Numerical Modelling of the Effects of Liquefaction on the Upheaval Buckling of Offshore Pipelines Using the PM4Sand Model

Abstract

:1. Introduction

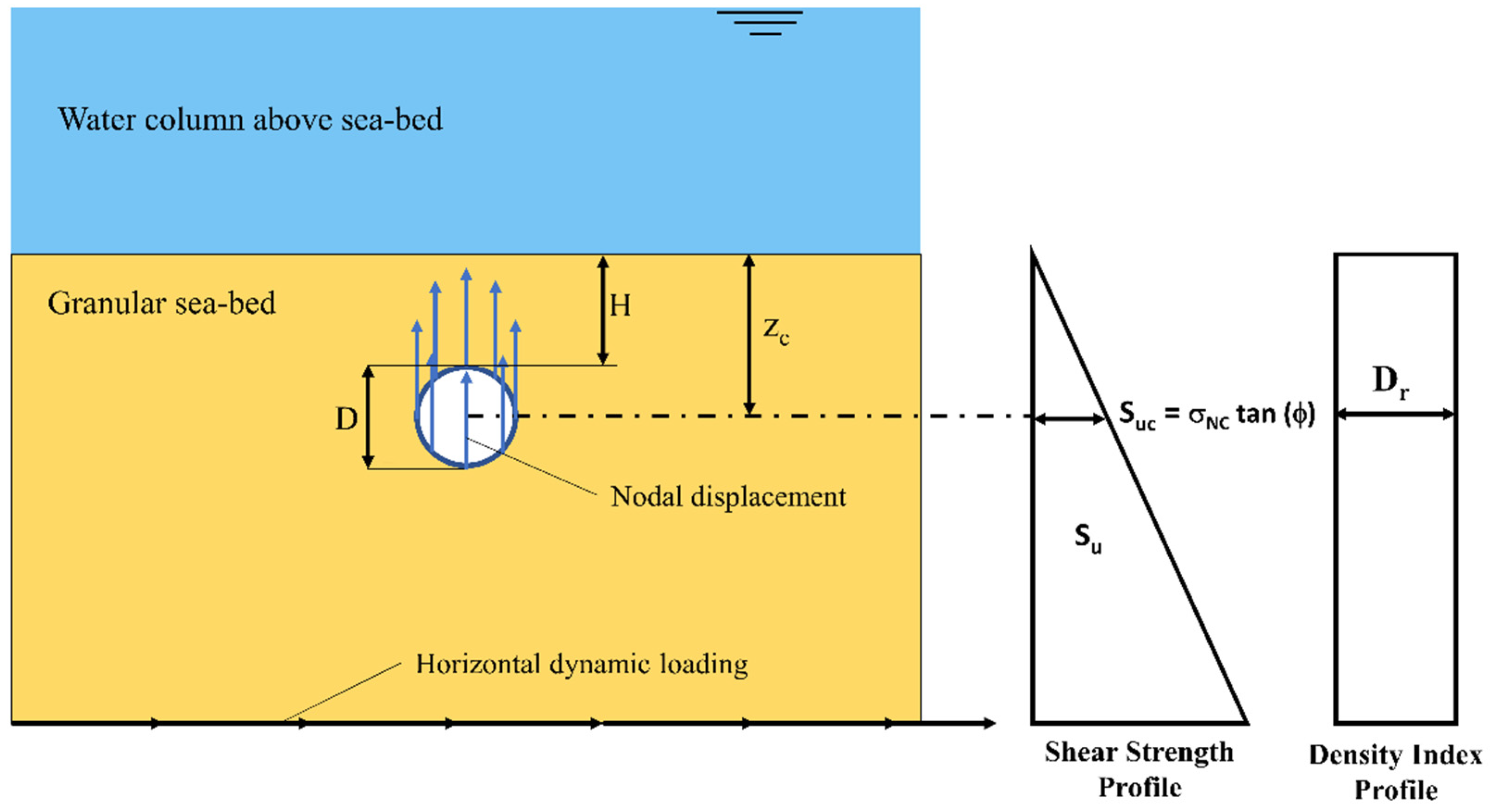

2. Problem Statement

- The soil is considered to be submerged.

- The outer surface of the pipeline is considered to be completely rough. Thus, the full friction angle of the soil is mobilized at the pipe–soil interface.

- The pipe–soil interface is considered to have negligible tensile capacity, and the soil does not remain connected to the pipe bottom during the pipe upheaval buckling.

- The pipeline is subjected to hydrostatic pressure from the outside, as it is buried within a submerged seabed. However, the inside of the pipeline is considered dry, and no internal pressure is considered in the current study.

- The stiffness of the pipeline is considered to be very high to prevent a change in the shape of the pipe cross-section under hydrostatic and soil pressure.

- The effect of the hydrodynamic wave loading is neglected in the post-earthquake stage.

- The problem is modelled as a 2D plain-strain problem, as the pipe-soil interaction is considered to be homogeneous throughout the pipeline length.

3. Numerical Modelling

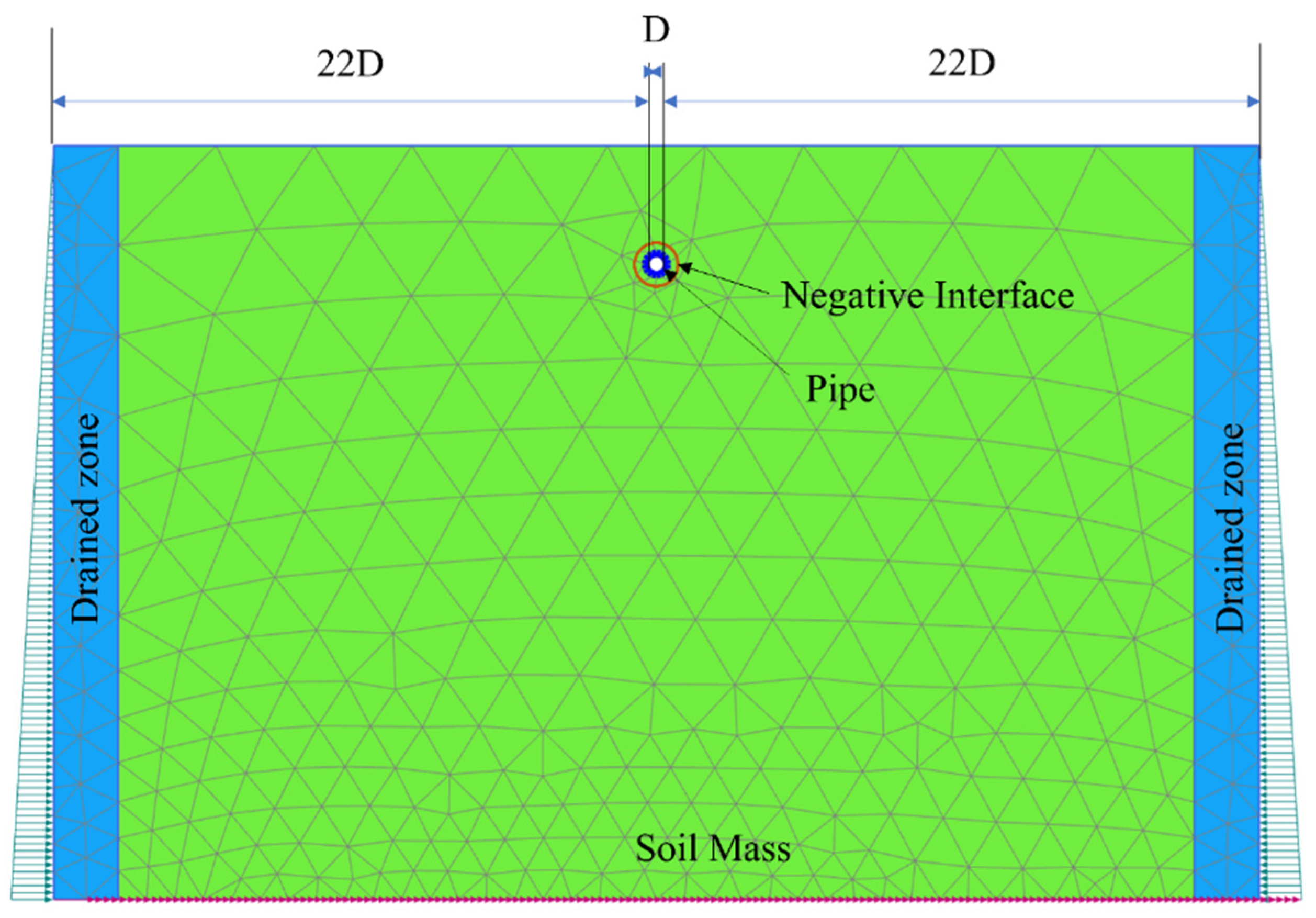

3.1. Boundary Dimensions, Condition and Model Discretization

3.2. Material Modelling

3.3. Phases of Analysis

3.3.1. Initial Phase

3.3.2. Phase 1—Installation

3.3.3. Phase 2—Earthquake

3.3.4. Phase 3—Post-Earthquake

3.4. Validation of the Selected Soil Model

4. Results and Discussions

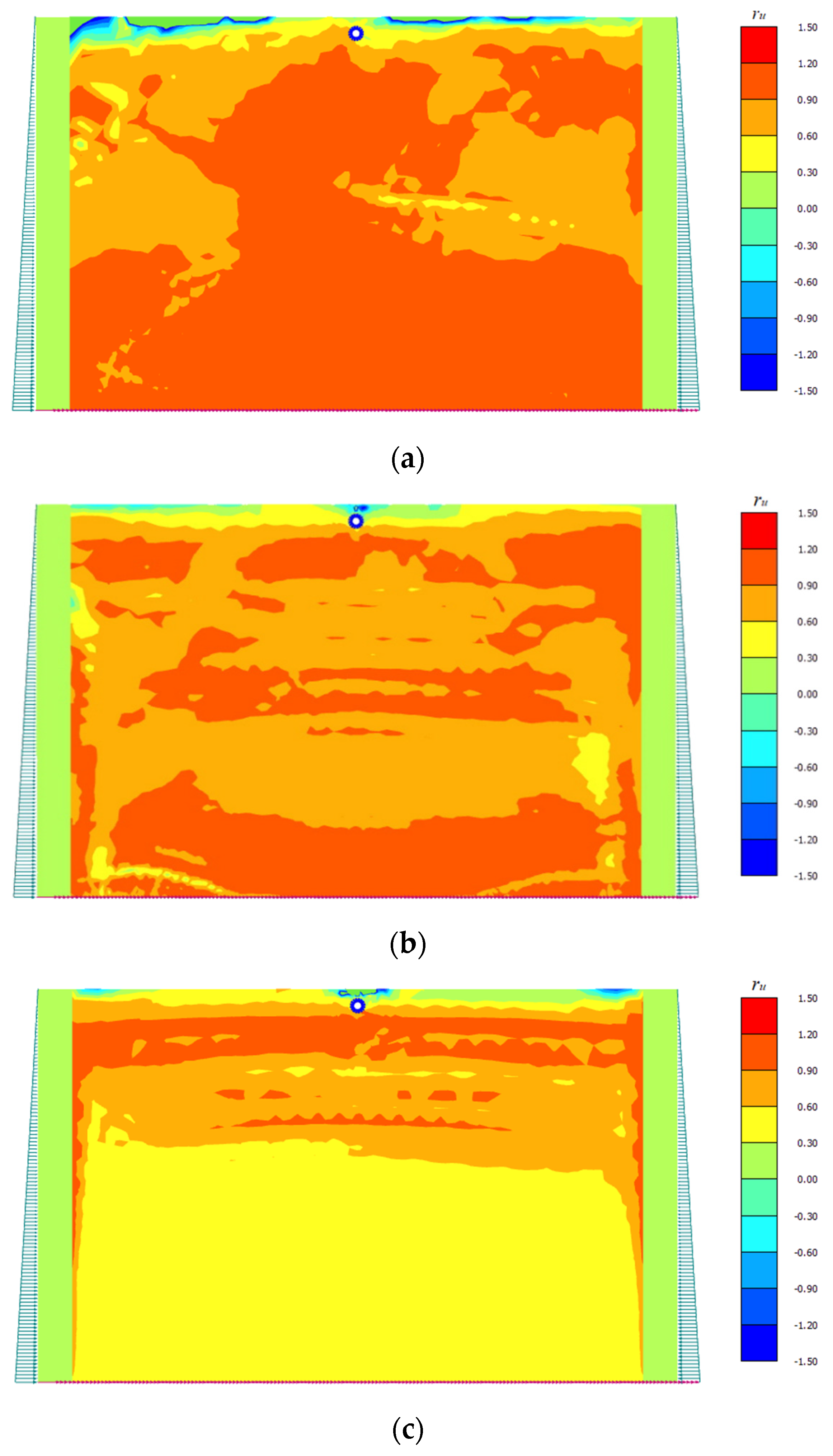

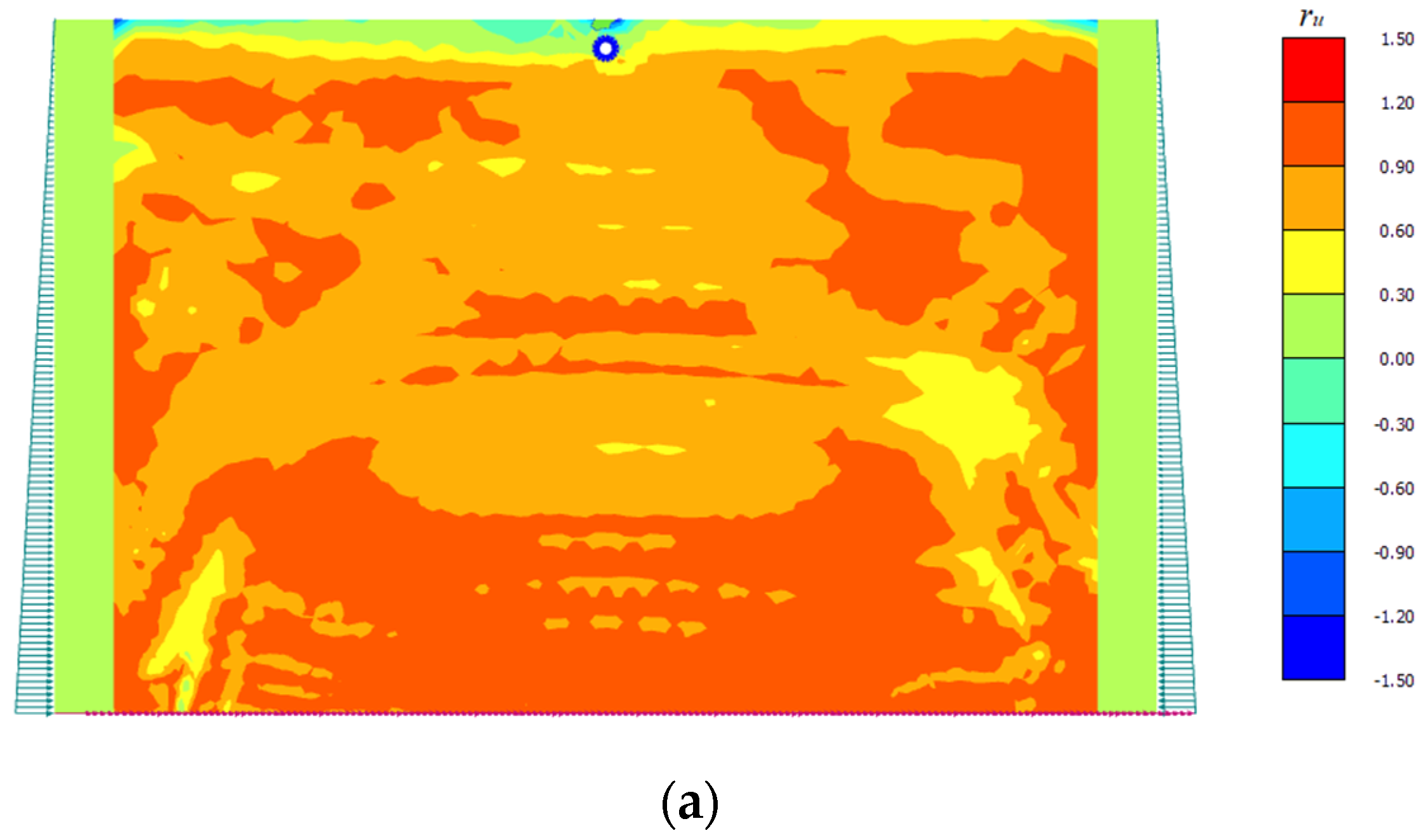

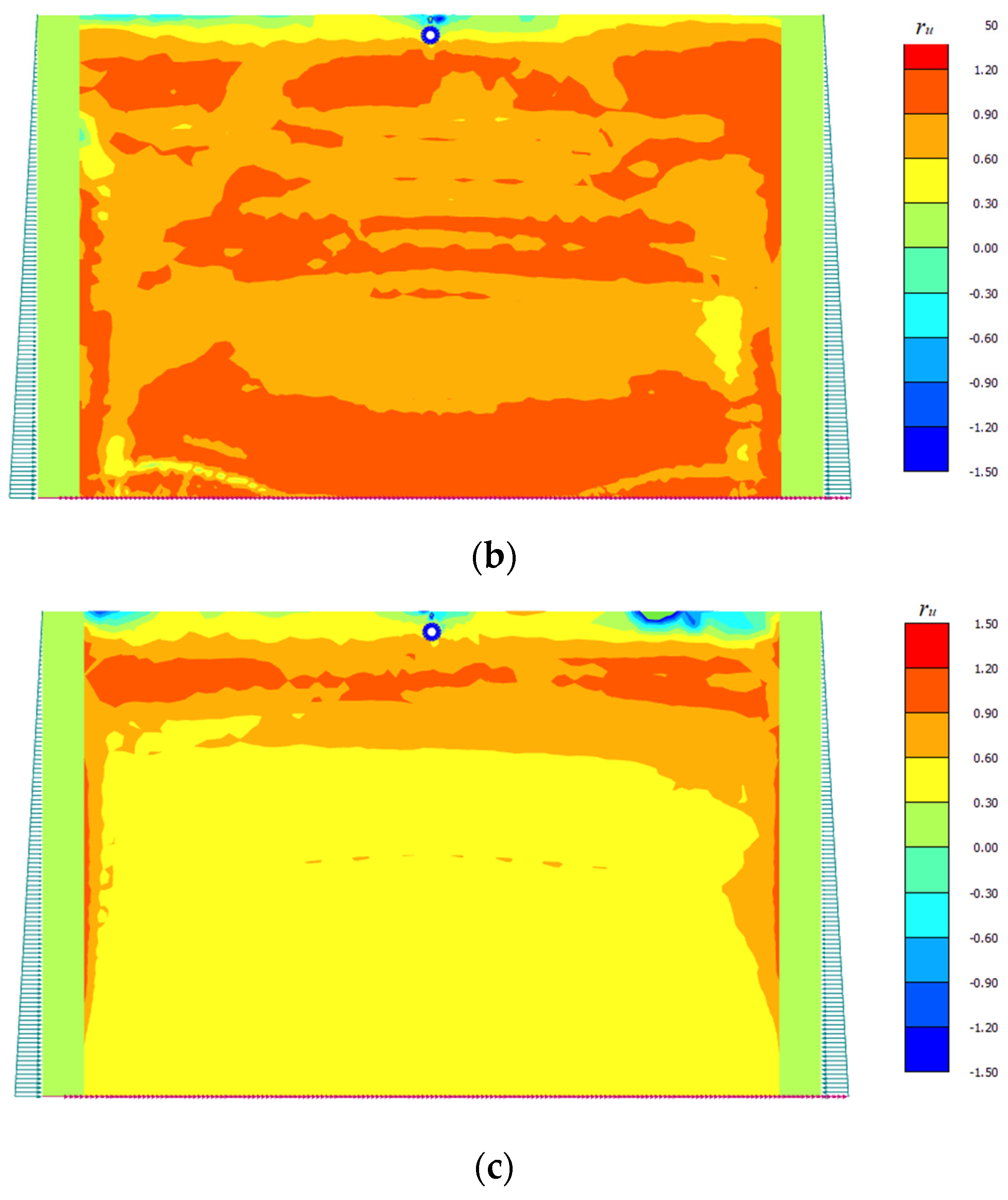

4.1. Liquefaction Potential of Soil Mass in the Earthquake Phase

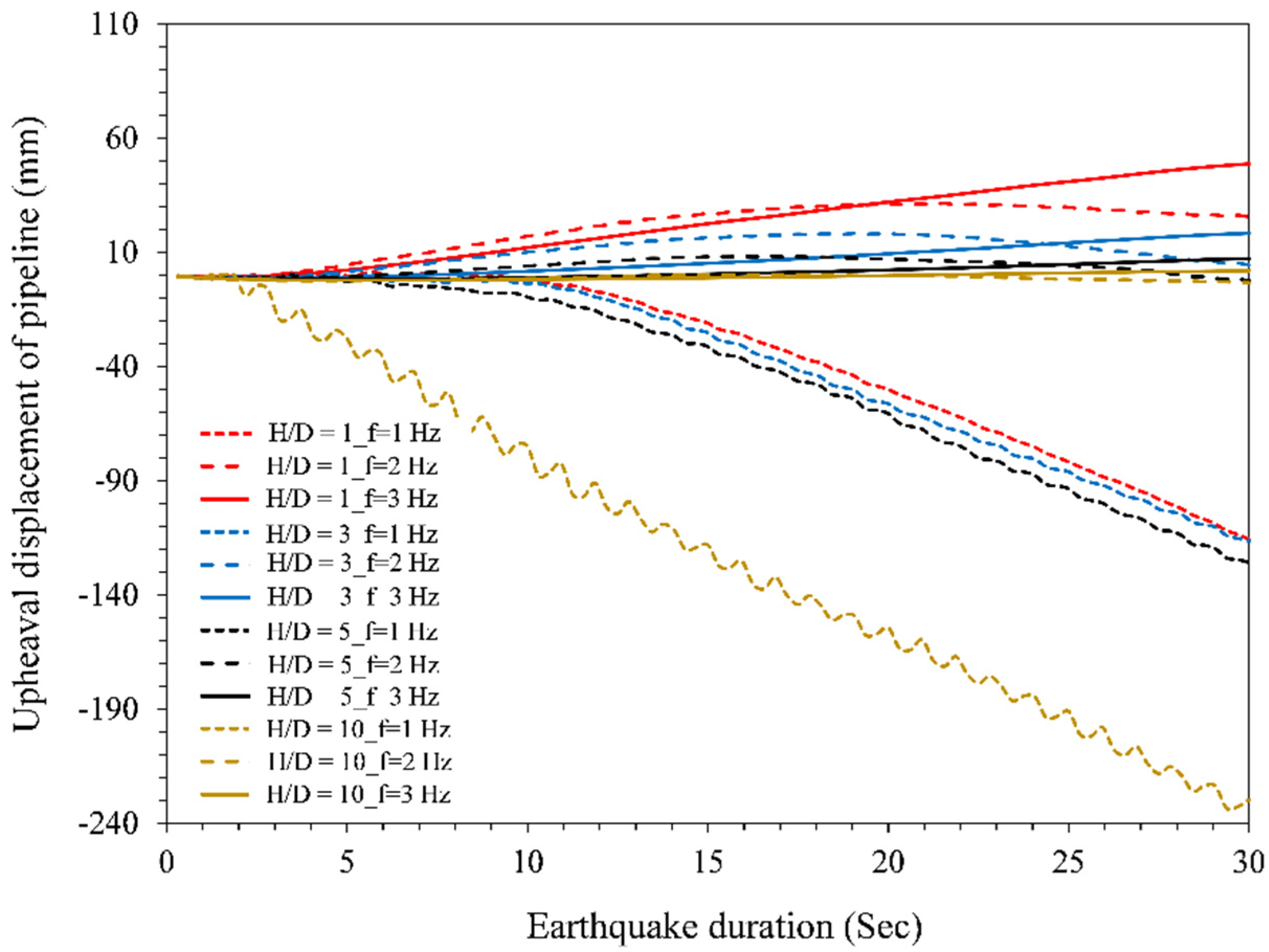

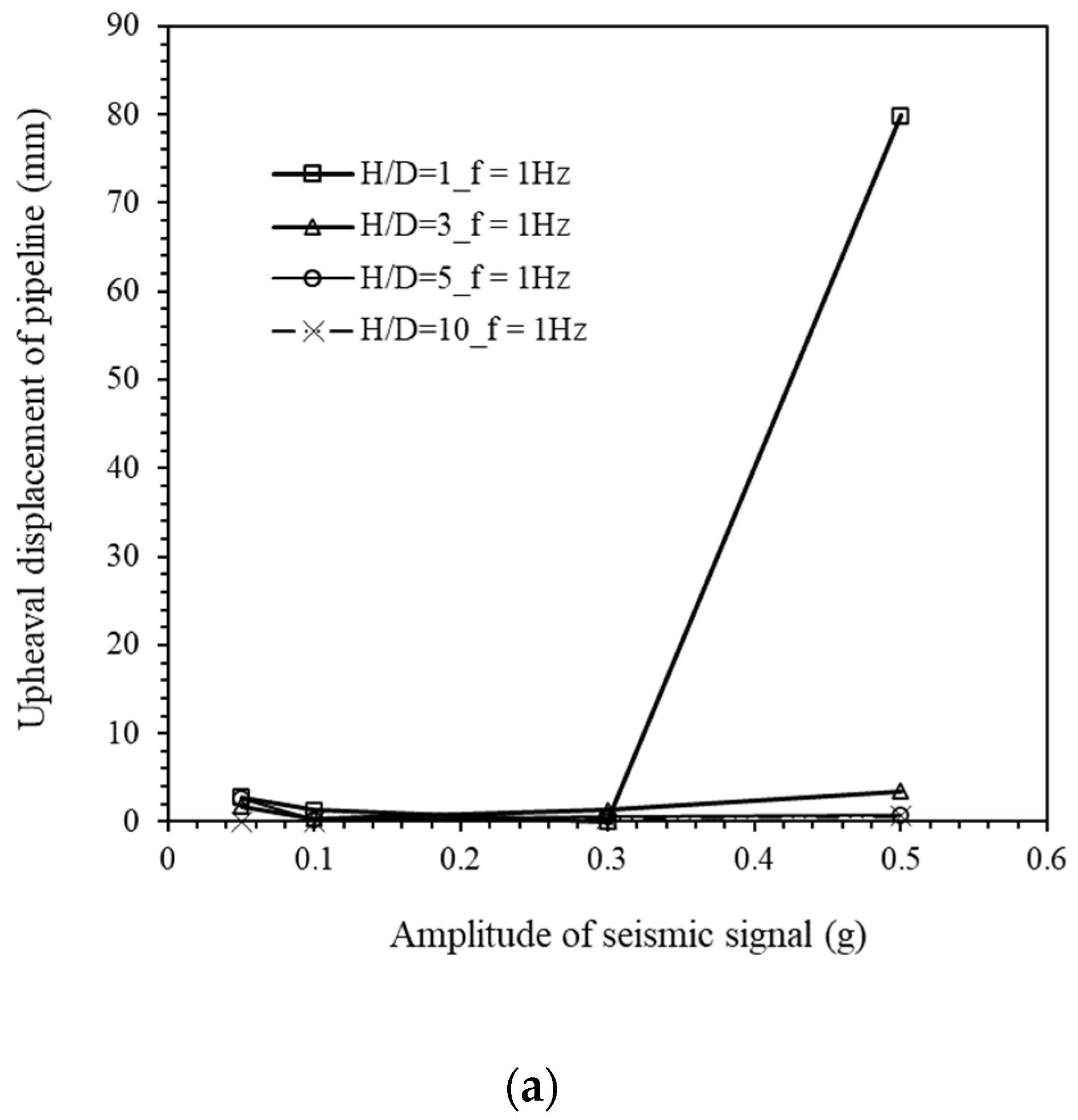

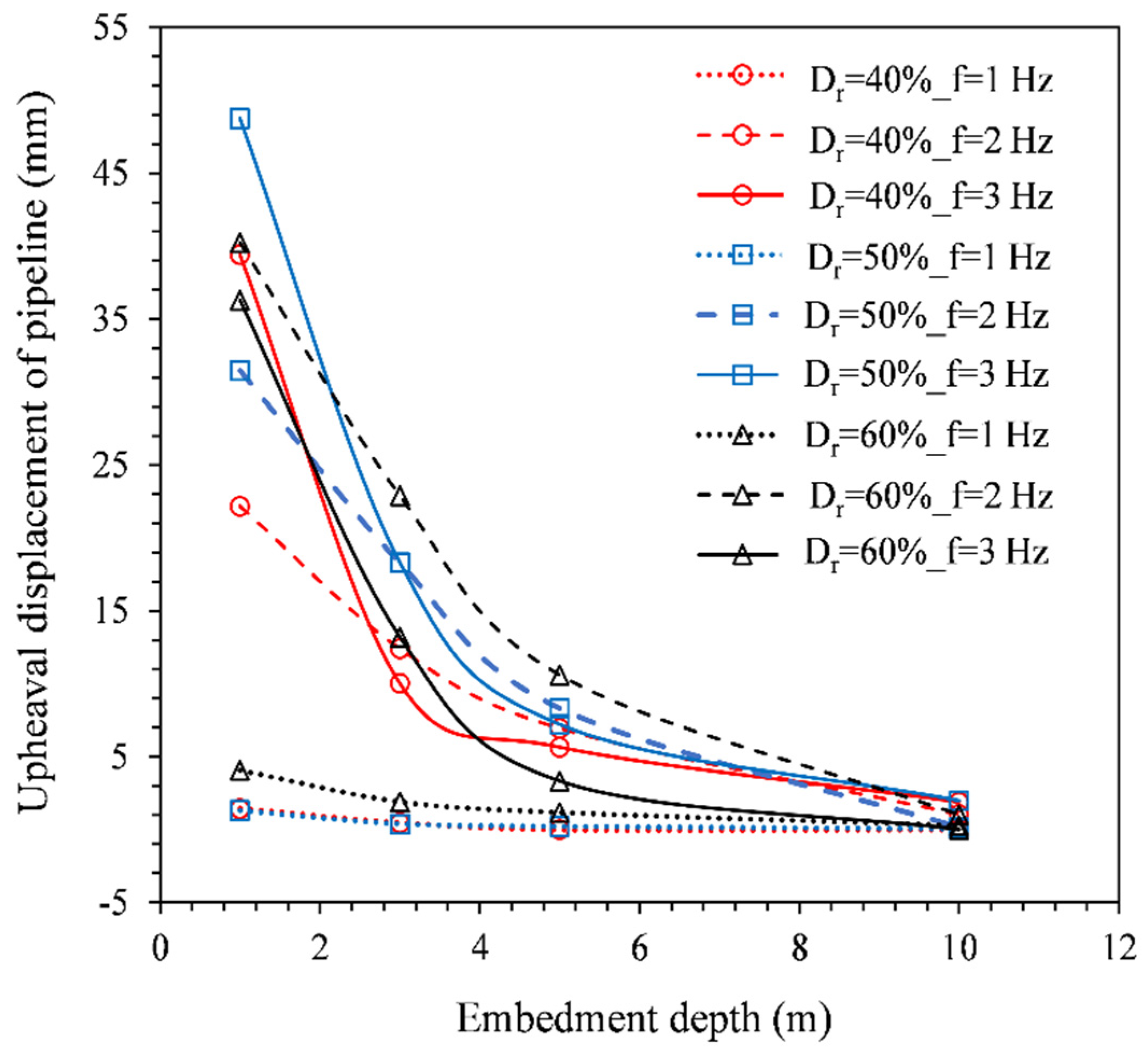

4.2. Upheaval Displacement/Floatation of the Pipeline in the Earthquake Phase

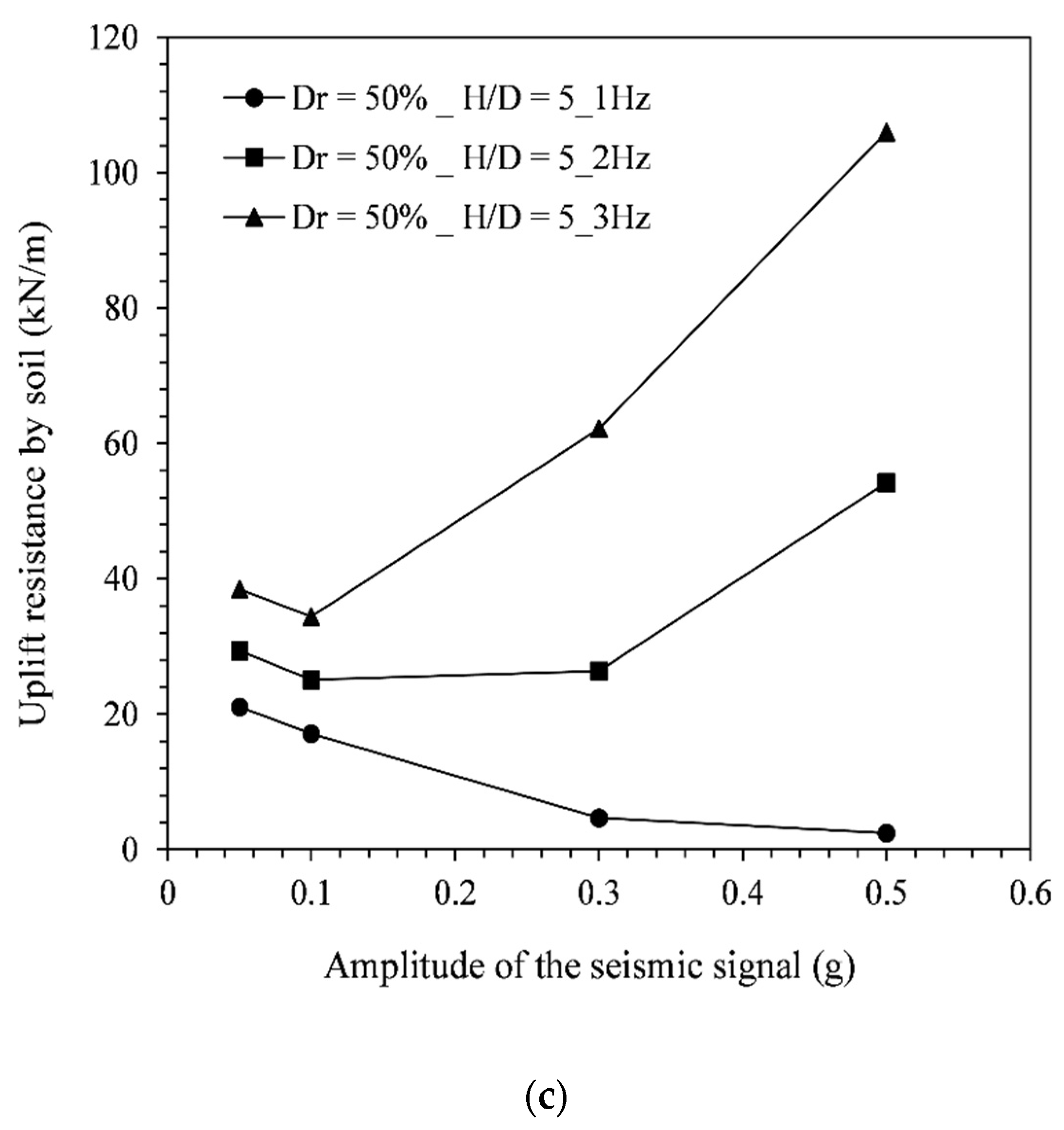

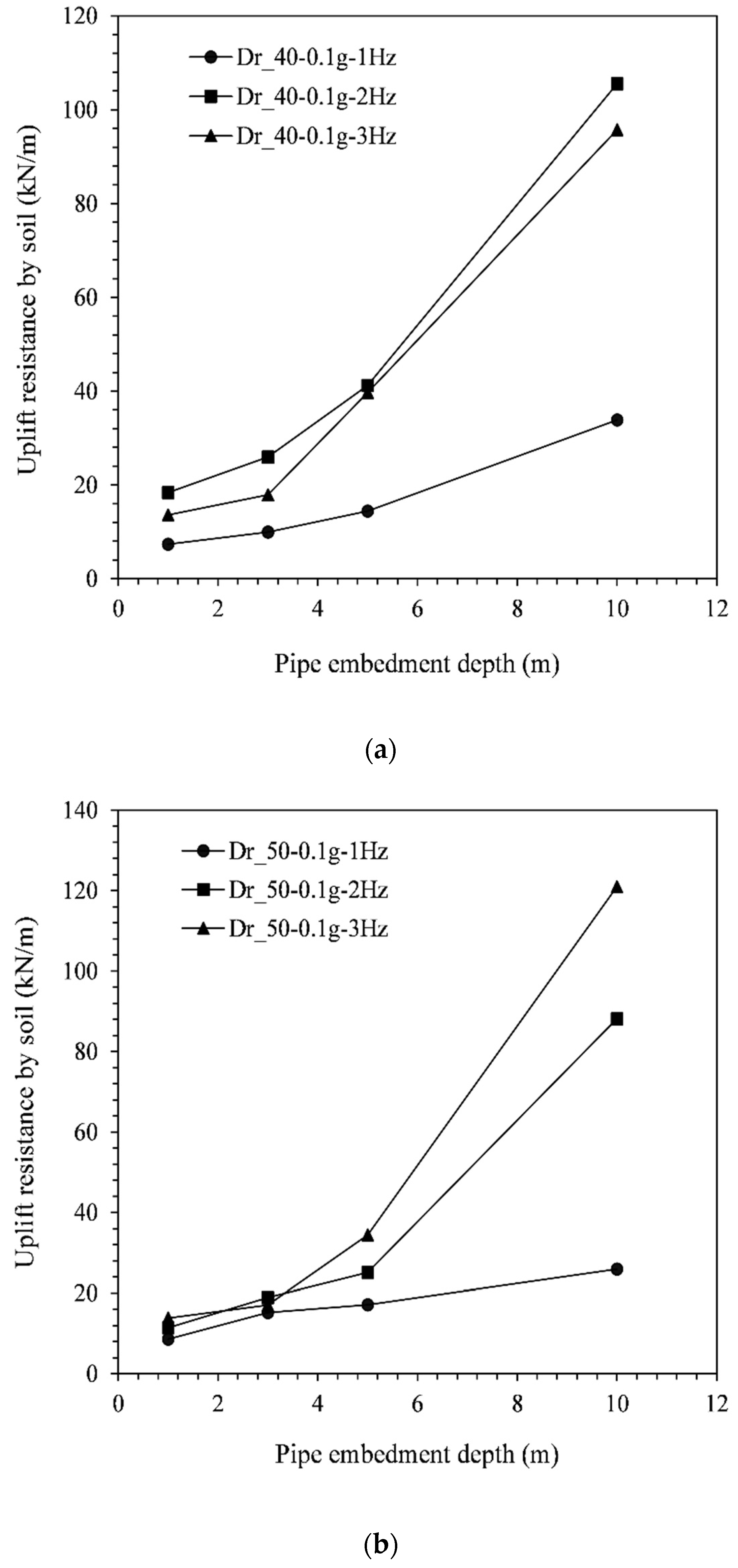

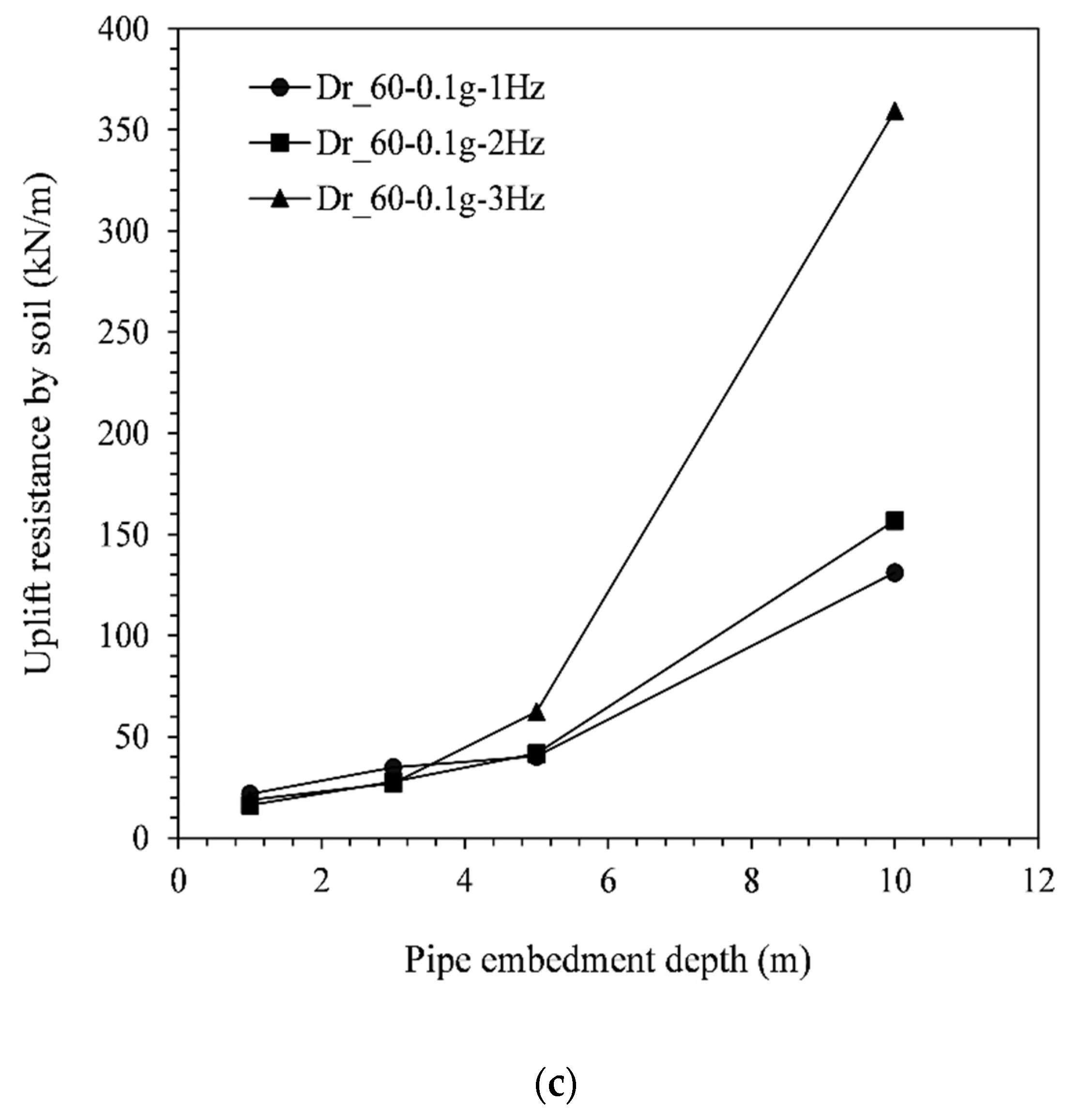

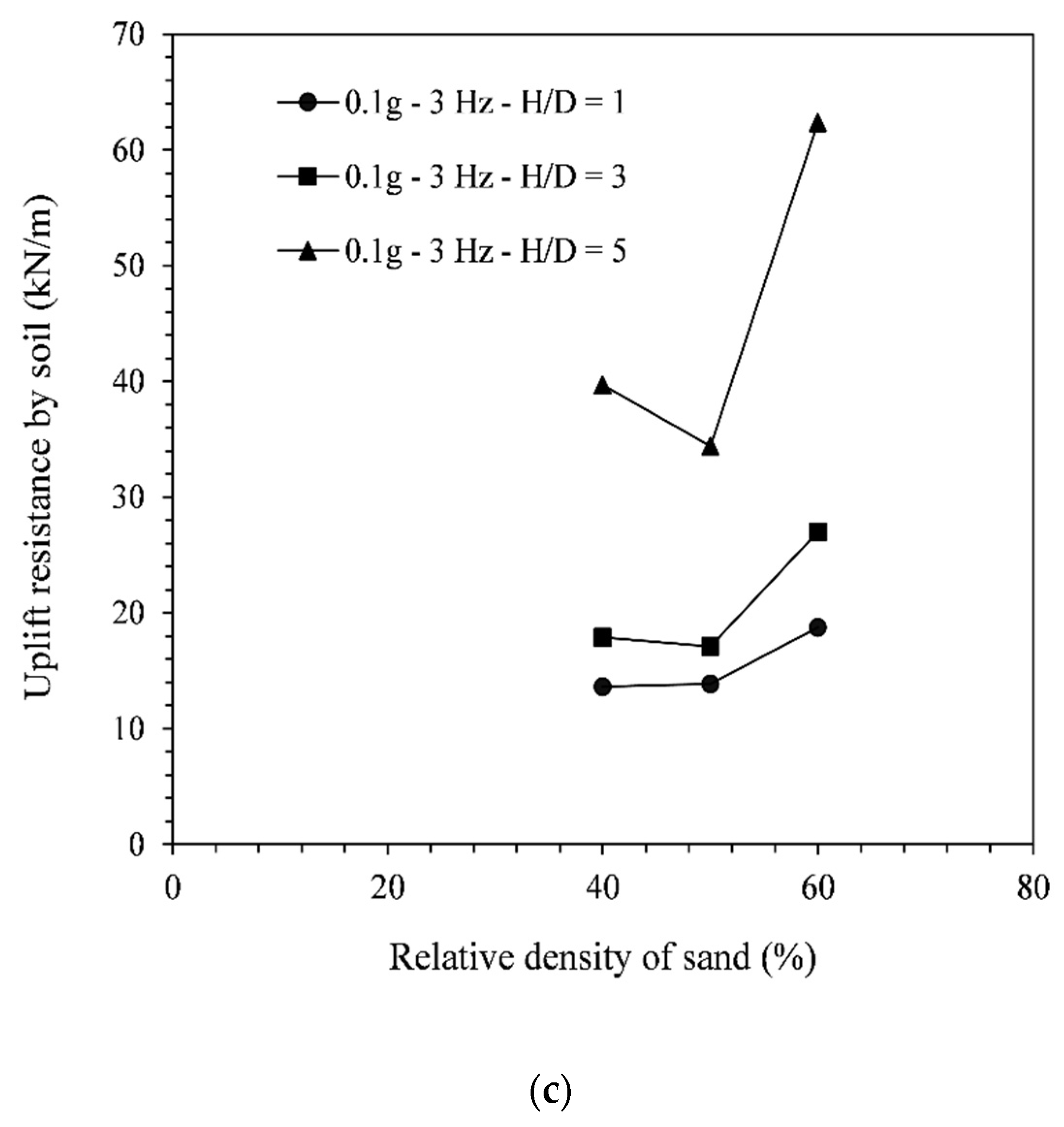

4.3. Post-Earthquake Uplift Resistance

5. Conclusions

- The liquefaction potential of the soil mass depends on the amplitude and frequency of the seismic signal, and on the relative density of the soil. For a given soil, the liquefaction potential was seen to decrease with the increase in the frequency and the amplitude of the seismic signal. However, when the soil relative density increases, the liquefaction potential at the upper layer of the soil was seen to increase, while the liquefaction potential at the middle and bottom layers of the soil was seen to decrease;

- The peak upheaval buckling of the pipeline is higher when the frequency of the seismic signal is also higher. However, the time to reach the peak upheaval buckling also increased with the increase of the signal frequency. On the other hand, the pipeline upheaval buckling decreased or remained the same initially when the amplitude of the seismic signal was increased for the analyzed cases;

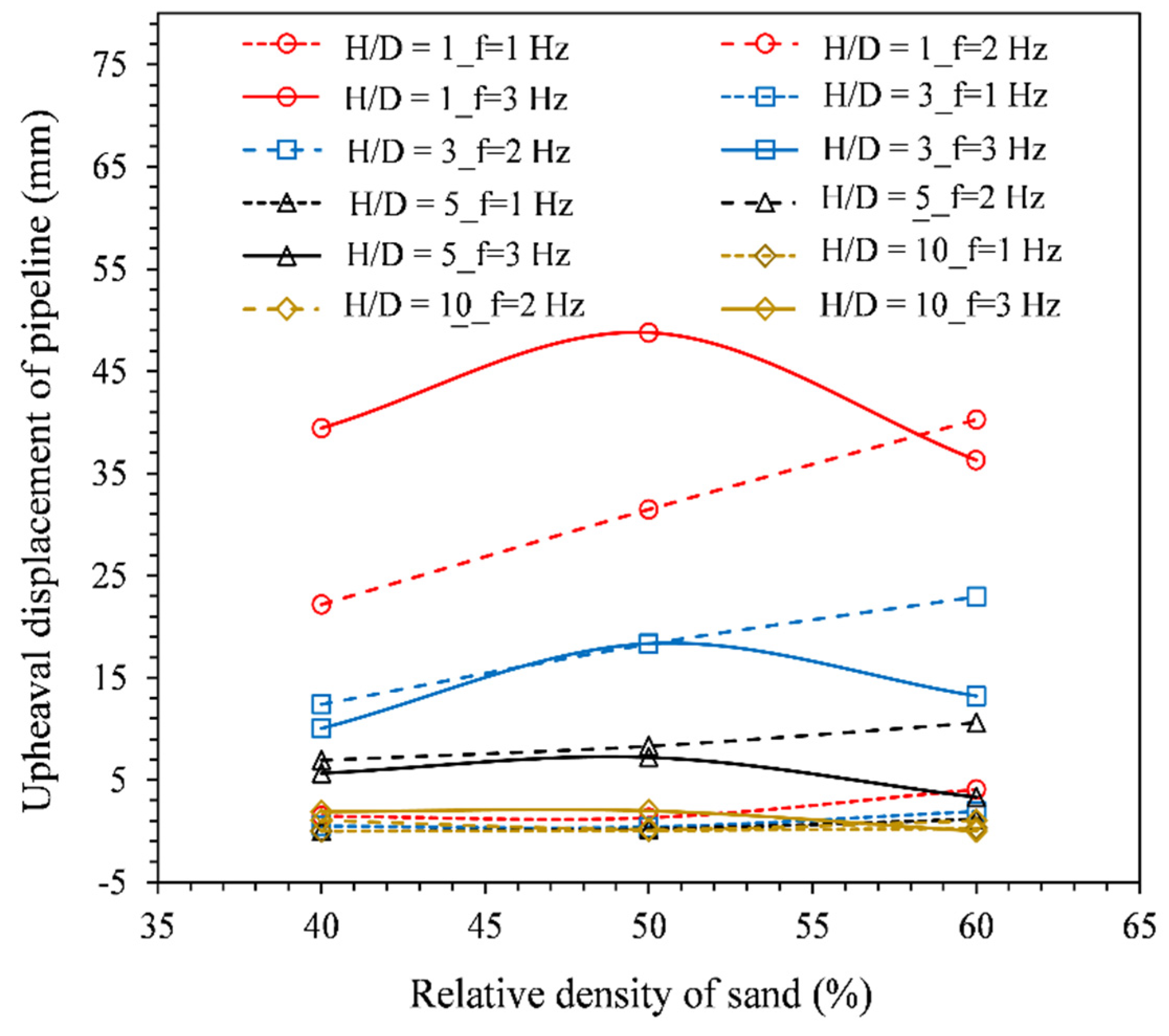

- The peak upheaval buckling of the pipeline was seen to consistently decrease when the embedment depth of the pipeline was increased. On the other hand, the relation between the pipeline upheaval buckling and the soil density was seen to also depend on the frequency of the seismic signal. For lower frequencies (1 Hz and 2 Hz), the upheaval buckling of the pipeline was seen to increase when the soil relative density was increased, while for a higher frequency (3 Hz) the pipeline upheaval buckling was higher for the mid value of the considered relative densities of the soil;

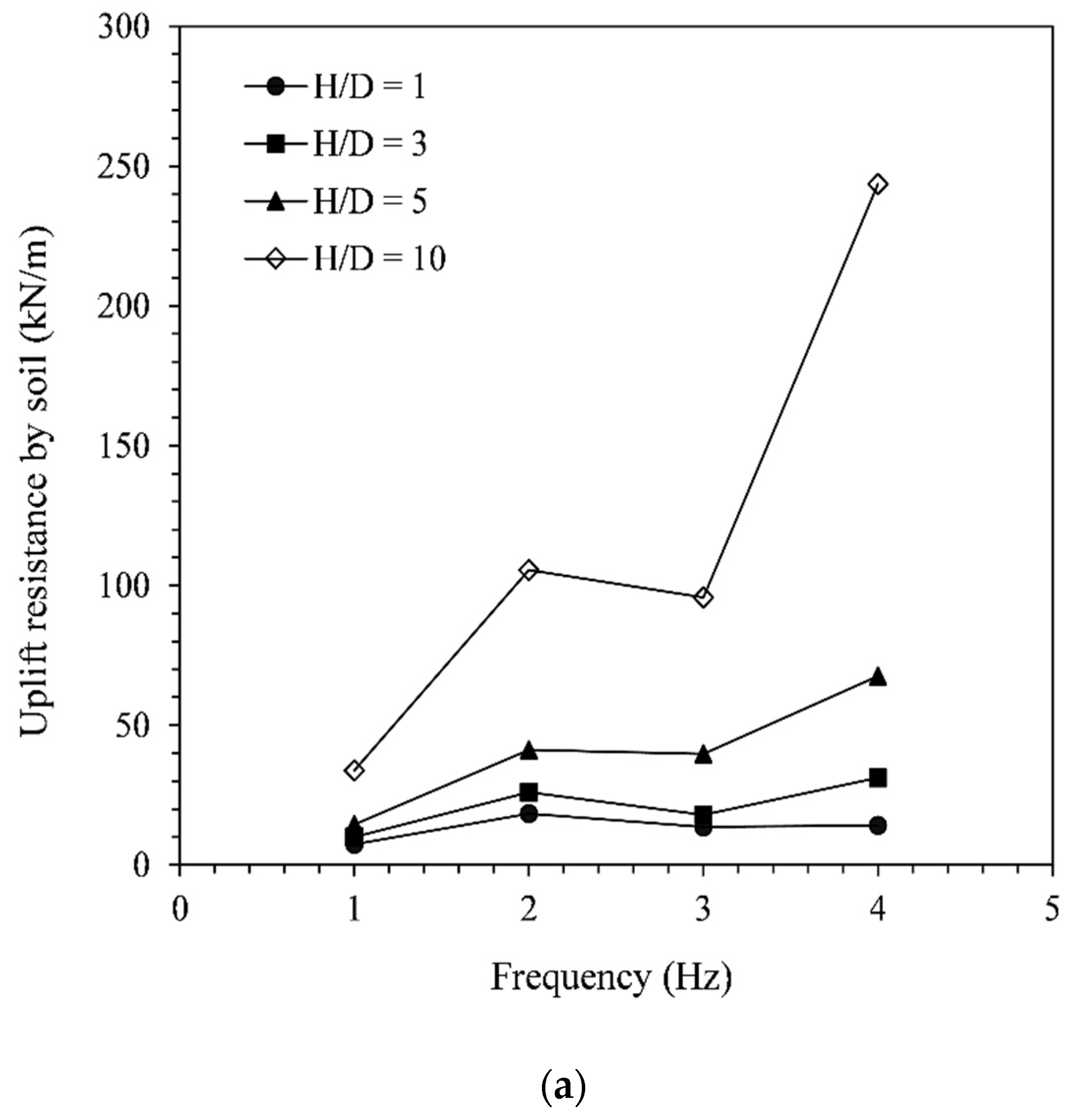

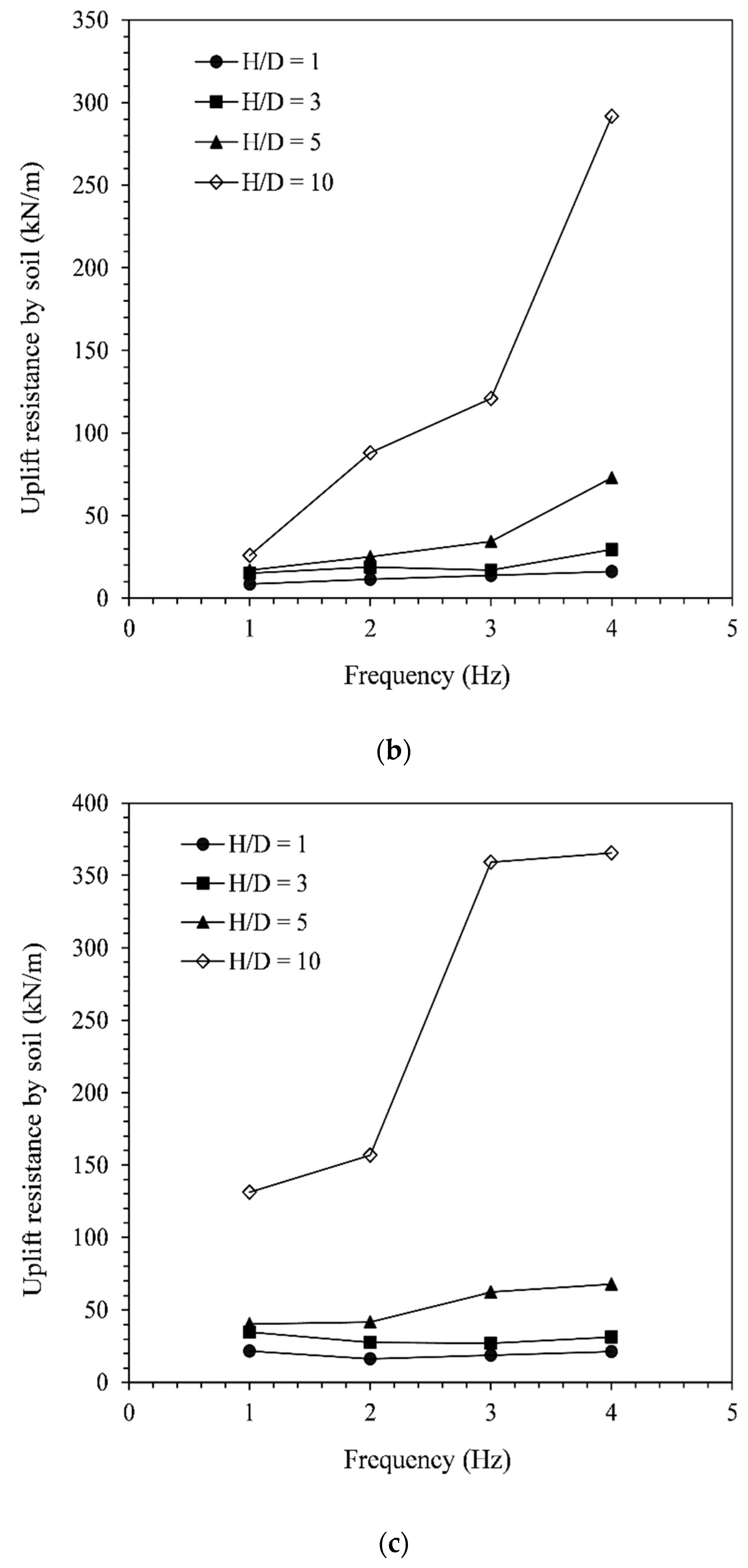

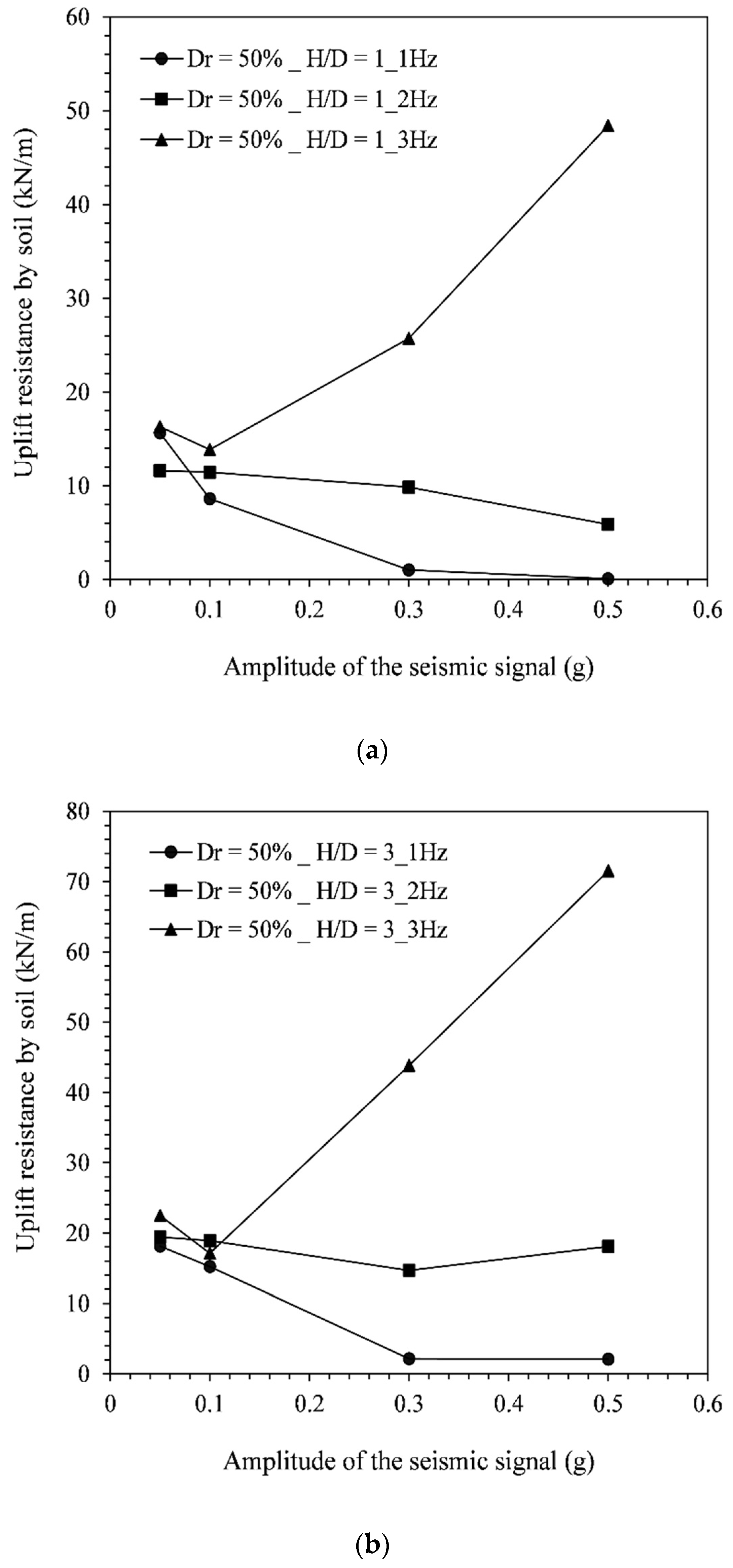

- The post-shake uplift resistance of the pipeline (Vup) showed an overall increasing trend with the seismic signal frequency. Moreover, the Vup initially decreased with the increasing seismic signal amplitude up to the lowest magnitude. After that, the Vup showed an increasing trend with the seismic signal amplitude. The relationship between Vup and signal amplitude is also observed to be influenced by the signal frequency and pipe embedment depth;

- The post-shake uplift resistance of the pipeline was seen to increase when increasing the embedment depth, and this variation was found to be independent of the seismic signal. However, the variation of Vup with the soil relative density was found to depend on the frequency of the seismic signal. For the lowest frequency (1 Hz), Vup increased when the soil density was increased, while for higher frequencies, Vup may decrease or increase when the soil density was increased.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Maitra, S.; Chatterjee, S.; Choudhury, D. Generalized framework to predict undrained uplift capacity of buried offshore pipelines. Can. Geotech. J. 2016, 53, 1841–1852. [Google Scholar] [CrossRef]

- Seth, D.; Manna, B.; Kumar, P.; Shahu, J.T.; Fazeres-Ferradosa, T.; Taveira-Pinto, F.; Rosa-Santos, P.; Carvalho, H. Uplift and lateral buckling failure mechanisms of offshore pipes buried in normally consolidated clay. Eng. Fail. Anal. 2021, 121, 105161. [Google Scholar] [CrossRef]

- Seth, D.; Manna, B.; Shahu, J.T.; Fazeres-Ferradosa, T.; Pinto, F.T.; Rosa-Santos, P.J. Buckling Mechanism of Offshore Pipelines: A State of the Art. J. Mar. Sci. Eng. 2021, 9, 1074. [Google Scholar] [CrossRef]

- Schiff, A.J. Northridge Earthquake: Lifeline Performance and Post-Earthquake Response; ASCE: New York, NY, USA, 1995. [Google Scholar]

- Chou, H.S.; Yang, C.Y.; Hsieh, B.J.; Chang, S.S. A study of liquefaction related damages on shield tunnels. Tunn. Undergr. Space Technol. 2001, 16, 185–193. [Google Scholar] [CrossRef]

- Murray, E.J.; Geddes, J.D. Uplift of anchor plates in sand. J. Geotech. Eng. 1987, 113, 202–215. [Google Scholar] [CrossRef]

- Singh, S.P.; Tripathy, D.P.; Ramaswamy, S.V. Estimation of uplift capacity of rapidly loaded plate anchors in soft clay. Mar. Georesour. Geotechnol. 2007, 25, 237–249. [Google Scholar] [CrossRef]

- Newson, T.A.; Deljoui, P. Finite element modelling of upheaval buckling of buried offshore pipelines in clayey soils. Soil Rock Behav. Model. 2006, 351–358. [Google Scholar]

- Liu, R.; Xiong, H.; Wu, X.; Yan, S. Numerical studies on global buckling of subsea pipelines. Ocean. Eng. 2014, 78, 62–72. [Google Scholar] [CrossRef]

- Schotman, G.J.M.; Stork, F.G. Pipe-soil interaction: A model for laterally loaded pipelines in clay. In Offshore Technology Conference; OnePetro: Richardson, TX, USA, 1987. [Google Scholar]

- El-Gharbawy, S. Uplift capacity of buried offshore pipelines. In Proceedings of the Sixteenth International Offshore and Polar Engineering Conference, San Francisco, CA, USA, 28 May–2 June 2006; OnePetro: Richardson, TX, USA, 2006. [Google Scholar]

- Gao, X.F.; Liu, R.; Yan, S.W. Model test based soil spring model and application in pipeline thermal buckling analysis. China Ocean. Eng. 2011, 25, 507–518. [Google Scholar] [CrossRef]

- Liu, R.; Yan, S.; Wu, X. Model test studies on soil restraint to pipeline buried in Bohai soft clay. J. Pipeline Syst. Eng. Pract. 2013, 4, 49–56. [Google Scholar] [CrossRef]

- Randolph, M.F.; Houlsby, G.T. The limiting pressure on a circular pile loaded laterally in cohesive soil. Geotechnique 1984, 34, 613–623. [Google Scholar] [CrossRef]

- Schaminee, P.E.L.; Zorn, N.F.; Schotman, G.J.M. Soil response for pipeline upheaval buckling analyses: Full-scale laboratory tests and modelling. In Offshore Technology Conference; OnePetro: Richardson, TX, USA, 1990. [Google Scholar]

- Liu, R.; Basu, P.; Xiong, H. Laboratory tests and thermal buckling analysis for pipes buried in Bohai soft clay. Mar. Struct. 2015, 43, 44–60. [Google Scholar] [CrossRef]

- Chen, R.P.; Zhu, B.; Ni, W.J. Uplift tests on full-scale pipe segment in lumpy soft clay backfill. Can. Geotech. J. 2016, 53, 578–588. [Google Scholar] [CrossRef]

- Seth, D.; Manna, B.; Shahu, J.T.; Fazeres-Ferradosa, T.; Taveira-Pinto, F.; Rosa-Santos, P.; Pinto, F.V.T. Offshore pipeline buried in Indian coastal clay: Buckling behaviour analysis. Ships Offshore Struct. 2021, 1–16. [Google Scholar] [CrossRef]

- Merifield, R.; White, D.J.; Randolph, M.F. The ultimate undrained resistance of partially embedded pipelines. Géotechnique 2008, 58, 461–470. [Google Scholar] [CrossRef]

- Trautmann, C.H. Behavior of Pipe in Dry Sand under Lateral and Uplift Loading. Ph.D. Thesis, Cornell University, New York, NY, USA, 1983. [Google Scholar]

- Robert, D.J.; Thusyanthan, N.I. Numerical and experimental study of uplift mobilization of buried pipelines in sands. J. Pipeline Syst. Eng. Pract. 2015, 6, 04014009. [Google Scholar] [CrossRef] [Green Version]

- Roy, K.; Hawlader, B.; Kenny, S.; Moore, I. Uplift failure mechanisms of pipes buried in dense sand. Int. J. Geomech. 2018, 18, 04018087. [Google Scholar] [CrossRef]

- Cheuk, C.Y.; White, D.J.; Bolton, M.D. Deformation mechanisms during uplift of buried pipes in sand. In Proceedings of the 16th International Conference on Soil Mechanics and Geotechnical Engineering, Osaka, Japan, 19–21 April 2005; IOS Press: Amsterdam, The Netherlands, 2005; pp. 1685–1688. [Google Scholar]

- Cheuk, C.Y.; Take, W.A.; Bolton, M.D.; Oliveira, J.R.M.S. Soil restraint on buckling oil and gas pipelines buried in lumpy clay fill. Eng. Struct. 2007, 29, 973–982. [Google Scholar] [CrossRef]

- Kumar, P.; Seth, D.; Manna, B.; Shahu, J.T. Lateral and Uplift Capacity of Pipeline Buried in Seabed of Homogeneous Clay. J. Pipeline Syst. Eng. Pract. 2021, 12, 04021020. [Google Scholar] [CrossRef]

- Pedersen, P.T.; Jensen, J.J. Upheaval creep of buried heated pipelines with initial imperfections. Mar. Struct. 1988, 1, 11–22. [Google Scholar] [CrossRef]

- Wang, Y.; Zhang, X.; Zhao, Y.; Chen, H.; Duan, M.; Estefen, S.F. Perturbation analysis for upheaval buckling of imperfect buried pipelines based on nonlinear pipe-soil interaction. Ocean. Eng. 2017, 132, 92–100. [Google Scholar] [CrossRef]

- Ling, H.I.; Sun, L.; Liu, H.; Mohri, Y.; Kawabata, T. Finite element analysis of pipe buried in saturated soil deposit subject to earthquake loading. J. Earthq. Tsunami 2008, 2, 1–17. [Google Scholar] [CrossRef]

- Saeedzadeh, R.; Hataf, N. Uplift response of buried pipelines in saturated sand deposit under earthquake loading. Soil Dyn. Earthq. Eng. 2011, 31, 1378–1384. [Google Scholar] [CrossRef]

- Wang, L.R.L.; Shim, J.S.; Ishibashi, I.; Wang, Y. Dynamic responses of buried pipelines during a liquefaction process. Soil Dyn. Earthq. Eng. 1990, 9, 44–50. [Google Scholar] [CrossRef]

- Maotian, L.; Xiaoling, Z.; Qing, Y.; Ying, G. Numerical analysis of liquefaction of porous seabed around pipeline fixed in space under seismic loading. Soil Dyn. Earthq. Eng. 2009, 29, 855–864. [Google Scholar] [CrossRef]

- Azadi, M.; Hosseini, S.M.M. Analyses of the effect of seismic behavior of shallow tunnels in liquefiable grounds. Tunn. Undergr. Space Technol. 2010, 25, 543–552. [Google Scholar] [CrossRef]

- Huang, B.; Liu, J.; Lin, P.; Ling, D. Uplifting behavior of shallow buried pipe in liquefiable soil by dynamic centrifuge test. Sci. World J. 2014, 2014, 838546. [Google Scholar] [CrossRef]

- Sharafi, H.; Parsafar, P. Seismic simulation of liquefaction-induced uplift behavior of buried pipelines in shallow ground. Arab. J. Geosci. 2016, 9, 215. [Google Scholar] [CrossRef]

- Kutanaei, S.S.; Choobbasti, A.J. Prediction of liquefaction potential of sandy soil around a submarine pipeline under earthquake loading. J. Pipeline Syst. Eng. Pract. 2019, 10, 04019002. [Google Scholar] [CrossRef]

- Ling, H.I.; Mohri, Y.; Kawabata, T.; Liu, H.; Burke, C.; Sun, L. Centrifugal modeling of seismic behavior of large-diameter pipe in liquefiable soil. J. Geotech. Geoenviron. Eng. 2003, 129, 1092–1101. [Google Scholar] [CrossRef]

- Kutanaei, S.S.; Choobbasti, A.J. Effect of the fluid weight on the liquefaction potential around a marine pipeline using CVFEM. EJGE 2013, 18, 633–646. [Google Scholar]

- Chian, S.C.; Madabhushi, S.P.G. Effect of buried depth and diameter on uplift of underground structures in liquefied soils. Soil Dyn. Earthq. Eng. 2012, 41, 181–190. [Google Scholar] [CrossRef]

- Boulanger, R.W.; Ziotopoulou, K. PM4Sand (Version 3.1): A Sand Plasticity Model for Earthquake Engineering Applications; Report No. UCD/CGM-17/01; Center for Geotechnical Modeling, Department of Civil and Environmental Engineering, University of California, Davis: Davis, CA, USA, 2017. [Google Scholar]

- Brinkgreve, R.B.J.; Kumarswamy, S.; Swolfs, W.M.; Waterman, D.; Chesaru, A.; Bonnier, P.G. PLAXIS 2016; PLAXIS B.V.: Delft, The Netherlands, 2016. [Google Scholar]

- Vilhar, G.; Brinkgreve, R. Plaxis the PM4Sand Model; PLAXIS B.V.: Delft, The Netherlands, 2018. [Google Scholar]

- Minga, E.; Burd, H.J. Validation of the PLAXIS MoDeTo 1D Model for Dense Sand. 2019. Available online: https://communities.bentley.com/products/geotech-analysis/w/plaxis-soilvision-wiki/45423/validation-report-of-plaxis-modeto-based-on-the-dunkirk-sand-pisa-field-tests (accessed on 25 June 2022).

- Bray, J.D.; Luque, R. Seismic performance of a building affected by moderate liquefaction during the Christchurch earthquake. Soil Dyn. Earthq. Eng. 2017, 102, 99–111. [Google Scholar] [CrossRef]

- Ziotopoulou, K. Seismic response of liquefiable sloping ground: Class A and C numerical predictions of centrifuge model responses. Soil Dyn. Earthq. Eng. 2018, 113, 744–757. [Google Scholar] [CrossRef]

- Millen, M.D.L.; Rios, S.; Quintero, J.; da Fonseca, A.V. Prediction of time of liquefaction using kinetic and strain energy. Soil Dyn. Earthq. Eng. 2020, 128, 105898. [Google Scholar] [CrossRef]

- Tosi, P.; Sbarra, P.; De Rubeis, V. Earthquake sound perception. Geophys. Res. Lett. 2012, 39, 24. [Google Scholar] [CrossRef]

- Dinesh, N.; Banerjee, S.; Rajagopal, K. Performance evaluation of PM4Sand model for simulation of the liquefaction remedial measures for embankment. Soil Dyn. Earthq. Eng. 2022, 152, 107042. [Google Scholar] [CrossRef]

- Sasaki, T.; Tamura, K. Prediction of liquefaction-induced uplift displacement of underground structures. In Proceedings of the 36th Joint Meeting US-Japan Panel on Wind and Seismic Effects, Gaithersburg, MD, USA, 17–22 May 2004. [Google Scholar]

- Castiglia, M. The Experimental Study of Buried Onshore Pipelines Seismic-Liquefaction Induced Vertical Displacement in Shaking Table Tests and Its Remedial Measures. Ph.D. Thesis, University of Molise, Campobasso, Italy, 2019. [Google Scholar]

- Kitaura, M.; Miyajima, M.; Suzuki, H. Response analysis of buried pipelines considering rise of ground water table in liquefaction processes. Doboku Gakkai Ronbunshu 1987, 1987, 173–180. [Google Scholar] [CrossRef] [Green Version]

- Kong, D. Quantifying Residual Resistance of Light Pipelines during Large-Amplitude Lateral Displacement Using Sequential Limit Analysis. J. Geotech. Geoenviron. Eng. 2022, 148, 04022054. [Google Scholar] [CrossRef]

- Sabetamal, H. Finite Element Algorithms for Dynamic Analysis of Geotechnical Problems. Ph.D. Thesis, The University of Newcastle, Newcastle, Australia, 2015. [Google Scholar]

- Dutta, S.; Hawlader, B.; Phillips, R. Finite element modeling of partially embedded pipelines in clay seabed using Coupled Eulerian–Lagrangian method. Can. Geotech. J. 2015, 52, 58–72. [Google Scholar] [CrossRef]

- Chen, B.; Wang, D.; Li, H.; Sun, Z.; Shi, Y. Characteristics of earthquake ground motion on the seafloor. J. Earthq. Eng. 2015, 19, 874–904. [Google Scholar] [CrossRef]

- Chen, B.; Wang, D.; Chen, S.; Hu, S. Influence of site factors on offshore ground motions: Observed Results and Numerical Simulation. Soil Dyn. Earthq. Eng. 2021, 145, 106729. [Google Scholar] [CrossRef]

- Fazeres-Ferradosa, T.; Rosa-Santos, P.; Taveira-Pinto, F.; Vanem, E.; Carvalho, H.; Correia, J. Editorial: Advanced research on offshore structures and foundation design: Part 1: Proceedings of the Institution of Civil Engineers. In Maritime Engineering; Thomas Telford Ltd.: London, UK, 2019; Volume 172, pp. 118–123. [Google Scholar] [CrossRef]

- Fazeres-Ferradosa, T.; Rosa-Santos, P.; Taveira-Pinto, F.; Pavlou, D.; Gao, F.-P.; Carvalho, H.; Oliveira-Pinto, S. Preface: Advanced Research on Offshore Structures and Foundation Design: Part 2 Proceedings of the Institution of Civil Engineers. In Maritime Engineering; Thomas Telford Ltd.: London, UK, 2020; Volume 173, pp. 96–99. [Google Scholar] [CrossRef]

- Taveira-Pinto, F.; Rosa-Santos, P.; Fazeres-Ferradosa, T. Marine renewable energy. Renew. Energy 2020, 150, 1160–1164. [Google Scholar] [CrossRef]

| Parameter | Input | ||

|---|---|---|---|

| Density Index of Nevada sand (Dr%) | 40 | 50 | 60 |

| Initial Void ratio (einit) | 0.715 | 0.682 | 0.649 |

| Saturated unit weight of soil (γsat) (kN/m3) | 19.25 | 19.55 | 19.74 |

| (kN/m2) | 2.40 × 104 | 3.00 × 104 | 3.60 × 104 |

| (kN/m2) | 2.40 × 104 | 3.00 × 104 | 3.60 × 104 |

| (kN/m2) | 7.20 × 104 | 9.00 × 104 | 1.08 × 105 |

| m | 0.58 | 0.54 | 0.52 |

| Friction angle (φ′) (degree) | 32.5 | 33.9 | 36.4 |

| Dilatancy angle (ψ) (degree) | 1.9 | 3.7 | 4.2 |

| (Mpa) | 87.2 | 94 | 100.8 |

| γ0.7 | 1.60 × 10−4 | 1.50 × 10−4 | 1.40 × 10−4 |

| Poisson ratio (ν′ur) | 0.3 | 0.3 | 0.3 |

| Pref (kN/m3) | 100 | 100 | 100 |

| Failure ratio (Rf) | 0.950 | 0.937 | 0.925 |

| Permeability of sand (Kx, Ky) (m/s) | 6.82 × 10−5 | 6.38 × 10−5 | 5.55 × 10−5 |

| Rayleigh damping α | 2 | 2 | 2 |

| Rayleigh damping β | 2.70 × 10−3 | 2.70 × 10−3 | 2.70 × 10−3 |

| Interface shear capacity (Rinter) | 1 | 1 | 1 |

| Interface tensile capacity | 0 | 0 | 0 |

| Parameter | Input | ||

|---|---|---|---|

| Density index of Nevada sand (Dr%) | 40 | 50 | 60 |

| Initial void ratio (einit) | 0.715 | 0.682 | 0.649 |

| Saturated unit weight of soil (γsat) (kN/m3) | 19.25 | 19.55 | 19.74 |

| Corrected SPT value ((N1)60) | 7 | 12 | 17 |

| Shear modulus coefficient (G0) | 514.73 | 635.92 | 737.45 |

| Contraction rate parameter (hp0) | 0.53 | 0.4 | 0.63 |

| Atmospheric pressure (pA) (kPa) | 101.3 | 101.3 | 101.3 |

| Maximum void ratio (emax) | 0.847 | 0.847 | 0.847 |

| Minimum void ratio (emin) | 0.517 | 0.517 | 0.517 |

| Bounding surface parameter (nb) | 0.5 | 0.5 | 0.5 |

| Dilatancy surface parameter (nd) | 0.1 | 0.1 | 0.1 |

| Critical state friction angle (φcv) (degree) | 33 | 33 | 33 |

| Poisson ratio (ν) | 0.3 | 0.3 | 0.3 |

| Critical state line parameter (Q) | 10 | 10 | 10 |

| Critical state line parameter (R) | 1.5 | 1.5 | 1.5 |

| Permeability of sand (Kx, Ky) (m/s) | 6.82 × 10−5 | 6.38 × 10−5 | 5.55 × 10−5 |

| Rayleigh damping α | 2 | 2 | 2 |

| Rayleigh damping β | 2.70 × 10−3 | 2.70 × 10−3 | 2.70 × 10−3 |

| Interface shear capacity (Rinter) | 1 | 1 | 1 |

| Interface tensile capacity | 0 | 0 | 0 |

| Parameter | Input |

|---|---|

| Element | Pipeline |

| Material type | Elastic |

| In-plane axial stiffness (kN/m) | 48 × 106 |

| Out-of-the-plane axial stiffness (kN/m) | 48 × 106 |

| Flexural rigidity (kN·m2/m) | 5.27 × 106 |

| Diameter (D) (m) | 1 |

| Unit weight of pipeline (kN/m/m) | 1 |

| Poisson’s ratio (ν) | 0.15 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Seth, D.; Manna, B.; Shahu, J.T.; Fazeres-Ferradosa, T.; Figueiredo, R.; Romão, X.; Rosa-Santos, P.; Taveira-Pinto, F. Numerical Modelling of the Effects of Liquefaction on the Upheaval Buckling of Offshore Pipelines Using the PM4Sand Model. Energies 2022, 15, 5561. https://doi.org/10.3390/en15155561

Seth D, Manna B, Shahu JT, Fazeres-Ferradosa T, Figueiredo R, Romão X, Rosa-Santos P, Taveira-Pinto F. Numerical Modelling of the Effects of Liquefaction on the Upheaval Buckling of Offshore Pipelines Using the PM4Sand Model. Energies. 2022; 15(15):5561. https://doi.org/10.3390/en15155561

Chicago/Turabian StyleSeth, Debtanu, Bappaditya Manna, Jagdish Telangrao Shahu, Tiago Fazeres-Ferradosa, Rui Figueiredo, Xavier Romão, Paulo Rosa-Santos, and Francisco Taveira-Pinto. 2022. "Numerical Modelling of the Effects of Liquefaction on the Upheaval Buckling of Offshore Pipelines Using the PM4Sand Model" Energies 15, no. 15: 5561. https://doi.org/10.3390/en15155561

APA StyleSeth, D., Manna, B., Shahu, J. T., Fazeres-Ferradosa, T., Figueiredo, R., Romão, X., Rosa-Santos, P., & Taveira-Pinto, F. (2022). Numerical Modelling of the Effects of Liquefaction on the Upheaval Buckling of Offshore Pipelines Using the PM4Sand Model. Energies, 15(15), 5561. https://doi.org/10.3390/en15155561