Electric Field Distribution and Dielectric Losses in XLPE Insulation and Semiconductor Screens of High-Voltage Cables

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Methods

2.2.1. Calculation of Electric Field Distribution

2.2.2. Calculation of Dielectric Losses

3. Results and Discussion

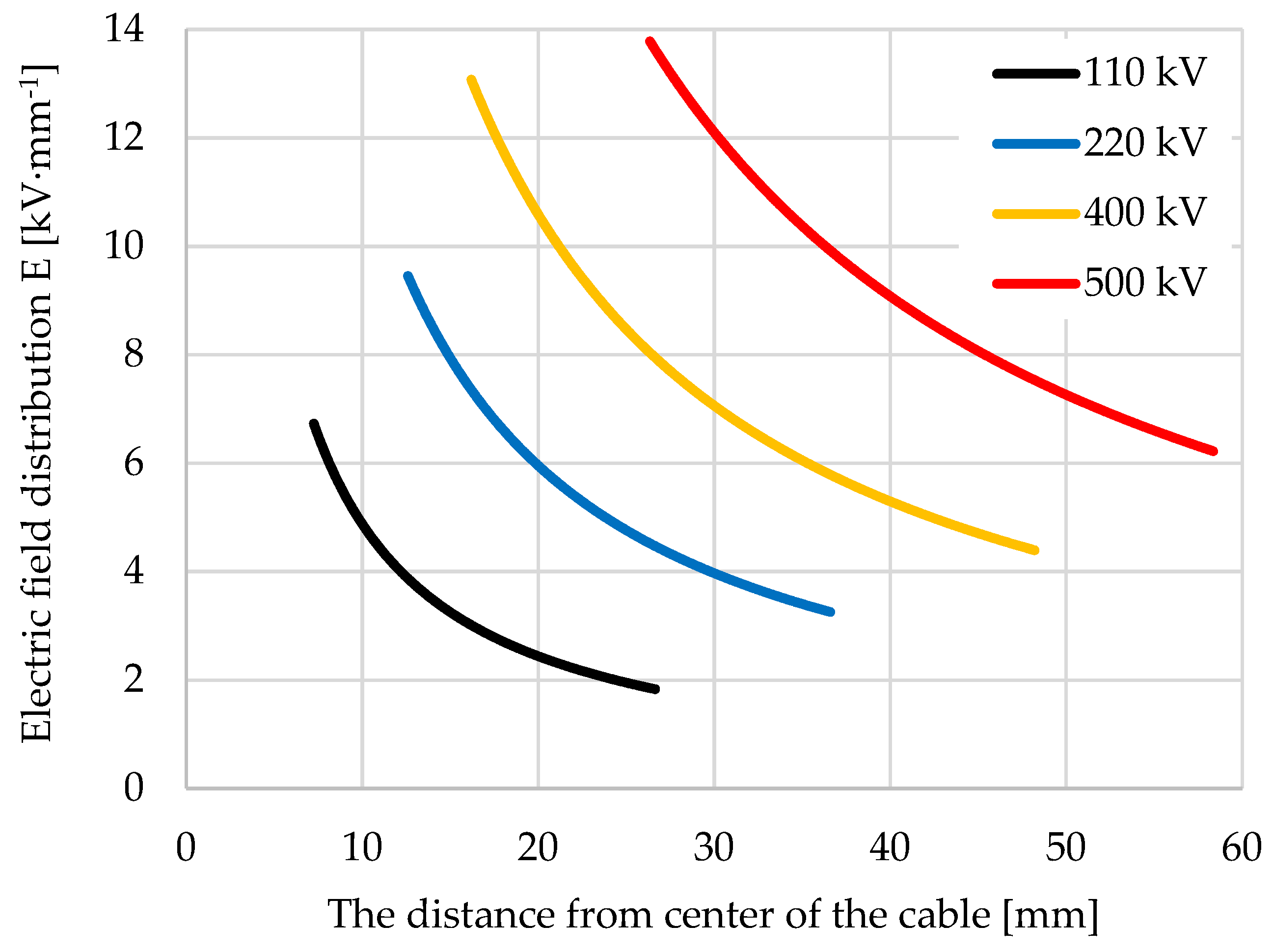

3.1. Electric Field Distribution in Semiconductor Screens and XLPE Insulation in High-Voltage Cables

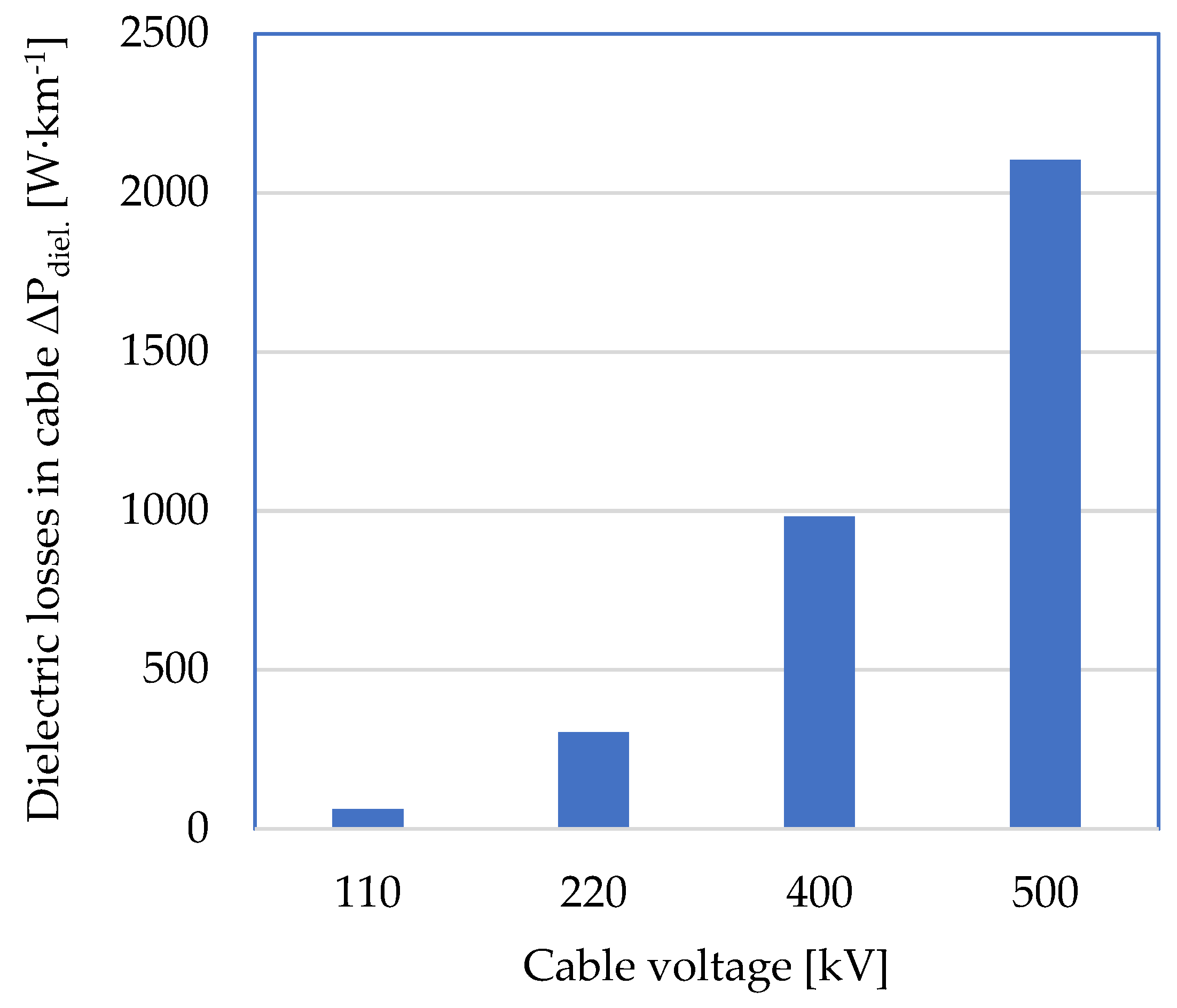

3.2. Dielectric Losses in Semiconductor Screens and XLPE Insulation of High-Voltage cables

3.3. Effect of Electrical Conductivity Not Taking into Account the Electric Field Distribution and Dielectric Losses in Semiconductor Screens and XLPE Insulation of High-Voltage cables

3.3.1. Fundamental Information

3.3.2. Electric Field Distributions

3.3.3. Dielectric Losses

4. Conclusions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Vu, T.T.N.; Teyssedre, G.; Le Roy, S. Electric Field Distribution in HVDC Cable Joint in Non-Stationary Conditions. Energies 2021, 14, 5401. [Google Scholar] [CrossRef]

- Zhang, Y.; Wu, Z.; Qian, C.; Tan, X.; Yang, J.; Zhong, L. Research on Lifespan Prediction of Cross-Linked Polyethylene Material for XLPE Cables. Appl. Sci. 2020, 10, 5381. [Google Scholar] [CrossRef]

- Fabiani, D.; Suraci, S.V. Broadband Dielectric Spectroscopy: A Viable Technique for Aging Assessment of Low-Voltage Cable Insulation Used in Nuclear Power Plants. Polymers 2021, 13, 494. [Google Scholar] [CrossRef] [PubMed]

- Plesa, I.; Notingher, P.V.; Stancu, C.; Wiesbrock, F.; Schlögl, S. Polyethylene Nanocomposites for Power Cable Insulations. Polymers 2018, 11, 24. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Diban, B.; Mazzanti, G. The Effect of Insulation Characteristics on Thermal Instability in HVDC Extruded Cables. Energies 2021, 14, 550. [Google Scholar] [CrossRef]

- Zhu, G.; Zhou, K.; Gong, W.; He, M.; Kong, J.; Li, K. Inhibition of Rejuvenation Liquid on Trees in XLPE Cables under Switching Impulse Voltages. Energies 2019, 12, 2133. [Google Scholar] [CrossRef] [Green Version]

- Qi, H.; Zhank, X.; Wang, R.; Xu, Z.; Wu, Q.; Wang, H.; Li, Z. Effect of Thermal Aging on Direct Current Integrated Charge Characteristics of XLPE Cable Insulation. In Proceedings of the 13th International Conference on the Properties and Applications of Dielectric Materials (ICPADM 2021), Johor Bahru, Malaysia, 11–15 July 2021. [Google Scholar]

- Fu, Y.; Wang, X.; Zhao, W.; Wen, Y. Effects of New Photoinitiator on Dielectric Properties of UV-irradiation XLPE. In Proceedings of the 11th International Conference on the Properties and Applications of Dielectric Materials (ICPADM 2015), Sydney, Australia, 19–22 July 2015. [Google Scholar]

- Mecheri, Y.; Nedjar, M.; Lamure, A.; Aufray, M.; Drouet, C. Influence of Moisture on the Electrical Properties of XLPE Insulation. In Proceedings of the Conference on Electrical Insulation and Dielectric Phenomena, West Lafayette, IN, USA, 17–20 October 2010. [Google Scholar]

- Du, Y.; Geng, P.; Song, J.; Tian, M.; Pang, D. Influence of Temperature and Frequency on Leakage Current of XLPE Cable Insulation. In Proceedings of the IEEE International Conference on High Voltage Engineering and Application (ICHVE), Chengdu, China, 19–22 September 2016. [Google Scholar]

- Nejdl, R.; Mentlík, V. Influence of Tools Setting on Processing Quality of XLPE Core Insulation. In Proceedings of the 15th International Scientific Conference on Electric Power Engineering, Brno-Bystrc, Czech Republic, 12–14 May 2014. [Google Scholar]

- Wang, X.; Gao, Z.; Zhu, Z.; Li, S.; Liu, Z.; Hao, J.; Ma, Z. Physicochemical and Electrical Property of a New AC 500kV XLPE Submarine Cable Insulation with Different Thermal Aging Condition. In Proceedings of the 12th IEEE International Conference on the Properties and Applications of Dielectric Materials, Xi’an, China, 20–24 May 2018. [Google Scholar]

- Yu, L.; Man, X.; Yi, Z.; Darong, X. Study of Structure and Dielectric Property on XLPE/porous-ZnCO3 Composites. In Proceedings of the IEEE International Conference on Solid Dielectrics, Bologna, Italy, 30 June–4 July 2013. [Google Scholar]

- Liu, Z.; Gao, Z.; Hao, J.; Liu, C.; Li, H.; Dai, X. Analysis of AC 500kV XLPE Submarine Cable Insulation Laboratory Aging Condition Based on Frequency Domain Dielectric Spectroscopy. In Proceedings of the Electrical Insulation Conference (EIC), Calgary, AB, Canada, 16–19 June 2019. [Google Scholar]

- Mecheri, Y.; Medjdoub, A.; Boubakeur, A.; Boujemâa, S. Characterization of Laboratory Aged MV XLPE Cables using Dielectric Losses Factor Measurements. In Proceedings of the 2014 International Conference on Electrical Sciences and Technologies in Maghreb (CISTEM), Tunis, Tunisia, 3–6 November 2014; IEEE: Piscataway, NJ, USA, 2014. ISBN 978-1-4799-7300-2. [Google Scholar] [CrossRef]

- Skjølberg, J.; Hvidsten, S.; Farmeo, H. Experience from On-Site Condition Assessment of XLPE MV Cables. In Proceedings of the IEEE International Symposium on Electrical Insulation, Toronto, ON, Canada, 11–14 June 2006. [Google Scholar]

- Zhang, Y.; Wu, K.; Zhao, C.; Xiang, J.; Li, J.; Li, S. Non-Debye Dielectric Behavior of Aged XLPE Cable Insulation. In Proceedings of the 12th IEEE International Conference on the Properties and Applications of Dielectric Materials, Xi’an, China, 20–24 May 2018. [Google Scholar]

- Bin, Z.; Zhidong, J.; Ye, Y.; Guojun, L.; Weinan, F.; Zhicheng, G. Research on the Insulation Properties of 10kV XLPE Damp Cable. In Proceedings of the IEEE 11th International Conference on the Properties and Applications of Dielectric Materials (ICPADM), Sydney, Australia, 19–22 July 2015. [Google Scholar]

- Ponniran, A.; Kamarudin, M.S. Study on the Performance of Underground XLPE Cables in Service Based on Tan Delta and Capacitance Measurements. In Proceedings of the 2nd IEEE International Conference on Power and Energy, Johor Baharu, Malaysia, 1–3 December 2008. [Google Scholar]

- Notingher, P.V.; Plopeanu, M.; Grigorescu, S.; Stancu, C. The Influence of Water Trees on Permittivity and Loss Factor of Medium Voltage Cables Polyethylene Insulation. In Proceedings of the 2010 International Conference on Solid Dielectrics, Potsdam, Germany, 4–9 July 2010. [Google Scholar]

- Wang, Z.; Wang, W.; Li, Z.; Li, S. Thermoelectric Coupling Study of Three-core XLPE Submarine Cable by Finite Element Simulation. In Proceedings of the IEEE Conference on Electrical Insulation and Dielectric Phenomena, Washington, DC, USA, 20–23 October 2019. [Google Scholar]

- Zhou, Y.; Wang, W.; Guo, T. Space Charge Accumulation Characteristics in HVDC Cable under Temperature Gradient. Energies 2020, 13, 5571. [Google Scholar] [CrossRef]

- Kumara, S.; Xu, X.; Hammarström, T.; Ouyang, Y.; Pourrahimi, A.M.; Müller, C.; Serdyuk, Y.V. Electrical Characterization of a New Crosslinked Copolymer Blend for DC Cable Insulation. Energies 2020, 13, 1434. [Google Scholar] [CrossRef] [Green Version]

- Guo, X.; Xing, Z.; Zhao, S.; Cui, Y.; Li, G.; Wei, Y.; Lei, Q.; Hao, C. Investigation of the Space Charge and DC Breakdown Behavior of XLPE/α-Al2O3 Nanocomposites. Materials 2020, 13, 1333. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Qiu, P.; Chen, L.Q.; Sun, W.F.; Zhao, H. Improved DC Dielectric Performance of Photon-Initiated Crosslinking Polyethylene with TMPTMA Auxiliary Agent. Materials 2019, 12, 3540. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Cao, L.; Zhong, L.; Li, Y.; Zhang, K.; Gao, J.; Chen, G. Enhanced High-Temperature DC Dielectric Performance of Crosslinked Polyethylene with a Polystyrene Pinning Structure. Materials 2019, 12, 1234. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Yahyaoui, H.; Castellon, J.; Agnel, S.; Hascoat, A.; Frelin, W.; Moreau, C.; Hondaa, P.; Roux, D.L.; Eriksson, V.; Andersson, C.J. Behavior of XLPE for HVDC Cables under Thermo-Electrical Stress: Experimental Study and Ageing Kinetics Proposal. Energies 2021, 14, 7344. [Google Scholar] [CrossRef]

- Zhang, C.C.; Li, Y.F.; Hu, M.Y.; Ma, F.L.; Zhao, H.; Han, B.Z. Conductivity Properties of XLPE Insulation Used for HVDC Cable after Accelerated Thermal Ageing. In Proceedings of the 12th IEEE International Conference on the Properties and Applications of Dielectric Materials, Xi’an, China, 20–24 May 2018. [Google Scholar]

- Ahmed, M.; Lisheng, Z.; Li, F.; Xu, N.; Ren, H. DC Conductivity Fluctuation Due to Temperature Dependence and Cross-linking Byproducts of XLPE Insulation Material in HVDC Cables. In Proceedings of the Electrical Insulation Conference (EIC), Virtual Event. 7–28 June 2021. [Google Scholar]

- Meng, F.; Dai, C.; Paramane, A.; Chen, X.; Tanaka, Y. Effect of Thermal Ageing on Insulation Properties of 500 kV DC XLPE Submarine Cable Insulation. In Proceedings of the IEEE Conference on Electrical Insulation and Dielectric Phenomena, East Rutherford, NJ, USA, 18–30 October 2020. [Google Scholar]

- Ren, H.; Zhong, L.; Liu, M.; Yu, Q.; Li, Y.; Zhao, W.; Zhou, Z. Effects of Degassing Duration on Space Charge and DC Conductivity in HVDC XLPE Cable Insulation. In Proceedings of the 12th IEEE International Conference on the Properties and Applications of Dielectric Materials, Xi’an, China, 20–24 May 2018. [Google Scholar]

- Paramane, A.; Chen, X.; Dai, C.; Tanaka, Y. Enhancing the Electrical Properties of XLPE Insulation by Blending Aromatic Voltage Stabilizer. In Proceedings of the 2020 IEEE International Conference on High Voltage Engineering and Application (ICHVE), Beijing, China, 6–10 September 2020; IEEE: Piscataway, NJ, USA, 2020. ISBN 978-1-7281-5511-1. [Google Scholar]

- Liu, Z.; Hao, J.; Liao, R.; Li, j.; Gao, Z.; Liang, Z. Morphological, Structural, and Dielectric Properties of Thermally Aged AC 500 kV XLPE Submarine Cable Insulation Material and Its Deterioration Condition Assessment. IEEE Access 2019, 7, 165065–165075. [Google Scholar] [CrossRef]

- Kahleras, S.; Boubakeur, A.; Boukezzi, L. Numerical Study Using FVM of Three Cavities within XLPE Insulation of HV Cables. In Proceedings of the 3rd International Conference on Electrical Sciences and Technologies in Maghreb CISTEM’18, Algiers, Algeria, 29–31 October 2018. [Google Scholar]

- Chongjun, T.; Ye, D.; Xing, W. Research on Aging Performance and Mechanism Analysis of Cross-linked Polyethylene Wire and Cable Materials. In Proceedings of the 13th International Conference on the Properties and Applications of Dielectric Materials (ICPADM), Johor Bahru, Malaysia, 12–14 July 2021. [Google Scholar]

- Yan, Z.; Han, B.; Zhao, H.; Yang, J.; Li, C. Space Charge and Conductivity Characteristics of CB/XLPE Nanocomposites. In Proceedings of the International Symposium on Electrical Insulating Materials (ISEIM), Niigata, Japan, 1–5 June 2014. [Google Scholar]

- Nam, J.H.; Jung, H.J.; Yang, Y.S.; Lee, T.H.; Park, W.K.; Kim, J.T.; Lee, J.H. Space Charge Formations and Electrical Conductities Characteristics of Nano Composite XLPE. In Proceedings of the International Symposium on Electrical Insulating Materials (ISEIM), Niigata, Japan, 1–5 June 2014. [Google Scholar]

- Zhu, Y.; Yang, F.; Xie, X.; Cao, W.; Sheng, G.; Jiang, S. Studies on Electric Field Distribution and Partial Discharges of XLPE Cable at DC Voltage. In Proceedings of the 12th IEEE International Conference on the Properties and Applications of Dielectric Materials, Xi’an, China, 20–24 May 2018. [Google Scholar]

- Li, J.; Zhao, X.; Yin, G.; Li, S.; Zhao, J.; Ouyang, B. The Effect of Accelerated Water Tree Ageing on the Properties of XLPE Cable Insulation. IEEE Trans. Dielectr. Electr. Insul. 2011, 18, 1562–1569. [Google Scholar] [CrossRef]

- Sekii, Y.; Ohbayashi, T.; Uchimura, T.; Mochizuki, K.; Maeno, T. The Effects of Material Properties and Inclusions on the Space Charge Profiles of LDPE and XLPE. In Proceedings of the Conference on Electrical Insulation and Dielectric Phenomena, Cancun, Mexico, 20–24 October 2002. [Google Scholar]

- Hvidsten, S.; Sætre, F. Dielectric Response of sPP and XLPE Insulations at High Temperatures and Electric Fields. In Proceedings of the Conference on Electrical Insulation and Dielectric Phenomena, Cancun, Mexico, 16–19 October 2011. [Google Scholar]

- Wan, D.; Zhou, H.; Zhao, M.; Duan, X.; Peng, S.; Mao, L. Fault Detection Technology and Analysis of 10 kV XLPE Power Cable. In Proceedings of the 3rd IEEE Conference on Energy Internet and Energy System Integration, Changsha, China, 8–10 November 2019. [Google Scholar]

- Fabiani, D.; Montanari, G.C.; Palmieri, F.; Toselli, M.; Saccani, A. DC Electrical Properties of XLPE Insulation with Nanostructured-coating. In Proceedings of the IEEE International Symposium on Electrical Insulation, San Juan, CA, USA, 10–13 June 2012. [Google Scholar]

- Wang, H.M.; Fang, S.C.; Meng, Z.Z.; Song, P.X.; Li, X.; Zhu, M.Z.; Zhu, X.H.; Yu, Y.; Du, B.X. Dielectric Properties of High Voltage XLPE Power Cables Taken from Service. In Proceedings of the IEEE Conference on Electrical Insulation and Dielectric Phenomena, Washington, DC, USA, 20–23 October 2019. [Google Scholar]

- Li, H.; Li, J.; Jia, R.; Zhang, X. Role of Degassing Process on Dielectric Performance of XLPE cable Insulation. In Proceedings of the 11th International Conference on the Properties and Applications of Dielectric Materials (ICPADM), Sydney, Australia, 19–22 July 2015. [Google Scholar]

- Du, B.X.; Huo, Z.X.; Li, H.B.; Gao, Y. Water Tree Deterioration Diagnosis for 10 kV XLPE cable based on Residual Charge Method. In Proceedings of the 9th International Conference on Properties and Applications of Dielectric Materials, Harbin, China, 19–23 July 2009. [Google Scholar]

- Abou-Dakka, M.; Bulinski, A.; Bamji, S.S.; Selsjord, M. Depolarization Current Measurements on Field-Aged XLPE Cable Insulation. In Proceedings of the Conference on Electrical Insulation Dielectric Phenomena, Quebec, QC, Canada, 26–29 October 2008. [Google Scholar]

- Yuan, Y.; Lu, G.; Wang, W.; Fan, W.; Liao, W.; Jia, Z.; Guan, Z. Dielectric Loss and Partial Discharge Test Analysis of 10 kV XLPE Cable. In Proceedings of the 2013 Annual Report Conference on Electrical Insulation and Dielectric Phenomena, Chenzhen, China, 20–23 October 2013. [Google Scholar]

- Zhang, X.; Hu, Q.; Ciao, J.; Liu, Y. Effect of DC Voltage on Dielectric Properties of Low-voltage Cable with XLPE Insulation. In Proceedings of the International Symposium on Electrical Insulating Materials, Kitakyushu, Japan, 5–9 June 2005. [Google Scholar]

- Richardson, B. Enhanced Energy Efficiency of Underground Cables. In Proceedings of the IEEE PES Transmission and Distribution Conference and Exposition, New Orleans, LA, USA, 19–22 April 2010. [Google Scholar]

- You, J.; Jia, Z.; Wang, Y.; Fan, W.; Yuan, Y.; Guan, Z. Evaluation Analysis of XLPE Cable’s Electrical Condition. In Proceedings of the Conference on Electrical Insulation and Dielectric Phenomena, Des Moines, IA, USA, 19–22 October 2014. [Google Scholar]

- Liu, T.; Fothergill, J.; Dodd, S.; Nilsson, U. Influence of Semicon Shields on the Dielectric Loss of XLPE Cables. In Proceedings of the Conference on Electrical Insulation and Dielectric Phenomena, Virginia Beach, VA, USA, 18–21 October 2009. [Google Scholar]

- Kurihara, T.; Sato, T.; Homma, K. Insulation Characteristics of Dry-cured and Extruded Three-layer (E-E Type) 6.6 kV Removed XLPE Cables with Additional Accelerated Water-tree Degradation. In Proceedings of the International Symposium on Electrical Insulating Materials (ISEIM), Toyohashi, Japan, 11–15 September 2017. [Google Scholar]

- Wang, H.; Wang, Y.; Han, A. Insulation Parameters Characteristics of XLPE Cable in the course of Its Aging within CuSO4 Electrolyte. In Proceedings of the International Conference on High Voltage Engineering and Application, Chongqing, China, 9–13 November 2008. [Google Scholar]

- Du, X.; Liu, X.; Tang, Y.; Li, T.; Wang, S.; Li, N. Research on the Optimization of Grounding Methods and Power Loss Reduction Based on AC 500kV XLPE Submarine Cable Project. In Proceedings of the 13th International Conference on the Properties and Applications of Dielectric Materials (ICPADM), Johor Bahru, Malaysia, 12–14 July 2021. [Google Scholar]

- Ye, G.; Li, H.; Lin, F.; Wu, X.; Huang, Z.; Zhang, Q.; Cai, J. Study on the Dielectric Response Characteristic of XLPE Cables. In Proceedings of the 2013 Annual Report Conference on Electrical Insulation and Dielectric Phenomena, Chenzhen, China, 20–23 October 2013. [Google Scholar]

- Song, P.; Liu, J.; Wang, H.; Meng, F.; Fang, S.; Zhang, Y. Ultra-Low Frequency Dielectric Loss Detection and Aging State Evaluation of 10 kV XLPE Cable. In Proceedings of the International Conference on Electricity Distribution, Tianjin, China, 17–19 September 2018. [Google Scholar]

- de Wild, F.; van Rossum, J.; Anders, G.; Brijs, B.; Bascom, R.; Pilgrim, J.; Coelho, M.; Huelsken, G.; Kuljaca, N.; Martinsson, B.; et al. A Guide for Rating Calculations of Insulated Cables; Working Group B1.35; CIGRE: Paris, France, 2015; ISBN 978-2-85873-343-9. [Google Scholar]

- Fan, Y.; Li, J.; Zhu, Y.; Wu, C. Research on Current-Carrying Capacity for XLPE Cables Installed in Pipes. In Proceedings of the 9th International Conference on Properties and Applications of Dielectric Materials, Harbin, China, 19–23 July 2009. [Google Scholar]

- Weinlein, A.; Memmer, H.; Peters, U.; Haring, D.; Burden, G.; Hammes, C.; Scheltinga, L. Experiences and Challenges with the 420 kV XLPE Cable Systems of the London Power Tunnels Project. In Proceedings of the 10th International Conference on Insulated Power Cables Jicable, Paris, France, 23–27 June 2019. [Google Scholar]

- Available online: https://www.tfkable.com (accessed on 15 May 2022).

- Grzybowski, S.; Dobroszewski, R. Insulation Systems Tasks; Poznan University of Technology Publishing House: Poznan, Poland, 1965; pp. 83–86. [Google Scholar]

- Florkowska, B.; Furgal, J. High Voltage Engineering; AGH University of Science and Technology Publishing House: Krakow, Poland, 2017; pp. 135–140. ISBN 978-83-7464-925-4. [Google Scholar]

- Florkowska, B.; Wlodek, R. High Voltage in Electric Power Engineering; AGH University of Science and Technology Publishing House: Krakow, Poland, 2020; pp. 219–221. ISBN 978-83-66364-35-6. [Google Scholar]

- Crisan, O.; Dan, I.; Palade, P.; Crisan, A.D.; Leca, A.; Pantelica, A. Magnetic Phase Coexistence and Hard–Soft Exchange Coupling in FePt Nanocomposite Magnets. Nanomaterials 2020, 10, 1618. [Google Scholar] [CrossRef] [PubMed]

| Radius | 110 kV | 220 kV | 400 kV | 500 kV |

|---|---|---|---|---|

| R0—radius of conductor (mm) | 7.20 | 11.80 | 15.20 | 24.80 |

| R1—radius of inner semiconductor screen (mm) | 7.25 | 12.60 | 16.20 | 26.35 |

| R2—radius of XLPE insulation (mm) | 26.65 | 36.60 | 48.20 | 58.35 |

| R3—radius of outer semiconductor screen (mm) | 26.70 | 37.40 | 49.20 | 59.90 |

| Properties | Semiconductor Screen | XLPE |

|---|---|---|

| Relative electrical permittivity ε (-) | 20.0 | 2.3 |

| Electrical conductivity γ (S·m−1) | 10−4 | 10−13 |

| Dielectric loss coefficient tan(delta) (-) | 0.002 | 0.002 |

| Properties | Semiconductor Screen | XLPE |

|---|---|---|

| Electrical permittivity of vacuum εo (F·m−1) | 8.84 × 10−12 | |

| Relative electrical permittivity εr (-) | 20.0 | 2.3 |

| Electrical permittivity ε (F·m−1) | 177 × 10−12 | 20 × 10−12 |

| Electrical conductivity γ (S·m−1) | 0.1 × 10−3 | 0.1 × 10−12 |

| ω·ε (S·m−1) | 55 × 10−9 | 6 × 10−9 |

| Radius | Inner Semiconductor Screen | XLPE Insulation | Outer Semiconductor Screen | |

|---|---|---|---|---|

| R | mm | V·m−1 | V·m−1 | V·m−1 |

| 110 kV | ||||

| R0 | 0.00 | |||

| R1 | 7.20 | 433 | ||

| R2 | 7.25 | 430 | 6,729,049 | |

| R3 | 26.65 | 1,830,604 | 117 | |

| R4 | 26.70 | 117 | ||

| 220 kV | ||||

| R0 | 0.00 | |||

| R1 | 11.80 | 645 | ||

| R2 | 12.60 | 604 | 9,453,419 | |

| R3 | 36.60 | 3,254,456 | 208 | |

| R4 | 37.40 | 203 | ||

| 400 kV | ||||

| R0 | 0.00 | |||

| R1 | 15.20 | 890 | ||

| R2 | 16.20 | 835 | 13,074,261 | |

| R3 | 48.20 | 4,394,254 | 281 | |

| R4 | 49.20 | 275 | ||

| 500 kV | ||||

| R0 | 0.00 | |||

| R1 | 24.80 | 935 | ||

| R2 | 26.35 | 880 | 13,780,452 | |

| R3 | 58.35 | 6,223,049 | 397 | |

| R4 | 59.90 | 387 | ||

| Dielectric Losses (W·km−1) | |||

|---|---|---|---|

| Cable Voltage (kV) | Inner Semiconductor Screen | XLPE Insulation | Outer Semiconductor Screen |

| 110 | 0.000000047 | 62 | 0.000000013 |

| 220 | 0.000002650 | 304 | 0.000000874 |

| 400 | 0.000008140 | 982 | 0.000002623 |

| 500 | 0.000022763 | 2103 | 0.000009844 |

| Radius | Inner Semiconductor Screen | XLPE Insulation | Outer Semiconductor Screen | |

|---|---|---|---|---|

| R | mm | V·m−1 | V·m−1 | V·m−1 |

| 110 kV | ||||

| R0 | 0.00 | |||

| R1 | 7.20 | 778,610 | ||

| R2 | 7.25 | 773,240 | 6,723,828 | |

| R3 | 26.65 | 1,829,184 | 210,356 | |

| R4 | 26.70 | 209,962 | ||

| 220 kV | ||||

| R0 | 0.00 | |||

| R1 | 11.80 | 1,150,036 | ||

| R2 | 12.60 | 1,077,018 | 9,365,376 | |

| R3 | 36.60 | 3,224,146 | 370,777 | |

| R4 | 37.40 | 362,846 | ||

| 400 kV | ||||

| R0 | 0.00 | |||

| R1 | 15.20 | 1,588,351 | ||

| R2 | 16.20 | 1,490,305 | 12,959,171 | |

| R3 | 48.20 | 4,355,572 | 500,891 | |

| R4 | 49.20 | 490,710 | ||

| 500 kV | ||||

| R0 | 0.00 | |||

| R1 | 24.80 | 1,662,921 | ||

| R2 | 26.35 | 1,565,102 | 13,609,583 | |

| R3 | 58.35 | 6,145,887 | 706,777 | |

| R4 | 59.90 | 688,488 | ||

| Dielectric Losses (W·km−1) | |||

|---|---|---|---|

| Cable Voltage (kV) | Inner Semiconductor Screen | XLPE Insulation | Outer Semiconductor Screen |

| 110 | 0.15 | 62.08 | 0.04 |

| 220 | 8.43 | 297.97 | 2.78 |

| 400 | 25.92 | 964.34 | 8.35 |

| 500 | 71.97 | 2051.60 | 31.12 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nadolny, Z. Electric Field Distribution and Dielectric Losses in XLPE Insulation and Semiconductor Screens of High-Voltage Cables. Energies 2022, 15, 4692. https://doi.org/10.3390/en15134692

Nadolny Z. Electric Field Distribution and Dielectric Losses in XLPE Insulation and Semiconductor Screens of High-Voltage Cables. Energies. 2022; 15(13):4692. https://doi.org/10.3390/en15134692

Chicago/Turabian StyleNadolny, Zbigniew. 2022. "Electric Field Distribution and Dielectric Losses in XLPE Insulation and Semiconductor Screens of High-Voltage Cables" Energies 15, no. 13: 4692. https://doi.org/10.3390/en15134692

APA StyleNadolny, Z. (2022). Electric Field Distribution and Dielectric Losses in XLPE Insulation and Semiconductor Screens of High-Voltage Cables. Energies, 15(13), 4692. https://doi.org/10.3390/en15134692