Research on the Time-Domain Dielectric Response of Multiple Impulse Voltage Aging Oil-Film Dielectrics †

Abstract

1. Introduction

2. Basic Principle and Selection of Characteristic Quantity

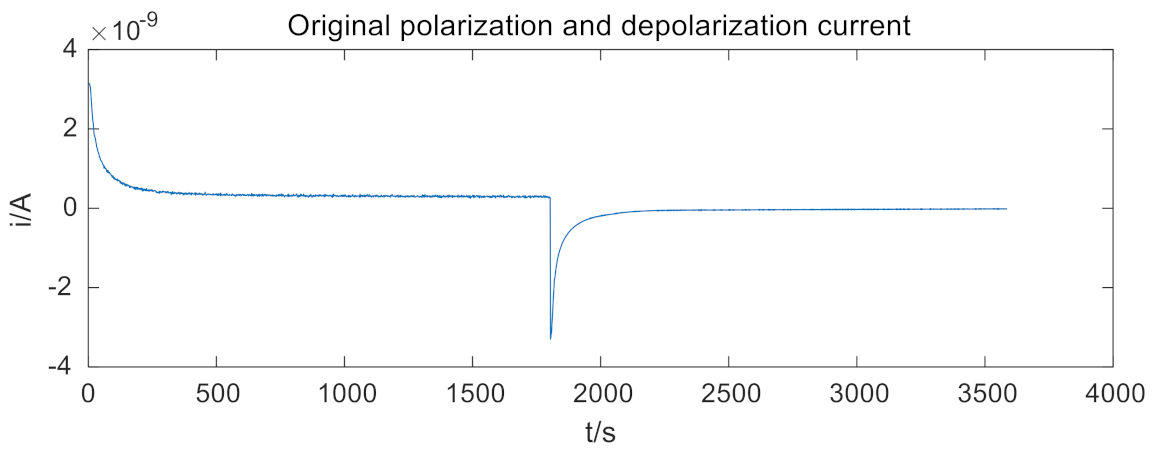

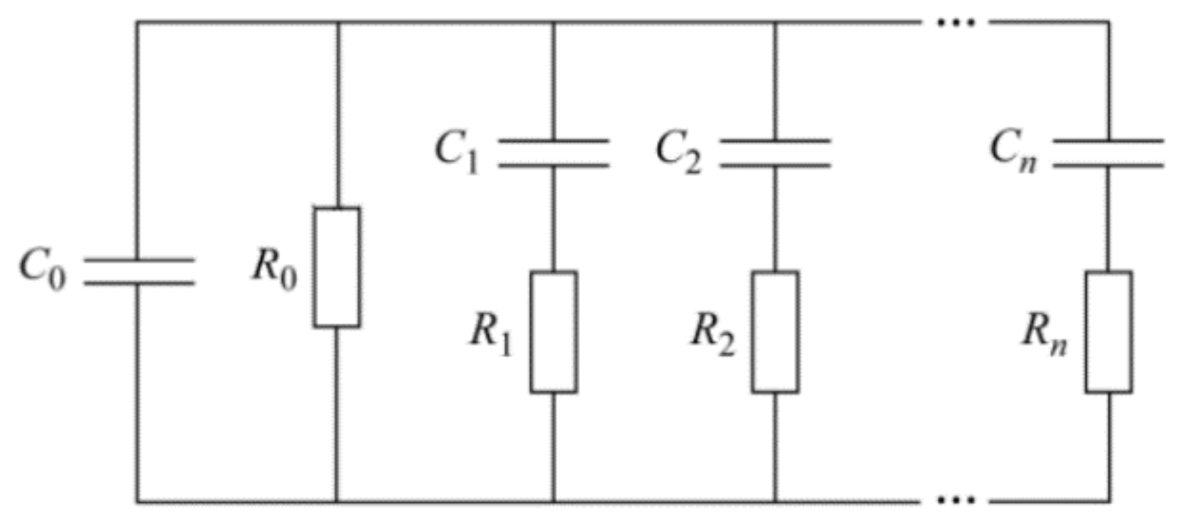

2.1. The Dielectric Response Theory

2.2. Matrix Pencil Algorithm

3. The Experimental Setup

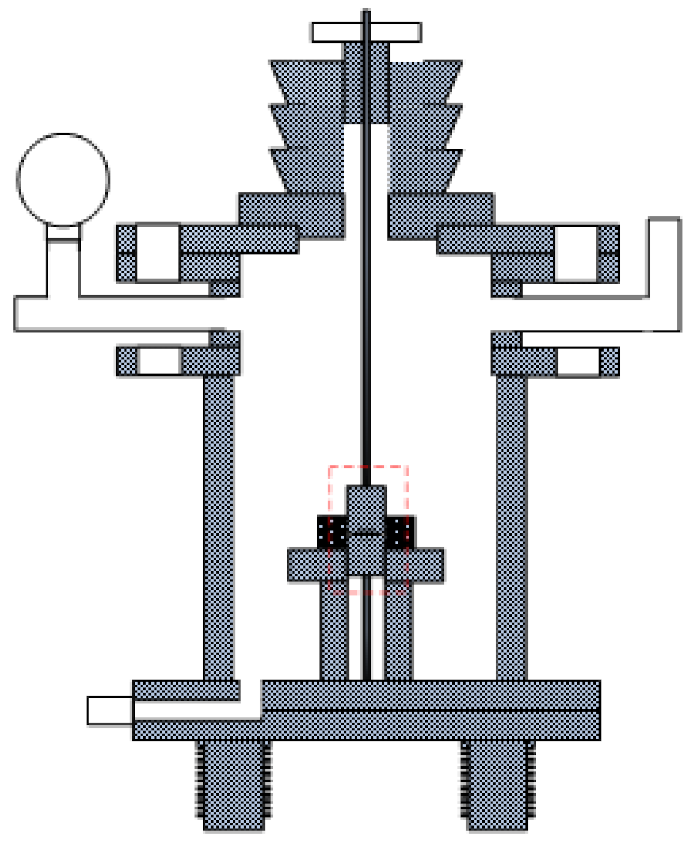

3.1. The Oil-Film Dielectric Samples

- (1)

- Putting the samples into the vacuum drying oven and setting the temperature to 50 °C, which aimed at removing the moisture from the oil and eliminating the bubles in the oil-film interface;

- (2)

- The samples were dried for 48 h with an air pressure of 100 Pa;

- (3)

- Taking out the samples and sealing them with plastic wrap. It can prevent the moisture and impurities in the air;

- (4)

- All the pretreated samples should be sealed in a dry, isolated and well-ventilated area. Lastly, waiting the temperature of the samples dropped to room temperature.

3.2. The Aging Platform

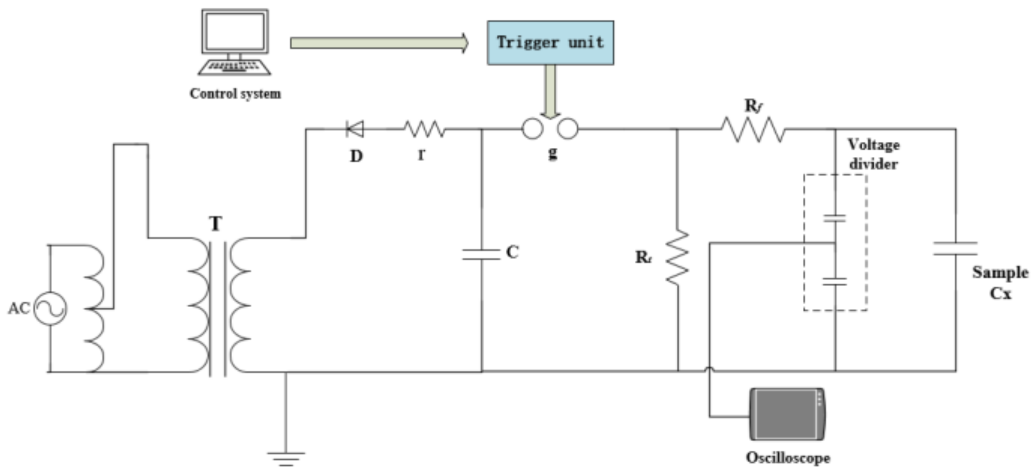

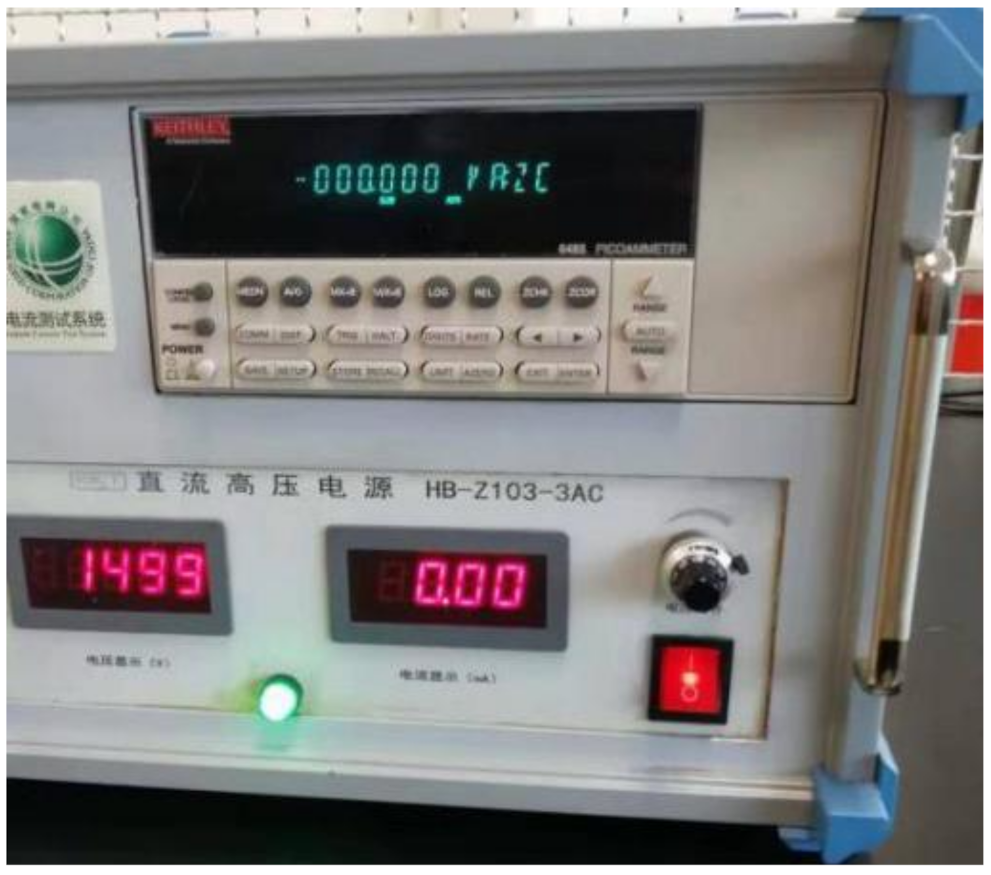

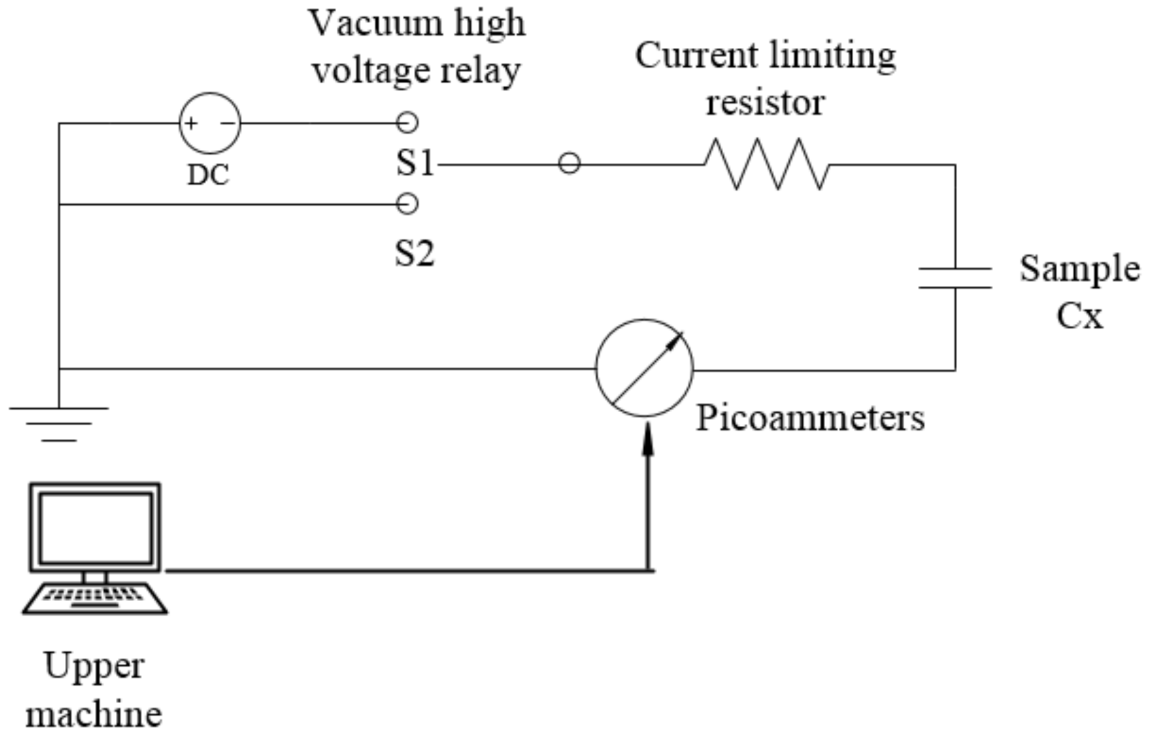

3.3. The PDC Test Platform

4. The Experiment Results

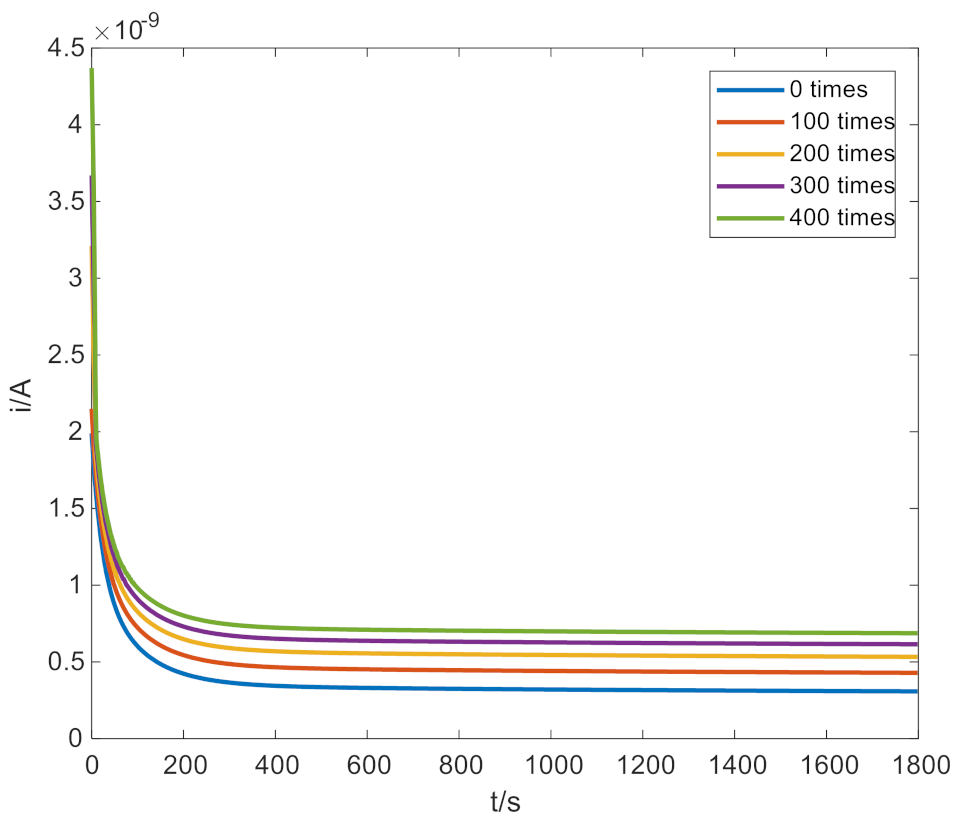

4.1. The Polarization Current of an Oil-Film Dielectric with Different Degree of Aging

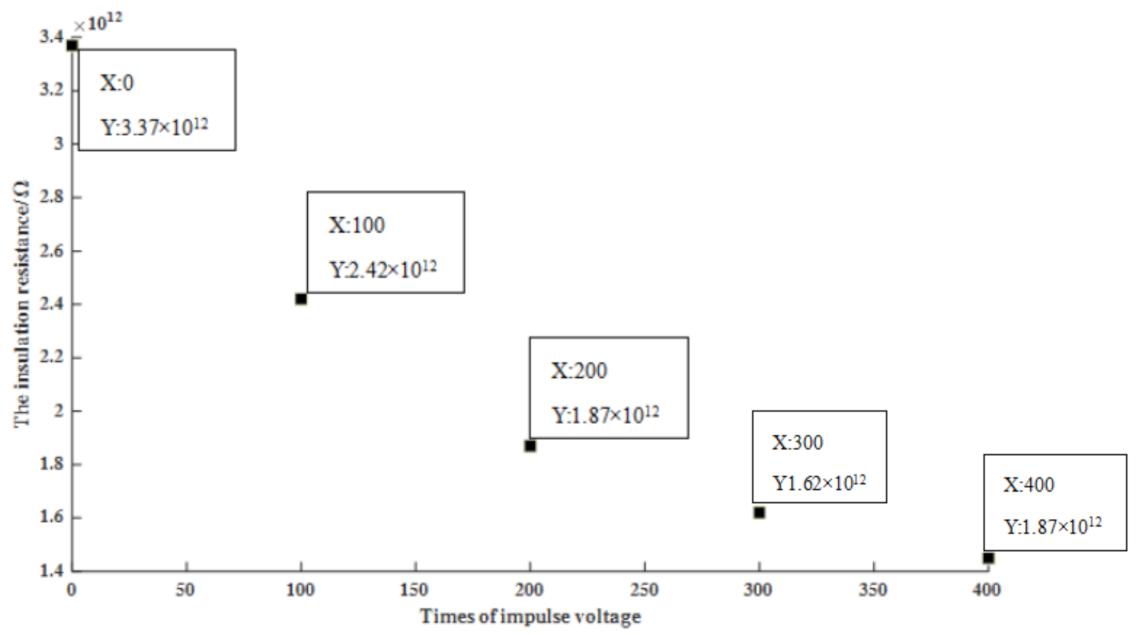

4.2. The Change of Insulation Resistance

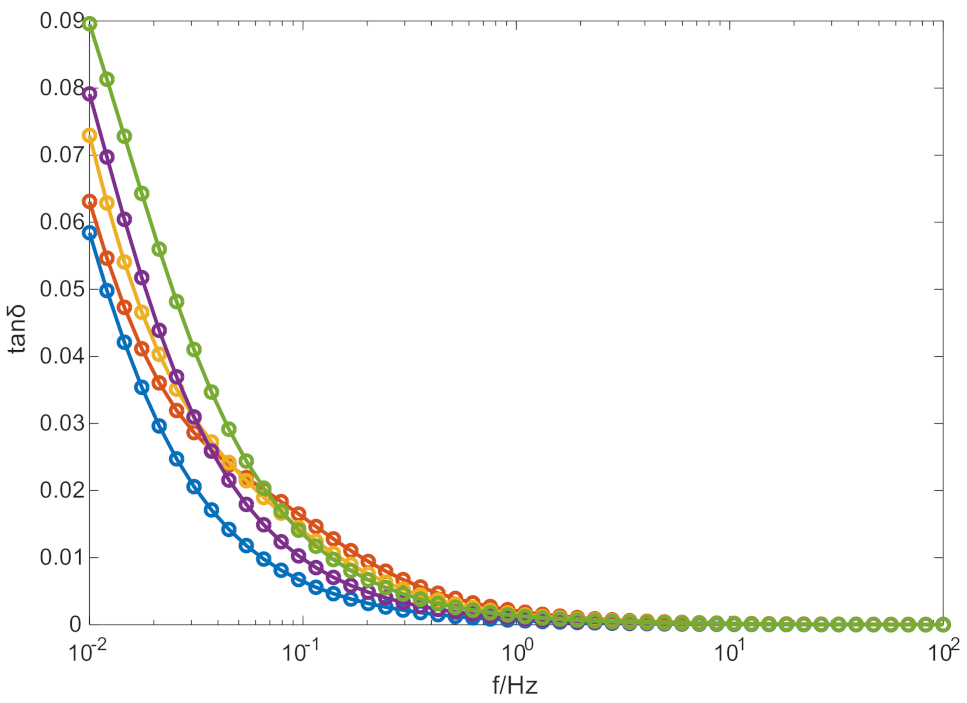

4.3. The Results of the Tangent Value of the Dielectric Loss Angle at Low Frequency

5. Discussion

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Saha, T.; Purkait, P. Investigation of an expert system for the condition assessment of transformer insulation based on dielectric response measurements. IEEE Trans. Power Deliv. 2004, 19, 1127–1134. [Google Scholar] [CrossRef]

- Koch, M.; Prevost, T. Analysis of dielectric response measurements for condition assessment of oil-paper transformer insulation. IEEE Trans. Dielectr. Electr. Insul. 2012, 19, 1908–1915. [Google Scholar] [CrossRef]

- Wang, M.; Vandermaar, A.J.; Srivastava, K.D. Review of condition assessment of power transformers in service. IEEE Electr. Insul. Mag. 2002, 18, 12–15. [Google Scholar] [CrossRef]

- Fofana, I.; Hadjadj, Y. Electrical-based diagnostic techniques for assessing insulation condition in aged transformers. Energies 2016, 6, 697. [Google Scholar] [CrossRef]

- Standring, W.G.; Hughes, R.C. Breakdown under impulse voltages of solid and liquid dielectrics in combination. IEEE Proc. Power Eng. 1956, 103, 583–597. [Google Scholar] [CrossRef]

- Zhang, C.; Xie, S.; Zhang, Y. Repeated impulse aging of oil-polypropylene insulation. IEEE Trans. Dielectr. Electr. Insul. 2019, 26, 1581–1587. [Google Scholar] [CrossRef]

- Sima, W.; Sun, P.; Yang, Q.; Yuan, T.; Lu, C.; Yang, M. Study on the accumulative effect of repeated lightning impulses on insulation characteristics of transformer oil impregnated paper. IEEE Trans. Dielectr. Electr. Insul. 2014, 21, 1933–1941. [Google Scholar] [CrossRef]

- Linhjell, D.; Lundgaard, L.; Gafvert, U. Dielectric response of mineral oil impregnated cellulose and the impact of aging. IEEE Trans. Dielectr. Electr. Insul. 2007, 14, 156–169. [Google Scholar] [CrossRef]

- Zdanowski, M. Streaming Electrification of Mineral Insulating Oil and Synthetic Ester MIDEL 7131. IEEE Trans. Dielectr. Electr. Insul. 2014, 21, 1127–1132. [Google Scholar] [CrossRef]

- Saha, T.K. Review of Modern Diagnostic Techniques for Assessing Insulation Condition in aged transformers. IEEE Trans. Dielectr. Electr. Insul. 2003, 10, 903–917. [Google Scholar] [CrossRef]

- Saha, T.K.; Yao, Z.T. Experience with return voltage measurements for assessing insulation conditions in service-aged transformers. IEEE Trans. Power Deliv. 2003, 18, 128–135. [Google Scholar] [CrossRef]

- N’cho, J.S.; Fofana, I.; Hadjadj, Y.; Beroual, A. Review of physicochemical-based diagnostic techniques for assessing insulation condition in aged transformers. Energies 2016, 9, 367. [Google Scholar] [CrossRef]

- Liao, R.; Liang, S.; Sun, C.; Yang, L.; Sun, H. A comparative study of thermal aging of transformer insulation paper impregnated in natural ester and in mineral oil. Eur. Trans. Electr. Power 2010, 20, 518–533. [Google Scholar] [CrossRef]

- Hao, J.; Liao, R.; Chen, G.; Ma, Z.; Yang, L. Quantitative analysis ageing status of natural ester-paper insulation and mineral oil-paper insulation by polarization/depolarization current. IEEE Trans. Dielectr. Electr. Insul. 2012, 19, 188–199. [Google Scholar]

- Darveniza, M.; Saha, T.; Hill, D.; Le, T. Investigations into effective methods for assessing the condition of insulation in aged power transformers. IEEE Trans. Power Deliv. 1998, 13, 1214–1223. [Google Scholar] [CrossRef]

- Zhao, K.; Zhang, C.; Deng, Y.; Li, L.; Xie, S.; Zhang, Y. Research on Time-domain Dielectric Response of Multiple Impulse Voltage Aging Oil-film Dielectric. In Proceedings of the 2020 IEEE International Conference on High-Voltage Engineering (ICHVE 2020), Beijing, China, 6–10 September 2020. [Google Scholar]

- Zhang, T.; Cai, J. Research on parameters identification for dielectric response equivalent circuit of transformers with oil-paper insulation. Adv. Technol. Electr. Eng. Energy 2010, 29, 35–39. [Google Scholar]

- Tang, P.; Yin, Y.; Wu, J.; Yan, X. Study of oil-paper insulated transformers’aging state based on depolarization current measurements. Adv. Technol. Electr. Eng. Energy 2012, 31, 39–42. [Google Scholar]

- Xu, S.; Middleton, R.; Fetherston, F.; Pantalone, D. A comparison of return voltage measurement and frequency domain spectroscopy test on high voltage insulation. In Proceedings of the 2003 IEEE International Conference on Properties and Applications of Ei Electric, Materials, Nagoya, Japan, 1–5 June 2003; pp. 351–355. [Google Scholar]

- Chen, J.; Jiang, X.; Cai, J.; Li, A. Application Circuit Analysis Method to Assess the State of Transformers Oil-paper Insulation. Proc. CSU-EPSA 2016, 28, 30–35. [Google Scholar]

- Yang, F.; Du, L.; Yang, L.; Wei, C.; Wang, Y.; Ran, L.; He, P. A Parameterization Approach for the Dielectric Response Model of Oil Paper Insulation Using FDS Measurements. Energies 2018, 11, 622. [Google Scholar] [CrossRef]

- Andrzej, K. Dielectric Relaxation in Solids: Chelsea Dielectric Press. J. Phys. Appl. Phys. 1983. [Google Scholar] [CrossRef]

- Walter, S. Dielectric spectroscopy in time and frequency domain for HV power equipment. I. Theoretical considerations. IEEE Electr. Insul. Mag. 2003, 19, 5–19. [Google Scholar]

- Subocz, J.; Mrozik, A.; Bohatyrewicz, P.; Zenker, M. Condition Assessment of HV Bushings with Solid Insulation based on the SVM and the FDS Methods. Energies 2020, 13, 853. [Google Scholar] [CrossRef]

- Hua, Y.; Sarkar, T. On SVD for estimating generalized eigen values of singular matrix pencil in noise. IEEE Trans. Signal Process. 1991, 39, 892–900. [Google Scholar] [CrossRef]

- Peter, B.; Vasile, S.; Matthias, V. L-Norm Computation for Continuous-Time Descriptor Systems Using Structured Matrix Pencils. IEEE Trans. Automat. Contr. 2012, 57, 233–238. [Google Scholar]

- Liu, Y.; Liu, H.; Nie, Z. Reducing the Number of Elements in the Synthesis of Shaped-Beam Patterns by the Forward-Backward Matrix Pencil Method. IEEE Trans. Antennas Propag. 2010, 58, 604–608. [Google Scholar]

- Yilmazer, N.; Koh, J.; Sarkar, T. Utilization of a unitary transform for efficient computation in the matrix pencil method to find the direction of arrival. IEEE Trans. Antennas Propag. 2006, 54, 175–181. [Google Scholar] [CrossRef]

- Tan, S.; Zhang, C. Aging Detection of Oil Film Insulation for Surge Capacitor Based on Polarization-depolarization Current Method. Sichuan Electr. Power Technol. 2019, 24, 42. [Google Scholar]

| Times of Impulse Voltage/Times | 0 | 100 | 200 | 300 | 400 |

|---|---|---|---|---|---|

| Rnew/1 | 0.97491 | 0.95491 | 0.95828 | 0.98086 | 0.96411 |

| Number of Impulse Voltages | 0 | 100 | 200 | 300 | 400 |

|---|---|---|---|---|---|

| The Value of Initial Amplitude/A | 1.986 × 10−9 | 2.151 × 10−9 | 2.536 × 10−9 | 3.147 × 10−9 | 3.493 × 10−9 |

| Number of Impulse Voltages | 0 | 100 | 200 | 300 | 400 |

|---|---|---|---|---|---|

| tan δ at 0.01 Hz | 0.0583 | 0.0631 | 0.0729 | 0.0787 | 0.0896 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, C.; Zhao, K.; Xie, S.; Hu, C.; Zhang, Y.; Jiang, N. Research on the Time-Domain Dielectric Response of Multiple Impulse Voltage Aging Oil-Film Dielectrics. Energies 2021, 14, 1948. https://doi.org/10.3390/en14071948

Zhang C, Zhao K, Xie S, Hu C, Zhang Y, Jiang N. Research on the Time-Domain Dielectric Response of Multiple Impulse Voltage Aging Oil-Film Dielectrics. Energies. 2021; 14(7):1948. https://doi.org/10.3390/en14071948

Chicago/Turabian StyleZhang, Chenmeng, Kailin Zhao, Shijun Xie, Can Hu, Yu Zhang, and Nanxi Jiang. 2021. "Research on the Time-Domain Dielectric Response of Multiple Impulse Voltage Aging Oil-Film Dielectrics" Energies 14, no. 7: 1948. https://doi.org/10.3390/en14071948

APA StyleZhang, C., Zhao, K., Xie, S., Hu, C., Zhang, Y., & Jiang, N. (2021). Research on the Time-Domain Dielectric Response of Multiple Impulse Voltage Aging Oil-Film Dielectrics. Energies, 14(7), 1948. https://doi.org/10.3390/en14071948