Study on the Algae Contamination and Its Effects on the Properties of RTV-Coated Insulators

Abstract

:1. Introduction

2. Distribution of Algae Contamination Layer on RTV Coating

2.1. Geographical Distribution of Algal Contamination-Prone Regions

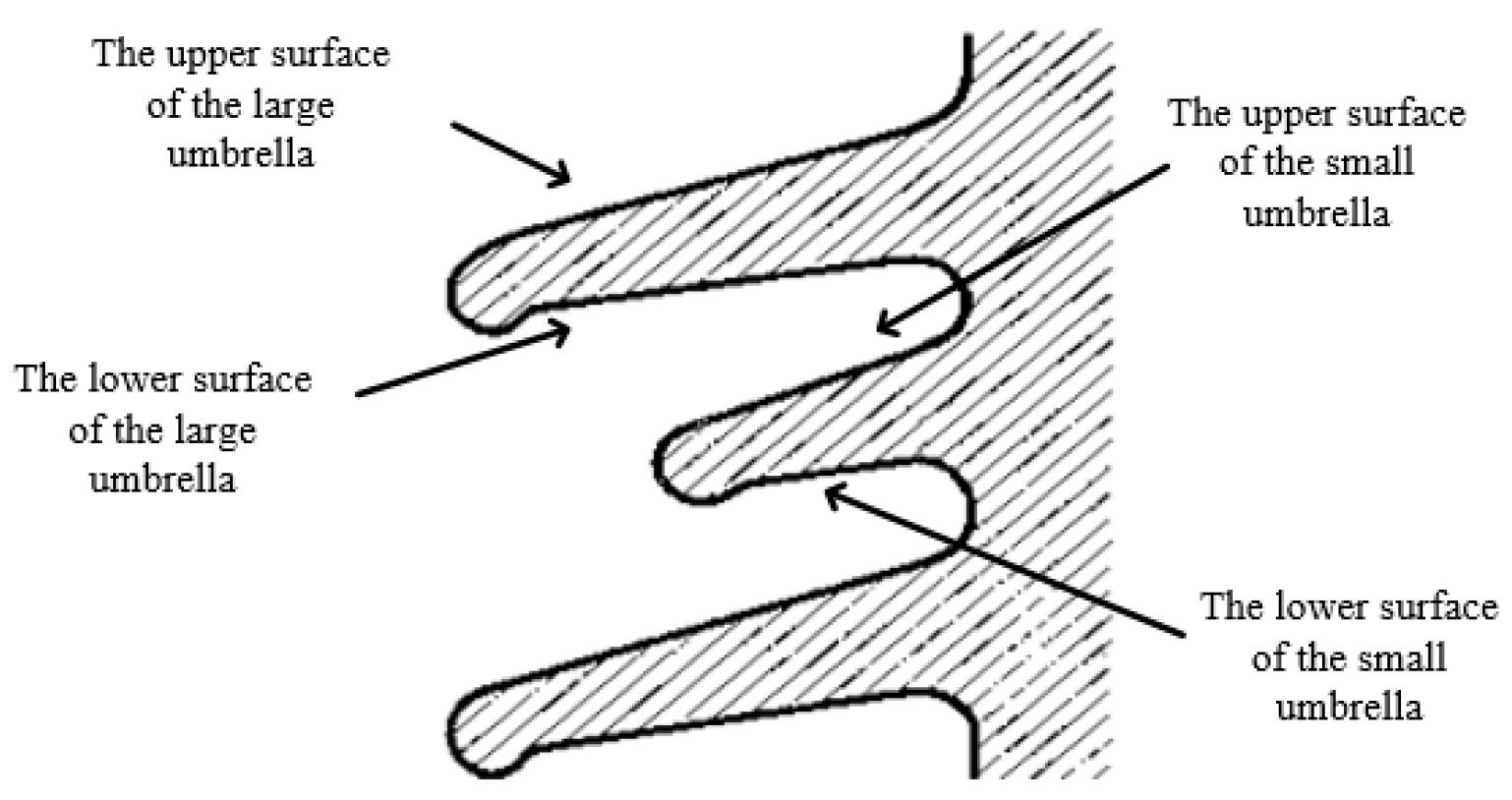

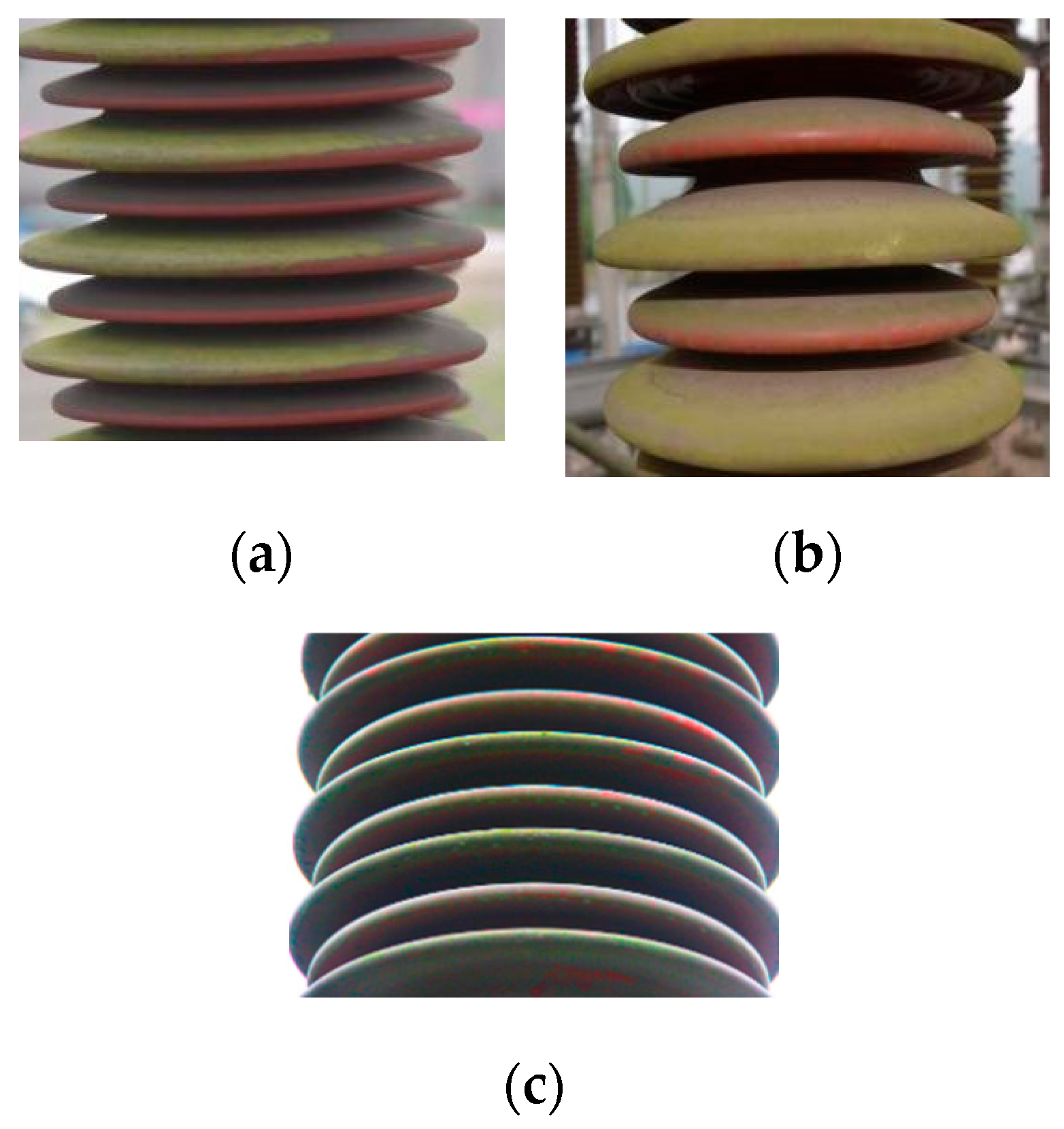

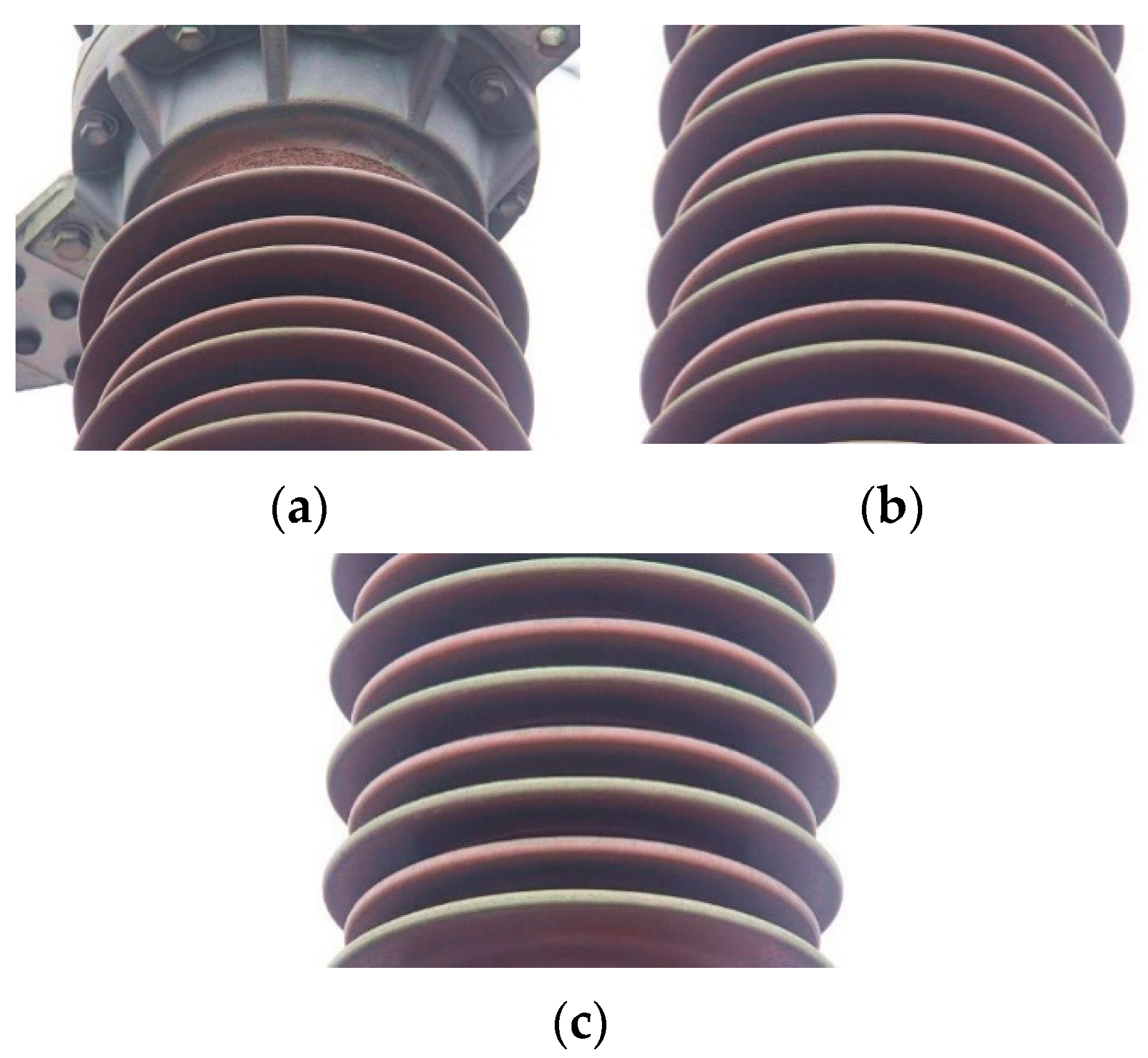

2.2. Spatial Distribution of Algae Contamination Layer on RTV Insulators

- (a)

- Orientation

- (b)

- Vertical Height

- (c)

- Voltage Type

2.3. Contamination Distribution

3. Properties of Algae Contamination Layer on RTV Coating

3.1. Soluble Components

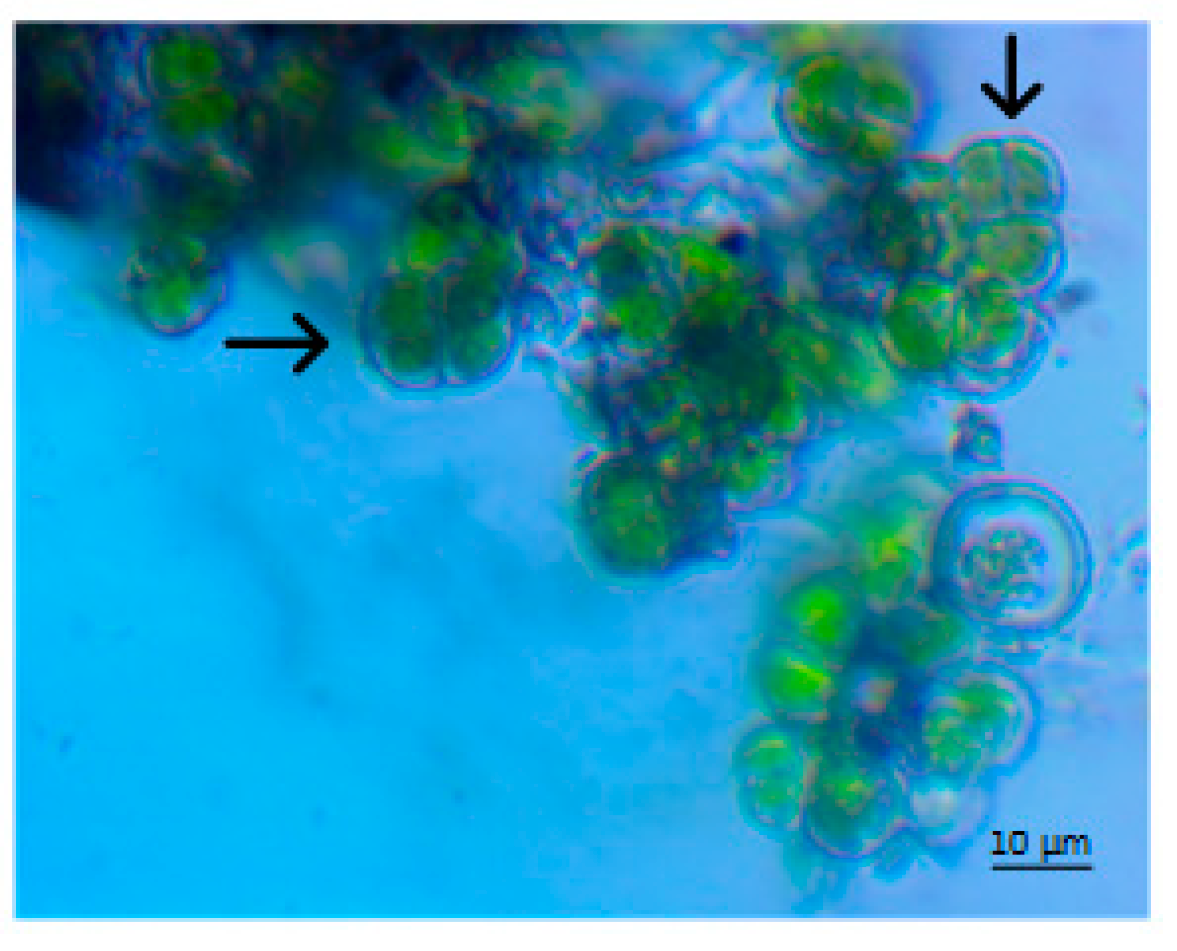

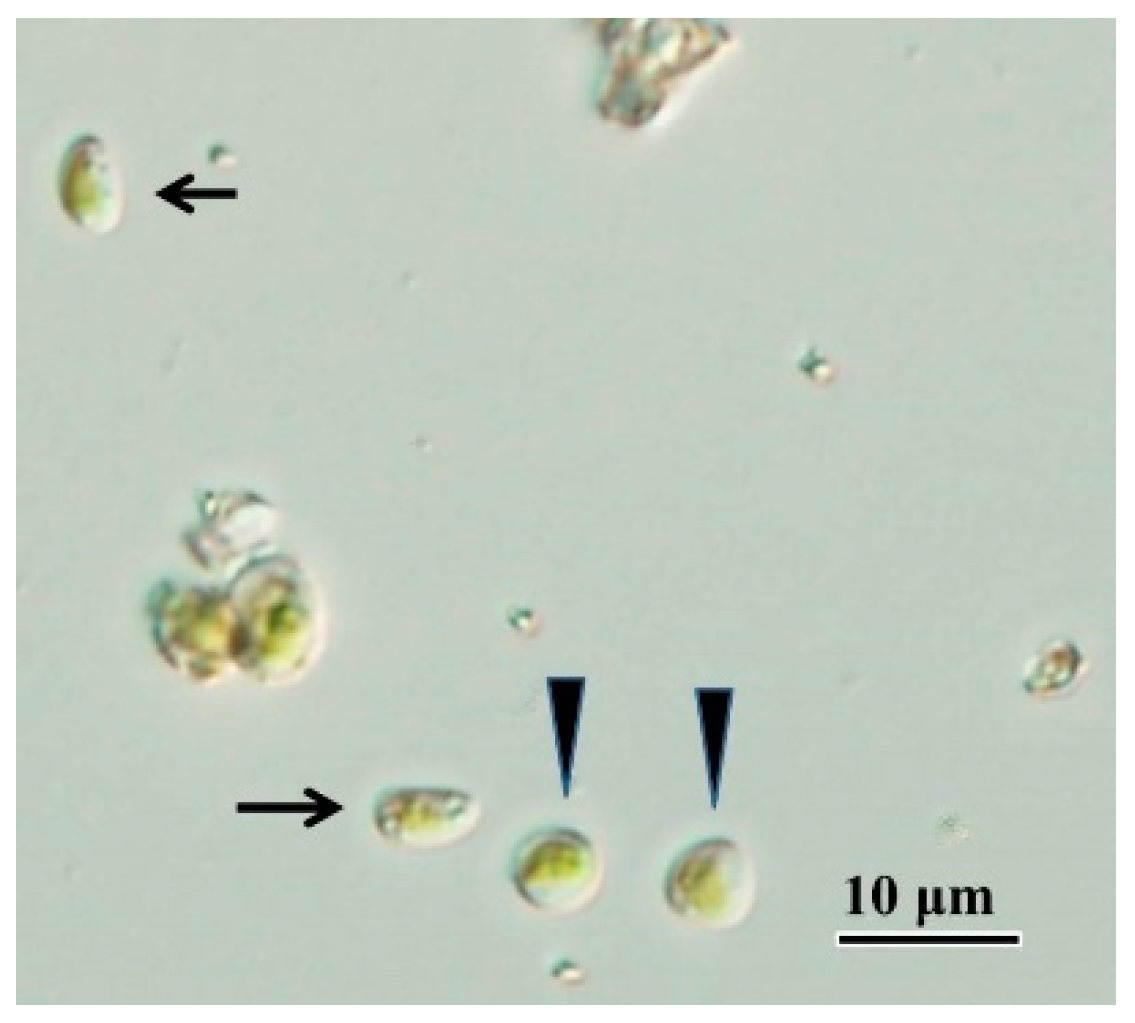

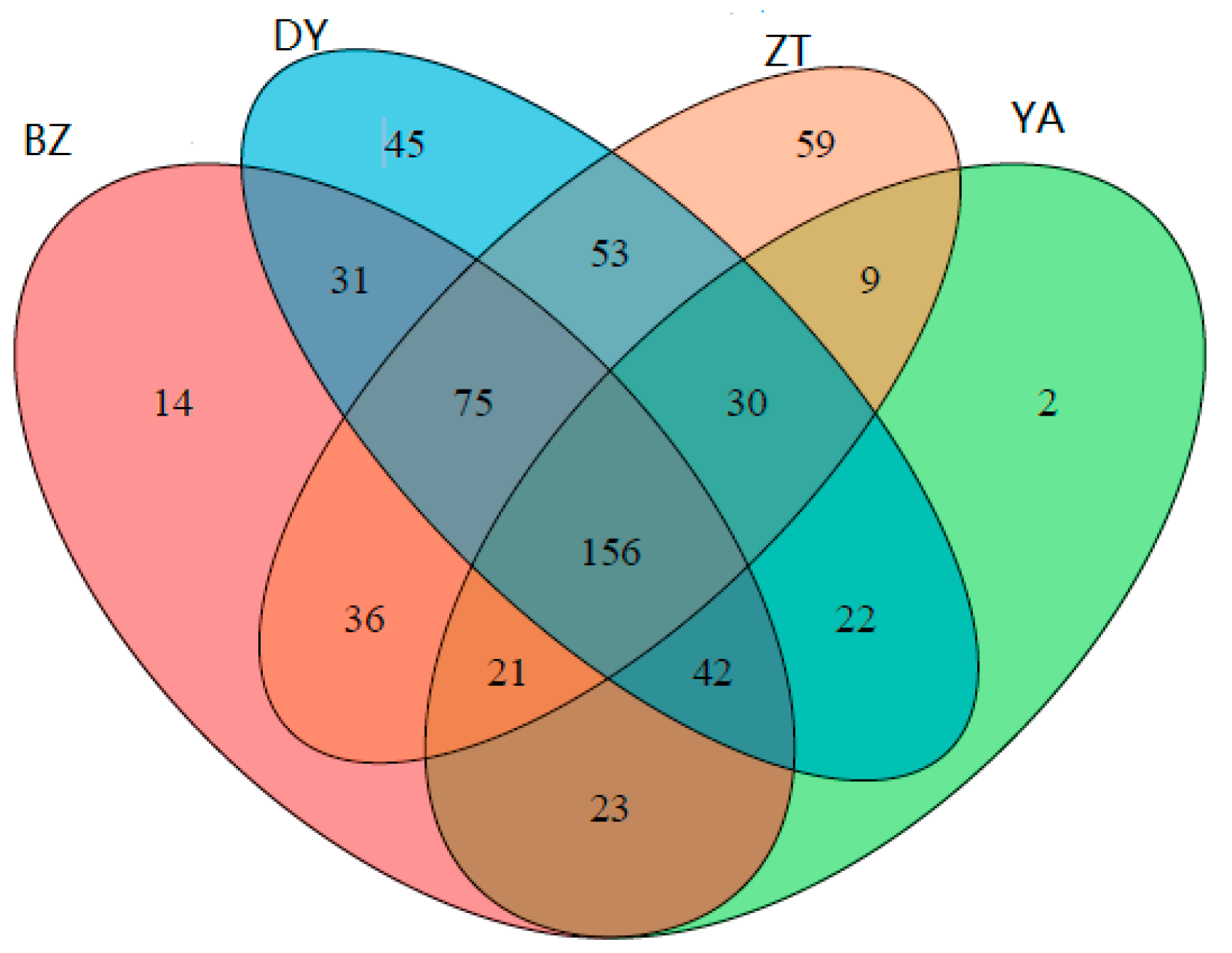

3.2. Algae Identification

3.3. Other Microorganisms

4. Influence of Algae Contamination on RTV Surface Properties

4.1. Influence of Algae Contamination on RTV Surface Conductivity

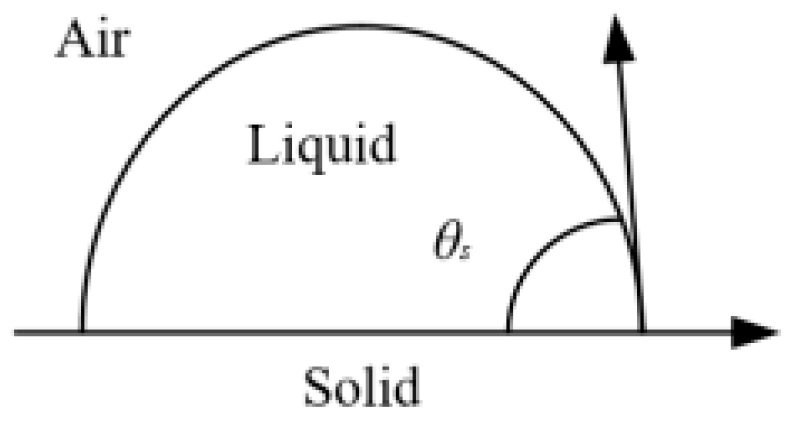

4.2. Hydrophobicity Analysis of RTV Coatings

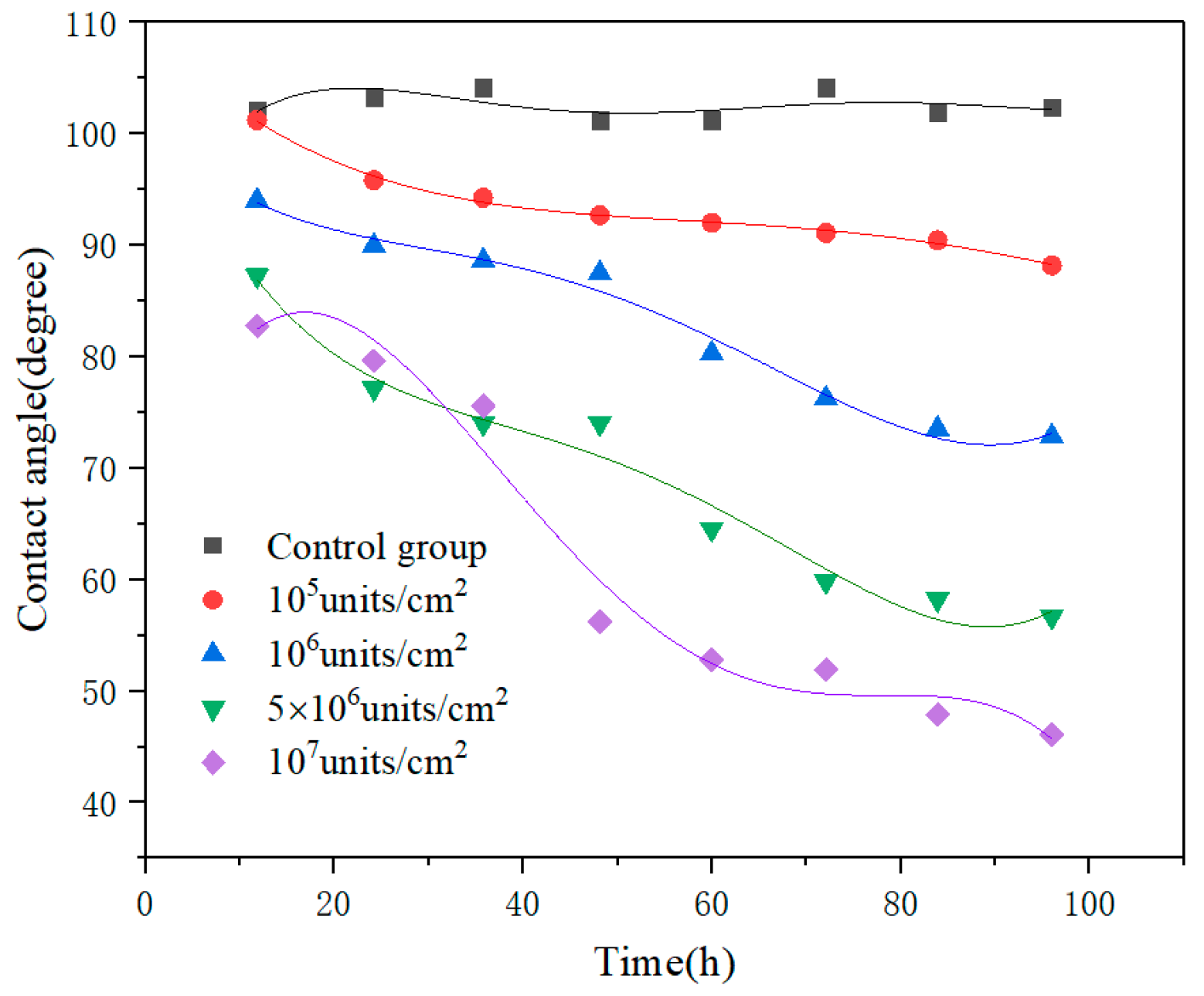

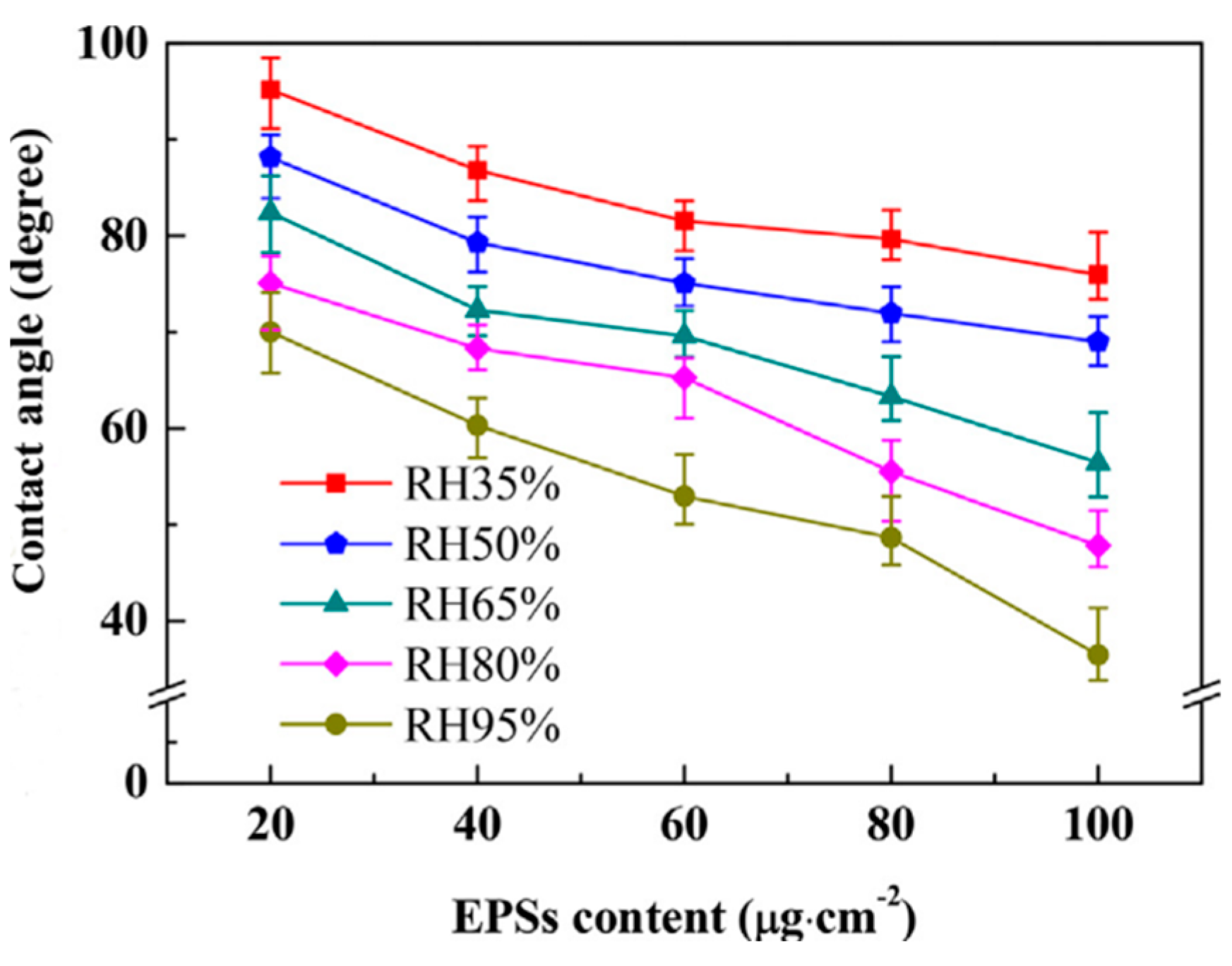

4.3. Effect of Extracellular Polymeric Substance on the Hydrophobicity of RTV

5. Influence of Algal Fouling Layer on the Structure of RTV Materials

5.1. On Site Measurement Points and Test Product Introduction

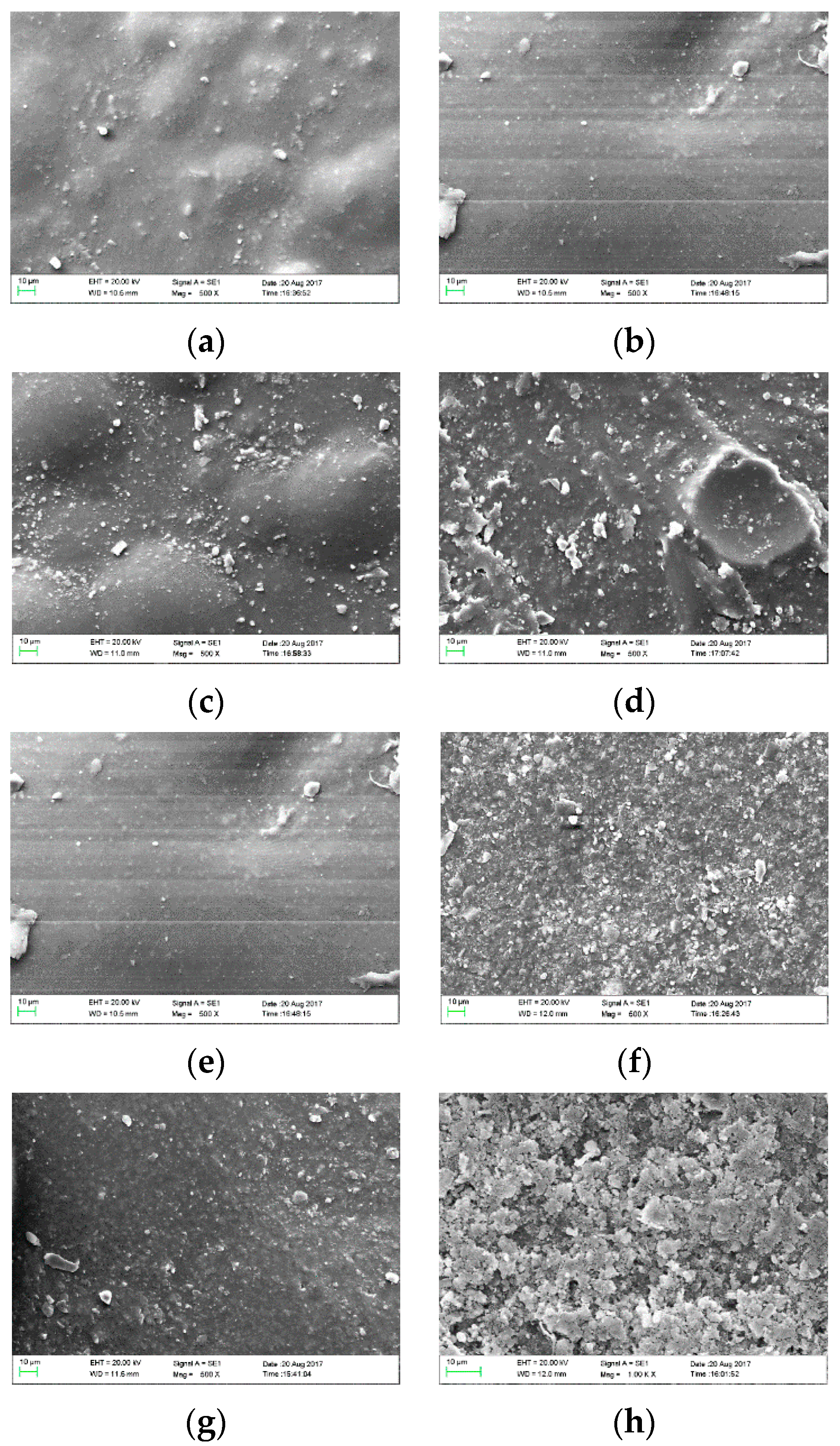

5.2. Surface Topography

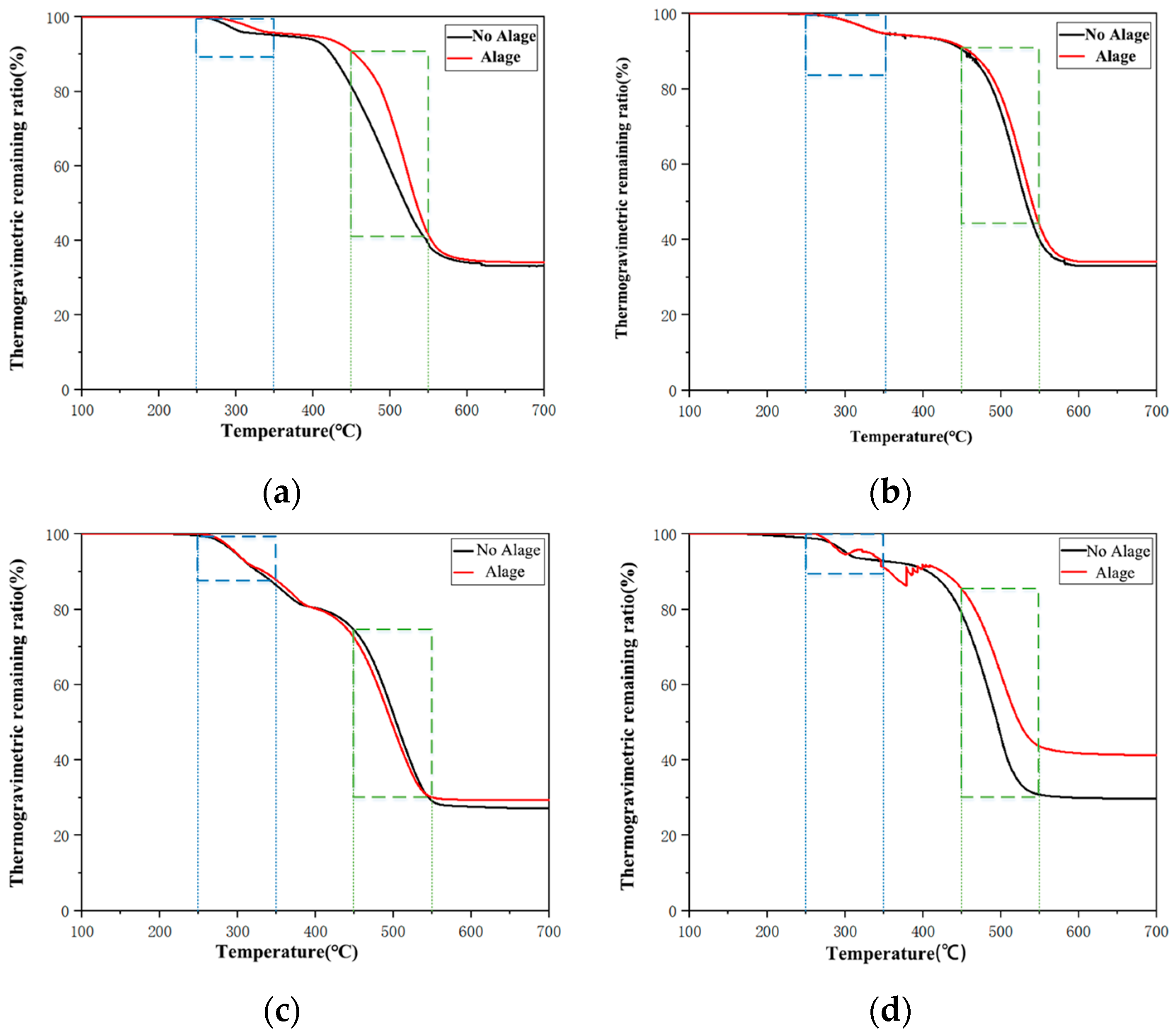

5.3. Thermogravimetric Analysis

6. Conclusions

- The degree of algal growth and coverage on the RTV insulator surface was positively correlated with its contamination level, and negatively correlated with the vertical height. No algal growth on the RTV surface was found under the DC voltage.

- The soluble component in the algae contamination layer was mainly CaSO4. Biological species include algae (Apatococcus lobatus, Chloroidium sp., Heterochlorella luteoviridis) and fungi.

- The coverage of algal cells reduced the surface resistance of RTV, and its extracellular secretions reduced the hydrophobicity.

- The algae contamination layer coverage accelerated the destruction of the siloxane in the silicone rubber and the precipitation of the aluminum hydroxide filler, generating a large number of pores on the surface. These pores accelerated the aging of the RTV and the loss of hydrophobicity transfer.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Wang, Z.; Yin, J.; Hao, X.; Wang, P.; Zhang, Q.; Lan, G.; Zhang, Q. Study on the Role of Algae in Travertine Deposition Based on Micro Lithofacies Analysis—A Case Study of Huanglong, Sichuan Province. Carsologica Sin. 2021, 40, 44–54. [Google Scholar]

- Wang, C.; Liang, Q.; Li, R. Influence of Interface Micro Air Gap on Insulation Performance of Composite Insulator. Water Resour. Power 2016, 34, 186–190. [Google Scholar]

- Nan, J.; Li, H.; Wan, X.; Huo, F.; Lin, F. Pollution Flashover Characteristics of Composite Crossarm Insulator with a Large Diameter. Energies 2021, 14, 6491. [Google Scholar] [CrossRef]

- Milner, H.W. The Chemical Composition of Algae. Algal Cult. Lab. Pilot Plant 1953, 600, 285–302. [Google Scholar]

- Guan, Z.; Zhang, R.; Xue, J.; Ma, S.; Li, N. Composition of Soluble Salt in Natural Pollution and its Influences on Flashover Voltage. Insul. Surge Arresters 1989, 6, 13–18. [Google Scholar]

- Ma, Z. A Comparision Experiment of Pollution Degree of Insulator at Work and Those out of Action. High Volt. Eng. 1993, 19, 33–35. [Google Scholar]

- Gubanski, S.M.; Fernando, M.A.R.M.; Pietr, S.J.; Matula, J.; Kyaruzi, A. Effects of Biological Contamination on Insulator Performance. In Proceedings of the 6th International Conference on Properties and Applications of Dielectric Materials (Cat. No. 00CH36347), Xi’an, China, 21–26 June 2000. [Google Scholar]

- Jia, Z.D.; Wang, Y.; Ouyang, X.G.; Zhang, X. Influence of Green Algae on Hydrophobic Property of HTV Silicon Rubber. High Volt. 2017, 43, 885–890. [Google Scholar]

- Cao, W.; Xue, H.; Shen, W.; Yang, H.; Zhao, L.; Wang, Y. The Effect of Dynamic Behaviours of the Water Droplet on DC/AC Flashover Performance on Silicone Rubber Surface: Experiment, Simulation and Theoretical Analysis. High Volt. 2021, 6, 637–646. [Google Scholar] [CrossRef]

- IEC/TS 60507; Artificial Pollution Tests on High Voltage Insulators to be Used on A. C. Systems. International Electrotechnical Commission: Geneva, Switzerland, 2013.

- IEC/TS 60815. Selection and Dimensioning of High-Voltage Insulators Intended for Use in Polluted Conditions. International Electrotechnical Commission: Geneva, Switzerland, 2008.

- Jiang, X. Effects of Temperatures, Light Intensities, and Nitro Gen Concentrations on the Growth and Fatty Acid Compositions of Nannochloropsis Oculata. Mar. Sci. 2002, 26, 9–13. [Google Scholar]

- Zhou, Z.; Chen, X.; Chen, C.; Zhang, Y. Effect of Apoprotein on Antioxidant Activity of Phycobiliproteins. Mar. Sci. 2003, 27, 73–76. [Google Scholar]

- Rocha, J.M.S.; Garcia, J.E.C.; Henriques, M.H.F. Growth Aspects of the Marine Microalga Nannochloropsis gaditana. Bimolecular Eng. 2003, 20, 237–242. [Google Scholar] [CrossRef] [Green Version]

- Fernando, M.A.R.M.; Gubanski, S.M. Tropical Environmental Impacts on Surface Properties of Nonceramic Insulators. In Proceedings of the PowerTech Budapest 99. Abstract Records (Cat. No. 99EX376), Budapest, Hungary, 29 August–2 September 1999. [Google Scholar]

- Gubanski, S.M.; Karlsson, S.; Fernando, M.A.R. Performance of Biologically Contaminated High Voltage Insulators. In Proceedings of the Industrial and Information Systems, First International Conference on IEEE, Tirtayasa, Indonesia, 8–11 August 2006. [Google Scholar]

- Gubanski, S.M.; Dernfalk, A.; Wallstrom, S.; Karlsson, S. Performance and Diagnostics of Biologically Contaminated Insulators. In Proceedings of the 2006 IEEE 8th International Conference on Properties & Applications of Dielectric Materials, Bali, Indonesia, 26–30 June 2006. [Google Scholar]

- Bengtsson, M.; Gronlund, R.; Sjoholm, M.; Weibring, P.; Kroll, S.; Edner, H.; Svanberg, S.; Dernfalk, A. Lidar Fluorescence Measurements of Algal Growth on Electrical Insulators. In Proceedings of the 2003 Conference on Lasers and Electro-Optics Europe (CLEO/Europe 2003) (IEEE Cat. No.03TH8666), Munich, Germany, 22–27 June 2003. [Google Scholar]

- Bengtsson, M.; Wallstrom, S.; Gronlund, R.; Anderson, B.; Sjoholm, M.; Larsson, A.; Kroll, S.; Svanberg, S. Development of a Tool for Remote Detection of Fungi and Algae on Electrical Insulators Using Laser Induced Fluorescence Combined with Principal Component Analysis. In Proceedings of the CLEO/Europe. 2005 Conference on Lasers and Electro-Optics Europe, San Jose, CA, USA, 12–17 June 2005. [Google Scholar]

- Sweden Transmission Research Institute. STRI Guide 92/1, Hydrophobicity Classification Guide; Sweden Transmission Research Institute: Ludvika, Sweden, 1992. [Google Scholar]

- Gu, Y.; Shi, Y.; Li, X.; Shi, Z.; Zhang, X.; Min, C.; Wei, J.; You, C. Effect of Microorganisms on Hydrophobicity of Silicone Rubber Materials. Insul. Surge Arresters 2020, 1, 166–173. [Google Scholar]

- Yang, S.; Jia, Z.; Ouyang, X.; Bai, H.; Liu, R. Hydrophobicity Characteristics of Algae-Fouled HVDC Insulators in Subtropical Climates. Electr. Power Syst. Res. 2018, 163, 626–637. [Google Scholar] [CrossRef]

- Lu, Z.; Yang, X. A Study on Hydrophobicity Transfer of Silicone Rubber. Proc. CSEE 2001, 5, 52–56, 74. [Google Scholar]

| City | Climatic Conditions | Number of Substations/Number of Substations with Algae | Contamination Level of the Substation with Algae/ESDD, mg/cm2 | ||||

|---|---|---|---|---|---|---|---|

| Average Annual Temperature (°C) | Average Annual Precipitation (mm) | Average Annual Humidity (%) | Annual Sunshine Hours(h) | C 0.1–0.25 | D 0.25–0.35 | ||

| CD | 15.8 | 892.2 | 76 | 875 | 65/3 | 2 | 1 |

| ZG | 17.9 | 989.2 | 76 | 843.1 | 24/10 | 1 | 9 |

| LZ | 17.1 | 1233.2 | 80 | 1008.2 | 37/1 | 1 | 0 |

| DY | 16 | 879.2 | 78 | 920.6 | 61/4 | 1 | 3 |

| MY | 16.5 | 782.1 | 71 | 1157.2 | 63/4 | 1 | 3 |

| GY | 16.3 | 1233.2 | 70 | 1198.4 | 34/3 | 1 | 2 |

| SN | 17.1 | 1033.2 | 72 | 989.2 | 22/6 | 2 | 4 |

| NJ | 17.3 | 899.1 | 81 | 1107.9 | 31/13 | 2 | 11 |

| LES | 17.3 | 1223.2 | 80 | 923.85 | 46/10 | 2 | 8 |

| NC | 17.7 | 768.9 | 74 | 1199.05 | 36/7 | 4 | 3 |

| MS | 17.2 | 873.2 | 77 | 945.65 | 41/4 | 1 | 3 |

| YB | 18.2 | 878.9 | 72 | 949.55 | 37/7 | 5 | 2 |

| GA | 17.6 | 980.2 | 77 | 1259.8 | 18/14 | 8 | 6 |

| DZ | 17.4 | 1222.8 | 71 | 1056.65 | 41/6 | 1 | 5 |

| YA | 16.2 | 1689.2 | 80 | 843.4 | 42/6 | 5 | 1 |

| BZ | 16.9 | 1246.8 | 72 | 1364 | 15/6 | 2 | 4 |

| ZY | 17.1 | 1002.7 | 75 | 1273.65 | 25/7 | 4 | 3 |

| AB | 9 | 789.1 | 62 | 2132.2 | 26/0 | / | |

| GZ | 7.1 | 786.2 | 69 | 1672.4 | 14/0 | / | |

| LS | 17.7 | 899.2 | 54 | 2366.6 | 29/0 | / | |

| PZH | 22 | 722.3 | 47 | 2896.1 | 34/0 | / | |

| ZT | 17 | 714 | 74 | 1900 | 26/6 | 2 | 4 |

| Total | / | / | / | / | 767/117 | 45 | 72 |

| Substation | Voltage Level | Pillar | Circuit Breaker | CT | PT | Arrester |

|---|---|---|---|---|---|---|

| YXS | 220 kV | Shady | Shady | / | / | Shady |

| DYS | 500 kV | Shady | Shady | / | / | / |

| CBS | 220 kV | All | All | Mainly Shady | Mainly Shady | Mainly Shady |

| BQS | 110 kV | All | All | Mainly Shady | Mainly Shady | All |

| EYS | 110 kV | All | All | Shady | Shady | Shady |

| XYS | 110 kV | Mainly Shady | Mainly Shady | Shady | Mainly Shady | Shady |

| JFS | 220 kV | Shady | Shady | Shady | Shady | Shady |

| XXS | 110 kV | Shady | Shady | Shady | Shady | Shady |

| CSS | 220 kV | Shady | Shady | Shady | Shady | / |

| DJWS | 220 kV | / | Shady | / | / | / |

| JNS | 220 kV | Shady | Shady | / | / | / |

| ZHS | 110 kV | / | Shady | / | / | / |

| Substation/Converter Station | Equipment | Algae Coverage (%) | ||

|---|---|---|---|---|

| Upper | Middle | Bottom | ||

| CBS | 220 kV circuit breaker | 9.7 | 12.1 | 19.3 |

| BQS | 110 kV circuit breaker | 13.3 | 15.6 | 16.7 |

| DYS | AC Filter Field 500 kV pillars | 10.2 | 15.4 | 17.8 |

| JFS | 220 kV circuit breaker | 32.7 | 44.9 | 42.2 |

| JNS | 110 kV knife switch insulator | 42.3 | 47.8 | 53.1 |

| XYS | 35 kV knife switch insulator | 22.9 | 33.7 | 34.3 |

| ZTS | Smoothing reactor | 12.1 | 15.6 | 24.3 |

| Number | Equipment | Position | ESDD (mg/cm2) | NSDD (mg/cm2) | Algae Coverage (%) |

|---|---|---|---|---|---|

| 1 | 500 kV#1 substation transformer high voltage side arrester B phase | Upper | 0.007 | 0.035 | 16.2 |

| Lower | 0.003 | 0.021 | 13.5 | ||

| 2 | #61M busbar high voltage arrester F1 A phase | Upper | 0.006 | 0.038 | 21.6 |

| Lower | 0.003 | 0.022 | 19.7 | ||

| 3 | #63M busbar high voltage arrester F1 A phase | Upper | 0.008 | 0.038 | 25.1 |

| Lower | 0.004 | 0.019 | 18.4 | ||

| 4 | DC field flattening opposite pillar Insulator | Upper | 0.024 | 0.065 | 0 |

| Lower | 0.015 | 0.051 | 0 |

| Shed Shapes | Shed Diameter D/D1/D2 | Shed Spacing S/S1/S2 | Shed Overhang P1/P2 | Creepage Distance | Amount | Dry Arc Distance | Total Creepage Distance |

|---|---|---|---|---|---|---|---|

| Large and small | 197/165/89 | 73/31/42 | 50/45 | 210 | 6L 5S | 420 | 1225 |

| Test Location | ESDD (mg/cm2) | Algae Coverage (%) |

|---|---|---|

| Group1, large shed, upper | 0.122 | 85.5 |

| Group1, large shed, lower | 0.095 | 16.1 |

| Group1, small shed, upper | 0.414 | 91.2 |

| Group1, small shed, lower | 0.110 | 17.4 |

| Group3, large shed, upper | 0.151 | 83.9 |

| Group3, large shed, lower | 0.072 | 16.3 |

| Group3, small shed, upper | 0.221 | 87.2 |

| Group3, small shed, lower | 0.106 | 16.1 |

| Group5, large shed, upper | 0.136 | 17.8 |

| Group5, large shed, lower | 0.068 | 13.2 |

| Group5, small shed, upper | 0.154 | 13.7 |

| Group5, small shed, lower | 0.078 | 16.7 |

| AVG | 0.141 | / |

| Test location | Upper Surface of XYS Substation Pillar Insulator Small Shed | Upper Surface of XYS Substation Pillar Insulator Large Shed | Upper Surface of CBS Substation Arrester Large Shed |

|---|---|---|---|

| Fe3+ | 1.475 | 3.828 | 0.689 |

| Na+ | 11.463 | 8.078 | 5.318 |

| Zn2+ | 0.725 | 0.461 | 0.477 |

| Cu2+ | / | / | 0.035 |

| Mn2+ | 0.761 | 0.678 | 0.411 |

| K+ | 12.678 | 10.183 | 5.993 |

| Mg2+ | 3.450 | 3.3 | 2.9408 |

| Ca2+ | 108.041 | 103.159 | 169.89 |

| Test Location | Upper Surface of XYS Substation Pillar Insulator Small Shed | Upper Surface of XYS Substation Pillar Insulator Large Shed | Upper Surface of CBS Substation Arrester Large Shed |

|---|---|---|---|

| Cl− | 15.625 | 12.031 | 19.2 |

| NO3− | <3.125 | <1.563 | 1.38 |

| SO42− | 219.375 | 145.469 | 147 |

| PO43− | <15.625 | <7.813 | — |

| Regions | Algae Species | |

|---|---|---|

| SCP | BZ | Apatococcus lobatus |

| YA | Apatococcus lobatus | |

| DY | Apatococcus lobatus | |

| YNP | ZT | Chloroidium sp. Heterochlorella luteoviridis |

| Sample Number | Liquid Conductivity (μS) | Surface Resistance (MΩ) |

|---|---|---|

| 1 | 1714 | 8.52 |

| 2 | 1750 | 835 |

| 3 | 1209 | 888 |

| Converter Station | Equipment | Areas Covered by Algae Contamination Layer | Areas Not Covered by Algae Contamination Layer |

|---|---|---|---|

| FLS | P1-WN-Q1 | HC5 | HC3 |

| WN-Q3 | HC5 | HC2 | |

| WN-Q1-Q11 | HC5 | HC3 | |

| DYS | WA-W3-T1-A | HC6 | HC4 |

| WA-Z1-W12-T1-C | HC4 | HC3 | |

| YBS | P2-WP-Q21-B | HC5 | HC3 |

| P1-WN-L1 | HC4 | HC2 | |

| P1-WN-L2 | HC4 | HC3 | |

| P2-WN-L2 | HC4 | HC2 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, Y.; Song, Z.; Tian, Y.; Yang, C.; Liu, F.; Bai, H.; Zhao, F.; Liu, X.; Yang, H. Study on the Algae Contamination and Its Effects on the Properties of RTV-Coated Insulators. Energies 2022, 15, 5216. https://doi.org/10.3390/en15145216

Li Y, Song Z, Tian Y, Yang C, Liu F, Bai H, Zhao F, Liu X, Yang H. Study on the Algae Contamination and Its Effects on the Properties of RTV-Coated Insulators. Energies. 2022; 15(14):5216. https://doi.org/10.3390/en15145216

Chicago/Turabian StyleLi, Yawei, Zhibo Song, Yuan Tian, Chao Yang, Fenglian Liu, Huan Bai, Fuping Zhao, Xingwen Liu, and Hao Yang. 2022. "Study on the Algae Contamination and Its Effects on the Properties of RTV-Coated Insulators" Energies 15, no. 14: 5216. https://doi.org/10.3390/en15145216

APA StyleLi, Y., Song, Z., Tian, Y., Yang, C., Liu, F., Bai, H., Zhao, F., Liu, X., & Yang, H. (2022). Study on the Algae Contamination and Its Effects on the Properties of RTV-Coated Insulators. Energies, 15(14), 5216. https://doi.org/10.3390/en15145216