Power and Voltage Modelling of a Proton-Exchange Membrane Fuel Cell Using Artificial Neural Networks

Abstract

:1. Introduction

2. Experimental Setup

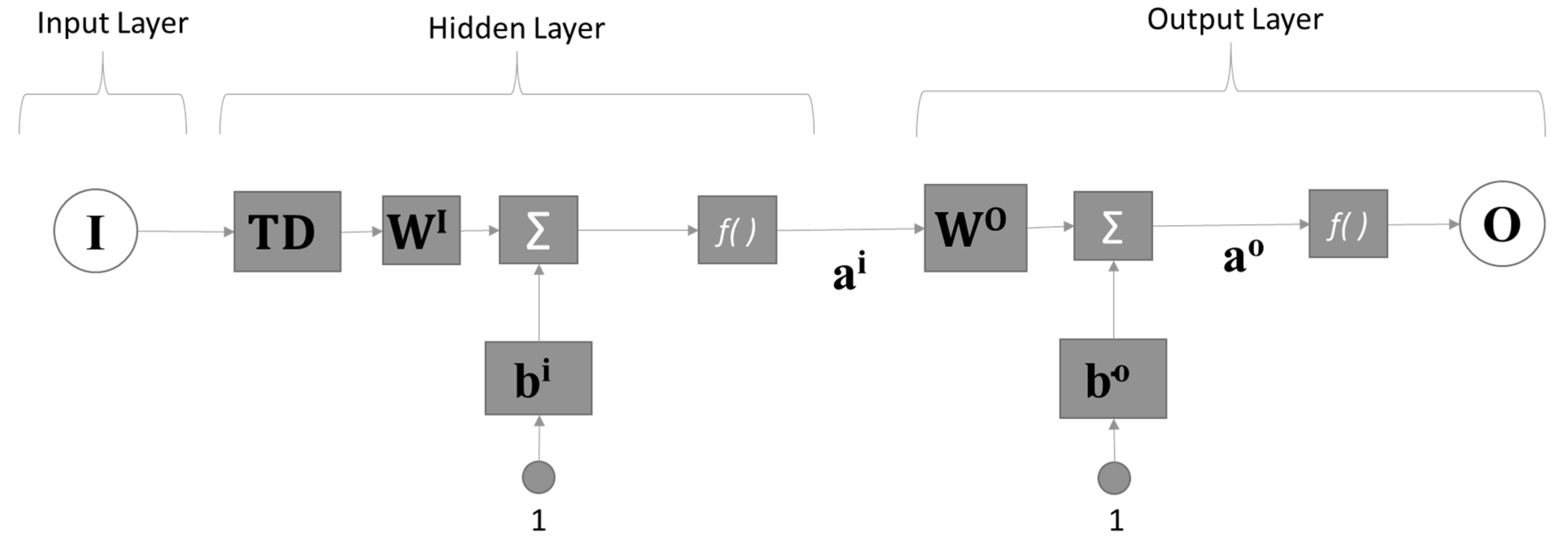

3. Artificial Neural Networks (ANNs)

- is denoted as the vector in space ;

- is the global error function;

- is the gradient of error;

- is the quadratic approximation of error function;

- is the set of non-zero weight vectors.

- is to be updated, such that,

4. Results and Discussion

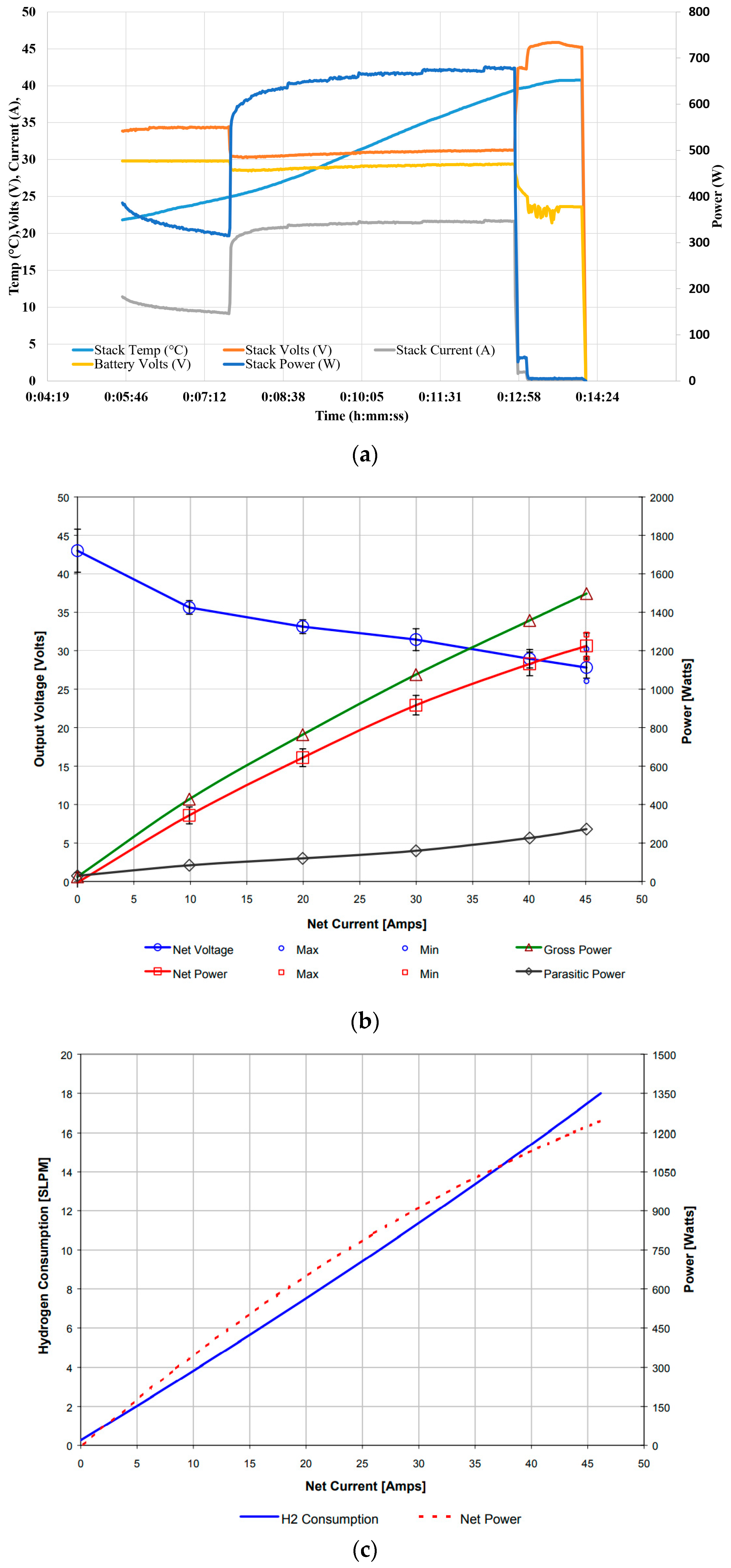

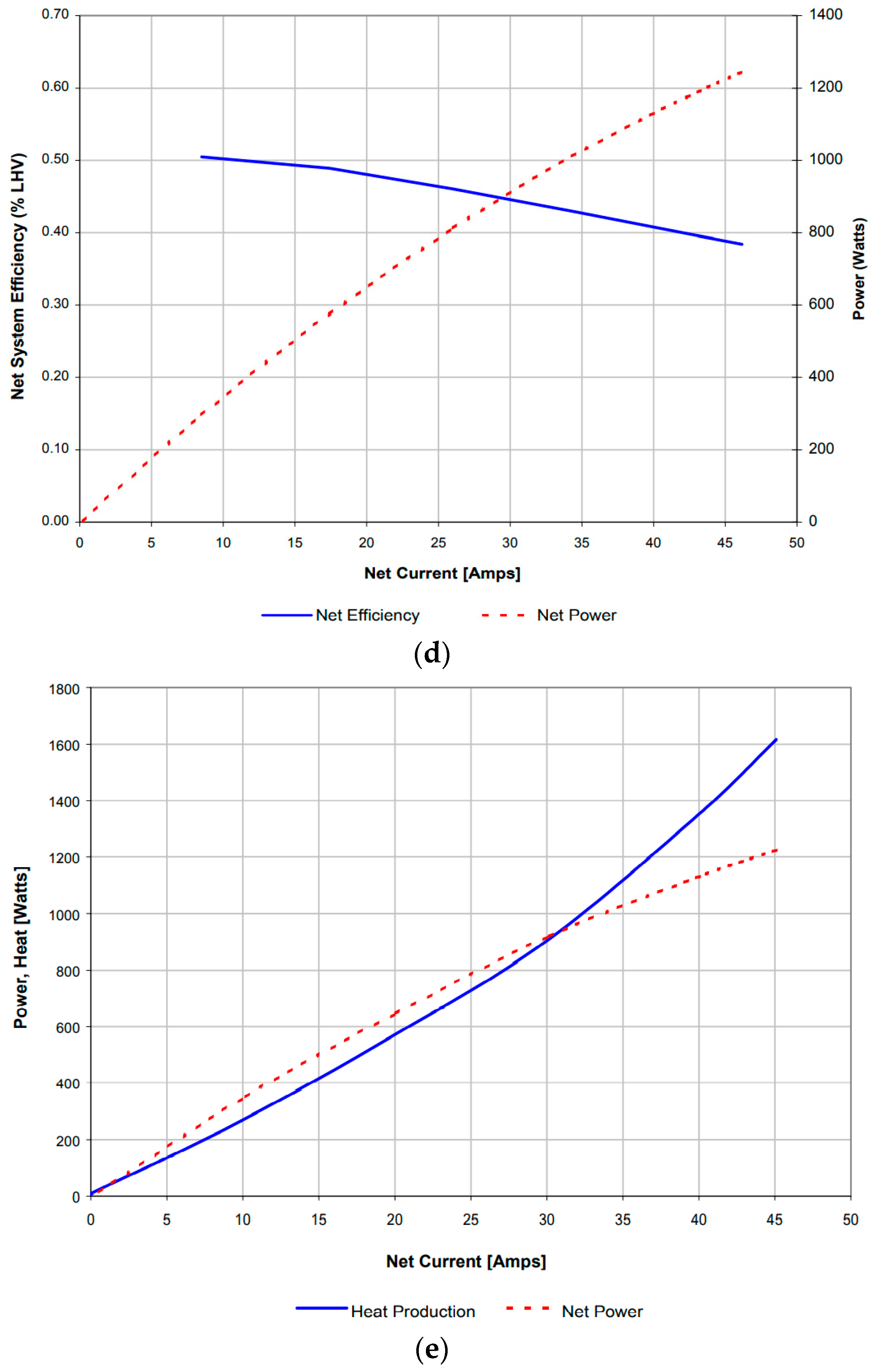

4.1. Experimental Results

4.2. ANN Results

4.3. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Biswas, M.A.R.; Robinson, M.D. Prediction of Direct Methanol Fuel Cell Stack Performance Using Artificial Neural Network. ASME J. Electrochem. Energy Convers. Storage 2017, 14, 031008. [Google Scholar] [CrossRef]

- Biswas, M.; Mudiraj, S.; Lear, W.; Crisalle, O. Systematic Approach for Modeling Methanol Mass Transport on the Anode Side of Direct Methanol Fuel Cells. Int. J. Hydrogen Energy 2014, 39, 8009–8025. [Google Scholar]

- Mudiraj, S.; Crisalle, O.D.; Biswas, M.; Lear, W. Comprehensive Mass Transport Modeling Technique for the Cathode Side of an Open-Cathode Direct Methanol Fuel Cell. Int. J. Hydrogen Energy 2015, 40, 8137–8159. [Google Scholar]

- Ogungbemi, E.; Ijaodola, O.; Khatib, F.N.; Wilberforce, T.; El Hassan, Z.; Thompson, J.; Ramadan, M.; Olabi, A.G. Fuel cell membranes—Pros and cons. Energy 2019, 172, 155–172. [Google Scholar] [CrossRef] [Green Version]

- Ogungbemi, E.; Wilberforce, T.; Ijaodola, O.; Thompson, J.; Olabi, A.G. Review of operating condition, design parameters and material properties for proton exchange membrane fuel cells. Int. J. Energy Res. 2020, 45, 1227–1245. [Google Scholar] [CrossRef]

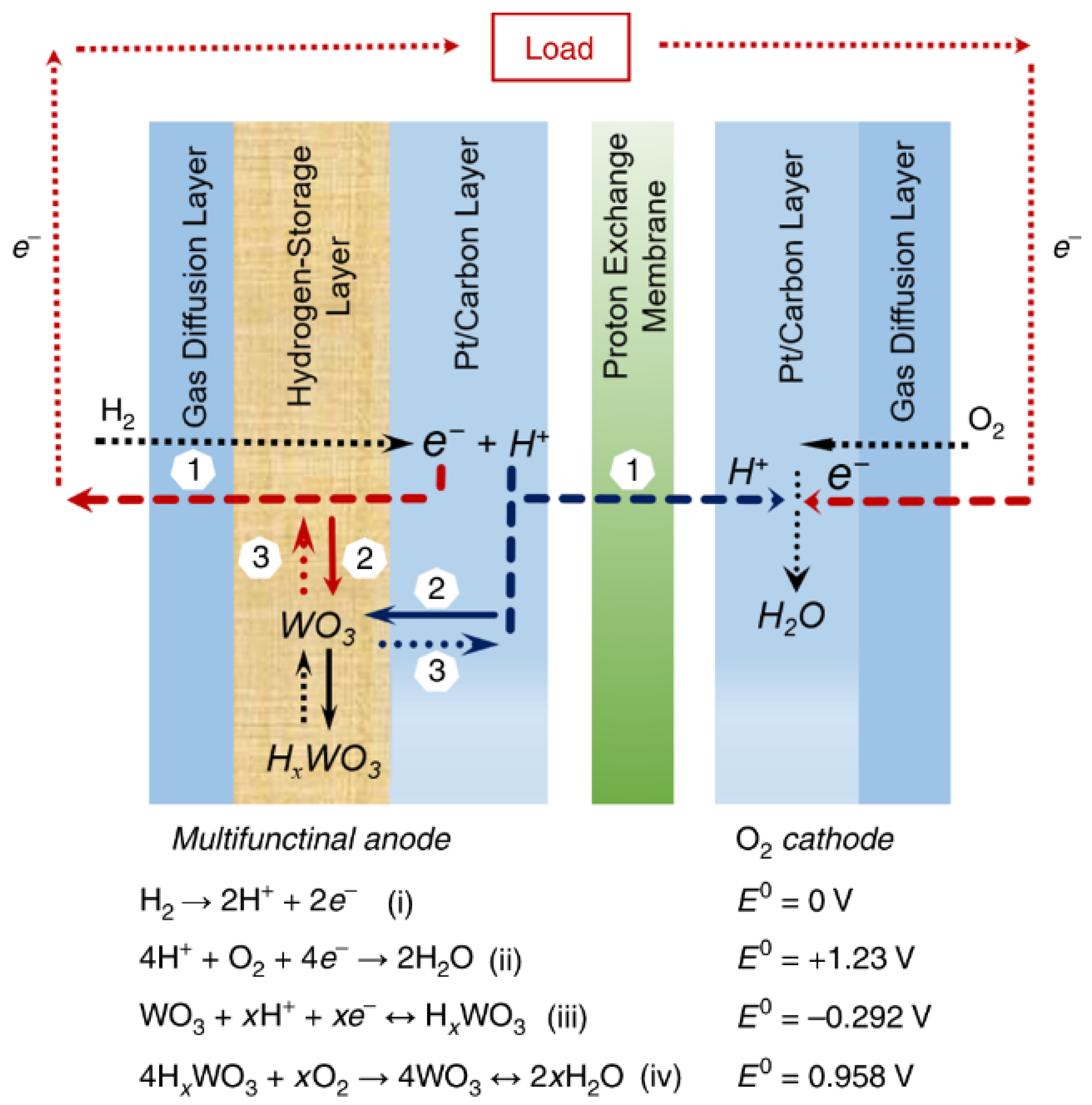

- Shen, G.; Liu, J.; Wu, H.B.; Xu, P.; Liu, F.; Tongsh, C.; Jiao, K.; Li, J.; Liu, M.; Cai, M.; et al. Multi-functional anodes boost the transient power and durability of proton exchange membrane fuel cells. Nat. Commun. 2020, 11, 1191. [Google Scholar] [CrossRef] [Green Version]

- Jayakumar, A.; Chalmers, A.; Lie, T.T. Review of prospects for adoption of fuel cell electric vehicles in New Zealand. IET Electr. Syst. Transp. 2017, 7, 259–266. [Google Scholar] [CrossRef]

- Miao, Q.; Cao, G.; Zhu, X. Performance analysis and fuzzy neural networks modeling of direct methanol fuel cell. J. Shanghai Univ. 2007, 11, 84–87. [Google Scholar]

- Biswas, M.A.R.; Robinson, M.D.; Fumo, N. Prediction of residential building energy consumption: A neural network approach. Energy 2016, 117, 84–92. [Google Scholar]

- Xu, L.; Xiao, J. Dynamic Modeling and Simulation of PEM Fuel Cells Based on BP Neural Network. In Proceedings of the 2011 3rd International Workshop on Intelligent Systems and Applications, Wuhan, China, 28–29 May 2011; pp. 1–3. [Google Scholar]

- Lopes, F.C.; Watanabe, E.H.; Rolim, L.G.B. Analysis of the time-varying behavior of a pem fuel cell stack and dynamical modeling by recurrent neural networks. In Proceedings of the Brazilian Power Electronics Conference (COBEP 2013), Gramado, Brazil, 27–31 October 2013. [Google Scholar]

- Li, P.; Chen, J.; Cai, T.; Liu, G. On-line identification of fuel cell model with variable neural network. In Proceedings of the 29th Chinese Control Conference, Beijing, China, 29–31 July 2010; IEEE: Piscataway, NJ, USA, 2010; pp. 1417–1421. [Google Scholar]

- Puranik, S.V.; Keyhani, A.; Khorrami, F. Neural Network Modeling of Proton Exchange Membrane Fuel Cell. IEEE Trans. Energy Convers. 2010, 25, 474–483. [Google Scholar] [CrossRef]

- Brunetto, C.; Moschetto, A.; Tina, G. PEM fuel cell testing by electrochemical impedance spectroscopy. Electr. Power Syst. Res. 2009, 79, 17–26. [Google Scholar]

- Hagan, M.T.; Demuth, H.B.; Beale, M.H. Neural Network Design; PWS Publishing Company: Boston, MA, USA, 1996. [Google Scholar]

- Robinson, M.D.; Manry, M.T. Two-Stage Second Order Training in Feedforward Neural Networks. In Proceedings of the Twenty-Sixth International FLAIRS Conference, St. Pete Beach, FL, USA, 22–24 May 2013. [Google Scholar]

- Wille, J. On the structure of the Hessian matrix in feedforward networks and second derivative methods. In Proceedings of the International Conference on Neural Networks, Houston, TX, USA, 12 June 1997. [Google Scholar]

- Dennis, J.E., Jr.; Schnabel, R.B. Numerical Methods for Unconstrained Optimization and Nonlinear Equations; Society for Industrial and Applied Mathematics: Philadelphia, PA, USA, 1996. [Google Scholar]

- Møller, M.F. A scaled conjugate gradient algorithm for fast supervised learning. Neural Netw. 1993, 6, 525–533. [Google Scholar] [CrossRef]

- Gill, P.; Murray, W. Algorithms for the solution of the nonlinear least-squares problem. SIAM J. Numer. Anal. 1978, 15, 977–992. [Google Scholar]

| Part Number | Item Name | Function in Setup |

|---|---|---|

| 1 | Batteries | 2 × 12 V batteries are connected in series. The batteries power the entire system during start up, as the auxiliary unit requires 5 W prior to NexaTM completing its start up process and running normally. |

| 2 | Fuse | Ensures the current via the circuit are below the threshold of the wires, as well as protecting the batteries and essential safety components |

| 3 | Resistor | Despite the desired resistances being low, the output power of the fuel cell was high; hence, a resistor to sustain the load was required. As a result, wire wound panel mount resistors with a ceramic core were selected. |

| 4 | Load bank cover | A cover was required as excess heat produced could cause body harm to the operator of the test rig. |

| 5 | DC/DC converter | The output power from the fuel cell is direct current that is not stable. The The DC/DC converter stabilizes the DC output at 24 V. It is able to elevate the voltage level from low to high and vice versa. |

| 6 | ISLE Display Unit | Supports when taking readings in terms of the operational characteristics of the fuel cell. |

| 7 | Isolator Switch | Supports the withdrawal of the batteries once the fuel cell is operating beyond its maximum parasitic load. |

| 8 | Relay | Connects the major test rig circuit with the batteries, which are independently connected in series. They are needed until the fuel cell starts operating after starting up. |

| 9 | Terminal blocks/Busbar | This device allows all the resistors to be connected to either the DC/DC converter or to the relay. Every output configuration from the switch box is connected to one of the two busbars. |

| 10 | Hydrogen sniffer | Supports the detection of potential hydrogen leakage. |

| 11 | Fuel/Hydrogen cylinder | Serves as a storage unit for the investigation. |

| 12 | Fuel regulator | For the monitoring of hydrogen in the cylinder. It also aid in regulating the output pressure from the fuel cell. |

| 13 | PC/Data logging software | NexamonOEM data logging software supports the reading and recording of data based on the experimental setup. |

| 14 | Hydrogen housing units | To ensure the hydrogen gas bottle is held in position during the experiment, a housing unit is required. |

| 15 | Cylinder brackets | Its also protects the gas bottle during the experiment |

| 16 | Power supply | The test rig was powered using energy from the grid with the aid of extension cables. |

| 17 | Switch boxes | Houses the switches. |

| 18 | Water collection unit | The water produced as by product from the operation of the fuel cell is carefully delivered to a tank, where the product water can be measured. |

| 19 | Ballard fuel cell | 1.2 kW PEMFC to be analysed via dynamic loading. |

| ANN Learning Algorithms | Number of Hidden Neurons | Coefficient of Determination | Mean Squared Error (V) |

|---|---|---|---|

| LM | 1 | 0.916 | 4.150 |

| LM | 5 | 0.919 | 3.998 |

| LM | 10 | 0.923 | 3.790 |

| LM | 15 | 0.923 | 3.842 |

| LM | 20 | 0.930 | 3.478 |

| SCG | 1 | 0.913 | 4.319 |

| SCG | 5 | 0.901 | 4.874 |

| SCG | 10 | 0.811 | 9.691 |

| SCG | 15 | 0.905 | 4.706 |

| SCG | 20 | 0.880 | 6.507 |

| Bayesian | 1 | 0.917 | 4.093 |

| Bayesian | 5 | 0.917 | 4.093 |

| Bayesian | 10 | 0.917 | 4.091 |

| Bayesian | 15 | 0.917 | 4.091 |

| Bayesian | 20 | 0.917 | 4.090 |

| ANN Structure | Number of Hidden Neurons | Coefficient of Determination | Mean Squared Error (°C) |

|---|---|---|---|

| LM | 1 | 0.961 | 3.131 |

| LM | 5 | 0.961 | 3.121 |

| LM | 10 | 0.961 | 3.141 |

| LM | 15 | 0.966 | 2.761 |

| LM | 20 | 0.964 | 2.922 |

| SCG | 1 | 0.952 | 3.807 |

| SCG | 5 | 0.941 | 4.861 |

| SCG | 10 | 0.959 | 3.306 |

| SCG | 15 | 0.959 | 3.312 |

| SCG | 20 | 0.942 | 4.665 |

| Bayesian | 1 | 0.961 | 3.126 |

| Bayesian | 5 | 0.961 | 3.121 |

| Bayesian | 10 | 0.961 | 3.122 |

| Bayesian | 15 | 0.961 | 3.122 |

| Bayesian | 20 | 0.961 | 3.121 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wilberforce, T.; Biswas, M.; Omran, A. Power and Voltage Modelling of a Proton-Exchange Membrane Fuel Cell Using Artificial Neural Networks. Energies 2022, 15, 5587. https://doi.org/10.3390/en15155587

Wilberforce T, Biswas M, Omran A. Power and Voltage Modelling of a Proton-Exchange Membrane Fuel Cell Using Artificial Neural Networks. Energies. 2022; 15(15):5587. https://doi.org/10.3390/en15155587

Chicago/Turabian StyleWilberforce, Tabbi, Mohammad Biswas, and Abdelnasir Omran. 2022. "Power and Voltage Modelling of a Proton-Exchange Membrane Fuel Cell Using Artificial Neural Networks" Energies 15, no. 15: 5587. https://doi.org/10.3390/en15155587

APA StyleWilberforce, T., Biswas, M., & Omran, A. (2022). Power and Voltage Modelling of a Proton-Exchange Membrane Fuel Cell Using Artificial Neural Networks. Energies, 15(15), 5587. https://doi.org/10.3390/en15155587