Machine Learning Methods for Automated Fault Detection and Diagnostics in Building Systems—A Review

Abstract

:1. Background: Prior Review Articles

1.1. Building Energy Consumption

1.2. History of FDD in Building Systems

2. Modern Machine Learning for Fault Detection in Building Systems

- Actuator malfunction

- Sensor faults

- Blocked ducts

- Filtration issues

- Fluctuation of pressure setpoints

- Motor failure

- Fan malfunction

- Coil fouling

2.1. Feature Selection

2.2. Data-Driven Methods

Principal Component Analysis

2.3. Supervised Learning

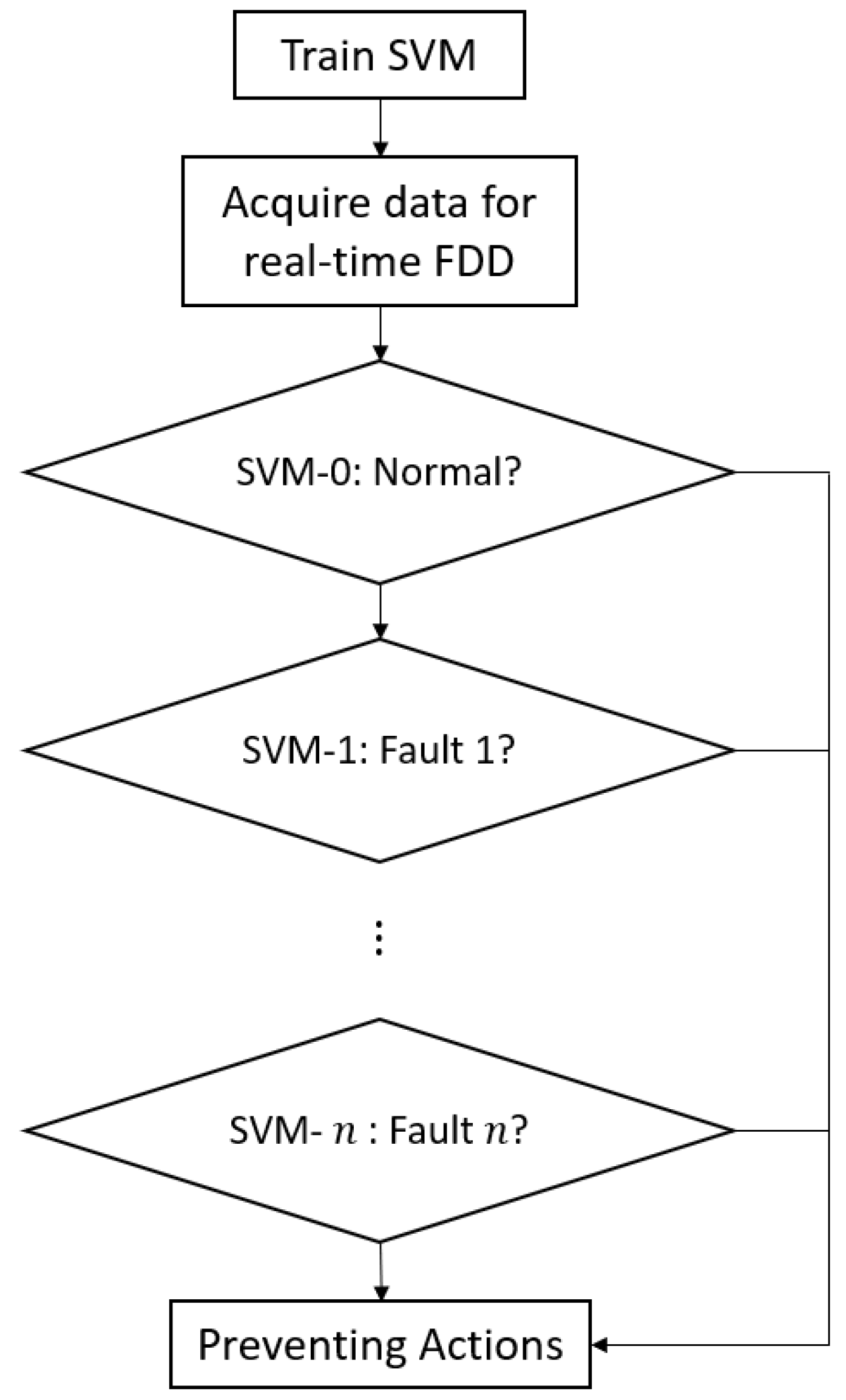

2.3.1. Support Vector Machines

2.3.2. Neural Networks

2.4. Unsupervised Learning

2.4.1. Clustering

2.4.2. Regression Algorithms

2.4.3. Rule-Based Methods

2.5. Characteristic Signatures

2.6. Challenges

2.7. Machine Learning Methods in the Future

3. Concluding Thoughts

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Nomenclature

| AFDD | Automated Fault Detection and Diagnostics |

| AHU | Air Handling Unit |

| AI | Artificial Intelligence |

| ANN | Artificial Neural Network |

| APAR | Air-Handling Unit Performance Assessment Rules |

| ARM | Association Rule Mining |

| ARX | Autoregressive Model with Exogenous Terms |

| ASHRAE | American Society of Heating, Refrigerating, and Air-Conditioning Engineers |

| BNMI | Best Network after Multiple Iterations |

| DBSCAN | Density-Based Spatial Clustering of Applications |

| FDD | Fault Detection and Diagnostics |

| GMM | Gaussian Mixture Model |

| HVAC | Heating, Ventilation, and Air Conditioning |

| IEA | International Energy Agency |

| kNN | k-Nearest Neighbor |

| LRN | Layer Recurrent Neural Networks |

| MAE | Mean Absolute Error |

| ML | Machine Learning |

| MLP | Multi-Layer Perceptron |

| MPC | Model Predictive Control |

| PCA | Principal Components Analysis |

| PMV | Predicted Mean Vote |

| RBF | Radial Basis Function |

| RMSE | Root Meat Squared Error |

| SVM | Support Vector Machines |

| SVR | Support Vector Regression |

| TB | Terminal Box |

| VAV | Variable Air Volume |

References

- Global Status Report towards a Zero-Emission, Efficient and Resilient Buildings and Construction Sector. Available online: https://www.iea.org/reports/2018-global-status-report (accessed on 19 April 2022).

- Yang, H.; Zhang, T.; Li, H.; Woradechjumroen, D.; Liu, X. HVAC Equipment, Unitary: Fault Detection and Diagnosis; CRC Press: Boca Raton, FL, USA, 2014; pp. 854–864. [Google Scholar] [CrossRef]

- Qin, J.; Wang, S. A fault detection and diagnosis strategy of VAV air-conditioning systems for improved energy and control performances. Energy Build. 2005, 37, 1035–1048. [Google Scholar] [CrossRef]

- Katipamula, S.; Brambley, M.R. Review Article: Methods for Fault Detection, Diagnostics, and Prognostics for Building Systems—A Review, Part I. HVACR Res. 2005, 11, 3–25. [Google Scholar] [CrossRef]

- Roth, K.W.; Detlef, W.; Patricia, L.; Michael, Y.; Feng, N.D. The Energy Impact of Faults in U.S. Commercial Buildings. In Proceedings of the 2004 International Refrigeration and Air Conditioning Conference, West Lafayette, Indiana, 12–15 July 2004. [Google Scholar]

- Seppänen, O.; Fisk, W.J.; Lei, Q.H. Effect of Temperature on Task Performance in Office Environment. 2006. Available online: https://indoor.lbl.gov/publications/effect-temperature-task-performance (accessed on 25 July 2022).

- Bendapudi, S.; Braun, J.E.; Groll, E.A. A Dynamic Model of a Vapor Compression Liquid Chiller. International. Available online: http://docs.lib.purdue.edu/iracc/568 (accessed on 1 April 2020).

- Bourdouxh, J.P.; Grodent, M.; Lebrun, J. HVAC1kit—A toolkit for primary HVAC system energy calculation. Energy 1999, 4, 694. [Google Scholar]

- Breuker, M.S.; Braun, J.E. Evaluating the Performance of a Fault Detection and Diagnostic System for Vapor Compression Equipment. HVACR Res. 1998, 4, 401–425. [Google Scholar] [CrossRef]

- Gertler, J.J. Fault Detection and Diagnosis in Engineering Systems; CRC Press: Boca Raton, FL, USA, 1998. [Google Scholar] [CrossRef]

- Wagner, J.; Shoureshi, R. Failure Detection Diagnostics for Thermofluid Systems. J. Dyn. Syst. Meas. Control 1992, 114, 699–706. [Google Scholar] [CrossRef]

- Haves, P.; Salsbury, T.I.; Wright, J.A. Condition monitoring in HVAC subsystems using first principles models. ASHRAE Trans. 1996, 102, 519–527. [Google Scholar]

- Salsbury, T.; Diamond, R. Fault detection in HVAC systems using model-based feedforward control. Energy Build. 2001, 33, 403–415. [Google Scholar] [CrossRef]

- Norford, L.K.; Wright, J.A.; Buswell, R.A.; Luo, D.; Klaassen, C.J.; Suby, A. Demonstration of fault detection and diagnosis methods for air-handling units (ASHRAE 1020-RP). HVAC R Res. 2002, 8, 41–71. [Google Scholar] [CrossRef]

- Castro, N. Performance Evaluation of a Reciprocating Chiller Using Experimental Data and Model Predictions for Fault Detection and Diagnosis. 2002. Available online: https://www.nist.gov/publications/performance-evaluation-reciprocating-chiller-using-experimental-data-and-model (accessed on 12 August 2019).

- PECI, B. Methods for Automated and Continuous Commissioning of Building Systems; Air-Conditioning and Refrigeration Technology Institute (US): Arlington, VA, USA, 2003; pp. 6–8. [Google Scholar] [CrossRef]

- Katipamula, S.; Pratt, R.G.; Chassin, D.P.; Taylor, Z.T.; Gowri, K.; Brambley, M.R. Automated fault detection and diagnostics for outdoor-air ventilation systems and economizers: Methodology and results from field testing. Trans. -Am. Soc. Heat. Refrig. Air Cond. Eng. 1999, 105, 555–567. [Google Scholar]

- House, J.M.; Vaezi-Nejad, H.; Whitcomb, J.M. An Expert Rule Set for Fault Detection in Air-Handling Units. Ashrae Trans. 2001, 107, 858. [Google Scholar]

- Zhao, Y.; Li, T.; Zhang, X.; Zhang, C. Artificial intelligence-based fault detection and diagnosis methods for building energy systems: Advantages, challenges and the future. Renew. Sustain. Energy Rev. 2019, 109, 85–101. [Google Scholar] [CrossRef]

- Chen, J.; Zhang, L.; Li, Y.; Shi, Y.; Gao, X.; Hu, Y. A review of computing-based automated fault detection and diagnosis of heating, ventilation and air conditioning systems. Renew. Sustain. Energy Rev. 2022, 161, 112395. [Google Scholar] [CrossRef]

- Mirnaghi, M.S.; Haghighat, F. Fault detection and diagnosis of large-scale HVAC systems in buildings using data-driven methods: A comprehensive review. Energy Build. 2020, 229, 110492. [Google Scholar] [CrossRef]

- Tidriri, K.; Chatti, N.; Verron, S.; Tiplica, T. Bridging data-driven and model-based approaches for process fault diagnosis and health monitoring: A review of researches and future challenges. Annu. Rev. Control 2016, 42, 63–81. [Google Scholar] [CrossRef]

- Maurya, M.R.; Rengaswamy, R.; Venkatasubramanian, V. A Signed Directed Graph and Qualitative Trend Analysis-Based Framework for Incipient Fault Diagnosis. Chem. Eng. Res. Des. 2007, 85, 1407–1422. [Google Scholar] [CrossRef]

- Siswantoro, J.; Prabuwono, A.S.; Abdullah, A.; Idrus, B. A linear model based on Kalman filter for improving neural network classification performance. Expert Syst. Appl. 2016, 49, 112–122. [Google Scholar] [CrossRef]

- Zhao, Y.; Wang, S.; Xiao, F. Pattern recognition-based chillers fault detection method using Support Vector Data Description (SVDD). Appl. Energy 2013, 112, 1041–1048. [Google Scholar] [CrossRef]

- Yan, K.; Zhong, C.; Ji, Z.; Huang, J. Semi-supervised learning for early detection and diagnosis of various air handling unit faults. Energy Build. 2018, 181, 75–83. [Google Scholar] [CrossRef]

- Chandrashekar, G.; Sahin, F. A survey on feature selection methods. Comput. Electr. Eng. 2014, 40, 16–28. [Google Scholar] [CrossRef]

- Yan, K.; Shen, W.; Mulumba, T.; Afshari, A. ARX model based fault detection and diagnosis for chillers using support vector machines. Energy Build. 2014, 81, 287–295. [Google Scholar] [CrossRef]

- Wang, S.; Cui, J. Sensor-fault detection, diagnosis and estimation for centrifugal chiller systems using principal-component analysis method. Appl. Energy 2005, 82, 197–213. [Google Scholar] [CrossRef]

- Li, S.; Wen, J. Application of pattern matching method for detecting faults in air handling unit system. Autom. Constr. 2014, 43, 49–58. [Google Scholar] [CrossRef]

- Du, Z.; Jin, X. Detection and diagnosis for sensor fault in HVAC systems. Energy Convers. Manag. 2007, 48, 693–702. [Google Scholar] [CrossRef]

- Hu, Y.; Li, G.; Chen, H.; Li, H.; Liu, J. Sensitivity analysis for PCA-based chiller sensor fault detection. Int. J. Refrig. 2016, 63, 133–143. [Google Scholar] [CrossRef]

- Zhao, Y.; Wang, S.; Xiao, F. A statistical fault detection and diagnosis method for centrifugal chillers based on exponentially-weighted moving average control charts and support vector regression. Appl. Therm. Eng. 2013, 51, 560–572. [Google Scholar] [CrossRef]

- Beghi, A.; Brignoli, R.; Cecchinato, L.; Menegazzo, G.; Rampazzo, M.; Simmini, F. Data-driven Fault Detection and Diagnosis for HVAC water chillers. Control Eng. Pract. 2016, 53, 79–91. [Google Scholar] [CrossRef]

- Mahadevan, S.; Shah, S.L. Fault detection and diagnosis in process data using one-class support vector machines. J. Process Control 2009, 19, 1627–1639. [Google Scholar] [CrossRef]

- Zhang, H.; Chen, H.; Guo, Y.; Wang, J.; Li, G.; Shen, L. Sensor fault detection and diagnosis for a water source heat pump air-conditioning system based on PCA and preprocessed by combined clustering. Appl. Therm. Eng. 2019, 160, 114098. [Google Scholar] [CrossRef]

- Xiao, F.; Wang, S.; Zhang, J. A diagnostic tool for online sensor health monitoring in air-conditioning systems. Autom. Constr. 2005, 15, 489–503. [Google Scholar] [CrossRef]

- Wang, S.; Xiao, F. Detection and diagnosis of AHU sensor faults using principal component analysis method. Energy Convers. Manag. 2004, 45, 2667–2686. [Google Scholar] [CrossRef]

- Wang, S.; Xiao, F. AHU sensor fault diagnosis using principal component analysis method. Energy Build. 2004, 36, 147–160. [Google Scholar] [CrossRef]

- Hu, Y.; Chen, H.; Xie, J.; Yang, X.; Zhou, C. Chiller sensor fault detection using a self-Adaptive Principal Component Analysis method. Energy Build. 2012, 54, 252–258. [Google Scholar] [CrossRef]

- Xu, X.; Xiao, F.; Wang, S. Enhanced chiller sensor fault detection, diagnosis and estimation using wavelet analysis and prin-cipal component analysis methods. Appl. Therm. Eng. 2008, 28, 226–237. [Google Scholar] [CrossRef]

- Yan, R.; Ma, Z.; Zhao, Y.; Kokogiannakis, G. A decision tree based data-driven diagnostic strategy for air handling units. Energy Build. 2016, 133, 37–45. [Google Scholar] [CrossRef]

- Dehestani, D.; Eftekhari, F.; Guo, Y.; Ling, S.; Su, S.; Nguyen, H. Online Support Vector Machine Applicationfor Model Based Fault Detection and Isolationof HVAC System. Int. J. Mach. Learn. Comput. 2011, 1, 66–72. [Google Scholar] [CrossRef] [Green Version]

- Han, H.; Gu, B.; Hong, Y.; Kang, J. Automated FDD of multiple-simultaneous faults (MSF) and the application to building chillers. Energy Build. 2011, 43, 2524–2532. [Google Scholar] [CrossRef]

- Kriegel, H.P.; Schubert, M.; Zimek, A. Angle-Based Outlier Detection in High-Dimensional Data; ACM: New York, NY, USA, 2008. [Google Scholar]

- Bode, G.; Thul, S.; Baranski, M.; Müller, D. Real-world application of machine-learning-based fault detection trained with experimental data. Energy 2020, 198, 117323. [Google Scholar] [CrossRef]

- Ebrahimifakhar, A.; Kabirikopaei, A.; Yuill, D. Data-driven fault detection and diagnosis for packaged rooftop units using statistical machine learning classification methods. Energy Build. 2020, 225, 110318. [Google Scholar] [CrossRef]

- Shohet, R.; Kandil, M.S.; Wang, Y.; McArthur, J. Fault detection for non-condensing boilers using simulated building automation system sensor data. Adv. Eng. Inform. 2020, 46, 101176. [Google Scholar] [CrossRef]

- Lee, D.; Lai, C.-W.; Liao, K.-K.; Chang, J.-W. Artificial intelligence assisted false alarm detection and diagnosis system development for reducing maintenance cost of chillers at the data centre. J. Build. Eng. 2020, 36, 102110. [Google Scholar] [CrossRef]

- Wang, H.; Chen, Y. A robust fault detection and diagnosis strategy for multiple faults of VAV air handling units. Energy Build. 2016, 127, 442–451. [Google Scholar] [CrossRef]

- Yu, Z.; Fung, B.C.; Haghighat, F.; Yoshino, H.; Morofsky, E. A systematic procedure to study the influence of occupant behavior on building energy consumption. Energy Build. 2011, 43, 1409–1417. [Google Scholar] [CrossRef] [Green Version]

- Liang, J.; Du, R. Model-based Fault Detection and Diagnosis of HVAC systems using Support Vector Machine method. Int. J. Refrig. 2007, 30, 1104–1114. [Google Scholar] [CrossRef]

- Suykens, J.A.K.; Vandewalle, J. Least Squares Support Vector Machine Classifiers. Neural Process. Lett. 1999, 9, 293–300. [Google Scholar] [CrossRef]

- Han, H.; Cui, X.; Fan, Y.; Qing, H. Least squares support vector machine (LS-SVM)-based chiller fault diagnosis using fault indicative features. Appl. Therm. Eng. 2019, 154, 540–547. [Google Scholar] [CrossRef]

- Van Every, P.M.; Rodriguez, M.; Jones, C.B.; Mammoli, A.A.; Martínez-Ramón, M. Advanced detection of HVAC faults using unsupervised SVM novelty detection and Gaussian process models. Energy Build. 2017, 149, 216–224. [Google Scholar] [CrossRef]

- Han, H.; Cao, Z.; Gu, B.; Ren, N. PCA-SVM-Based Automated Fault Detection and Diagnosis (AFDD) for Vapor-Compression Refrigeration Systems. HVACR Res. 2010, 16, 295–313. [Google Scholar] [CrossRef]

- Li, B.; Zhao, Y.-P. Simultaneous fault diagnosis for aircraft engine using multi-label learning. Proc. Inst. Mech. Eng. Part I J. Syst. Control. Eng. 2022, 09596518221085756. [Google Scholar] [CrossRef]

- Wu, B.; Cai, W.; Zhang, X. A fault detection model for air handling units based on the machine learning algorithms. In Proceedings of the IECON 2020 The 46th Annual Conference of the IEEE Industrial Electronics Society, Singapore, 18–21 October 2020; pp. 4789–4793. [Google Scholar] [CrossRef]

- Tran, D.A.T.; Chen, Y.; Jiang, C. Comparative investigations on reference models for fault detection and diagnosis in centrifugal chiller systems. Energy Build. 2016, 133, 246–256. [Google Scholar] [CrossRef]

- Jordan, M. The Kernel Trick. In CS281B: Advanced Topics in Learning & Decision Making; Class lecture; University of California: Berkeley, CA, USA, 2004. [Google Scholar]

- Yang, H.; Lee, K.; Choo, Y.; Kim, K. Underwater Acoustic Research Trends with Machine Learning: General Background. J. Ocean Eng. Technol. 2020, 34, 147–154. [Google Scholar] [CrossRef]

- Hou, Z.; Lian, Z.; Yao, Y.; Yuan, X. Data mining based sensor fault diagnosis and validation for building air conditioning system. Energy Convers. Manag. 2006, 47, 2479–2490. [Google Scholar] [CrossRef]

- Afram, A.; Janabi-Sharifi, F.; Fung, A.S.; Raahemifar, K. Artificial neural network (ANN) based model predictive control (MPC) and optimization of HVAC systems: A state of the art review and case study of a residential HVAC system. Energy Build. 2017, 141, 96–113. [Google Scholar] [CrossRef]

- Hornik, K.; Stinchcombe, M.; White, H. Multilayer feedforward networks are universal approximators. Neural Netw. 1989, 2, 359–366. [Google Scholar] [CrossRef]

- Taheri, S.; Ahmadi, A.; Mohammadi-Ivatloo, B.; Asadi, S. Fault detection diagnostic for HVAC systems via deep learning algorithms. Energy Build. 2021, 250, 111275. [Google Scholar] [CrossRef]

- Tang, F.; Kusiak, A.; Wei, X. Modeling and short-term prediction of HVAC system with a clustering algorithm. Energy Build. 2014, 82, 310–321. [Google Scholar] [CrossRef]

- Du, Z.; Fan, B.; Chi, J.; Jin, X. Sensor fault detection and its efficiency analysis in air handling unit using the combined neural networks. Energy Build. 2014, 72, 157–166. [Google Scholar] [CrossRef]

- Du, Z.; Fan, B.; Jin, X.; Chi, J. Fault detection and diagnosis for buildings and HVAC systems using combined neural net-works and subtractive clustering analysis. Build. Environ. 2014, 73, 1–11. [Google Scholar] [CrossRef]

- Fan, B.; Du, Z.; Jin, X.; Yang, X.; Guo, Y. A hybrid FDD strategy for local system of AHU based on artificial neural network and wavelet analysis. Build. Environ. 2010, 45, 2698–2708. [Google Scholar] [CrossRef]

- Guo, Y.; Li, G.; Chen, H.; Hu, Y.; Li, H.; Xing, L.; Hu, W. An enhanced PCA method with Savitzky-Golay method for VRF system sensor fault detection and diagnosis. Energy Build. 2017, 142, 167–178. [Google Scholar] [CrossRef]

- Magoulès, F.; Zhao, H.-X.; Elizondo, D. Development of an RDP neural network for building energy consumption fault detection and diagnosis. Energy Build. 2013, 62, 133–138. [Google Scholar] [CrossRef]

- Zhu, Y.; Jin, X.; Du, Z. Fault diagnosis for sensors in air handling unit based on neural network pre-processed by wavelet and fractal. Energy Build. 2012, 44, 7–16. [Google Scholar] [CrossRef]

- Yang, X.-B.; Jin, X.-Q.; Du, Z.; Zhu, Y.-H. A novel model-based fault detection method for temperature sensor using fractal correlation dimension. Build. Environ. 2011, 46, 970–979. [Google Scholar] [CrossRef]

- Fan, C.; Liu, X.; Xue, P.; Wang, J. Statistical characterization of semi-supervised neural networks for fault detection and diagnosis of air handling units. Energy Build. 2021, 234, 110733. [Google Scholar] [CrossRef]

- Fan, C.; Liu, Y.; Liu, X.; Sun, Y.; Wang, J. A study on semi-supervised learning in enhancing performance of AHU unseen fault detection with limited labeled data. Sustain. Cities Soc. 2021, 70, 102874. [Google Scholar] [CrossRef]

- Shahnazari, H.; Mhaskar, P.; House, J.M.; Salsbury, T.I. Modeling and fault diagnosis design for HVAC systems using recurrent neural networks. Comput. Chem. Eng. 2019, 126, 189–203. [Google Scholar] [CrossRef]

- Shahnazari, H.; Mhaskar, P. Distributed fault diagnosis for networked nonlinear uncertain systems. Comput. Chem. Eng. 2018, 115, 22–33. [Google Scholar] [CrossRef]

- Shahnazari, H.; Mhaskar, P.; House, J.M.; Salsbury, T.I. Heating, ventilation and air conditioning systems: Fault detection and isolation and safe parking. Comput. Chem. Eng. 2018, 108, 139–151. [Google Scholar] [CrossRef]

- Li, G.; Hu, Y. Improved sensor fault detection, diagnosis and estimation for screw chillers using density-based clustering and principal component analysis. Energy Build. 2018, 173, 502–515. [Google Scholar] [CrossRef]

- Ester, M.; Kriegel, H.P.; Sander, J.; Xu, X. A Density-Based Algorithm for Discovering Clusters in Large Spatial Databases with Noise. In Proceedings of the The Second International Conference on Knowledge Discovery and Data Mining (KDD-96), Portland, Oregon, 2–4 August 1996. [Google Scholar]

- Dey, M.; Rana, S.P.; Dudley, S. Smart building creation in large scale HVAC environments through automated fault detection and diagnosis. Futur. Gener. Comput. Syst. 2018, 108, 950–966. [Google Scholar] [CrossRef]

- Gaitani, N.; Lehmann, C.; Santamouris, M.; Mihalakakou, G.; Patargias, P. Using principal component and cluster analysis in the heating evaluation of the school building sector. Appl. Energy 2010, 87, 2079–2086. [Google Scholar] [CrossRef]

- Piech, C. K-Means. 2013. Available online: https://stanford.edu/~cpiech/cs221/handouts/kmeans.html (accessed on 29 July 2022).

- Luo, X.J.; Fong, K.F.; Sun, Y.J.; Leung, M.K.H. Development of clustering-based sensor fault detection and diagnosis strategy for chilled water system. Energy Build. 2019, 186, 17–36. [Google Scholar] [CrossRef]

- Yang, J.; Ning, C.; Deb, C.; Zhang, F.; Cheong, D.; Lee, S.E.; Sekhar, C.; Tham, K.W. k-Shape clustering algorithm for building energy usage patterns analysis and forecasting model accuracy improvement. Energy Build. 2017, 146, 27–37. [Google Scholar] [CrossRef]

- Hsu, D. Comparison of integrated clustering methods for accurate and stable prediction of building energy consumption data. Appl. Energy 2015, 160, 153–163. [Google Scholar] [CrossRef] [Green Version]

- Lavin, A.; Klabjan, D. Clustering time-series energy data from smart meters. Energy Effic. 2014, 8, 681–689. [Google Scholar] [CrossRef] [Green Version]

- Iglesias, F.; Kastner, W. Analysis of Similarity Measures in Times Series Clustering for the Discovery of Building Energy Patterns. Energies 2013, 6, 579–597. [Google Scholar] [CrossRef] [Green Version]

- Capozzoli, A.; Piscitelli, M.S.; Gorrino, A.; Ballarini, I.; Corrado, V. Data analytics for occupancy pattern learning to reduce the energy consumption of HVAC systems in office buildings. Sustain. Cities Soc. 2017, 35, 191–208. [Google Scholar] [CrossRef]

- D’Oca, S.; Hong, T. A data-mining approach to discover patterns of window opening and closing behavior in offices. Build. Environ. 2014, 82, 726–739. [Google Scholar] [CrossRef] [Green Version]

- Jakkula, V.; Cook, D. Outlier Detection in Smart Environment Structured Power Datasets. In Proceedings of the 2010 Sixth International Conference on Intelligent Environments, Kuala Lumpur, Malaysia, 19–21 July 2010; pp. 29–33. [Google Scholar] [CrossRef]

- Yuwono, M.; Guo, Y.; Wall, J.; Li, J.; West, S.; Platt, G.; Su, S.W. Unsupervised feature selection using swarm intelligence and consensus clustering for automatic fault detection and diagnosis in Heating Ventilation and Air Conditioning systems. Appl. Soft Comput. 2015, 34, 402–425. [Google Scholar] [CrossRef]

- Shao, H.; Marwah, M.; Ramakrishnan, N. A Temporal Motif Mining Approach to Unsupervised Energy Disaggregation: Applications to Residential and Commercial Buildings. Proc. Conf. AAAI Artif Intell 2013, 27, 1327–1333. [Google Scholar] [CrossRef]

- Guo, Y.; Chen, H. Fault diagnosis of VRF air-conditioning system based on improved Gaussian mixture model with PCA approach. Int. J. Refrig. 2020, 118, 1–11. [Google Scholar] [CrossRef]

- Karami, M.; Wang, L. Fault detection and diagnosis for nonlinear systems: A new adaptive Gaussian mixture modeling approach. Energy Build. 2018, 166, 477–488. [Google Scholar] [CrossRef]

- Cheng, Z.; Qi, L.; Cheng, Y.; Wu, Y.; Zhang, H. Interlacing Orchard Canopy Separation and Assessment using UAV images. Remote Sens. 2020, 12, 767. [Google Scholar] [CrossRef] [Green Version]

- Li, D.; Zhou, Y.; Hu, G.; Spanos, C.J. Fault detection and diagnosis for building cooling system with a tree-structured learning method. Energy Build. 2016, 127, 540–551. [Google Scholar] [CrossRef]

- Jones, C.B. Fault Detection and Diagnostics of an HVAC Sub-System Using Adaptive Resonance Theory Neural Networks; The University of New Mexico: Albuquerque, NM, USA, 2015. [Google Scholar]

- Lee, W.-Y.; House, J.M.; Kyong, N.-H. Subsystem level fault diagnosis of a building’s air-handling unit using general regression neural networks. Appl. Energy 2004, 77, 153–170. [Google Scholar] [CrossRef]

- Howard, P.; Reddy, T.A.; Runger, G.; Katipamula, S. Automated Data Mining Methods for Identifying Energy Efficiency Opportunities Using Whole-Building Electricity Data. ASHRAE Trans. 2016, 122, 422. [Google Scholar]

- Yang, X.-B.; Jin, X.-Q.; Du, Z.-M.; Zhu, Y.-H.; Guo, Y.-B. A hybrid model-based fault detection strategy for air handling unit sensors. Energy Build. 2013, 57, 132–143. [Google Scholar] [CrossRef]

- Yoshida, H.; Kumar, S.; Morita, Y. Online fault detection and diagnosis in VAV air handling unit by RARX modeling. Energy Build. 2001, 33, 391–401. [Google Scholar] [CrossRef]

- Yoshida, H.; Kumar, S. ARX and AFMM model-based on-line real-time data base diagnosis of sudden fault in AHU of VAV system. Energy Convers. Manag. 1999, 40, 1191–1206. [Google Scholar] [CrossRef]

- Kumar, S.; Sinha, S.; Kojima, T.; Yoshida, H. Development of parameter based fault detection and diagnosis technique for energy ecient building management system. Energy Convers. Manag. 2001, 42, 833–854. [Google Scholar] [CrossRef]

- Mulumba, T.; Afshari, A.; Yan, K.; Shen, W.; Norford, L.K. Robust model-based fault diagnosis for air handling units. Energy Build. 2015, 86, 698–707. [Google Scholar] [CrossRef]

- Schein, J.; Bushby, S.T. A Hierarchical Rule-Based Fault Detection and Diagnostic Method for HVAC Systems. HVACR Res. 2006, 12, 111–125. [Google Scholar] [CrossRef]

- Tran, D.A.T.; Chen, Y.; Chau, M.Q.; Ning, B. A robust online fault detection and diagnosis strategy of centrifugal chiller systems for building energy efficiency. Energy Build. 2015, 108, 441–453. [Google Scholar] [CrossRef]

- Claridge, D.E. Mingsheng Liu Use of Calibrated HVAC System Models to Optimize System Operation. 1998. Available online: https://asmedigitalcollection.asme.org/solarenergyengineering/article-pdf/120/2/131/5666077/131_1.pdf (accessed on 1 April 2020).

- Lin, G.; Claridge, D.E. A temperature-based approach to detect abnormal building energy consumption. Energy Build. 2015, 93, 110–118. [Google Scholar] [CrossRef]

- Yang, C.; Shen, W.; Gunay, B.; Shi, Z. Toward machine learning-based prognostics for heating ventilation and air- conditioning systems. ASHRAE 2019, 125, 106–115. [Google Scholar]

- Wen, J.; Li, S. ASHRAE RP-1312. ASHRAE 2012. Available online: https://www.techstreet.com/standards/rp-1312-tools-for-evaluating-fault-detection-and-diagnostic-methods-for-air-handling-units?product_id=1833299 (accessed on 13 April 2022).

- Granderson, J.; Lin, G.; Singla, R.; Mayhorn, E.; Ehrlich, P.; Vrabie, D.; Frank, S. Commercial Fault Detection and Diagnostics Tools: What They Offer, How They Differ, and What’s Still Needed. Available online: https://doi.org/10.20357/B7V88H (accessed on 18 February 2020).

- Hacker, A.; Gorthala, R.; Thompson, A. An Approach to Bringing Automated Fault Detection and Diagnosis (AFDD) Tools for HVAC&R into the Mainstream. 2019. Available online: http://asmedigitalcollection.asme.org/IMECE/proceedings-pdf/IMECE2019/59438/V006T06A050/6513234/v006t06a050-imece2019-11941.pdf (accessed on 25 April 2022).

- Bricks Schema. Available online: https://brickschema.org/ (accessed on 6 June 2022).

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nelson, W.; Culp, C. Machine Learning Methods for Automated Fault Detection and Diagnostics in Building Systems—A Review. Energies 2022, 15, 5534. https://doi.org/10.3390/en15155534

Nelson W, Culp C. Machine Learning Methods for Automated Fault Detection and Diagnostics in Building Systems—A Review. Energies. 2022; 15(15):5534. https://doi.org/10.3390/en15155534

Chicago/Turabian StyleNelson, William, and Charles Culp. 2022. "Machine Learning Methods for Automated Fault Detection and Diagnostics in Building Systems—A Review" Energies 15, no. 15: 5534. https://doi.org/10.3390/en15155534

APA StyleNelson, W., & Culp, C. (2022). Machine Learning Methods for Automated Fault Detection and Diagnostics in Building Systems—A Review. Energies, 15(15), 5534. https://doi.org/10.3390/en15155534