1. Introduction

Studies of the long-term time-dependent creep and stress relaxation behaviors of rocks are common in geotechnical engineering. Laboratory testing data are always needed for the prediction of time-dependent creep and stress relaxation behavior, and many studies on the time-dependent behaviors of rocks at the laboratory-scale have been reported [

1,

2,

3]. For example, Mishra and Verma [

4] undertook many single and multistage creep tests on laminated shale in both uniaxial compression and triaxial compression to study the creep characteristics in roof falls. Cong and Hu [

5] performed creep tests on the Jurassic sandstones in the Majiagou landslide in triaxial compression under different low confining pressures, and proposed a modified Burges model to reflect the time-dependent creep behavior of sandstone. With regard to stress relaxation studies, Paraskevopoulou et al. [

6] conducted many triaxial compressive stress relaxation tests on limestones and investigated the characteristics of the three relaxation stages to predict and evaluate the stress relaxation behaviors of the limestone samples. Tian et al. [

7] performed triaxial compressive stress relaxation tests under different confining stresses on argillaceous sandstone samples and adopted an empirical formula in the expression of a power-law to study the impact of confining pressure on relaxation.

With respect to the creep behavior and stress relaxation behavior description and prediction, the strain/stress evolution is always analyzed, thus correspondingly, many models have been proposed or developed [

8,

9]. The component models with specific physical meanings of parameters are the most commonly and widely used. Many component models can flexibly reflect the time-evolving creep behaviors and stress relaxation behaviors of rocks, and plenty of modified component models have been proposed, supplementing nonlinear viscous elements or viscous–elastic elements or other elements on traditional models [

10,

11,

12,

13]. Unlike empirical models and component models, damage models have been put forward on the basis of crack propagation and damage evolution. For example, Wang et al. [

14] established a creep–damage model to reflect the complete creep–damage curves of rock salt, and the evolution of the deformation and damage in the three creep phases were deduced. Yang et al. [

15] analyzed the damage process during creep and introduced a damage factor into the creep model and then constructed a nonlinear creep damage model. The damage models could directly reflect the damage evolution and reveal the rheology mechanism in rock. Nevertheless, the models are confusingly used in the creep behavior and stress relaxation behavior descriptions of rocks; specifically, there is a common phenomenon where one constitutive model is developed for one rock’s creep behavior, but another model is built for this rock’s stress relaxation behavior. For example, Li et al. [

16] proposed an improved nonlinear Burgers model for the creep behavior of silty mudstone, while Yu et al. [

17] took a modified generalized Maxwell model for the stress relaxation behavior of silty mudstone. Both testing samples in the two studies were silty mudstones and both the creep tests and the stress relaxation tests were conducted in the triaxial compression state, but the two constitutive models they developed were completely different. Creep behaviors and the stress relaxation behaviors are both critically essential rheology behaviors of rocks. It is of great necessity to build a unified constitutive model that can both reflect the creep and stress relaxation characteristics to describe the time-dependent behavior of rocks (creep and stress relaxation).

Coal is a special kind of rock with great heterogeneity. It usually contains many pores and fractures with different sizes and many mineral crystal grains distributed in the coal matrix. The stress–strain response and time-dependent stress/strain evolution may be quite different from other hard rocks [

18]. In our previous work, the time-dependent creep and relaxation behaviors of raw lean coal were preliminarily discussed. Similarly, for mechanism reflection and better model accuracy, we once developed an improved harden-damage model for lean coal’s creep behavior [

19], but built another fractional derivation generalized Kelvin model for the stress relaxation behaviors of lean coal [

20]. In essence, it is much more appropriate to use a unified constitutive model, which can both reflect and predict the time-dependent creep and stress relaxation behavior of rocks, instead of the respective models to describe and predict the creep or stress relaxation behaviors of coal, separately. However, many models have been improved in creep or stress relaxation separately for better accuracy, while few efforts have been attempted to make these models unified, concise, and of specific physical meaning.

In this paper, a core damage constitutive model was established on the basis of model development, which can both reflect the nonlinear creep and stress relaxation behaviors of rocks, and then the data from the creep tests and the stress relaxation tests of lean coal in the uniaxial compressive state were used for model validation. Additionally, the model comparison on the accuracy and parameter meanings between the core damage model, traditional classic models, and modified models were discussed, and the core damage model was further popularized for the creep behavior and the stress relaxation behavior depiction of other rocks. The results of this work can help to understand the long-term time-dependent behaviors of rocks and provide references for their long-term stability in geotechnical engineering.

2. Model Development

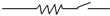

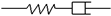

Traditional component models are composed of different elastic, viscous, and plastic elements, which are combined in series or in parallel. The traditional component models can well flexibly reflect the time-dependent elastic, viscous, and plastic behaviors (creep and stress relaxation) of rocks. Many modifications in the improved models have been made based on them. The traditional and some improved models are listed and compared in

Table 1.

As can be seen concerning the two-element models, the St. Venant model failed to depict the creep behavior of rocks, nor the stress relaxation behaviors. As for the ideal viscous–plastic model and the Kelvin model, these could reflect the time-dependent creep but failed to describe the stress relaxation behavior, while the Maxwell model could only describe the linear creep behavior and stress relaxation behavior of rocks, being unable to depict the nonlinear time-dependent behaviors. Therefore, we came to the conclusion that the two-element models could not both reflect the nonlinear time-dependent creep behaviors and the stress relaxation behaviors of rocks. When the models expanded to three elements, the combinations of the elastic and viscous elements in series or in parallel could both reflect the nonlinear creep and stress relaxation behaviors well such as the Poyting–Thomson model and the generalized Kelvin model (GK model). Furthermore, when the model expanded to more elements such as the Burgers model and the Nishihara model, both of them could reflect the nonlinear creep and stress relaxation behavior of rocks from the perspective of model elements, which is because the two models are improvements on the generalized Kelvin model by supplementing the viscous element and the ideal elastic–viscous element, respectively. In essence, the Burgers model and the Nishihara model are the further extension versions of the generalized Kelvin model, so the two models can well describe the nonlinear creep behaviors and the stress relaxation behaviors of rocks, let alone those improved models modified with specific elements supplemented by the Burgers model or the Nishihara model. These modified and improved models are still, in essence, further versions of the generalized Kelvin model (GK model).

Therefore, we can conclude that the core component elements for the traditional and modified models that best reflect the nonlinear time-dependent behaviors of rocks (creep and stress relaxation) are a combination of elastic and viscous elements in series or in parallel. The generalized Kelvin model has such typical core component elements. A core unified constitutive model was established to depict the nonlinear time-dependent behaviors of rocks (creep and stress relaxation) based on the generalized Kelvin model.

3. A Unified Core Damage Constitutive Model

3.1. Model Establishment

As stated, the generalized Kelvin model is a typical core component for the traditional and modified models to both reflect the nonlinear time-dependent creep behaviors and stress relaxation behaviors of rocks. The model establishment and component are analyzed below. Generally, at the initial time of stress/strain loading, the rock specimens generally initially respond, behaving as instantaneous strain/stress, which means that there should be an independent elastic element in the model to reflect the initial responding of samples. In creep, the strain of the specimens grows gradually, and the stress on the specimens in stress relaxation decreases over time, showing remarkably nonlinear time-evolving characteristics, which indicates that there should be a combination of elements in series or in parallel in the model to reflect the nonlinear time-dependent strain/stress evolution characteristics [

21]. The generalized Kelvin model contains the independent elastic element and the combination of elastic and viscous elements, and it meets the above component analysis and can well reflect the nonlinear time-dependent strain/stress evolution, so a core unified constitutive model was established to depict the nonlinear time-dependent behaviors of coal (creep and stress relaxation) based on the generalized Kelvin model.

In our former multi-stage creep tests, there was a creep start stress threshold in the stress [

21]. At low stress, the specimens only behaved as instantaneous strain, and the specimens did not show time-dependent creep strain until the stress on the specimens reached or exceeded the critical creep start stress threshold. Therefore, a plastic element, specifically, a stress-triggering mode, was introduced into the model to make the plastic element work or not at different stresses.

In the long-term time-dependent behavior of rocks, especially in heterogenous coal specimens, internal structural adjustments always occur, and the internal damage affects the rock viscosity remarkably. In the creep behaviors and the stress relaxation behaviors of rocks, it is the internal damage evolution that makes the viscosity change and the time-dependent strain/stress evolution show [

14,

22]. Therefore, a damage factor was introduced to the time-dependent viscous element to reflect the internal time-evolving damage evolution. The time-evolving damage factor is always adopted in an expression of exponential law [

23,

24], as seen below.

where

D is damage factor;

t is time; and

is a material constant.

After introducing the damage factor into the generalized Kelvin model, the viscosity of the element evolves and is damaged with time, and the viscous coefficient can be written as

where

is the viscosity evolving with damage factor and time after damage factor is introduced, and

is the viscosity before the damage factor is introduced.

Moreover, to reflect the nonlinear accelerating creep phase in coal, a nonlinear viscous–plastic element is supplemented to the core unified generalized Kelvin model [

25]. The constitutive equation of the viscous–plastic element is:

where

is the strain;

is the stress;

is the critical stress for the viscous element to work;

is the viscosity; and

is a material constant.

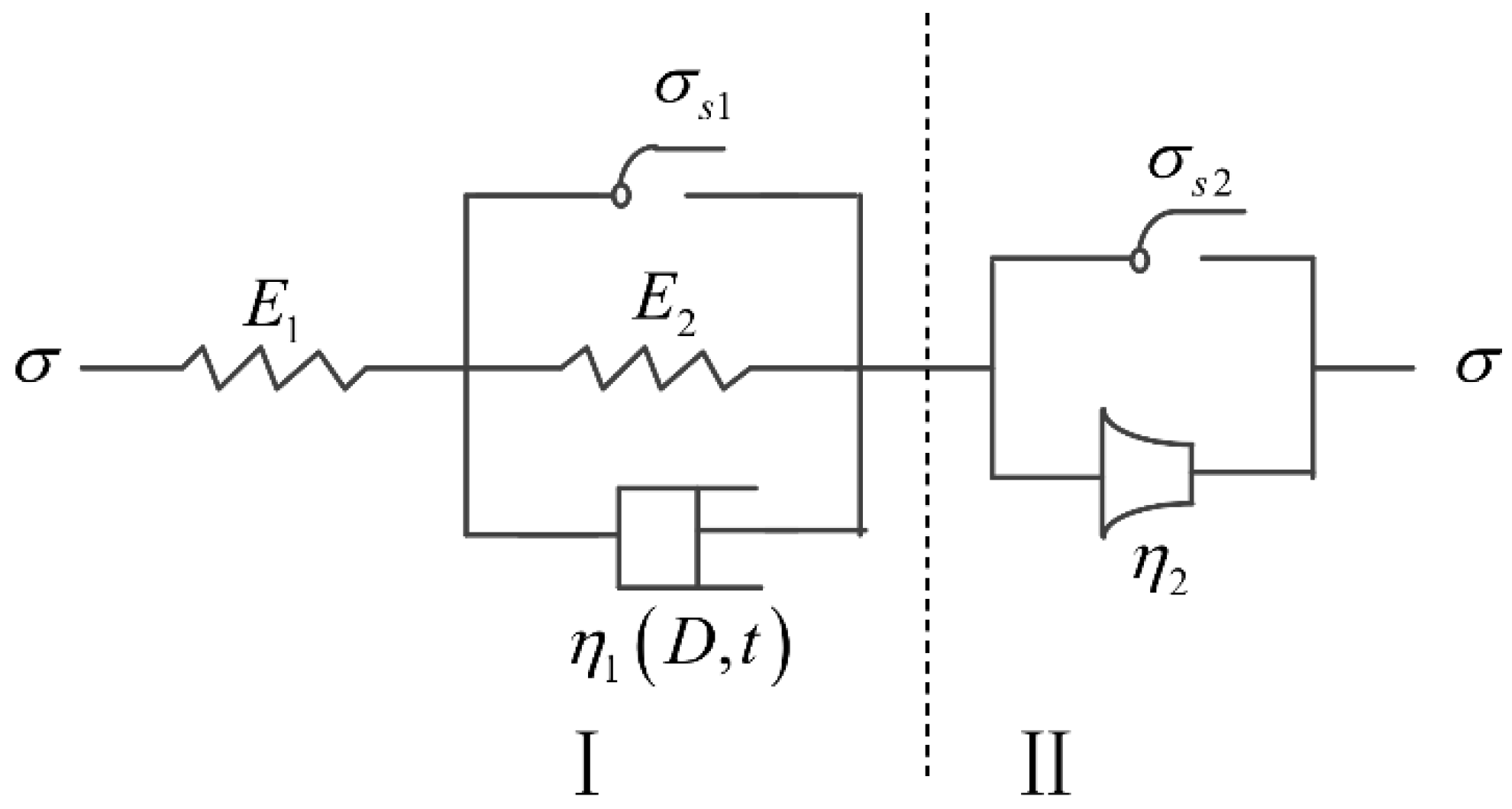

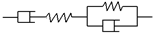

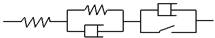

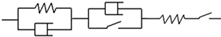

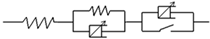

Consequently, a core unified damage model that can both reflect the nonlinear damage evolution in the creep and stress relaxation of coal is obtained (

Figure 1). In this model, in Section Ⅰ, there is a core component element combination containing damage evolution to both reflect the nonlinear creep behavior and the stress relaxation behavior of coal, and in Section Ⅱ, there is a viscous–plastic element to reflect the nonlinear accelerating creep. This core unified damage model can both reflect the creep and stress relaxation behaviors of coal with damage evolution.

3.2. Creep Equation

If the stress on the specimens does not reach the value of the critical creep start stress, that is,

, the elastic element and the viscous element in parallel in Section Ⅰ do not work, let along the plastic–viscous element in Section Ⅱ, thus, there is only an elastic element in the model. The constitutive relation at such stress is:

where

is the elastic coefficient.

If the stress on the specimens is greater than the critical creep start stress

but less than the critical stress for the viscous element

, that is,

, the elastic, viscous, and plastic elements in Section Ⅰ work in the model, and the unified core damage model turns into a model that evolves with the time and damage factor. The constitutive relation in the model in this circumstance can be written as,

where

is the elasticity;

is the stress rate; and

is the strain rate.

When the stress is held constant, at the time of

t = 0, the initial strain

, and then the initial strain and Equation (2) are substituted into the above equation, so we obtain

Similarly, when

, the creep of the unified damage model can be obtained as,

Consequently, we obtain the creep equation at different stresses as below.

Equation (8) can well describe the instantaneous strain, steady creep, and accelerating creep phase.

3.3. Stress Relaxation Equation

As stated before, the two plastic elements in the unified core damage model are both of the stress-triggering mode. Similarly, when the stress on the specimens does not reach the value of the critical creep start stress, that is, , there is only an elastic element in the model. Under these circumstances, when the strain is held constant, there is no stress relaxation in the core damage model. When , the stress is quite great and specimens are prone to fail at such great strain levels. Such conditions are quite rare for model use. When the stress on the specimens is greater than the critical creep start stress , but less than the critical stress for viscous element , that is, , this stress is suitable for the most stress relaxation behaviors of rocks to occur and we can obtain the stress relaxation equation under such circumstances. At this time, the constitutive equation of the core damage model is still Equation (5) and this model is appropriate to depict the stress relaxation behaviors at most circumstances.

At the constant strain, Equation (5) is

Substitute Equation (2) into Equation (9), and the integral is taken. Additionally, in the initial stage, the responding stress is

at the time of

t = 0, so we obtain

The above stress relaxation equation is appropriate for most stress relaxation behaviors.

4. Model Validation

In this section, the multistage creep and stress relaxation test results of lean coal in uniaxial compression were used for model validation [

19,

20]). The samples were raw lean coal from the Heshun Mine in the Qinshui Coalfield in Yangquan, Shanxi, North China. Cylindrical core samples with a size of

were prepared as suggested by the International Society for Rock Mechanics (ISRM) [

26]. Basic mechanical parameter tests of the raw lean coal were performed and the results are shown in

Table 2. In creep, the axial stress at the first stress level was set at 30~40% of the uniaxial compressive strength of the coal samples, and the maximum axial stress was set at 70~80% of the uniaxial compressive strength. The middle stress levels were designed with equal or close intervals. Each stress was applied to the samples quickly, and then kept constant for no less than 2~3 days. When the axial displacement of the sample was steady, the next stress level was applied to the sample until failure was reached.

The core damage model was validated to the multi-stage creep data and the multi-stage stress relaxation data to check the model’s accuracy. In the model validation to the creep data, is the critical creep start stress threshold for the time-dependent strain evolution to occur and is the critical stress threshold for the accelerating creep phase; both stress parameters were acquired as the testing data showed. Distinctly, in the unified core damage model and as seen in Equation (8), is the independent elasticity, and it reflects the initial response of the elastic modulus in the specimens. was calculated by the stress and the initial instantaneous strain.

Regarding the other parameters in the core damage model, in creep,

,

,

, and

are substituted into Equation (8), and then the other parameters of

,

, and

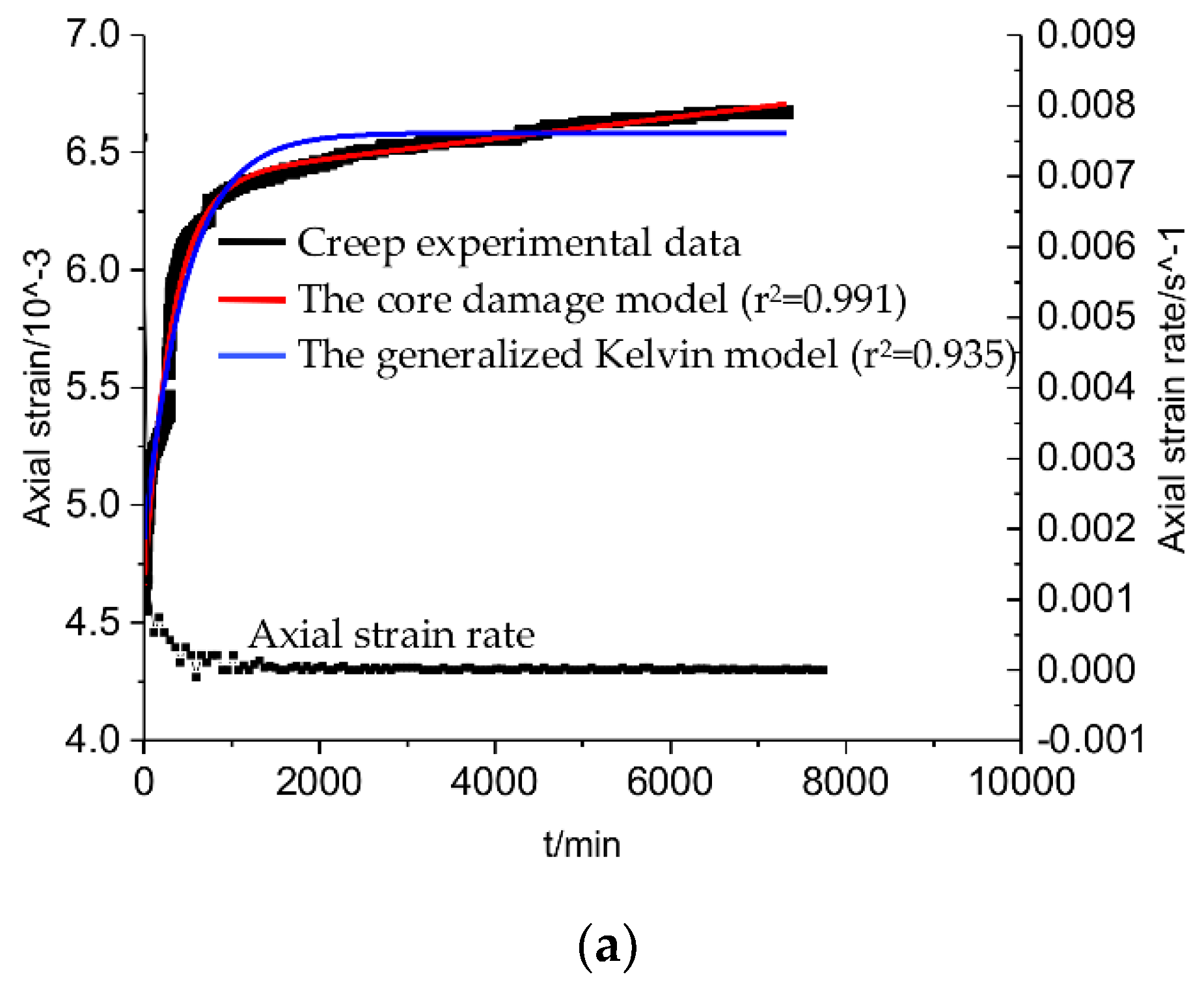

can be determined by the least-squares fitting in Origin software. The fitting results of the core damage model curves to the experimental creep data of the five different lean coal specimens at different stresses are shown in

Figure 2. The corresponding parameters after calculation and identification are listed in

Table 3.

Similarly, in stress relaxation, Equation (10) is appropriate to depict the stress relaxation behaviors at different strains. At the initial start of strain loading, the instantaneous responding stress is

at the time of

t = 0, and from Equation (10), the initial stress is

. Additionally, the final stable stress approaches

, so

can be obtained and the relation between

,

, and

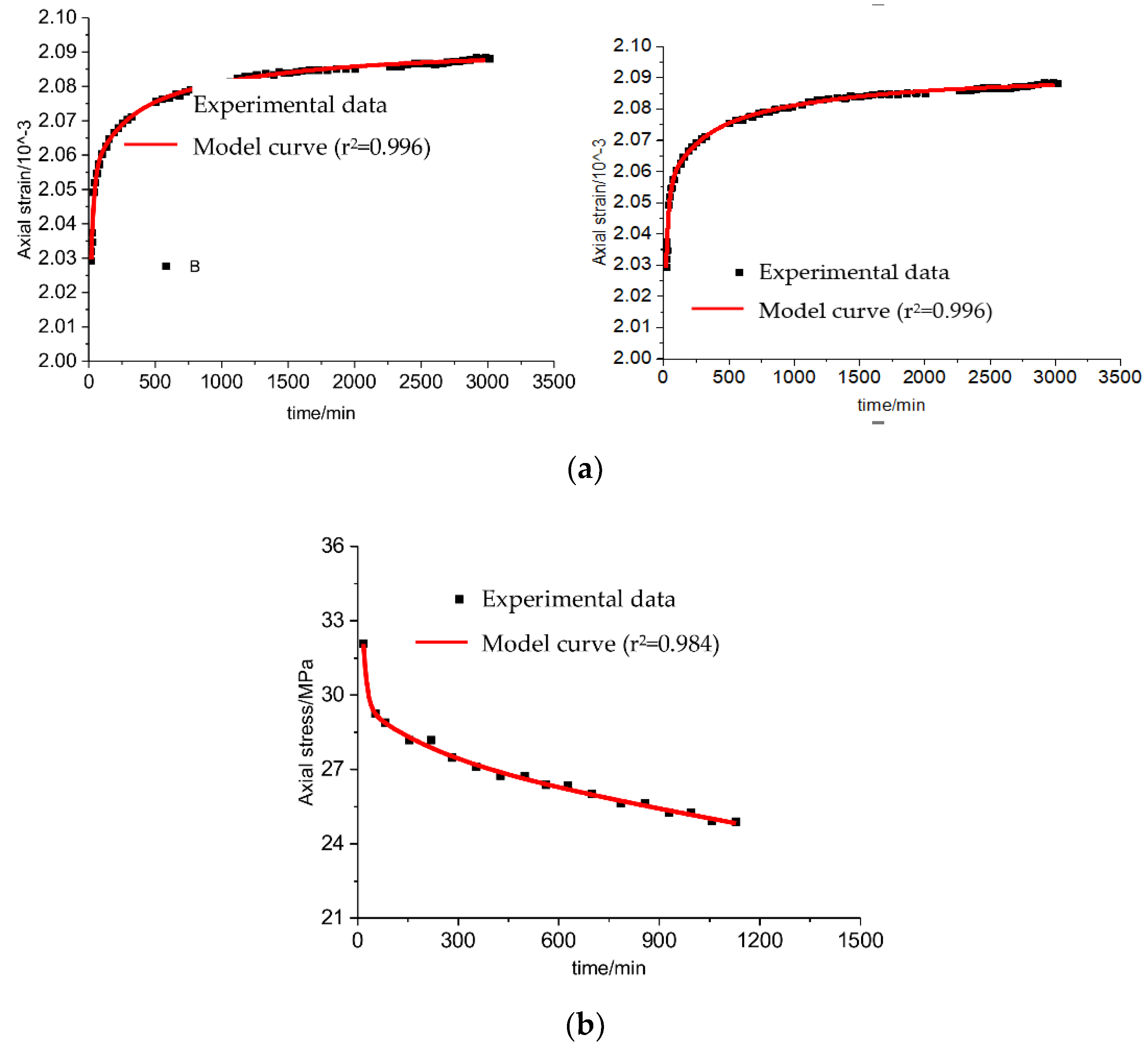

are obtained and substituted into Equation (10), so the other parameters can be obtained through the least-squares fitting. The model curves of the unified core damage model were compared to the stress relaxation data of the six lean coal specimens at different strains, and the comparisons are shown in

Figure 3. The corresponding parameters after calculation and identification are listed in

Table 4.

In

Figure 2 and

Figure 3, the black curves are the experimental strain/stress data in creep/stress relaxation and the red ones are the core damage model curves. As seen in the two figures, the model curves were in high accordance with the time-dependent creep data at different stresses and the stress relaxation data at different stains. Remarkably, the correlation coefficients of the fitting results to the creep testing data and the stress relaxation testing data were quite high, as much as 0.993, which indicate that this unified core damage model can very well depict the nonlinear creep data at different stresses and the stress relaxation data at different strains of lean coal in relation to damage evolution.

5. Discussions

5.1. Model Comparison

The core damage model was put forward based on the generalized Kelvin model. In the generalized Kelvin model, the creep equation at the constant stress and the stress relaxation equation at the constant strains are listed as:

where

K1 and

K2 are the elastic coefficients in the generalized Kelvin model;

is the viscosity coefficient; and the other parameters are of the same physical meaning as stated previously.

The model validation accuracy of the two models to the experimental creep data and stress relaxation data were compared. The axial strain of sample #c-4 in creep at 7.2 MPa was taken as an example as well as the stress relaxation data of specimen #r-4 at the strain of 1.2%. The unified core damage model and the traditional generalized Kelvin model were validated to the sample testing data. Consequently, the comparison results are shown in

Figure 4. Remarkably, the unified core damage model accorded with the experimental data much better than the traditional generalized Kelvin model. This can mainly be attributed to the introduced damage factor. It is the introduced damage factor that makes the unified core damage model depict the nonlinear time-dependent behavior more flexibly, showing much better accuracy.

Regarding the improved models, in creep, the core damage model was similar to the hardening-damage creep constitutive model proposed in Cai’s work [

19]. The hardening-damage model was proposed based on the hardening-damage mechanism of lean coal, in which the creep equation is:

where

E10 and

E2 are the elastic coefficients in the hardening-damage model;

α is the damage factor;

m is the material constant in relation to rocks; and the other parameters have the same physical meaning as stated before.

Comparing Equation (8) and Equation (13), when the stress on specimens was greater than the critical creep start stress but less than the critical stress for viscous element , that is, , the two equations were similar to exponential expressions. Both models could well reveal the damage evolution characteristics in the nonlinear creep of lean coal. In essence, is there is no obvious difference in the model accuracy, then the fitting results of the two models to the experimental data and the identified parameter of the two models would be the same. From the perspective of model component, the hardening effect was only reflected in the instantaneous strain phases; once the specimen showed time-dependent nonlinear strains, the core damage model and the hardening-damage model had the same depiction and accuracy in the experimental creep data. Furthermore, the hardening-damage model failed to depict the nonlinear accelerating creep phase, while the core damage model supplemented a viscous–plastic element, which could well overcome this shortcoming.

Regarding the stress relaxation, we developed an improved model with a fractional derivative Abel dashpot [

18], in which the stress relaxation equation is:

where

γ is the fractional derivative order of the dashpot;

is the Mittag–Leffler function; and the other parameters had the same physical meanings as stated before.

Similarly, the unified core damage model and the fractional model were validated to the experimental stress relaxation data for the comparison of the model accuracy. The stress relaxation data of specimen r-4 is taken as an example and the model validation accuracy comparison results were shown in

Figure 5. As can be seen, the fractional model showed much greater accuracy in the time-dependent stress relaxation description of raw lean coal. Such a difference in accuracy is mainly attributed to the fractional derivation dashpot, in which the parameters

and

can adjust to the nonlinear stress relaxation data as closely as possible, while the introduced damage factor in the unified core damage model is analogous to the traditional viscous element. Therefore, the fractional model showed much better accuracy while the unified core damage model showed limited improvement. However, though the core damage model was less accurate in the nonlinear stress relaxation curve description, the parameters in the unified core damage model had clear physical significances. There were elastic, plastic, and viscous elements in the models and the viscosity

evolving with damage and time well revealed the time-dependent damage evolution inside the samples, while in the Abel dashpot in the fractional derivative model, the viscous coefficient was a nonlinear function of fractional derivation, and the physical meaning of parameter

was unclear and ranged with the experimental data. Moreover, the equation of the fractional derivative model is complicated with many parameters and is difficult to popularize in practical engineering.

5.2. Model Popularization

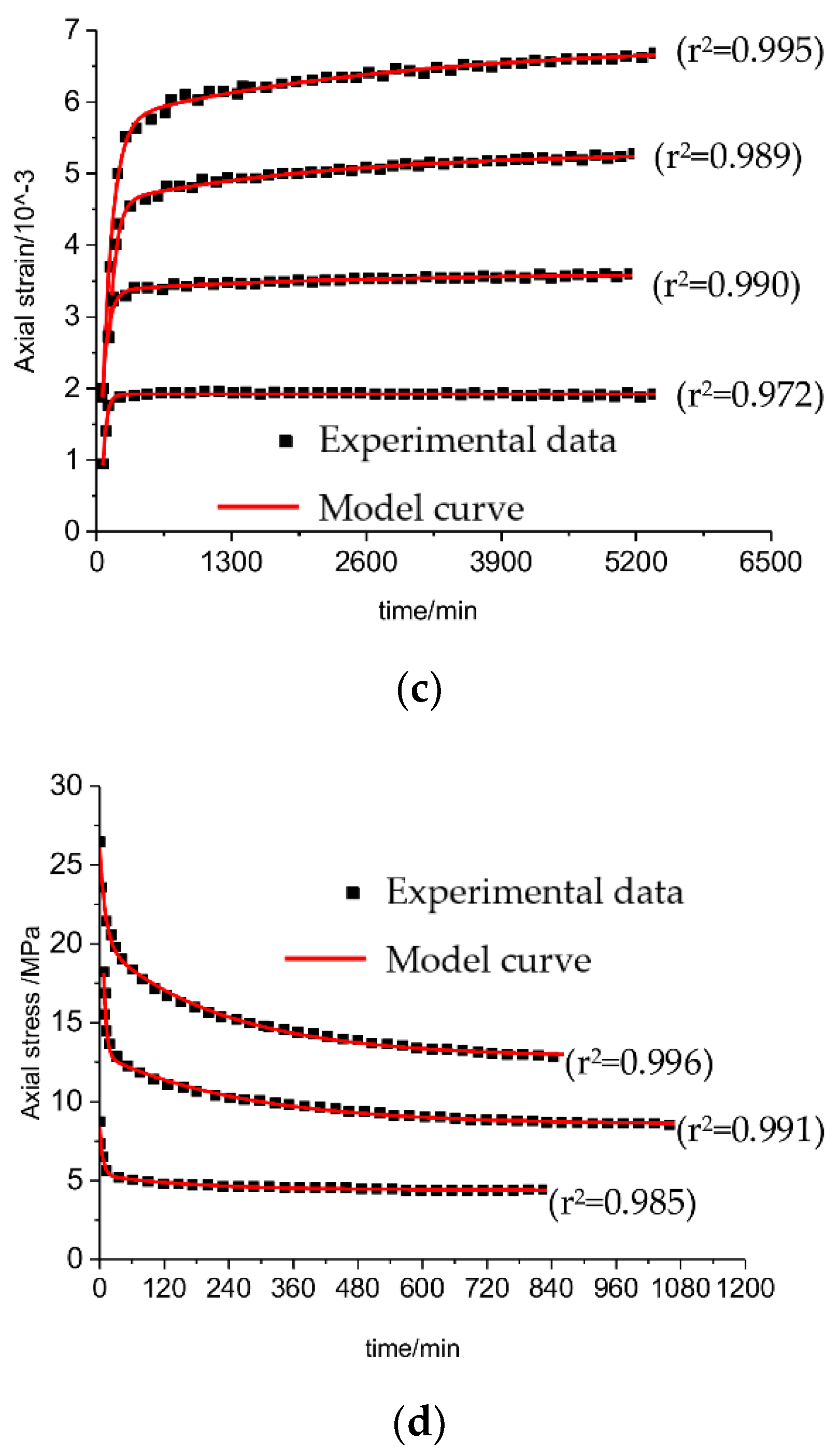

To further validate and popularize this core damage model, the creep testing data of a marble at a stress of 69 MPa in the uniaxial state [

27] and the stress relaxation test data of a Cobourg limestone (Cbrg_16R) under uniaxial compression [

6] were taken as examples, and the model curve and the experimental data are shown in

Figure 6a,b. As seen, the unified core damage model curves could well describe the axial strain of marble at a stress of 69 MPa and the stress relaxation of the Cobourg limestone (Cbrg_16R) and the correlation coefficients were as high as 0.996. Generally, this core damage model is not only suitable to describe the creep and relaxation behavior of raw lean coal, but can also be used to describe the time-dependent damage evolution behavior of the other rocks.

In model popularization, we should also note the model limitations. In the establishment of our model, the special initial elastic phase of coal was taken into consideration when the stress did not reach the creep start initial stress, as can be seen in the first situation in Equation (8). Consequently, there are three situations or two situations (the first and second situations without accelerating phase) to describe the creep behavior of coal that may take place. For other rocks, there may be two other situations (the second and third situation) and the first elastic phase can be ignored. When using this model to describe the rheological behaviors of other rocks, we can start from the second situation.

The unified core damage model is established in the 2D state, so to popularize the model, the equations of creep and stress relaxation were induced in the 3D state, as follows:

The above equations were used to validate the creep and stress relaxation data of silty mudstone in triaxial compression. The model depiction curves compared to the experimental creep and stress relaxation data are shown in

Figure 6c,d. As seen, when the model was expanded to the 3D state, the unified core damage model could still well describe the nonlinear time-dependent creep and stress relaxation behaviors of the other rocks.

5.3. Model Further Improvement

In further studies, this core damage model could be modified and improved for higher accuracy. It can be inferred that these modifications and improvements can be made in the following two parts:

- (1)

Modifications and improvements may be made in Section Ⅰ in the model, and some viscous elements, elastic elements, or nonlinear elastic-viscous elements can be added. However, as stated previously, this model is core and concise to describe the time-dependent behaviors of rocks (creep and stress relaxation). These modifications may improve the model accuracy, but they may also make the physical meanings of the elements unclear. Furthermore, the model expressions will be much more complicated with more parameters to be identified, so the modified models would have limited guidance in engineering practice.

- (2)

The other modifications may be made in Section Ⅱ in the model. The viscous–plastic element to reflect the accelerating creep phase could be modified into any nonlinear viscous combination. Those modified models may have a more accurate description in the nonlinear accelerating creep phase, but for the transient creep and steady creep phases, the expressions of the models after modification were the same as that in the core damage model proposed in this paper.

The core damage model can approximately depict the time-dependent behaviors of rocks (creep and stress relaxation) and the model is suitable for popularizing in practical engineering. Further model modification on this core damage model may have limited improvements.