A Review on Heat Extraction Devices for CPVT Systems with Active Liquid Cooling

Abstract

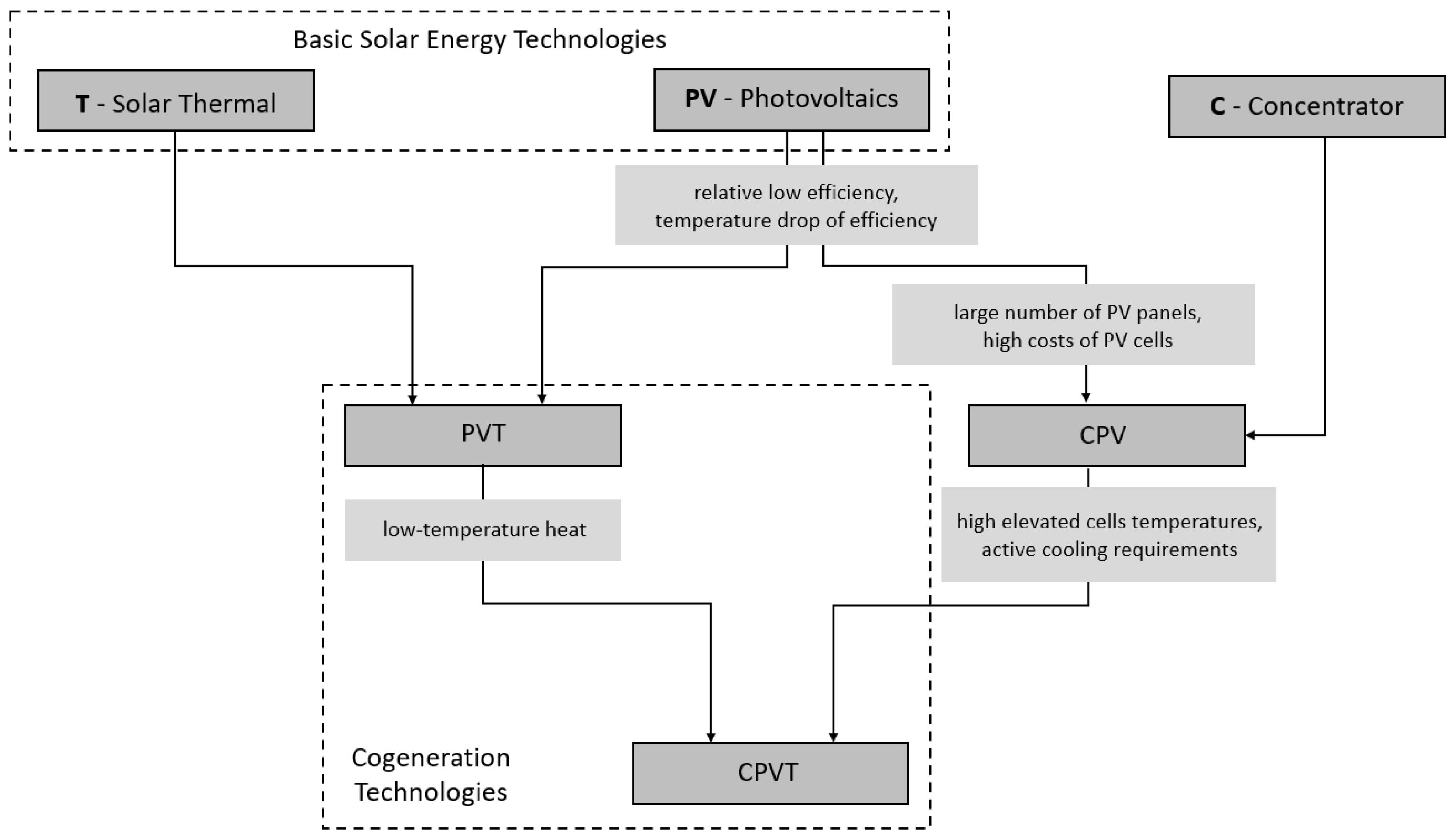

:1. Introduction

1.1. Utilization of Solar Energy

1.2. Cooling of PV Cells

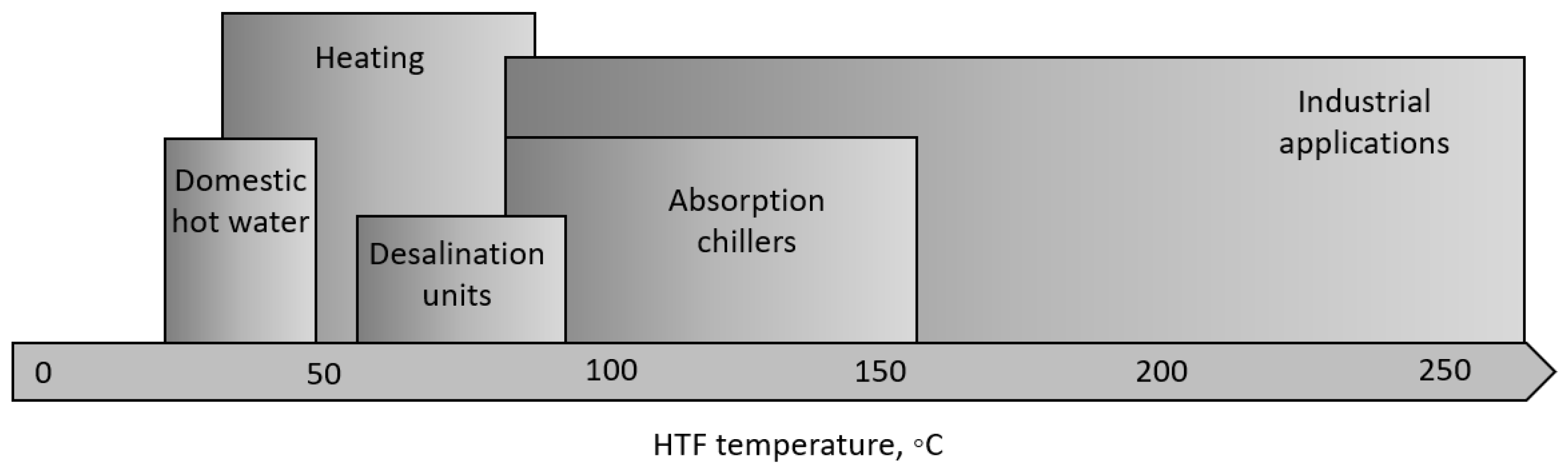

2. Concentrating Photovoltaic—Thermal Systems

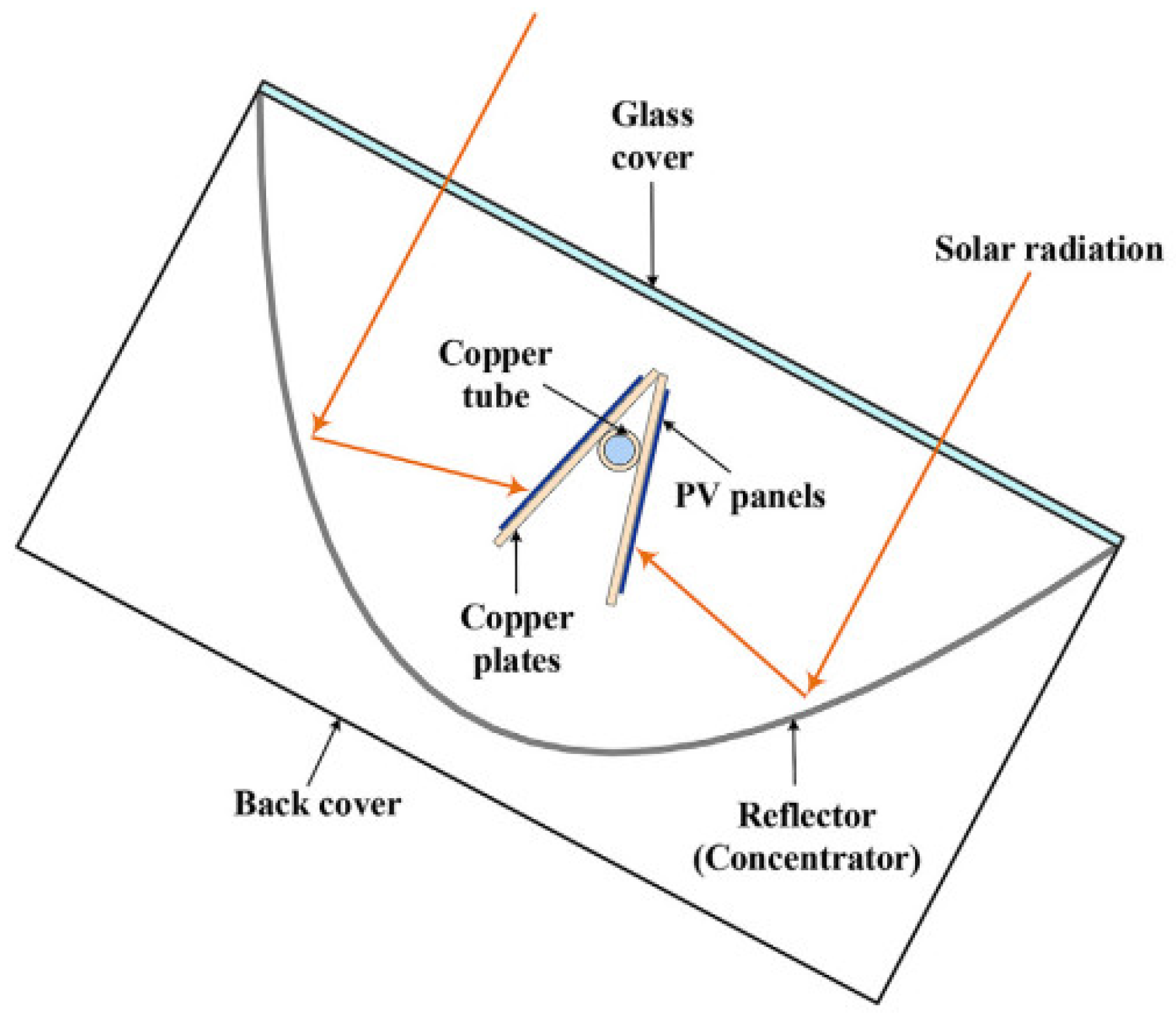

2.1. Concentrator

2.2. Photovoltaic Cells

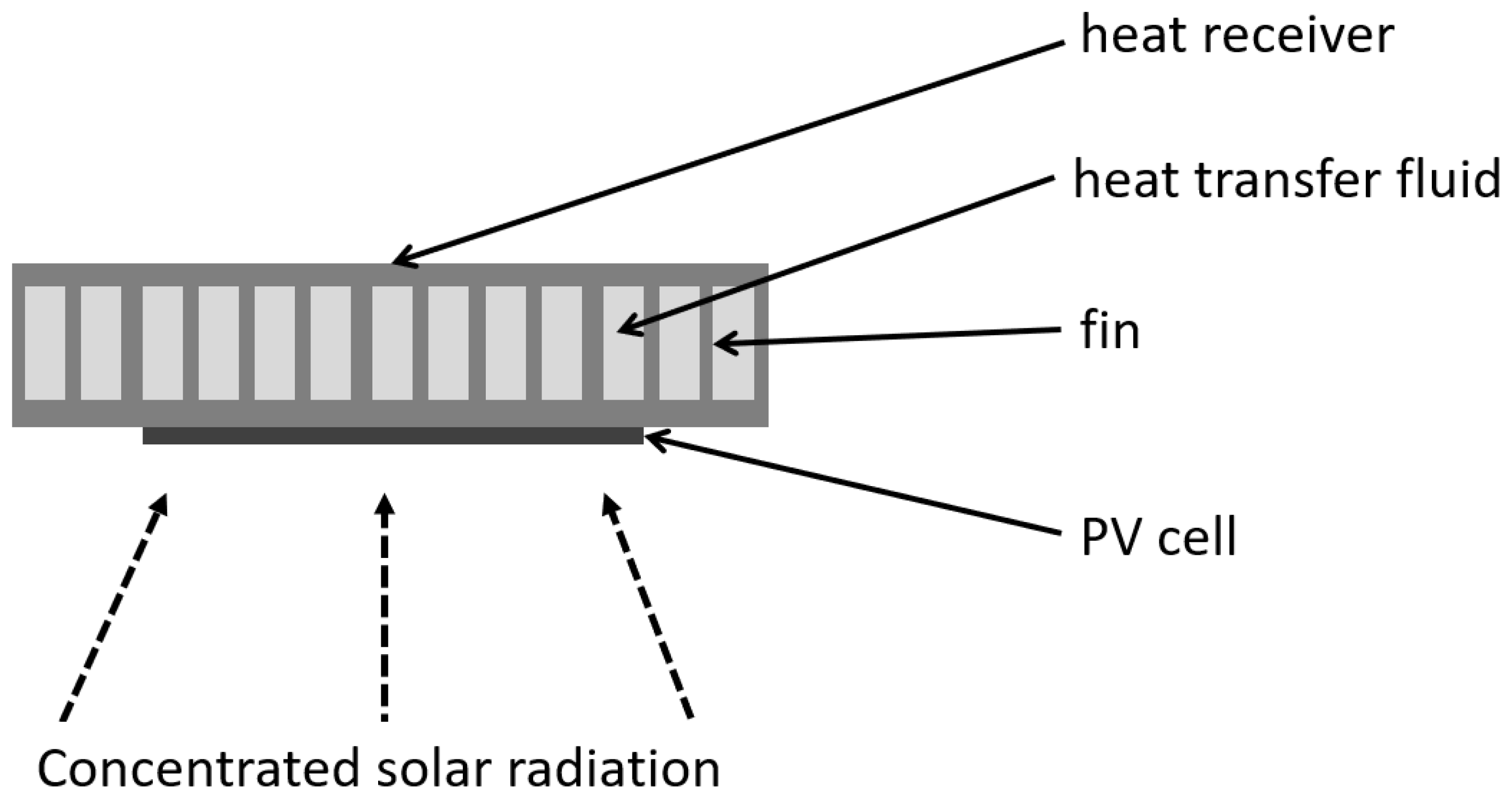

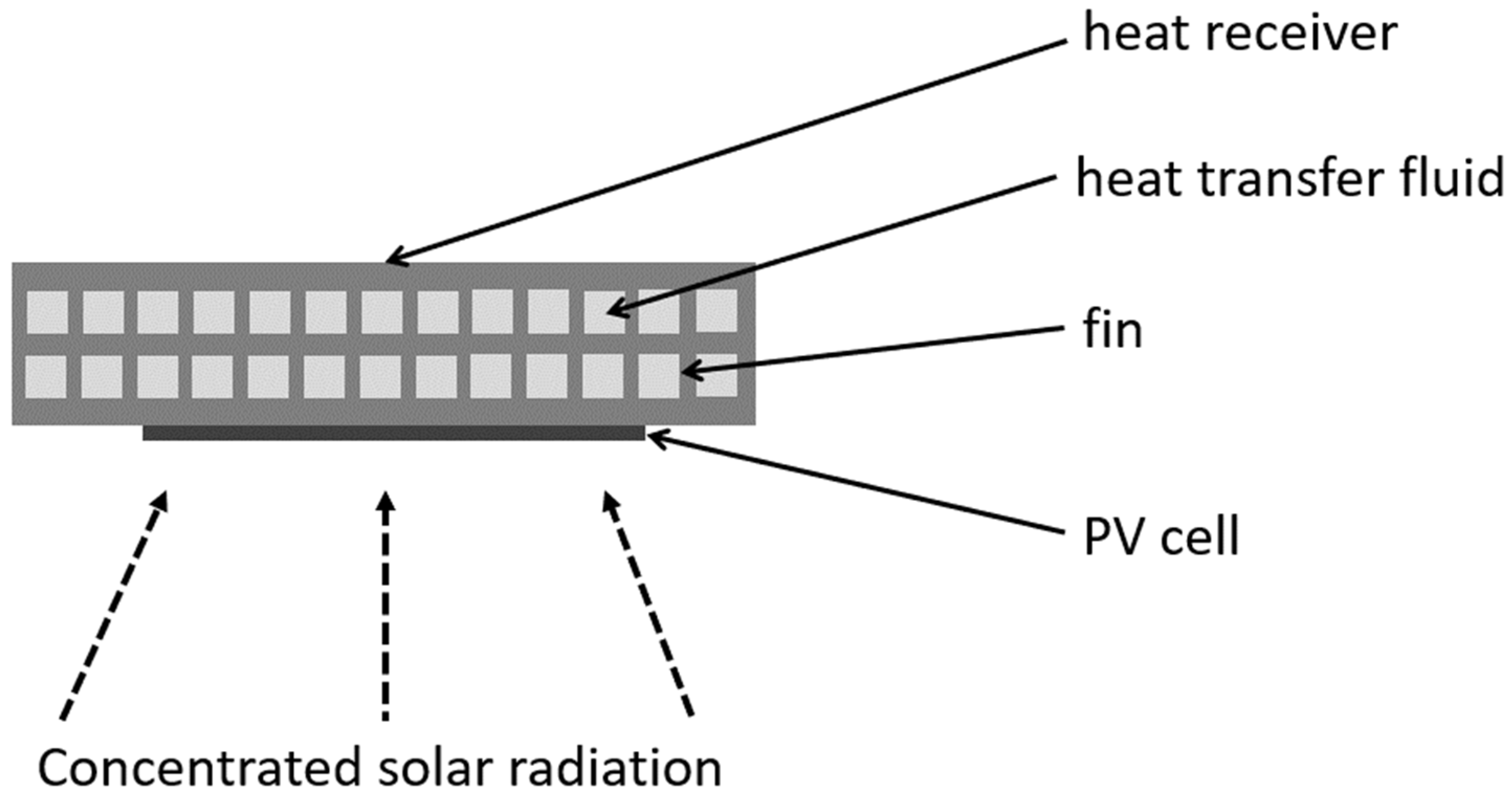

2.3. Heat Extraction Device

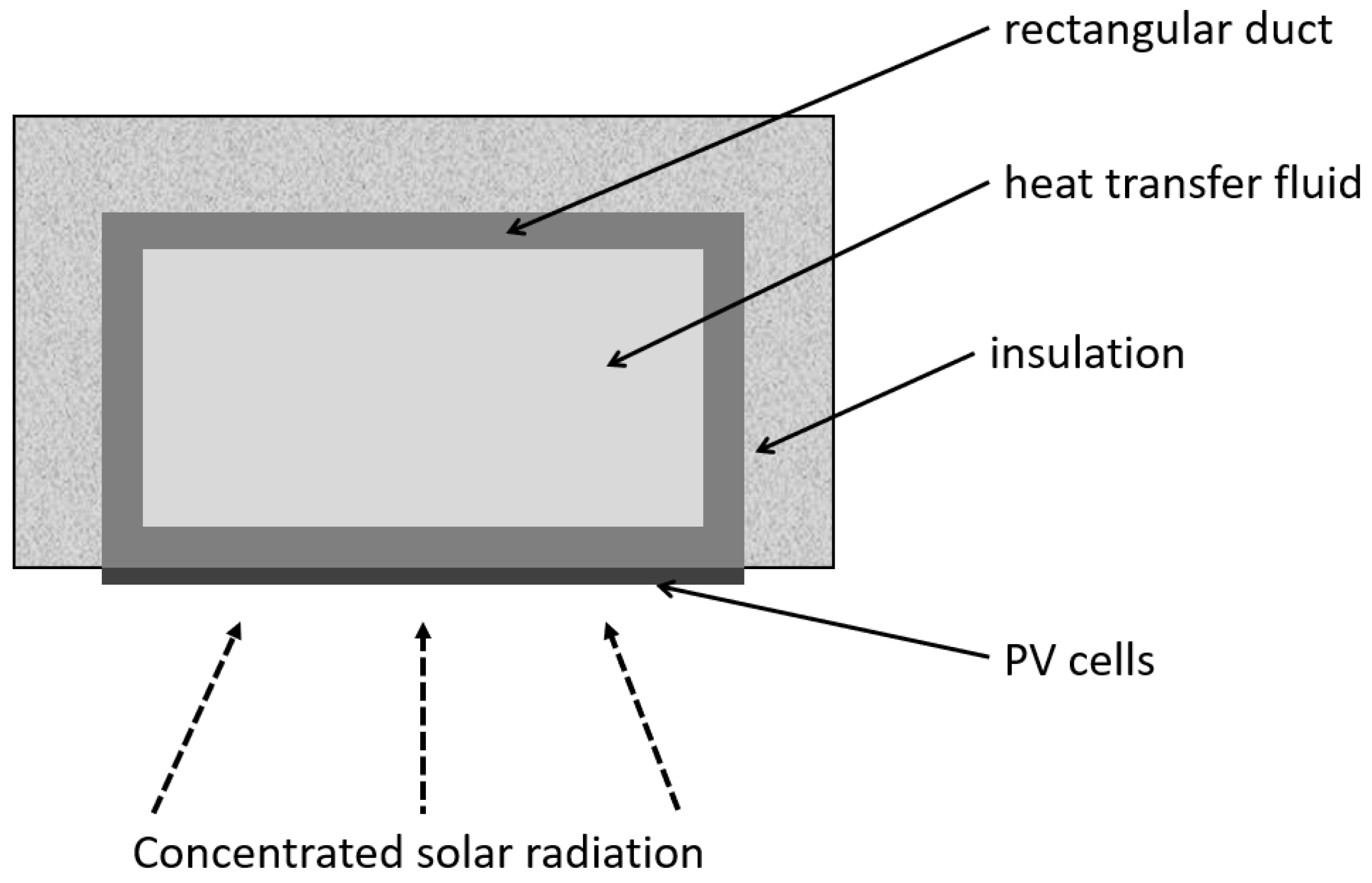

3. Heat Extraction Devices with Macro-Scale Channels/Ducts

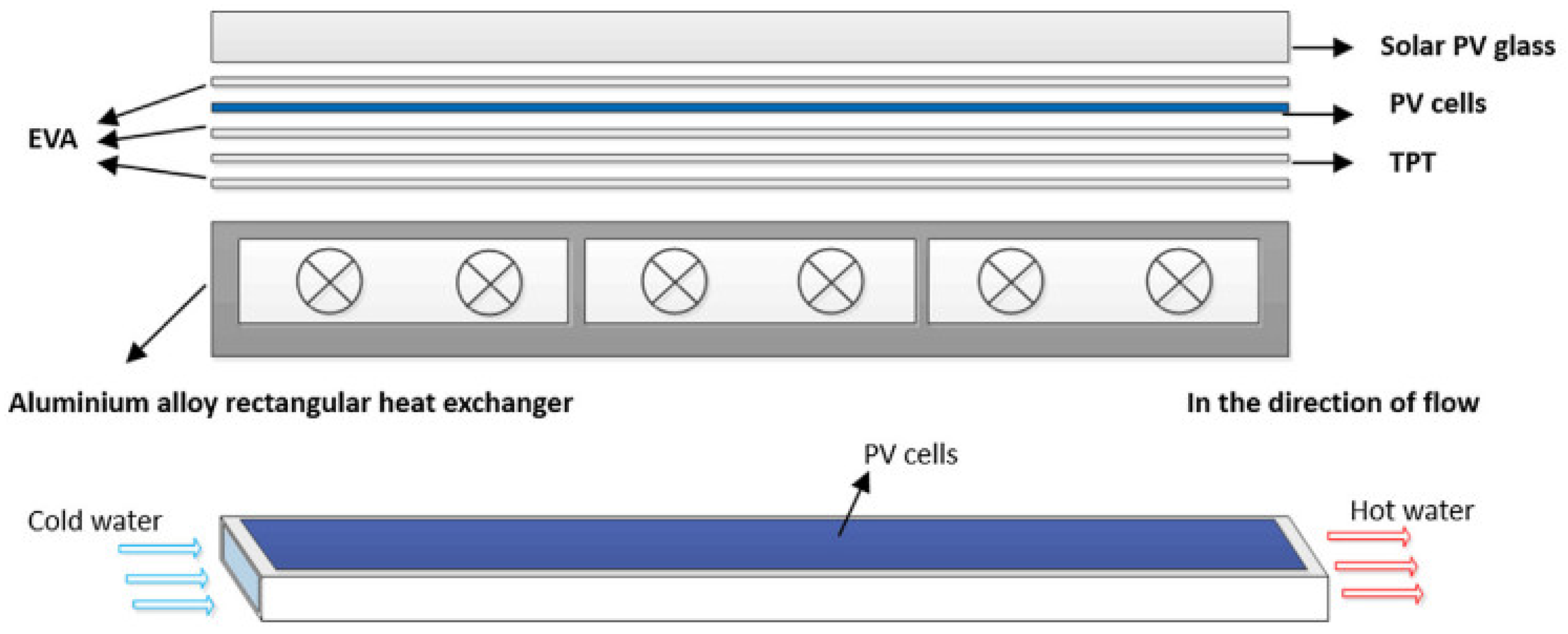

3.1. Rectangular Ducts

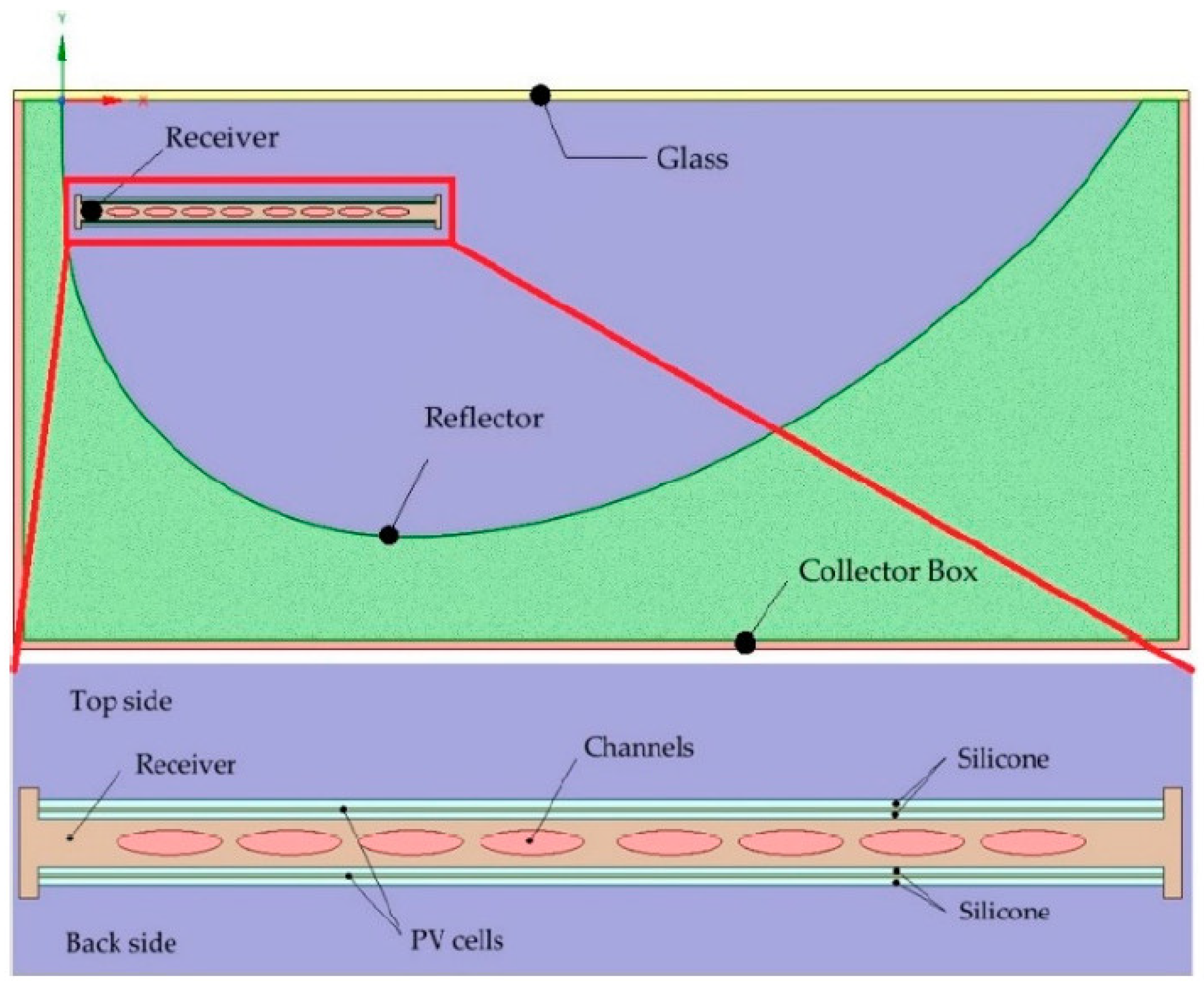

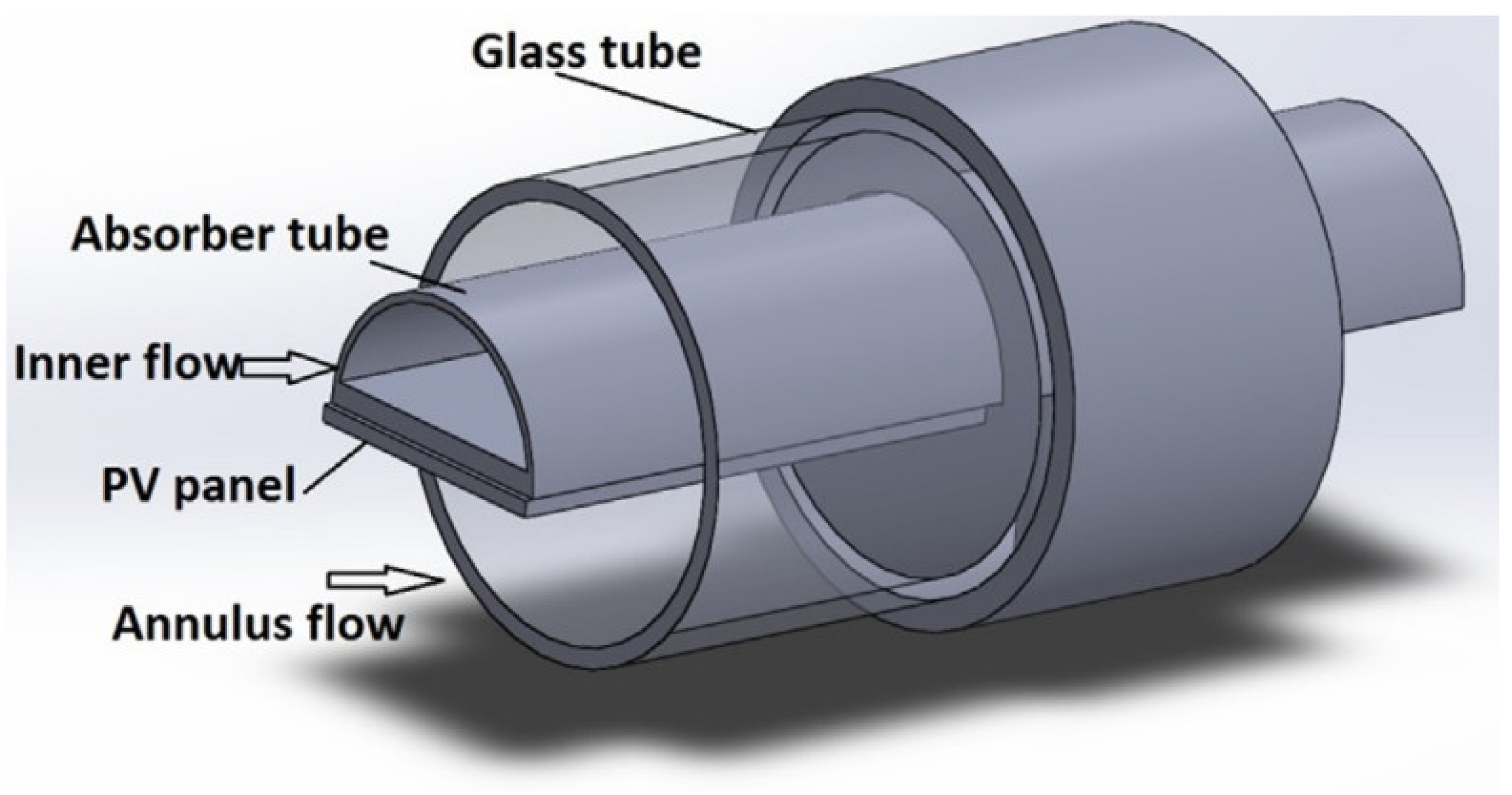

3.2. Circular Ducts

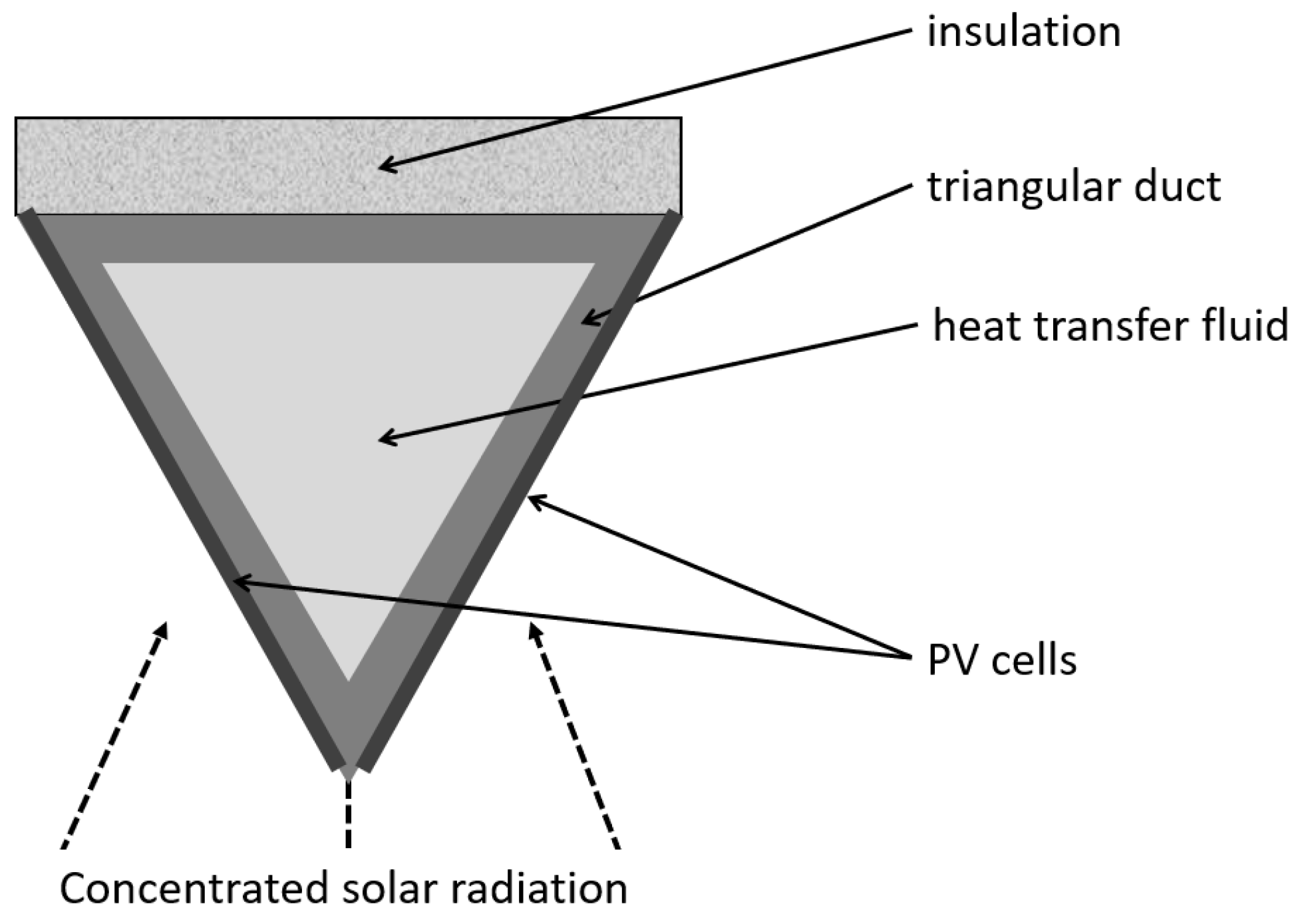

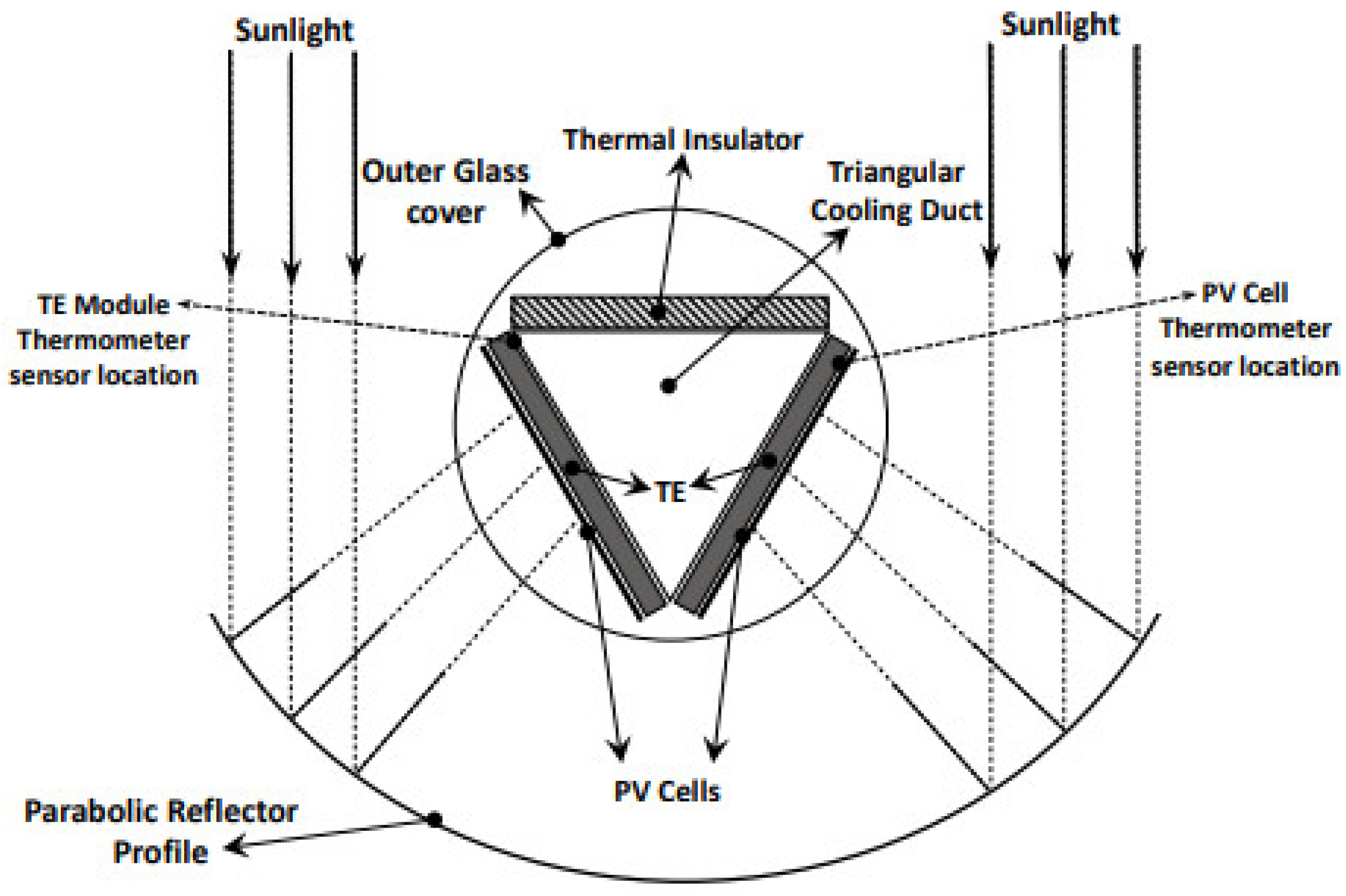

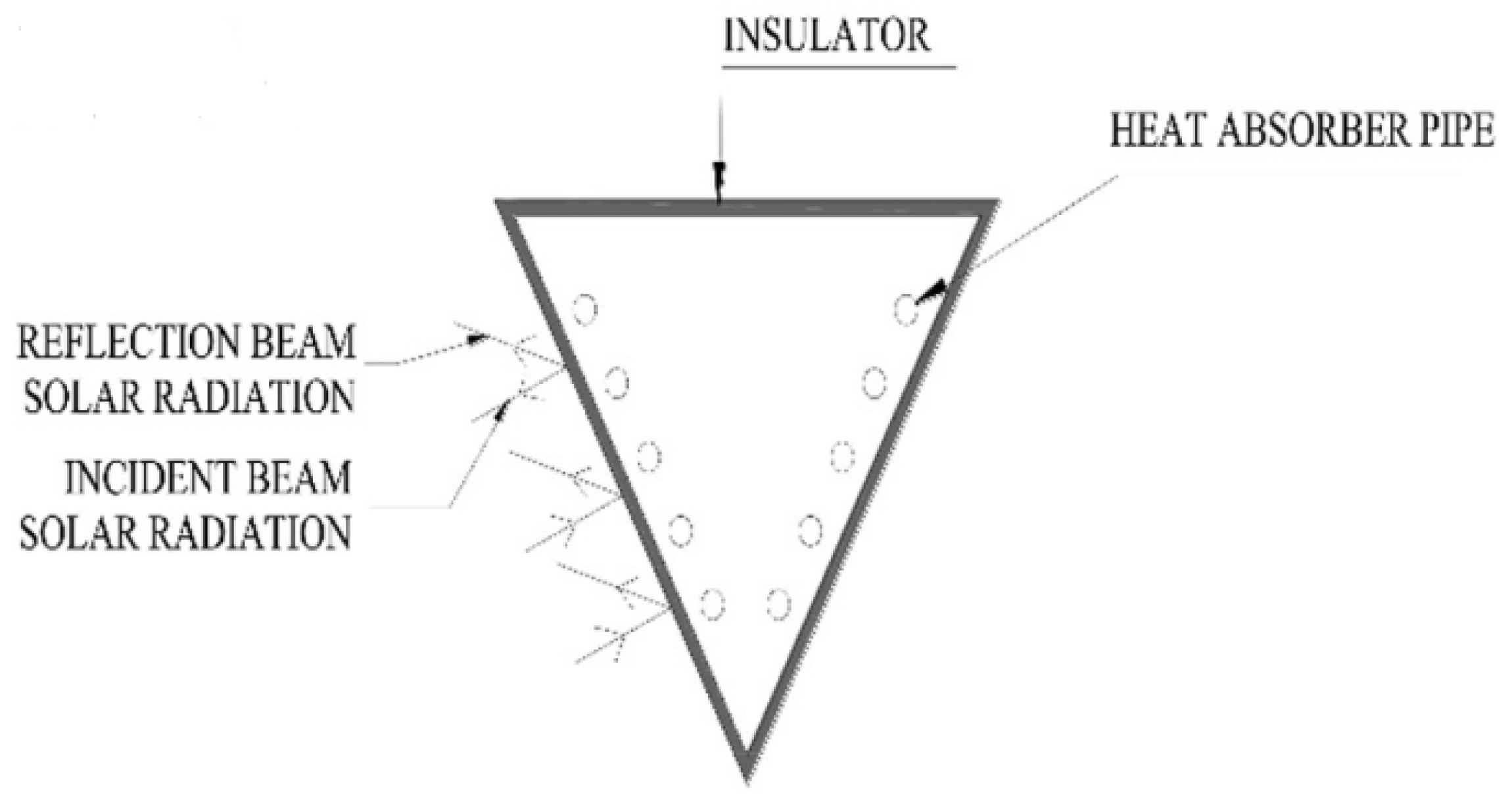

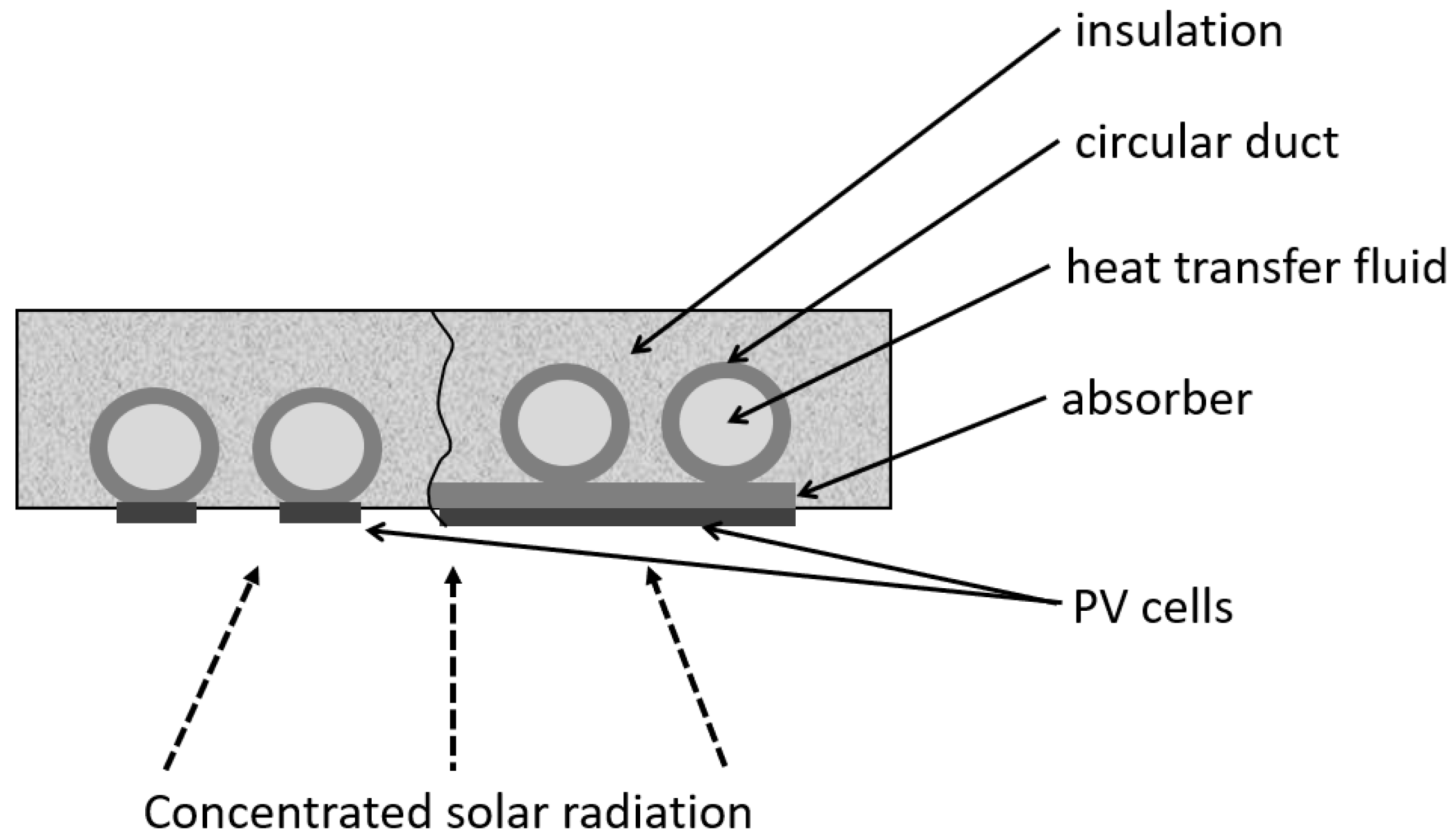

3.3. Triangular Ducts

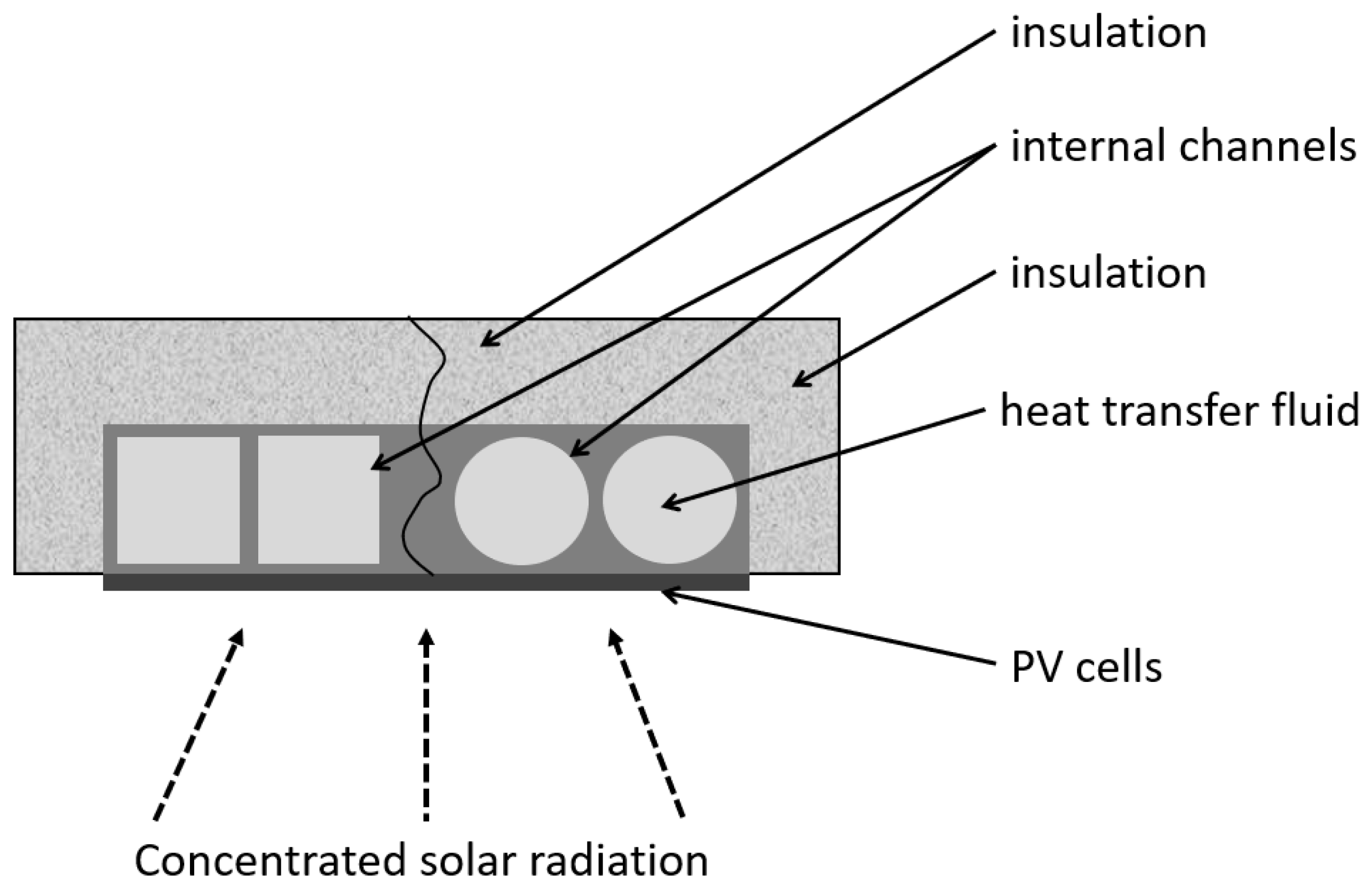

3.4. Metal Block with Inner Channels

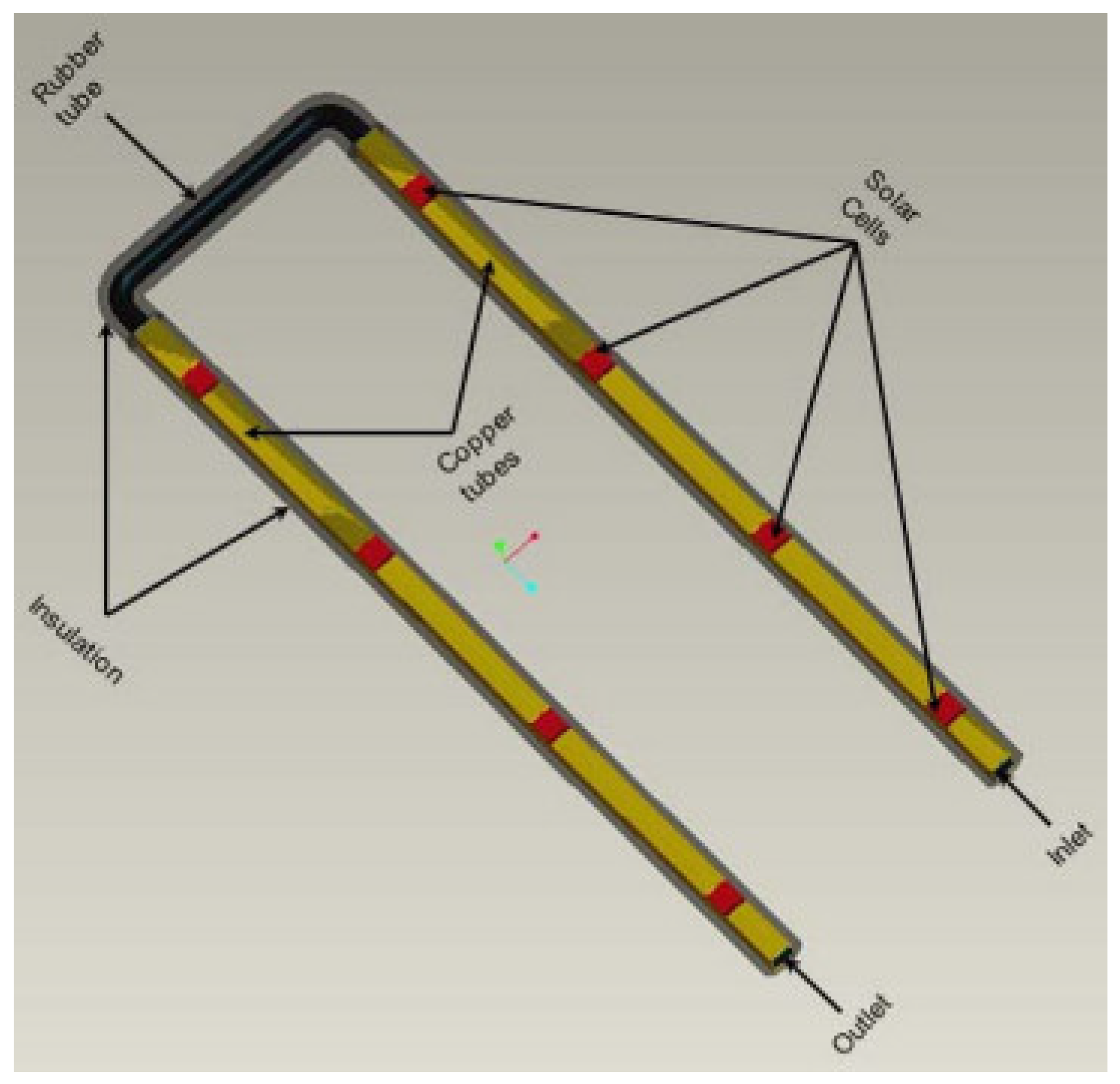

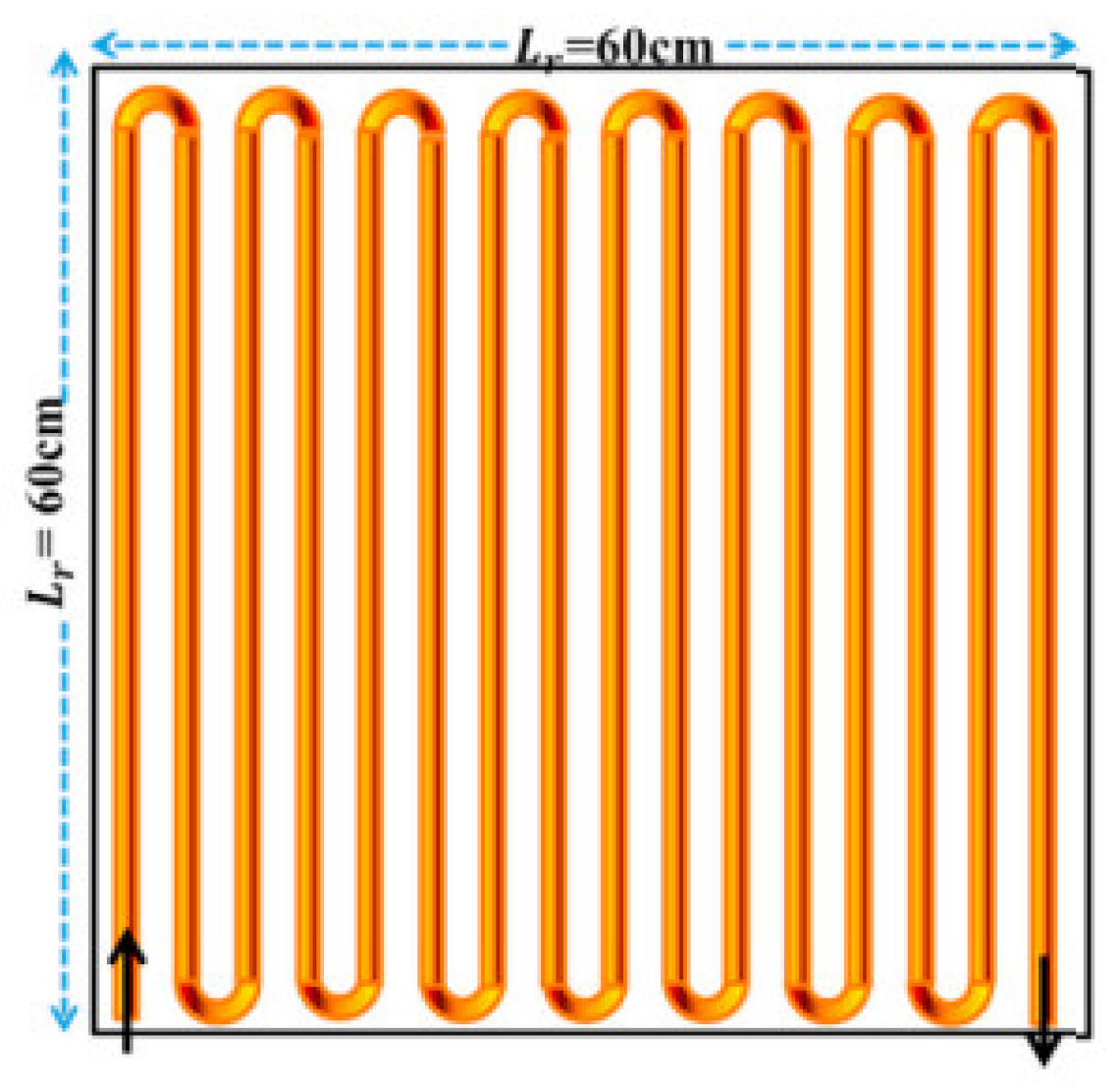

3.5. Serpentine Ducts

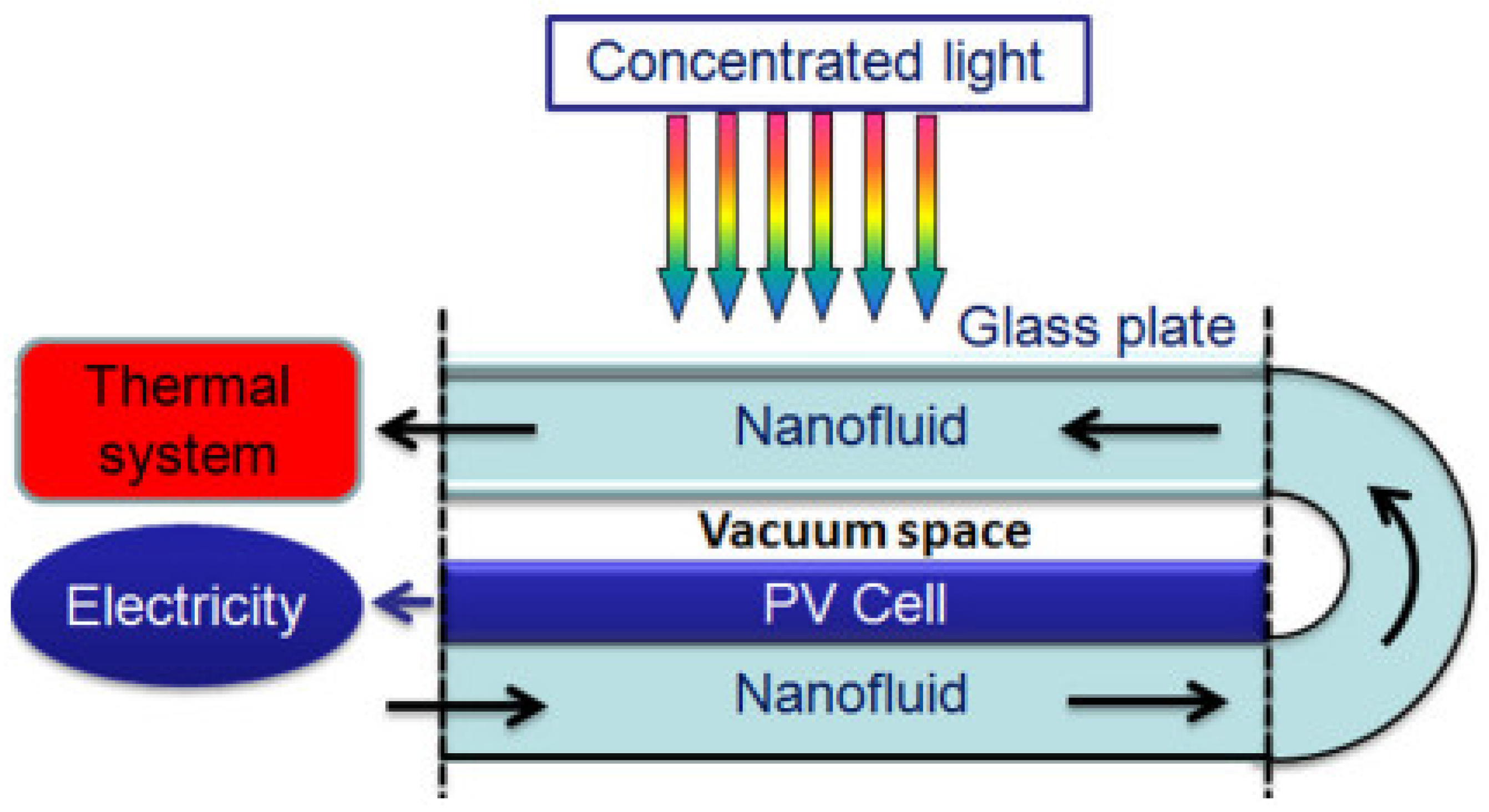

3.6. Flow between Two Flat Plates

3.7. Other Designs

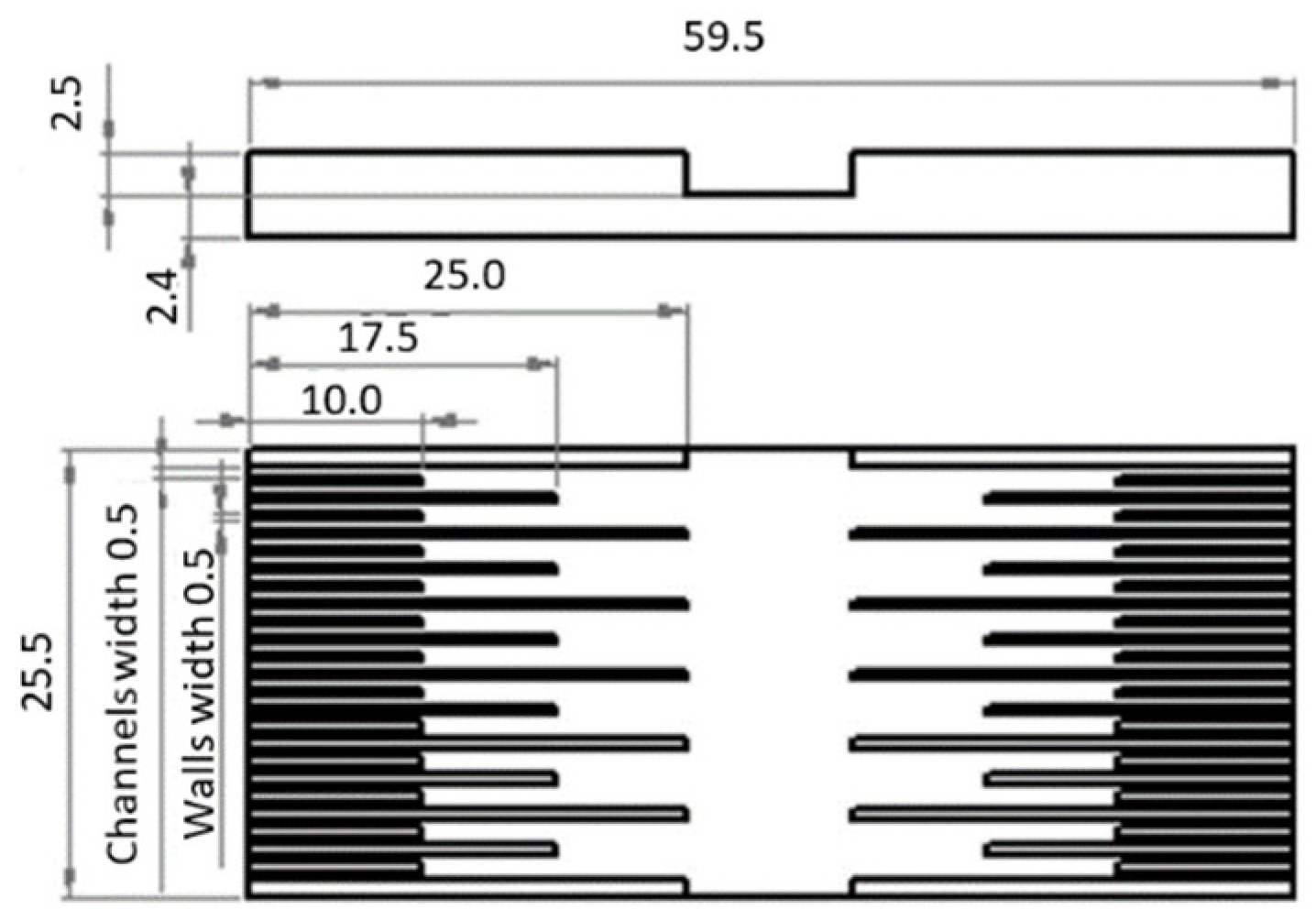

4. Heat Extraction Devices with Microchannels

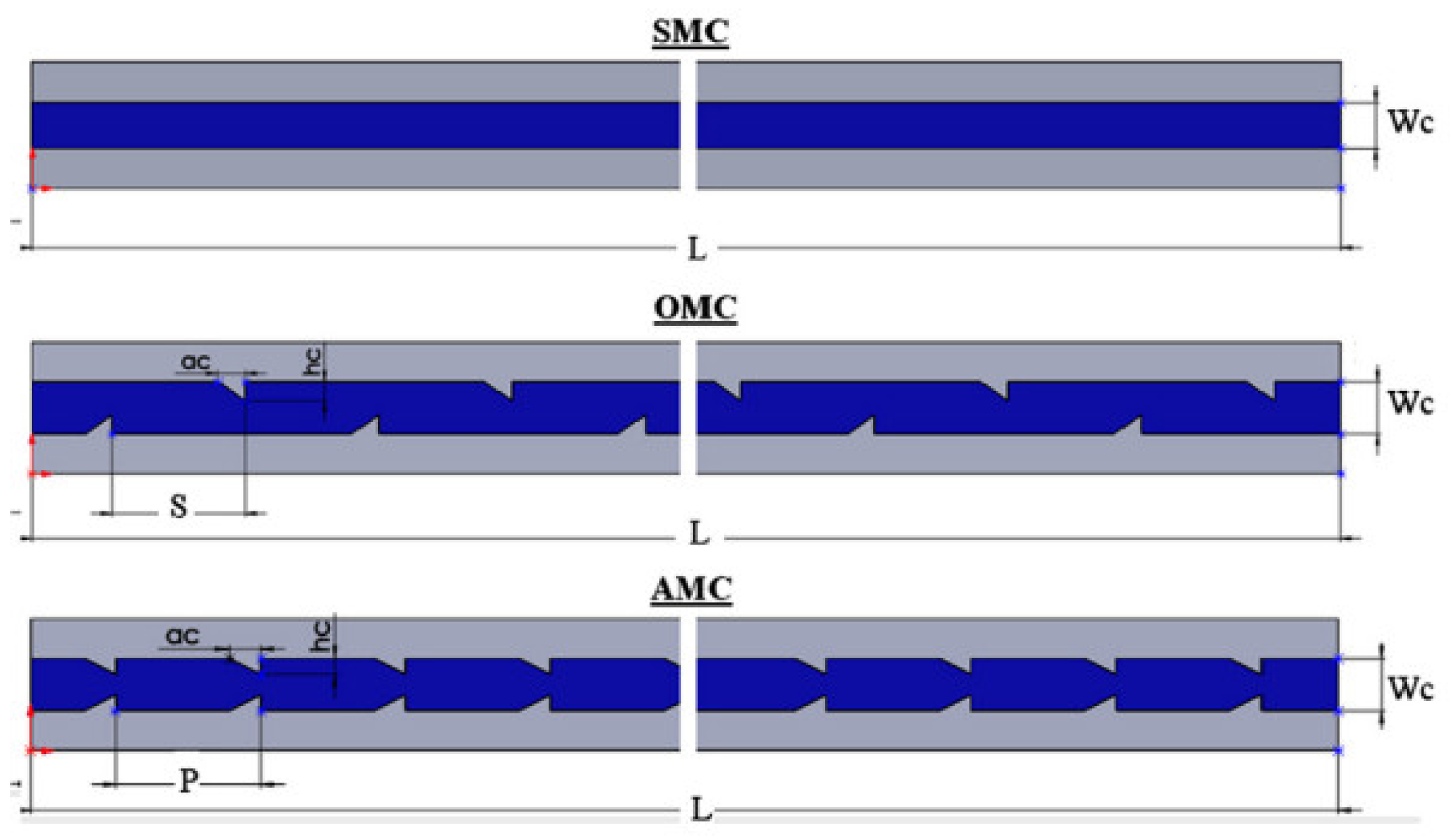

4.1. Single-Layered Microchannel Devices

4.2. Multi-Layered Microchannel Devices

4.3. Microchannel with Internal Features

4.4. Microchannel with Pin Fins

4.5. Other Designs

5. Summary

- The design of the heat extraction device in a CPVT system should be adjusted to the particular thermal and electrical requirements;

- Microchannel heat receivers should be used when high heat dissipation is required, which means CPVT systems with high and ultra-high concentration ratios;

- The thinner the fins in the microchannels are, the more efficient the heat transfer and the higher pressure losses;

- Internal features may be introduced to microchannels, but they require a low velocity of HTF;

- Heat extraction devices equipped with macro-scale channels are suitable for CPVT systems with low- and medium concentration ratios;

- The length of the linear heat receiver should be adjusted to the required outlet temperature of the HTF, taking into consideration a temperature gradient along the receiver, which leads to mechanical stress over the receiver body;

- Straight macrochannels provide the lowest pressure drop;

- Rectangular channels are accompanied by hot spots and stagnation zones close to the right angles, contrary to the macrochannels with a circular or elliptical cross-section.

- An increase in the area of heat transfer in macro-scale channels may be provided by the application of internal features such as ribs, fins, etc. Caution: They increase the pressure drop and parasitic load;

- Insulation of all walls which are not covered by PV cells increases the electrical efficiency but negatively influences the thermal performance;

- The area of walls that are not collecting the concentrated solar radiation should be limited to reduce thermal losses, e.g., by the usage of semicircular pipes;

- The inlet of the HTF should be placed near the location with the highest irradiance, such as the middle of a PV cell in point-focus systems;

- Additional PV cells may be placed on the walls that do not collect the concentrated solar radiation to increase the electrical output;

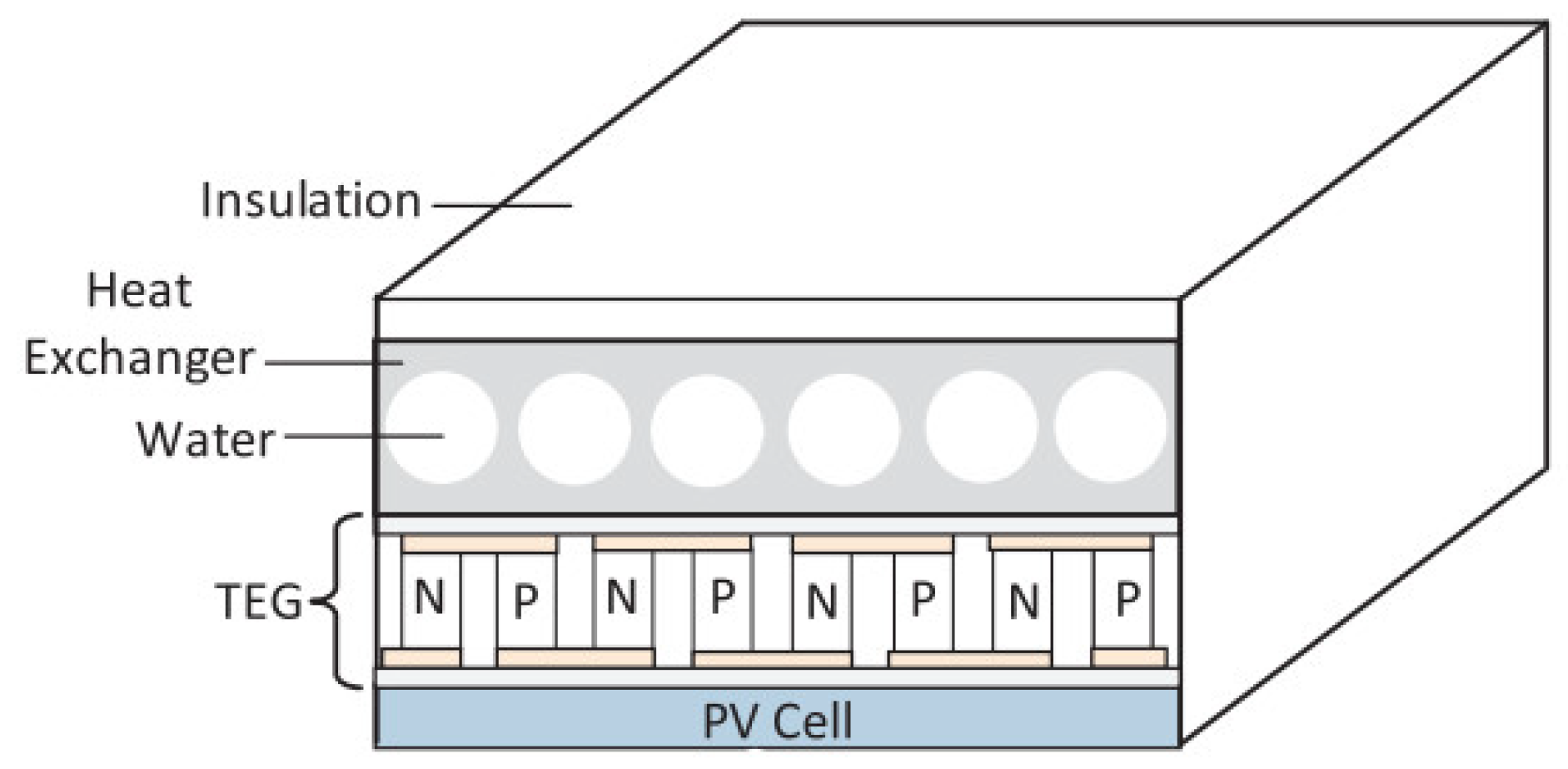

- Electrical output may also be increased by the application of thermoelectric generators between the heat receiver and PV cells, but this configuration limits the cooling efficiency of PV cells;

- The application of nanofluids instead of pure water increases the thermal conductivity of HTF and induces higher pressure losses when the concentration ratio increases;

- The application of antireflective coatings over the heat receiver leads to an increase in the amount of absorbed solar energy;

- The use of glass coatings reduces thermal and optical losses but negatively influences the operation of photovoltaic cells;

- A change in the receiver material from aluminum to copper may be not beneficial;

- Coupled pre- and post-illumination methods of cooling are promising.

Author Contributions

Funding

Institutional Review Board Statement

Acknowledgments

Conflicts of Interest

References

- Statista. Primary Energy Consumption Worldwide from 2000 to 2021. 2022. Available online: https://www.statista.com/statistics/265598/consumption-of-primary-energy-worldwide/ (accessed on 20 July 2022).

- Ju, X.; Xu, C.; Liao, Z.; Du, X.; Wei, G.; Wang, Z.; Yang, Y. A review of concentrated photovoltaic-thermal (CPVT) hybrid solar systems with waste heat recovery (WHR). Sci. Bull. 2017, 62, 1388–1426. [Google Scholar] [CrossRef]

- Jacob, J.; Pandey, A.; Rahim, N.A.; Selvaraj, J.; Samykano, M.; Saidur, R.; Tyagi, V. Concentrated Photovoltaic Thermal (CPVT) systems: Recent advancements in clean energy applications, thermal management and storage. J. Energy Storage 2022, 45, 103369. [Google Scholar] [CrossRef]

- Indira, S.S.; Vaithilingam, C.A.; Chong, K.-K.; Saidur, R.; Faizal, M.; Abubakar, S.; Paiman, S. A review on various configurations of hybrid concentrator photovoltaic and thermoelectric generator system. Sol. Energy 2020, 201, 122–148. [Google Scholar] [CrossRef]

- Shubbak, M.H. Advances in solar photovoltaics: Technology review and patent trends. Renew. Sustain. Energy Rev. 2019, 115, 109383. [Google Scholar] [CrossRef]

- Mittelman, G.; Kribus, A.; Dayan, A. Solar cooling with concentrating photovoltaic/thermal (CPVT) systems. Energy Convers. Manag. 2007, 48, 2481–2490. [Google Scholar] [CrossRef]

- Alzahrani, M.; Shanks, K.; Mallick, T.K. Advances and limitations of increasing solar irradiance for concentrating photovoltaics thermal system. Renew. Sustain. Energy Rev. 2020, 138, 110517. [Google Scholar] [CrossRef]

- Su, Y.; Sui, P.; Davidson, J.H. A sub-continuous lattice Boltzmann simulation for nanofluid cooling of concentrated photovoltaic thermal receivers. Renew. Energy 2022, 184, 712–726. [Google Scholar] [CrossRef]

- Renno, C.; Petito, F. Design and modeling of a concentrating photovoltaic thermal (CPV/T) system for a domestic application. Energy Build. 2013, 62, 392–402. [Google Scholar] [CrossRef]

- Kerzmann, T.; Schaefer, L. System simulation of a linear concentrating photovoltaic system with an active cooling system. Renew. Energy 2012, 41, 254–261. [Google Scholar] [CrossRef]

- Herez, A.; El Hage, H.; Lemenand, T.; Ramadan, M.; Khaled, M. Review on photovoltaic/thermal hybrid solar collectors: Classifications, applications and new systems. Sol. Energy 2020, 207, 1321–1347. [Google Scholar] [CrossRef]

- Sultan, S.M.; Efzan, M.N.E. Review on recent Photovoltaic/Thermal (PV/T) technology advances and applications. Sol. Energy 2018, 173, 939–954. [Google Scholar] [CrossRef]

- Gagliano, A.; Tina, G.M.; Aneli, S.; Nižetić, S. Comparative assessments of the performances of PV/T and conventional solar plants. J. Clean. Prod. 2019, 219, 304–315. [Google Scholar] [CrossRef]

- Mittelman, G.; Kribus, A.; Mouchtar, O.; Dayan, A. Water desalination with concentrating photovoltaic/thermal (CPVT) systems. Sol. Energy 2009, 83, 1322–1334. [Google Scholar] [CrossRef]

- Riahi, A.; Ali, A.B.H.; Fadhel, A.; Guizani, A.; Balghouthi, M. Performance investigation of a concentrating photovoltaic thermal hybrid solar system combined with thermoelectric generators. Energy Convers. Manag. 2019, 205, 112377. [Google Scholar] [CrossRef]

- Hasan, A.; Sarwar, J.; Shah, A.H. Concentrated photovoltaic: A review of thermal aspects, challenges and opportunities. Renew. Sustain. Energy Rev. 2018, 94, 835–852. [Google Scholar] [CrossRef]

- Shahabuddin, M.; Alim, M.A.; Alam, T.; Mofijur, M.; Ahmed, S.F.; Perkins, G. A critical review on the development and challenges of concentrated solar power technologies. Sustain. Energy Technol. Assess. 2021, 47, 101434. [Google Scholar] [CrossRef]

- Powell, K.M.; Rashid, K.; Ellingwood, K.; Tuttle, J.; Iverson, B.D. Hybrid concentrated solar thermal power systems: A review. Renew. Sustain. Energy Rev. 2017, 80, 215–237. [Google Scholar] [CrossRef]

- Barlev, D.; Vidu, R.; Stroeve, P. Innovation in concentrated solar power. Sol. Energy Mater. Sol. Cells 2011, 95, 2703–2725. [Google Scholar] [CrossRef]

- Ahmed, S.F.; Khalid, M.; Vaka, M.; Walvekar, R.; Numan, A.; Rasheed, A.K.; Mubarak, N.M. Recent progress in solar water heaters and solar collectors: A comprehensive review. Therm. Sci. Eng. Prog. 2021, 25, 100981. [Google Scholar] [CrossRef]

- Acosta-Pazmiño, I.P.; Rivera-Solorio, C.; Gijón-Rivera, M. Hybridization of a parabolic trough-based thermal plant for industrial heat and power generation. Renew. Energy 2022, 191, 961–973. [Google Scholar] [CrossRef]

- George, M.; Pandey, A.; Rahim, N.A.; Tyagi, V.; Shahabuddin, S.; Saidur, R. Concentrated photovoltaic thermal systems: A component-by-component view on the developments in the design, heat transfer medium and applications. Energy Convers. Manag. 2019, 186, 15–41. [Google Scholar] [CrossRef]

- Sharaf, O.Z.; Orhan, M.F. Concentrated photovoltaic thermal (CPVT) solar collector systems: Part I—Fundamentals, design considerations and current technologies. Renew. Sustain. Energy Rev. 2015, 50, 1500–1565. [Google Scholar] [CrossRef]

- Sharaf, O.Z.; Orhan, M.F. Concentrated photovoltaic thermal (CPVT) solar collector systems: Part II—Implemented systems, performance assessment, and future directions. Renew. Sustain. Energy Rev. 2015, 50, 1566–1633. [Google Scholar] [CrossRef]

- Felsberger, R.; Buchroithner, A.; Gerl, B.; Wegleiter, H. Conversion and testing of a solar thermal parabolic trough collector for CPV-T application. Energies 2020, 13, 6142. [Google Scholar] [CrossRef]

- Fernández, E.F.; Almonacid, F.; Rodrigo, P.; Pérez-Higueras, P. Calculation of the cell temperature of a high concentrator photovoltaic (HCPV) module: A study and comparison of different methods. Sol. Energy Mater. Sol. Cells 2014, 121, 144–151. [Google Scholar] [CrossRef]

- Nishioka, K.; Takamoto, T.; Agui, T.; Kaneiwa, M.; Uraoka, Y.; Fuyuki, T. Annual output estimation of concentrator photovoltaic systems using high-efficiency InGaP/InGaAs/Ge triple-junction solar cells based on experimental solar cell’s characteristics and field-test meteorological data. Sol. Energy Mater. Sol. Cells 2006, 90, 57–67. [Google Scholar] [CrossRef]

- Karathanassis, I.K.; Papanicolaou, E.; Belessiotis, V.; Bergeles, G.C. Design and experimental evaluation of a parabolic-trough concentrating photovoltaic/thermal (CPVT) system with high-efficiency cooling. Renew. Energy 2017, 101, 467–483. [Google Scholar] [CrossRef]

- Ju, X.; Xu, C.; Han, X.; Du, X.; Wei, G.; Yang, Y. A review of the concentrated photovoltaic/thermal (CPVT) hybrid solar systems based on the spectral beam splitting technology. Appl. Energy 2017, 187, 534–563. [Google Scholar] [CrossRef]

- Al Falah, G.; Maatallah, T.S.; Al-Amri, F.G. Performance analysis of a single cell-ultra-high concentration photovoltaic thermal module based on pin-fins cooling microchannel. Int. J. Energy Res. 2022, 46, 2947–2969. [Google Scholar] [CrossRef]

- Royne, A.; Dey, C.J.; Mills, D.R. Cooling of photovoltaic cells under concentrated illumination: A critical review. Sol. Energy Mater. Sol. Cells 2005, 86, 451–483. [Google Scholar] [CrossRef]

- Kasaeian, A.; Bellos, E.; Shamaeizadeh, A.; Tzivanidis, C. Solar-driven polygeneration systems: Recent progress and outlook. Appl. Energy 2020, 264, 114764. [Google Scholar] [CrossRef]

- Fernandes, M.R.; Schaefer, L.A. Long-term environmental impacts of a small-scale spectral filtering concentrated photovoltaic-thermal system. Energy Convers. Manag. 2019, 184, 350–361. [Google Scholar] [CrossRef]

- Al-Hrari, M.; Ceylan, İ.; Nakoa, K.; Ergün, A. Concentrated photovoltaic and thermal system application for fresh water production. Appl. Therm. Eng. 2020, 171, 115054. [Google Scholar] [CrossRef]

- Zhang, Z.; Hu, Z.; Xu, H.; Dai, X.; Wang, J.; Jiao, W.; Yuan, Y.; Phelan, P. Theoretical analysis of a solar-powered multi-effect distillation integrated with concentrating photovoltaic/thermal system. Desalination 2019, 468, 114074. [Google Scholar] [CrossRef]

- Ong, C.L.; Escher, W.; Paredes, S.; Khalil, A.S.G.; Michel, B. A novel concept of energy reuse from high concentration photovoltaic thermal (HCPVT) system for desalination. Desalination 2012, 295, 70–81. [Google Scholar] [CrossRef]

- Aboelmaaref, M.M.; Zayed, M.E.; Zhao, J.; Li, W.; Askalany, A.A.; Ahmed, M.S.; Ali, E.S. Hybrid solar desalination systems driven by parabolic trough and parabolic dish CSP technologies: Technology categorization, thermodynamic performance and economical assessment. Energy Convers. Manag. 2020, 220, 113103. [Google Scholar] [CrossRef]

- Imtiaz Hussain, M.; Ali, A.; Lee, G.H. Multi-module concentrated photovoltaic thermal system feasibility for greenhouse heating: Model validation and techno-economic analysis. Sol. Energy 2016, 135, 719–730. [Google Scholar] [CrossRef]

- Wu, G.; Yang, Q.; Fang, H.; Zhang, Y.; Zheng, H.; Zhu, Z.; Feng, C. Photothermal/day lighting performance analysis of a multifunctional solid compound parabolic concentrator for an active solar greenhouse roof. Sol. Energy 2019, 180, 92–103. [Google Scholar] [CrossRef]

- Lin, L.; Tian, Y.; Luo, Y.; Chen, C.; Jiang, L. A novel solar system integrating concentrating photovoltaic thermal collectors and variable effect absorption chiller for flexible co-generation of electricity and cooling. Energy Convers. Manag. 2020, 206, 112506. [Google Scholar] [CrossRef]

- Buonomano, A.; Calise, F.; Palombo, A. Solar heating and cooling systems by CPVT and ET solar collectors: A novel transient simulation model. Appl. Energy 2013, 103, 588–606. [Google Scholar] [CrossRef]

- Moaleman, A.; Kasaeian, A.; Aramesh, M.; Mahian, O.; Sahota, L.; Nath Tiwari, G. Simulation of the performance of a solar concentrating photovoltaic-thermal collector, applied in a combined cooling heating and power generation system. Energy Convers. Manag. 2018, 160, 191–208. [Google Scholar] [CrossRef]

- Yang, L.; Heng, Z.; Haiping, C.; Han, Y.; Fei, Y. Simulating and experimental research on a low-concentrating PV/T triple-generation system. Energy Convers. Manag. 2019, 199, 111942. [Google Scholar] [CrossRef]

- Rahbar, K.; Riasi, A.; Sangjoeei, H.K.B.; Razmjoo, N. Heat recovery of nano-fluid based concentrating Photovoltaic Thermal (CPV/T) Collector with Organic Rankine Cycle. Energy Convers. Manag. 2019, 179, 373–396. [Google Scholar] [CrossRef]

- Bamisile, O.; Huang, Q.; Dagbasi, M.; Adebayo, V.; Okonkwo, E.C.; Ayambire, P.; Al-Ansari, T.; Ratlamwala, T.A. Thermo-environ study of a concentrated photovoltaic thermal system integrated with Kalina cycle for multigeneration and hydrogen production. Int. J. Hydrog. Energy 2020, 45, 26716–26732. [Google Scholar] [CrossRef]

- Kosmadakis, G.; Manolakos, D.; Papadakis, G. Simulation and economic analysis of a CPV/thermal system coupled with an organic Rankine cycle for increased power generation. Sol. Energy 2011, 85, 308–324. [Google Scholar] [CrossRef]

- Renno, C.; Petito, F.; D’Agostino, D.; Minichiello, F. Modeling of a CPV/T-ORC combined system adopted for an industrial user. Energies 2020, 13, 3476. [Google Scholar] [CrossRef]

- Ben Youssef, W.; Maatallah, T.; Menezo, C.; Ben Nasrallah, S. Assessment viability of a concentrating photovoltaic/thermal-energy cogeneration system (CPV/T) with storage for a textile industry application. Sol. Energy 2018, 159, 841–851. [Google Scholar] [CrossRef]

- Chemisana, D. Building integrated concentrating photovoltaics: A review. Renew. Sustain. Energy Rev. 2011, 15, 603–611. [Google Scholar] [CrossRef]

- Al-Yasiri, Q.; Szabó, M.; Arıcı, M. A review on solar-powered cooling and air-conditioning systems for building applications. Energy Rep. 2022, 8, 2888–2907. [Google Scholar] [CrossRef]

- Calise, F.; D’Accadia, M.D.; Piacentino, A.; Vicidomini, M. Thermoeconomic optimization of a renewable polygeneration system serving a small isolated community. Energies 2015, 8, 995–1024. [Google Scholar] [CrossRef]

- Jilte, R. Concentrating optics in slar concentrators. J. Emerg. Technol. Innov. Res. 2019, 6, 743–746. [Google Scholar]

- Tian, Z.; Su, Y.; Zheng, H.; Pei, G.; Li, G.; Riffat, S. A review on the recent research progress in the compound parabolic concentrator (CPC) for solar energy applications. Renew. Sustain. Energy Rev. 2018, 82, 1272–1296. [Google Scholar] [CrossRef]

- Islam, M.; Yarlagadda, P.; Karim, A. Effect of the orientation schemes of the energy collection element on the optical performance of a parabolic trough concentrating collector. Energies 2019, 12, 128. [Google Scholar] [CrossRef]

- Gharat, P.V.; Bhalekar, S.S.; Dalvi, V.H.; Panse, S.V.; Deshmukh, S.P.; Joshi, J.B. Chronological development of innovations in reflector systems of parabolic trough solar collector (PTC)—A review. Renew. Sustain. Energy Rev. 2021, 145, 111002. [Google Scholar] [CrossRef]

- Wang, F.; Cheng, Z.; Tan, J.; Yuan, Y.; Shuai, Y.; Liu, L. Progress in concentrated solar power technology with parabolic trough collector system: A comprehensive review. Renew. Sustain. Energy Rev. 2017, 79, 1314–1328. [Google Scholar] [CrossRef]

- Gomaa, M.R.; Mustafa, R.J.; Rezk, H.; Al-Dhaifallah, M.; Al-Salaymeh, A. Sizing methodology of a multi-mirror solar concentrated hybrid PV/thermal system. Energies 2018, 11, 3276. [Google Scholar] [CrossRef]

- Xie, W.T.; Dai, R.Z.; Wang, R.Z.; Sumathy, K. Concentrated solar energy applications using Fresnel lenses: A review. Renew. Sustain. Energy Rev. 2011, 15, 2588–2606. [Google Scholar] [CrossRef]

- Tan, N.Y.J.; Zhang, X.; Neo, D.W.K.; Huang, R.; Liu, K.; Senthil Kumar, A. A review of recent advances in fabrication of optical Fresnel lenses. J. Manuf. Processes 2021, 71, 113–133. [Google Scholar] [CrossRef]

- Malik, M.Z.; Shaikh, P.H.; Zhang, S.; Lashari, A.A.; Leghari, Z.H.; Baloch, M.H.; Memon, Z.A.; Caiming, C. A review on design parameters and specifications of parabolic solar dish Stirling systems and their applications. Energy Rep. 2022, 8, 4128–4155. [Google Scholar] [CrossRef]

- Hafez, A.Z.; Soliman, A.; El-Metwally, K.A.; Ismail, I.M. Solar parabolic dish Stirling engine system design, simulation, and thermal analysis. Energy Convers. Manag. 2016, 126, 60–75. [Google Scholar] [CrossRef]

- Verma, S.; Verma, A.; Kumar, V.; Gangil, B. Concentrated photovoltaic thermal systems using Fresnel lenses—A review. Mater. Today Proc. 2020, 44, 4256–4260. [Google Scholar] [CrossRef]

- Shanks, K.; Senthilarasu, S.; Mallick, T.K. Optics for concentrating photovoltaics: Trends, limits and opportunities for materials and design. Renew. Sustain. Energy Rev. 2016, 60, 394–407. [Google Scholar] [CrossRef]

- Li, M.; Ji, X.; Li, G.; Wei, S.; Li, Y.F.; Shi, F. Performance study of solar cell arrays based on a Trough Concentrating Photovoltaic/Thermal system. Appl. Energy 2011, 88, 3218–3227. [Google Scholar] [CrossRef]

- Shaltout, M.A.M.; El-Nicklawy, M.M.; Hassan, A.F.; Rahoma, U.A.; Sabry, M. The Temperature Dependence of the Spectral and efficiency Behavior of Si Solar Cell under Low Concentrated Solar Radiation. Available online: www.sciencedirect.com/science/article/pii/S0960148100000756 (accessed on 30 July 2022).

- Al Siyabi, I.; Khanna, S.; Sundaram, S.; Mallick, T. Experimental and numerical thermal analysis of multi-layered microchannel heat sink for concentrating photovoltaic application. Energies 2019, 12, 122. [Google Scholar] [CrossRef]

- Barrau, J.; Perona, A.; Dollet, A.; Rosell, J. Outdoor test of a hybrid jet impingement/micro-channel cooling device for densely packed concentrated photovoltaic cells. Sol. Energy 2014, 107, 113–121. [Google Scholar] [CrossRef]

- Krishna, Y.; Faizal, M.; Saidur, R.; Ng, K.C.; Aslfattahi, N. State-of-the-art heat transfer fluids for parabolic trough collector. Int. J. Heat Mass Transf. 2020, 152, 119541. [Google Scholar] [CrossRef]

- Al-Amri, F.; Mallick, T.K. Alleviating operating temperature of concentration solar cell by air active cooling and surface radiation. Appl. Therm. Eng. 2013, 59, 348–354. [Google Scholar] [CrossRef]

- Hamzat, A.K.; Omisanya, M.I.; Sahin, A.Z.; Ropo Oyetunji, O.; Abolade Olaitan, N. Application of nanofluid in solar energy harvesting devices: A comprehensive review. Energy Convers. Manag. 2022, 266, 115790. [Google Scholar] [CrossRef]

- Motamedi, M.; Chung, C.-Y.; Rafeie, M.; Hjerrild, N.; Jiang, F.; Qu, H.; Taylor, R.A. Experimental testing of hydrophobic microchannels, with and without nanofluids, for solar PV/T collectors. Energies 2019, 14, 3036. [Google Scholar] [CrossRef]

- Campos, C.S.; Torres, J.P.N.; Fernandes, J.F.P. Effects of the heat transfer fluid selection on the efficiency of a hybrid concentrated photovoltaic and thermal collector. Energies 2019, 12, 1814. [Google Scholar] [CrossRef]

- El Manssouri, O.; Hajji, B.; Tina, G.M.; Gagliano, A.; Aneli, S. Electrical and Thermal Performances of Bi-Fluid PV/Thermal Collectors. Energies 2021, 14, 1633. [Google Scholar] [CrossRef]

- Helmers, H.; Bett, A.W.; Parisi, J.; Agert, C. Modeling of concentrating photovoltaic and thermal systems. Prog. Photovolt. Res. Appl. 2014, 22, 427–439. [Google Scholar] [CrossRef]

- Kribus, A.; Kaftori, D.; Mittelman, G.; Hirshfeld, A.; Flitsanov, Y.; Dayan, A. A miniature concentrating photovoltaic and thermal system. Energy Convers. Manag. 2006, 47, 3582–3590. [Google Scholar] [CrossRef]

- Künnemeyer, R.; Anderson, T.N.; Duke, M.; Carson, J.K. Performance of a V-trough photovoltaic/thermal concentrator. Sol. Energy 2014, 101, 19–27. [Google Scholar] [CrossRef]

- Chaabane, M.; Charfi, W.; Mhiri, H.; Bournot, P. Performance evaluation of concentrating solar photovoltaic and photovoltaic/thermal systems. Sol. Energy 2013, 98, 315–321. [Google Scholar] [CrossRef]

- Xie, H.; Wei, J.; Wang, Z.; Yang, G.; Ma, Q. Design and performance research on eliminating multiple reflections of solar radiation within compound parabolic concentrator (CPC) in hybrid CPV/T system. Sol. Energy 2016, 129, 126–146. [Google Scholar] [CrossRef]

- Sonneveld, P.; Swinkels, G.; van Tuijl, B.; Janssen, H.; Campen, J.; Bot, G. Performance of a concentrated photovoltaic energy system with static linear Fresnel lenses. Sol. Energy 2011, 85, 432–442. [Google Scholar] [CrossRef]

- Li, G.; Pei, G.; Ji, J.; Yang, M.; Su, Y.; Xu, N. Numerical and experimental study on a PV/T system with static miniature solar concentrator. Sol. Energy 2015, 120, 565–574. [Google Scholar] [CrossRef]

- Ben Youssef, W.; Maatallah, T.; Menezo, C.; Ben Nasrallah, S. Modeling and optimization of a solar system based on concentrating photovoltaic/thermal collector. Sol. Energy 2018, 170, 301–313. [Google Scholar] [CrossRef]

- Maatallah, T.; Ben Youssef, W. Simulation and performance analysis of concentrating photovoltaic/thermal collector (CPV/T) with three-sided thermal insulation based on coupled optothermal model. Sol. Energy 2019, 181, 308–324. [Google Scholar] [CrossRef]

- Bellos, E.; Tzivanidis, C. Investigation of a nanofluid-based concentrating thermal photovoltaic with a parabolic reflector. Energy Convers. Manag. 2019, 180, 171–182. [Google Scholar] [CrossRef]

- Li, M.; Li, G.L.; Ji, X.; Yin, F.; Xu, L. The performance analysis of the Trough Concentrating Solar Photovoltaic/Thermal system. Energy Convers. Manag. 2011, 52, 2378–2383. [Google Scholar] [CrossRef]

- Li, M.; Ji, X.; Li, G.L.; Yang, Z.M.; Wei, S.X.; Wang, L.L. Performance investigation and optimization of the Trough Concentrating Photovoltaic/Thermal system. Sol. Energy 2011, 85, 1028–1034. [Google Scholar] [CrossRef]

- Ustaoglu, A.; Ozbey, U.; Torlaklı, H. Numerical investigation of concentrating photovoltaic/thermal (CPV/T) system using compound hyperbolic—Trumpet, V-trough and compound parabolic concentrators. Renew. Energy 2020, 152, 1192–1208. [Google Scholar] [CrossRef]

- Renno, C. Experimental and theoretical analysis of a linear focus CPV/T system for cogeneration purposes. Energies 2018, 11, 2960. [Google Scholar] [CrossRef]

- Renno, C. Theoretical and experimental evaluation of the working fluid temperature levels in a CPV/T system. Energies 2020, 13, 3077. [Google Scholar] [CrossRef]

- Renno, C.; Perone, A.; D’agostino, D.; Minichiello, F. Experimental and economic analysis of a concentrating photovoltaic system applied to users of increasing size. Energies 2021, 14, 4968. [Google Scholar] [CrossRef]

- Gorouh, H.A.; Salmanzadeh, M.; Nasseriyan, P.; Hayati, A.; Cabral, D.; Gomes, J.; Karlsson, B. Thermal modelling and experimental evaluation of a novel concentrating photovoltaic thermal collector (CPVT) with parabolic concentrator. Renew. Energy 2022, 181, 535–553. [Google Scholar] [CrossRef]

- Cabral, D.; Gomes, J.; Hayati, A.; Karlsson, B. Experimental investigation of a CPVT collector coupled with a wedge PVT receiver. Sol. Energy 2021, 215, 335–345. [Google Scholar] [CrossRef]

- Coventry, J.S. Performance of a concentrating photovoltaic/thermal solar collector. Sol. Energy 2005, 78, 211–222. [Google Scholar] [CrossRef]

- Xu, N.; Ji, J.; Sun, W.; Huang, W.; Jin, Z. Electrical and Thermal Performance Analysis for a Highly Concentrating Photovoltaic/Thermal System. Int. J. Photoenergy 2015, 2015, 537538. [Google Scholar] [CrossRef]

- Xu, N.; Ji, J.; Sun, W.; Han, L.; Chen, H.; Jin, Z. Outdoor performance analysis of a 1090× point-focus Fresnel high concentrator photovoltaic/thermal system with triple-junction solar cells. Energy Convers. Manag. 2015, 100, 191–200. [Google Scholar] [CrossRef]

- Mohsenzadeh, M.; Shafii, M.B.; Jafari Mosleh, H. A novel concentrating photovoltaic/thermal solar system combined with thermoelectric module in an integrated design. Renew. Energy 2017, 113, 822–834. [Google Scholar] [CrossRef]

- Shadmehri, M.; Narei, H.; Ghasempour, R.; Shafii, M.B. Numerical simulation of a concentrating photovoltaic-thermal solar system combined with thermoelectric modules by coupling Finite Volume and Monte Carlo Ray-Tracing methods. Energy Convers. Manag. 2018, 172, 343–356. [Google Scholar] [CrossRef]

- Bernardo, L.R.; Perers, B.; Håkansson, H.; Karlsson, B. Performance evaluation of low concentrating photovoltaic/thermal systems: A case study from Sweden. Sol. Energy 2011, 85, 1499–1510. [Google Scholar] [CrossRef]

- Calise, F.; Vanoli, L. Parabolic trough photovoltaic/thermal collectors: Design and simulation model. Energies 2012, 5, 4186–4208. [Google Scholar] [CrossRef]

- Wang, Z.; Wei, J.; Zhang, G.; Xie, H.; Khalid, M. Design and performance study on a large-scale hybrid CPV/T system based on unsteady-state thermal model. Sol. Energy 2019, 177, 427–439. [Google Scholar] [CrossRef]

- Alves, P.; Fernandes, J.F.P.; Torres, J.P.N.; Costa Branco, P.J.; Fernandes, C.; Gomes, J. From Sweden to Portugal: The effect of very distinct climate zones on energy efficiency of a concentrating photovoltaic/thermal system (CPV/T). Sol. Energy 2019, 188, 96–110. [Google Scholar] [CrossRef]

- Nasseriyan, P.; Gorouh, H.A.; Gomes, J.; Cabral, D.; Salmanzadeh, M.; Lehmann, T.; Hayati, A. Numerical and experimental study of an asymmetric CPC-PVT solar collector. Energies 2020, 13, 1669. [Google Scholar] [CrossRef]

- Rejeb, O.; Shittu, S.; Li, G.; Ghenai, C.; Zhao, X.; Ménézo, C.; Jemni, A.; Jomaa, M.H.; Bettayeb, M. Comparative investigation of concentrated photovoltaic thermal-thermoelectric with nanofluid cooling. Energy Convers. Manag. 2021, 235, 113968. [Google Scholar] [CrossRef]

- Cappelletti, A.; Reatti, A.; Martelli, F. Numerical and experimental analysis of a CPV/T receiver suitable for low solar concentration factors. Energy Procedia 2015, 82, 724–729. [Google Scholar] [CrossRef]

- Imtiaz Hussain, M.; Lee, G.H. Experimental and numerical studies of a U-shaped solar energy collector to track the maximum CPV/T system output by varying the flow rate. Renew. Energy 2015, 76, 735–742. [Google Scholar] [CrossRef]

- Du, B.; Hu, E.; Kolhe, M. Performance analysis of water cooled concentrated photovoltaic (CPV) system. Renew. Sustain. Energy Rev. 2012, 16, 6732–6736. [Google Scholar] [CrossRef]

- Chaabane, M.; Mhiri, H.; Bournot, P. Performance optimization of water-cooled concentrated photovoltaic system. Heat Transf. Eng. 2016, 37, 76–81. [Google Scholar] [CrossRef]

- Renno, C.; Petito, F. Experimental and theoretical model of a concentrating photovoltaic and thermal system. Energy Convers. Manag. 2016, 126, 516–525. [Google Scholar] [CrossRef]

- Renno, C.; de Giacomo, M. Dynamic simulation of a CPV/T system using the finite element method. Energies 2014, 7, 7395–7414. [Google Scholar] [CrossRef]

- Askari, I.B.; Shahsavar, A.; Jamei, M.; Calise, F.; Karbasi, M. A parametric assessing and intelligent forecasting of the energy and exergy performances of a dish concentrating photovoltaic/thermal collector considering six different nanofluids and applying two meticulous soft computing paradigms. Renew. Energy 2022, 193, 149–166. [Google Scholar] [CrossRef]

- Su, Y.; Kulacki, F.A.; Davidson, J.H. Experimental and numerical investigations on a solar tracking concentrated photovoltaic-thermal system with a novel non-dimensional lattice Boltzmann method. Sol. Energy 2014, 107, 145–158. [Google Scholar] [CrossRef]

- Gakkhar, N.; Soni, M.K.; Jakhar, S. Experimental and theoretical analysis of hybrid concentrated photovoltaic/thermal system using parabolic trough collector. Appl. Therm. Eng. 2020, 171, 115069. [Google Scholar] [CrossRef]

- Jing, D.; Hu, Y.; Liu, M.; Wei, J.; Guo, L. Preparation of highly dispersed nanofluid and CFD study of its utilization in a concentrating PV/T system. Sol. Energy 2015, 112, 30–40. [Google Scholar] [CrossRef]

- Gupta, M.; Dubey, A.K.; Kumar, V.; Mehta, D.S. Experimental study of combined transparent solar panel and large Fresnel lens concentrator based hybrid PV/thermal sunlight harvesting system. Energy Sustain. Dev. 2021, 63, 33–40. [Google Scholar] [CrossRef]

- Gholami, H.; Sarwat, A.I.; Hosseinian, H.; Khalilnejad, A. Evaluation of optimal dual axis concentrated photovoltaic thermal system with active ventilation using Frog Leap algorithm. Energy Convers. Manag. 2015, 105, 782–790. [Google Scholar] [CrossRef]

- Bahaidarah, H.M.; Tanweer, B.; Gandhidasan, P.; Rehman, S. A combined optical, thermal and electrical performance study of a V-trough PV system-experimental and analytical investigations. Energies 2015, 8, 2803–2827. [Google Scholar] [CrossRef]

- Papis-Frączek, K.; Żołądek, M.; Filipowicz, M. The possibilities of upgrading an existing concentrating solar thermal system—Case study. Energy Rep. 2021, 7, 28–32. [Google Scholar] [CrossRef]

- del Col, D.; Bortolato, M.; Padovan, A.; Quaggia, M. Experimental and numerical study of a parabolic trough linear CPVT system. Energy Procedia 2014, 57, 255–264. [Google Scholar] [CrossRef]

- Kong, C.; Xu, Z.; Yao, Q. Outdoor performance of a low-concentrated photovoltaic-thermal hybrid system with crystalline silicon solar cells. Appl. Energy 2013, 112, 618–625. [Google Scholar] [CrossRef]

- Su, B.; Wang, H.; Zhang, X.; He, H.; Zheng, J. Using photovoltaic thermal technology to enhance biomethane generation via biogas upgrading in anaerobic digestion. Energy Convers. Manag. 2021, 235, 113965. [Google Scholar] [CrossRef]

- Yazdanifard, F.; Ebrahimnia-Bajestan, E.; Ameri, M. Performance of a parabolic trough concentrating photovoltaic/thermal system: Effects of flow regime, design parameters, and using nanofluids. Energy Convers. Manag. 2017, 148, 1265–1277. [Google Scholar] [CrossRef]

- Ahmed, H.E.; Salman, B.H.; Kherbeet, A.S.; Ahmed, M.I. Optimization of thermal design of heat sinks: A review. Int. J. Heat Mass Transf. 2018, 118, 129–153. [Google Scholar] [CrossRef]

- Jakhar, S.; Soni, M.S.; Gakkhar, N. Historical and recent development of concentrating photovoltaic cooling technologies. Renew. Sustain. Energy Rev. 2016, 60, 41–59. [Google Scholar] [CrossRef]

- Sharaf, O.Z.; Orhan, M.F. Thermodynamic analysis and optimization of densely-packed receiver assembly components in high-concentration CPVT solar collectors. Energy Convers. Manag. 2016, 121, 113–144. [Google Scholar] [CrossRef]

- Lashin, A.; Al Turkestani, M.; Sabry, M. Concentrated photovoltaic/thermal hybrid system coupled with a thermoelectric generator. Energies 2019, 12, 2623. [Google Scholar] [CrossRef]

- Tan, W.; Chong, K.; Tan, M. Performance study of water-cooled multiple-channel heat sinks in the application of ultra-high concentrator photovoltaic system. Sol. Energy 2017, 147, 314–327. [Google Scholar] [CrossRef]

- Karathanassis, I.K.; Papanicolaou, E.; Belessiotis, V.; Bergeles, G.C. Experimental and numerical evaluation of an elongated plate-fin heat sink with three sections of stepwise varying channel width. Int. J. Heat Mass Transf. 2015, 84, 16–34. [Google Scholar] [CrossRef]

- Karathanassis, I.K.; Papanicolaou, E.; Belessiotis, V.; Bergeles, G.C. Dynamic simulation and exergetic optimization of a Concentrating Photovoltaic/Thermal (CPVT) system. Renew. Energy 2019, 135, 1035–1047. [Google Scholar] [CrossRef]

- Abo-Zahhad, E.M.; Ookawara, S.; Esmail, M.F.C.; El-Shazly, A.H.; Elkady, M.F.; Radwan, A. Thermal management of high concentrator solar cell using new designs of stepwise varying width microchannel cooling scheme. Appl. Therm. Eng. 2020, 172, 115124. [Google Scholar] [CrossRef]

- Abo-Zahhad, E.M.; Ookawara, S.; Radwan, A.; El-Shazly, A.H.; Elkady, M.F. Numerical analyses of hybrid jet impingement/microchannel cooling device for thermal management of high concentrator triple-junction solar cell. Appl. Energy 2019, 253, 113538. [Google Scholar] [CrossRef]

- Xu, X.; Meyers, M.M.; Sammakia, B.G.; Murray, B.T. Thermal modeling of hybrid concentrating PV/T collectors with tree-shaped channel networks cooling system. In Proceedings of the 13th InterSociety Conference on Thermal and Thermomechanical Phenomena in Electronic Systems, San Diego, CA, USA, 30 May–1 June 2012; pp. 1131–1138. [Google Scholar] [CrossRef]

- Alfaryjat, A.A.; Mohammed, H.A.; Adam, N.M.; Ariffin, M.K.A.; Najafabadi, M.I. Influence of geometrical parameters of hexagonal, circular, and rhombus microchannel heat sinks on the thermohydraulic characteristics. Int. Commun. Heat Mass Transf. 2014, 52, 121–131. [Google Scholar] [CrossRef]

- Tran, N.; Chang, Y.-J.; Teng, J.-T.; Greif, R. A study on five different channel shapes using a novel scheme for meshing and a structure of a multi-nozzle microchannel heat sink. Int. J. Heat Mass Transf. 2017, 105, 429–442. [Google Scholar] [CrossRef]

- Vafaii, K.; Zhu, L. Analysis of two-layered micro-channel heat sink concept in electronic cooling. Int. J. Heat Mass Transf. 1999, 42, 2287–2297. [Google Scholar] [CrossRef]

- Al Siyabi, I.; Shanks, K.; Mallick, T.; Sundaram, S. Indoor and outdoor characterization of concentrating photovoltaic attached to multi-layered microchannel heat sink. Sol. Energy 2020, 202, 55–72. [Google Scholar] [CrossRef]

- Radwan, A.; Ahmed, M. The influence of microchannel heat sink configurations on the performance of low concentrator photovoltaic systems. Appl. Energy 2017, 206, 594–611. [Google Scholar] [CrossRef]

- Wei, X.; Joshi, Y. Optimization study of stacked micro-channel heat sinks for micro-electronic cooling. In Proceedings of the ITherm 2002. Eighth Intersociety Conference on Thermal and Thermomechanical Phenomena in Electronic Systems (Cat. No.02CH37258), San Diego, CA, USA, 30 May–1 June 2002; pp. 441–448. [Google Scholar] [CrossRef]

- Di Capua, H.M.; Escobar, R.; Diaz, A.J.; Guzmán, A.M. Enhancement of the cooling capability of a high concentration photovoltaic system using microchannels with forward triangular ribs on sidewalls. Appl. Energy 2018, 226, 160–180. [Google Scholar] [CrossRef]

- Aldossary, A.; Mahmoud, S.; Al-Dadah, R. Technical feasibility study of passive and active cooling for concentrator PV in harsh environment. Appl. Therm. Eng. 2016, 100, 490–500. [Google Scholar] [CrossRef]

- Ramos-Alvarado, B.; Li, P.; Liu, H.; Hernandez-Guerrero, A. CFD study of liquid-cooled heat sinks with microchannel flow field configurations for electronics, fuel cells, and concentrated solar cells. Appl. Therm. Eng. 2011, 31, 2494–2507. [Google Scholar] [CrossRef]

- Yang, K.; Zuo, C. A novel multi-layer manifold microchannel cooling system for concentrating photovoltaic cells. Energy Convers. Manag. 2015, 89, 214–221. [Google Scholar] [CrossRef]

- Deymi-Dashtebayaz, M.; Rezapour, M.; Farahnak, M. Modeling of a novel nanofluid-based concentrated photovoltaic thermal system coupled with a heat pump cycle (CPVT-HP). Appl. Therm. Eng. 2022, 201, 117765. [Google Scholar] [CrossRef]

- Hmouda, R.A.; Muzychka, Y.S.; Duan, X. Experimental and Theoretical Modelling of Concentrating Photovoltaic Thermal System with Ge-Based Multi-Junction Solar Cells. Energies 2022, 15, 4056. [Google Scholar] [CrossRef]

- Ahmed, M.; Radwan, A. Performance evaluation of new modified low-concentrator polycrystalline silicon photovoltaic/thermal systems. Energy Convers. Manag. 2017, 149, 593–607. [Google Scholar] [CrossRef]

| Advantages | Disadvantages |

|---|---|

| High thermal efficiency | Non-homogenous irradiance distribution |

| Medium- and high-temperature thermal output | Significant optical losses |

| High electrical efficiency * | Usage of only direct irradiation |

| Low elevated temperature of PV cells | Possibility of PV cells overheating/damage |

| Reduced area of PV cells | High complexity of the system |

| Lower investment costs in PV cells * | Requirement for active cooling |

| Wide range of applications | Parasitic load connected with active cooling |

| Ease of integration with other devices | Limited maximum temperature of HTF |

| Cogeneration, trigeneration or polygeneration unit |

| Concentration | Low | Medium | High | Ultra-High |

|---|---|---|---|---|

| CR [sun] | <10 | 10–100 | 100–2000 | >2000 |

| Concentrator | Compound Parabolic V-trough | Linear Fresnel Reflector Parabolic Trough Linear Fresnel Lens | Parabolic dish Central Receiver System Fresnel Lens Non-imaging dish concentrator | Parabolic dish+ Compound Parabolic Central Receiver System+ Compound Parabolic Fresnel Lens+ Compound Parabolic Non-imaging dish concentrator+ Compound Parabolic |

| Irradiation utilization | Direct/Partially diffusive | Direct | Direct | Direct |

| Cooling requirement | Passive | Passive/Active | Passive/Active | Active |

| Tracking | No/Maybe | Yes | Yes | Yes |

| Heat Transfer Fluid | Advantages | Disadvantages |

|---|---|---|

| water | High heat capacity and thermal conductivity Widely available and inexpensive Environmentally friendly | Upper temperature limit 100 °C Lower temperature limit 4 °C Causes corrosion in hydraulic system Threat of Legionnaires disease |

| nanofluids | Enhanced thermal conductivity Higher thermal efficiency than water | Bad performance in turbulent flows Higher pressure drop than for water Causes corrosion Higher costs |

| diathermic oil | High working temperatures (>100 °C) Enhanced thermal efficiency | Significant thermal inertia Reduced thermal conductivity Higher pressure drop than for water Not safe for environment |

| Ref. | Receiver | Heat Transfer Fluid | Concentrator | PV | Efficiency, % | Studies | Highlights | ||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Description | Material | Type | CR | Electrical | Thermal | Total | |||||

| [8] | Rectangular channel between two flat plates | - | 1–10% Al2O3 nanoparticles 99–90% water | Parabolic dish | 88.3 | multi-crystalline silicon | - | - | 45 | Numerical | Nanofluids allow to control the temperature in a CPV receiver |

| [110] | water | - | - | 20–45 | Experimental, Numerical | Cooling system enhances the electricalpower 2.5 times compared to a non- concentrated PV. Inlet should be located in the upper part of receiver, outlet counter side. | |||||

| [9] | pipes placed under the plate, insulated at the bottom | - | glycol-water | Fresnel lens/Parabolic dish | 600–900 | triple-junction | 20 | 67 | - | Numerical | The outlet fluid temperature is 90C and allows one to use an AHP with CPVT system |

| [10] | rectangular tube, insulated at the sides and bottom | aluminum | Water | Linear Fresnel lenses | 80 | triple-junction | 34.75 | - | - | Numerical | System produced 5.1 MWh of thermal energy and 14.2 MWh of electricity |

| [15] | parallel circular channels arrangedat equal spacing throughout the heat exchanger with common inlet andoutlet ports. TEGs between receiver and PV cells. | aluminum | water | Parabolic trough | - | monocrystalline silicon | 6.76 | 47.35 | - | Experimental, Numerical | TEGs improve the electrical efficiency by 7.46% |

| [21] | triangular geometry receiver | aluminum | water | Parabolic trough | 14.8 | Back-contact monocrystalline silicon | 8.0 | 37.7 | - | Numerical | Upgrade of CT to CPVT required the change in receiver duct shape from circular to triangular |

| [42] | triangular prism-shaped duct with PV panels on two sides and five cooling tubes beneath each panel, insulation on the third wall | copper | 70% wt. glycol 30% wt. water | linear Fresnel | 15 | monocrystalline silicon | 12.8 | 58.0 | 71.8 | numerical | Designed system is able to provide heat and cool for residential building. Electrical energy has to be provided from the grid. |

| [75] | insulated cooling plate | - | water | parabolic dish | 400 | triple-junction | 20 | >60 | >80 | Numerical | |

| [76] | rectangular channel from bent steel sheet under the PV cells | steel | water | V-trough | - | polycrystalline | 15 | 20 | 35 | Experimental, Theoretical | Design needs improvement in heat transfer and insulation to reduce thermal losses. |

| [77] | Rectangular pipe | - | water | parabolic trough | 14.5 | Crystalline silicon | 10.2 | 16 | - | experimental, numerical | Further work should be focused on geometry optimization |

| [78] | thin-walled rectangular channel insulated at the sides and bottom | aluminum | water | Compound parabolic | 4 | Polycrystalline silicon | - | - | 71 | Experimental, numerical | Elimination of multiple reflections enhances the CPVT performance |

| [99] | rectangular channel | aluminum | water | compound parabolic | 4 | Polycrystalline silicon | 13 | 55 | - | experimental, numerical | The steady-state model cannot predict the thermal performance in cases of rapid changes of solar radiation |

| [79] | rectangular tube | - | Water | Linear Fresnel lenses | 25 | monocrystalline silicon | 11 | 56 | - | Experimental | AR coatings and lamination of Fresnel lenses could improve the optical efficiency of the system. |

| [80] | square pipe, insulated at the sides and bottom | copper | water | Miniature compound parabolic | - | Silicon | 9.5–10.6 | 31.2–37.2 | - | Experimental, numerical | miniature CPVT system has low heat losses so it could produce medium-temperature heat |

| [81] | rectangular channel, with three wall insulation | copper | 0.2% Cu nanoparticles99.8% water | Parabolic trough | 5–30 | Triple-junction | - | - | - | numerical | Nanofluid improves the thermal efficiency about 15% and electrical efficiency about 0.2%. Presence of insulation increases the thermal efficiency about 2%. |

| [82] | water | 20 | - | - | - | numerical | Temperature gradient and hot spots lead to an average drop in thermal efficiency about 6%. | ||||

| [83] | insulated flat receiver with circular pipe | - | 5% nanoparticles CuO 95% thermal oil (Syltherm 800) | Parabolic trough | 10 | Monocrystalline silicon | 6.6 | 46.84 | - | numerical | nanofluid leads to enhancement in thermal and electrical performance |

| [84] | Insulated tubular duct | Aluminum alloy | water | Parabolic trough | 20 | silicon, Supercell, GaAs cell | GaAs 9.88 Silicon 7.51 | GaAs 49.84Silicon 42.4 | - | experimental | The electrical efficiency is the best for GaAs cell. CPVT system with silicon cells is economically viable. |

| [85] | 30.8 | Supercell 3.63%, GaAs 8.94%, silicon 3.67% | Supercell 45.17%, GaAs 41.69%, silicon 34.53% | - | experimental | The width of the solar cells should be adjusted to the width of focal spot to fully utilize concentrating irradiance. | |||||

| [86] | circular pipe | copper | water | Three variants: hyperbolic trumpet, V-trough, compound parabolic | 1.94 | silicon | 18.44–18.59 | - | - | numerical | All concentrators can generate almost the same electrical power. |

| [87] | tube | copper | water | parabolic trough | 90 | triple-junction | - | - | - | Experimental, numerical | The outlet fluid temperature above 80 °C allows integration of the sorption chiller. |

| [90] | - | - | water | - | - | - | 6.1% | 69.6% | - | Numerical | Without the glass cover, the optical losses are reduced but the thermal losses increase. |

| [91] | wedge receiver with angle of 20° between the two receiver copper plates. | copper | 20% ethylene glycol 80% water | Parabolic trough | 2 | monocrystalline silicon | 8% | 59% | - | Experimental | design concept reduced the thermal stress and high radiation intensity over PV cells |

| [92] | Circular tube with internal fins mounted under the flat plate absorber. Back and sides insulated and encased. | aluminum | Water Anti-freeze additions | Parabolic trough | 37 | monocrystalline silicon | 11 | 58 | 69 | Experimental | Internal fins enhance the heat transfer rate. Illumination non-uniformities over the receiver surface have a significant effect on the overall electrical performance. |

| [93] | Flat plate with circular, grooved tube on the rear side | aluminum | water | point-focus Fresnel lens | 1090 | triple-junction | 30 | 30 | >60 | Experimental | |

| [94] | 28 | 54 | >80 | Experimental, numerical | Mainly the direct irradiance determines the electrical and thermal performance of the system. | ||||||

| [95] | equilateral triangle duct with TEG modules and PV cells on two sides and thermal insulation on the backside | iron | water | parabolic trough | 8.34 | monocrystalline silicon | With glass cover | experimental | Presence of glass cover increases the thermal efficiency and decreases the electrical efficiency. Non-uniform irradiation distribution through receiver decreases the electrical efficiency of PV cells. | ||

| 4.83 | 46.16 | 50.99 | |||||||||

| Without glass cover | |||||||||||

| 4.94 | 42.36 | 47.30 | |||||||||

| [96] | - | - | - | numerical | Optimum reflector aperture width 1.6–2.2 m and optimum apex angle 80°–120°. | ||||||

| [97] | Triangular duct with PV cells on two sides | aluminum | water | Parabolic trough | 7.8 | Monocrystalline silicon | 6.4 | - | - | experimental | Irradiation intensity is an essential factor determining the amount of generated energy |

| [98] | linear triangular receiver with circular fluid channel inside | - | water | parabolic trough | 110 | triple-junction | 20–25 | 60–65 | - | Numerical | Insulating the top surface is recommended to increase the electrical efficiency |

| [100] | Flat plate with eight channels with different cross-sections: ellipse, rectangle, circle, square | aluminum | water | a combination of involute, circular and parabola shape | - | Monocrystalline silicon | 17.8–19.0 | - | - | numerical | elliptical channels ensure the most uniform distribution of the temperature |

| [102] | Flat plate with parallel elliptic channels, insulated. TEGs between receiver and PV cells. | - | 0.5% graphene 99.5% water | - | - | silicon cell | - | - | - | Numerical | TEGs improve the electrical efficiency by 5–10% |

| [103] | Rectangular tube with circular inner channel, bend in U shape to provide counter-flow | aluminum | water | low profile linearparabolic | 20 | monocrystalline silicon | - | 64 | - | experimental, numerical | The maximal outlet temperature is limited by the U-shaped geometry of the water channel. Two separate channels may provide higher outlet temperature. |

| [104] | U-shaped, two parallel copper tubes which are connected together with rubber tube, insulated | copper | water | Fresnel lenses | - | triple-junction | - | - | 76 | experimental, numerical | Flow rate allows to control thermal and electrical power. Optimum value was found to be 0.033 kg/s |

| [105] | double tubular pipe | aluminum | water | Parabolic trough | 8.5 | Monocrystalline silicon | 8.3 | 45 | - | experimental | Operating temperature of PV cell is reduced under 60 °C. Electricity production in CPVT system is 4.7–5.2 times higher than for PV |

| [106] | Rectangular receiver with 2, 3, 4 or 6 internal channels | aluminum | water | parabolic trough | - | Monocrystalline silicon | 8.45–9.30 | 59.8–74.2 | - | Numerical | The higher number of pipes, the higher total performance. Rectangular pipes reduce cell temperature by 17 °C |

| [107] | Circular pipe in meander configuration | copper | glycol-water | Fresnel lens + kaleidoscope | 208.6 | triple-junction | 23–29 | - | - | Numerical | kaleidoscope allows to uniform the solar irradiance on the surface of the cell |

| [109] | squired-shaped riser tubes surrounded by the metallic substrate and insulated upper wall | - | six engine oil-based nanofluids | Parabolic dish | - | triple-junction | - | - | - | numerical | Nanofluids enhance the total efficiency and increase the pressure drop |

| [114] | Header-riser structure | copper | water | Concentrated dish | 600–800 | triple-junction | 48 | 38 | 85 | numerical | Active cooling enhances electrical efficiency of the system and increases the total efficiency up to 85% |

| [111] | D-shaped receiver (semi- cylindrical tube) | copper | water | parabolic trough | 6 | monocrystalline silicon | 12.39 | 49.48 | - | analytical, experimental | Cooling efficiency strongly depends on the mass flow rate of the HTF. |

| [112] | C-shaped, HTF flows above and below the PV cell. Vacuum between PV cell and upper layer of coolant | glass | 2% SiO2 nanoparticles98% water | - | 40, 100, 150 | Monocrystalline silicon | - | - | 25.5 (CR = 40), 16.7 (CR = 100) 16.2 (CR = 150) | numerical | Nanofluids significantly enhance the heat transfer |

| [113] | Tube bent into spiral shape. Inlet close to the edge, outlet in the middle. | copper | water | Fresnel lens | - | semi-transparent CdTe | 2.6–3.4 | 55–65 | Experimental | Usage of red filter above PV cell allows to increase thermal and electrical efficiencies | |

| [115] | Commercial thermal collector | - | water | V-trough | 2 | Monocrystalline silicon | - | - | - | Experimental, numerical | 31.5% increase in electric power due to the active cooling of PV cells in CPVT system |

| [116] | Cylindrical receiver with M-shaped internal channel | aluminum | thermal oil | Double parabolic dish | 105 | - | - | - | - | Numerical | The reduction of absorber temperature is required |

| [117] | Roll bond plate with duct | aluminum | water | parabolic trough | 130 | triple-junction | 10–20 | 40–60 | 70 | Experimental, numerical | It is possible to increase the operating temperature of PV cell to produce heat at medium temperature (80–90 °C) |

| [118] | rectangular channel, insulation on the back and side walls | aluminum | water | Fresnel lens and flat mirrors | 5 | Monocrystal-line silicon | 10 | 56 | - | experimental, numerical | Double optics makes the irradiation distribution over PV cells surface more uniform |

| [119] | rectangular duct with insulation on three sides | aluminum | water | Parabolic trough | 53 | - | 22.2 | 61.6 | 83.8 | Numerical | Payback time is only 5.6 years |

| [120] | Flat plat absorber with circular tube | copper | 4–20% TiO2 96–80% water | parabolic trough | 15 | Supercell, GaAs | Supercell 11.67 15.55 | Supercell 68.5 5.93 | Supercell 79.12 6.97 | Elongation of receiver tube reduces the total efficiency. Nanofluids are more effective for laminar flow. | |

| Ref. | Receiver | Heat Transfer Fluid | Concentrator | PV | Efficiency, % | Studies | Highlights | ||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Description | Material | Type | CR | Electrical | Thermal | Total | |||||

| [28] | elongated plate-fin heat sink with microchannels of constant or stepwise-varying width configuration | aluminum | water | parabolic trough | 14.3 | monocrystalline silicon | 6 | 44 | 50 | experimental | Fins with varying width significantly reduce pumping power |

| [30] | Heat sink with pin fins: in-line cylindrical, staggered cylindrical, in-line conical, and staggered conical | Aluminum/copper | water | Fresnel lens | 500–2500 | Multi-junction | - | - | 80 | numerical | cylindrical-shaped pin fins are suitable for CR < 2500, whereas conical-shaped only for CR < 2000. Staggered configuration reduces pressure drop. |

| [67] | jet impingement microchannel with varying width of channels | - | water | Parabolic (primary optics), Kaleidoscope (secondary optics) | 537 | dummy | - | - | - | experimental | step varying width of the microchannel sections reduce the pressure drop and thermal resistance along the flow, resulting in a uniform temperature distribution. |

| [123] | Rectangular with insulated enclosure | aluminum | Water; Al2O3 Water/oil | - | - | Multi-junction | - | - | - | numerical | The thinner fins, the better thermal and hydraulic performance |

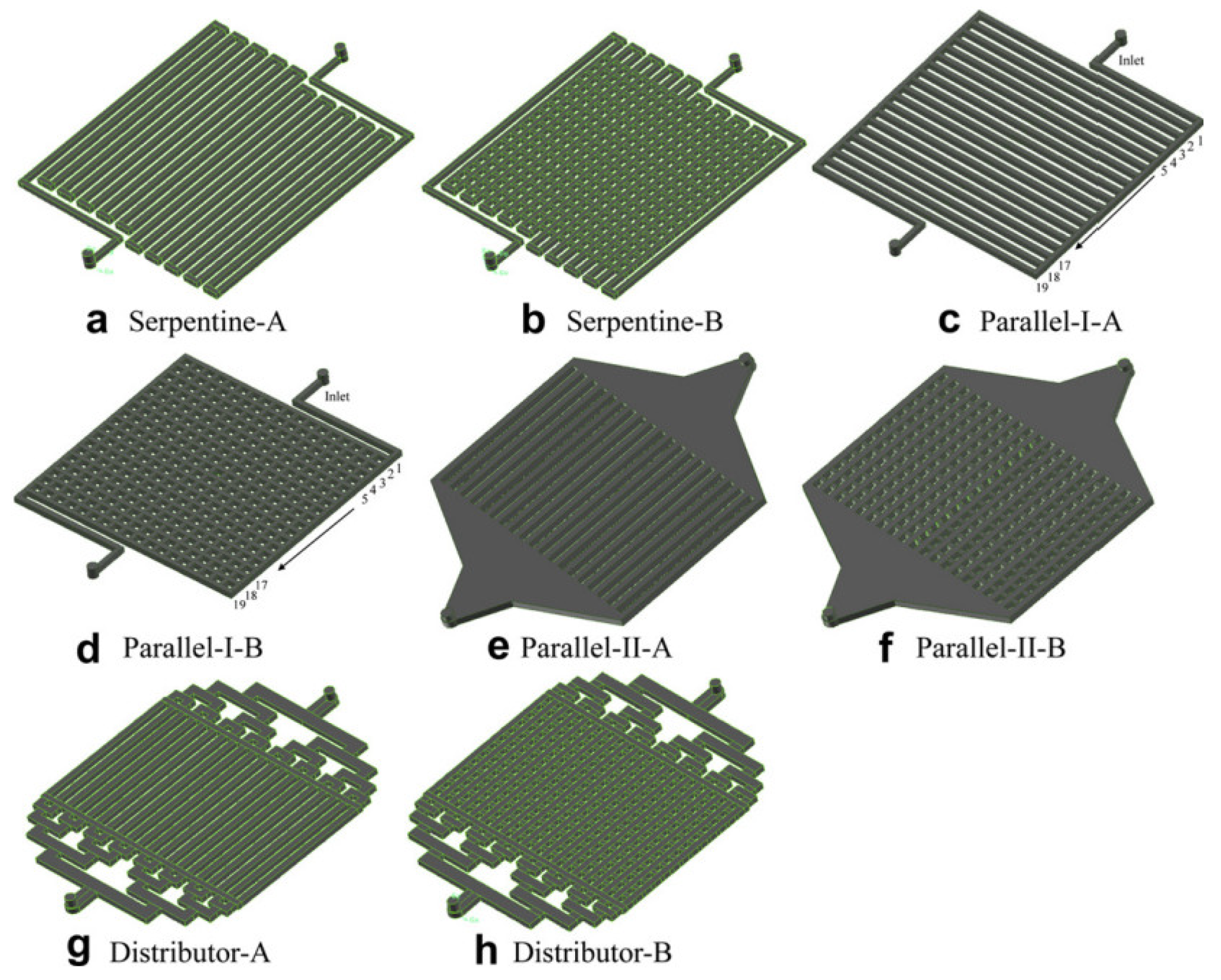

| [104] | Eight designs of channel configurations: serpentine, parallel, parallel with manifolds, distributor (each type with and without transverse slots) | aluminum | deionized water | - | 40/50 | - | - | - | - | numerical | Distributors provide uniform flow uniformity, surface temperature distribution and low-pressure loss. |

| [124] | Heat sink with parallel microchannels immersed in flowing water | - | water | Fresnel Lens | 70, 100, 130 | Multi-junction/Laser Grooved Buried Contact silicon | - | - | - | Experimental | TEGs enhance the overall output power, but PV performs better when connected directly to the heat sink |

| [125] | multiple-channel heat sink with parallel long plate fins | - | water | Primary: dish concentrator, secondary: array of compound parabolic lenses | 1800 | Triple-junction | 31.8 | - | - | numerical | Higher number of fins contribute to larger heat transfer area. It is possible to maintain cell temperature below 100° |

| [126] | elongated plate heat sink with channels of stepwise decreasing hydraulic diameter | aluminum | water | linear | - | - | - | - | - | numerical | The buoyancy in the first heat sink section has a beneficial impact on thermal performance. Enhanced eat transfer due to contraction-induced vortices. |

| [128] | stepwise varying width microchannel with fins of different length | Aluminum | water | Fresnel lens | 1000 | Multi-junction | 38–40 | - | - | numerical | Hhigher flow rates and increase in number and length of fins lead to lower thermal resistance and higher pressure drop |

| [129] | jet impingement microchannel with varying width of channels. Inlet located under the central part of the receiver. | Aluminum | water | Fresnel lenses | 1000 | Multi-junction | 39.7 | 60.4 | - | numerical | Location of inlet under the central part of the receiver provides a higher reduction in the maximum temperature |

| [130] | tree-shaped channel | - | water | - | 50 | Silicon | - | - | - | numerical | Tree shaped channel provides 10 °C lower temperature of PV cell than straight channel |

| [134] | Multi-layered heat sink with parallel flow | aluminum | water | primary and secondary reflector | 529 | triple-junction | 9.8 | - | - | experimental | Heat sink with 3-layers provided an increase in electrical power of 9.4% compared to the 1-layer |

| [135] | Five configurations of microchannel: wide rectangular, single-layer parallel-flow, single-layer counter-flow, double-layer parallel-flow, double-layer counter-flow | aluminum | water | linear Fresnel lens | 20 | polycrystalline silicon | - | - | - | numerical | The best design for PV cooling: single-layer heat sink with parallel-flow. The worst design: single-layer heat sink with counter-flow |

| [137] | Microchannels with forward triangular ribs on sidewalls in aligned and offset distribution | silicon | water | Fresnel lens | 1000 | Multi-junction | 40 | - | - | numerical | Forward triangular ribs installed on the sidewalls enhance the heat transfer capability |

| [138] | Heat sink with Round Pins and Straight Fins | aluminum | water | - | 500 | triple-junction | 39.5 | - | - | Experimental, nu-merical | The heat sink with straight fins keeps the PV surface temperature lower than that of a sink with round pins |

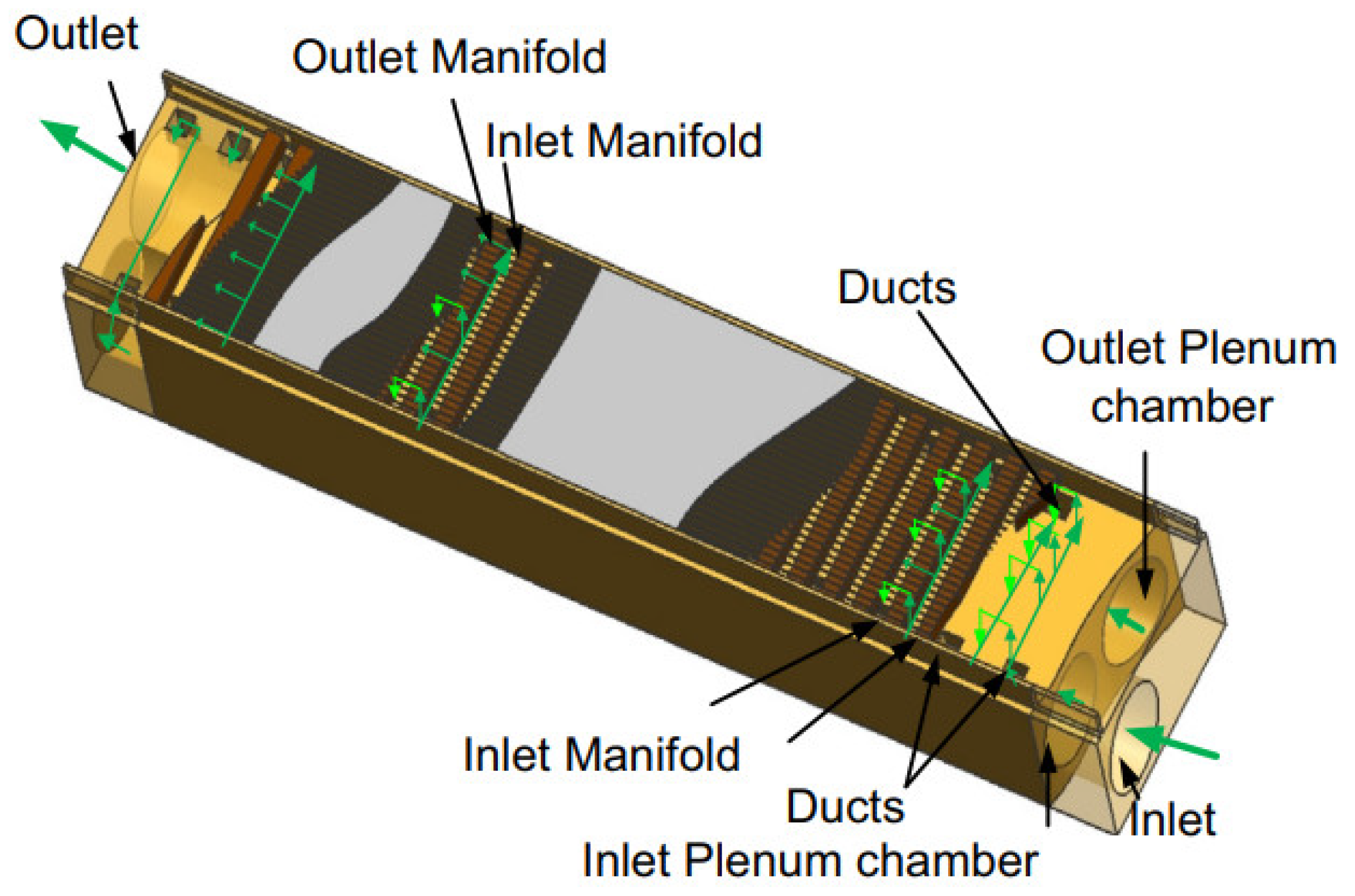

| [140] | Three layers: the microchannels, the manifolds, and the plenum chamber with ducts | copper, steel | water | - | ≤98 | silicon | - | - | - | experimental | Multi-layer design maximizes the contact area between the microchannels and the cell surface. A short flow path reduces pressure drop. |

| [141] | porous channel collector with rectangular cross-section | Aluminum foam | Al2O3 nanoparticles water | Parabolic trough | - | Monocrystal-line silicon | 18.8–19.7 | - | 62–73 | numerical | |

| [142] | Heat sink mounted on the circular pipe | copper | water | Fresnel Lens | 784 | Multi-junction | 36.5 | 49.5 | 68.7 | Experimental, numerical | Numerical model gives higher efficiencies than experimental tests due to the heat losses associated to experiment. |

| [143] | Rectangular duct with aspect ratio 8, 106 parallel microchannels | aluminum | water | - | 20 | polycrystalline silicon | 17.5 | 70.8 | - | numerical | Aspect ratio eight provides maximum heat transfer coefficient for the rectangular ducts. For CR > 3.5 cooling system is recommended. |

| Discussed Aspect | Macroscale Channels | Microscale Channels |

|---|---|---|

| Shape | Straight ducts with rectangular or triangular cross-section, Metal blocks with internal channels, Serpentine channels arrangement, Flow between two flat plates | Single- or multi-layered Microchannels, constant or varying spacing between fins and fin thickness, Various shapes of pin-fins |

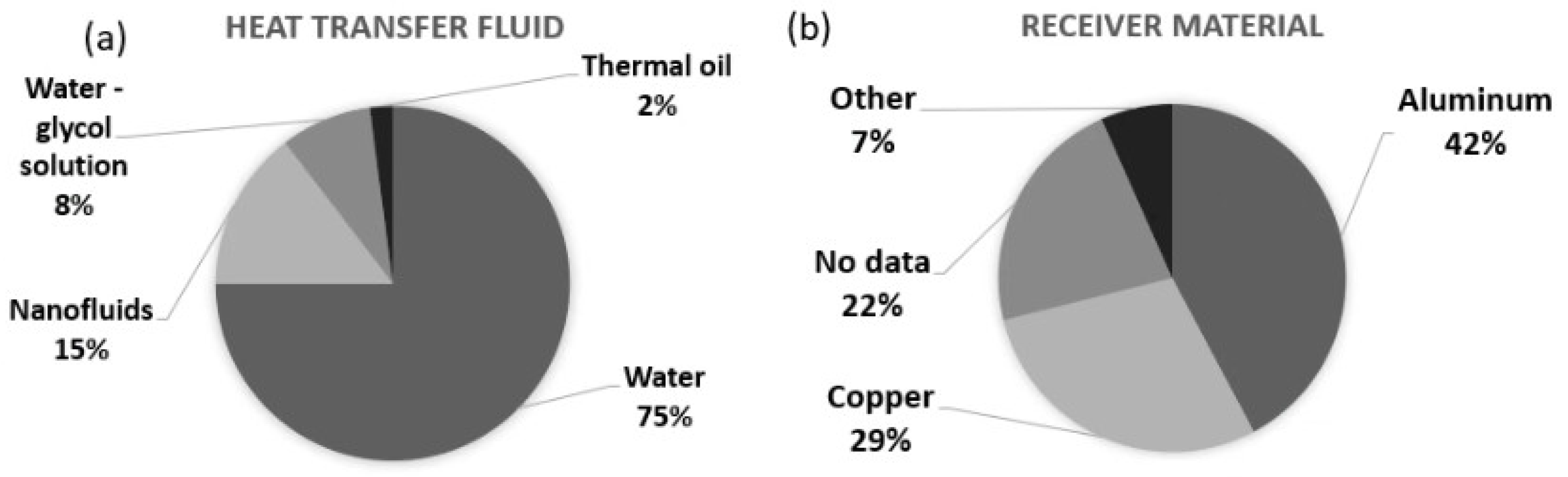

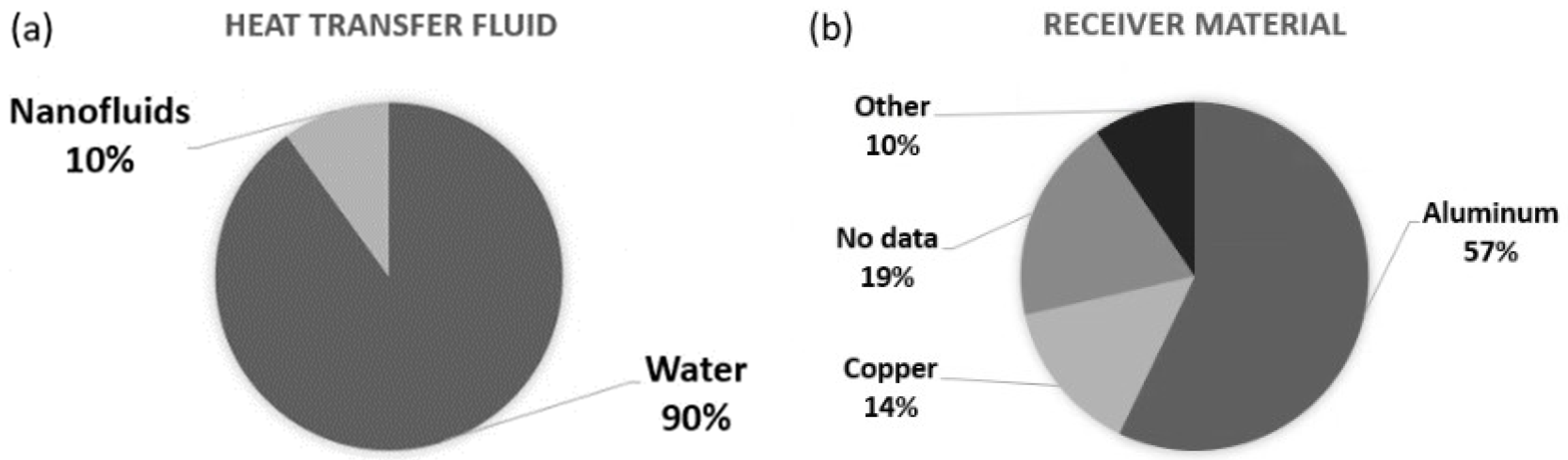

| Heat transfer fluid | Usually: Water, Nanofluids, Water—glycol solutions, Rare: Thermal Oils | Usually: Water, Nanofluids, Rare: Thermal oils |

| Concentration Ratio | Usually low and medium | Usually high and ultrahigh |

| Accompanying concentrator | V-trough, compound parabolic, linear Fresnel lenses | Parabolic trough, parabolic dish, Fresnel lenses, presence of secondary optics such as a kaleidoscope |

| Accompanying PV cell | Usually crystalline Silicon cells, but also: thin-film cells, multi-junction cells | Usually multi-junction cells, but also: crystalline silicon cells, thin-film cells, |

| Pressure drop | Strongly depends on the shape and length of the channels | Very high |

| Manufacturing | Simple constructions based on commercially-available components | Requires specified machines and processes |

| Advantages |

|

|

| Disadvantages |

|

|

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Papis-Frączek, K.; Sornek, K. A Review on Heat Extraction Devices for CPVT Systems with Active Liquid Cooling. Energies 2022, 15, 6123. https://doi.org/10.3390/en15176123

Papis-Frączek K, Sornek K. A Review on Heat Extraction Devices for CPVT Systems with Active Liquid Cooling. Energies. 2022; 15(17):6123. https://doi.org/10.3390/en15176123

Chicago/Turabian StylePapis-Frączek, Karolina, and Krzysztof Sornek. 2022. "A Review on Heat Extraction Devices for CPVT Systems with Active Liquid Cooling" Energies 15, no. 17: 6123. https://doi.org/10.3390/en15176123

APA StylePapis-Frączek, K., & Sornek, K. (2022). A Review on Heat Extraction Devices for CPVT Systems with Active Liquid Cooling. Energies, 15(17), 6123. https://doi.org/10.3390/en15176123