Analysis of the Thermal Conductivity of a Bio-Based Composite Made of Hemp Shives and a Magnesium Binder

Abstract

:1. Introduction

2. Materials and Methods

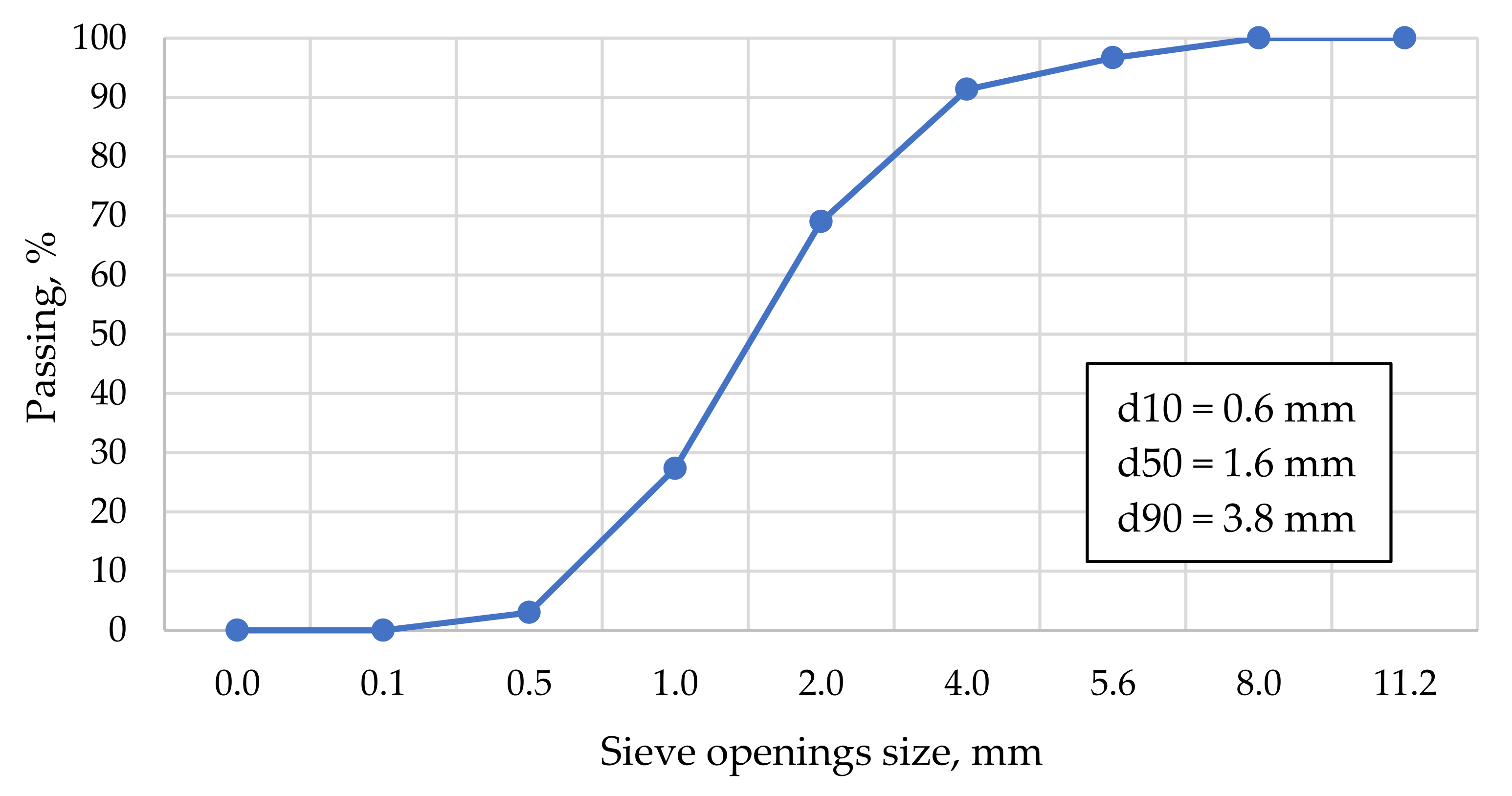

2.1. Raw Materials and Manufacturing Method of Hemp Shive-Reinforced Composites

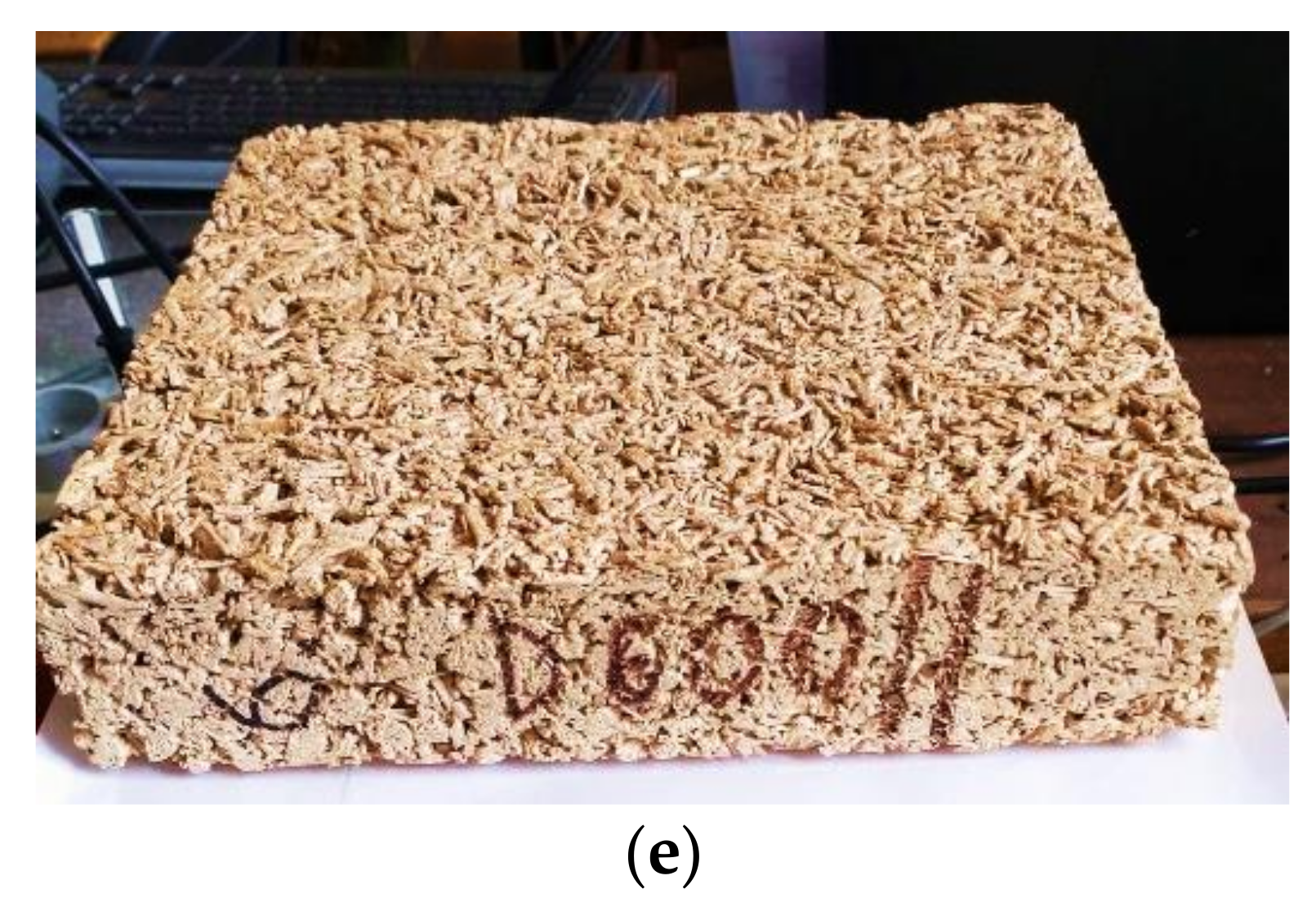

2.2. Hemp Shive-Reinforced Composites

2.3. Conditioning and Measurement Method

2.3.1. Sample Conditioning

- Drying (drier): T = 50–60 °C and very low relative humidity.

- Conditioning (climatic chamber): T = 23 °C and RH = 50%, 75%, and 90%.

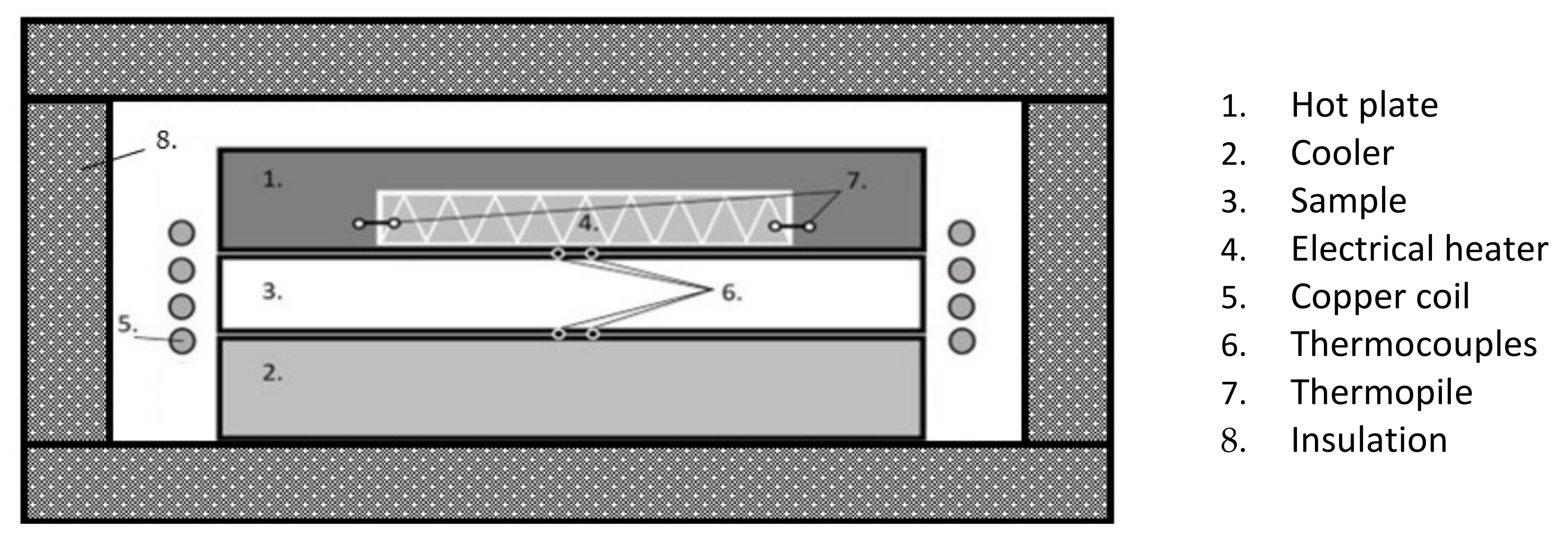

2.3.2. Measurement Method for Thermal Conductivity

3. Results

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zhang, K.; Zheng, S.; Liu, Y.; Lin, J. Isolation of hierarchical cellulose building blocks from natural flax fibers as a separation membrane barrier. Int. J. Biol. Macromol. 2020, 155, 666–673. [Google Scholar] [CrossRef] [PubMed]

- Sari, N.P.; Olivia, M.; Djauhari, Z. The mechanical behavior of mortar cement mixing with palm sugar due to exposed to heat (high temperature). IOP Conf. Ser. Earth Environ. Sci. 2021, 737, 012039. [Google Scholar] [CrossRef]

- Carcassi, O.B.; Minotti, P.; Habert, G.; Paoletti, I.; Claude, S.; Pittau, F. Carbon Footprint Assessment of a Novel Bio-Based Composite for Building Insulation. Sustainability 2022, 14, 1384. [Google Scholar] [CrossRef]

- Budiman, I.; Sumarno, A.; Triastuti; Prasetyo, A.M.; Maidina; Widodo, E.; Akbar, F.; Subiyanto, B.; Nugroho, A. The properties of cement boards reinforced with coconut coir fiber (Cocos nucifera) as building materials. IOP Conf. Ser. Earth Environ. Sci. 2021, 762, 4–12. [Google Scholar] [CrossRef]

- Bertoft Eric, E.; Laohaphatanalert, K.; Piyachomkwan, K.; Sriroth, K. The fine structure of cassava starch amylopectin. Part 2: Building block structure of clusters. Int. J. Biol. Macromol. 2010, 47, 325–335. [Google Scholar] [CrossRef] [PubMed]

- Brzyski, P.; Gładecki, M.; Rumińska, M.; Pietrak, K.; Kubiś, M.; Łapka, P. Influence of Hemp Shives Size on Hygro-Thermal and Mechanical Properties of a Hemp-Lime Composite. Materials 2020, 13, 5383. [Google Scholar] [CrossRef]

- Adesina, I.; Bhowmik, A.; Sharma, H.; Shahbazi, A. A Review on the Current State of Knowledge of Growing Conditions, Agronomic Soil Health Practices and Utilities of Hemp in the United States. Agriculture 2020, 10, 129. [Google Scholar] [CrossRef] [Green Version]

- Duque Schumacher, A.G.; Pequito, S.; Pazour, J. Industrial hemp fiber: A sustainable and economical alternative to cotton. J. Clean. Prod. 2020, 268, 122180. [Google Scholar] [CrossRef]

- Piatkiewicz, W.; Narloch, P.; Pietruszka, B. Influence of hemp-lime composite composition on its mechanical and physical properties. Arch. Civ. Eng. 2020, 66, 487–503. [Google Scholar] [CrossRef]

- Kosiński, P.; Brzyski, P.; Tunkiewicz, M.; Suchorab, Z.; Wiśniewski, D.; Palczyński, P. Thermal Properties of Hemp Shives Used as Insulation Material in Construction Industry. Energies 2022, 15, 2461. [Google Scholar] [CrossRef]

- Citterio, S.; Santagostino, A.; Fumagalli, P.; Prato, N.; Ranalli, P.; Sgorbati, S. Heavy Metal Tolerance and Accumulation of Cd, Cr and Ni by Cannabis sativa L. Plant Soil 2003, 56, 243–252. [Google Scholar] [CrossRef]

- Crini, G.; Lichtfouse, E.; Chanet, G.; Morin-Crini, N. Applications of hemp in textiles, paper industry, insulation and building materials, horticulture, animal nutrition, food and beverages, nutraceuticals, cosmetics and hygiene, medicine, agrochemistry, energy production and environment: A review. Environ. Chem. Lett. 2020, 18, 1451–1476. [Google Scholar] [CrossRef]

- Cierpucha, W.; Kozłowski, R.; Mańkowski, J.; Waśko, J.; Mańkowski, T. Applicability of flax and hemp as raw materials for production of cotton-like fibres and blended yarns in Poland. Fibres Text. East. Eur. 2004, 12, 13–18. [Google Scholar]

- Ahmed, A.T.M.F.; Islam, M.Z.; Mahmud, M.S.; Sarker, M.E.; Islam, M.R. Hemp as a potential raw material toward a sustainable world: A review. Heliyon 2022, 8, e08753. [Google Scholar] [CrossRef] [PubMed]

- Elfordy, S.; Lucas, F.; Tancret, F.; Scudeller, Y.; Goudet, L. Mechanical and thermal properties of lime and hemp concrete (“hempcrete”) manufactured by a projection process. Constr. Build. Mater. 2008, 22, 2116–2123. [Google Scholar] [CrossRef]

- Abdellatef, Y.; Khan, M.A.; Khan, A.; Alam, M.I.; Kavgic, M. Mechanical, Thermal, and Moisture Buffering Properties of Novel Insulating Hemp-Lime Composite Building Materials. Materials 2020, 13, 5000. [Google Scholar] [CrossRef]

- Williams, J.; Lawrence, M.; Walker, P. The influence of constituents on the properties of the bio-aggregate composite hemp-lime. Constr. Build. Mater. 2018, 159, 9–17. [Google Scholar] [CrossRef]

- Brzyski, P.; Gleń, P.; Gładecki, M.; Rumińska, M.; Suchorab, Z.; Łagód, G. Influence of the Direction of Mixture Compaction on the Selected Properties of a Hemp-Lime Composite. Materials 2021, 14, 4629. [Google Scholar] [CrossRef]

- Mazhoud, B.; Collet, F.; Pretot, S.; Lanos, C. Development and hygric and thermal characterization of hemp-clay composite. Eur. J. Environ. Civ. Eng. 2018, 22, 1511–1521. [Google Scholar] [CrossRef]

- Walker, R.; Pavía, S. Moisture transfer and thermal properties of hemp-lime concretes. Constr. Build. Mater. 2014, 64, 270–276. [Google Scholar] [CrossRef]

- EN 933-1; Tests for Geometrical Properties of Aggregates—Part 1: Determination of Particle Size Distribution—Sieving Method. European Committee for Standardization: Brussels, Belgium, 2012.

- Sahmenko, G.; Sinka, M.; Namsone, E.; Korjakins, A.; Bajare, D. Sustainable Wall Solutions Using Foam Concrete and Hemp Composites. Environ. Clim. Technol. 2021, 25, 917–930. [Google Scholar] [CrossRef]

- ISO 12571; Hygrothermal Performance of Building Materials and Products—Determination of Hygroscopic Sorption Properties. International Organization for Standardization: Geneva, Switzerland, 2013.

- ISO 8302; Thermal Insulation—Determination of Steady-State Thermal Resistance and Related Properties—Guarded Hot Plate Apparatus. International Organization for Standardization: Geneva, Switzerland, 1991.

| Sample Type | Hemp Shives | MgO | MgCl2 Sol. 1:1 with Water | Density (kg/m3) | Thickness, P1/P2 (m) |

|---|---|---|---|---|---|

| D200 | 1.00 | 0.50 | 0.32 | 201 | 0.05004/0.04951 |

| D300 | 1.00 | 1.00 | 0.63 | 279 | 0.05066/0.05073 |

| D400 | 1.00 | 1.93 | 1.22 | 394 | 0.04998/0.04981 |

| D500 | 1.00 | 2.44 | 1.53 | 489 | 0.05145/0.05078 |

| D600 | 1.00 | 3.00 | 1.89 | 576 | 0.05150/0.05090 |

| Sample Type | Thermal Conductivity (W/m/K) | |||

|---|---|---|---|---|

| Dry | RH = 50% | RH = 75% | RH = 90% | |

| D200 P1 | 0.055 | 0.062 | 0.070 | 0.093 |

| Std dev. | 0.001 | 0.002 | 0.001 | 0.001 |

| D200 P2 | 0.057 | 0.062 | 0.067 | 0.088 |

| Std dev. | 0.001 | 0.001 | 0.001 | 0.005 |

| D200 avg | 0.056 | 0.062 | 0.069 | 0.091 |

| D300 P1 | 0.074 | 0.085 | 0.090 | 0.131 |

| Std dev. | 0.001 | 0.001 | 0.001 | 0.001 |

| D300 P2 | 0.072 | 0.083 | 0.089 | 0.132 |

| Std dev. | 0.001 | 0.001 | 0.002 | 0.001 |

| D300 avg | 0.073 | 0.084 | 0.090 | 0.132 |

| D400 P1 | 0.104 | 0.121 | 0.127 | 0.159 |

| Std dev. | 0.001 | 0.001 | 0.002 | 0.003 |

| D400 P2 | 0.106 | 0.118 | 0.126 | 0.155 |

| Std dev. | 0.002 | 0.001 | 0.001 | 0.002 |

| D400 avg | 0.105 | 0.120 | 0.127 | 0.157 |

| D500 P1 | 0.127 | 0.138 | 0.150 | 0.184 |

| Std dev. | 0.001 | 0.003 | 0.001 | 0.002 |

| D500 P2 | 0.130 | 0.135 | 0.159 | 0.194 |

| Std dev. | 0.001 | 0.002 | 0.001 | 0.001 |

| D500 avg | 0.129 | 0.137 | 0.155 | 0.184 |

| D600 P1 | 0.158 | 0.159 | 0.182 | 0.240 |

| Std dev. | 0.001 | 0.001 | 0.001 | 0.002 |

| D600 P2 | 0.160 | 0.169 | 0.176 | 0.241 |

| Std dev. | 0.002 | 0.003 | 0.001 | 0.001 |

| D600 avg | 0.159 | 0.163 | 0.179 | 0.241 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kubiś, M.; Łapka, P.; Cieślikiewicz, Ł.; Sahmenko, G.; Sinka, M.; Bajare, D. Analysis of the Thermal Conductivity of a Bio-Based Composite Made of Hemp Shives and a Magnesium Binder. Energies 2022, 15, 5490. https://doi.org/10.3390/en15155490

Kubiś M, Łapka P, Cieślikiewicz Ł, Sahmenko G, Sinka M, Bajare D. Analysis of the Thermal Conductivity of a Bio-Based Composite Made of Hemp Shives and a Magnesium Binder. Energies. 2022; 15(15):5490. https://doi.org/10.3390/en15155490

Chicago/Turabian StyleKubiś, Michał, Piotr Łapka, Łukasz Cieślikiewicz, Genadijs Sahmenko, Maris Sinka, and Diana Bajare. 2022. "Analysis of the Thermal Conductivity of a Bio-Based Composite Made of Hemp Shives and a Magnesium Binder" Energies 15, no. 15: 5490. https://doi.org/10.3390/en15155490

APA StyleKubiś, M., Łapka, P., Cieślikiewicz, Ł., Sahmenko, G., Sinka, M., & Bajare, D. (2022). Analysis of the Thermal Conductivity of a Bio-Based Composite Made of Hemp Shives and a Magnesium Binder. Energies, 15(15), 5490. https://doi.org/10.3390/en15155490