Cable-Partial-Discharge Recognition Based on a Data-Driven Approach with Optical-Fiber Vibration-Monitoring Signals

Abstract

:1. Introduction

2. Acquisition of Cable-PD-Monitoring Signals

2.1. Typical Insulation Defects

- The micropore defect: Gas by-products from the extrusion of cables with extruded insulation may remain in the cross-linked polyethylene (XLPE), forming air gaps. The air gaps have a higher-electric field intensity than the insulation, resulting in PDs.

- The scratch defect: When cables are dragged during the laying process, the outermost insulation is easily scratched, producing an uneven voltage distribution at the insulation/air interface, resulting in PDs.

- The floating-electrode defect: During the production of cables, the residual impurities on the surface of cable insulation, such as metal detritus, become suspensions and result in PDs.

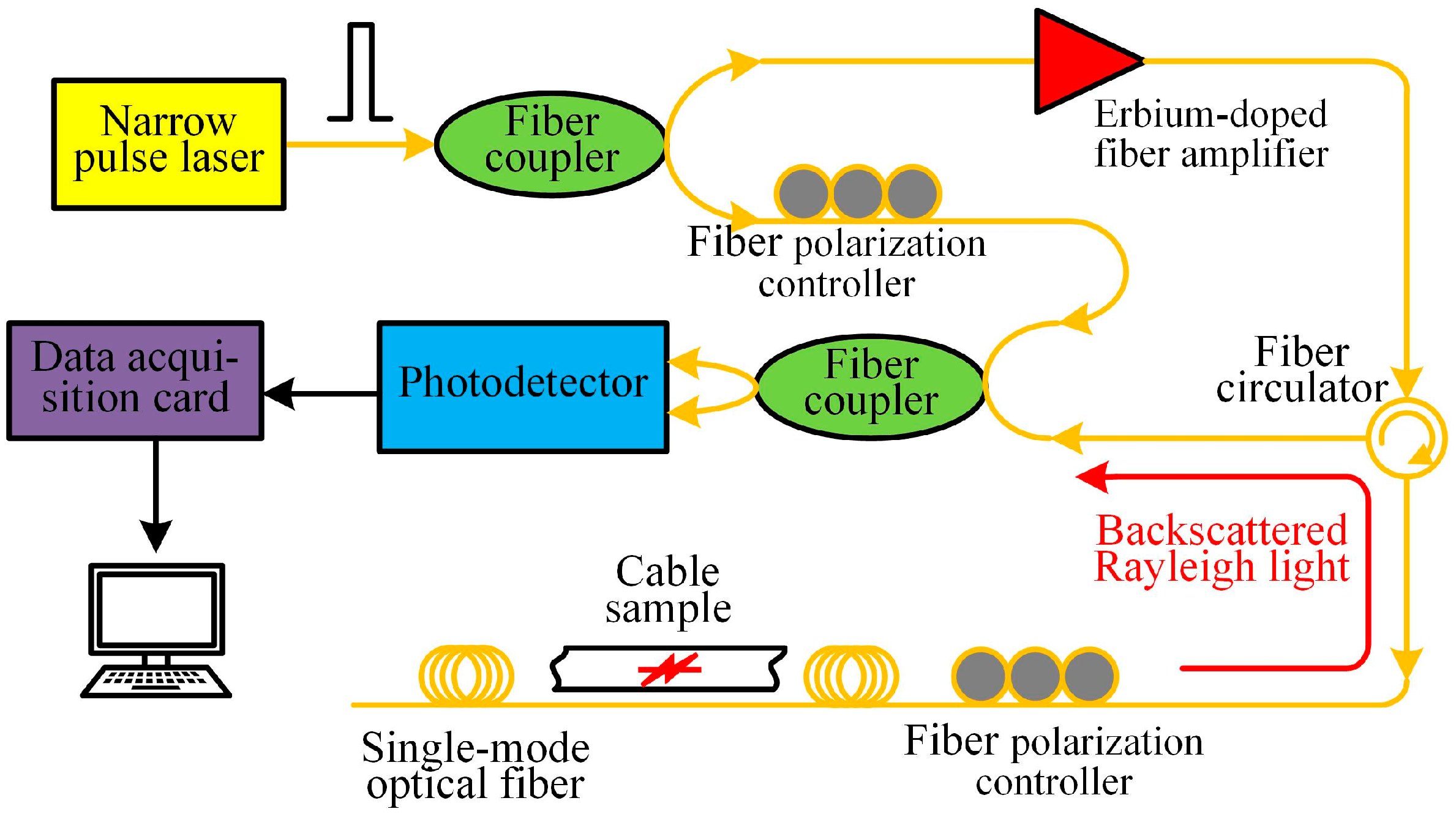

2.2. Optical-Fiber Monitoring-Signal Collection for PDs

3. Feature Extraction Based on ARMA Model

3.1. Data Preprocessing

3.2. Randomness and Stationarity Tests

3.3. Order Determination of ARMA Model

4. Random Forest for PD Recognition

- Establishment of training set: The bootstrap sampling method is used to obtain the training set of the RF. It conducts sampling m times with a replacement for a given data set D containing m samples, and each time the sampling number is one, then the training set is obtained. The probability that a sample in data set D is not be selected is 36.8%, that is, 36.8% of the samples in D are not be collected, and these samples are formed as the out-of-bag data set, which is recorded as .

- Training of base leaners: The classification and regression tree (CART) decisions are used as base learners. CART decision selects the features of data partition through the Gini index. A certain feature in the data set D is denoted as a. Let a have two values , because CART is a binary tree. Divide D based on a, and the data set with the feature value is denoted as . The expression of the Gini index of D iswhere the symbol represents the number of samples in the data set. The smaller the , the greater the consistency of the samples in the data set divided by a, and the better the classification effect.

- Combination of decision results: The data set is classified by the multi-layer CART to obtain the classification results of the subtree. The RF has multiple subtrees, and their results are not unique. Therefore, a combination strategy is needed to obtain the final results. Voting is a commonly used combination strategy. To obtain the final output, plurality voting was chosen to be the combination method of the RF. If the subtrees with a classification result account for the largest proportion of all subtrees, the result is output as the final result.

- Validation of RF model: Since few sample time series were obtained in the experiment, the out-of-bag estimate (OOB) and 10-fold cross validation were used to validate the classification effect of the RF model. The test sets are different in the two methods. The OOB takes the above-mentioned data set as the test set. The 10-fold cross validation divides the data set D into 10 subsets of the same size, and they have the relationship shown in

5. Analysis of the PD-Recognition Results

5.1. Model Test and Comparative Analysis

5.2. Optimization of the Recognition Model

6. Conclusions

- The BRLI changes acquired by the distributed optical-fiber vibration monitoring of cable PDs can reflect different PD patterns. With little prior knowledge of the optical signals, a data-driven approach based on the principle of mathematical statistics and machine learning can achieve good results in cable-PD recognition.

- The combination of the feature extraction based on the ARMA model of the BRLI changes and the RF classification model had a significant effect on the PD recognition. The precision, sensitivity, and specificity were 98.81%, 98.77%, and 99.31%, respectively, according to the experimental data.

- Selecting the ARMA model coefficients with high importance in the RF decision as features can effectively improve the recognition efficiency and ensure high accuracy (about 98%), producing a simple optimization of the PD-recognition model.

- This paper provides a new approach to identifying different PDs of cable bodies, with the potential for application to optical-fiber composite power-cable-monitoring systems. However, because the monitoring data were obtained through the experiment, further research on denoising in an engineering site is required.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ra, N.; Mustafa, N.S.B.; Kawashima, T.; Murakami, Y.; Hozumi, N. Development of a partial discharge measuring method for a long-distance cable line. IEEJ Trans. Elect. Electron. Eng. 2019, 14, 996–1001. [Google Scholar] [CrossRef]

- IEC60270; High-Voltage Test Techniques: Partial Discharge Measurements. International Electrotechnical Commission: Geneva, Switzerland, 2015.

- Li, J.H.; Han, X.T.; Liu, Z.H.; Li, Y.M. Review on partial discharge measurement technology of electrical equipment. High Volt. Eng. 2015, 41, 2583–2601. [Google Scholar]

- Gao, A.; Zhu, Y.L.; Cai, W.H.; Zhang, Y. Pattern recognition of partial discharge based on VMD-CWD spectrum and optimized CNN with cross-layer feature fusion. IEEE Access 2020, 8, 151296–151306. [Google Scholar] [CrossRef]

- Peng, X.S.; Yang, F.; Wang, G.J.; Wu, Y.; Li, L.; Li, Z.; Bhatti, A.A.; Zhou, C.; Hepburn, D.M.; Reid, A.J. A convolutional neural network-based deep learning methodology for recognition of partial discharge patterns from high-voltage cables. IEEE Trans. Power Deliv. 2019, 34, 1460–1469. [Google Scholar] [CrossRef]

- Wu, J.; Hu, Y.G.; Jiang, C.H.; Zhang, X.X.; Li, K.Y.; Zhao, Z.Z. Classification of partial discharge signals in high-voltage cables based on convolutional neural network. J. Wuhan Univ. (Nat. Sci. Ed.) 2021, 67, 232–240. [Google Scholar]

- Chang, C.K.; Boyanapalli, B.K.; Wu, R.N. Application of fuzzy entropy to improve feature selection for defect recognition using support vector machine in high voltage cable joints. IEEE Trans. Dielectr. Electr. Insul. 2020, 27, 2147–2155. [Google Scholar] [CrossRef]

- Wang, Y. Study on Partial Discharge Fault Diagnosis Based on Support Vector Machine and Information Fusion. Ph.D. Thesis, North China Electric Power University, Beijing, China, 2015. [Google Scholar]

- Gu, F.C.; Yau, H.T.; Chen, H.C. Application of chaos synchronization technique and pattern clustering for diagnosis analysis of partial discharge in power cables. IEEE Access 2019, 7, 76185–76193. [Google Scholar] [CrossRef]

- Chen, J.M.; Xu, C.H.; Li, P.; Shao, X.J.; Li, C.L. Feature extraction method for partial discharge pattern in GIS based on time-frequency analysis and fractal theory. High Volt. Eng. 2021, 47, 287–295. [Google Scholar]

- Yang, G. Study on Ultrasonic Signal Characteristics and Pattern Recognition Method of Typical Defect Partial Discharge. Master’s Thesis, Southwest Jiaotong University, Chengdu, China, 2020. [Google Scholar]

- Zhang, L.Q.; Sheng, B.J.; Jiang, W.; Zhou, W.J.; Tian, Z.; Dong, X.; Tang, Z.Y. On-line partial discharge localization in cross-bonded HV cable systems. High Volt. Eng. 2015, 41, 2706–2715. [Google Scholar]

- Ni, H.L.; Yao, W.Q.; Fu, C.Z.; Wei, B.G.; Yan, N.P.; Wu, X.T.; Si, W.R. Review on Technical Standards for Measurement of Partial Discharge in Electrical Equipment. High Voltage Apparatus. Available online: https://kns.cnki.net/kcms/detail/61.1127.tm.20210420.1419.002.html (accessed on 21 April 2021).

- Philipp, R.; René, E.; Katerina, K. Distributed acoustic sensing: Towards partial discharge monitoring. In Proceedings of the 24th International Conference on Optical Fiber Sensors, Curitiba, Brazil, 28 September–2 October 2015; pp. 96341C1–96341C14. [Google Scholar]

- Sun, T.X.; Chen, H.; Qian, S.; Guo, X.K.; Xu, Y. Progress of fiber optic sensor in partial discharge detection for power cables. High Volt. Appar. 2018, 54, 1–8. [Google Scholar]

- Xie, R.; Ge, X.Y.; Zhu, J.P.; Hu, R.P.; Sun, Z. Study on optical-electrical signal characteristics of partial discharge of gas-insulated electric equipment. In Proceedings of the 3rd International Electrical and Energy Conference (CIEEC), Beijing, China, 7 September–9 September 2019; pp. 354–358. [Google Scholar]

- Tang, J.; Zeng, F.P.; Fan, Q.T.; Liu, Y.G.; Zhang, X.X. Multifractal spectrum identification of partial discharge in GIS based on fluorescence optical fiber detection. High Volt. Eng. 2014, 2, 465–473. [Google Scholar]

- Hao, Y.P.; Chen, Y.W.; Chen, Y.; Huang, T.; Xiao, J.P.; Yang, L. A partial discharge detection system for XLPE cable terminals and acoustic wave sensing characteristics based on fiber optic mach-zehnder interferometer. IEEE Sens. J. 2021, 21, 21782–21790. [Google Scholar] [CrossRef]

- Li, R.D. Research on Detection Methods of Cable Partial Discharge Based on Optical Fiber Sensing. Master’s Thesis, North China Electric Power University, Beijing, China, 2020. [Google Scholar]

- Wu, X.T.; Li, R.D.; Ni, H.; Ding, P.; Li, X.G.; Zhou, X.; Cheng, Y.C.; Yu, H.B. Integrated detection of temperature and partial discharge on cables based on FBG. In Proceedings of the 2nd International Conference on Electrical Materials and Power Equipment (ICEMPE), Guangzhou, China, 7 April–10 April 2019; pp. 385–389. [Google Scholar]

- Pan, W.X.; Zhao, K.; Xie, C.; Li, X.R.; Chen, J.; Hu, L.B. Distributed online monitoring method and application of cable partial discharge based on φ-OTDR. IEEE Access 2019, 7, 144444–144450. [Google Scholar] [CrossRef]

- Zhu, P.; Wen, H.q.; Che, Q.; Li, X.Y. Disturbed partial discharge detection system based on improved φ-OTDR assisted by a wFBG array. Appl. Opt. 2020, 59, 4367–4370. [Google Scholar] [CrossRef]

- Che, Q.; Wen, H.Q.; Li, X.Y.; Peng, Z.Q.; Chen, K.P. Partial discharge recognition based on optical fiber distributed acoustic sensing and a convolutional neural network. IEEE Access 2019, 7, 101758–101764. [Google Scholar] [CrossRef]

- Chen, K.J.; Vantuch, T.; Zhang, Y.; Hu, J.; He, J.L. Fault detection for covered conductors with high-frequency voltage signals: From local patterns to global features. IEEE Trans. Smart Grid 2021, 12, 1602–1614. [Google Scholar] [CrossRef]

- Li, Z.; Xu, Y.P.; Jiang, X.C. Pattern recognition of DC partial discharge on XLPE cable based on ADAM-DBN. Energies 2020, 13, 4566. [Google Scholar] [CrossRef]

- Zhou, L.; Wang, F.; Wang, X.C.; Pan, Y.; Sun, Z.Q.; Hua, J.; Zhang, X.P. Distributed strain and vibration sensing system based on phase-sensitive OTDR. IEEE Photon. Technol. Lett. 2015, 27, 1884–1887. [Google Scholar] [CrossRef]

- Wang, Y. Applied Time Series Analysis, 3rd ed.; China Renmin University Press: Beijing, China, 2012; pp. 41–82. [Google Scholar]

- Fernandez-Delgado, M.; Cernadas, E.; Barro, S.; Amorim, D. Do we need hundreds of classifiers to solve real world classification problems? J. Mach. Learn. Res. 2014, 15, 3133–3181. [Google Scholar]

- Zhou, Z.H. Machine Learning; Tsinghua University Press: Beijing, China, 2016. [Google Scholar]

- Rosle, N.; Muhamad, N.A.; Rohani, M.N.K.H.; Jamil, M.K.M. Partial discharges classification methods in XLPE cable: A review. IEEE Access 2021, 9, 133258–133273. [Google Scholar] [CrossRef]

- Li, J.S.; Wu, Y.J.; Wang, G.J.; Peng, X.S.; Liu, T.W.; Jiao, Y.H. Gradient boosting decision tree and random forest based partial discharge pattern recognition of HV cable. In Proceedings of the China International Conference on Electricity Distribution (CICED), Tianjin, China, 17–19 September 2018; pp. 327–331. [Google Scholar]

- Duan, Y.B.; Zhang, H.; Hu, X.L.; Jin, A.L.; Sun, X.B. PD pattern recognition of XLPE cable based on parameter optimal support vector machine algorithm. In Proceedings of the 14th IEEE Conference on Industrial Electronics and Applications (ICIEA), Xi’an, China, 19–21 June 2019; pp. 355–359. [Google Scholar]

- Jin, S.; Zhang, R.B.; Du, G. Partial discharge pattern recognition of cables considering attenuation of damped AC voltages. High Volt. Eng. 2021, 47, 2583–2590. [Google Scholar]

| ACF | PACF | Order Determination |

|---|---|---|

| trailing | p-order truncation | AR(p) model |

| q-order truncation | trailing | MA(q) model |

| trailing | trailing | ARMA(p, q) model |

| Actual | Predicted | ||

|---|---|---|---|

| Scratch | Micropore | Floating | |

| Scratch | 21 | 0 | 0 |

| Micropore | 0 | 27 | 0 |

| Floating | 0 | 1 | 26 |

| Method | Monitoring Method | Feature Extraction | Classifier | Accuracy |

|---|---|---|---|---|

| 1 (proposed method) | Optical-fiber vibration sensing | Extract the ARMA model coefficients of the BRLI changes | RF | 98.7% |

| 2 [23] | fiber-optic distributed acoustic sensing | Calculate the mel-frequency cepstrum Coefficients (MFCC) of the acoustic signals | 2D CNN | 96.3% |

| 3 [5] | HFCT | Combine 17 parameters of PD pulse signals and 16 wavelet features | CNN SVM BPNN | 92.57% 87.81% 86.10% |

| 4 [25] | HFCT | Extract PD pulse waveform features preproce-ssed by Canny | ADAM-DBN | 93.8% |

| 5 [32] | Pulse-current method | Extract fractal dimensions representing the intrinsic fractal features of the gray image | GA-SVM | 96.5% |

| 6 [33] | oscillating wave test | Transform PD signals to periodic phase-resolved partial discharge (P-PRPD) and extract a combined feature by a CNN | RNN | 92% |

| Parameter | ||||||||

|---|---|---|---|---|---|---|---|---|

| Utilization factor (%) | 0.69 | 9.73 | 2.68 | 17.04 | 6.29 | 17.12 | 23.25 | 23.2 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pan, W.; Chen, X.; Zhao, K. Cable-Partial-Discharge Recognition Based on a Data-Driven Approach with Optical-Fiber Vibration-Monitoring Signals. Energies 2022, 15, 5686. https://doi.org/10.3390/en15155686

Pan W, Chen X, Zhao K. Cable-Partial-Discharge Recognition Based on a Data-Driven Approach with Optical-Fiber Vibration-Monitoring Signals. Energies. 2022; 15(15):5686. https://doi.org/10.3390/en15155686

Chicago/Turabian StylePan, Wenxia, Xingchi Chen, and Kun Zhao. 2022. "Cable-Partial-Discharge Recognition Based on a Data-Driven Approach with Optical-Fiber Vibration-Monitoring Signals" Energies 15, no. 15: 5686. https://doi.org/10.3390/en15155686

APA StylePan, W., Chen, X., & Zhao, K. (2022). Cable-Partial-Discharge Recognition Based on a Data-Driven Approach with Optical-Fiber Vibration-Monitoring Signals. Energies, 15(15), 5686. https://doi.org/10.3390/en15155686