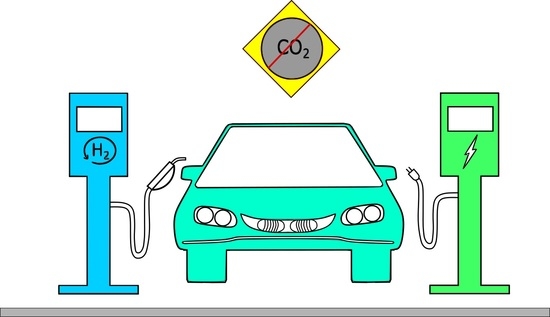

A Perspective on Decarbonizing Mobility: An All-Electrification vs. an All-Hydrogenization Venue

Abstract

:1. Introduction

2. Materials and Methods

2.1. Estimation of Annual Fuel Demand

2.2. Estimation of Required Electrical Energy to Compensate Diesel and Gasoline

2.3. Estimation of Required Hydrogen Amount to Compensate Diesel and Gasoline

2.4. Estimation of the Equivalent Electricity Cost

2.5. Estimation of the CAPEX for Blue Hydrogen Plant

2.6. Estimation of Electrolyzer CAPEX

3. Results

3.1. Analysis of a Transition toward E-Mobility

3.2. Analysis of A Transition toward Hydrogen-Mobility

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- IPCC. Global Warming of 1.5 °C; An IPCC Special Report on the Impacts of Global Warming of 1.5 °C above Pre-Industrial Levels and Related Global Greenhouse Gas Emission Pathways, in the Context of Strengthening the Global Response to the Threat of Climate Change, Sustainable Development, and Efforts to Eradicate Poverty; Masson-Delmotte, V., Zhai, P., Pörtner, H.-O., Roberts, D., Skea, J., Shukla, P.R., Pirani, A., Moufouma-Okia, W., Péan, C., Pidcock, R., et al., Eds.; Cambridge University Press: Cambridge, UK, 2022. [Google Scholar] [CrossRef]

- IEA. Global Energy Review: CO2 Emissions in 2020; IEA: Paris, France, 2021; Available online: https://www.iea.org/articles/global-energy-review-co2-emissions-in-2020 (accessed on 2 September 2021).

- Kober, T.; Schiffer, H.-W.; Densing, M.; Panos, E. Global energy perspectives to 2060—WEC’s World Energy Scenarios 2019. Energy Strategy Rev. 2020, 31, 100523. [Google Scholar] [CrossRef]

- IEA Data and Statistics. Available online: https://www.iea.org/data-and-statistics/data-browser?country=WORLD&fuel=CO2%20emissions&indicator=CO2BySector (accessed on 2 September 2021).

- Ford to Go All-Electric in Europe by 2030. Available online: https://www.bbc.com/news/business-56084500 (accessed on 2 September 2021).

- Volkswagen to Stop Making Combustion Engine Cars by 2035 in Europe. Available online: https://www.dw.com/en/volkswagen-to-stop-making-combustion-engine-cars-by-2035-in-europe/a-58066090 (accessed on 2 September 2021).

- Audi to Stop Making Fossil Fuel Cars by 2033: CEO. Available online: https://www.france24.com/en/live-news/20210622-audi-to-stop-making-fossil-fuel-cars-by-2033-ceo (accessed on 2 September 2021).

- Toyota Develops Packaged Fuel Cell System Module to Promote the Hydrogen Utilization toward the Achievement of Carbon Neutrality. Available online: https://global.toyota/en/newsroom/corporate/34799439.html (accessed on 2 September 2021).

- The EU Aims to be Climate-Neutral by 2050—An Economy with Net-Zero Greenhouse Gas Emissions. This Objective Is at the Heart of the European Green Deal and in Line with the EU’s Commitment to Global Climate Action under the Paris Agreement. Available online: https://ec.europa.eu/clima/policies/strategies/2050_en (accessed on 2 September 2021).

- Samsun, R.C.; Rex, M.; Antoni, L.; Stolten, D. Deployment of Fuel Cell Vehicles and Hydrogen Refueling Station Infrastructure: A Global Overview and Perspectives. Energies 2022, 15, 4975. [Google Scholar] [CrossRef]

- Acar, C.; Dincer, I. Review and evaluation of hydrogen production options for better environment. J. Clean. Prod. 2019, 218, 835–849. [Google Scholar] [CrossRef]

- Jovan, D.J.; Dolanc, G. Can Green Hydrogen Production Be Economically Viable under Current Market Conditions. Energies 2020, 13, 6599. [Google Scholar] [CrossRef]

- Qazi, U.Y. Future of Hydrogen as an Alternative Fuel for Next-Generation Industrial Applications; Challenges and Expected Opportunities. Energies 2022, 15, 4741. [Google Scholar] [CrossRef]

- Breuer, J.L.; Scholten, J.; Koj, J.C.; Schorn, F.; Fiebrandt, M.; Samsun, R.C.; Albus, R.; Görner, K.; Stolten, D.; Peters, R. An Overview of Promising Alternative Fuels for Road, Rail, Air, and Inland Waterway Transport in Germany. Energies 2022, 15, 1443. [Google Scholar] [CrossRef]

- Ala, G.; Colak, I.; Di Filippo, G.; Miceli, R.; Romano, P.; Silva, C.; Valtchev, S.; Viola, F. Electric Mobility in Portugal: Current Situation and Forecasts for Fuel Cell Vehicles. Energies 2021, 14, 7945. [Google Scholar] [CrossRef]

- Rabiega, W.; Gorzałczyński, A.; Jeszke, R.; Mzyk, P.; Szczepański, K. How Long Will Combustion Vehicles Be Used? Polish Transport Sector on the Pathway to Climate Neutrality. Energies 2021, 14, 7871. [Google Scholar] [CrossRef]

- Lahnaoui, A.; Wulf, C.; Dalmazzone, D. Optimization of Hydrogen Cost and Transport Technology in France and Germany for Various Production and Demand Scenarios. Energies 2021, 14, 744. [Google Scholar] [CrossRef]

- Demand Outlook for Selected Oil Products Worldwide from 2019 to 2045. Available online: https://www.statista.com/statistics/282774/global-product-demand-outlook-worldwide/ (accessed on 2 September 2021).

- Volkswagen Tiguan 1.4 TSI ACT BMT DSG (150 hp) WLTP, MPG, Fuel Consumption. Available online: https://motoreu.com/volkswagen-tiguan-1.4-tsi-act-bmt-mpg-fuel-consumption-technical-specifications-37329 (accessed on 2 September 2021).

- Kia EV6 Standard Range 2WD. Available online: https://ev-database.org/car/1480/Kia-EV6-Standard-Range-2WD (accessed on 2 September 2021).

- The New Toyota Mirai. Available online: https://newsroom.toyota.eu/the-new-toyota-mirai/ (accessed on 2 September 2021).

- Levelised Cost of Electricity LCOE for Solar PV and Coal-Fired Power Plants in India in the New Policies Scenario, 2020–2040. Available online: https://www.iea.org/data-and-statistics/charts/levelised-cost-of-electricity-lcoe-for-solar-pv-and-coal-fired-power-plants-in-india-in-the-new-policies-scenario-2020-2040 (accessed on 2 September 2021).

- Transparent Cost Database. Available online: https://openei.org/wiki/Transparent_Cost_Database (accessed on 2 September 2021).

- Projected Costs of Generating Electricity 2020. Available online: https://www.iea.org/reports/projected-costs-of-generating-electricity-2020 (accessed on 2 September 2021).

- Projected Costs of Generating Electricity—2015 Edition. Available online: https://www.oecd-nea.org/jcms/pl_14756/projected-costs-of-generating-electricity-2015-edition?details=true (accessed on 2 September 2021).

- Economics of Nuclear Power. Available online: https://world-nuclear.org/information-library/economic-aspects/economics-of-nuclear-power.aspx (accessed on 2 September 2021).

- Hu, B.; Zhai, H. The cost of carbon capture and storage for coal-fired power plants in China. Int. J. Greenh. Gas Control 2017, 65, 23–31. [Google Scholar] [CrossRef]

- IRENA. Renewable Power Generation Costs in 2020; International Renewable Energy Agency: Abu Dhabi, United Arab Emirates, 2021. [Google Scholar]

- IEA. The Future of Hydrogen; IEA G20 Hydrogen Report; IEA: Paris, France, 2019; Available online: https://www.iea.org/reports/the-future-of-hydrogen (accessed on 2 September 2021).

- IRENA. Green Hydrogen Cost Reduction: Scaling Up Electrolysers to Meet the 1.5 °C Climate Goal; International Renewable Energy Agency: Abu Dhabi, United Arab Emirates, 2020. [Google Scholar]

- Bellotti, D.; Sorce, A.; Rivarolo, M.; Magistri, L. Techno-economic analysis for the integration of a power to fuel system with a CCS coal power plant. J. CO2 Util. 2019, 33, 262–272. [Google Scholar] [CrossRef]

- Steam Methane Reforming—Hydrogen Production. Available online: https://www.engineering-airliquide.com/steam-methane-reforming-hydrogen-production (accessed on 2 September 2021).

- IEA Data and Statistics. Available online: https://www.iea.org/data-and-statistics/data-browser?country=WORLD&fuel=Electricity%20and%20heat&indicator=TotElecCons (accessed on 2 September 2021).

- Brad Page, Guloren Turan, Alex Zapantis The Global Status of CCS Report 2020. Available online: https://www.globalccsinstitute.com/resources/global-status-report/ (accessed on 2 September 2021).

- Gasoline Prices, Litre. 30 August 2021. Available online: https://www.globalpetrolprices.com/gasoline_prices/?__cf_chl_jschl_tk__=pmd_uKCmLrV88BoJ9Csa623C0JFUYNU1bfx8FpbOAp0E_h4-1629905725-0-gqNtZGzNAeWjcnBszQil (accessed on 2 September 2021).

- Mathew Martin Saudi Aramco Bets on Blue Hydrogen Exports Ramping Up from 2030. Available online: https://www.bloomberg.com/news/articles/2021-06-27/aramco-says-timing-of-next-blue-ammonia-cargo-depends-on-buyers (accessed on 2 September 2021).

| Energy Source | Coal-Fired Power Plant | Coal-Fired Power Plant with CCS | NG Power Plant | Solar Power Plant | Nuclear Power Plant |

|---|---|---|---|---|---|

| LCOE, USD/MWh | 65.3 | 89.1 | 50.2 | 86.1 | 71.3 |

| Capacity factor (%) | 58.4% | 58.4% | 56.2% | 23% | 92% |

| Mass of CO2 emitting per 1 MWh, tons of CO2 | 0.952 | 0.095 | 0.560 | 0.048 | 0.012 |

| Lifetime (years) | 40 | 40 | 30 | 25 | 60 |

| Construction period (years) | 4 | 4 | 3 | 1 | 7 |

| Lowest CAPEX-factor USD/kW | 500 | 800 | 1066 | 883 | 2021 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Manakhov, A.; Orlov, M.; Babiker, M.; Al-Qasim, A.S. A Perspective on Decarbonizing Mobility: An All-Electrification vs. an All-Hydrogenization Venue. Energies 2022, 15, 5440. https://doi.org/10.3390/en15155440

Manakhov A, Orlov M, Babiker M, Al-Qasim AS. A Perspective on Decarbonizing Mobility: An All-Electrification vs. an All-Hydrogenization Venue. Energies. 2022; 15(15):5440. https://doi.org/10.3390/en15155440

Chicago/Turabian StyleManakhov, Anton, Maxim Orlov, Mustafa Babiker, and Abdulaziz S. Al-Qasim. 2022. "A Perspective on Decarbonizing Mobility: An All-Electrification vs. an All-Hydrogenization Venue" Energies 15, no. 15: 5440. https://doi.org/10.3390/en15155440

APA StyleManakhov, A., Orlov, M., Babiker, M., & Al-Qasim, A. S. (2022). A Perspective on Decarbonizing Mobility: An All-Electrification vs. an All-Hydrogenization Venue. Energies, 15(15), 5440. https://doi.org/10.3390/en15155440