3.1. Relation between Faults and the Values of Diagnostic Signals

Diagnostic signals result from the binary or multivalent evaluation of the residuals calculated on the basis of the models to detect faults. They can also be the outputs of heuristic tests. For the diagnosis, it is necessary to know the representation of the space of diagnostic signals’ values:

in the space of faults:

The FIS was defined in [

21] in the form of the following four:

where:

assigning a subset of the values of diagnostic signals to each element of the Cartesian product

:

which can receive this signal when

fault occurs.

Furthermore, let us assume that the value of a diagnostic signal corresponds to a no-faults state, and the other values are symptoms of the faults.

FIS is then a table defining model values of diagnostic signals for the particular faults. It is a generalisation of the binary diagnostic matrix. If the set of all values of diagnostic signals is identical and equal to and is a singleton, FIS is simplified to a binary diagnostic matrix. Significant extensions of FIS concerning the binary diagnostic matrix are as follows:

Each diagnostic signal may have an individual set of its values .

set of the j-th value of diagnostic signal includes the value of 0 and the values that differ from 0, which are the fault symptoms.

element of a Cartesian product is in a general case, a subset of the values , which may be taken by a j-th diagnostic signal when the k-th fault appears.

FIS provides a greater distinguishability of faults when compared to the binary diagnostic matrix, what has been presented in [

21,

37,

38].

Suppose that, for the analogy from BDM we present a graphical representation of FIS in the form of a table (Example 1,

Table 1), the rows of which correspond to

diagnostic signals, and the columns to

faults. In such a case, the signature of the fault corresponds to the FIS column and is described by the following dependence:

The above notation of the relation between faults and diagnostic signal values is especially useful for the three-valued evaluation of residual values, as it enables the residual sign to be considered. However, this form is more general, which allows for the interpretation of diagnostic signals obtained by other methods, e.g., visual. If the fault symptoms are related to the colours of the flame, the FIS allows to express this relationship for, e.g., four distinct colours: yellow, orange, red and purple.

Classical signature-based reasoning is realised on the basis of all diagnostic signals. Diagnosis is formulated as a result of the comparison of the obtained values of diagnostic signals with the signature of the state including only zeros and signatures of the particular faults (7). The diagnosis indicates a subset of faults, the signatures of which are compliant with the current values of diagnostic signals:

The signature of

k-th fault (7) corresponds to the rule referring to this fault:

The rule for the no-faults state of the object is as follows:

However, the signatures of the faults in the form of (7) and a rule (9) are not a reasonable ground for formulating diagnoses on the faults. This form of notation of the relationship between faults and symptoms is not resistant to the changes in the structure of the diagnosed object, including the changes in the set of the available measuring path. When changing a set of the available measuring signals in (9) type of rules, a set of premises is changed. What is more, in LSS, the rules corresponding to the columns of a FIS are inconvenient due to a large number of premises. That is why the rules assigned to particular diagnostic signals are applied in reasoning on the faults.

On the basis of FIS, we are able to determine

subsets of faults detected by particular

diagnostic signals. These are the faults for which

diagnostic signals are different from 0. We are also able to define a subset of faults that may cause a symptom with the

value for each value of a

diagnostic signal:

On the basis of (11), we may specify the rules for particular non-zero values of the diagnostic signal:

This solution is analogous to the Row Reasoning used in the DX approach. The difference is that the evaluation of residuals is multivalued, and one diagnostic signal can generate subsets of symptom values. A different rule (12) corresponds to each of them. The proposed form of the notation of the faults-symptoms relation has significant advantages. In the case of changing the structure of the process, or as a consequence of previous diagnoses, such a rule may be temporarily eliminated from the set of active rules, but its form is invariable. This rule has a compact form because the number of possible faults indicated in conclusion is not high. Moreover, such a form of rules is convenient when extending the rule base after introducing new tests.

Dependences (11) or the rules (12) corresponding to them are the basis of knowledge of the discussed diagnostic system. The proposed diagnostic algorithm also uses the available knowledge about the relationship between delays of the symptoms defined for particular faults.

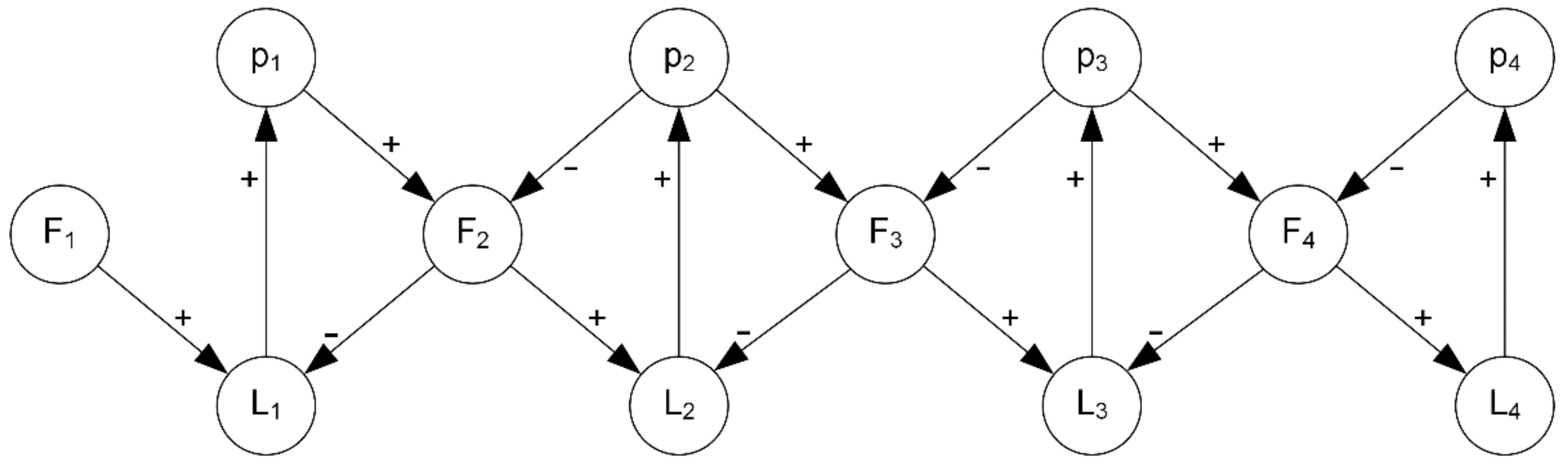

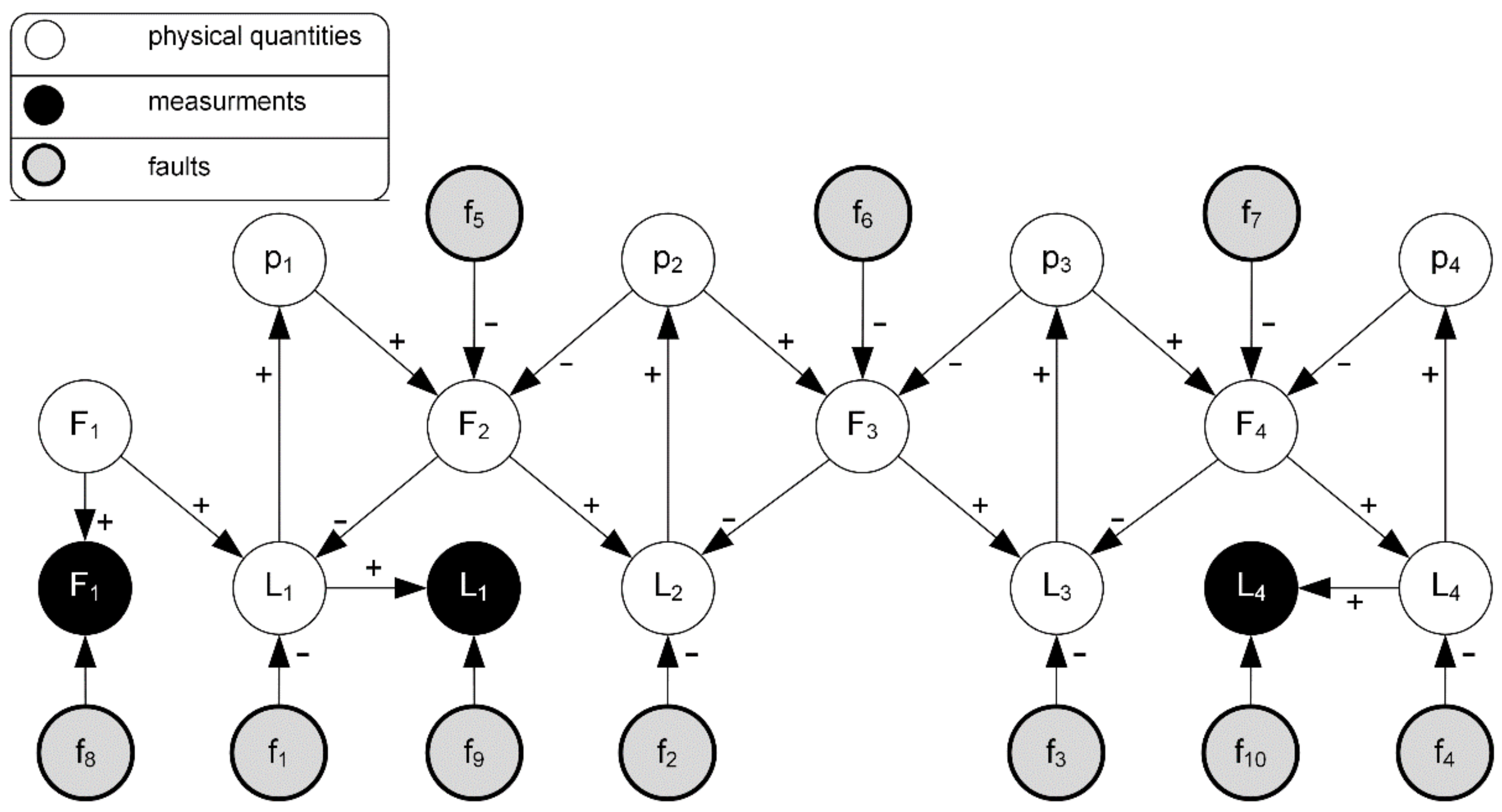

Example 1. Consider an example of the fault isolation system given inTable 1. Here:

, , , , , , .

Subsetsare as follows:,,.

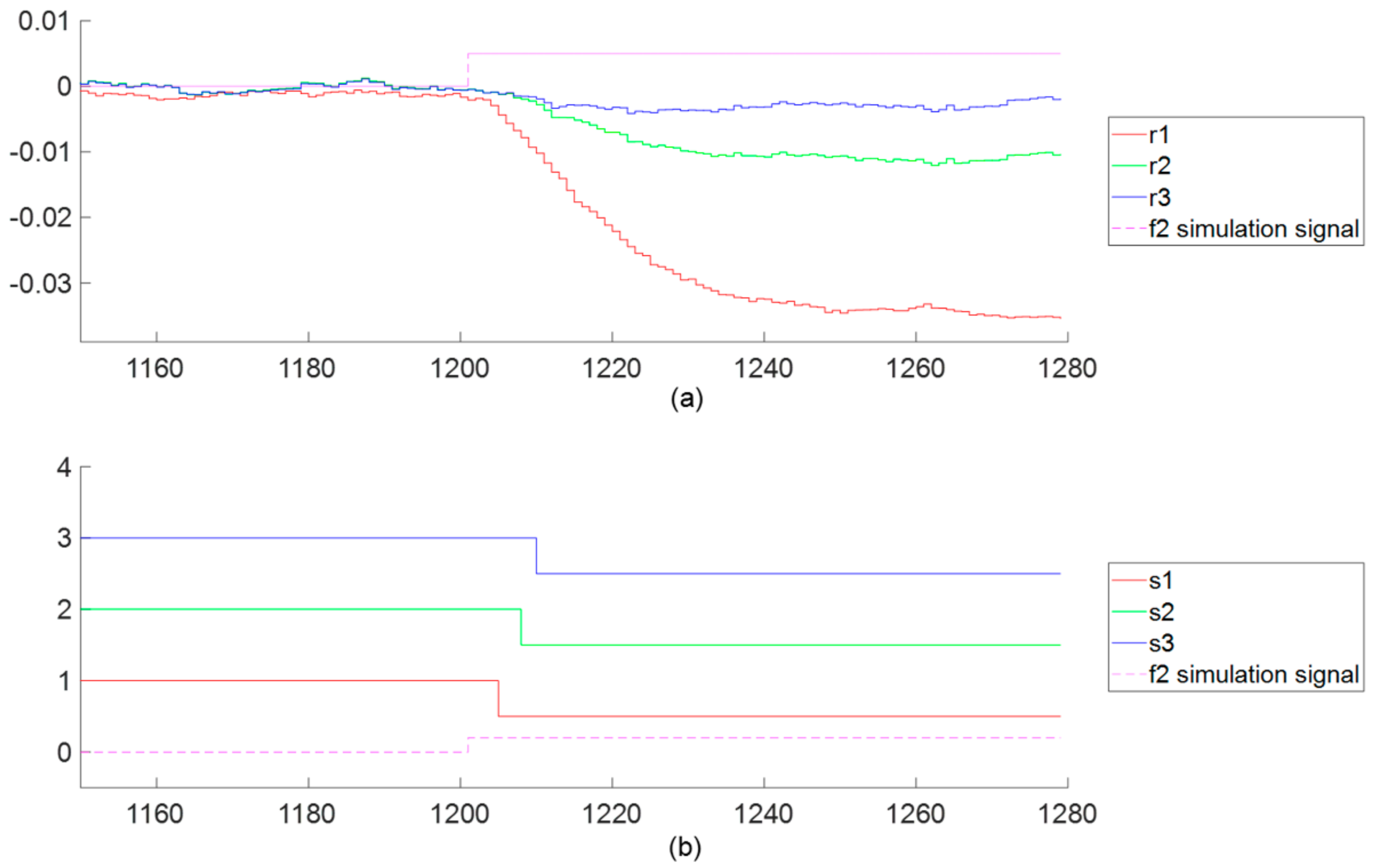

3.2. Knowledge about Symptom Forming Order

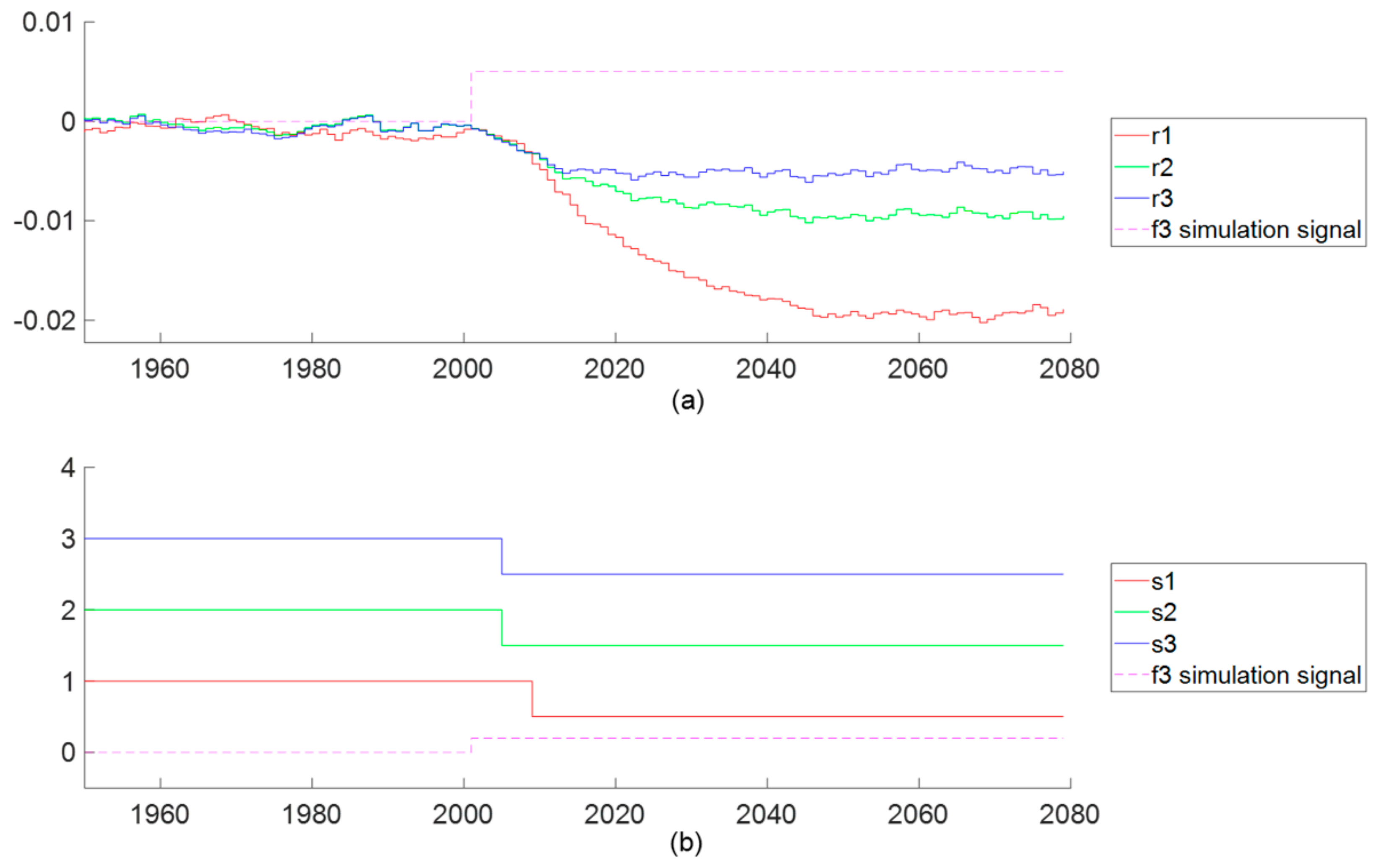

The relationship between faults and the values of diagnostic signals saved in the form of BMD or FIS does not include information on the symptom forming order for particular faults. Such knowledge may be used in a similar way as the values of diagnostic signals for isolating faults.

In practice, in many cases, it is possible to determine the order of the different symptoms of the same fault. Let us denote the elementary sequence as i.e., a sequence of two symptoms—j and p for the fault. The notation indicates that after the emergence of fault, the symptom will appear before the symptom.

Elementary sequences can, in many cases, make it possible to distinguish faults that are indistinguishable based on the values of diagnostic signals. The following definitions of faults distinguishability, indistinguishability, and conditional distinguishability, based on elementary sequences, can be formulated:

Definition 1. Faultsare unconditionally indistinguishable on the basis of elementary symptom sequences if the corresponding elementary symptom sequences are the same: Definition 2. Faultsare unconditionally distinguishable on the basis of elementary symptom sequences, if, and only if, the corresponding elementary symptom sequences with the same symptoms are different (differ in the order of symptoms): Definition 3. Faultsare conditionally distinguishable on the basis of elementary sequences of symptoms, if, and only if, these faults are not unconditionally indistinguishable and there is a pair of diagnostic signals for which the faultcorresponds to the sequenceand for the faultboth sequences,are possible. One obtains distinguishability in the case of the occurrence of a sequence, which unambiguously indicates the fault.

Elementary sequences may not usually be defined for all faults and not for all pairs of symptoms of a given fault.