Municipal Sewage Sludge Composting in the Two-Stage System: The Role of Different Bulking Agents and Amendments

Abstract

:1. Introduction

2. Materials and Methods

2.1. Experimental Setup

2.2. Sewage Sludge and Feedstock Characteristics

2.2.1. Sewage Sludge

2.2.2. Lignocellulosic Materials and Feedstock Composition

2.3. Kinetic Equations

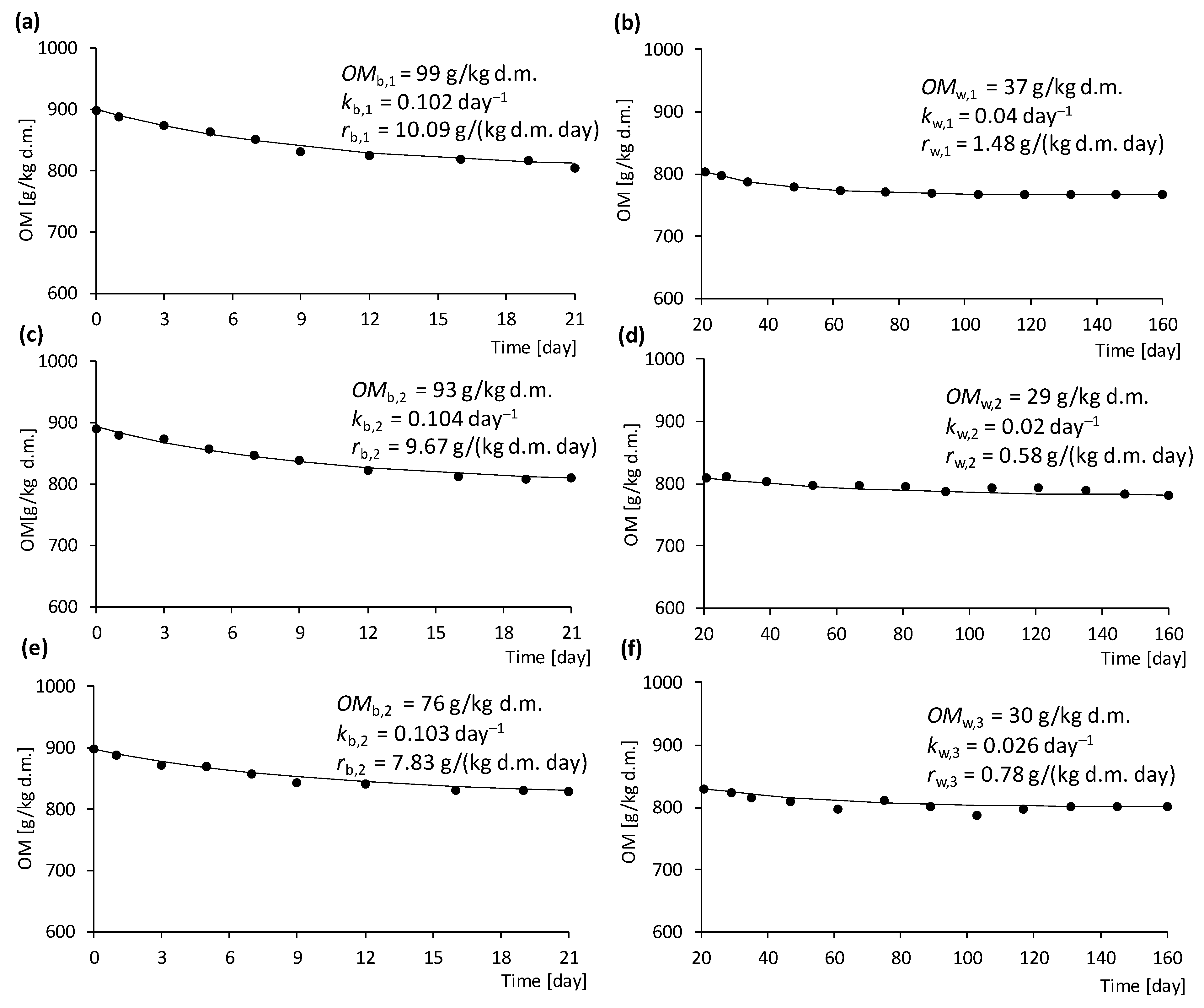

2.3.1. Organic Matter Removal

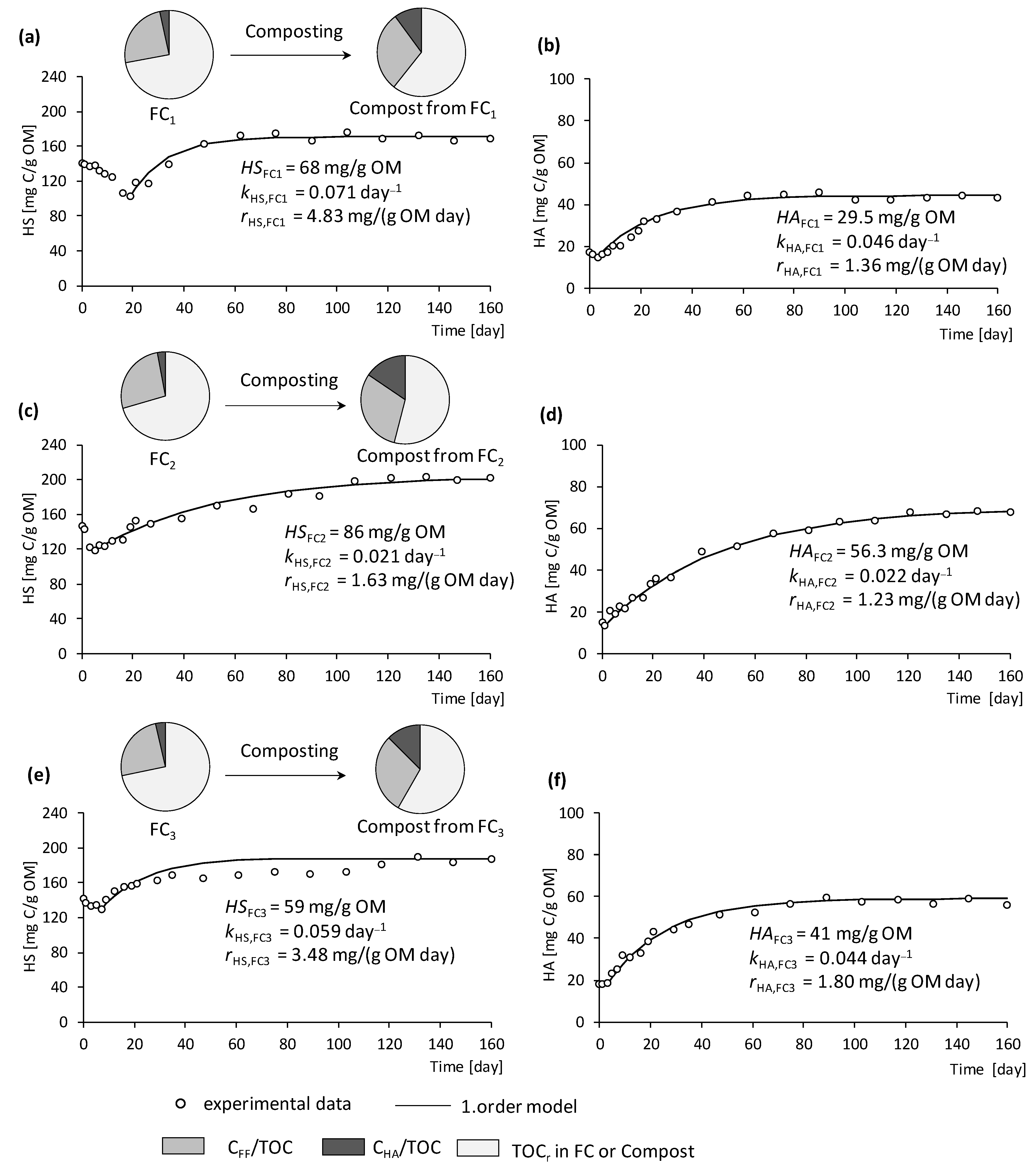

2.3.2. Humic Substances and Humic Acid Formation

2.4. Analytical Methods

3. Results and Discussion

3.1. Temperature Profiles and Organics Removal

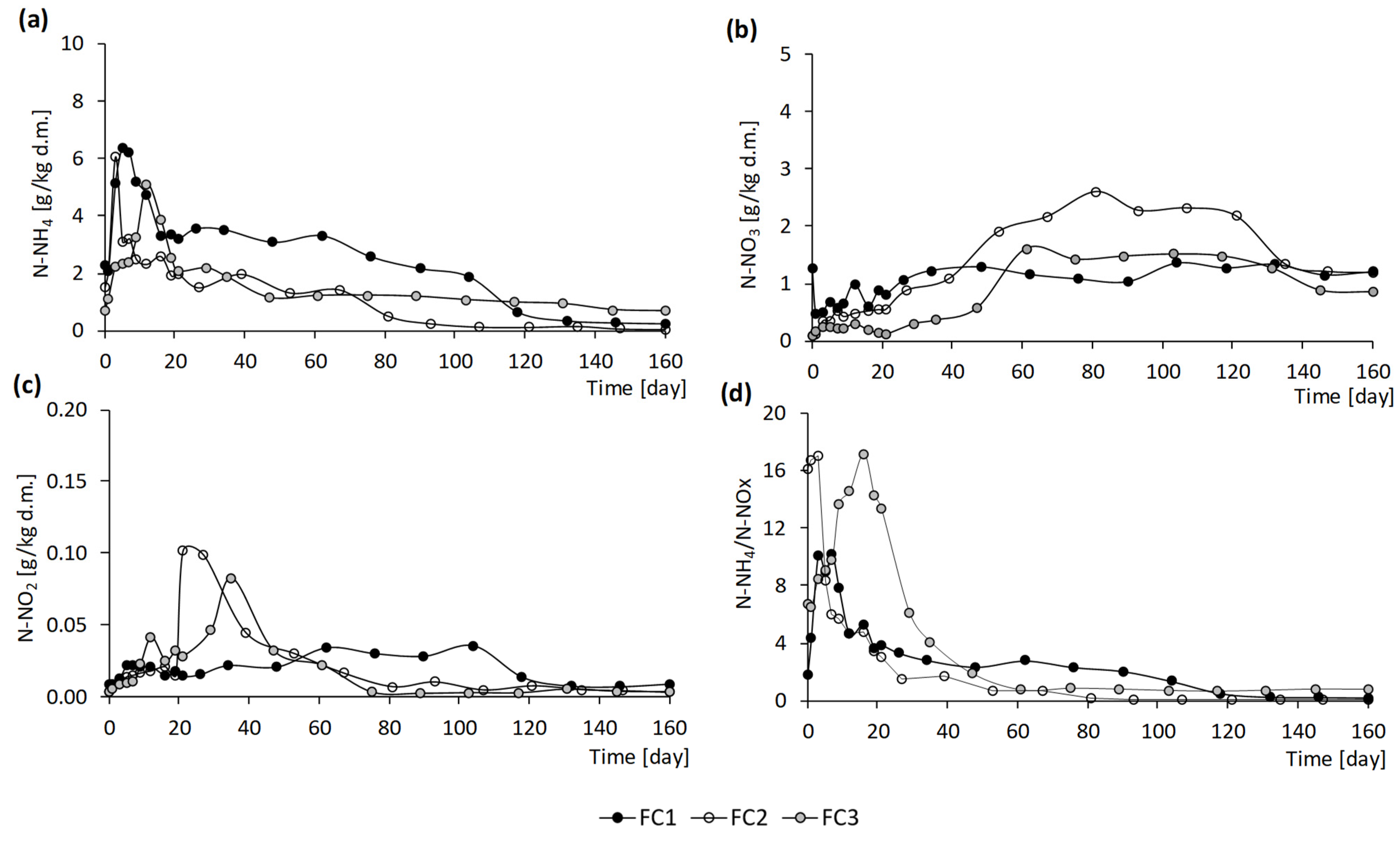

3.2. Nitrogen Profiles

3.3. Compost Stability

3.4. Humification Progress

3.5. Compost Quality

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- VI Aktualizacja Krajowego Programu Oczyszczania Ścieków Komunalnych (Update of the National Program for Municipal Sewage Treatment (UNMSTP)). Warsaw, Poland. 2022. Available online: https://www.gov.pl/attachment/a7096f8e-5961-4719-8c03-4b36cf61f56a (accessed on 15 June 2022). (In Polish)

- Kulikowska, D. Kinetics of organic matter removal and humification progress during sewage sludge composting. Waste Manag. 2016, 49, 196–203. [Google Scholar] [CrossRef] [PubMed]

- Mao, H.; Zhang, H.; Fu, Q.; Zhong, M.; Li, R.; Zhai, B.; Wang, Z.; Zhou, L. Effects of four additives in pig manure composting on greenhouse gas emission reduction and bacterial community change. Bioresour. Technol. 2019, 292, 121896. [Google Scholar] [CrossRef] [PubMed]

- Bai, M.; Impraim, R.; Coates, T.; Flesch, T.; Trouve, R.; van Grinsven, H.; Cao, Y.; Hill, J.; Chen, D. Lignite effects on NH3, N2O, CO2 and CH4 emissions during composting of manure. J. Environ. Manag. 2020, 271, 110960. [Google Scholar] [CrossRef] [PubMed]

- Kulikowska, D.; Bernat, K. Waste willow-bark from salicylate extraction successfully reused as an amendment for sewage sludge composting. Sustainability 2021, 13, 6771. [Google Scholar] [CrossRef]

- Uçaroğlu, S.; Alkan, U. Composting of wastewater treatment sludge with different bulking agents. J. Air Waste Manag. Assoc. 2016, 66, 288–295. [Google Scholar] [CrossRef] [Green Version]

- Nguyen, T.B.; Shima, K. Composting of sewage sludge with a simple aeration method and its utilization as a soil fertilizer. Environ. Manag. 2019, 63, 455–465. [Google Scholar] [CrossRef]

- Ma, C.; Hu, B.; Wei, M.B.; Zhao, J.H.; Zhang, H.Z. Influence of matured compost inoculation on sewage sludge composting: Enzyme activity, bacterial and fungal community succession. Bioresour. Technol. 2019, 294, 122165. [Google Scholar] [CrossRef]

- Meng, L.; Li, W.; Zhang, S.; Zhang, X.; Zhao, Y.; Chen, L. Improving sewage sludge compost process and quality by carbon sources addition. Sci. Rep. 2021, 11, 1319. [Google Scholar] [CrossRef]

- Cardoso, P.H.S.; Gonçalves, P.W.B.; de Oliveira Alves, G.; Pegoraro, R.F.; Fernandes, L.A.; Frazão, L.A.; Sampaio, R.A. Improving the quality of organic compost of sewage sludge using grass cultivation followed by composting. J. Environ. Manag. 2022, 314, 115076. [Google Scholar] [CrossRef]

- Chen, Z.; Li, Y.; Peng, Y.; Mironov, V.; Chen, J.; Jin, H.; Zhang, S. Feasibility of sewage sludge and food waste aerobic co-composting: Physicochemical properties, microbial community structures, and contradiction between microbial metabolic activity and safety risks. Sci. Total Environ. 2022, 825, 154047. [Google Scholar] [CrossRef]

- Liu, Y.; Ding, L.; Wang, B.; He, Q.; Wan, D. Using the modified pine wood as a novel recyclable bulking agent for sewage sludge composting: Effect on nitrogen conversion and microbial community structures. Bioresour. Technol. 2020, 309, 123357. [Google Scholar] [CrossRef] [PubMed]

- Song, X.Y.; Liu, S.T.; Liu, Q.H.; Zhang, W.J.; Hu, C.G. Carbon sequestration in soil humic substances under long-term fertilization in a wheat-maize system from North China. J. Integr. Agric. 2014, 13, 562–569. [Google Scholar] [CrossRef]

- Minister of the Environment. Regulation of the Minister of the Environment of 6 February 2015 on the Municipal Sewage Sludge (J. L.2015, No. 0, Item. 257); Minister of the Environment: Warsaw, Poland, 2015.

- The European Parliament and the Council of the European Union. Regulation (EU) 2019/1009 of the European Parliament and of the Council of 5 June 2019 Laying Down Rules on the Making Available on the Market of EU Fertilising Products and Amending Regulation (EC) No 1069/2009 and (EC) No 1107/2009 and Repealing Regulat; European Parliament: Bruxelles, Belgium, 2019. [Google Scholar]

- AbfAblV 2001: Verordnung über die umweltverträgliche Ablagerung von Siedlungsabfällen. In Bundesgesetzblatt Teil I.; No. 11; Bundesministerium der Justiz und für Verbraucherschutz: Bonn, Germany, 2001; pp. 305–324.

- Brinton, W.F.; Evans, E.; Droffner, M.L.; Brinton, R.B. A standardized Dewar test for evaluation of compost self-heating. Biocycle 1995, 36, 1–16. [Google Scholar]

- Pecorini, I.; Peruzzi, E.; Albini, E.; Doni, S.; Macci, C.; Masciandaro, G.; Iannelli, R. Evaluation of MSW compost and digestate mixtures for a circular economy application. Sustainability 2020, 12, 3042. [Google Scholar] [CrossRef] [Green Version]

- PN−EN 12880:2004; Characteristics of Sewage Sludge, Determination of Dry Residue and Water Content. Polish Committee for Standardization: Warszawa, Poland, 2004.

- PN-EN 15169:2011; Characterization of Waste-Determination of Loss on Ignition in Waste, Sludge and Sediments. Polish Committee for Standardization: Warszawa, Poland, 2011.

- PN-Z-15011-3:2001; Municipal Waste Compost-Determination of pH, Organic Matter, Organic Carbon, Nitrogen, Phosphorus and Potassium. Polish Committee for Standardization: Warszawa, Poland, 2001.

- Kulikowska, D.; Klimiuk, E. Organic matter transformations and kinetics during sewage sludge composting in a two-stage system. Bioresour. Technol. 2011, 102, 10951–10958. [Google Scholar] [CrossRef] [PubMed]

- 23. PN-EN 5664:2002; Water Quality. Determination of Ammonium Nitrogen. Distillation Method with Titration. The Polish Committee for Standardization: Warsaw, Poland, 2002.

- PN-EN 26777:1999; Determination of Nitrite Nitrogen by Colorimetric Method with Sulfanilic Acid and 1-Naphthylamine. The Polish Committee for Standardization: Warsaw, Poland, 1999.

- PN-C-04576/08:1982; Tests for the Content of Nitrogen Compounds. Determination of Nitrate Nitrogen by Colorimetric Method with Sodium Salicylate. The Polish Committee for Standardization: Warsaw, Poland, 1982.

- PN-EN ISO 6579-1:2017-04; A Method for the Detection, Enumeration and Serotyping of Salmonella. The Polish Committee for Standardization: Warsaw, Poland, 2017.

- Kumar, M.; Ou, Y.L.; Lin, J.G. Co-composting of green waste and food waste at low C/N ratio. Waste Manag. 2010, 30, 602–609. [Google Scholar] [CrossRef]

- Yuan, J.; Yang, Q.; Zhang, Z.; Li, G.; Luo, W.; Zhang, D. Use of additive and pretreatment to control odors in municipal kitchen waste during aerobic composting. J. Environ. Sci. 2015, 37, 83–90. [Google Scholar] [CrossRef]

- De Bertoldi, M.; Vallini, G.; Pera, A. The biology of composting: A review. Waste Manag. Res. 1993, 1, 157–176. [Google Scholar] [CrossRef]

- Hamoda, M.F.; Abu Qdais, H.A.; Newham, J. Evaluation of municipal solid waste composting kinetics. Res. Conserv. Rec. 1998, 23, 209–223. [Google Scholar] [CrossRef]

- McCartney, D.; Tingley, J. Development of a rapid moisture content method for compost materials. Compost Sci. Util. 1998, 6, 73–91. [Google Scholar] [CrossRef]

- Liang, C.; Das, K.C.; McClendon, R.W. The influence of temperature and moisture contents regimes on the aerobic microbial activity of a biosolids composting blend. Biores. Technol. 2003, 86, 131–137. [Google Scholar] [CrossRef]

- Bożym, M.; Siemiątkowski, G. Characterization of composted sewage sludge during the maturation process: A pilot scale study. Environ. Sci. Pollut. Res. 2018, 25, 34332–34342. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Kulikowska, D.; Sindrewicz, S. Effect of barley straw and coniferous bark on humification process during sewage sludge composting. Waste Manag. 2018, 79, 207–213. [Google Scholar] [CrossRef] [PubMed]

- Becher, M.; Symanowicz, B.; Jaremko, D.; Trzcinska, E. Chemical composition of compost from municipal waste in the context of use as fertiliser. Acta Agroph. 2018, 25, 329–341. [Google Scholar] [CrossRef]

- Ministry of Agriculture and Rural Development. Regulation of the Minister of Agriculture and Rural Development of 18 June 2008 Regarding the Implementation of Certain Provisions of the Act on Fertilizers and Fertilization (no. 119 item 765); Minister of Agriculture and Rural Development: Warsaw, Poland, 2008.

| Characteristics | Unit | FC1 | FC2 | FC3 |

|---|---|---|---|---|

| Basic analysis of physicochemical characteristics and nutrient contents | ||||

| Moisture | % | 89.0 | 89.3 | 89.2 |

| Dry mass (d.m.) | % | 11.0 | 10.7 | 10.8 |

| OM | % d.m. | 84.6 | 85.3 | 84.9 |

| Reaction | pH | 8.16 | 8.06 | 8.12 |

| N | g/kg d.m. | 70.1 | 70.3 | 71.3 |

| N-NH4 | 6.49 | 7.82 | 6.78 | |

| P | 11.2 | 11.5 | 12.3 | |

| P2O5 | 25.8 | 26.4 | 28.3 | |

| K2O | 10.10 | 9.11 | 9.58 | |

| K | 8.38 | 7.56 | 7.95 | |

| Mg | 2.91 | 2.87 | 2.68 | |

| MgO | 4.82 | 4.76 | 4.44 | |

| Ca | 5.02 | 5.18 | 5.71 | |

| CaO | 7.02 | 7.24 | 7.98 | |

| Heavy-metal contents | ||||

| Cd (20 *) | mg/kg d.m. | 1.15 | 1.43 | 3.80 |

| Pb (750 *) | 5.3 | 6.4 | 6.1 | |

| Ni (300 *) | 7.1 | 7.4 | 7.6 | |

| Cr (500 *) | 21.2 | 19.9 | 18.4 | |

| Cu (1000 *) | 74.0 | 87.9 | 79.0 | |

| Zn (2500 *) | 603.0 | 614.0 | 626.0 | |

| Hg (16 *) | 0.0260 | 0.0841 | 0.0910 | |

| Characteristic | Wood Chips | Wheat Straw | Energy Willow | Pine Bark | Conifer Sawdust |

|---|---|---|---|---|---|

| Moisture (%) | 42.3 | 11.2 | 40.7 | 52.9 | 10.7 |

| OM (%) | 96.10 | 93.23 | 98.05 | 97.90 | 99.67 |

| N (%) | 0.84 | 0.66 | 0.49 | 0.47 | 0.39 |

| Feedstock | Moisture (%) | OM (%) | TOC * (%) | N (%) | OM/N | C/N |

|---|---|---|---|---|---|---|

| FC1 | 73.1 | 89.7 | 50.23 | 3.14 | 28.6 | 16.0 |

| FC2 | 74.2 | 88.9 | 49.78 | 3.19 | 27.8 | 15.6 |

| FC3 | 75.8 | 89.8 | 50.30 | 3.01 | 29.8 | 16.7 |

| Characteristics | Unit | FC1 | FC2 | FC3 |

|---|---|---|---|---|

| Basic analysis of physicochemical characteristics and nutrient contents | ||||

| Moisture | % | 37.3 | 36.8 | 36.4 |

| Dry mass (d.m.) | % | 62.7 | 63.2 | 63.6 |

| OM | % d.m. | 76.6 | 78.2 | 80.2 |

| Reaction | pH | 6.66 | 6.32 | 6.20 |

| N | g/kg d.m. | 29.1 | 31.4 | 32.6 |

| P | 12.60 | 12.87 | 13.60 | |

| P2O5 | 28.9 | 29.4 | 31.2 | |

| K2O | 14.56 | 15.67 | 16.28 | |

| K | 12.08 | 13.06 | 13.54 | |

| Mg | 4.41 | 3.92 | 4.83 | |

| MgO | 7.32 | 6.34 | 8.01 | |

| Ca | 17.30 | 18.84 | 18.51 | |

| CaO | 24.2 | 26.3 | 25.9 | |

| Heavy-metal contents | ||||

| Cd (5 *) | mg/kg d.m. | 1.23 | 1.40 | 4.70 |

| Pb (140 *) | 6.1 | 6.2 | 7.4 | |

| Ni (60 *) | 10.2 | 9.6 | 11.1 | |

| Cr (100 *) | 22.4 | 20.0 | 21.1 | |

| Cu (n.r. *) | 102.3 | 97.5 | 94.6 | |

| Zn (n.r. *) | 734 | 806 | 761 | |

| Hg (2 *) | 0.0940 | 0.1128 | 0.1230 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kulikowska, D.; Bernat, K.; Zaborowska, M.; Zielińska, M. Municipal Sewage Sludge Composting in the Two-Stage System: The Role of Different Bulking Agents and Amendments. Energies 2022, 15, 5014. https://doi.org/10.3390/en15145014

Kulikowska D, Bernat K, Zaborowska M, Zielińska M. Municipal Sewage Sludge Composting in the Two-Stage System: The Role of Different Bulking Agents and Amendments. Energies. 2022; 15(14):5014. https://doi.org/10.3390/en15145014

Chicago/Turabian StyleKulikowska, Dorota, Katarzyna Bernat, Magdalena Zaborowska, and Magdalena Zielińska. 2022. "Municipal Sewage Sludge Composting in the Two-Stage System: The Role of Different Bulking Agents and Amendments" Energies 15, no. 14: 5014. https://doi.org/10.3390/en15145014

APA StyleKulikowska, D., Bernat, K., Zaborowska, M., & Zielińska, M. (2022). Municipal Sewage Sludge Composting in the Two-Stage System: The Role of Different Bulking Agents and Amendments. Energies, 15(14), 5014. https://doi.org/10.3390/en15145014