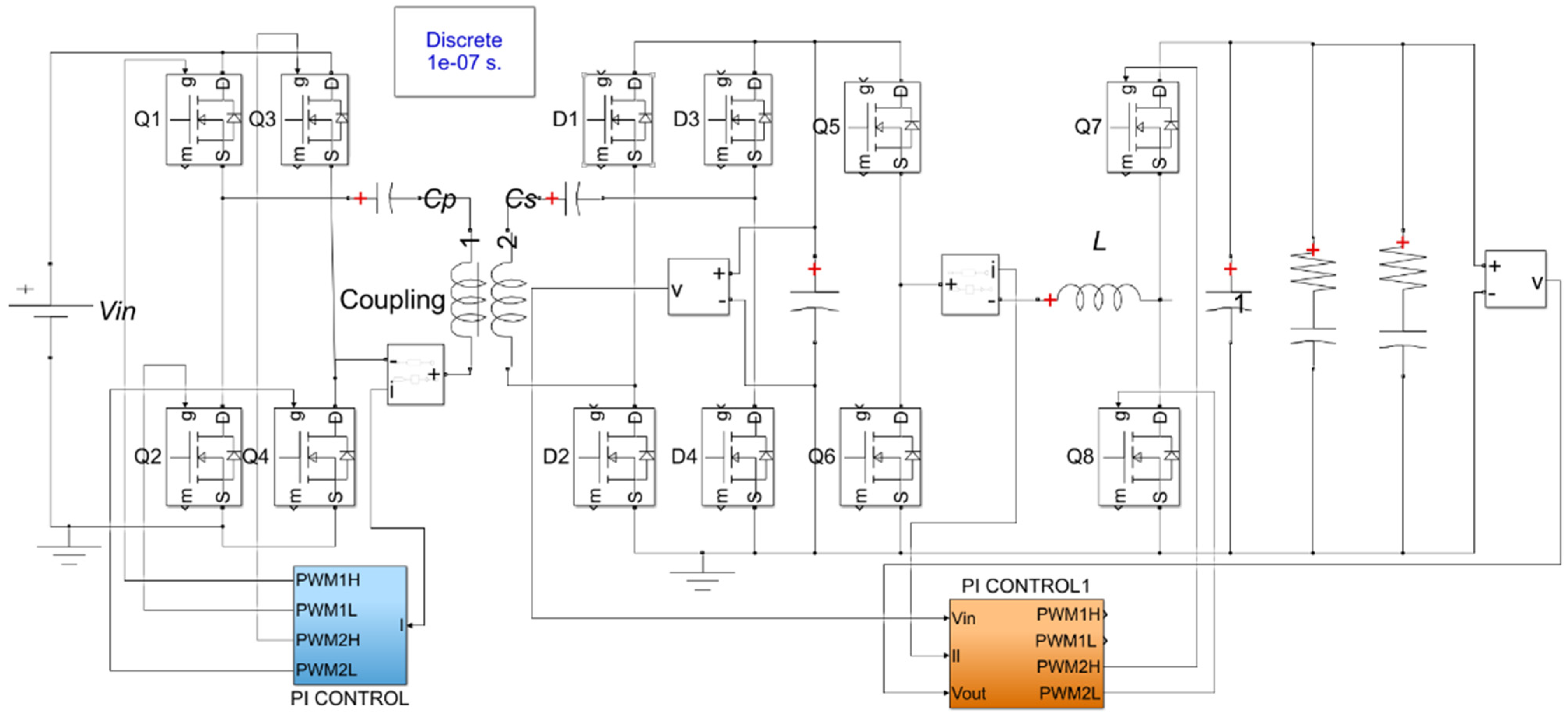

2.1. Coupling Tank Analysis

2.2. Coil Current Constant Characteristics

3. Control System Design

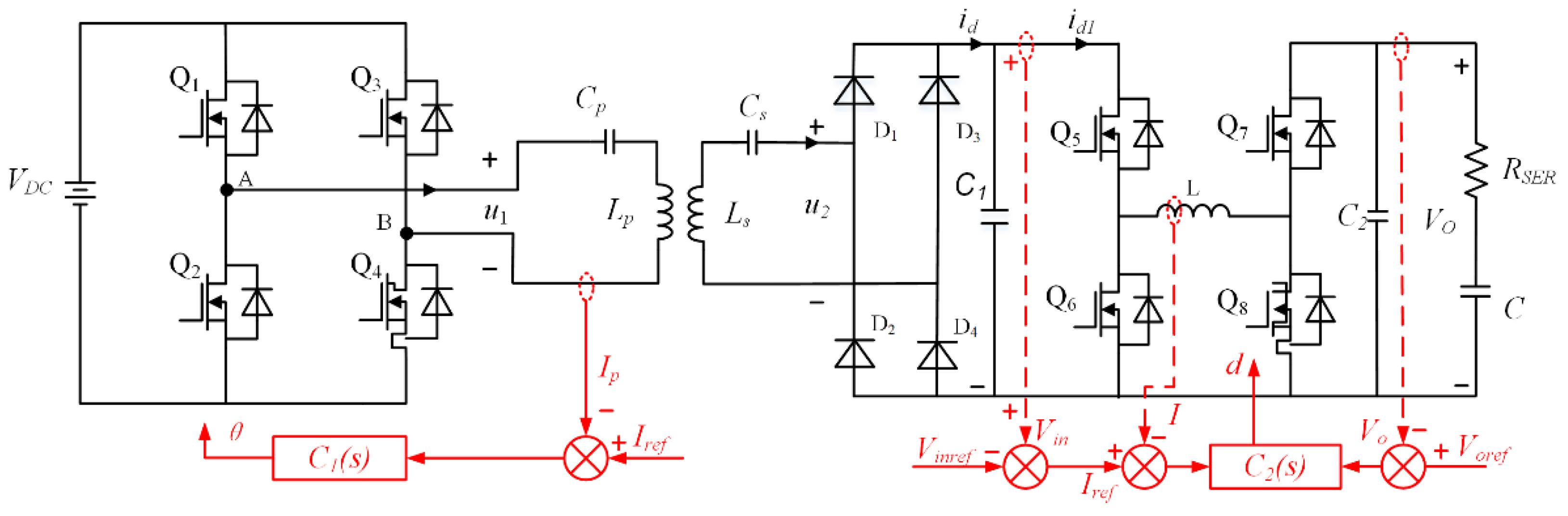

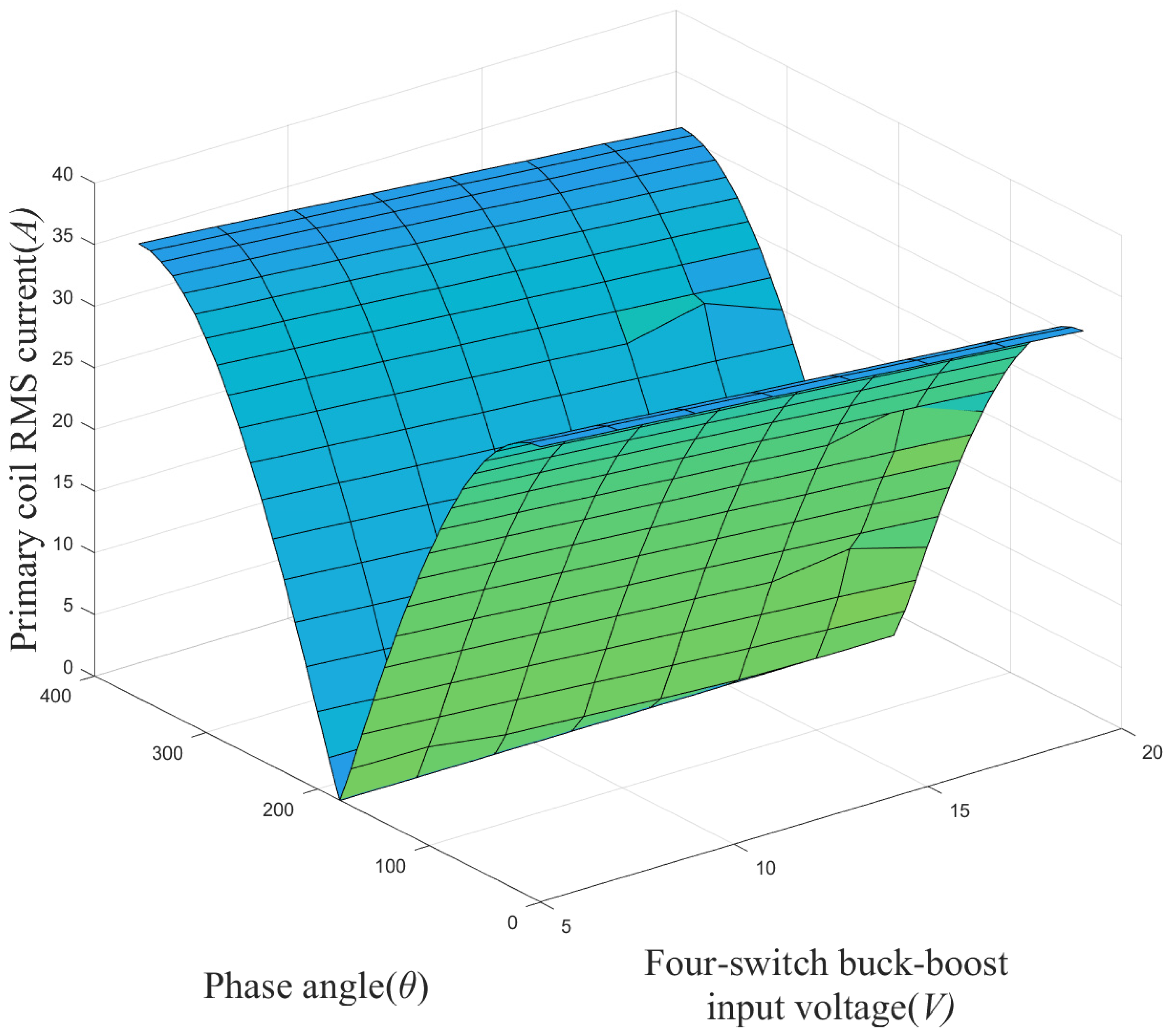

3.1. Primary Coil RMS Current Control

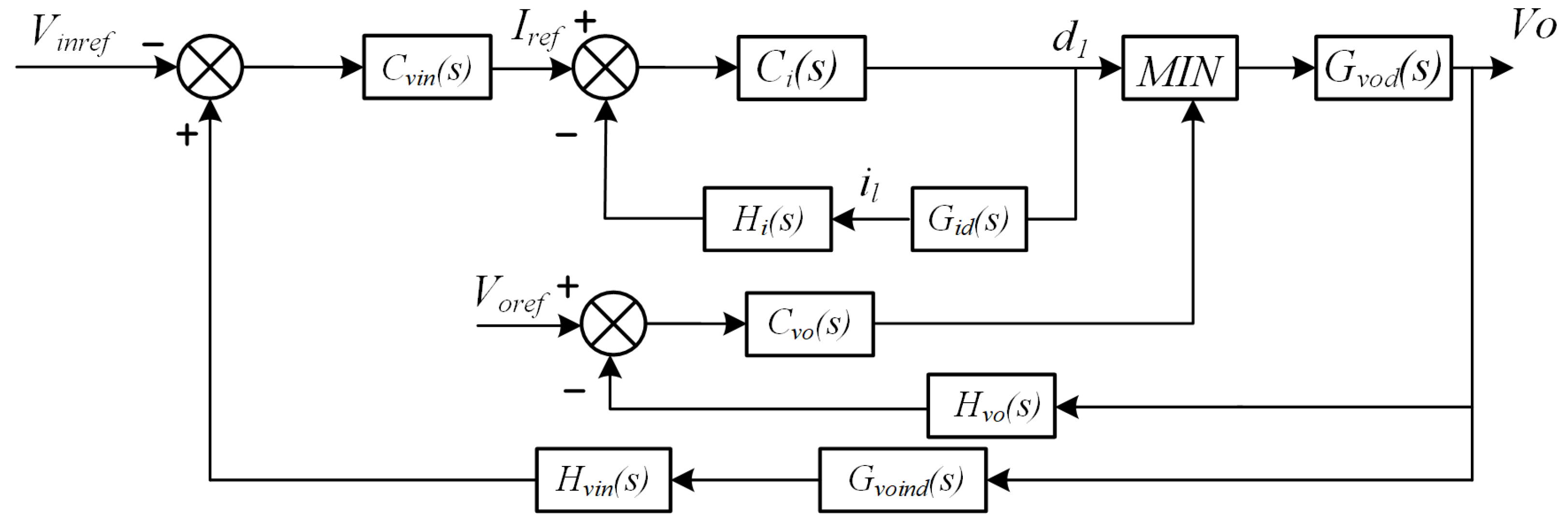

3.2. Secondary Side Power Regulation Control

4. System Simulation Results

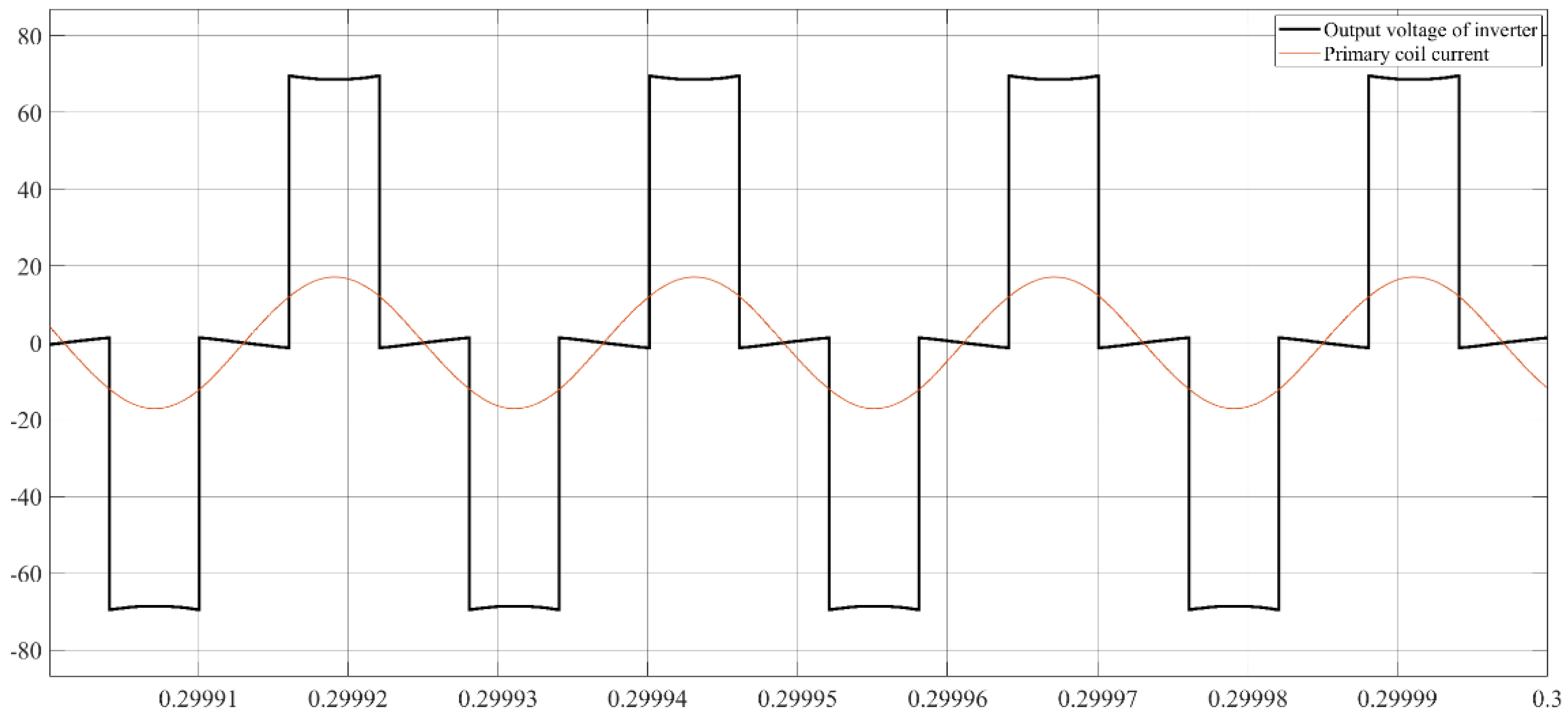

4.1. Open-Loop System Simulation Results

4.2. Closed-Loop Simulation Results

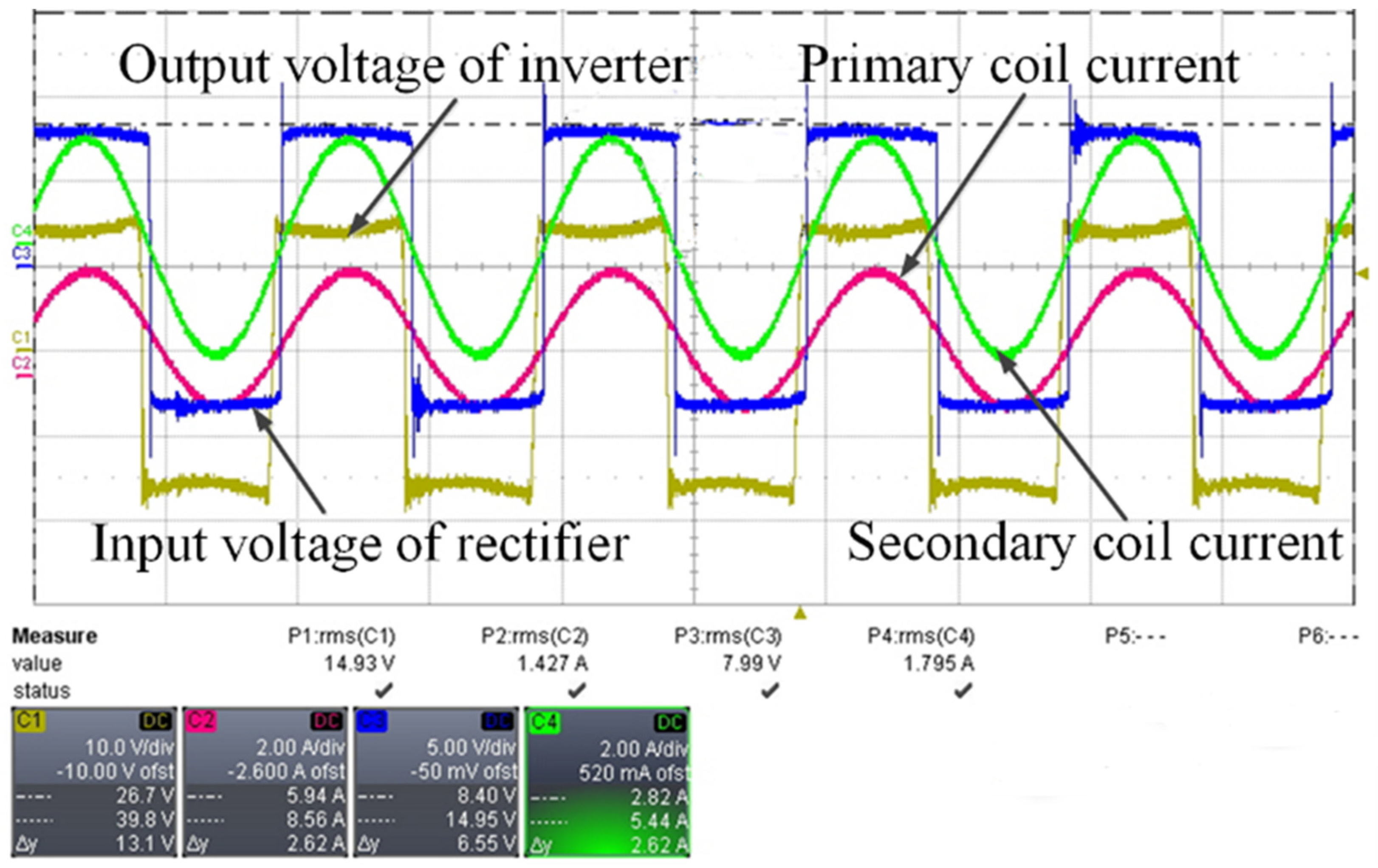

5. Supercapacitor Wireless Charging Experiment

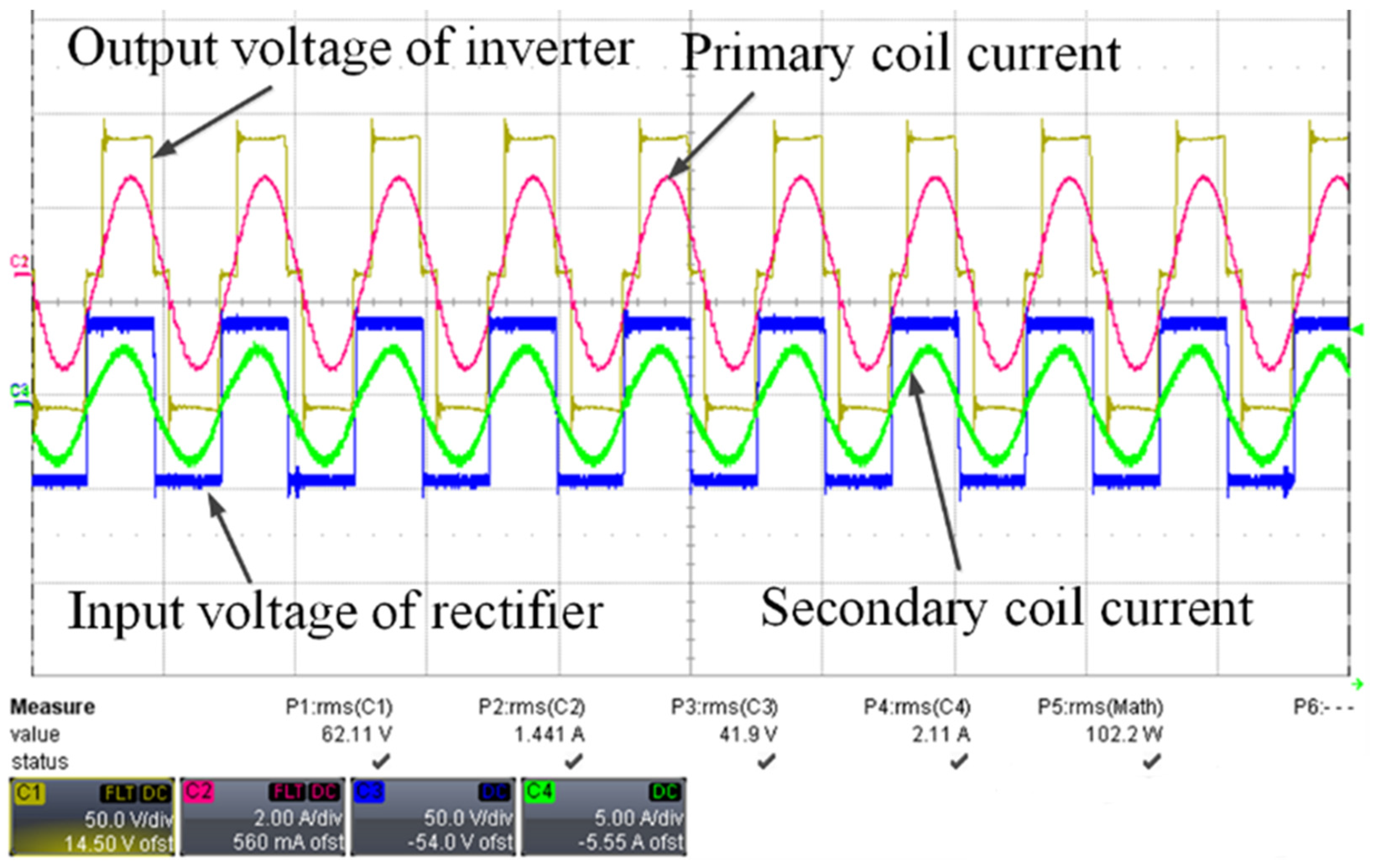

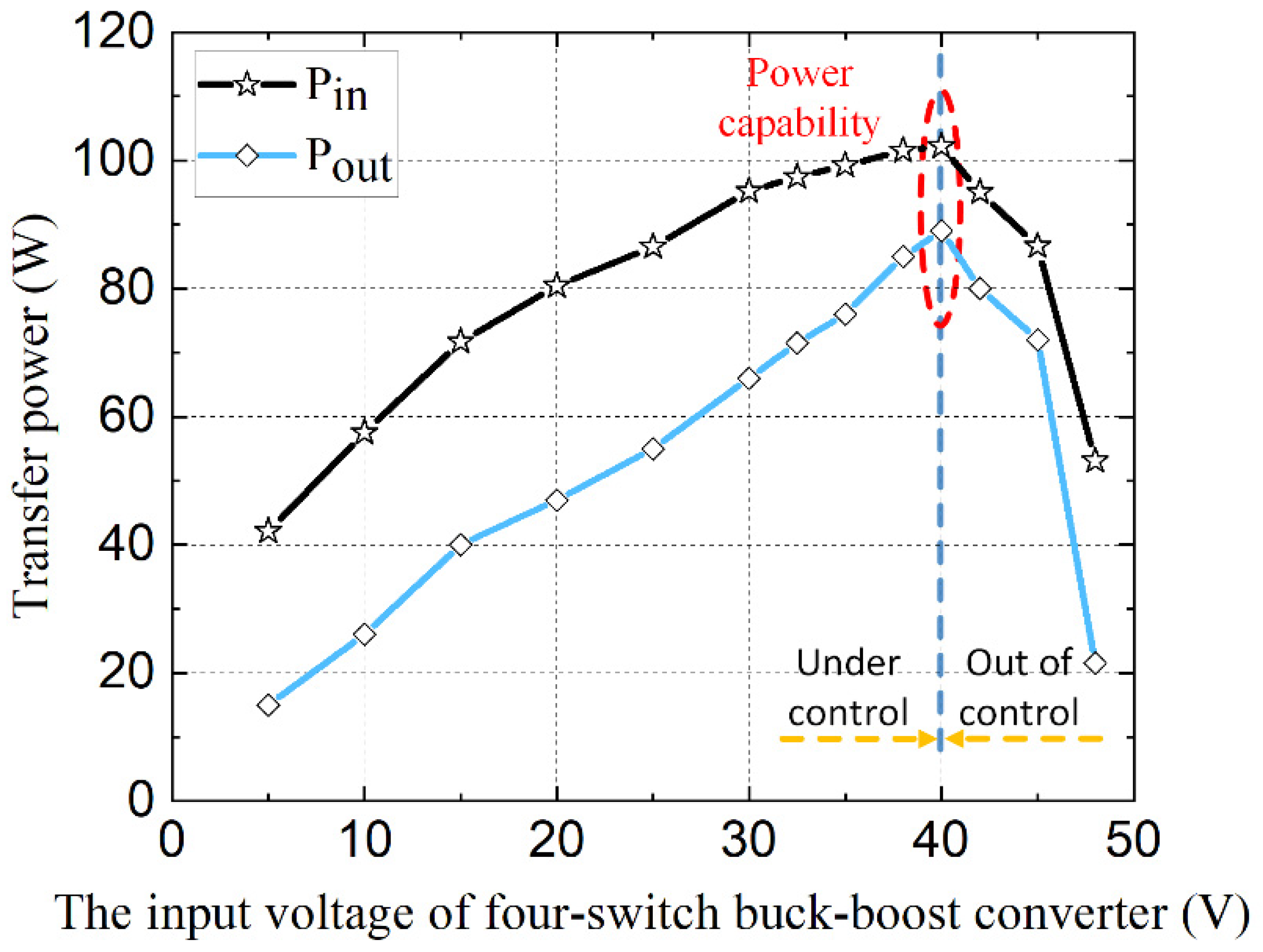

5.1. Start-Up Estimation Experiments

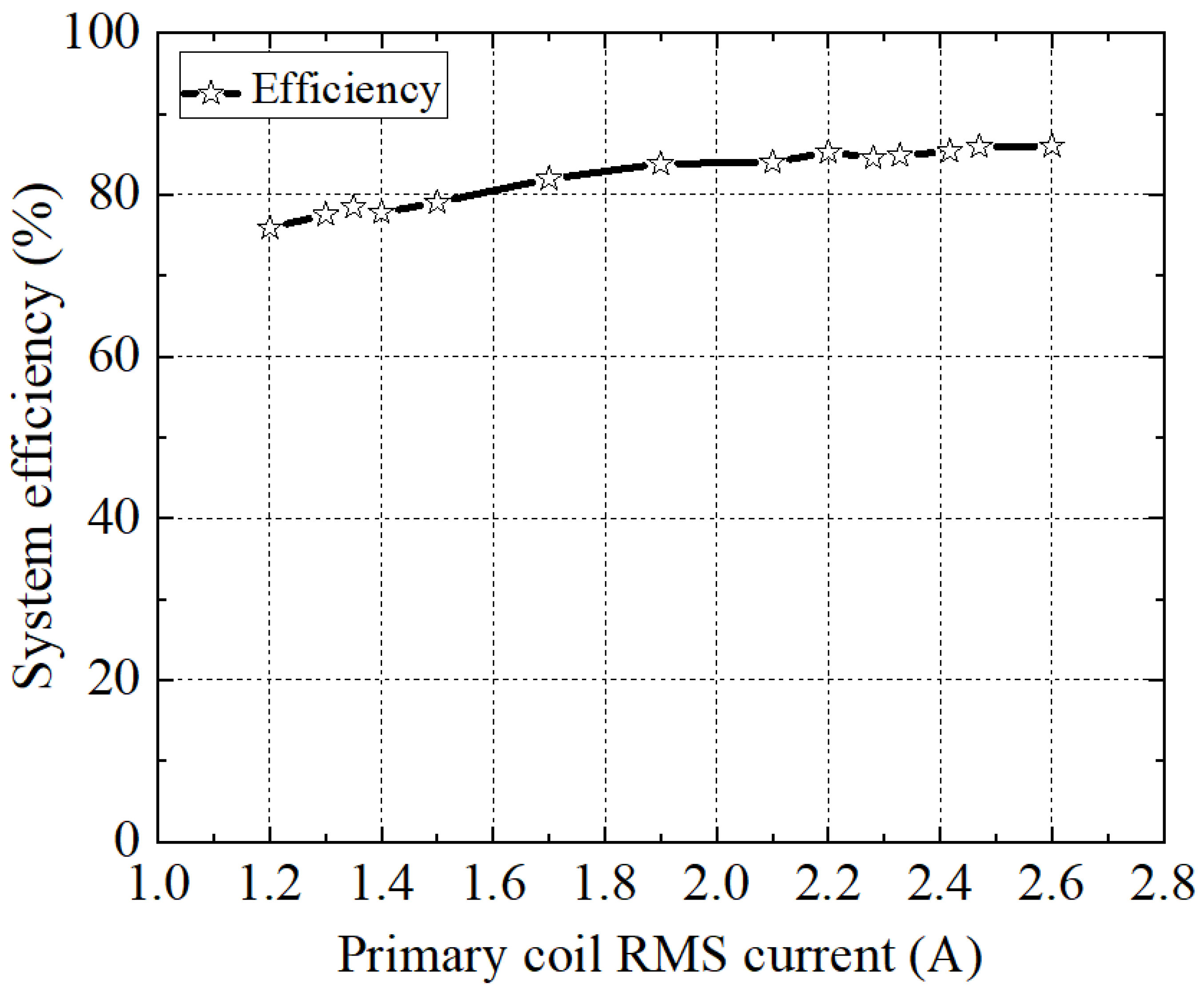

5.2. Primary Coil RMS Current Control Results

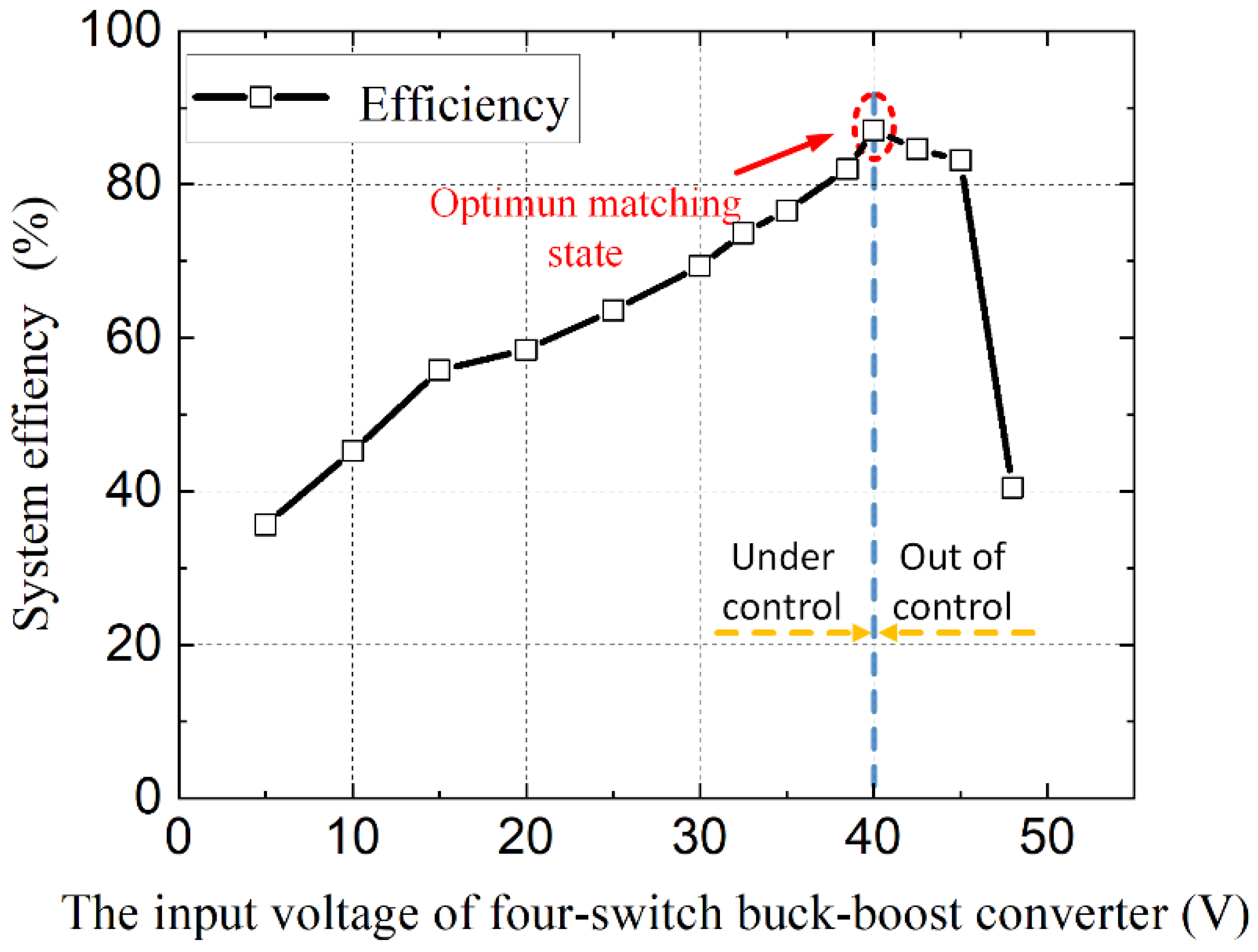

5.3. Secondary Side Constant Input Voltage Control Results

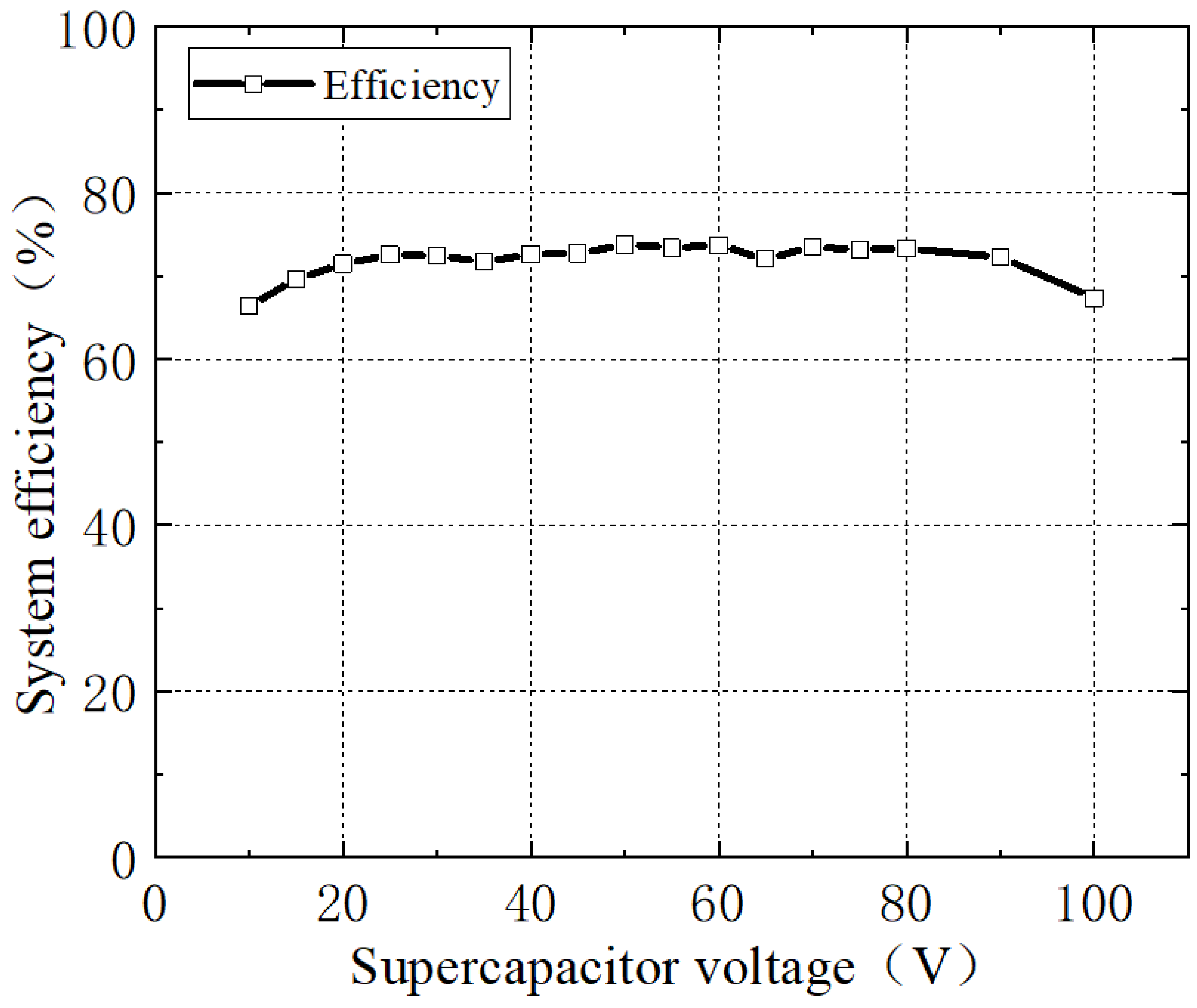

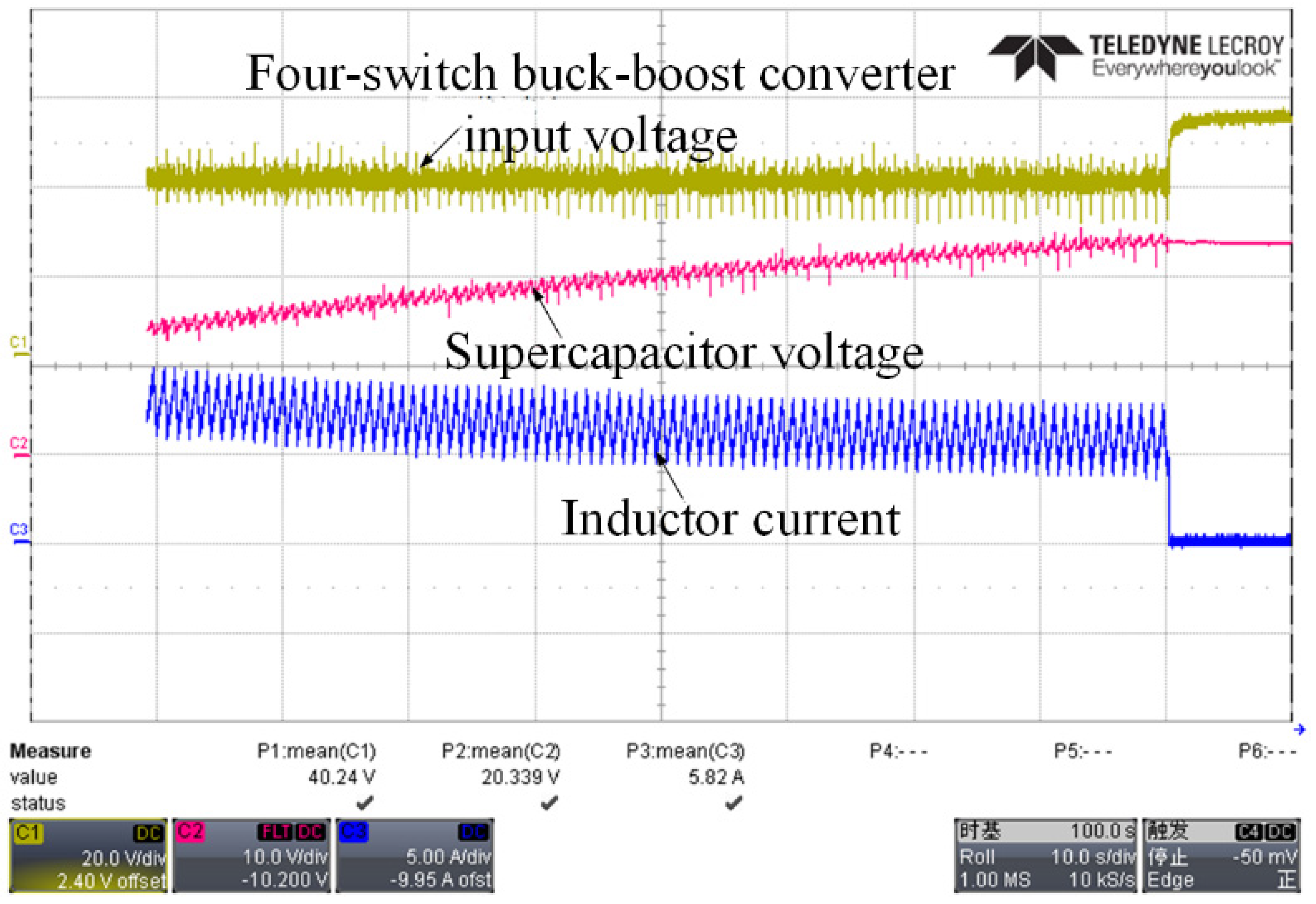

5.4. System Stability to Changes in the Supercapacitor Voltage Results

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Wang, S. Research on a New Lithium Battery Applied in Onboard Energy Storage Device of Light Rail Vehicle. In Proceedings of the 2018 2nd IEEE Advanced Information Management, Communicates, Electronic and Automation Control Conference (IMCEC), Xi’an, China, 25–27 May 2018. [Google Scholar]

- Castaings, A.; Caron, H.; Kharrat, H.; Ovalle, A.; Vulturescu, B. Energy Storage System based on Supercapacitors for a 750 V DC railway power supply. In Proceedings of the 2018 IEEE International Conference on Electrical Systems for Aircraft, Railway, Ship Propulsion and Road Vehicles & International Transportation Electrification Conference (ESARS-ITEC), Nottingham, UK, 7–9 November 2018; pp. 1–5. [Google Scholar]

- Ayad, M.Y.; Becherif, M.; Henni, A.; Aboubou, A.; Wack, M. Sliding mode control and Unit Power Factor applied to embarked supercapacitors for electrical train traction. In Proceedings of the 2010 IEEE International Symposium on Industrial Electronics, Bari, Italy, 4–7 July 2010; pp. 2163–5145. [Google Scholar]

- Cheng, L.; Acuna, P.; Wei, S.; Fletcher, J.; Wang, W.; Jiang, J. Fast-Swap Charging: An Improved Operation Mode For Catenary-Free Light Rail Networks. IEEE Trans. Veh. Technol. 2018, 67, 2912–2920. [Google Scholar] [CrossRef]

- Covic, G.A.; Boys, J.T. Modern trends in inductive power transfer for transportation applications. IEEE J. Emerg. Sel. Top. Power Electron. 2013, 1, 28–41. [Google Scholar] [CrossRef]

- Huh, J.; Lee, S.W.; Lee, W.Y.; Cho, G.H. Narrow-width inductive power transfer system for online electrical vehicles. IEEE Trans. Power Electron. 2011, 26, 3666–3679. [Google Scholar] [CrossRef]

- Shin, J.; Shin, S.; Kim, Y.; Ahn, S.; Lee, S.; Jung, G.; Jeon, S.; Cho, D. Design and implementation of shaped magnetic-resonance-based wireless power transfer system for roadway-powered moving electric vehicles. IEEE Trans. Power Electron. 2014, 61, 1179–1192. [Google Scholar] [CrossRef]

- Wang, Y.; Zhang, L.; Hou, H.; Xu, W.; Duan, G.; He, S.; Liu, K.; Jiang, S. Recent progress in carbon-based materials for supercapacitor electrodes: A review. J. Mater. Sci. 2021, 56, 173–200. [Google Scholar] [CrossRef]

- Yin, J.; Zhang, W.; Alhebshi, N.A.; Salah, N.; Alshareef, H.N. Synthesis strategies of porous carbon for supercapacitor applications. Small Methods 2020, 4, 1900853. [Google Scholar] [CrossRef]

- Cheng, F.; Yang, X.; Zhang, S.; Lu, W. Boosting the supercapacitor performances of activated carbon with carbon nanomaterials. J. Power Sources 2020, 450, 227678. [Google Scholar] [CrossRef]

- Saikia, B.K.; Benoy, S.M.; Bora, M.; Tamuly, J.; Pandey, M.; Bhattacharya, D. A brief review on supercapacitor energy storage devices and utilization of natural carbon resources as their electrode materials. Fuel 2020, 282, 118–196. [Google Scholar] [CrossRef]

- Kandasamy, M.; Sahoo, S.; Nayak, S.K.; Chakraborty, B.; Rout, C.S. Recent advances in engineered metal oxide nanostructures for supercapacitor applications: Experimental and theoretical aspects. J. Mater. Chem. A 2021, 9, 17643–17700. [Google Scholar] [CrossRef]

- Yassine, M.; Fabris, D. Performance of Commercially Available Supercapacitors. Energies 2017, 10, 1340. [Google Scholar] [CrossRef]

- Münchgesang, W.; Meisner, P.; Yushin, G. Supercapacitors specialities-Technology review. AIP Conf. Proc. 2014, 1597, 196–203. [Google Scholar]

- Zhu, F.; Yang, Z.; Zhao, Z.; Lin, F. Two-Stage Synthetic Optimization of Supercapacitor-Based Energy Storage Systems, Traction Power Parameters and Train Operation in Urban Rail Transit. IEEE Trans. Veh. Technol. 2021, 70, 8590–8605. [Google Scholar] [CrossRef]

- Fedele, E.; Pasquale, A.D.; Iannuzzi, D.; Pagano, M. Integration of Onboard Batteries and Supercapacitors Based on the Multi-Source Inverter for Light Rail Vehicle. In Proceedings of the 2022 International Power Electronics Conference (IPEC-Himeji 2022—ECCE Asia), Himeji, Japan, 15–19 May 2022; pp. 698–704. [Google Scholar]

- Yıldırım, D.; Akşit, M.H.; Yolaçan, C.; Pul, T.; Ermiş, C.; Aghdam, B.H.; Çadırcı, I.; Ermiş, M. Full-Scale Physical Simulator of All SiC Traction Motor Drive With Onboard Supercapacitor ESS for Light-Rail Public Transportation. IEEE Trans. Ind. Electron. 2020, 67, 6290–6630. [Google Scholar] [CrossRef]

- Li, J.; Xin, D.; Wang, H.; Liu, C. Application of Energy Storage System in Rail Transit: A Review. In Proceedings of the 2022 International Conference on Power Energy Systems and Applications (ICoPESA), Virtual Conference, 25–27 February 2022; pp. 539–552. [Google Scholar]

- Chu, A.; Braatz, P. Comparison of commercial supercapacitors and high-power lithium-ion batteries for power-assist applications in hybrid electric vehicles: I. Initial characterization. J. Power Sources 2002, 112, 236–246. [Google Scholar] [CrossRef]

- Yasha, P.; Vahidi, A.; Fayazi, S.A. Heuristic versus optimal charging of supercapacitors, lithium-ion, and lead-acid batteries: An efficiency point of view. IEEE Trans. Control Syst. Technol. 2018, 26, 167–180. [Google Scholar]

- Yang, H. Analysis of supercapacitor charge redistribution through constant power experiments. In Proceedings of the 2017 IEEE Power & Energy Society General Meeting, Chicago, IL, USA, 16–20 July 2017; pp. 1–5. [Google Scholar]

- Şahİn, M.E.; Blaabjerg, F.; Sangwongwanİch, A. Modelling of supercapacitors based on simplified equivalent circuit. CPSS TPEA 2021, 6, 31–39. [Google Scholar] [CrossRef]

- Guo, W.; Yu, C.; Li, S.; Qiu, J. Toward commercial-level mass-loading electrodes for supercapacitors: Opportunities, challenges and perspectives. Energy Environ. Sci. 2021, 14, 576–601. [Google Scholar] [CrossRef]

- Zhang, S.; Pan, N. Supercapacitors Performance Evaluation. Adv. Energy Mater. 2015, 5, 1401401. [Google Scholar] [CrossRef]

- Zhu, Q.; Zhao, D.; Cheng, M.; Zhou, J.; Owusu, K.A.; Mai, L.; Yu, Y. A new view of supercapacitors: Integrated supercapacitors. Adv. Energy Mater. 2019, 9, 1901081. [Google Scholar] [CrossRef]

- Geng, Y.; Yang, Z.; Lin, F. Design and Control for Catenary Charged Light Rail Vehicle Based on Wireless Power Transfer and Hybrid Energy Storage System. IEEE Trans. Power Electron. 2020, 35, 7894–7903. [Google Scholar] [CrossRef]

- Li, Y.; Mai, R.; Lin, T.; Liu, Y.; Li, Y.; He, Z.; Yu, J. Design and implementation of a novel WPT system for railway applications. In Proceedings of the 2017 IEEE PELS Workshop on Emerging Technologies: Wireless Power Transfer (WoW), Chongqing, China, 20–22 May 2017; pp. 213–221. [Google Scholar]

- Song, K.; Zhu, C.; Koh, K.E.; Imura, T.; Hori, Y. Wireless power transfer for running EV powering using multi-parallel segmented rails. In Proceedings of the 2015 IEEE PELS Workshop on Emerging Technologies: Wireless Power (2015 WoW), Daejeon, Korea, 5–6 June 2015; pp. 1–6. [Google Scholar]

- Pang, J.; Li, Z.; Xu, C. Design of Automatic Switch of Charging Rail for Electric Vehicle Dynamic Charging System Based on Wireless Power Transmission. In Proceedings of the 2021 IEEE International Conference on Advances in Electrical Engineering and Computer Applications (AEECA), Dalian, China, 27–28 August 2021; pp. 731–737. [Google Scholar]

| Parameters | Value |

|---|---|

| Input supply voltage Vin | 72 V |

| Inverter switching frequency fs | 85 kHz |

| Load matching converter switching frequency fdc | 40 kHz |

| Inductance L | 220 μH |

| Primary resonant inductance Lp | 500 μH |

| Primary capacitor Cp | 32 nF |

| Secondary inductance Ls | 100 μH |

| Secondary capacitor Cs | 4 μF |

| Resonant frequency fr | 85 kHz |

| Components | Pattern/Parameter |

|---|---|

| Digital controller | dsPIC33FJ64GS606 |

| Driving power supplier | KA7805, FSL336 |

| Current sensor | 56200C, CHCS-GB5-50A |

| Primary inductance Lp | 500 μH |

| Primary capacitor Cp | 7 nF |

| Secondary inductance Ls | 43.6 μH |

| Resonant frequency fr | 85.07 kHz |

| Secondary capacitor Cs | 0.1 μF |

| Supercapacitor | 25 V/15 F |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xu, S.; Wang, Z.; Chen, J.; Jiang, W. Research and Design of LC Series Resonant Wireless Power Transfer System with Modulation Control Method for Supercapacitor Charging in Linear Motion Systems. Energies 2022, 15, 6739. https://doi.org/10.3390/en15186739

Xu S, Wang Z, Chen J, Jiang W. Research and Design of LC Series Resonant Wireless Power Transfer System with Modulation Control Method for Supercapacitor Charging in Linear Motion Systems. Energies. 2022; 15(18):6739. https://doi.org/10.3390/en15186739

Chicago/Turabian StyleXu, Song, Zhenlin Wang, Jingfei Chen, and Wei Jiang. 2022. "Research and Design of LC Series Resonant Wireless Power Transfer System with Modulation Control Method for Supercapacitor Charging in Linear Motion Systems" Energies 15, no. 18: 6739. https://doi.org/10.3390/en15186739

APA StyleXu, S., Wang, Z., Chen, J., & Jiang, W. (2022). Research and Design of LC Series Resonant Wireless Power Transfer System with Modulation Control Method for Supercapacitor Charging in Linear Motion Systems. Energies, 15(18), 6739. https://doi.org/10.3390/en15186739