Inkjet 3D Printed MEMS Electromagnetic Multi-Frequency Energy Harvester

Abstract

:1. Introduction

2. Materials and Methods

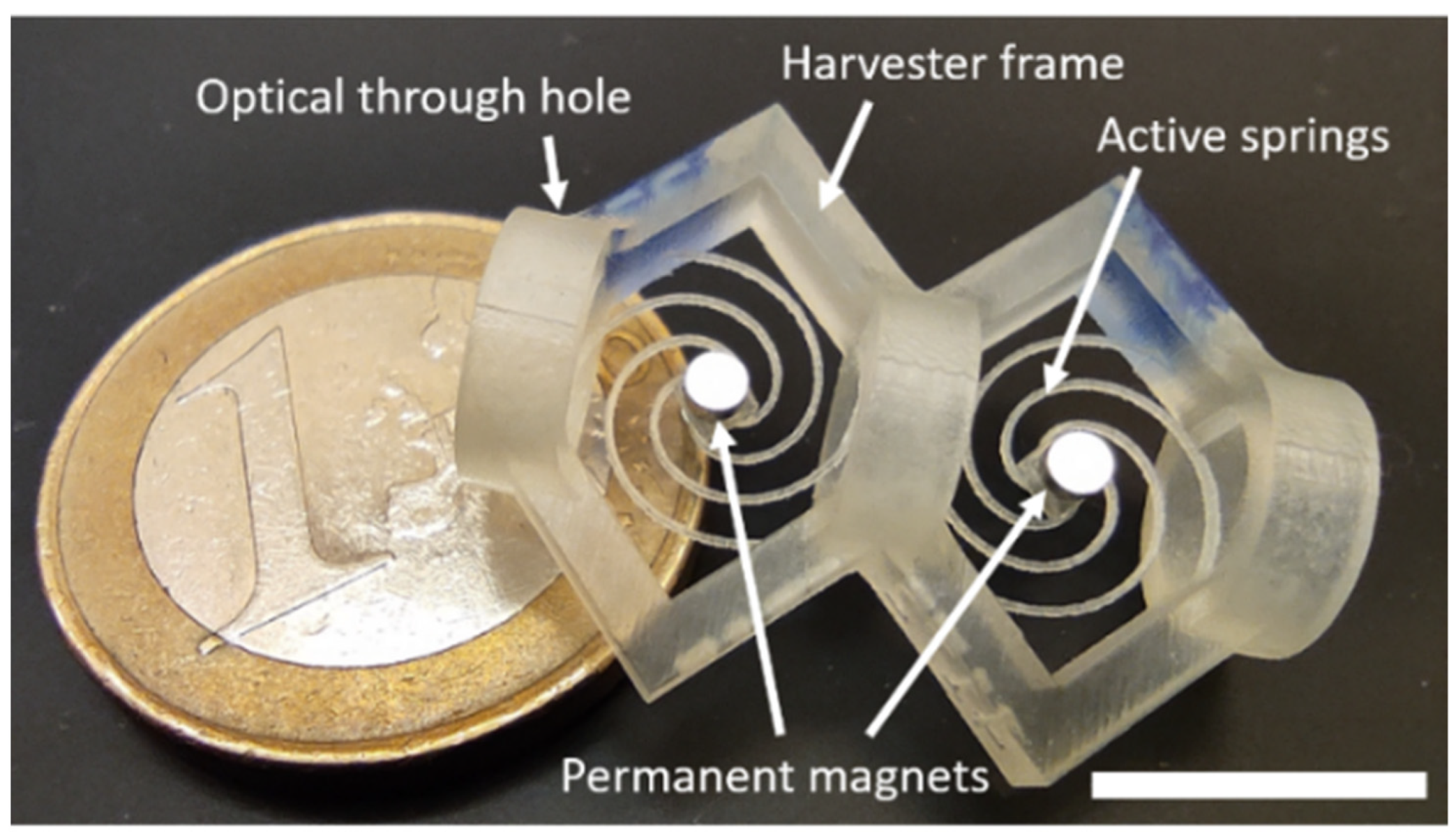

2.1. Design, Numerical Simulations, and Fabrication

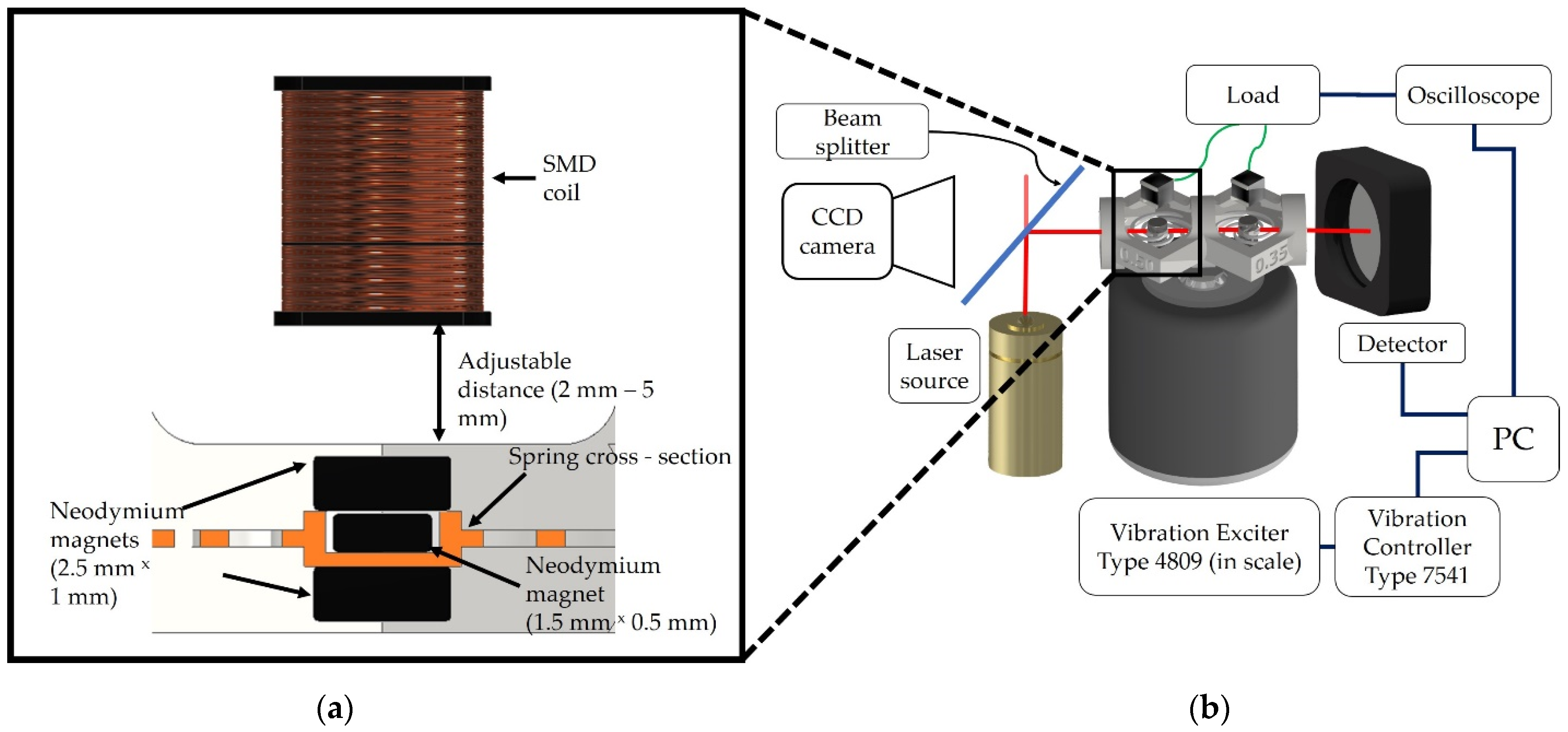

2.2. Harvester Assembly and Measurement Setup

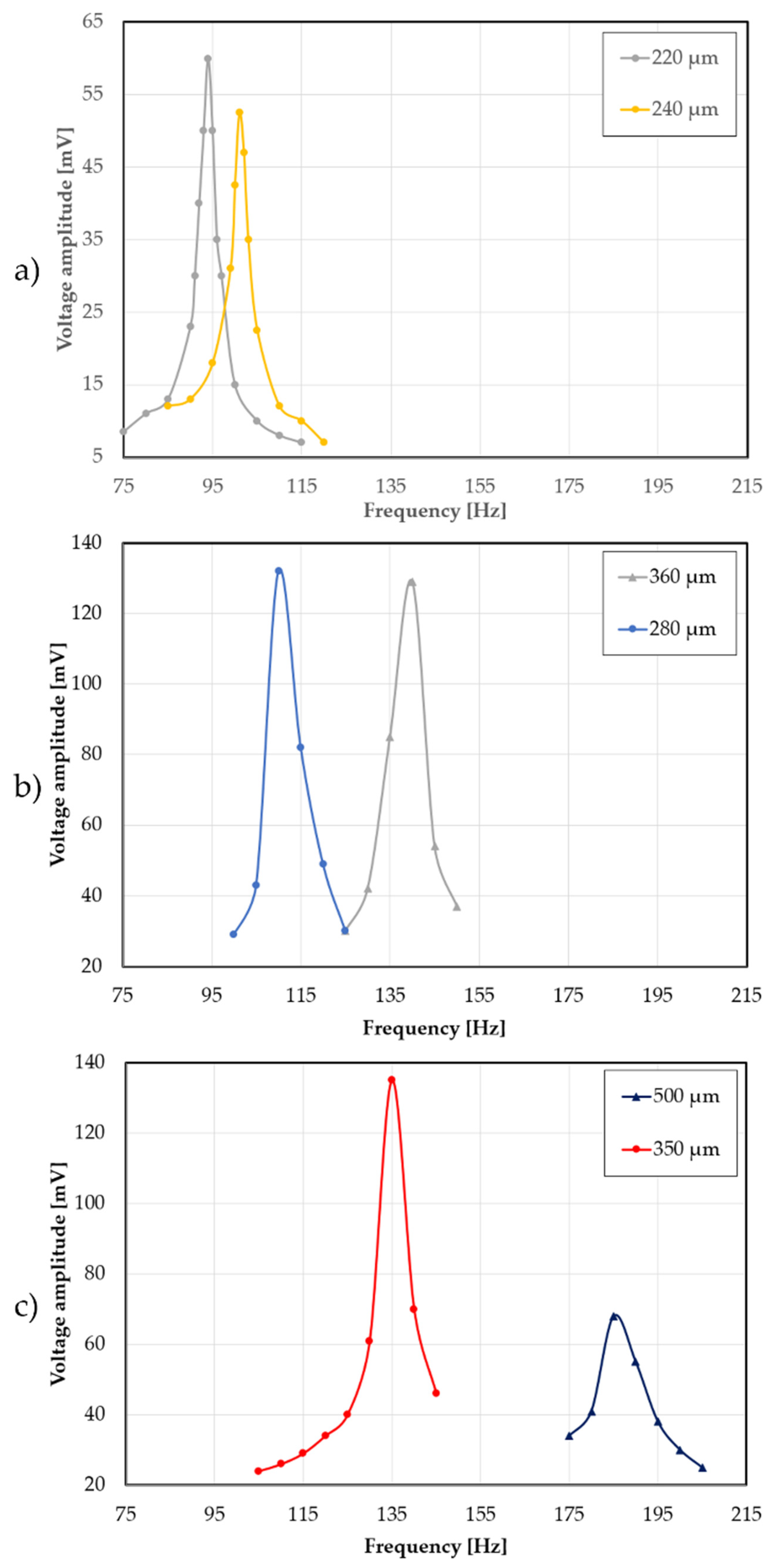

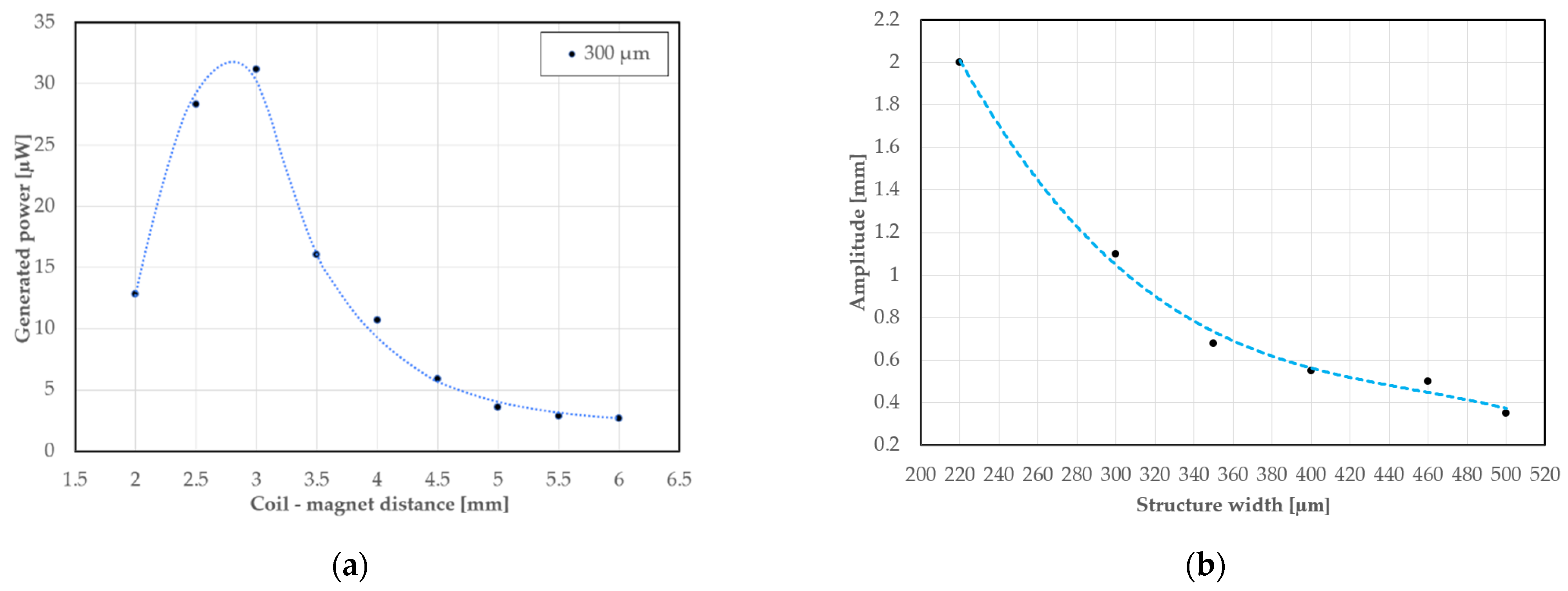

3. Results

4. Discussion

5. Summary and Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Iqbal, M.; Nauman, M.; Khan, F.; Abas, P.; Cheok, Q.; Iqbal, A.; Aissa, B. Vibration-based piezoelectric, electromagnetic, and hybrid energy harvesters for microsystems applications: A contributed review. Int. J. Energy Res. 2021, 45, 65–102. [Google Scholar] [CrossRef]

- Landaluce, H.; Arjona, L.; Perallos, A.; Falcone, F.; Angulo, I.; Muralter, F. A Review of IoT Sensing Applications and Challenges Using RFID and Wireless Sensor Networks. Sensors 2020, 20, 2495. [Google Scholar] [CrossRef] [PubMed]

- Bryzek, J. Trillion Sensors Movement in Support of Abundance and Internet of Everything. In Proceedings of the Materials of Sensors Conference, Santa Clara, CA, USA, 6 March 2014. [Google Scholar]

- Mohanty, A.; Parida, S.; Behera, R.; Tarapada, R. Vibration Energy harvesting: A review. J. Adv. Dielectr. 2019, 9, 1930001. [Google Scholar] [CrossRef]

- Kim, Y.; Keun, H. Elastic Member and Vibration Absorption Apparatus for a Refrigerator Compressor. U.S. Patent 6,912,865, 5 July 2005. [Google Scholar]

- Yang, B.; Lee, C.; Xiang, W.; Xie, J.; He, J.; Kotlanka, R.; Low, S.; Feng, H. Electromagnetic Energy harvesting from vibrations of multiple frequencies. J. Micromech. Microeng. 2009, 19, 035001. [Google Scholar] [CrossRef]

- Liu, H.; Qian, Y.; Lee, C. A multi-frequency vibration-based MEMS electromagnetic energy harvesting device. Sens. Actuators Phys. 2013, 204, 37–43. [Google Scholar] [CrossRef]

- Chen, J.; Chen, D.; Yuan, T.; Chen, X. A multi-frequency sandwich type electromagnetic vibration energy harvester. Appl. Phys. Lett. 2012, 100, 213509. [Google Scholar] [CrossRef]

- Foisal, A.; Hong, C.; Chung, G. Multi-frequency electromagnetic energy harvester using a magnetic spring cantilever. Sens. Actuators Phys. 2012, 182, 106–113. [Google Scholar] [CrossRef]

- Deng, H.; Du, Y.; Wang, Z.; Zhang, J.; Ma, M.; Zhong, X. A multimodal and multidirectional vibrational energy harvester using a double-branched beam. Appl. Phys. Lett. 2018, 112, 213901. [Google Scholar] [CrossRef]

- Liu, D.; Haisheng, L.; Feng, H.; Yalkun, T.; Hajj, M. A multi-frequency piezoelectric vibration energy harvester with liquid filled container as the proof mass. Appl. Phys. Lett. 2019, 114, 213902. [Google Scholar] [CrossRef]

- Mazeika, D.; Ceponis, A.; Yang, Y. Multifrequency piezoelectric energy harvester based on poligon-shaped Cantilever array. Shock. Vib. 2018, 2018, 5037187. [Google Scholar]

- Shin, Y.H.; Choi, J.; Kim, S.J.; Kim, S.; Maurya, D.; Sung, T.H.; Song, H.C. Automatic resonance tuning mechanism for ultrawide bandwidth mechanical energy harvesting. Nano Energy 2020, 77, 104986. [Google Scholar] [CrossRef]

- Wang, Z.; Du, Y.; Li, T.; Yan, Z.; Tan, T. A flute-inspired broadband piezoelectric vibration energy harvesting device with mechanical intelligent design. Appl. Energy 2021, 303, 117577. [Google Scholar] [CrossRef]

- Walczak, R.; Adamski, K.; Lizanets, D. Inkjet 3D printed check microvalve. J. Micromech. Microeng. 2017, 27, 047002. [Google Scholar] [CrossRef]

- Walczak, R.; Kawa, B.; Adamski, K. Inkjet 3D printed microfluidic device for growing seed root and stalk mechanical characterization. Sens. Actuators Phys. 2019, 297, 111557. [Google Scholar] [CrossRef]

- Walczak, R. Inkjet 3D printing–towards new micromachining tool for MEMS fabrication. Bull. Polish Acad. Sci. Tech. Sci. 2018, 66, 179–186. [Google Scholar]

- Ju, S.; Ji, C.-H. Impact-based piezoelectric vibration energy harvester. Appl. Energy 2018, 214, 139–151. [Google Scholar] [CrossRef]

- Maharjan, P.; Cho, H.; Rasel, M.; Salauddin, M.; Park, J.Y. A fully enclosed, 3D printed, hybridized nanogenerator with flexible flux concentrator for harvesting diverse human biomechanical energy. Nano Energy 2018, 53, 213–224. [Google Scholar] [CrossRef]

- Seol, M.-L.; Ivaskeviciute-Povilauskiene, R.; Ciappesoni, M.A.; Thompson, F.V.; Moon, D.-I.; Kim, S.J.; Han, J.-W.; Meyyappan, M.; Kim, S.J. All 3D printed energy harvester for autonomous and sustainable resource utilization. Nano Energy 2018, 52, 271–278. [Google Scholar] [CrossRef]

- Seol, M.-L.; Han, J.-W.; Moon, D.-I.; Yoon, K.J.; Hwang, C.S.; Meyyappan, M. All-printed triboelectric nanogenerator. Nano Energy 2018, 44, 82–88. [Google Scholar] [CrossRef]

- Hadas, Z.; Zouhar, J.; Singule, V.; Ondrusek, C. Design of energy harvesting generator base on rapid prototyping parts. In Proceedings of the 2008 13th International Power Electronics and Motion Control Conference, Poznan, Poland, 1–3 September 2008; pp. 1665–1669. [Google Scholar]

- Rubes, O.; Smilek, J.; Hadas, Z. Development of vibration energy harvester fabricated by rapid prototyping technology. In Proceedings of the 16th International Conference on Mechatronics—Mechatronika 2014, Brno, Czech Republic, 3–5 December 2014; pp. 178–182. [Google Scholar]

- Bowers, B.; Arnold, D. Spherical magnetic generator for bio-motional energy harvesting. In Proceedings of the PowerMEMS 2008 Conference, Sendai, Japan, 9–12 November 2008; pp. 281–284. [Google Scholar]

- Constantinou, P.; Roy, S. A 3D printed electromagnetic nonlinear vibration energy harvester. Smart Mater. Struct. 2016, 25, 95053. [Google Scholar] [CrossRef] [Green Version]

- Gawron, P.; Wendt, T.M.; Stiglmeier, L.; Hangst, N.; Himmelsbach, U.B. A review on kinetic energy harvesting with focus on 3D printed electromagnetic vibration harvesters. Energies 2021, 14, 6961. [Google Scholar] [CrossRef]

- Kawa, B.; Śliwa, K.; Lee, C.; Shi, Q.; Walczak, R. Inkjet 3D printed MEMS vibrational electromagnetic energy harvester. Energies 2020, 13, 2800. [Google Scholar] [CrossRef]

- Walczak, R.; Adamski, K. Inkjet 3D printing of microfluidic structures—on the selection of the printer towards printing your own microfluidic chips. J. Micromech. Microeng. 2015, 26, 085013. [Google Scholar] [CrossRef]

- Yan, Z.; Sun, W.; Hajj, M.R.; Zhang, W.; Tan, T. Ultra-broadband piezoelectric energy harvesting via bistable multi-hardening and multi-softening. Nonlinear Dyn. 2020, 100, 1057–1077. [Google Scholar] [CrossRef]

- Yu, T.; Zhou, S. Performance investigations of nonlinear piezoelectric energy harvesters with a resonant circuit under white Gaussian noises. Nonlinear Dyn. 2021, 103, 183–196. [Google Scholar] [CrossRef]

- Bonnin, M.; Traversa, F.L.; Bonani, F. An Impedance Matching Solution to Increase the Harvested Power and Efficiency of Nonlinear Piezoelectric Energy Harvesters. Energies 2022, 15, 2764. [Google Scholar] [CrossRef]

- Kimionis, J.; Isakov, M.; Georgiadis, A.; Koh, B.S.; Tentzeris, M.M. 3D-Printed Origami Packaging with Inkjet-Printed Antennas for RF Harvesting Sensors. IEEE Trans. Microw. Theory Tech. 2015, 63, 4521–4532. [Google Scholar] [CrossRef] [Green Version]

- Nammari, A.; Caskey, L.; Negrete, J.; Bardaweel, H. Fabrication and characterization of non-resonant magneto-mechanical low-frequency vibration energy harvester. Mech. Syst. Signal Process. 2018, 102, 298–311. [Google Scholar] [CrossRef]

| Transduction | Resonant Frequencies [Hz] or Band Width [Hz] | Maximal Output Power P [μW] or Power Density PD [μW/cm3] | Characteristic Dimensions | Fabrication Technology | Ref. |

|---|---|---|---|---|---|

| Electromagnetic | 369, 938 and 1184 | P = 3.2 | Length of acrylic beam 54 mm; width of single-layer coil area 10 mm. | PCB, laser machining | [6] |

| 840, 1070 and 1490 | PD = 0.1257 | MEMS chip 10 × 8 × 2.5 mm3; cylindrical magnet radius 1.5 mm, 2 mm high; center circular mass outer radius 2.5 mm; thickness of the circular rings 100–350 μm. | MEMS | [7] | |

| 235, 330 and 430 | P = 10 | Platform outer dimension 4 × 4 × 2 mm3, spring thickness 30 μm | MEMS | [8] | |

| 7.32, 8.67, 8.92, 10.48 | PD = 52.02 | Magnets size from 6 × 12 to 6 × 16 mm2, total volume of the harvesters from 40.18 to 108 cm3. | Traditional machining | [9] | |

| Piezoelectric | 3–25 | PD = 1.76 | PVDF film dimension 30 × 12 mm2, thickness 28 μm; length of primary cantilever beam 100 mm; length of each branch 86.8 mm | Traditional machining | [10] |

| 14.4/15.2, 11.5/12.4, 14.5/15.6, 12/12.8 | P = 1000 | PZT patch 55 mm long, 20 mm wide, 0.2 mm thick; substrate beam 150 mm long, 20 mm wide, 1 mm thick; water container diameter 46 mm, depth 22 mm. | Traditional machining | [11] | |

| 14.5, 26.1, 74.2, 199.5, 215.3 | P = 65.24 | Length of polygon arms from 2 to 23 mm, width 5 mm. | Metal and PZT machining | [12] |

| Spring width [µm] | 220 | 240 | 260 | 280 | 300 | 320 | 340 | 360 | 380 | 400 | 420 | 440 | 460 | 480 | 500 |

| Percentage error [%] | 3.5 | 0.4 | 1.9 | 1.1 | 2.8 | 3.9 | 0.9 | 1.7 | 2.5 | 0.5 | 0.5 | 5.7 | 3.4 | 7.8 | 6.9 |

| Transducer Type | Dimensions | Generated Voltage | Energy Density | Multi-Frequency | Ref. |

|---|---|---|---|---|---|

| Radio frequency | 5.7 × 5.7 × 5.7 cm | 150 mV | No data. | No | [32] |

| Piezoelectric | 26 × 10 × 10 mm | 35 V | 0.3 mW/cm3 | No | [18] |

| Triboelectric | Disc with a diameter of a dozen cm and a thickness of a few mm | 230 V | 4.52 mW/cm3 | No | [20] |

| Electromagnetic | 45 × 55 × 40 mm | 9 V | 1.28 mW/cm3 | No | [23] |

| 80 × 40 mm | 3 V | 0.133 mW/cm3 | No | [33] | |

| 20 × 10 × 6 mm | 140 mV | 0.227 mW/cm3 | Yes | This work |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kawa, B.; Lee, C.; Walczak, R. Inkjet 3D Printed MEMS Electromagnetic Multi-Frequency Energy Harvester. Energies 2022, 15, 4468. https://doi.org/10.3390/en15124468

Kawa B, Lee C, Walczak R. Inkjet 3D Printed MEMS Electromagnetic Multi-Frequency Energy Harvester. Energies. 2022; 15(12):4468. https://doi.org/10.3390/en15124468

Chicago/Turabian StyleKawa, Bartosz, Chengkuo Lee, and Rafał Walczak. 2022. "Inkjet 3D Printed MEMS Electromagnetic Multi-Frequency Energy Harvester" Energies 15, no. 12: 4468. https://doi.org/10.3390/en15124468

APA StyleKawa, B., Lee, C., & Walczak, R. (2022). Inkjet 3D Printed MEMS Electromagnetic Multi-Frequency Energy Harvester. Energies, 15(12), 4468. https://doi.org/10.3390/en15124468