The computational and simulation work is divided into two parts: modelling of laminar flow and heat transfer analysis. The behaviour of air along the surface is predicted with the help of a nonlinear grey model for discreet sampling rate, whereas the heat transfer is based on a continuous-time state–space model.

3.1. Airflow Modelling

The variation in dimensionless velocity

with the stretching factor (

η) is shown in

Figure 3. In the case of a solar collector equipped with a circular chimney, the analytical solution of the Blasius equation was compared with the grey model box proposed for a similar flow regime (

Figure 3a). According to the physical interpretation, the ratio of local velocity (

u) to the mainstream velocity (

U) near the solid boundary of the absorber plate predicts the slip condition for the proposed grey model. As compared to the analytical solution, the gradient of the dimensionless velocity

derived from the grey model was increased by 27.86% near the vicinity of the solid boundary. With the further increase in the stretching factor (

η), the relative change in the gradient of the dimensionless velocity derived from the grey model dropped by 11.41%. This also implies that the nonlinear model has relatively poor approximation near the solid boundary if the system is operated by a circular chimney. Thus, the model is unable to distinguish whether it is continuum flow or slip flow. The Knudsen value would always be greater than 0.01 if the flow velocity is measured by the proposed scheme. The velocity at the boundary layer thickness (δ) was estimated to be lowered by 2% for the constant change in the stretching factor,

η. The relative skewness in the distribution pattern of

dropped by 18.76% for the grey model. Similarly, the kurtosis (Kr) in the grey model solution is 37.14% lower than that obtained through the analytical method. Relatively speaking, the solution derived from the grey model is more symmetric than the white box model. The likelihood of predicting the boundary condition through the white box model is relatively good as compared to the grey model. Despite the involvement of the viscous effect near the solid boundary, the grey model is relatively resilient to influencing the dimensionless velocity,

at

.

Likewise, to predict the solution for the conventional system (without a chimney), the change in the

ratio is shown in

Figure 3b. The slip condition was also predicted by the grey model solution for the conventional system. Relatively, a sharp rise in the gradient of dimensionless velocity by 174.57% was observed for the analytical solution (Blasius) in the vicinity of the solid boundary. The skewness in the distribution pattern of the dimensionless velocity fell by 96.90% in the solution of the grey model for the conventional system, which implies that the relative variation in the local velocity inside the boundary layer would be more symmetric or Gaussian in nature than that noticed in a system fitted with the circular chimney. Unlike the chimney system, the local velocity will approach the mainstream velocity with the increase in the stretching factor. The kurtosis of the dimensionless velocity distribution for the grey model was observed to drop by 40.38%. It is also clear that the analytical solution would have a better ability to determine the extreme values inside the boundary layer. It can be concluded the grey model would be much more reliable to predict the solution for the conventional system with the numerical uncertainty of ±0.06, which is 14.93% lower than that derived for the circular chimney.

The other solutions of the Blasius equation are also compared with the grey box model.

The change in the function value

f (

η) with the stretching factor (

η) for a circular chimney is shown in

Figure 4a. With the functional value of

f (

η), the stream function for the two-dimensional flow of air was computed. Unlike the derived solution of the Blasius equation, the functional value of

f (

η) derived through the nonlinear grey model dropped by 68.60% near the solid boundary of the absorber plate. This implies that the stream function value for the constant

η would be relatively low for the grey model. However, an inflexion in the mathematical solution of the grey model was noticed at

η = 1.3. Both the grey and the white box models exhibit the linearity of

f (

η) with the stretching factor,

η.

The stream function will not be zero at the solid boundary for the grey model, which shows that the normal and tangential components of velocity along the boundary layer would exist at the solid boundary. Thus, there is an existence of yield stress, for the air if its flow is monitored with the grey model, whereas it does not exist for the analytical solution of the Blasius equation. The distribution function of

f (

η) derived for the grey model is positively skewed (0.047). Conversely, the analytical solution exhibits negative skewness (−0.367) to the normal distribution function. It can be concluded that the prediction of stream function value through the grey model would be high near the boundary layer thickness,

δ. On the contrary, this is not the case for the analytical model, and the stream function may attain a higher value near the solid boundary of the absorber plate. Unlike

Figure 3, the asymmetric behaviour would differ while estimating the stream function value through the grey model. The kurtosis of the distribution function of

f (

η) was estimated to decrease by 11.67% for the grey model. As it was seen in the derived solutions of the dimensionless velocity, the probability of predicting the extreme value of stream function determined by the analytical model would not be properly estimated. However, the most important thing when estimating the solution is the adaptability of a model to the actual environment.

Similarly, both models were also compared for the conventional system in

Figure 4b. The characteristic of function

f (

η) for a conventional system is similar to the system equipped with the circular chimney, except there is no inflexion point observed. The stream function value proportionally dropped by 93.57% at the solid boundary for the conventional system. The distribution function of

f (

η) was also noticed to be positively skewed (0.0544), whereas the Blasius model for the conventional unit has a negative skewness of −0.0968. However, the kurtosis (Kr) of the solution derived through the grey model is marginally reduced by 0.74%. Relatively, to some extent, the forecasting ability of the grey model is akin to the Blasius model for the conventional system.

The second derivative of

f (η) for a system equipped with a circular chimney is illustrated in

Figure 5. The second derivative denotes the gradient of the dimensionless velocity discussed in

Figure 1. In the case of the nonlinear grey model, the gradient

would remain constant in the vicinity of the absorber plate, whereas the recorded drop in the analytical solution of

was 58% for the same domain of

η. Moving along the

Y-axis, the phenomenal change in

derived by the nonlinear grey model was 43.60% higher than that obtained for the analytical solution in the domain of

η (1.3, 1.95). In the given domain of stretching factor (

η), the change in

was relatively gradual for the analytical solution (Blasius). Both the models have a positive skewness, but the degree of skewness in the nonlinear grey model increased by 36%. In the same fashion, kurtosis is elevated by 44% for the grey model, which implies that the likelihood of variability in the gradient would be rather high for the grey model than its counterpart, the white box model.

The variation in

with the stretching factor for the conventional system (without chimney) is shown in

Figure 5b. At the solid boundary, as compared to the analytical solution (Blasius), the gradient value derived from the grey model is relatively decreased by 10.81% for the conventional system. However, the characteristic of the gradient curve derived from the grey model is the same for both the systems ((a) and (b)) near the surface of the absorber plate. The only difference is the gradual shift in the value of

with the stretching factor. Near the solid boundary, the gradient value for a system with a circular chimney would be 8.32% higher than that estimated for the conventional system by the same nonlinear grey model. It can be concluded that the boundary values, as well as the shape factor, will change with the change in the flow parameter of air at the inlet of the solar collector. A 2% drop in

was observed at the solid boundary when the same system was investigated with the help of the Blasius solution. The distribution of the numerical solution obtained from the nonlinear grey model has negative skewness, whereas the Blasius solution is positively skewed about the mean position of the normal distribution function. The difference proves that the likelihood of the existence of a higher gradient is more near the surface of the absorber plate for the grey model, while this is not the case for the numerical solution estimated from the Blasius equation. Upon comparing the fourth central moment in the data distribution, the kurtosis in the grey model solution is 10.45% higher than that derived for the analytical solution. So, the variability would be noticeably higher in the conventional system if the flow pattern is estimated via the nonlinear grey model than the Blasius model. The sharp change in the gradient would occur at

η = 1.245 for the Blasius model, whereas it happens at 1.761 if the same system is examined by a nonlinear grey model. The susceptibility of the model to being affected by the stretching factor is relatively low in the nonlinear grey model.

In

Figure 6, the numerical solutions derived from the white and grey box models are compared with the instrumental value of mainstream velocity for a system with/without a circular chimney. The numerical solutions derived from the analytical and grey models were used to forecast the mainstream velocity of air calculated using the anemometer. From the statistical analysis, the experimental data obtained for the solar collector equipped with the circular chimney have a negative skewness, whereas the positive skewness is obtained for the conventional system. Similarly, the kurtosis derived for the circular chimney dropped by 57.10% compared with the conventional system. Thus, the characteristic of measured velocity for the circular chimney is binomial in nature, whereas the conventional system possesses the characteristic of a super-Gaussian or leptokurtic curve. Both the simulated curves derived from Blasius and the nonlinear grey model for the circular chimney are negatively skewed about the mean value of the normal distribution. Comparatively, the negative skewness in the numerical solution of the nonlinear grey model decreased by 5.66%, whereas it increased by 195% when it was compared with the experimental data set for a system with a circular chimney. Likewise, the kurtosis of the numerical solution obtained from the nonlinear is 6.66% lower than the corresponding value estimated for the Blasius model. Both models have a propensity to behave as a binomial curve if they are applied to forecast the mainstream velocity of air for a system with a circular chimney. In the case of the conventional system, grey and Blasius models are positively skewed. However, the skewness in the numerical solution of the grey model increased by 2.16% when it was equated with the skewness of the Blasius model, whereas the kurtosis of the grey model dropped by 1.69%. Both models share the characteristic of super-Gaussian distribution. Moreover, for the conventional system, the distribution characteristic resonates with the experimentally derived data.

The statistical behaviours of both the experimental data and the models share similar traits; therefore, the relative accuracy of the model can be predicted with the mean absolute error percentage that is provided for both the models in

Figure 7.

To determine the accuracy of the proposed model, the mean absolute percentage error (MAPE%) was determined while computing the mainstream velocity of the air. The change in MAPE value with time is shown in

Figure 7. From the statistical analyses of white and grey models, it was confirmed that the nonlinear grey box model would show affinity with the analytical model for the conventional system, and its effect was also felt while computing the mean absolute percentage error between the true and predicted values. The rate of convergence with time was noticed to be higher for the grey model than for the Blasius model. For a system with a circular chimney, the convergence of the solution estimated from the proposed model was 23.72% higher than the Blasius model for the same time interval. As compared to the analytical solution, the maximum error that can occur while forecasting velocity for a system with a circular chimney was reduced by 28.49% for the nonlinear grey model. However, the error % in the grey model becomes asymptotic for a system that operates for a prolonged period, which is not true for the Blasius solution. The analytical solution derived through the Blasius equation converges slowly and steadily with time and provides better forecasting if a given system runs for a long period.

Conversely, the nonlinear grey model seems to have better predictability for a unit without a circular chimney; however, it converges slower than its counterpart grey model for a system equipped with a circular chimney. According to the MAPE data, the rate of convergence dropped by 43% for the nonlinear grey model when it was deployed for the conventional system. However, in long run, the nonlinear grey model competes with the analytical model at a similar pace. While operating a conventional system for a prolonged duration, the convergence of the analytical solution relatively increased by 11% when it was compared with the nonlinear grey model. In the case of a system operated with the circular chimney, the average MAPE% for a grey model is reduced by 24.63%, while it was marginally increased by 6% for the conventional unit. So, the overall mean absolute percentage error remains lower for the nonlinear grey model if it is used to forecast the velocity distribution of air, which is not true for the conventional system.

The velocity gradient along the

x and

y directions with the shear stress is illustrated in

Figure 8a–c. As compared to the analytical solution for the velocity gradient

, the maximum velocity gradient predicted by the grey model is reduced by 18.73% at the inlet of the collector. Similarly, the lowest possible value of

obtained through the grey model was 1.95% higher than that estimated by the Blasius solution. Similarly, for the conventional system, the highest possible value derived for

dropped by 29.36%, which is 56.75% lower than its counterpart grey model for a system equipped with a circular chimney. Unlike in the case of the circular chimney, the lowest derived value of

is curtailed by 10% while equating it with the corresponding value of

calculated through the Blasius model. In comparison to the corresponding average values of

for the circular chimney, the average value of

for the conventional system dropped by 88% for the grey model, whereas it decreased by 81.91% for the Blasius model.

According to the statistical perspective, both the models (grey and Blasius models) are positively skewed around the mean value of the normal distribution function for a system with a circular chimney. The skewness in the grey model dwindled by 17.34% as compared to the skewness in the Blasius solution. The kurtosis of the numerical solutions does not significantly differ for both models. A similar kind of variability would be noticed. Comparatively, the skewness in the numerical solution of the nonlinear grey model for the conventional unit dropped by 17.81%, which implies that the computational uncertainty in estimating

would be rather low. The excessive kurtosis (Kr) (leptokurtic) in the numerical solutions was seen in both grey and Blasius models for the conventional system, which also implies that the concentration of the data points would be relatively higher around the mean value. The shear rate or velocity gradient along the air passage thickness (

y) is illustrated in

Figure 8b. The shear rate near the solid boundary dropped by 18.72% when it was estimated by the grey model. The lowest shear rate was obtained at y = 0.039 m from the surface of the absorber plate. Relatively, the shear rate derived from the grey model for a system with a circular chimney is 1.98% higher than its counterpart grey model designed for the conventional system. The shear rate would change its orientation in the interval of 0.028–0.032 m. This implies that the shear stress would act along the flow direction for the given air passage thickness. However, a similar event would occur much earlier for the conventional unit. For the conventional unit, the inflexion in the numerical solution of

would lie in the domain of 0.0036–0.0072 m. This can also be explained through the distribution of shear stress in the transverse direction. The least shear rate for the conventional system is estimated to be −9.814 s

−1 by the nonlinear grey model, which is 9.63% higher than the corresponding value obtained at the same point by the Blasius model. The numerical solutions derived by grey and Blasius models have a positive skewness for non-conventional systems (with chimney). Comparatively, for grey models, the skewness in the numerical solution for a non-conventional system is 83.99% lower than the skewness in the derived solution for the conventional system. As compared to the non-conventional system, the kurtosis in the numerical solution of the grey model for the conventional system dropped by 58.67%. The average value of the shear rate

obtained from the nonlinear grey model is 4.420 s

−1, which is 22.45% lower than the average value derived through the Blasius model. Similarly, for the conventional system, the estimated value of

by the nonlinear grey model was reduced by 49.20% compared with the Blasius model.

The graphical plot of shear stress is shown in

Figure 8c. The wall shear stress

computed by the grey model for the non-conventional and conventional systems is 7.04 × 10

−4 N·m

−2 and 3.88 × 10

−4 N·m

−2, respectively, and it varies from 5.49 × 10

−4 N·m

−2 to 8.65 × 10

−4 N·m

−2 for the Blasius model. The shear stress would be zero in the open interval of 0.0288–0.0324 m for the non-conventional system. In the case of the non-conventional model, the lowest shear stress would be obtained at a transverse distance of 0.0396 m from the solid boundary for both the models, whereas it would attain the lowest value at 0.018 m for the conventional system. With the increase in the transverse distance, the shear stress would change its orientation along the flow direction and support the flow of air inside the solar collector. However, this event would occur much earlier for the conventional system than for the non-conventional system. Therefore, it can be concluded that the involvement of natural draught with the solar collector would eventually increase the wall shear stress and hydrodynamic losses, but this will not happen with the conventional unit. However, it can also be seen that the shear rate would promote a healthy flow system inside the non-conventional unit, whereas the amplitude of the shear rate would not be that high for the conventional system.

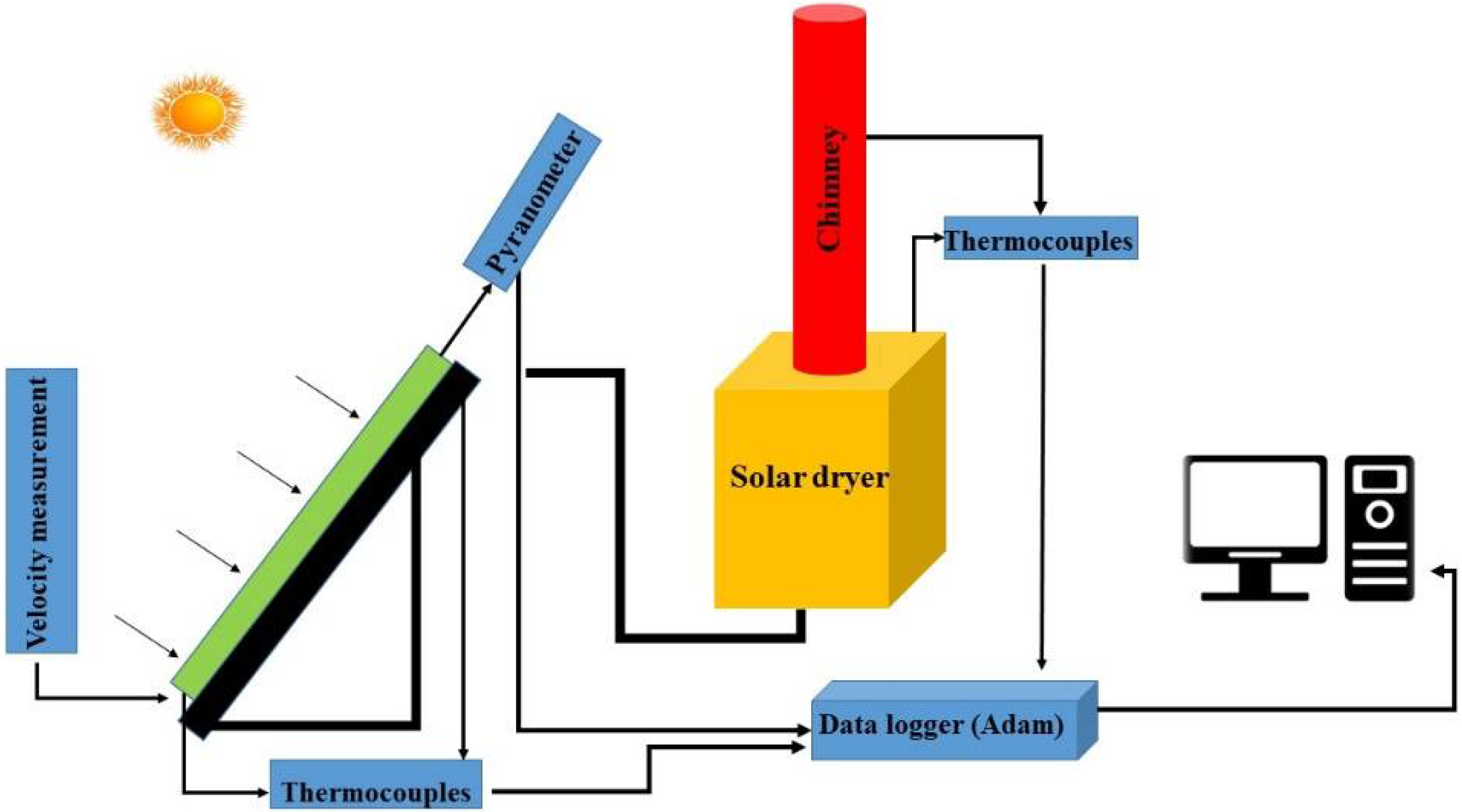

3.2. Linear Grey Modelling of Thermal Energy

The modelling of heat flow and temperature distribution was examined using the linear grey model for the one-dimensional heat flow problem for the absorber plate. Similarly, the linear grey model of the Whillier equation [

20] was also developed for the air stream. The change in the temperature of the absorber plate and air with time is shown in

Figure 9. The average temperature of the absorber plate derived from the linear grey model was estimated to be 377.94 K for a non-conventional system, which is 0.17% higher than the average temperature of the absorber plate determined by the thermocouple. The instrumental uncertainty in the temperature measurement of the absorber plate was estimated to be ±0.45 K, whereas it was ±0.43 K for the numerical solution derived through the linear grey model. The negative skewness of −0.0158 was found in the proposed grey model. Conversely, the experimental data are positively skewed about the mean position of the normal distribution. The kurtosis of the numerical and experimental data exhibits characteristics of the binomial distribution. In the same way, the simulated temperature for the carrier fluid (air) has a skewness of −1.03, which is 2.5% higher than the corresponding skewness value for the instrumental data set. The uncertainty in the numerical solution of air temperature was ±0.53, whereas the thermocouple installed at the inlet of the solar air heater provided the instrumental uncertainty of ±0.54. The percentage fit of the linear grey model is 96% with the experimental data obtained for the air temperature at the inlet of the solar air collector.

In the case of the conventional unit (

Figure 9b), the uncertainty in the experimental value is ±0.52 K, which is 0.19% higher than the corresponding uncertainty recorded in the simulated solution of the linear grey model for absorber plate temperature. The average experimental temperature of the absorber plate was estimated to be 493.75 K, which is insignificantly higher than the average value derived through the linear grey model. Both experimental and simulated data sets are negatively skewed around the mean value of the normal distribution function. The kurtosis of the simulated solution was relatively reduced by 0.57% as compared to the corresponding value of the kurtosis estimated for the experimental data. The distribution characteristic of both the simulated and experimental is equivalent to the super-Gaussian function. The average value of experimental air temperature at the inlet of the solar collector is 320.23 K for the conventional unit. The uncertainty in the air temperature measurement is ±1.23 K. As compared to the experimental data set, the average value derived from the numerical solution dropped by 0.37%. The uncertainty is ±1.47 for the linear grey model. The statistical investigation depicts that both the experimental and simulated data sets have a negative skewness to the normal distribution function.

Relatively, the kurtosis of the numerical solution is increased by 1.086%. The nature of the distribution pattern is leptokurtic. To investigate the model in more detail, the error analysis is performed to determine whether the solution estimated through the linear grey model is feasible or not. The mean absolute percentage error (MAPE(T)) estimated while predicting the temperature of the absorber plate and inlet temperature of the carrier is shown in

Figure 10. The maximum MAPE(T) for the linear grey model was 0.037% while comparing the instrumental data of the absorber plate, whereas the lowest possible MAPE(T) was 3.46 × 10

−4% during the time interval of 14,000–16,000 s. When the generated solutions were compared, the maximum value of MAPE(T) dropped by 85.18% for the numerical solution derived for the conventional system. The lowest possible MAPE(T) was also reduced by a margin of 51.64%.

Similarly, for the carrier fluid (air), the MAPE(T) has a maximum value of 9.97 × 10−3% for the non-conventional system, which is 39.72% lower than the MAPE(T) value evaluated for the conventional system. So, it could be seen that the linear grey model is suitable to predict the temperature distribution of air at the inlet of the solar air heater, whereas in the case of forecasting the absorber plate temperature, the proposed model provided a robust solution for the conventional solar air heater. The convergence of the nonlinear grey model is also better than the analytical model to forecast the velocity of air inside the collector, although it is susceptible to the duration of the experiment.

The complied average values of discussed parameters are provided in

Table 4. The average value of stream function estimated through the nonlinear grey model dropped by 2.56% as compared to the Blasius solution. The vertical component of mainstream velocity (

v) reduced by 9.90% while simulating it with the nonlinear grey model for a non-conventional system. In the case of the conventional system, the margin of percentage drop in the vertical component of velocity was reduced by 40.60%. The average shear stress experienced by the conventional unit was remarkably reduced by 88% while using the proposed nonlinear grey model, whereas it was estimated to be diminished by 81.80% when the same parameters were computed through the analytical model.