Modeling Near-Miscible Gas Foam Injection in Fractured Tight Rocks and Its Challenges

Abstract

1. Introduction

2. Experimental Description and Model Set-Up

2.1. Experimental Description

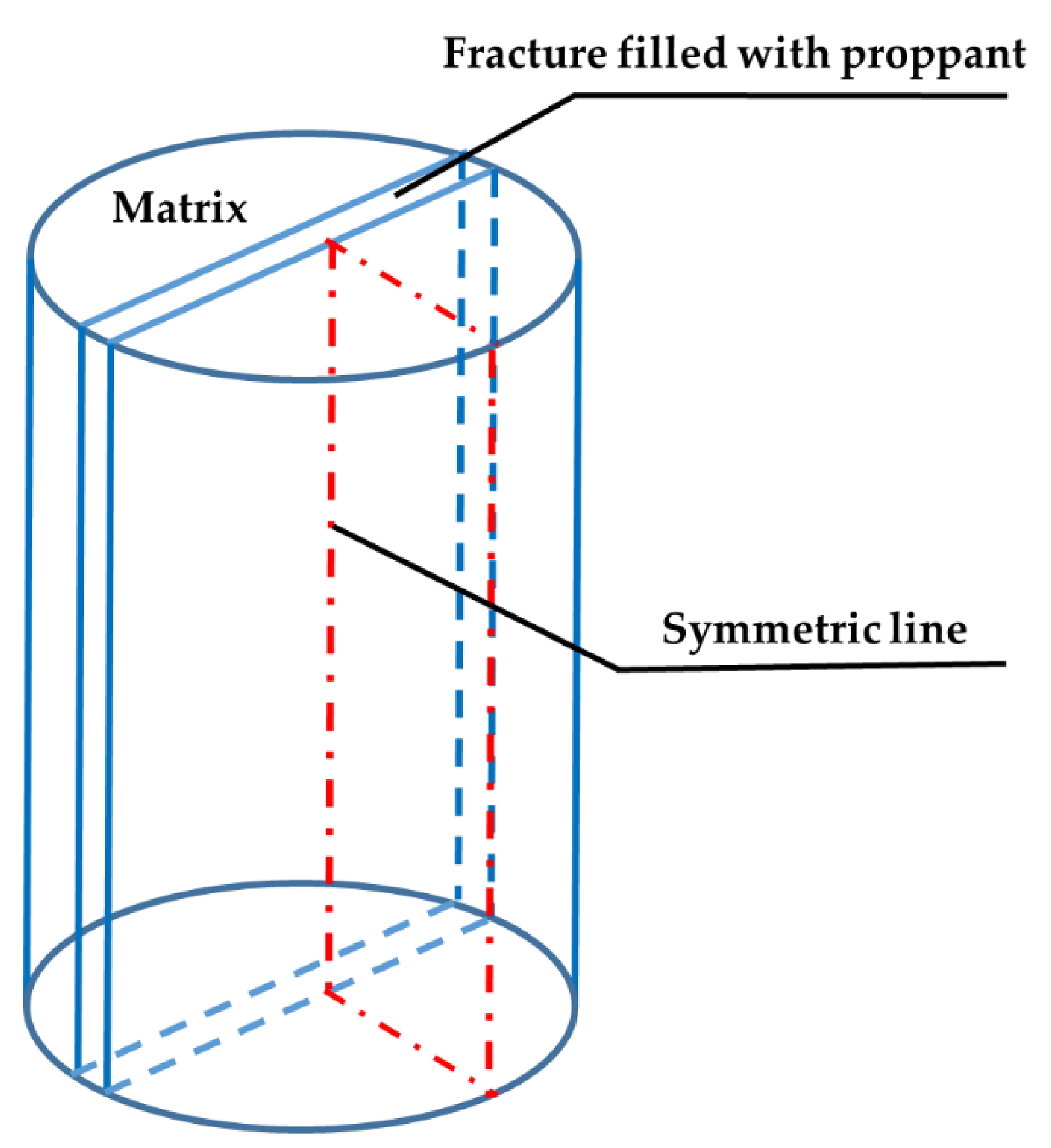

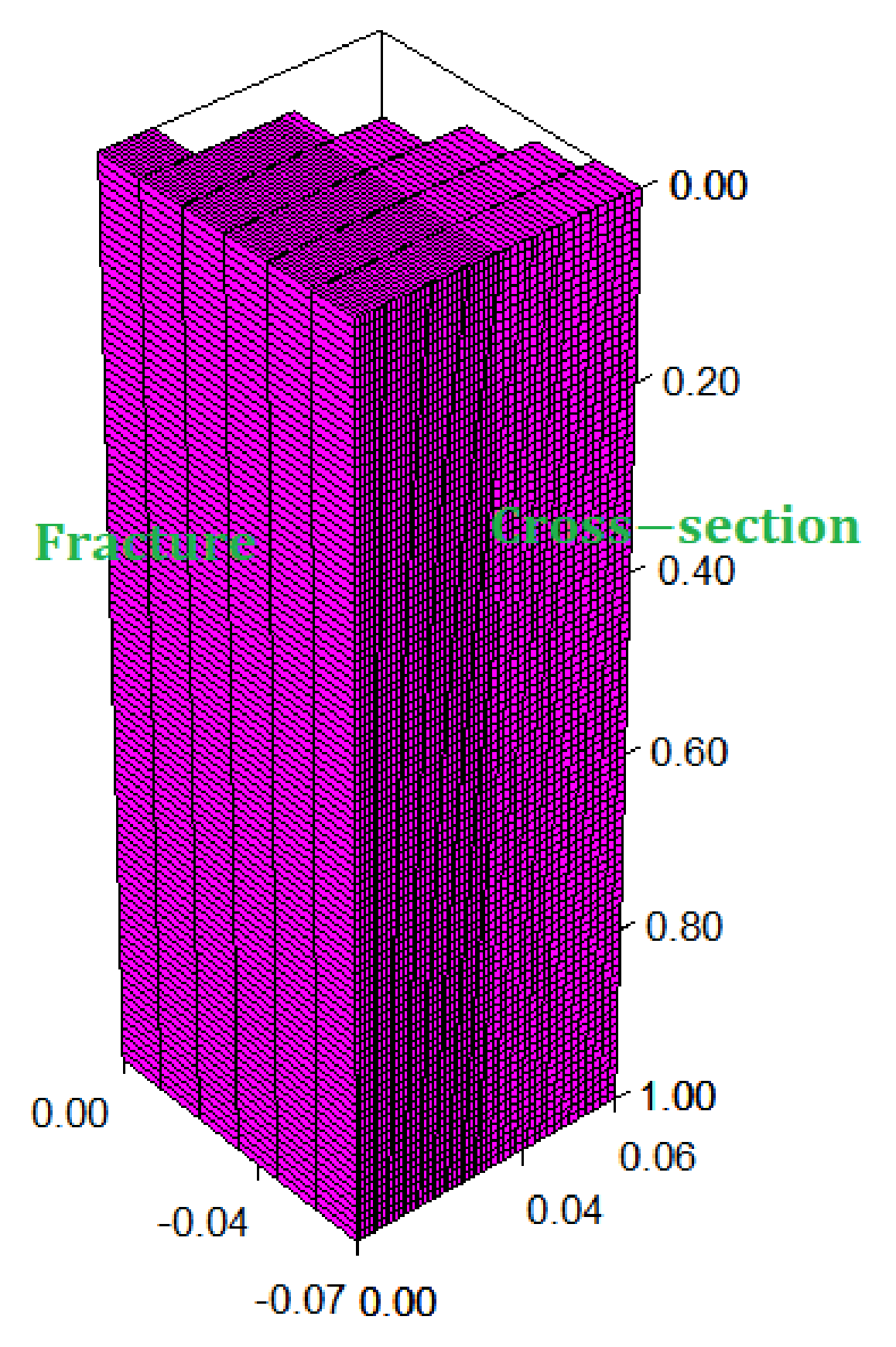

2.2. Fractured Core Model

2.3. Foam Model

3. Simulation Cases

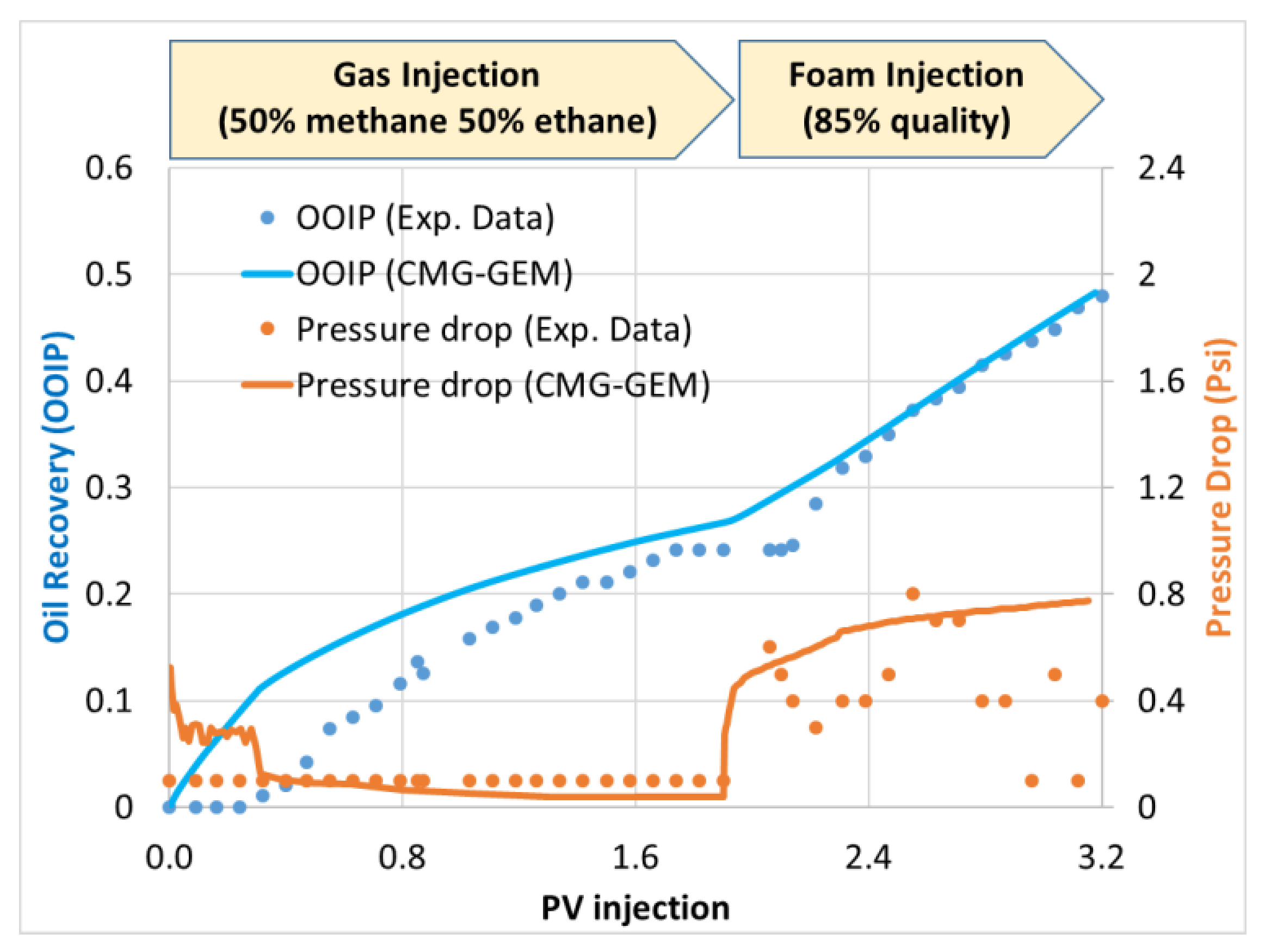

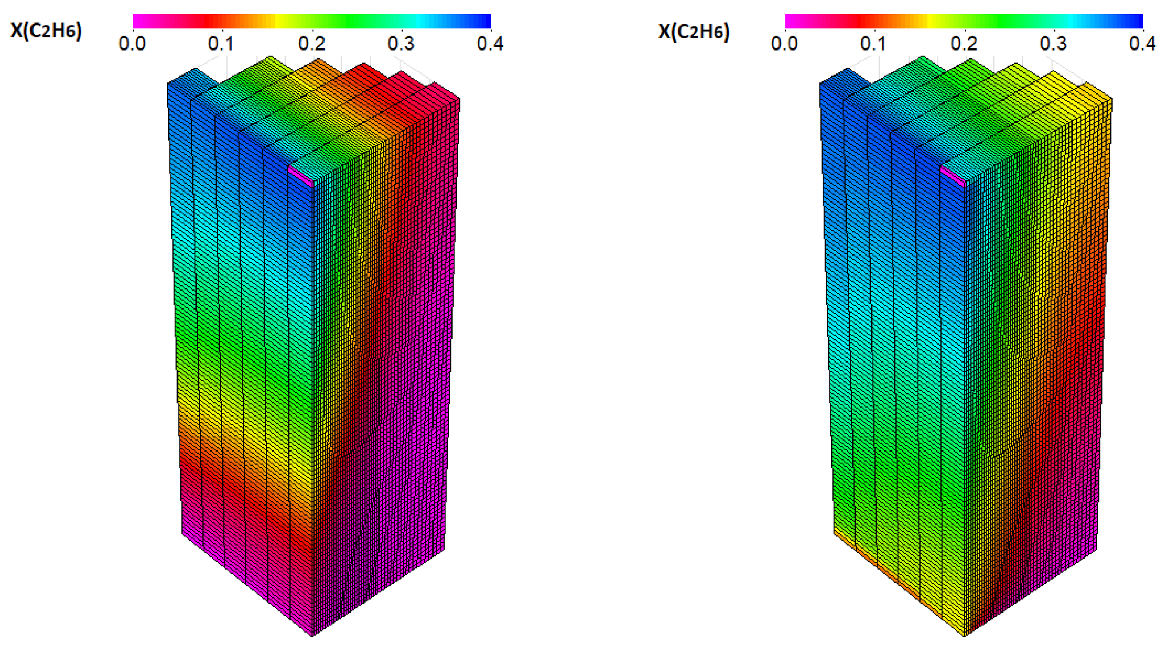

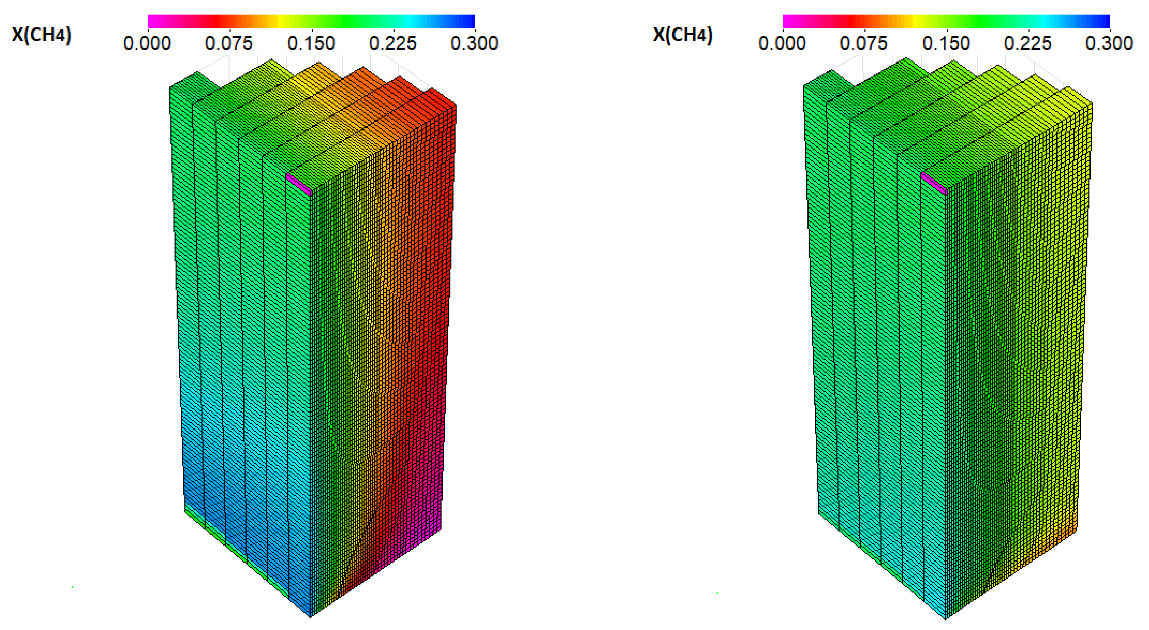

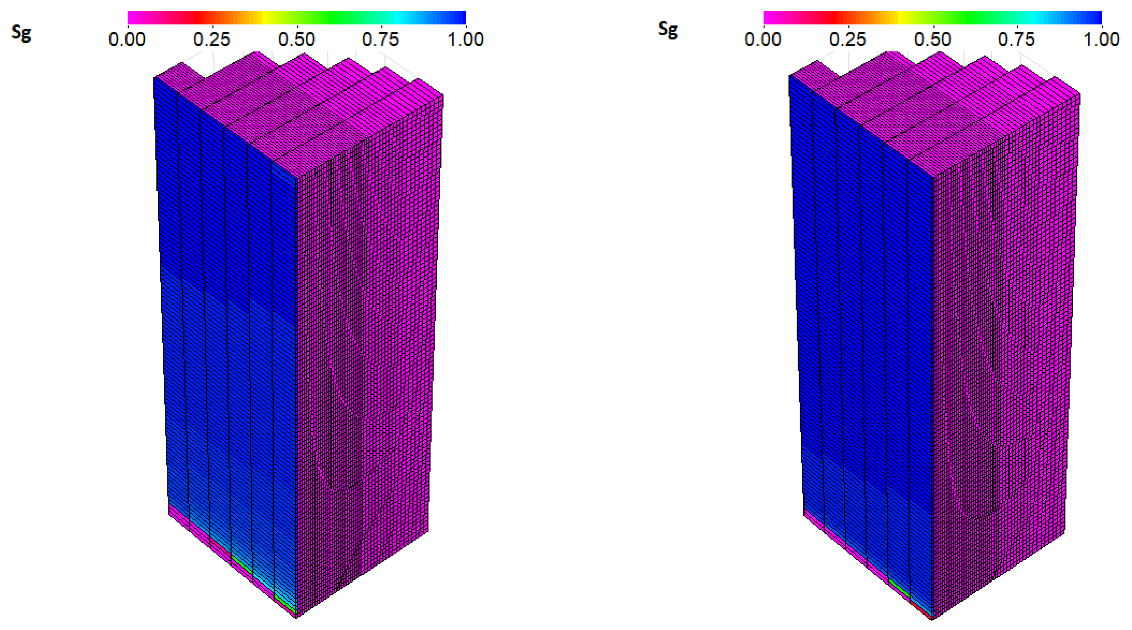

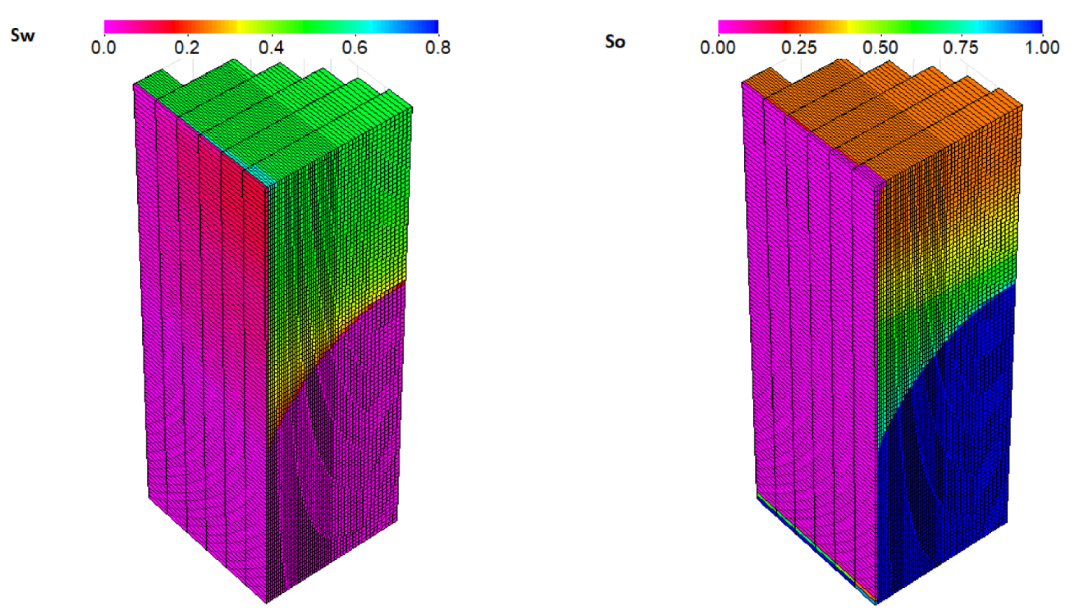

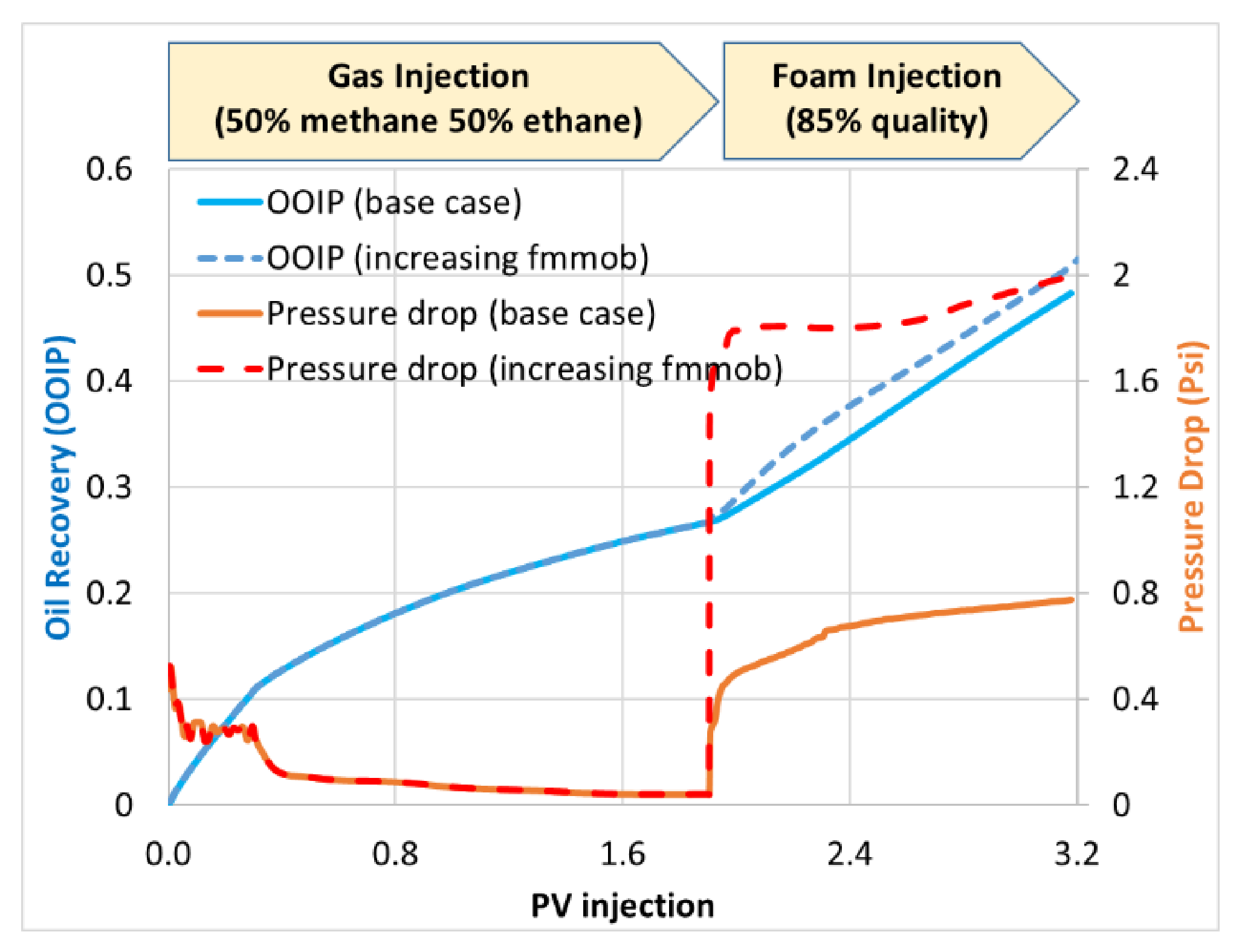

3.1. Simulation of 50% Ethane 50% Methane Near-Miscible Foam Injection

3.2. Sensitivity Study by Increasing Foam Strength

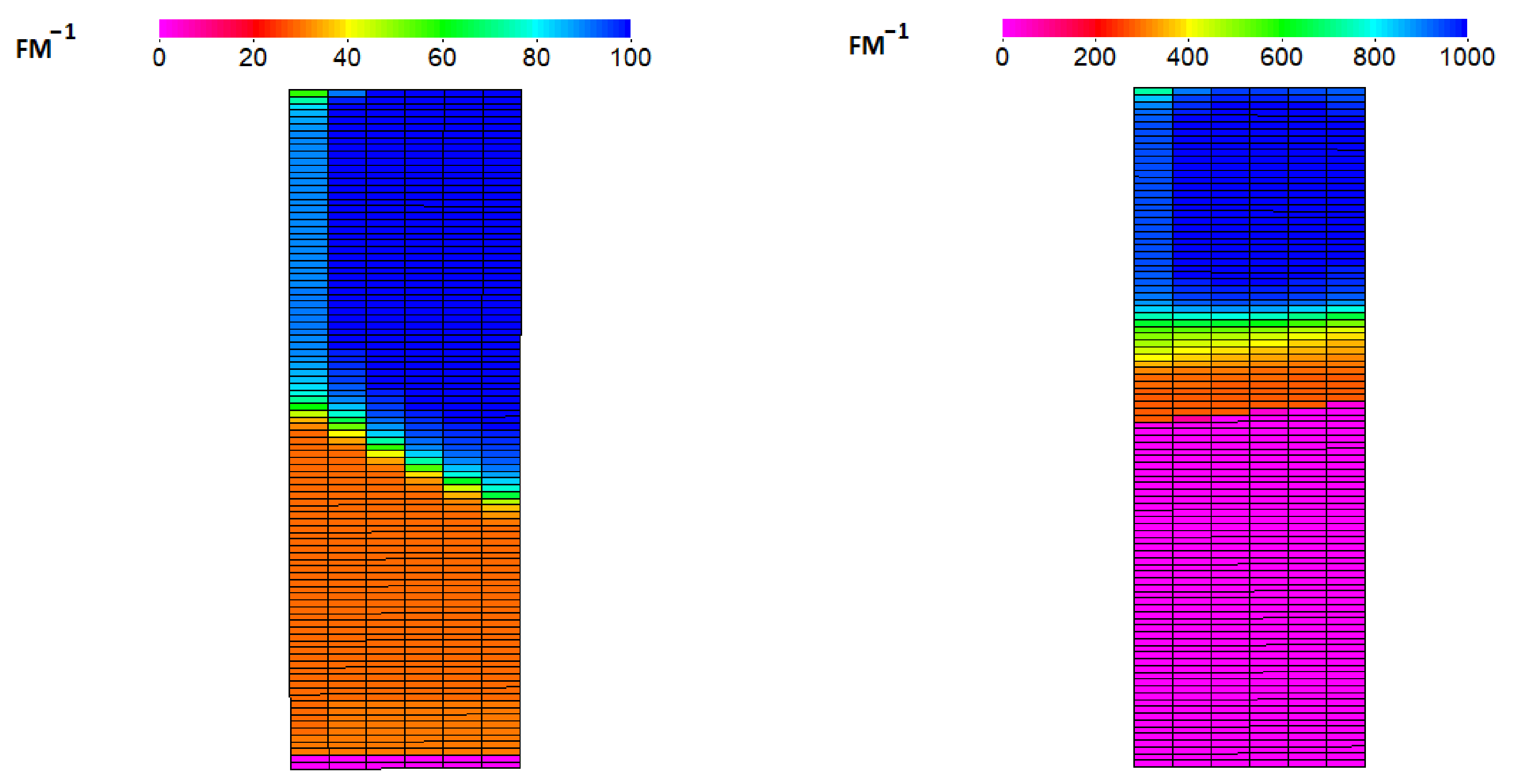

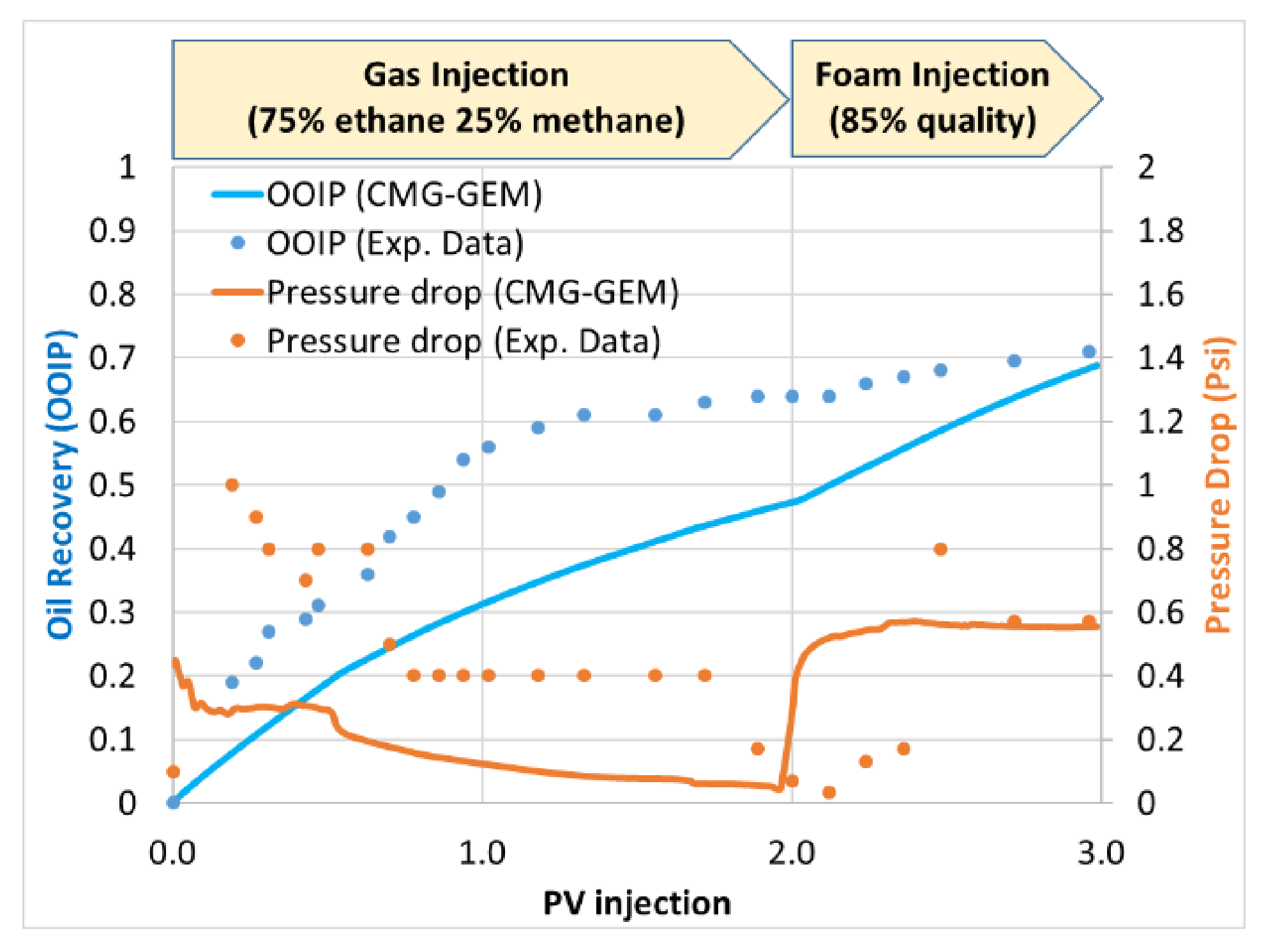

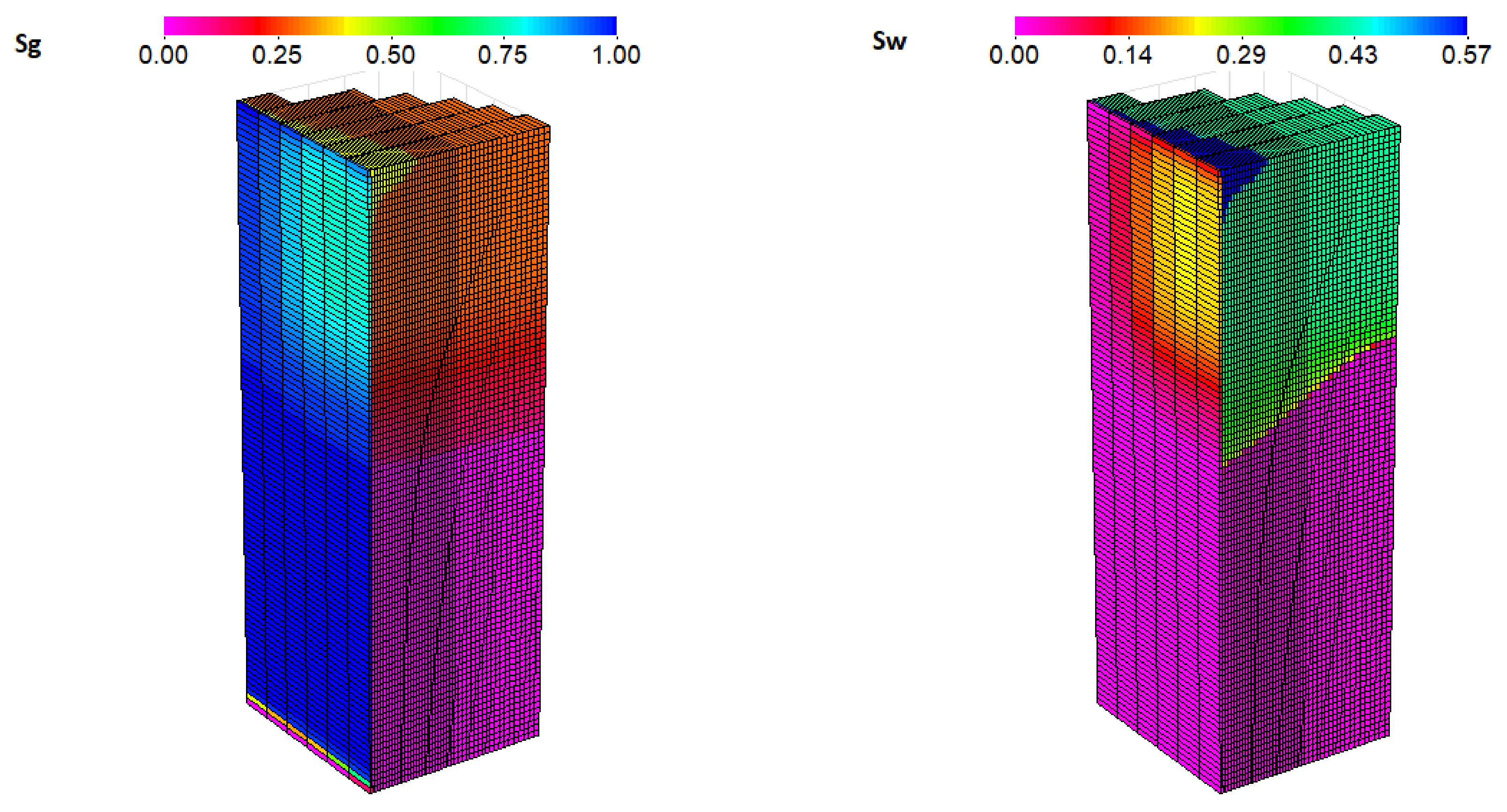

3.3. Simulation of 75% Ethane 25% Methane Near Miscible Foam Injection

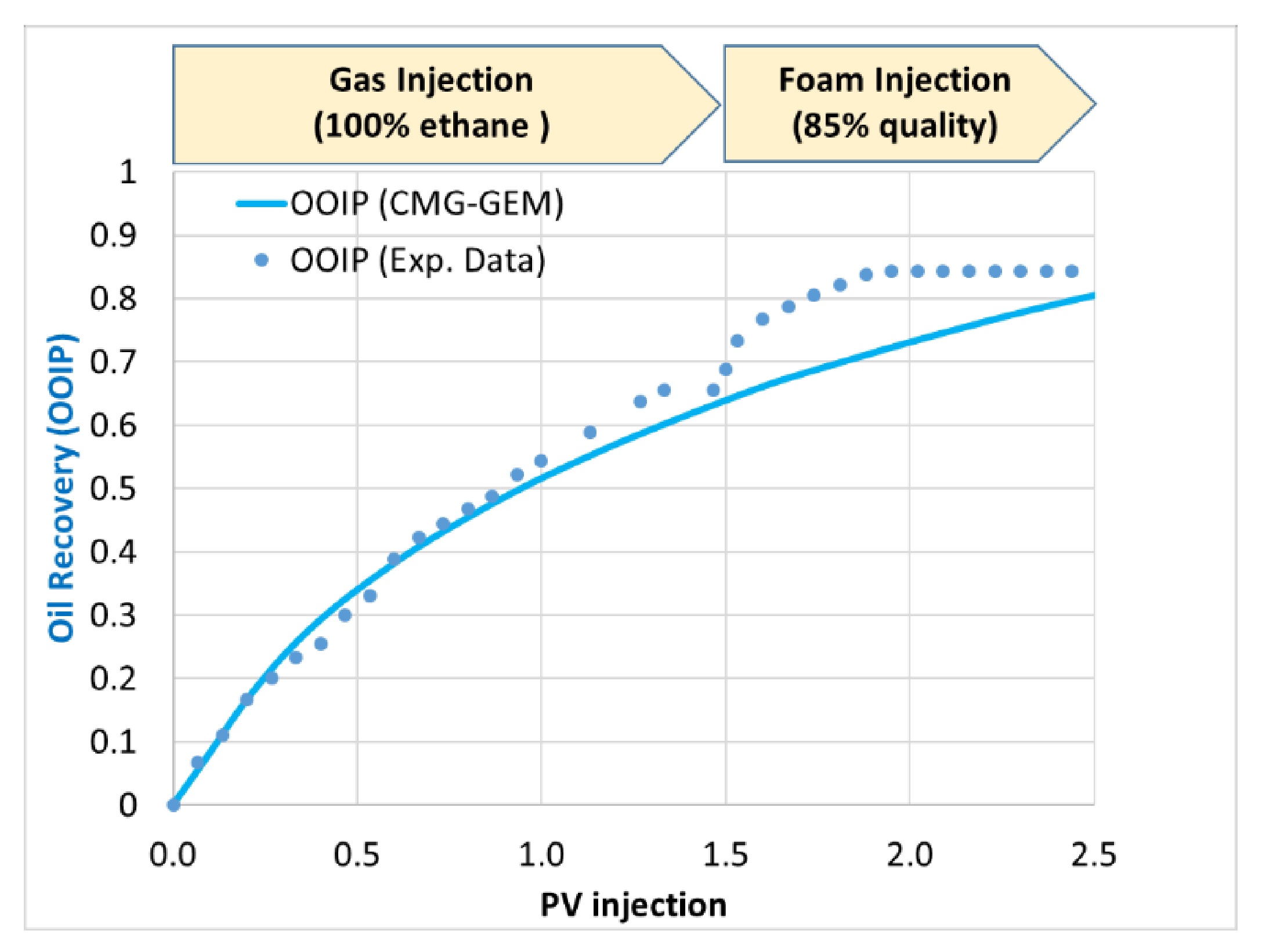

3.4. Simulation of 100% Ethane Miscble Foam Injection

4. Discussion

5. Conclusions

- Simulations were successfully carried out and able to match the experimental data of near miscible gas foam injection corefloods with respect to both oil recovery and pressure drop. Molecular diffusion of different components from fracture to matrix rock helped the displacement of in-situ oil. Water was diverted to the matrix with the help of foam that created higher pressure gradients. Invasion of both water and gas enforced in-situ oil from the matrix into the lower side of the facture.

- Simulation results indicate that increasing the foam strength can moderately improve the oil recovery. Modifying the injected gas composition towards higher miscibility with in-situ oil is very helpful to boost the oil recovery as evidenced by both simulations and experiments. For a specific reservoir pressure, there can be an optimal injection strategy for gas and foam injection depending on the gas availability.

- Miscible gas-foam injection leads to a high oil recovery, but the foam is not properly modeled in this process due to the difficulties in distinguishing the oil and gas in the simulator. Since gas phase in not present above MMP, the foam model fails to modify the mobility of the fluids that has high flow resistance. A few preliminary references attempted to investigate the effect of composition variations on foam strength.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Akbar, M.; Vissapragada, B.; Alghamdi, A.H.; Allen, D.; Herron, M.; Carnegie, A.; Dutta, D.; Olesen, J.R.; Chourasiya, R.D.; Logan, D.; et al. A snapshot of carbonate reservoir evaluation. Oilfield Rev. 2000, 12, 20–21. [Google Scholar]

- Wardlaw, N.C. Factors affecting oil recovery from carbonate reservoirs and prediction of recovery. Dev. Pet. Sci. 1996, 44, 867–903. [Google Scholar]

- Hirasaki, G.; Zhang, D.L. Surface chemistry of oil recovery from fractured, Oil-Wet, Carbonate Formations. SPE J. 2003, 9, 151–162. [Google Scholar] [CrossRef]

- Manrique, E.J.; Muci, V.E.; Gurfinkel, M.E. EOR field experiences in carbonate reservoirs in the United States. SPE Reserv. Eval. Eng. 2006, 10, 667–686. [Google Scholar] [CrossRef]

- Rossen, W.R. Foams in Enhanced Oil Recovery. In Foams: Theory, Measurements, and Applications; Marcel Dekker: New York, NY, USA, 1996; Volume 57, pp. 413–464. [Google Scholar]

- Li, R.F.; Yan, W.; Liu, S.; Hirasaki, G.; Miller, C.A. Foam mobility control for surfactant enhanced oil recovery. SPE J. 2010, 15, 928–942. [Google Scholar] [CrossRef]

- Kovscek, A.R.; Radke, C.J. Fundamentals of Foam Transport in Porous Media. In Foams: Fundamentals and Applications in the Petroleum Industry; ACS: Washington, DC, USA, 1994. [Google Scholar]

- Kovscek, A.R.; Bertin, H.J. Foam mobility in heterogeneous porous media. Transp. Porous Media 2003, 52, 17–35. [Google Scholar] [CrossRef]

- Ma, K.; Liontas, R.; Conn, C.A.; Hirasaki, G.J.; Biswal, S.L. Visualization of improved sweep with foam in heterogeneous porous media using microfluidics. Soft Matter 2012, 8, 10669–10675. [Google Scholar] [CrossRef]

- Myers, T.J.; Radke, C.J. Transient foam displacement in the presence of residual oil: Experiment and simulation using a population-balance model. Ind. Eng. Chem. Res. 2020, 39, 2725–2741. [Google Scholar] [CrossRef]

- Yan, W.; Miller, C.A.; Hirasaki, G.J. Foam sweep in fractures for enhanced oil recovery. Colloids Surf. A Physicochem. Eng. Asp. 2006, 282, 348–359. [Google Scholar] [CrossRef]

- Buchgraber, M.; Castanier, L.M.; Kovscek, A.R. Microvisual investigation of foam flow in ideal fractures: Role of fracture aperture and surface roughness. In Proceedings of the SPE Annual Technical Conference and Exhibition, San Antonio, TX, USA, 8–10 October 2012. [Google Scholar]

- Seethepalli, A.; Adibhatla, B.; Mohanty, K.K. Physicochemical interactions during surfactant flooding of fractured carbonate reservoirs. SPE J. 2004, 9, 411–418. [Google Scholar] [CrossRef]

- Singh, R.; Mohanty, K.K. Foams with wettability-altering capabilities for oil-wet carbonates: A synergistic approach. SPE J. 2016, 21, 1–26. [Google Scholar] [CrossRef]

- Szlendak, S.M.; Nguyen, N.M.; Nguyen, Q.P. Laboratory investigation of low-tension-gas flooding for improved oil recovery in tight formations. SPE J. 2013, 15, 851–866. [Google Scholar] [CrossRef]

- Hahn, R.; Spilker, K.; Alexis, D.; Linnemeyer, H.; Malik, T.; Dwarakanath, V. Low tension foam flooding for chemical enhanced oil recovery in heterogeneous systems. In Proceedings of the SPE Annual Technical Conference and Exhibition, Dallas, TX, USA, 24–26 September 2018. [Google Scholar]

- Dong, P.; Puerto, M.; Ma, K.; Mateen, K.; Ren, G.; Bourdarot, G.; Morel, D.; Biswal, S.L.; Hirasaki, G. Ultralow-Interfacial-Tension foam injection strategy inverstigation in high temperature Ultra-High Salinity fractured carbonate reservoirs. In Proceedings of the SPE Improved Oil Recovery Conference, Tulsa, OK, USA, 14–18 April 2018. [Google Scholar]

- Chevallier, E.; Bouquet, S.; Gland, N.; Douarche, F.; Batôt, G. Advanced EOR Foam in Naturally Fractured Carbonates Reservoirs: Optimal Balance between Foam and Interfacial Tension Properties. In Proceedings of the SPE Middle East Oil and Gas Show and Conference, Manama, Bahrain, 18–21 March 2019. [Google Scholar]

- Farajzadeh, R.; Andrianov, A.; Zitha, P.L. Investigation of immiscible and miscible foam for enhancing oil recovery. Ind. Eng. Chem. Res. 2010, 169, 1910–1919. [Google Scholar] [CrossRef]

- Ren, G.; Nguyen, Q.P.; Lau, H.C. Laboratory investigation of oil recovery by CO2 foam in a fractured carbonate reservoir using CO2-Soluble surfactants. J. Pet. Sci. Eng. 2018, 169, 277–296. [Google Scholar] [CrossRef]

- Cui, L.; Klimenko, A.; Dubos, F.; Lagorse, M.; Bourrel, M. Novel Switchable Alkyl-Amine Surfactants for CO2 Emulsion. In Proceedings of the SPE Improved Oil Recovery Conference, Tulsa, OK, USA, 14–18 April 2018. [Google Scholar]

- Mukherjee, J.; Nguyen, Q.P.; Scherlin, J.; Vanderwal, P.; Rozowski, P. CO2 Foam Pilot in Salt Creek Field, Natrona County, WY: Phase III: Analysis of Pilot Performance. In Proceedings of the SPE Improved Oil Recovery Conference, Tulsa, OK, USA, 11–13 April 2016. [Google Scholar]

- Fredriksen, S.B.; Alcorn, Z.P.; Frøland, A.; Viken, A.; Rognmo, A.U.; Seland, J.G.; Graue, A. Surfactant prefloods during carbon dioxide foam injection for integrated enhanced oil recovery in fractured oil-wet carbonates. SPE J. 2019, 24, 1139–1153. [Google Scholar] [CrossRef]

- Zhou, J.; Sharma, H.; Mohanty, K. Improved gravity drainage by gas in fractured, oil-wet carbonate rocks using mobility control agents. In Proceedings of the SPE Annual Technical Conference and Exhibition, Dallas, TX, USA, 24 September 2018. [Google Scholar]

- Jian, G.; Zhang, L.; Da, C.; Puerto, M.; Johnston, K.P.; Biswal, S.L.; Hirasaki, G.J. Evaluating the transport behavior of CO2 foam in the presence of crude oil under high-temperature and high-salinity conditions for carbonate reservoirs. Energy Fuels 2019, 33, 6038–6047. [Google Scholar] [CrossRef]

- Sharma, M.; Alcorn, Z.P.; Fredriksen, S.B.; Rognmo, A.U.; Fernø, M.A.; Skjæveland, S.M.; Graue, A. Model calibration for forecasting CO2-foam enhanced oil recovery field pilot performance in a carbonate reservoir. Pet. Geosci. 2020, 26, 141–149. [Google Scholar] [CrossRef]

- Eide, Ø.; Fernø, M.; Bryant, S.; Kovscek, A.; Gauteplass, J. Population-balance modeling of CO2 foam for CCUS using nanoparticles. J. Nat. Gas Sci. Eng. 2020, 80, 103378. [Google Scholar] [CrossRef]

- Zuta, J.; Fjelde, I.; Berenblyum, R. Experimental and simulation of CO2-foam flooding in fractured chalk rock at reservoir conditions: Effect of mode of injection on oil recovery. Proceedings of SPE EOR Conference at Oil & Gas West Asia, Muscat, Oman, 11–13 April 2010. [Google Scholar]

- Farajzadeh, R.; Wassing, B.M.; Boerrigter, P.M. Foam assisted gas–oil gravity drainage in naturally-fractured reservoirs. J. Pet. Sci. Eng. 2012, 94, 112–122. [Google Scholar] [CrossRef]

- Ren, G.; Yu, W. Numerical investigations of key aspects influencing CO2 foam performance in fractured carbonate system using CO2 soluble surfactants. J. CO2 Util. 2019, 33, 96–113. [Google Scholar] [CrossRef]

- Cheng, L.; Reme, A.B.; Shan, D.; Coombe, D.A.; Rossen, W.R. Simulating foam processes at high and low foam qualities. In Proceedings of the SPE/DOE Improved Oil Recovery Symposium, Tulsa, OK, USA, 3–5 April 2000. [Google Scholar]

- CMG GEM. GEM User Guide; Computer Modelling Group Ltd.: Calgary, AB, Canada, 2017. [Google Scholar]

- Chen, Q.; Gerritsen, M.; Kovscek, A.R. Modeling foam displacement with the local-equilibrium approximation: Theory and experimental verification. SPE J. 2010, 15, 171–183. [Google Scholar] [CrossRef]

- Kam, S.I. Improved mechanistic foam simulation with foam catastrophe theory. Colloids Surf. A Physicochem. Eng. Asp. 2008, 318, 62–77. [Google Scholar] [CrossRef]

- Luo, H.; Mateen, K.; Ma, K.; Ren, G.; Neillo, V.; Blondeau, C.; Dong, P.; Puerto, M.; Biswal, S.; Hirasaki, G. In-Depth understanding of the ultra-low-interfacial-tension foam flood in oil-wet fractured media through simulation with an integrative mechanistic foam model. In Proceedings of the SPE Annual Technical Conference and Exhibition, Calgary, AB, Canada, 23 September 2019. [Google Scholar]

- Ma, K.; Ren, G.; Mateen, K.; Morel, D.; Cordelier, P. Modeling techniques for foam flow in porous media. SPE J. 2015, 20, 453–470. [Google Scholar] [CrossRef]

- CMG WinProp. WinProp User Guide; Computer Modelling Group Ltd.: Calgary, AB, Canada, 2017. [Google Scholar]

- Sigmund, P.M. Prediction of molecular diffusion at reservoir conditions. Part II—Estimating the effects of molecular diffusion and convective mixing in multicomponent systems. JCPT 1976, 15, 53–62. [Google Scholar] [CrossRef]

- Tang, J. The Effect of Oil on Foam for Enhanced Oil Recovery: Theory and Measurements. Ph.D. Thesis, Delft University of Technology, Delft, The Netherlands, 2019. [Google Scholar]

- Kahrobaei, S.; Li, K.; Bonnieu, S.V.; Farajzadeh, R. Effects of compositional variations on CO2 foam under miscible conditions. AIChE J. 2018, 64, 758–764. [Google Scholar] [CrossRef]

| Property | Value |

|---|---|

| Fracture Permeability | 2250 mD |

| Fracture Porosity | 0.8 |

| Matrix Permeability | 10 mD |

| Matrix Porosity | 0.28 |

| Initial oil saturation | 1.0 |

| Swr in matrix | 0.2 |

| Sorw in matrix | 0.2 |

| Sorg in matrix | 0.2 |

| Sgc in matrix | 0.08 |

| Water capillary entry pressure | 0.1 psi |

| Gas capillary entry pressure | 0.2 psi |

| Resistivity (Sigmund model) | 4.8 |

| fmmob | 110 |

| fmoil | 0.2 |

| floil | 0.1 |

| epoil | 1 |

| sfdry | 0.01 |

| sfbet | 100 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Luo, H.; Mohanty, K.K. Modeling Near-Miscible Gas Foam Injection in Fractured Tight Rocks and Its Challenges. Energies 2021, 14, 1998. https://doi.org/10.3390/en14071998

Luo H, Mohanty KK. Modeling Near-Miscible Gas Foam Injection in Fractured Tight Rocks and Its Challenges. Energies. 2021; 14(7):1998. https://doi.org/10.3390/en14071998

Chicago/Turabian StyleLuo, Haishan, and Kishore K. Mohanty. 2021. "Modeling Near-Miscible Gas Foam Injection in Fractured Tight Rocks and Its Challenges" Energies 14, no. 7: 1998. https://doi.org/10.3390/en14071998

APA StyleLuo, H., & Mohanty, K. K. (2021). Modeling Near-Miscible Gas Foam Injection in Fractured Tight Rocks and Its Challenges. Energies, 14(7), 1998. https://doi.org/10.3390/en14071998