Abstract

Real-time and accurate state-of-charge estimation performs an important role in the smooth operation of various electric vehicle battery management systems. Neural network theory represents one of the most effective and commonly used methods of SOC prediction. However, traditional neural network methods are disadvantaged by such issues as the limited range of application, limited generalization ability, and low accuracy, which makes it difficult to meet the increasing safety requirements on electric vehicles. In view of these problems, an ensemble learning algorithm based on the AdaBoost.Rt is proposed in this paper. AdaBoost.Rt recurrent neural network model is purposed to ensure the accurate prediction of lithium battery SOC. Relying on a chain-connected recurrent neural network model, this method enables the correlation adaptability of sample data in the spatio-temporal dimension. The ensemble learning method was adopted to devise a method of multi-RNN model integration, with the RNN model as the base learner, thus constructing the AdaBoost.Rt-RNN strong learner model. According to the results of simulation and experimental comparisons, the integrated algorithm proposed in this paper is applicable to improve the accuracy of SOC prediction and the generalization performance of the model.

1. Introduction

Lithium batteries are regarded as an ideal power source for the new-generation electric vehicles due to their stable operating voltage, high energy density and charging efficiency, low self-discharge rate, no need for memory, and long service life [1]. The BMS electric vehicle battery management system performs an important role as the intermediary between the vehicle power battery and the electric vehicle [2]. As one of the technologies essential for the development and application BMS, battery SOC estimation is requisite for ensuring its accuracy and stability. Therefore, an accurate prediction of SOC for the battery performs a crucial role in achieving the best possible performance of the electric vehicle and predicting the driving range of the electric vehicle [3,4].

It is difficult to measure the battery SOC directly, and its size can be estimated only by using such parameters as battery terminal voltage, charge, and discharge current, and internal resistance [5]. However, these parameters tend to be affected by various uncertainties such as battery aging, ambient temperature changes, and driving conditions [6]. Therefore, it is imperative to achieve accurate SOC estimation for the future development of electric vehicles [7].

Instead of requiring a complex mathematical modeling process, the neural network algorithm learns the mapping relationship directly through the data. The model can be established in a simple yet accurate way. The battery is equivalent to a complex collection of time-varying nonlinear systems, while the neural network performs such functions as self-organization, self-adaptation, self-learning, etc. It can be used to model and simulate complex nonlinear objects, which makes it capable to capture the battery system [8]. Therefore, the neural network related algorithms are most commonly used for SOC estimation in various battery management systems.

In the literature [9], the estimation algorithm is realized by adopting a gradient correction method for system identification and the unscented Kalman filter and H∞ observer for state estimation, which can select a suitable model from the model library online. In the literature [10], the mathematical programming method was adopted to improve the BP neural network, with the overfitting of the model addressed through regularization. In the literature [11], Radial-based function neural network (RBF) which introduces the concept of saliency was applied to predict SOC, with a different estimation models set for different input parameters of the network. It was found that the ampere-hour model based on the ampere-hour integration method performed best. In the literature [12], the Back Propagation neural network (BP) was adopted. After the training of large data samples, the genetic algorithm was used to denoise the prediction. Then, the SOC was predicted and a good prediction effect was achieved. Moreover, the convergence speed was improved, and the risk of falling into a local minimum was reduced. In the literature [13], a genetic algorithm was applied to optimize the initial weight of BP neural network, and the optimized BP neural network was used to predict SOC. It was found that the initial weight of the optimized neural network was much more desirable than that of the unoptimized neural network, which significantly improves the convergence speed of the neural network. In the literature [14], the least squares support vector machine was employed to predict the SOC of electric vehicle battery, and the support vector machine was compared by using polynomial kernel function and radial basis kernel function to predict the advantages and disadvantages of each SOC. For the specific application, it is necessary to choose different kernel functions according to the real-world conditions.

It can be seen from above that the neural network and its improved algorithm have been widely used and are highly feasible in the research of battery SOC estimation. How-ever, there remain many problems with the improved traditional neural network algorithm, such as overfitting, gradient disappearance, local minimization, and others. The more typical neural networks belong to feedforward neural networks, such as Perceptrons, Back Propagation (BP) networks, Radial Basis Function (RBF) networks, etc. Due to a lack of the time series memory mechanism, these algorithms place a demanding requirement on data sample capacity.

As a type of recurrent neural network, Recurrent Neural Network (RNN) takes sequence data as input to perform recursion in the evolution direction of the sequence and to connect all the nodes (recurrent units) in a chain. With memory, parameter sharing and Turing completeness, the network shows certain advantages in learning the nonlinear characteristics of the sequence, which compensates for the correlation and adaptability of the sample data of the feedforward neural network in the spatiotemporal dimension. Therefore, this paper takes into account the research route of battery SOC based on cyclic neural network.

An ensemble learning algorithm is defined as a machine learning method that adopts multiple models and fuses the prediction results of multiple models to obtain the best prediction result out of the model. In the literature [15], the GBDT ensemble learning algorithm was proposed to extract the statistical and spectral features of the data, with Pearson used for correlation verification. In the literature [16], the ampere-hour integration method and the open-circuit voltage method with fuzzy control were combined to obtain the initial SOC value, and then the RBF neural network was used to estimate the dynamic SOC model. Despite the combined advantages of each model, the battery SOC estimation results remain short of the SOC accuracy requirements in the actual operation of electric vehicles. As one of the representatives of classical ensemble learning, the AdaBoost algorithm is frequently used to perform binary classification. In 1999, Freund and Schapire et al. [17] proposed the classic AdaBoost algorithm, and then the AdaBoost.M1 and AdaBoost.M2 algorithms to solve multi-classification problems. In terms of regression, Freund and Schapire proposed the AdaBoost.R algorithm which is capable to simplify the regression problem into a classification problem by finding an error boundary, thus ascertaining whether the sample is correctly predicted. Proposed by Solomatine [18] in 2004, the AdaBoost.Rt algorithm is effective in improving the usability of the AdaBoost.R algorithm. The AdaBoost.Rt algorithm demonstrates such advantages as high accuracy and excellent generalization performance in dealing with prediction regression problems.

To sum, for addressing the low accuracy and poor generalization of neural network algorithm in lithium battery SOC estimation research, this paper proposes that an integrated learning algorithm of AdaBoost.Rt cyclical neural network model can be adopted to ensure the accurate prediction of lithium battery SOC. Through a chain-connected recurrent neural network model, this method addresses the correlation adaptability of sample data in the spatio-temporal dimension. Moreover, the ensemble learning method was adopted to construct a multi-RNN model integration method, with the RNN model as the base learner, AdaBoost.Rt-RNN strong learner model. As suggested by the simulation results, the method proposed in this paper is capable of improving the accuracy of estimation for lithium battery state-of-charge under various complex operating conditions, and the model is highly effective.

2. AdaBoost.Rt-RNN Algorithm Principle

2.1. Recurrent Neural Network

As a vitally important neural network framework in the field of deep learning, Recurrent Neural Network (RNN) can be used to process and predict the neural network model of sequence data [19]. Compared with the traditional neural network, RNN takes sequence data as input, and the output of its internal neurons at a certain time can be inputted into the neurons again as input. The network cannot handle the input problem that is contextual in time or space [20]. Recurrent neural network can be used to predict various event sequences due to its memory, and it is widely used in the field of natural language processing, such as speech recognition, language modeling, and machine translation.

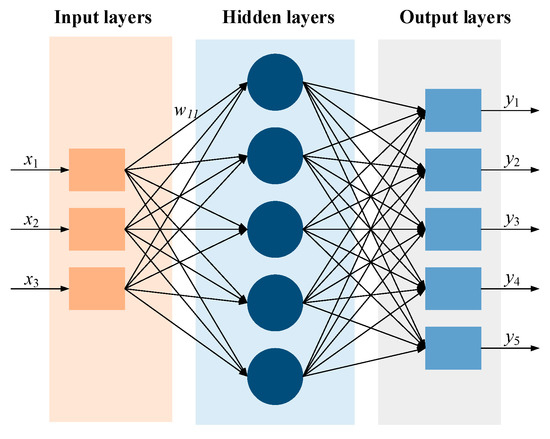

In the traditional neural network, the value of its hidden layer only depends on the input value and is irrelevant to the output. A schematic diagram of the traditional neural network is shown in Figure 1.

Figure 1.

Schematic diagram of traditional neural network.

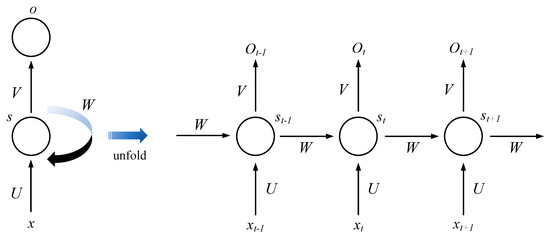

The most striking difference between the recurrent neural network and the traditional neural network is that the RNN is capable of maintaining the state of the hidden layer at the previous moment, which shows that the value of the hidden layer depends not only on the current input value, but also on the value of the hidden layer at the previous moment. Therefore, RNN has a strong learning ability. The structural diagram of RNN is shown in Figure 2.

Figure 2.

Schematic diagram of recurrent neural network.

The output layer and hidden layer of RNN are calculated as follows.

where denotes the output value of the RNN at time t, denotes the weight matrix between the output layer and the hidden layer, denotes the value of the hidden layer of the RNN at time t, denotes the input value of the RNN at time t, denotes the weight matrix between the input layer and the hidden layer, represents the weight matrix between and , and represents the activation function of the hidden layer. By combining the two formulas, it can be known that:

where the output value shows a relationship with the input quantity , , …, .

SOC Estimation of Lithium Battery Based on Recurrent Neural Network

In this paper, the SOC of lithium-ion power batteries was estimated by using a recurrent neural network. The RNN used in this study consists of 6 input neurons, 1 hidden layer and 1 output neurons. The layers of the neural network are described below.

- Input layer: open-circuit voltage at time t, high-frequency resistance (real part) , ohmic resistance , time constant , voltage change rate and the differential value of specific capacity as the input to the model, among them, the open-circuit voltage of the battery , the high-frequency resistance (real part) , ohmic resistance and time constant are tested through the HPPC working condition test, and ;

- Hidden layer: The hidden layer node at time t, where n represents the number of hidden layer nodes:where tanh represents the activation function of the hidden layer;

- Output layer: The SOC at time t is treated as the output of the model.

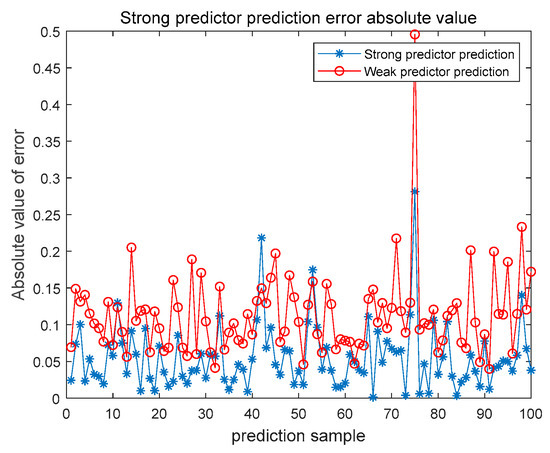

Figure 3 shows a comparison of the absolute value of the error in estimating the SOC of a lithium battery as performed by a single recurrent neural network and by integrating multiple RNNs into a strong predictor according to weight. It can be seen from the figure that the error of the strong predictor is closer to 0, which is less significant than the prediction error result of a single RNN. Therefore, in order to improve the accuracy of lithium battery SOC estimation results, this paper adopts an ensemble learning algorithm, with RNN as a basic learner to estimate the SOC of lithium batteries.

Figure 3.

Strong predictor prediction error absolute value.

2.2. AdaBoost.Rt Ensemble Algorithm

2.2.1. Ensemble Learning

Ensemble learning refers to a machine learning method that uses a series of learners to learn, with certain rules applied to integrate each learning result for obtaining a better learning effect than a single learner. In general, the multiple learners in ensemble learning are homogeneous “weak learners”.

The boosting algorithm of integrated learning generates multiple weak learners in series and generates strong learners according to a certain combination strategy. The AdaBoost.Rt algorithm [21] is one of the boosting series of algorithms.

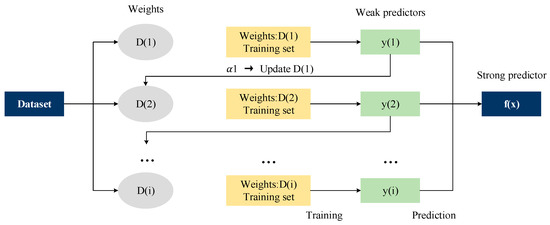

2.2.2. AdaBoost.Rt Ensemble Algorithm

The AdaBoost.Rt algorithm improves the accuracy of any given learning algorithm, and each individual predictor has dependencies. The entire learning process improves performance by increasing the weight of the previous misclassified data, that is, the construction of the next predictor related to the previous predictor. The implementation method is shown in Figure 4.

Figure 4.

Schematic diagram of AdaBoost.Rt algorithm.

The calculation process of the AdaBoost.RT algorithm is as follows:

- Given a training set of m samples, determine the number of iterations and the threshold . According to relevant research, when > 0.38, the prediction error begins to shake violently, and the performance of the strong learning machine is gradually unstable. Therefore, the selected threshold should not exceed 0.38;

- Initialize the sample weight , where is the number of training sets, is the current number of iterations; the error rate is ;

- Train a weak predictor and calculate the relative error of each sample ;

- Calculate the error rate ;

- Update sample weights ;Among them, is the normalization factor, which means the sum of the updated weights of all samples is 1.

- Determine whether it is established. If so, let , and continue to iterate; if , build a strong predictor and output.

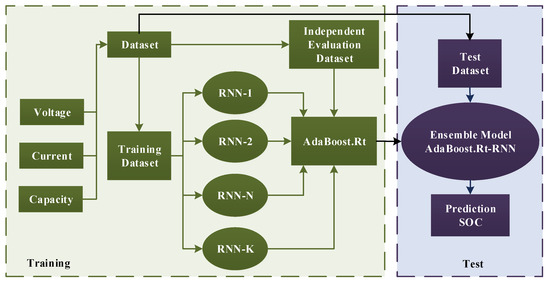

2.3. AdaBoost.Rt-RNN Ensemble Algorithm

In this paper, the SOC of the battery was predicted by establishing the AdaBoost.Rt-RNN model. The preprocessed battery data set is inputted into the model using the initial weight training within the network to obtain a predictor, the learning error rate of the predictor is calculated, and the weight of the training sample is updated according to the error rate. Among them, the combination strategy of each sub-model of AdaBoost.Rt adopts the weighted average method and the initial weights . Moreover, the sample points with high a learning error rate in the predictor are improved, and the next trainer is trained based on the weighted training set until all predictors are completed. Finally, all trainers are assembled into a strong learner to predict the lithium battery SOC accurately. Figure 5 shows its implementation method.

Figure 5.

Schematic diagram of AdaBoost.Rt-RNN algorithm.

Training phase:

- Input the sample training set , where , , and represent the ith feature vector of the voltage, current, and capacity [16] in the lithium battery training samples, respectively; represents the number of training samples;

- Initialize the initial weight of the sample training set , train the weak predictor RNN1, calculate the relative error, update the weight of the training sample according to the error result, and iterate continuously until the weight of the K weak predictor RNNs is determined. The calculation method is expressed as Formula (9) below;

- In combination with the independent evaluation data set , K RNN models are assembled through AdaBoost.Rt. Finally, the AdaBoost.Rt-RNN model is constructed.

Test phase:

- Input the test data set ;

- Use the K RNN models formed by the AdaBoost.Rt-RNN model to predict the test data set, and obtain the prediction result ;

- Finally, the prediction result of the final lithium battery SOC is obtained.

3. Simulation Experiment and Result Analysis

To verify the model, the single RNN model and the AdaBoost.Rt-RNN model were applied to estimate the state-of-charge of lithium-ion batteries under the same conditions.

3.1. Experimental Data

3.1.1. Experimental Data Selection

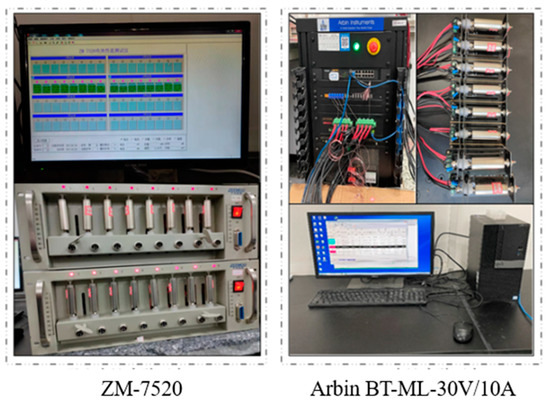

The experimental data used in this paper were obtained on two experimental platforms, such as Figure 6, the Arbin BT-ML-30V/10A power battery tester produced by Arbin Instruments in University City, Texas, USA and the ZM-7520 battery performance tester produced by Harbin Zimu Company in Harbin, China.

Figure 6.

Schematic diagram of battery experiment platform.

Among them, the voltage measurement range of the Arbin device is 0–30 V, the current measurement range is 0–10 A, and the measurement resolution of voltage and current can reach 0.1 mV and 0.1 mA, respectively. In this article, the ZM-7520 battery performance tester was used to carry out the aging test of the lithium battery. The instrument consists of two devices, each with 16 channels. The experimental conditions are shown in Table 1.

Table 1.

Lithium battery experimental conditions.

The actual SOC value of the lithium battery is obtained by the ampere-hour integration method. Assume that the initial state of battery charge and discharge is [22]. The current state of the SOC is shown in the following formula:

where is the rated capacity, is the charging and discharging current of the battery, and is the charging and discharging efficiency. In summary, the ampere-hour integration method needs to measure the charge and discharge current of the battery and the initial SOC value of the battery to estimate the SOC of the battery. In this paper, the charging and discharging voltage and current of the battery were obtained through the above-mentioned experimental equipment. Since the initial capacity of the battery is known, the initial SOC value of the battery can be obtained, and the charging and discharging capacity is known. Therefore, the experimental data are obtained through the ampere-hour integration method to estimate the battery SOC authenticity.

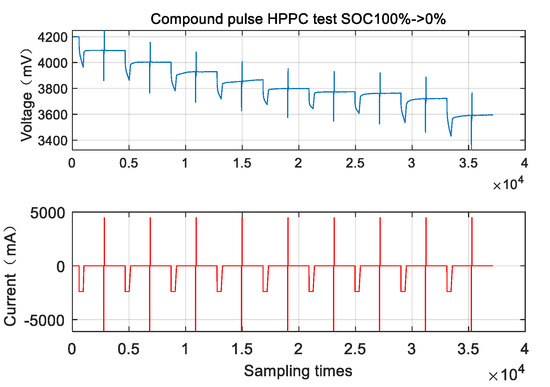

In this paper, the open-circuit voltage of the battery , the high-frequency resistance (real part) , ohmic resistance and time constant were tested through the HPPC working condition test. The specific test steps are as follows:

- Allow the lithium battery to stand for 60 min;

- Charging at 1 C constant current to 3.65 V, keep the voltage constant at 3.65 V, and stop charging when the current is less than 0.05 C;

- After standing for 60 min, use 1 C rate to discharge 10% SOC.

The simulation results of HPPC are shown in Figure 7.

Figure 7.

The experimental process of HPPC.

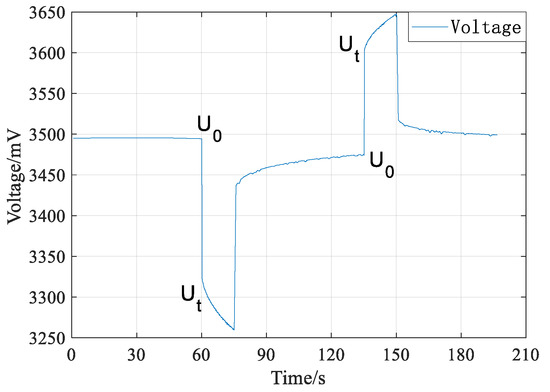

The test principle is to calculate the ohmic internal resistance of the lithium-ion battery by applying a large inrush current at both ends of the lithium-ion battery, in accordance with the change in battery terminal voltage [23]. As shown in Figure 8, is the voltage point at the beginning moment of discharge and is the voltage point at the end moment of discharge, respectively, and the ratio of the voltage difference to the current change is the ohmic internal resistance value, as shown in Formula (17).

where is the terminal voltage of the battery at time t; is the terminal voltage of the battery before the current changes; is the current after the change; and is the current before the change.

Figure 8.

The 80% SOC HPPC test process.

3.1.2. Data Normalization

In order to reduce computational complexity for the neural network, the lithium battery input data are normalized in this paper. The min-max normalization method was used to normalize the data, which speeds up the solution and improves the accuracy of the optimal solution [24]. The result falls within the [0, 1] interval, as shown in the following formula:

where and are the data before and after normalization, respectively, while and are the maximum and minimum values of the data before normalization, respectively.

3.2. Algorithm Evaluation Index

In order to evaluate the established SOC estimation model and compare the predicted data with the actual data, this paper selected two indicators, mean absolute error (MAE) and root mean square error (RMSE) [25]. The calculation of the error is detailed as follows:

Mean Absolute Error (MAE):

Root Mean Square Error (RMSE):

3.3. Simulation and Results Analysis

In this paper, based on the MATLAB platform, the simulation test was carried out, and the number of input layer nodes of the weak predictor RNN was set to 6, including the open-circuit voltage of the battery , the high-frequency resistance (real part) , ohmic resistance , time constant , voltage change rate and the differential value of specific capacity . Among them, the open-circuit voltage of the battery , the high-frequency resistance (real part) , ohmic resistance and time constant were tested through the HPPC working condition test, and . The number of hidden layer nodes is 1, which contains 16 neurons, the number of nodes in the output layer is 1, which is the predicted value of the battery SOC, and the number K of weak predictors is 10.

In the data set, the first group, the 17th group, the 38th group, the 57th group, the 82nd group, and the 86th group were randomly selected to comprise the training data set of the model. The 61 groups and the 72nd group of data were used as the independent evaluation data sets of the model. The 91st group of data were selected as the test data set of the model. The SOC estimation results of the single RNN model and the AdaBoost.Rt-RNN model obtained according to the experimental steps are shown in Figure 9 and Figure 10, respectively.

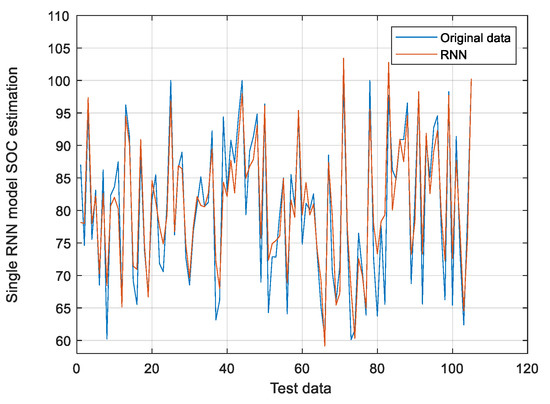

Figure 9.

Single RNN model SOC estimation comparison chart.

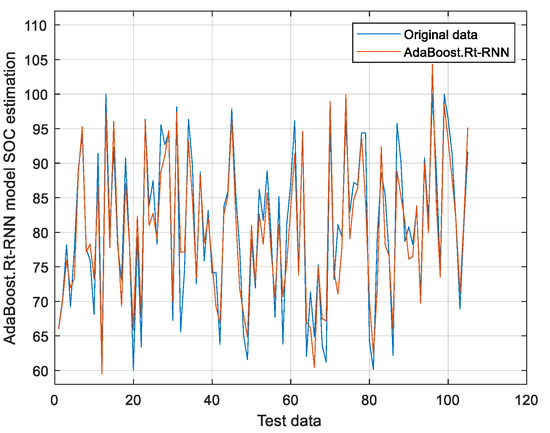

Figure 10.

AdaBoost.Rt-RNN model SOC estimation comparison chart.

The simulation in this paper was carried out under FUDS. From the comparison shown in Figure 9 and Figure 10, it can be seen that compared with the single RNN model, the SOC estimation value of the AdaBoost.Rt-RNN model is more consistent with the true value.

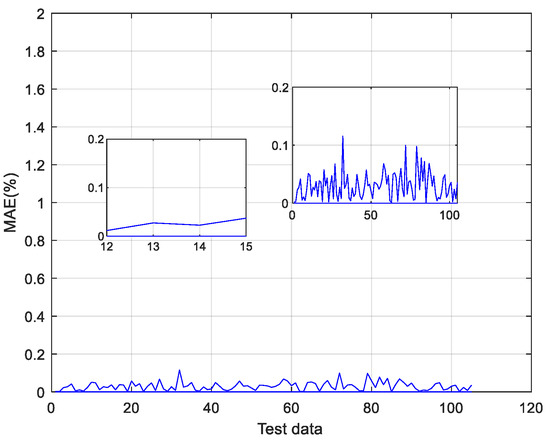

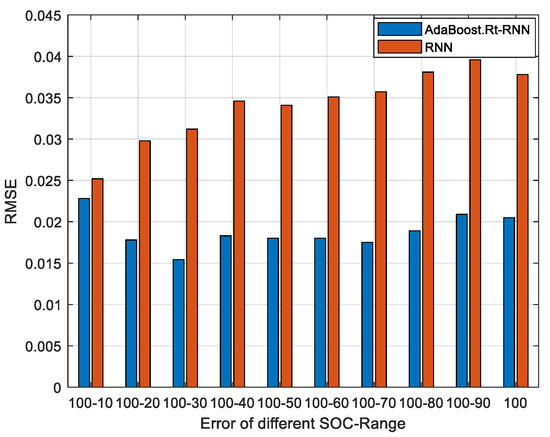

Figure 11 show the mean absolute error. The abscissa in the figure is the test data of the battery SOC, where MAE represents the average value of the absolute value of the error between the observed value and the actual value, and the stability of the MAE change map of the battery SOC indicates that the predicted battery SOC is closer to the actual value of the battery SOC. Figure 12 shows the root mean square error (RMSE) values of a single RNN and AdaBoost.Rt-RNN models under different SOCs, which can describe the dispersion degree of battery SOC error more accurately. The RMSE values under different SOCs are different, and more representative values are selected from 0 to 100% SOC to compare the RMSE values of the two models under different SOCs more intuitively. In the figure, we can find that the RMSE values of the AdaBoost.Rt-RNN model under different SOCs are all smaller than that of the single RNN model. These show that the SOC estimated by the AdaBoost.Rt-RNN model used in this paper is closer to the real value, and the model is highly feasible.

Figure 11.

The MAE of SOC estimation.

Figure 12.

RMSE of AdaBoost.Rt-RNN and RNN.

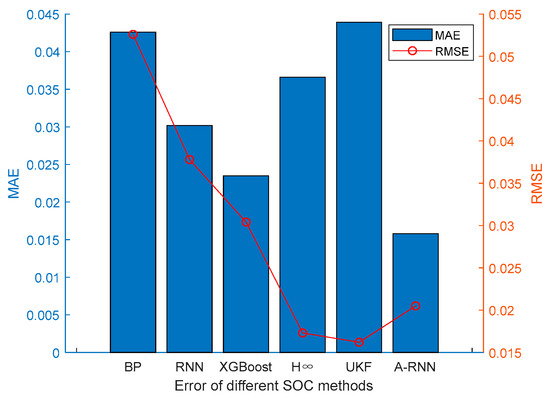

Table 2 shows the mean absolute error and root mean square error of BP neural network [26], RNN, XGBoost [27], [28], UKF [28], and AdaBoost.Rt-RNN model. It can be seen that the mean absolute errors of BP, RNN, XGBoost, , UKF, and AdaBoost.Rt-RNN prediction results are 4.26%, 3.02%, 2.35%, 3.66%, 4.39%, and 1.58%, and the root mean square errors are 5.26%, 3.78%, 3.04%, 1.73%, 1.62%, and 2.05%, respectively.

Table 2.

Comparison of prediction accuracy of lithium battery.

From the results of the mean absolute value error and the root mean square error, it can be seen that the error of the RNN prediction result is lower than that of the BP neural network, which confirms that the cyclic neural network algorithm achieves a higher prediction accuracy than the traditional neural network. Compared with other methods, such as and UKF, AdaBoost.Rt-RNN has relatively higher accuracy. However, in terms of calculation speed, AdaBoost.Rt-RNN needs to be improved. Compared with the single RNN algorithm and the XGBoost integration algorithm, the AdaBoost.Rt-RNN further improves the accuracy of SOC estimation and performs well in generalization, which not only reflects the feasibility of combining the AdaBoost.Rt algorithm and RNN, but also proves that AdaBoost.Rt-RNN model algorithm is effective in improving the accuracy of SOC estimation. Figure 13 can more intuitively describe the prediction accuracy of lithium battery SOC by different methods.

Figure 13.

RMSE and MAE of different methods.

4. Conclusions

The real-time and accurate estimation of lithium battery SOC is essential but challenging for the electric vehicle battery management system. The neural network algorithm proposed in this paper is one of the most effective and commonly used methods of lithium battery SOC prediction. To solve the problems facing traditional neural network, such as the limited range of application, poor generalization performance, and low accuracy, this paper proposes an improved AdaBoost.Rt recurrent neural network model algorithm. Through a chain recurrent neural network model, this method solves the correlation adaptability of sample data in the space-time dimension. In addition, the AdaBoost.Rt ensemble learning algorithm is adopted to form a AdaBoost.Rt according to the weight of multiple weak learner RNNs. The RNN strong learner model significantly improves the accuracy of prediction for the SOC of lithium batteries. According to the simulation and experimental results, the average absolute value errors of the prediction results of the single RNN and the AdaBoost.Rt-RNN are 3.02% and 1.58%, respectively, while the root mean square errors are 3.78% and 2.05%, respectively. That is to say, the AdaBoost.Rt-RNN achieves high estimation accuracy and performs well in convergence. Thus, the AdaBoost.Rt-RNN model in estimating the SOC of lithium batteries is verified as feasible.

Despite the excellent performance of the AdaBoost.Rt-RNN model in estimating the SOC of lithium batteries, there remains room for improvement in the following aspects. Since the SOC estimation of lithium batteries in this paper was carried out at a room temperature of 24 °C, it is impossible to verify the algorithm as applicable for Lithium Battery SOC Estimation at other temperatures. Therefore, the focus of future research is how to integrate the cross-correlation between temperature and lithium battery SOC into the lithium battery SOC estimation model based on AdaBoost.Rt-RNN, for the improved accuracy of lithium battery SOC estimation. In addition, it is also necessary to improve the calculation speed of the AdaBoost.Rt-RNN model.

Author Contributions

Conceptualization, R.L. and H.S.; methodology, H.S.; software, R.L.; validation, R.L., H.S., X.W., W.T. and H.W.; formal analysis, R.L. and H.W.; investigation, H.S.; resources, R.L. and H.S.; data curation, R.L. and H.S.; writing—original draft preparation, H.S.; writing—review and editing, R.L. and H.S.; visualization, H.S. and X.W.; supervision, R.L., W.T. and H.W.; project administration, R.L. and H.S.; funding acquisition, R.L. All authors have read and agreed to the published version of the manuscript.

Funding

This work was supported by the joint fund project of the Ministry of Education of China (8091B022133).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Informed consent was obtained from all subjects involved in the study.

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest.

Abbreviations

| SOC | State-of-charge |

| RNN | Recurrent neural network |

| BMS | Battery management system |

| RBF | Radial-based function neural network |

| BP | Back Propagation |

| FCL | Fuzzy logic control |

| GBDT | Gradient Boosting Decision Tree |

| XGBoost | eXtreme Gradient Boosting |

| OCV | Open-circuit voltage |

| HPPC | Hybrid Pulse Power Characteristic |

| MAE | Mean absolute error |

| RMSE | Root mean square error |

References

- Yang, B.; Wang, Y.; Zhan, Y. Lithium Battery State-of-Charge Estimation Based on a Bayesian Optimization Bidirectional Long Short-Term Memory Neural Network. Energies 2022, 15, 4670. [Google Scholar] [CrossRef]

- Tan, Z.; Sun, R.; Yang, R. Overview of Battery Management System. J. Chongqing Univ. Technol. Nat. Sci. 2019, 33, 40–45. [Google Scholar]

- Zhang, D.; Couto, L.D.; Moura, S.J. Electrode-Level state estimation in lithium-ion batteries via kalman decomposition. J. IEEE Control Syst. Lett. 2021, 5, 1657–1662. [Google Scholar] [CrossRef]

- Ma, Y.; Chen, Q.; Qi, Z. Research on the soc definition and measurement method of batteries used in EVs. J. Tsinghua Univ. Sci. Tech. 2001, 11, 96–98. [Google Scholar]

- Fan, W.; Xu, G.; Yu, B.; Zhang, Z.; Lei, W.; Ren, M.; Dong, M. On-line Estimation Method for Internal Temperature of Lithium-ion Battery Based on Electrochemical Impedance Spectroscopy. J. Proc. CSEE 2021, 41, 3283–3293. [Google Scholar]

- Yang, N.; Zhang, X.; Shang, B.; Li, G. Unbalanced discharging and aging due to temperature differences among the cells in a lithium-ion battery pack with parallel combination. J. Power Sources 2016, 306, 733–741. [Google Scholar] [CrossRef]

- Tang, X.; Wang, Y.; Zou, C.; Yao, K.; Xia, Y.; Gao, F. A novel framework for Lithium-ion battery modeling considering uncertainties of temperature and aging. Energy Convers. Manag. 2018, 180, 162–170. [Google Scholar] [CrossRef]

- Xueyuan, W.; Xuezhe, W.; Jiangong, Z.; Haifeng, D.; Yuejiu, Z.; Xiaoming, X.; Qijun, C. A review of modeling, acquisition, and application of lithium-ion battery impedance for onboard battery management. J. eTransp. 2021, 7, 100093. [Google Scholar]

- Tang, X.; Gao, F.; Zou, C.; Yao, K.; Hu, W. Load-responsive model switching estimation for state of charge of lithium-ion batteries. Appl. Energy 2019, 238, 423–434. [Google Scholar] [CrossRef]

- Tang, H.; Zhang, Z.; Wu, B. Low Temperature Estimation of Battery SOC Based on BP Neural Network under HPPC Conditions. J. Comput. Syst. Appl. 2021, 30, 293–299. [Google Scholar]

- Lei, X.; Chen, Q.; Liu, K.; Ma, L. Radial-Based-Function Neural Network Based SOC Estimation. J. Trans. China Electrotech. Soc. 2008, 5, 81–87. [Google Scholar]

- Liu, X.; Dai, Y. Energy storage battery SOC estimate based on improved BP neural network. J. Phys. Conf. Ser. 2022, 2187, 012042. [Google Scholar] [CrossRef]

- Guan, K.; Wei, Z.; Yin, B. SOC Prediction Method of a New Lithium Battery Based on GA-BP Neural Network. In Lecture Notes in Electrical Engineering, Proceedings of the 4th International Conference on Computer Engineering and Networks, Shanghai, China, 19–20 July 2014; Springer International Publishing: Berlin/Heidelberg, Germany, 2015; pp. 141–153. [Google Scholar]

- Lei, X.; Chen, Q.; Liu, K.; Ma, L. Support Vector Machine Based SOC Estimation for Electric Vehicles. J. Proc. CSEE 2008, 18, 114–118. [Google Scholar]

- Liu, S.; Cui, Y.; Ma, Y.; Peng, L. Short-term Load Forecasting Based on GBDT Combinatorial Optimization. In Proceedings of the 2018 2nd IEEE Conference on Energy Internet and Energy System Integration (EI2), Beijing, China, 20–22 October 2018; pp. 1–5. [Google Scholar]

- Zhang, S.; Yang, L.; Zhao, X.; Qiang, J. A GA optimization for lithium-ion battery aqualization based on SOC estimation by NN and FCL. Int. J. Electr. Power Energy Syst. 2015, 73, 318–328. [Google Scholar] [CrossRef]

- Freund, Y.; Schapire, R.E. A Decision-Theoretic Generalization of On-Line Learning and an Application to Boosting. J. Comput. Syst. Sci. 1999, 55, 119–139. [Google Scholar] [CrossRef] [Green Version]

- Solomatine, D.P.; Shrestha, D.L. AdaBoost.RT: A boosting algorithm for regression problems. In Proceedings of the 2004 IEEE International Joint Conference on Neural Networks (IEEE Cat. No. 04CH37541), Budapest, Hungary, 25–29 July 2004; pp. 1163–1168. [Google Scholar]

- Li, H. Areview of natural language processing based on RNN and Transformer models. J. Inf. Rec. Mater. 2021, 22, 7–10. [Google Scholar]

- Schuster, M.; Paliwal, K.K. Bidirectional recurrent neural networks. J. IEEE Trans. Signal Process. 1997, 45, 2673–2681. [Google Scholar] [CrossRef] [Green Version]

- Wei, Z.; Song, S.; Xia, H. State-of-charge Estimation Using Random Forest for Lithium Ion Battery. J. Guangxi Norm. Univ. Nat. Sci. Ed. 2018, 36, 27–33. [Google Scholar]

- Kurzweil, P.; Scheuerpflug, W.; Frenzel, B.; Schell, C.; Schottenbauer, J. Differential Capacity as a Tool for SOC and SOH Estimation of Lithium Ion Batteries Using Charge/Discharge Curves, Cyclic Voltammetry, Impedance Spectroscopy, and Heat Events: A Tutorial. Energies 2022, 15, 4520. [Google Scholar] [CrossRef]

- Shieh, Y.-T.; Wu, C.-C.; Liu, C.-Y.; Chieng, W.-H.; Su, Y.-S.; Jeng, S.-L.; Chang, E.-Y. Lithium Battery Model and Its Application to Parallel Charging. Energies 2022, 15, 4767. [Google Scholar] [CrossRef]

- El-Sehiemy, R.; Hamida, M.A.; Elattar, E.; Shaheen, A.; Ginidi, A. Nonlinear Dynamic Model for Parameter Estimation of Li-Ion Batteries Using Supply–Demand Algorithm. Energies 2022, 15, 4556. [Google Scholar] [CrossRef]

- Luo, Y.; Qian, Y.; Zeng, Z.; Zhang, Z. Simulation and Analysis of Operating Characteristics of Power Battery for Flying Car Utilization. J. eTransp. 2021, 8, 100111. [Google Scholar] [CrossRef]

- Yu, M.; Shi, W.; Jiang, L.; Wang, H. SOC estimation of power lithium battery based on GA-BP neural network. J. Appl. Electron. Tech. 2020, 46, 104–107112. [Google Scholar]

- Jiang, F.; Yang, J.; Cheng, Y.; Zhang, X.; Huang, Z. An Aging-Aware SOC Estimation Method for Lithium-Ion Batteries using XGBoost Algorithm. In Proceedings of the 2019 IEEE International Conference on Prognostics and Health Management (ICPHM), San Francisco, CA, USA, 17–20 June 2019. [Google Scholar]

- Li, J.; Liu, M. State-of-charge estimation of lithium-ion batteries using composite multi-dimensional features and a neural network. J. IET Power Electron. 2019, 12, 1470–1478. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).