Predictive Modeling of Bioenergy Production from Fountain Grass Using Gaussian Process Regression: Effect of Kernel Functions

Abstract

:1. Introduction

2. Materials and Methods

3. Results and Discussion

3.1. Parametric Analysis and Effect of Interaction of Process Factors on Bioethanol Production

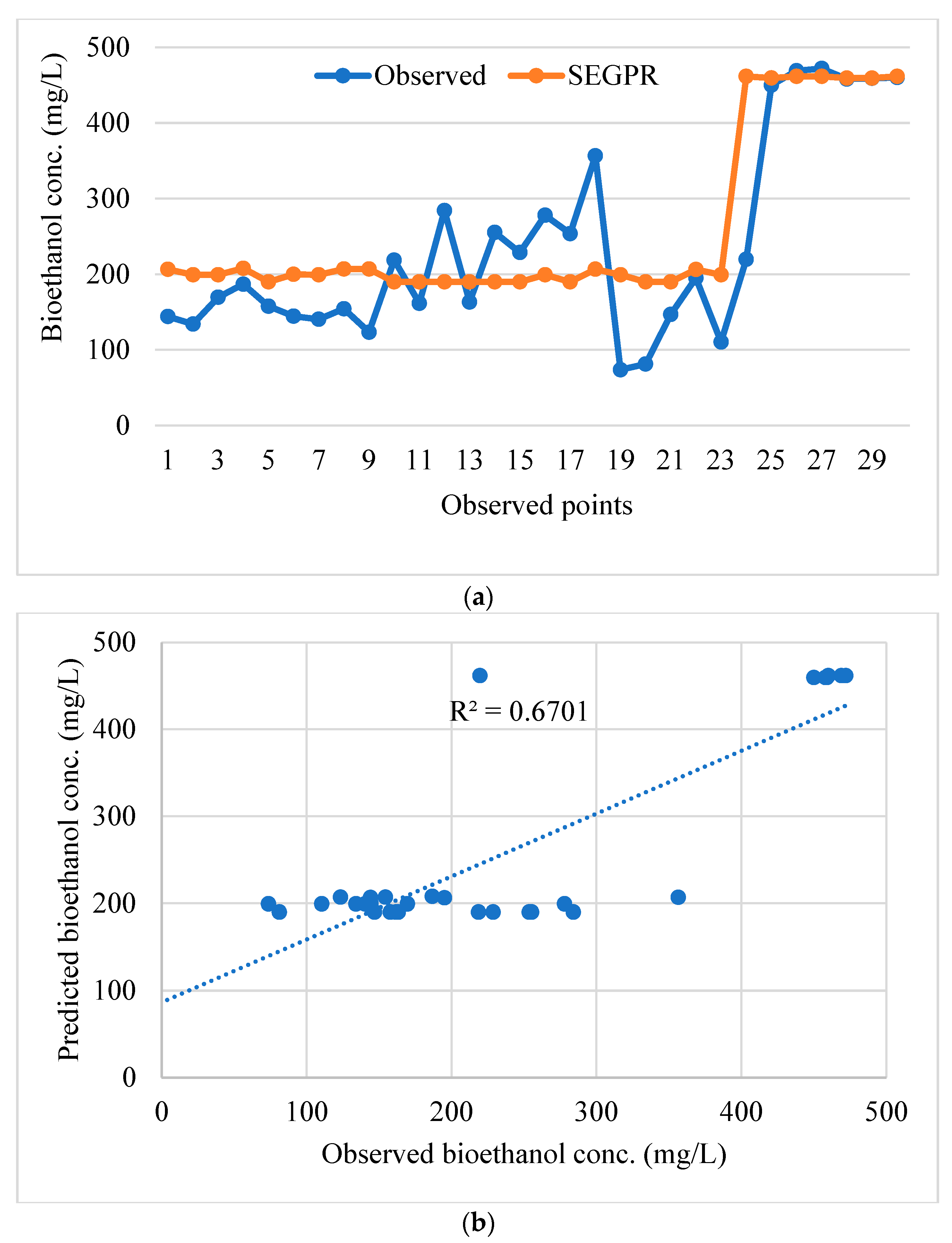

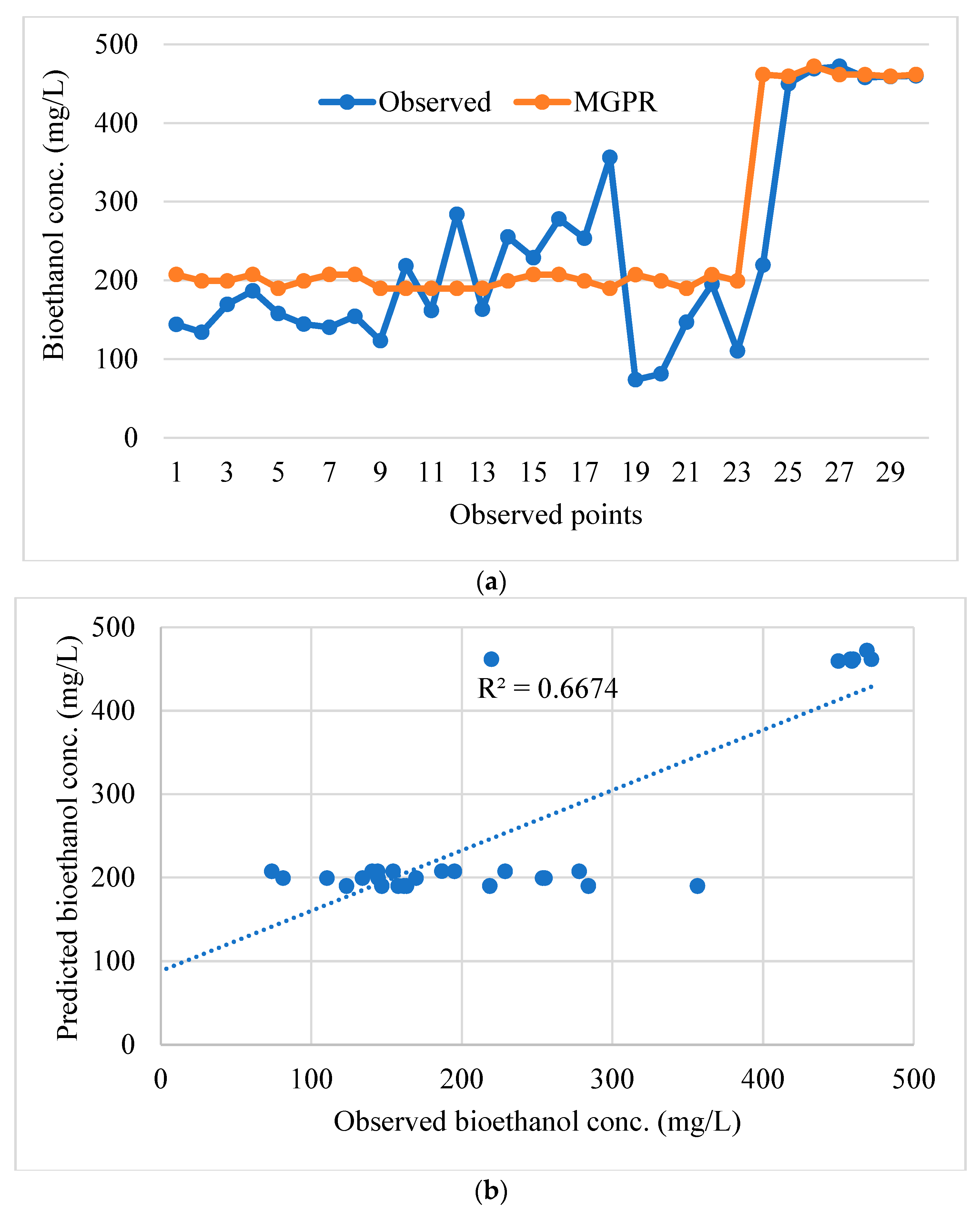

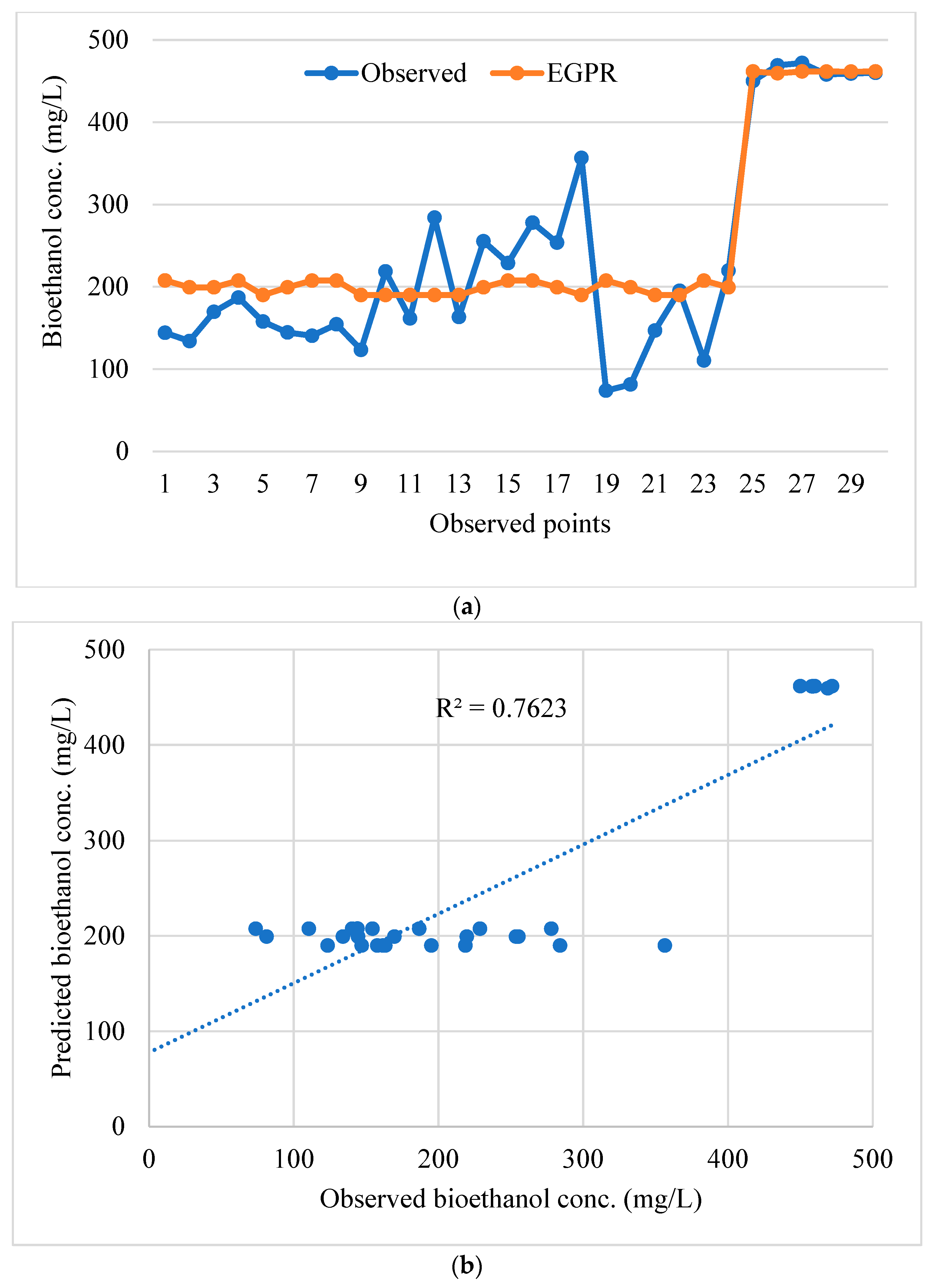

3.2. Performance Evaluation and Comparative Analysis of the Models

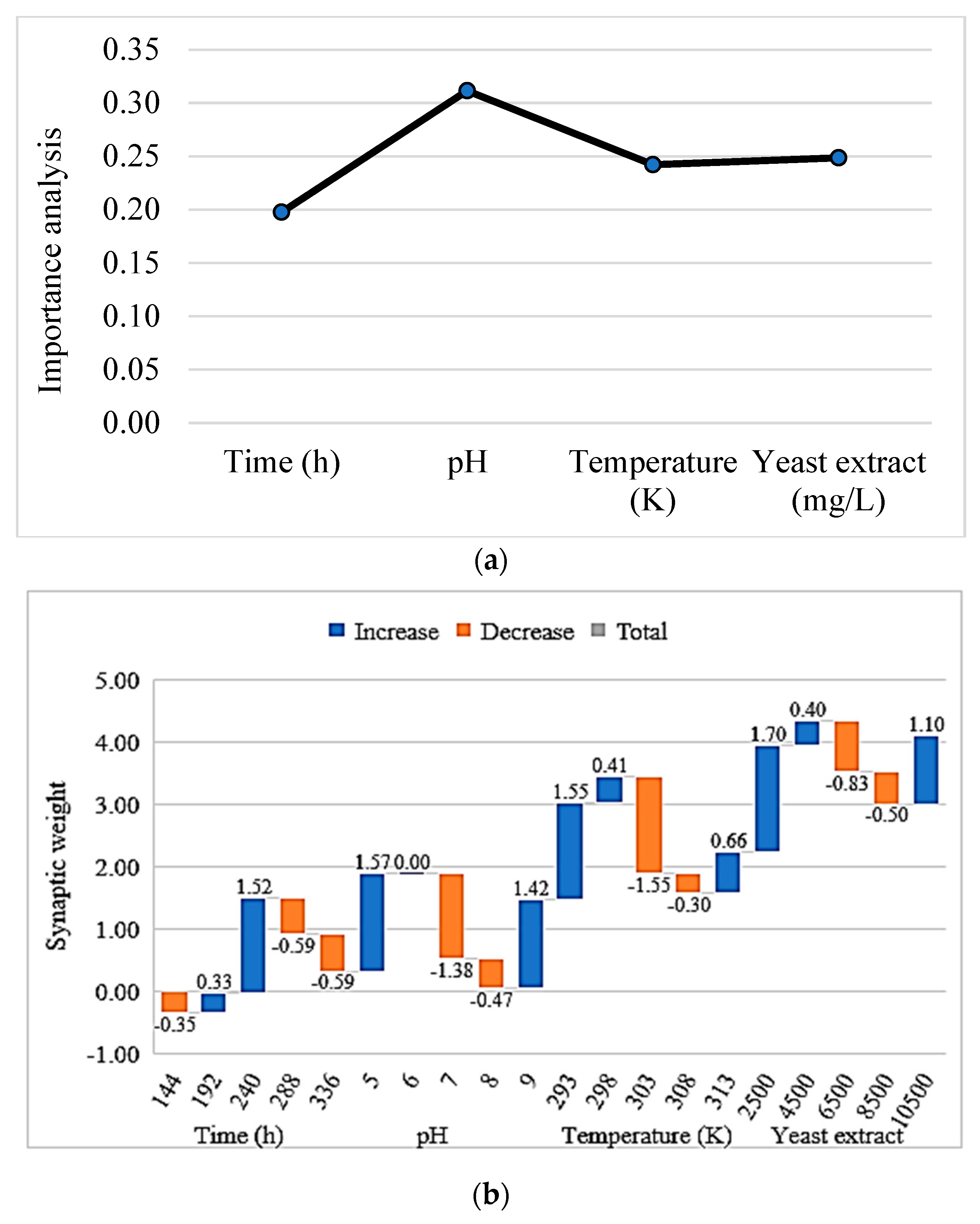

3.3. Input Parameters Importance Analysis and Study Implications

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Bhatia, S.K.; Mehariya, S.; Bhatia, R.K.; Kumar, M.; Pugazhendhi, A.; Awasthi, M.K.; Atabani, A.E.; Kumar, G.; Kim, W.; Seo, S.-O.; et al. Wastewater based microalgal biorefinery for bioenergy production: Progress and challenges. Sci. Total Environ. 2021, 751, 141599. [Google Scholar] [CrossRef] [PubMed]

- Zani, S.H.M.; Asri, F.M.; Azmi, N.S.; Yussof, H.W.; Zahari, M.A.K.M. Optimization of process parameters for bioethanol production from oil palm frond juice by Saccharomyces cerevisiae using response surface methodology as a tool. IOP Conf. Ser. Mater. Sci. Eng. 2019, 702, 012003. [Google Scholar] [CrossRef]

- Scordia, D.; Testa, G.; Cosentino, S.L. Perennial grasses as lignocellulosic feedstock for second-generation bioethanol production in Mediterranean environment. Ital. J. Agron. 2014, 9, 84. [Google Scholar] [CrossRef]

- Valentine, J.; Clifton-Brown, J.; Hastings, A.; Robson, P.; Allison, G.; Smith, P. Food vs. fuel: The use of land for lignocellulosic ‘next generation’ energy crops that minimize competition with primary food production. GCB Bioenergy 2012, 4, 1–19. [Google Scholar] [CrossRef]

- Lewandowski, I. The Role of Perennial Biomass Crops in a Growing Bioeconomy. In Perennial Biomass Crops for a Resource-Constrained World; Barth, S., Murphy-Bokern, D., Kalinina, O., Taylor, G., Jones, M., Eds.; Springer International Publishing: Cham, Switzerland; pp. 3–13.

- Shafiee, S.; Topal, E. When will fossil fuel reserves be diminished? Energy Policy 2009, 37, 181–189. [Google Scholar] [CrossRef]

- Wu, Y.; Zhao, F.; Liu, S.; Wang, L.; Qiu, L.; Alexandrov, G.; Jothiprakash, V. Bioenergy production and environmental impacts. Geosci. Lett. 2018, 5, 14. [Google Scholar] [CrossRef] [Green Version]

- Jin, E.; Sutherland, J.W. An integrated sustainability model for a bioenergy system: Forest residues for electricity generation. Biomass Bioenergy 2018, 119, 10–21. [Google Scholar] [CrossRef]

- Kaniapan, S.; Hassan, S.; Ya, H.; Nesan, K.P.; Azeem, M. The Utilisation of Palm Oil and Oil Palm Residues and the Related Challenges as a Sustainable Alternative in Biofuel, Bioenergy, and Transportation Sector: A Review. Sustainability 2021, 13, 3110. [Google Scholar] [CrossRef]

- Jaiswal, K.K.; Dutta, S.; Banerjee, I.; Pohrmen, C.B.; Kumar, V. Photosynthetic microalgae–based carbon sequestration and generation of biomass in biorefinery approach for renewable biofuels for a cleaner environment. Biomass Convers. Biorefinery 2021, 1–19. [Google Scholar] [CrossRef]

- Gabrielli, P.; Gazzani, M.; Mazzotti, M. The Role of Carbon Capture and Utilization, Carbon Capture and Storage, and Biomass to Enable a Net-Zero-CO2 Emissions Chemical Industry. Ind. Eng. Chem. Res. 2020, 59, 7033–7045. [Google Scholar] [CrossRef] [Green Version]

- Fózer, D.; Tóth, A.J.; Varbanov, P.S.; Klemeš, J.J.; Mizsey, P. Sustainability assessment of biomethanol production via hydrothermal gasification supported by artificial neural network. J. Clean. Prod. 2021, 318, 128606. [Google Scholar] [CrossRef]

- Huang, Y.; Yang, L.; Gao, C.; Jiang, Y.; Dong, Y. A Novel Prediction Approach for Short-Term Renewable Energy Consumption in China Based on Improved Gaussian Process Regression. Energies 2019, 12, 4181. [Google Scholar] [CrossRef] [Green Version]

- Bahadar, A.; Kanthasamy, R.; Sait, H.H.; Zwawi, M.; Algarni, M.; Ayodele, B.V.; Cheng, C.K.; Wei, L.J. Elucidating the effect of process parameters on the production of hydrogen-rich syngas by biomass and coal Co-gasification techniques: A multi-criteria modeling approach. Chemosphere 2021, 287, 132052. [Google Scholar] [CrossRef] [PubMed]

- Jambo, S.A.; Abdulla, R.; Marbawi, H.; Gansau, J.A. Response surface optimization of bioethanol production from third generation feedstock—Eucheuma cottonii. Renew. Energy 2018, 132, 1–10. [Google Scholar] [CrossRef]

- Chaudhary, A.; Hussain, Z.; Aihetasham, A.; El-Sharnouby, M.; Rehman, R.A.; Khan, M.A.U.; Zahra, S.; Saleem, A.; Azhar, S.; Alhazmi, A.; et al. Pomegranate peels waste hydrolyzate optimization by Response Surface Methodology for Bioethanol production. Saudi J. Biol. Sci. 2021, 28, 4867–4875. [Google Scholar] [CrossRef]

- Manmai, N.; Unpaprom, Y.; Ramaraj, R. Bioethanol production from sunflower stalk: Application of chemical and biological pretreatments by response surface methodology (RSM). Biomass Convers. Biorefinery 2020, 11, 1759–1773. [Google Scholar] [CrossRef]

- El-Mekkawi, S.A.; Abdo, S.M.; Samhan, F.A.; Ali, G.H. Optimization of some fermentation conditions for bioethanol production from microalgae using response surface method. Bull. Natl. Res. Cent. 2019, 43, 164. [Google Scholar] [CrossRef]

- Raina, N.; Slathia, P.S.; Sharma, P. Response surface methodology (RSM) for optimization of thermochemical pretreatment method and enzymatic hydrolysis of deodar sawdust (DS) for bioethanol production using separate hydrolysis and co-fermentation (SHCF). Biomass Convers. Biorefinery 2020, 1–21. [Google Scholar] [CrossRef]

- Chen, J.; Wang, X.; Zhang, B.; Yang, Y.; Song, Y.; Zhang, F.; Liu, B.; Zhou, Y.; Yi, Y.; Shan, Y.; et al. Integrating enzymatic hydrolysis into subcritical water pretreatment optimization for bioethanol production from wheat straw. Sci. Total Environ. 2021, 770, 145321. [Google Scholar] [CrossRef] [PubMed]

- Chouaibi, M.; Ben Daoued, K.; Riguane, K.; Rouissi, T.; Ferrari, G. Production of bioethanol from pumpkin peel wastes: Comparison between response surface methodology (RSM) and artificial neural networks (ANN). Ind. Crop. Prod. 2020, 155, 112822. [Google Scholar] [CrossRef]

- Yildirim, O.; Tunay, D.; Ozkaya, B. Optimization of enzymatic hydrolysis conditions of chemical pretreated cotton stalk using response surface methodology for enhanced bioethanol production yield. Biomass Convers. Biorefinery 2021, 1–12. [Google Scholar] [CrossRef]

- Murari, C.S.; Machado, W.R.C.; Schuina, G.L.; Del Bianchi, V.L. Optimization of bioethanol production from cheese whey using Kluyveromyces marxianus URM 7404. Biocatal. Agric. Biotechnol. 2019, 20, 101182. [Google Scholar] [CrossRef]

- Lin, C.-W.; Tran, D.-T.; Lai, C.-Y.; I, Y.-P.; Wu, C.-H. Response surface optimization for ethanol production from Pennisetum Alopecoider by Klebsiella oxytoca THLC0409. Biomass Bioenergy 2010, 34, 1922–1929. [Google Scholar] [CrossRef]

- Deng, Z.; Hu, X.; Lin, X.; Che, Y.; Xu, L.; Guo, W. Data-driven state of charge estimation for lithium-ion battery packs based on Gaussian process regression. Energy 2020, 205, 118000. [Google Scholar] [CrossRef]

- Gao, W.; Karbasi, M.; Hasanipanah, M.; Zhang, X.; Guo, J. Developing GPR model for forecasting the rock fragmentation in surface mines. Eng. Comput. 2017, 34, 339–345. [Google Scholar] [CrossRef]

- Mahmoodzadeh, A.; Mohammadi, M.; Noori, K.M.G.; Khishe, M.; Ibrahim, H.H.; Ali, H.F.H.; Abdulhamid, S.N. Presenting the best prediction model of water inflow into drill and blast tunnels among several machine learning techniques. Autom. Constr. 2021, 127, 103719. [Google Scholar] [CrossRef]

- Sheela, K.G.; Deepa, S.N. Review on Methods to Fix Number of Hidden Neurons in Neural Networks. Math. Probl. Eng. 2013, 2013, 425740. [Google Scholar] [CrossRef] [Green Version]

- Fang, D.; Zhang, X.; Yu, Q.; Jin, T.C.; Tian, L. A novel method for carbon dioxide emission forecasting based on improved Gaussian processes regression. J. Clean. Prod. 2018, 173, 143–150. [Google Scholar] [CrossRef]

- Adun, H.; Wole-Osho, I.; Okonkwo, E.C.; Ruwa, T.; Agwa, T.; Onochie, K.; Ukwu, H.; Bamisile, O.; Dagbasi, M. Estimation of thermophysical property of hybrid nanofluids for solar Thermal applications: Implementation of novel Optimizable Gaussian Process regression (O-GPR) approach for Viscosity prediction. Neural Comput. Appl. 2022, 34, 11233–11254. [Google Scholar] [CrossRef]

- Baraldi, P.; Mangili, F.; Zio, E. A prognostics approach to nuclear component degradation modeling based on Gaussian Process Regression. Prog. Nucl. Energy 2015, 78, 141–154. [Google Scholar] [CrossRef] [Green Version]

- Nasirpour, N.; Mousavi, S.M. RSM based optimization of PEG assisted ionic liquid pretreatment of sugarcane bagasse for enhanced bioethanol production: Effect of process parameters. Biomass Bioenergy 2018, 116, 89–98. [Google Scholar] [CrossRef]

- Bibi, F.; Yasmin, H.; Jamal, A.; Al-Harbi, M.S.; Ahmad, M.; Zafar, M.; Ahmad, B.; Samra, B.N.; Ahmed, A.F.; Ali, M.I. Deciphering role of technical bioprocess parameters for bioethanol production using microalgae. Saudi J. Biol. Sci. 2021, 28, 7595–7606. [Google Scholar] [CrossRef] [PubMed]

- Hossain, S.S.; Ali, S.S.; Rushd, S.; Ayodele, B.V.; Cheng, C.K. Interaction effect of process parameters and Pd-electrocatalyst in formic acid electro-oxidation for fuel cell applications: Implementing supervised machine learning algorithms. Int. J. Energy Res. 2022. [Google Scholar] [CrossRef]

| Bioenergy Type | Parameters Investigated | Conversion Process | Biofuel Produced | Reference |

|---|---|---|---|---|

| Seaweed | Cellulose loading, Enzyme loading, temperature, pH, and incubation term | Enzymatic hydrolysis and fermentation | 9.77 g/L | [15] |

| Pomegranate peels | HNO3 concentration, Temperature, and hydrolysis time | Enzymatic hydrolysis and fermentation | 61.45 g/L | [16] |

| Sunflower stalk | Concentration of NaOH, time for pretreatment | Enzymatic hydrolysis and fermentation | 49.06 g/L | [17] |

| Microalgae | Algal biomass amount, the yeast volume, and the time of fermentation | Enzymatic hydrolysis and fermentation | 18.57 g/L | [18] |

| Deodar sawdust | Chemical concentration, incubation time, and biomass loading | Thermochemical pretreatment method and enzymatic hydrolysis Separate hydrolysis and co-fermentation | 14.25 g/L | [19] |

| Wheat straw | Extraction temperature, extraction time, and substrate loading | Subcritical water pretreatment and high solid hydrolysis | 37.00 g/L | [20] |

| Pumpkin peel wastes | Hydrolysis loading substrate, α-amylase concentration, and amyloglucosidase concentration | Enzymatic hydrolysis and fermentation | 84.36 g/L | [21] |

| Cotton stalk | Effect of pre-treatment method, enzymatic hydrolysis load, and retention time | Enzymatic hydrolysis and fermentation | 9.5 g/L | [22] |

| Cheese whey | pH (4–6), temperature (30–36 °C), and lactose concentration | Fermentation | 2.57 g/L | [23] |

| Oil palm frond juice | initial pH, rotation rate, and temperature. | Fermentation | 0.50 g/g * | [2] |

| Parameters | Range | Minimum | Maximum | Mean | Std. Deviation | Variance |

|---|---|---|---|---|---|---|

| Time (h) | 192.00 | 144.00 | 336.00 | 240.00 | 43.67 | 1906.76 |

| pH | 4.00 | 5.00 | 9.00 | 7.00 | 0.91 | 0.83 |

| Temperature (K) | 20.00 | 293.00 | 313.00 | 303.00 | 4.55 | 20.69 |

| Yeast extract (mg/L) | 8000.00 | 2500.00 | 10,500.00 | 6500.00 | 1819.44 | 3,310,344.83 |

| bioethanol concentration (mg/L) | 398.21 | 73.79 | 472.00 | 238.34 | 128.62 | 16,542.49 |

| Performance Matrix | RQGPR | SEGPR | MGPR | EGPR | OptiGPR |

|---|---|---|---|---|---|

| R2 | 0.648 | 0.670 | 0.667 | 0.762 | 0.993 |

| RMSE | 63.15 | 62.93 | 63.13 | 63.11 | 45.13 |

| MAE | 50.65 | 48.29 | 48.43 | 48.44 | 32.07 |

| Prediction speed (obs/s) | 2000 | 1600 | 1800 | 1500 | 1500 |

| Training time (s) | 2.61 | 6.50 | 2.43 | 2.67 | 65.95 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hossain, S.S.; Ayodele, B.V.; Almithn, A. Predictive Modeling of Bioenergy Production from Fountain Grass Using Gaussian Process Regression: Effect of Kernel Functions. Energies 2022, 15, 5570. https://doi.org/10.3390/en15155570

Hossain SS, Ayodele BV, Almithn A. Predictive Modeling of Bioenergy Production from Fountain Grass Using Gaussian Process Regression: Effect of Kernel Functions. Energies. 2022; 15(15):5570. https://doi.org/10.3390/en15155570

Chicago/Turabian StyleHossain, SK Safdar, Bamidele Victor Ayodele, and Abdulrahman Almithn. 2022. "Predictive Modeling of Bioenergy Production from Fountain Grass Using Gaussian Process Regression: Effect of Kernel Functions" Energies 15, no. 15: 5570. https://doi.org/10.3390/en15155570

APA StyleHossain, S. S., Ayodele, B. V., & Almithn, A. (2022). Predictive Modeling of Bioenergy Production from Fountain Grass Using Gaussian Process Regression: Effect of Kernel Functions. Energies, 15(15), 5570. https://doi.org/10.3390/en15155570