Design, Analysis and Application of Single-Wheel Test Bench for All-Electric Antilock Braking System in Electric Vehicles

Abstract

:1. Introduction

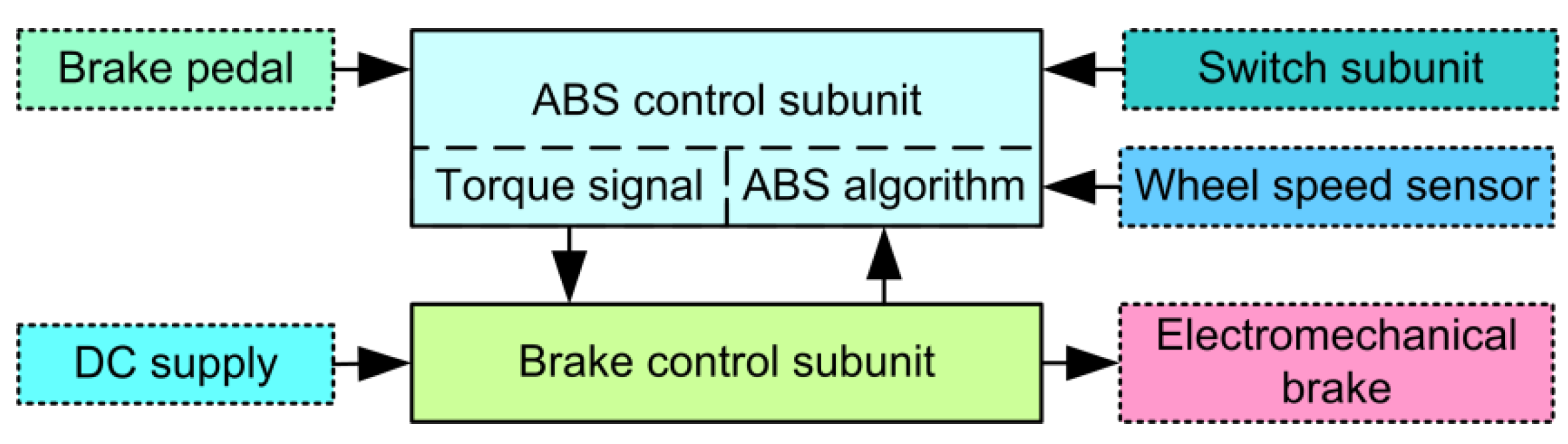

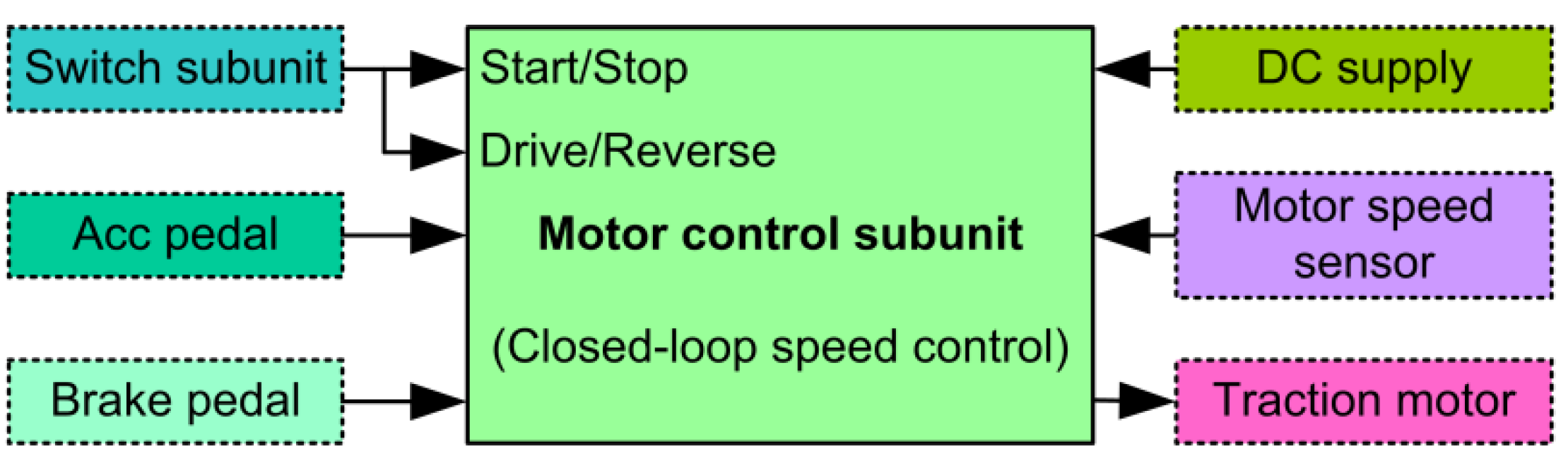

2. Requirements on Single-Wheel ABS Test Bench

2.1. ABS Performance

2.2. Factors Affecting ABS Performance

2.3. Requirements on Single-Wheel ABS Test Bench

- The braking distance can be measured.

- The longitudinal vehicle velocity can be measured.

- The wheel’s circumferential velocity can be measured.

- The vertical force to the wheel can be measured.

- The vertical force to the wheel can be regulated.

- The condition of the road surface can be changed.

- The condition of the tire can be changed.

- The condition of the wheel brake can be changed.

- The longitudinal vehicle velocity can be controlled.

- The kinetic energy of the rotary part in the test bench should be approximately equal to the one of the quarter vehicle model.

3. Scheme of Proposed Single-Wheel All-Electric ABS Test Bench

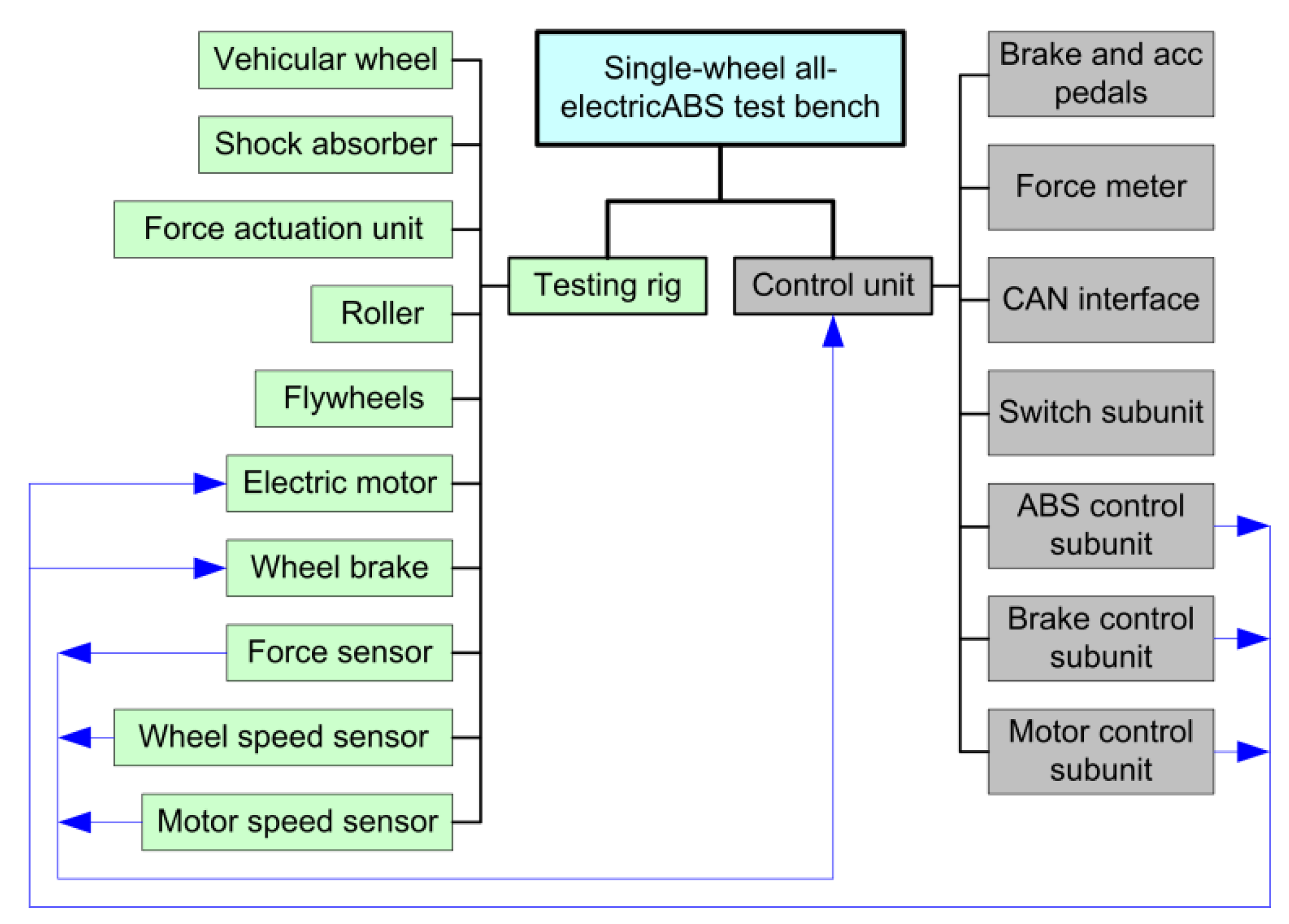

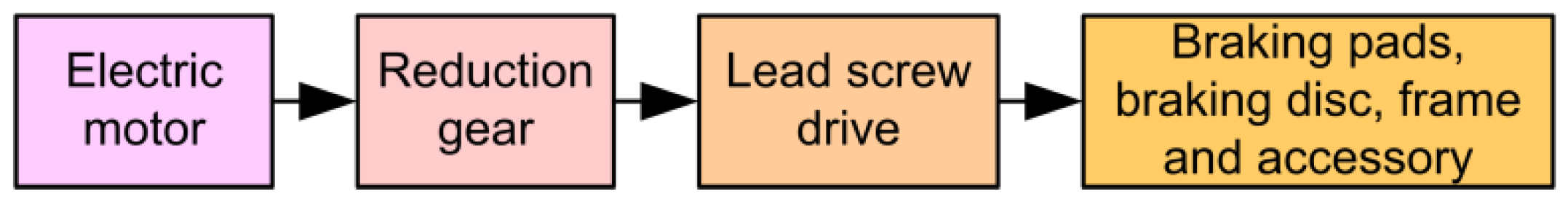

3.1. Schematic Structure of Proposed Single-Wheel ABS Test Bench

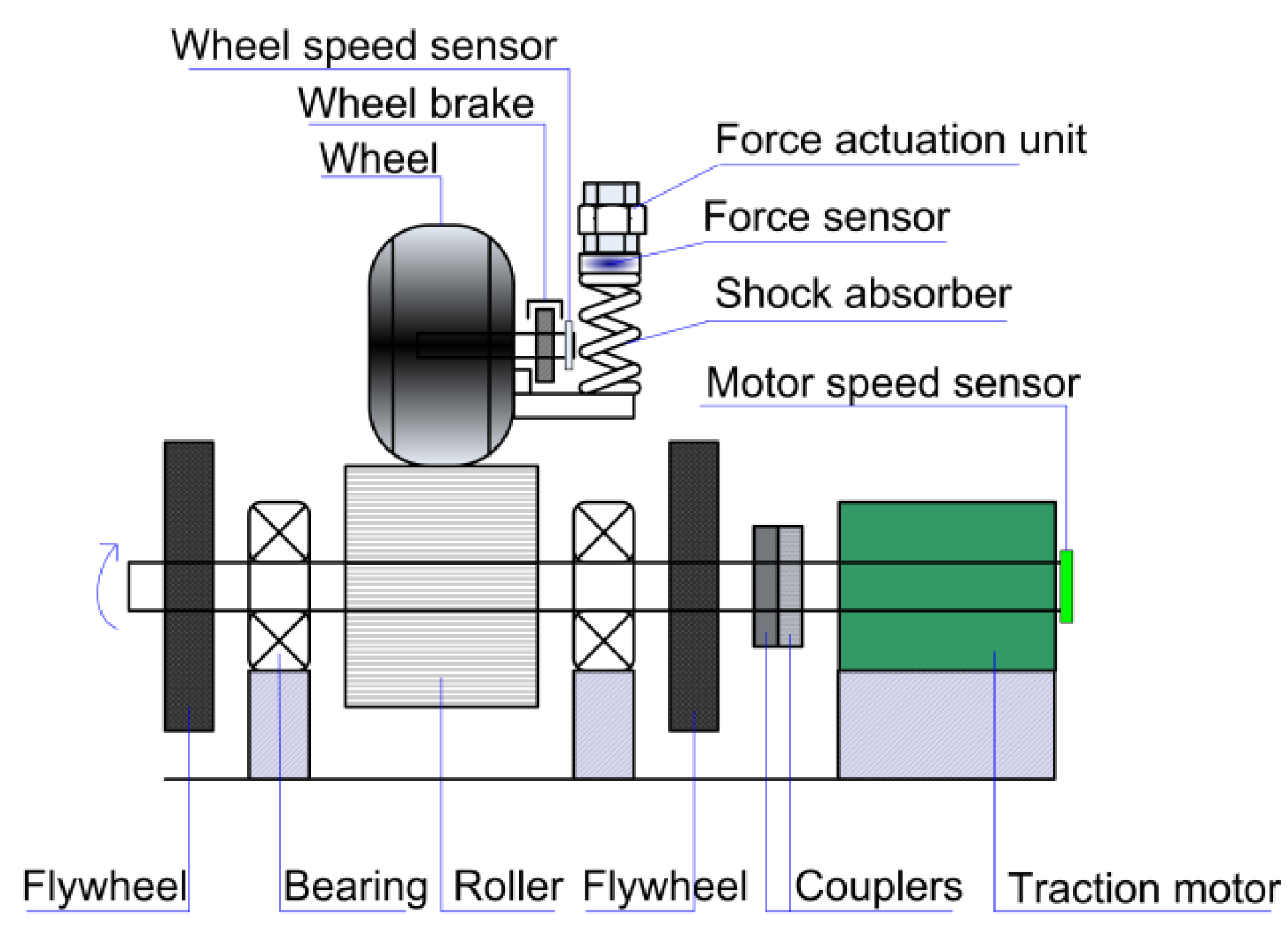

3.2. Model of Proposed Single-Wheel ABS Test Bench

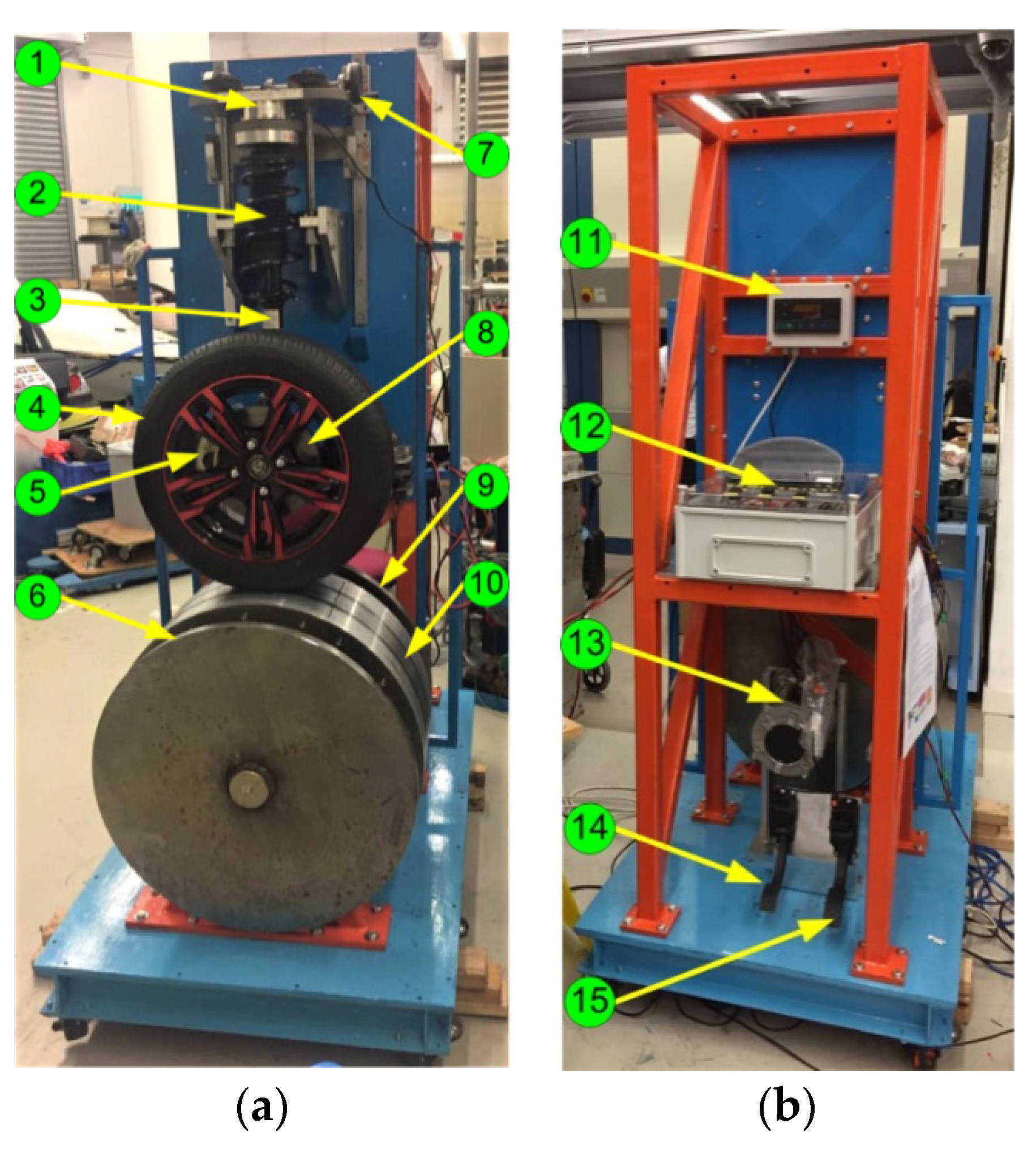

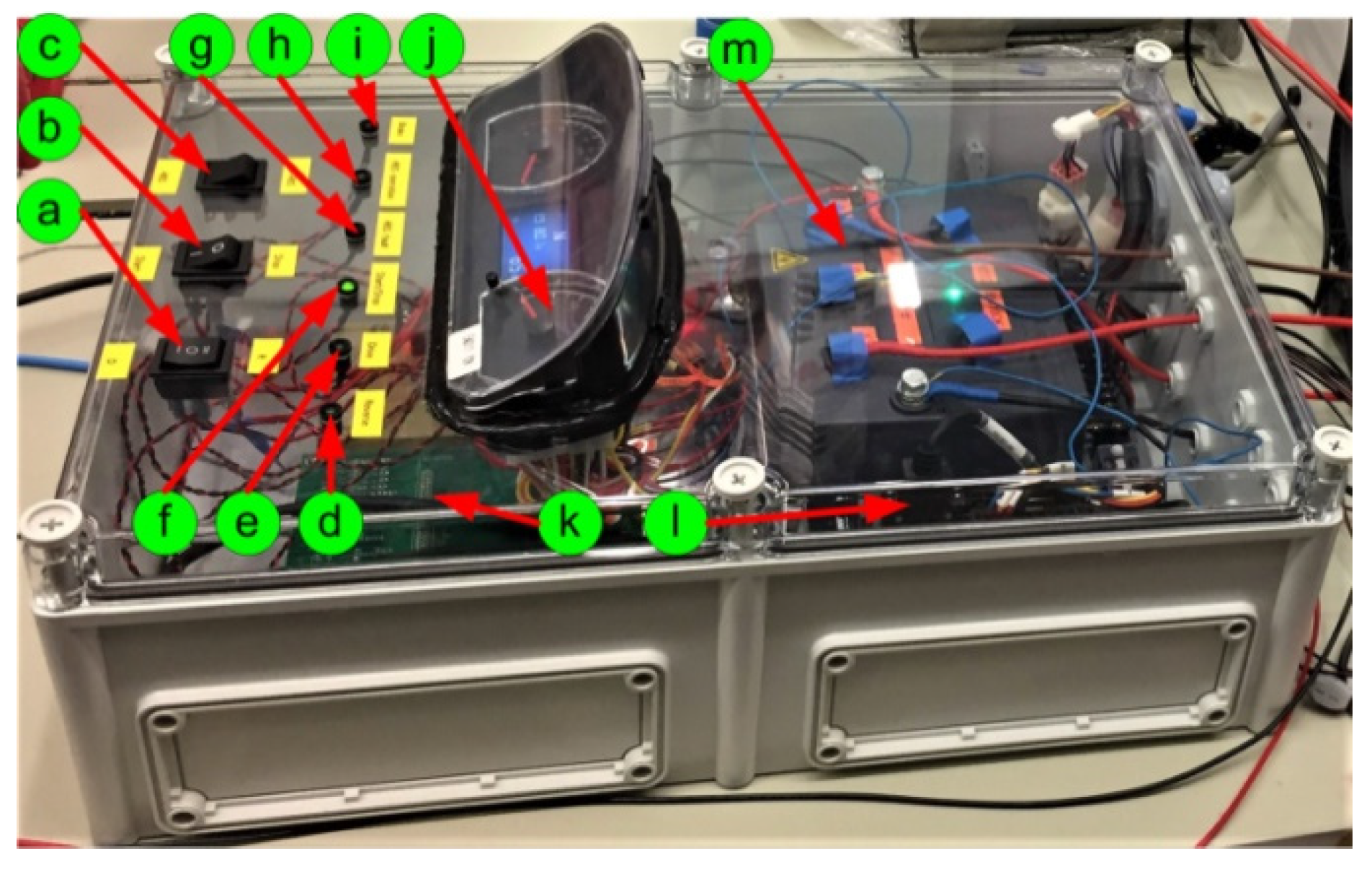

4. Developed Single-Wheel All-Electric ABS Test Bench

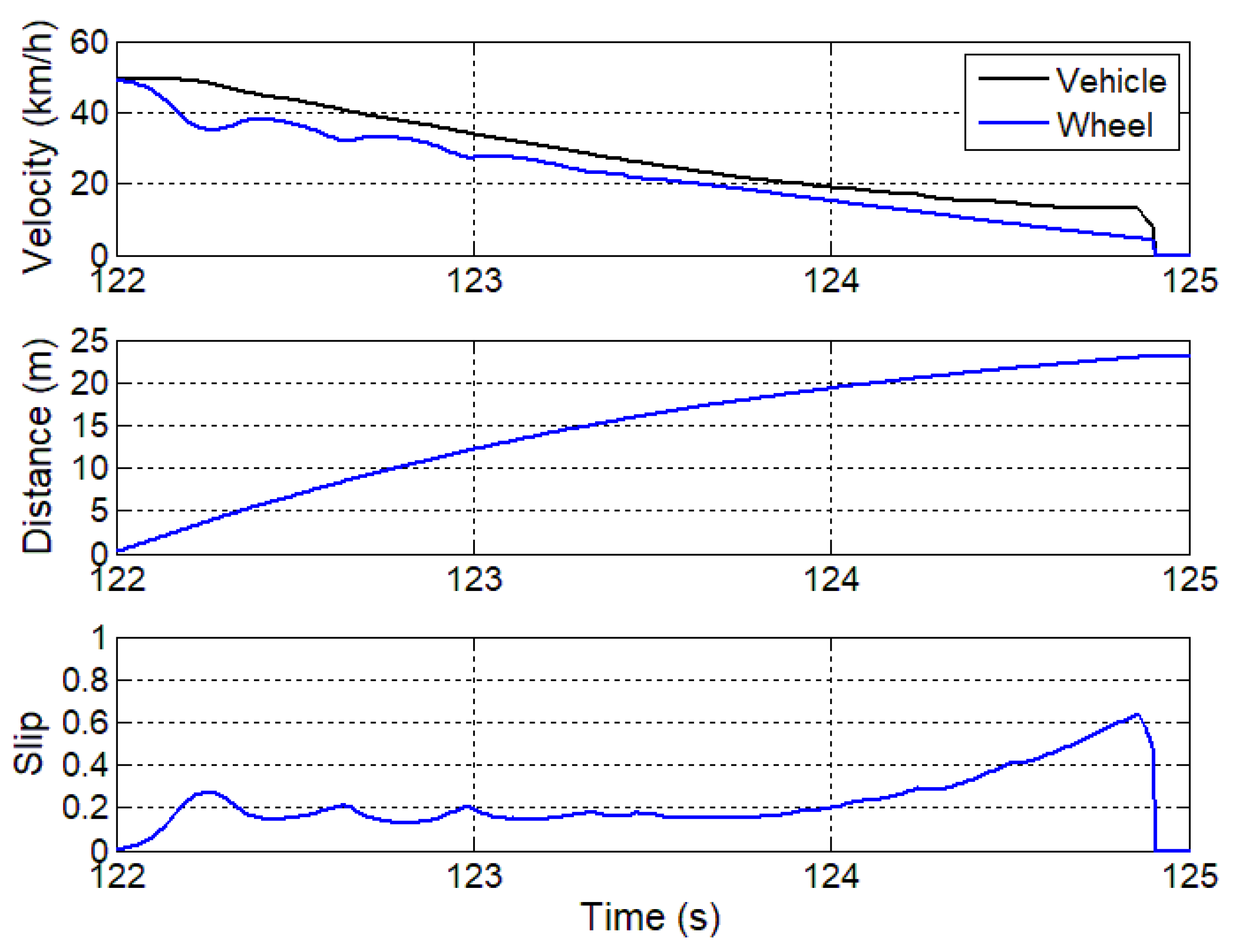

5. Application

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Acknowledgments

Conflicts of Interest

References

- Guo, J.; Jian, X.; Lin, G. Performance Evaluation of an Anti-Lock Braking System for Electric Vehicles with a Fuzzy Sliding Mode Controller. Energies 2014, 7, 6459–6476. [Google Scholar] [CrossRef] [Green Version]

- Juan, A.C.; Antonio, O.; Juan, J.C.; Antonio, S. A Fuzzy Logic Control for Antilock Braking System Integrated in the IMMa Tire Test Bench. IEEE Trans. Veh. Technol. 2005, 54, 1937–1949. [Google Scholar]

- Shim, T.; Chang, S.; Lee, S. Investigation of Sliding-Surface Design on the Performance of Sliding Mode Controller in Antilock Braking Systems. IEEE Trans. Veh. Technol. 2008, 57, 747–759. [Google Scholar] [CrossRef]

- Patil, A.; Ginoya, D.; Shendge, P.D.; Phadke, S.B. Uncertainty-Estimation-Based Approach to Antilock Braking Systems. IEEE Trans. Veh. Technol. 2015, 65, 1171–1185. [Google Scholar] [CrossRef]

- Sun, J.H.; Xue, X.D.; Cheng, K.W.E. Fuzzy Sliding Mode Wheel Slip Ratio Control for Smart Vehicle Anti-Lock Braking System. Energies 2019, 12, 2501. [Google Scholar] [CrossRef] [Green Version]

- Hoseinnezhad, R.; Bab-Hadiashar, A. Efficient Antilock Braking by Direct Maximization of Tire–Road Frictions. IEEE Trans. Ind. Electron. 2010, 58, 3593–3600. [Google Scholar] [CrossRef]

- Morselli, R.; Zanasi, R. Self-Tuning Control Strategy for Antilock Braking Systems. In Proceedings of the 2006 American Control Conference, Minneapolis, MN, USA, 14–16 June 2006; pp. 5861–5866. [Google Scholar]

- Han, K.; Lee, B.; Choi, S.B. Development of an antilock brake system for electric vehicles without wheel slip and road friction information. IEEE Trans. Veh. Technol. 2019, 68, 5506–5517. [Google Scholar] [CrossRef]

- Sun, J.H.; Xue, X.D.; Cheng, K.W.E. Four-Wheel Anti-Lock Braking System with Robust Adaptation under Complex Road Conditions. IEEE Trans. Veh. Technol. 2021, 70, 292–302. [Google Scholar] [CrossRef]

- Tomasikova, M.; Tropp, M.; Gajdosik, T.; Krzywonos, L.; Brumercik, F. Analysis of transport mecha-tronic system properties. Procedia Eng. 2017, 192, 881–886. [Google Scholar] [CrossRef]

- Pugi, L.; Grasso, F.; Pratesi, M.; Cipriani, M.; Bartolomei, A. Design and preliminary performance evaluation of a four wheeled vehicle with degraded adhesion conditions. Int. J. Electr. Hybrid Veh. 2017, 9, 1–32. [Google Scholar] [CrossRef]

- Oniz, Y.; Kayacan, E.; Kaynak, O. A Dynamic Method to Forecast the Wheel Slip for Antilock Braking System and Its Experimental Evaluation. IEEE Trans. Syst. Man Cybern. Part B Cybern. 2009, 39, 551–560. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Khatun, P.; Bingham, C.M.; Schofield, N.; Mellor, P.H. An Experimental Laboratory Bench Setup to Study Electric Vehicle Antilock Braking/Traction Systems and their Control. In Proceedings of the IEEE 56th Vehicular Technology Conference, Vancouver, BC, Candad, 24–28 September 2002; Volume 3, pp. 1490–1494. [Google Scholar]

- Horn, M.; Zehetner, J. A Brake-Testbench for Research and Education. In Proceedings of the 16th IEEE International Conference on Control Applications, Singapore, 1–3 October 2007; pp. 444–448. [Google Scholar]

- Huang, D.; Shen, J. Study on Mathematical Model of Test Bench for Vehicle Anti-Lock Braking System. In Proceedings of the 2009 Second International Conference on Intelligent Computation Technology and Automation, Changsha, China, 10–11 October 2009; pp. 268–270. [Google Scholar]

- Wang, R.; Wang, B.; Sun, H. Development of a Single wheel Test Bench for Anti-lock Brake System. In Proceedings of the 2010 International Conference on Optoelectronics and Image Processing, Hainan, China, 11–12 November 2010; pp. 429–431. [Google Scholar]

- Hao, R.; Zhao, X.; Xu, Z. Auto Anti-lock Braking System Bench Test Results Classification Model Based on Neural Network. In Proceedings of the 2011 International Conference on Electronics, Communications and Control (ICECC), Ningbo, China, 9–11 September 2011; pp. 758–761. [Google Scholar]

- Zhang, Z.; Cheung, N.C.; Cheng, K.W.E.; Xue, X.D.; Lin, J.K. Longitudinal and Transversal End-Effects Analysis of Linear Switched Reluctance Motor. IEEE Trans. Ind. Electron. 2019, 67, 3990–4001. [Google Scholar] [CrossRef]

- Tavernini, D.; Vacca, F.; Metzler, M.; Savitski, D.; Ivanov, V.; Gruber, P.; Hartavi, A.E.; Dhaens, M.; Sorniotti, A. An explicit nonlinear model predictive ABS controller for electro-hydraulic braking systems. IEEE Trans. Ind. Electron. 2020, 67, 3990–4001. [Google Scholar] [CrossRef]

- Reif, K. Brakes, Brake Control and Driver Assistance Systems: Function, Regulation and Components; Springer Fachmedien Wiesbaden: Hessen, Deutschland, 2014; pp. 22–23. [Google Scholar]

| Parameter | Value |

|---|---|

| Model of commercial car | BYD-F0 |

| Nominal car mass | 870 kg |

| Tire model | 165/60 R14 |

| Nominal radius of tire | 0.276 m |

| Force actuation unit | 0–300 kg |

| Rated clamping force of EMB | 11 kN |

| Model of traction motor | Induction motor |

| Rated power of motor | 5 kW |

| Rated speed of motor | 3000 rpm |

| Material of roller surface | Aluminum alloy |

| External diameter of roller | 0.680 m |

| Thickness of roller | 0.274 m |

| Material of roller side | Aluminum alloy |

| Out-diameter of roller side | 0.680 m |

| Thickness of roller side | 0.180 m |

| Roller surface | Polished |

| Material of flywheels | Structural steel |

| Out-diameter of flywheel | 0.670 m |

| Thickness of flywheel | 0.028 m |

| Height of stand frame | 1.840 m |

| Length of stand frame | 0.600 m |

| Width of stand frame | 0.600 m |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

XUE, X.; CHENG, K.W.E.; CHAN, W.W.; FONG, Y.C.; KAN, K.L.J.; FAN, Y. Design, Analysis and Application of Single-Wheel Test Bench for All-Electric Antilock Braking System in Electric Vehicles. Energies 2021, 14, 1294. https://doi.org/10.3390/en14051294

XUE X, CHENG KWE, CHAN WW, FONG YC, KAN KLJ, FAN Y. Design, Analysis and Application of Single-Wheel Test Bench for All-Electric Antilock Braking System in Electric Vehicles. Energies. 2021; 14(5):1294. https://doi.org/10.3390/en14051294

Chicago/Turabian StyleXUE, Xiangdang, Ka Wai Eric CHENG, Wing Wa CHAN, Yat Chi FONG, Kin Lung Jerry KAN, and Yulong FAN. 2021. "Design, Analysis and Application of Single-Wheel Test Bench for All-Electric Antilock Braking System in Electric Vehicles" Energies 14, no. 5: 1294. https://doi.org/10.3390/en14051294

APA StyleXUE, X., CHENG, K. W. E., CHAN, W. W., FONG, Y. C., KAN, K. L. J., & FAN, Y. (2021). Design, Analysis and Application of Single-Wheel Test Bench for All-Electric Antilock Braking System in Electric Vehicles. Energies, 14(5), 1294. https://doi.org/10.3390/en14051294