An Experimental Study on the Characteristics of NOx Distributions at the SNCR Inlets of a Large-Scale CFB Boiler

Abstract

1. Introduction

2. Experimental Section

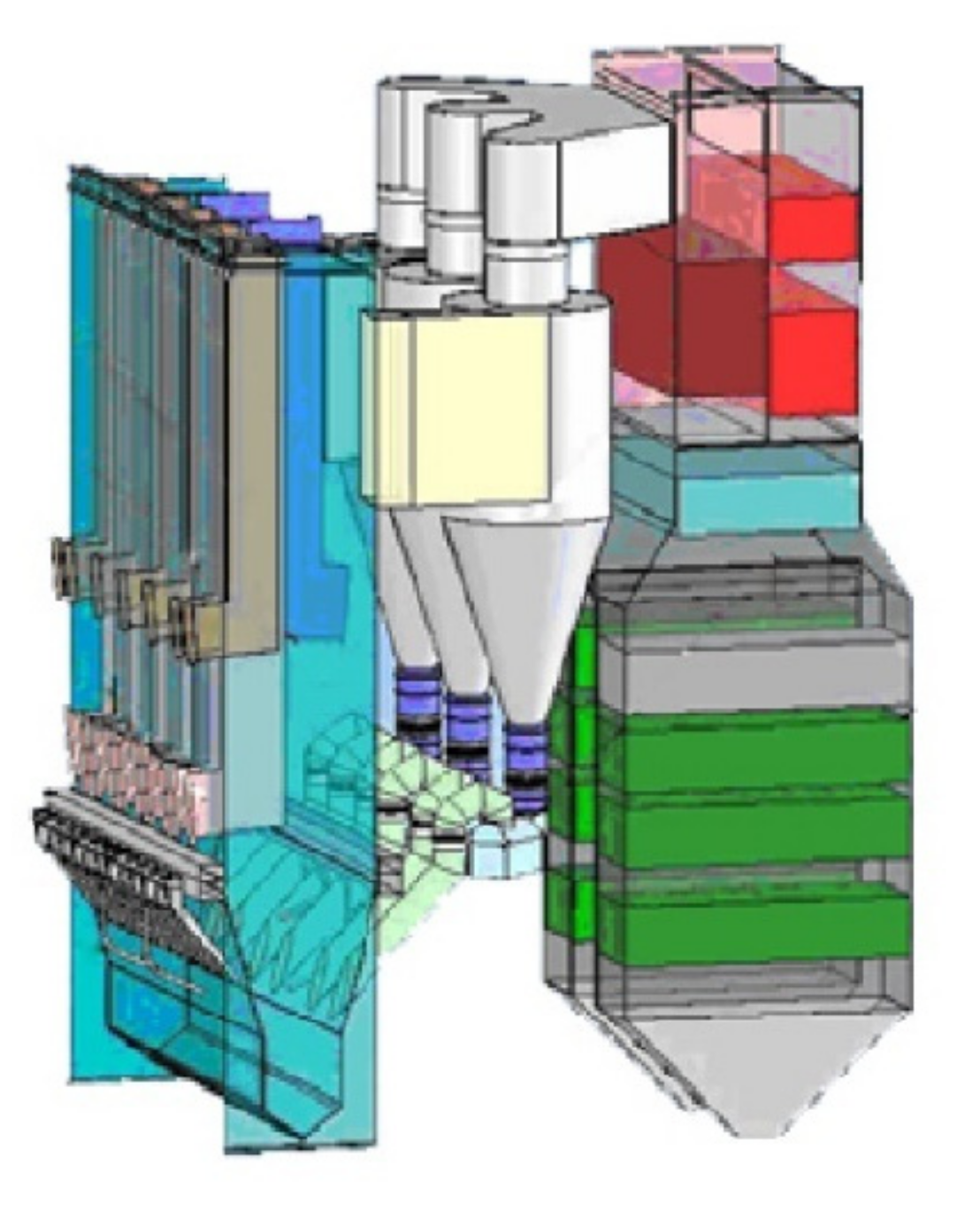

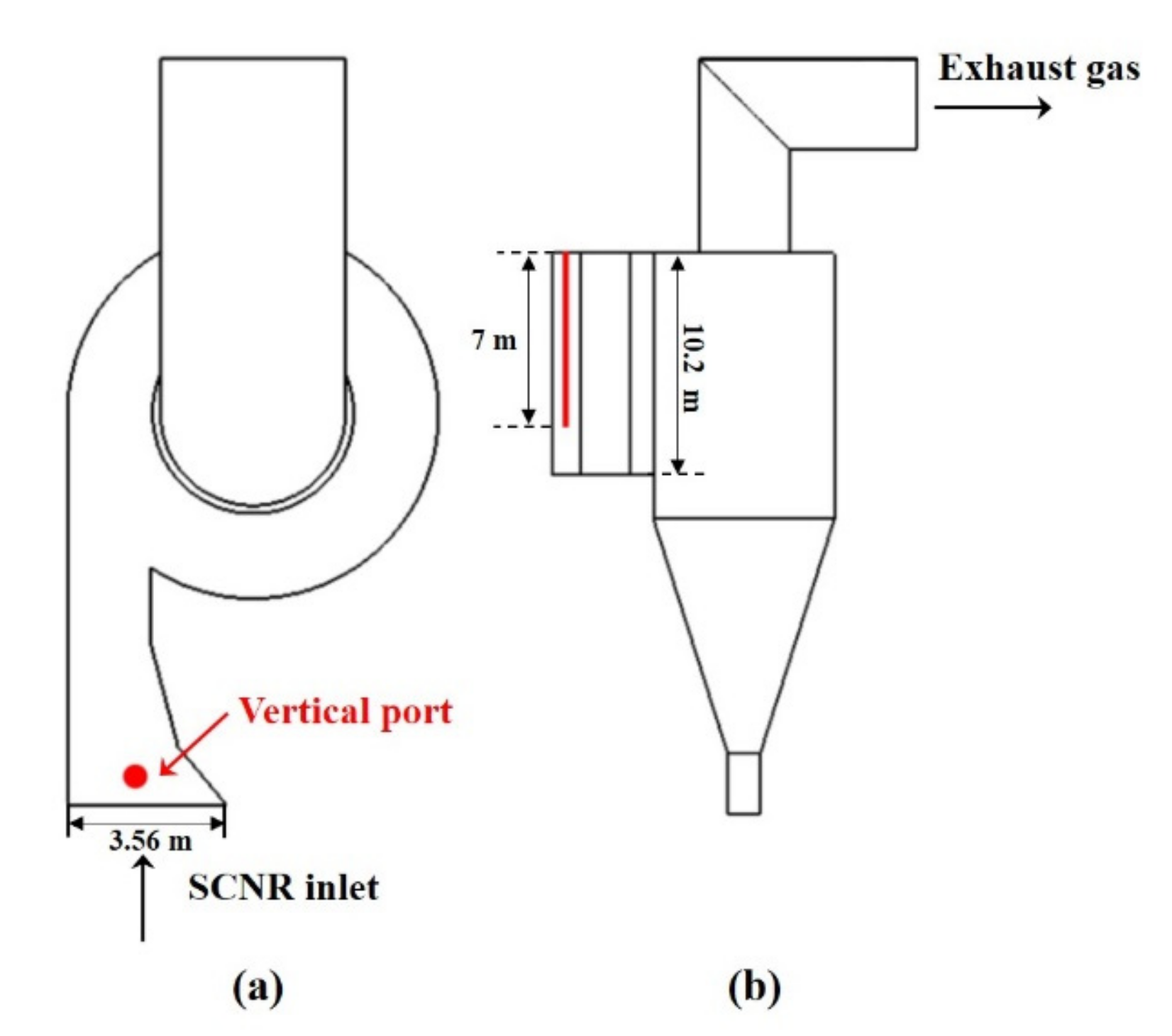

2.1. The 300 MW Utility CFB Boiler

2.2. Measurement Port Arrangement and Test Procedure

2.3. Working Condition Arrangement

3. Results and Discussion

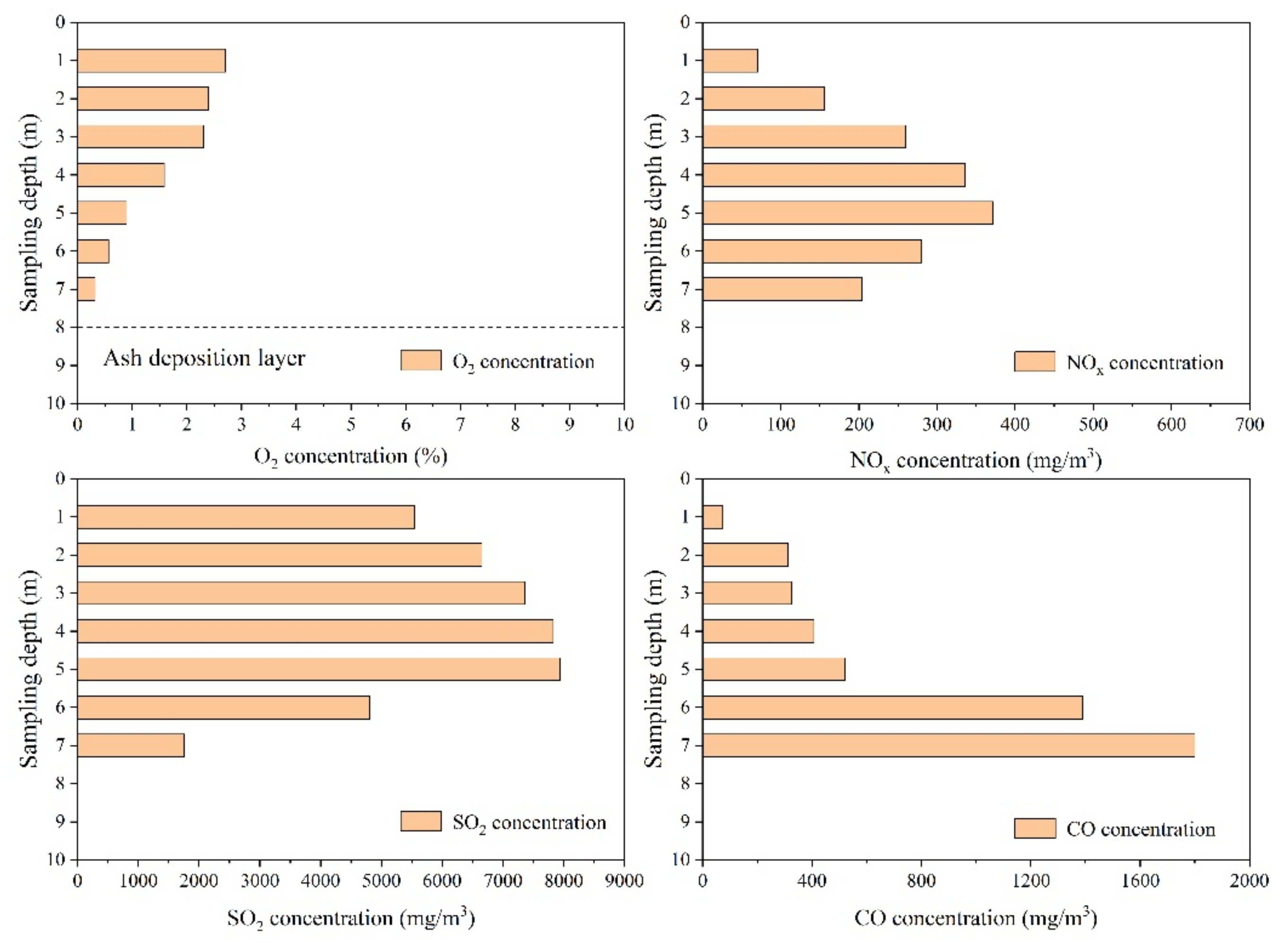

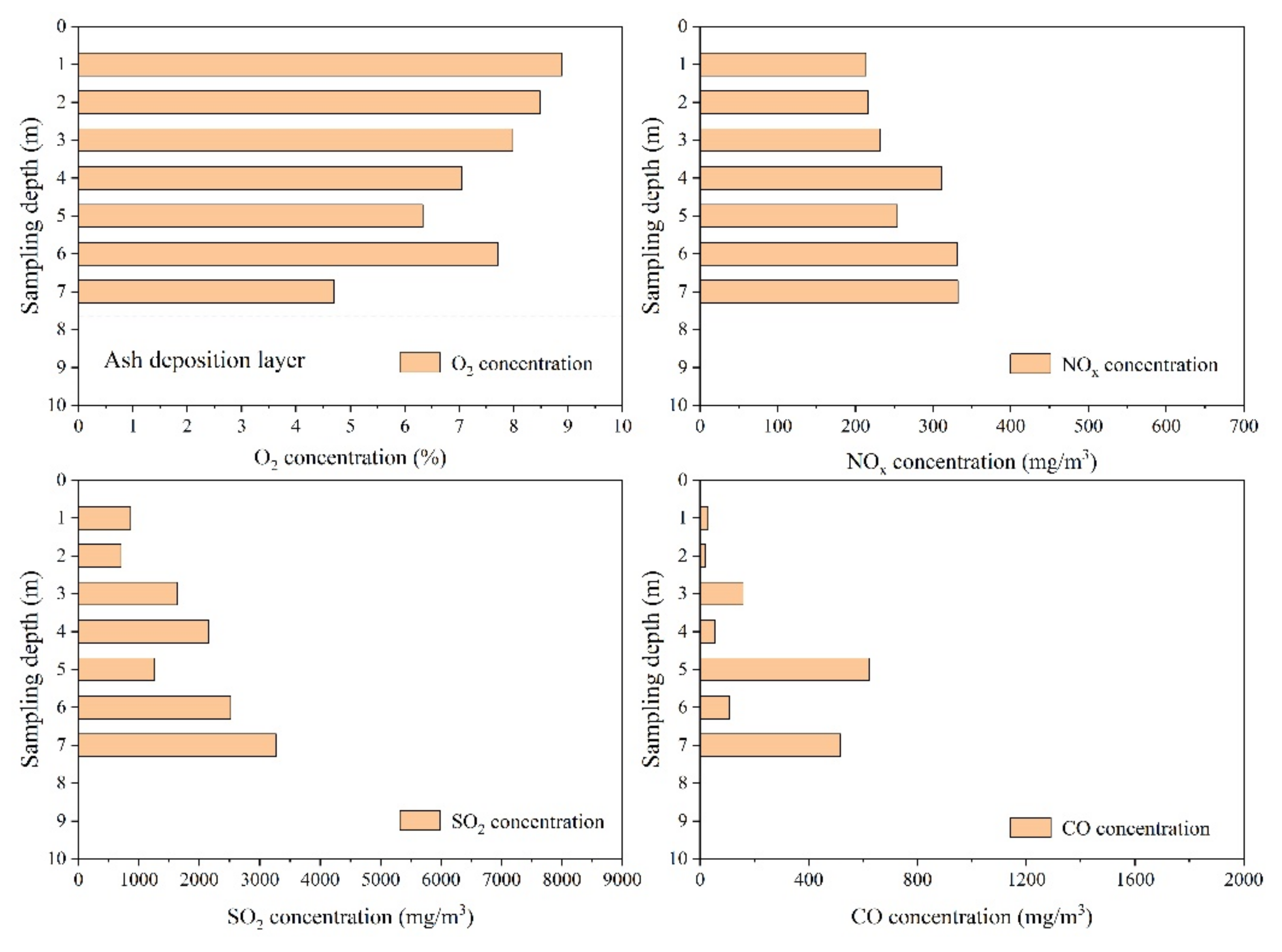

3.1. Vertical Distributions of Flue Gas Composition at the SNCR Inlets

3.1.1. Vertical Distributions of Flue Gas Composition at #A SNCR Inlet

3.1.2. Vertical Distributions of Flue Gas Composition at #B SNCR Inlet

3.1.3. Vertical Distributions of Flue Gas Composition at #C SNCR Inlet

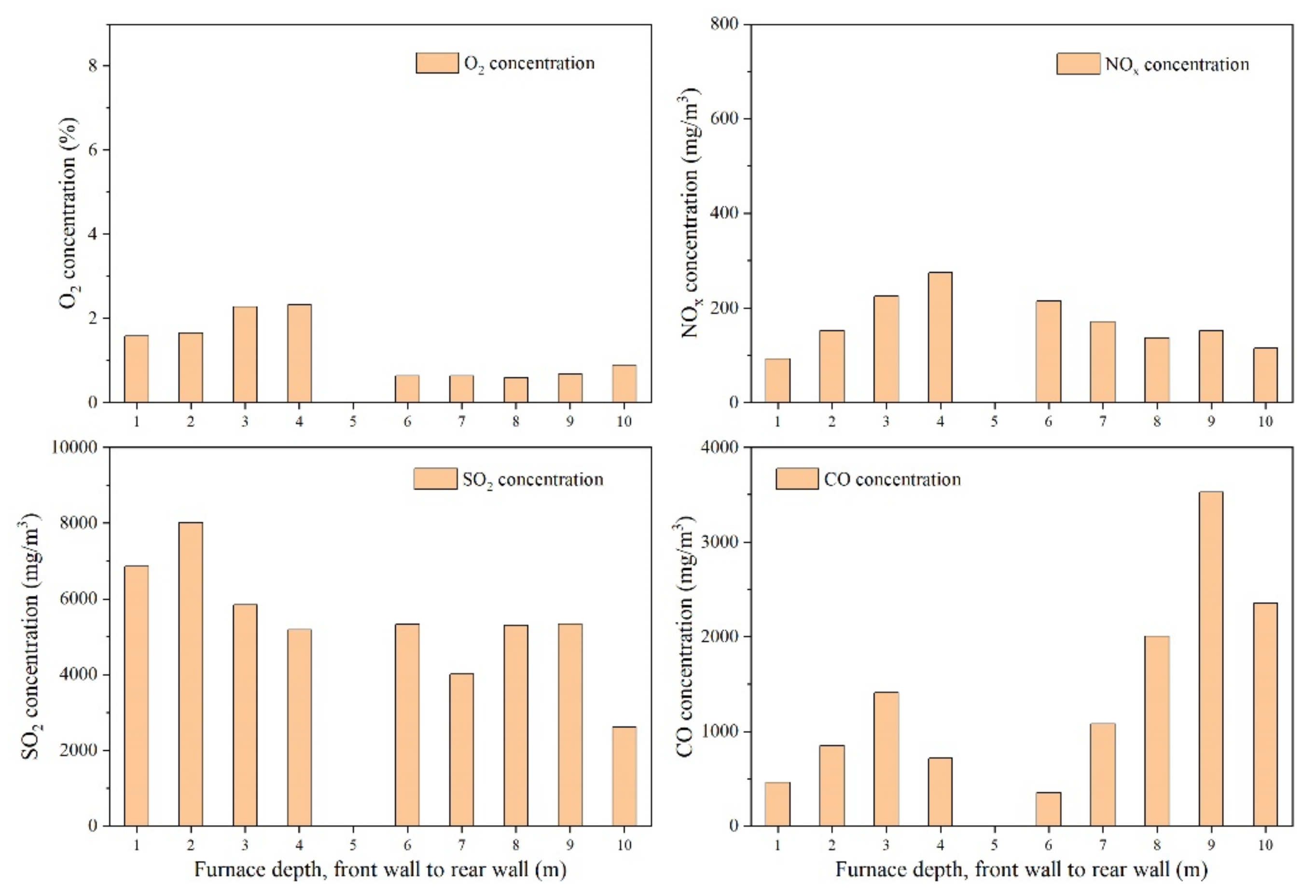

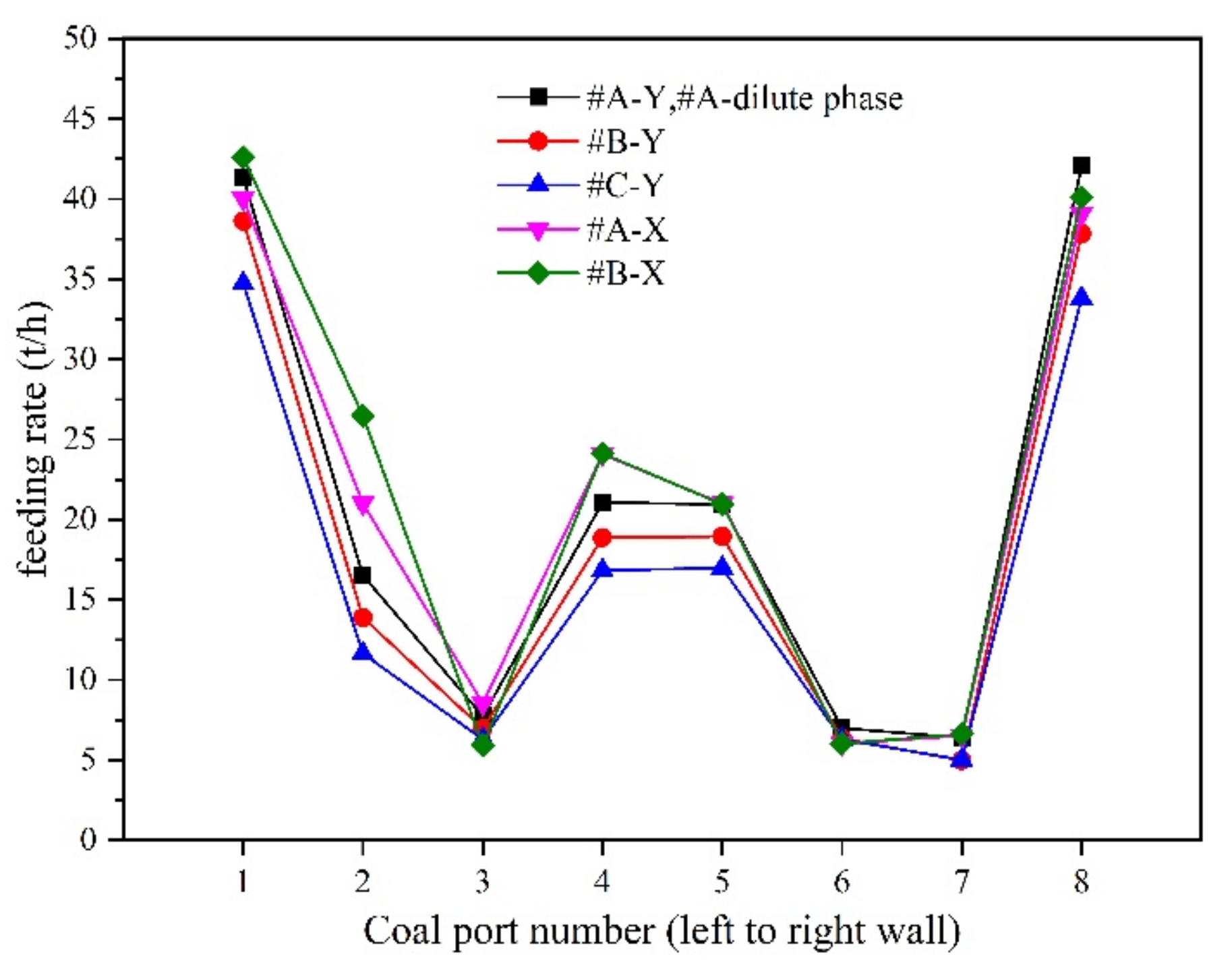

3.2. Horizontal NOx Distributions at the Cross Section of the SNCR Inlets

3.3. Optimization of Urea Injections Based on Uneven NOx Distributions

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Blaszczuk, A.; Nowak, W. Heat transfer behavior inside a furnace chamber of large-scale supercritical CFB reactor. Int. J. Heat Mass Tran. 2015, 87, 464–480. [Google Scholar] [CrossRef]

- Yue, G.X.; Cai, R.X.; Lyu, J.F.; Zhang, H. From a CFB reactor to a CFB boiler—The review of R&D progress of CFB coal combustion technology in China. Powder Technol. 2017, 316, 18–28. [Google Scholar]

- Blaszczuk, A.; Pogorzelec, M.; Shimizu, T. Heat transfer characteristics in a large-scale bubbling fluidized bed with immersed horizontal tube bundles. Energy 2018, 162, 10–19. [Google Scholar] [CrossRef]

- Chen, H.W.; Song, Y.F.; Yang, S.; Xin, Y. Prediction of particle circulation rate in an internally circulating fluidized bed with a central draft tube. Powder Technol. 2021, 380, 497–505. [Google Scholar] [CrossRef]

- Ji, J.Q.; Cheng, L.M.; Wei, Y.J.; Wang, J.F.; Gao, X.Y.; Fang, M.X.; Wang, Q.H. Predictions of NOx/N2O emissions from an ultra-supercritical CFB boiler using a 2-D comprehensive CFD combustion model. Particuology 2020, 49, 77–87. [Google Scholar] [CrossRef]

- Blaszczuk, A.; Nowak, W.; Jagodzik, S. Effects of operating conditions on deNOx system efficiency in supercritical circulating fluidized bed boiler. J. Power Technol. 2013, 93(1), 1–8. [Google Scholar]

- Ke, X.W.; Li, D.F.; Li, Y.R.; Jiang, L.; Cai, R.X.; Lyu, J.F.; Yang, H.R.; Zhang, M.; Jeon, C.H. 1-Dimensional modelling of in-situ desulphurization performance of a 550 MWe ultra-supercritical CFB boiler. Fuel 2021, 290, 120088. [Google Scholar] [CrossRef]

- Li, J.J.; Yang, H.R.; Wu, Y.X.; Lv, J.F.; Yue, G.X. Effects of the updated national emission regulation in China on circulating fluidized bed boilers and the solutions to meet them. Environ. Sci. Technol. 2013, 47, 6681–6687. [Google Scholar] [CrossRef]

- Ke, X.W.; Cai, R.X.; Zhang, M.; Miao, M.; Lyu, J.F.; Yang, H.R. Application of ultra-low NOx emission control for CFB boilers based on theoretical analysis and industrial practices. Fuel Process. Technol. 2018, 181, 252–258. [Google Scholar] [CrossRef]

- The Upgrade and Retrofitting Action Plan of Energy Saving and Emission Reduction for Coal-Fired Power Plants; National Development and Reform Commission: Beijing, China, 2014.

- Sirisomboon, K.; Charernporn, P. Effects of air staging on emission characteristics in a conical fluidized-bed combustor firing with sunflower shells. J. Energy Inst. 2017, 90, 316–323. [Google Scholar] [CrossRef]

- Misiulia, D.; Antonyuk, S.; Andersson, A.G.; Lundstrom, T.S. High-efficiency industrial cyclone separator: A CFD study. Powder Technol. 2020, 364, 943–953. [Google Scholar] [CrossRef]

- Liu, X.M.; Yang, H.R.; Lyu, J.F. Optimization of fluidization state of a circulating fluidized bed boiler for economical operation. Energies 2020, 13, 376. [Google Scholar] [CrossRef]

- Fang, D.D.; Zhang, L.H.; Duan, F.; Chyang, C.S.; Wang, Y.C. Combustion and pollutant emissions characteristics of Camellia oleifera shells in a vortexing fluidized-bed combustor. J. Energy Inst. 2020, 93, 739–751. [Google Scholar] [CrossRef]

- Ljungdahl, B.; Larfeldt, J. Optimised NH3 injection in CFB boilers. Powder Technol. 2001, 120, 55–62. [Google Scholar] [CrossRef]

- Kang, Z.Z.; Yuan, Q.X.; Zhao, L.Z.; Dai, Y.K.; Sun, B.M.; Wang, T. Study of the performance, simplification and characteristics of SNCR de-NOx in large-scale cyclone separator. Appl. Therm. Eng. 2017, 123, 635–645. [Google Scholar] [CrossRef]

- Yao, T.; Duan, Y.F.; Yang, Z.Z.; Li, Y.; Wang, L.W.; Zhu, C.; Zhou, Q.; Zhang, J.; She, M.; Liu, M. Experimental characterization of enhanced SNCR process with carbonaceous gas additives. Chemosphere 2017, 177, 149–156. [Google Scholar] [CrossRef] [PubMed]

- Rahman, Z.; Wang, X.B.; Zhang, J.Y.; Baleta, J.; Vujanovic, M.; Tan, H.Z. Kinetic study and optimization on SNCR process in pressurized oxy-combustion. J. Energy Inst. 2021, 94, 263–271. [Google Scholar] [CrossRef]

- Świeboda, T.; Krzyżyńska, R.; Bryszewska-Mazurek, A.; Mazurek, W.; Czapliński, T.; Przygoda, A. Advanced approach to modeling of pulverized coal boilers for SNCR process optimization—Review and recommendations. Int. J. Thermofluid. 2020, 7–8, 100051. [Google Scholar] [CrossRef]

- Yan, J.; Lu, X.F.; Wang, Q.H.; Kang, Y.H.; Li, J.B.; Zhou, J.; Zhang, Y.; Lv, Z.; Sicong, S. Experimental and numerical study on air flow uniformity in the isobaric windbox of a 600 MW supercritical CFB boiler. Appl. Therm. Eng. 2017, 122, 311–321. [Google Scholar] [CrossRef]

- Zheng, W.J.; Zhang, M.; Zhang, Y.; Lyu, J.F.; Yang, H.R. The effect of the secondary air injection on the gas–solid flow characteristics in the circulating fluidized bed. Chem. Eng. Res. Des. 2019, 141, 220–228. [Google Scholar] [CrossRef]

- Yan, J.; Lu, X.F.; Zheng, X.; Xue, R.; Lei, X.J.; Fan, X.C.; Liu, S.R. Experimental investigations on lateral dispersion coefficients of fuel particles in large-scale circulating fluidized bed boilers with different coal feeding modes. Energies 2020, 13, 6336. [Google Scholar] [CrossRef]

- Ma, S.X.; Chang, W.M.; Zhang, J.C.; Luo, D.L. Optimizing calculation of particle size distribution of feeding coal for circulating fluidized bed boiler. Appl. Therm. Eng. 2015, 87, 463–470. [Google Scholar] [CrossRef]

- Yan, J.; Lu, X.F.; Song, Y.F.; Zheng, X.; Lei, X.J.; Liu, Z.; Fan, X.C.; Liu, C.C. A comprehensive understanding of the non-uniform characteristics and regulation mechanism of six external loops in a 600 MW supercritical CFB boiler. Energy 2021, 120032, in press. [Google Scholar] [CrossRef]

- Yuan, Z.W.; Meng, L.; Gu, X.B.; Bai, Y.Y.; Cui, H.M.; Jiang, C.Y. Prediction of NOx emissions for coal-fired power plants with stacked-generalization ensemble method. Fuel 2021, 289, 119748. [Google Scholar] [CrossRef]

- Zhou, G.Y.; Jin, B.S. Ammonia injection method for SCR based on non-uniform inlet condition. J. Huazhong Univ. Sci. Tech. 2016, 44, 121–126. [Google Scholar] [CrossRef]

- Liu, G.F.; Zhang, Y.; Shen, D.K.; Yuan, B.; Li, R.; Sun, Y. Anticipatory NH3 injection control for SCR system based on the prediction of the inlet NOx concentration. J. Energy Inst. 2021, 94, 167–175. [Google Scholar] [CrossRef]

- Niklasson, F.; Johnsson, F.; Leckner, B. Locao air ratio measured by zirconia cell in a circulating fluidised bed furnace. Chem. Eng. J. 2003, 96, 145–155. [Google Scholar] [CrossRef]

- Hartge, E.-U.; Fehr, M.; Werther, J.; Ochodek, T.; Noskievic, P.; Krzin, I.; Kallner, P.; Gadowski, J. Gas concentration measurements in the combustion chamber of the 235 MWe circulating fluidized bed boiler Turow no 3. In Proceedings of the 18th International Conference on Fluidized Bed Combustion, Toronto, ON, Canada, 22–25 May 2005. [Google Scholar]

- Yan, J.; Lu, X.F.; Wang, Q.H.; Kang, Y.H.; Li, J.B.; Xu, Z.; Lei, X.; Zheng, X.; Fan, X.; Liu, Z. Study on the influence of secondary air on the distributions of flue gas composition at the lower part of a 600 MW supercritical CFB boiler. Fuel Process. Technol. 2019, 196, 106035. [Google Scholar] [CrossRef]

- Werther, J.; Hartge, E.-U.; Ratschow, L.; Wischnewski, R. Simulation-supported measurements in large circulating fluidized bed combustors. Particuology 2009, 7, 324–331. [Google Scholar] [CrossRef]

- Lu, J.Y.; Lu, X.F.; He, H.H.; Wang, H.; Gan, L.; Zhao, P.; Tang, X.N. Combustion characteristics of the external circulation loop on Baima’s 300 MWe circulating fluidized bed boiler. Energy Fuel 2011, 25, 3456–3464. [Google Scholar] [CrossRef]

- Yan, J.; Lu, X.F.; Xue, R.; Lu, J.Y.; Zheng, Y.; Zhang, Y.; Liu, Z. Validation and application of CPFD model in simulating gas-solid flow and combustion of a supercritical CFB boiler with improved inlet boundary conditions. Fuel Process. Technol. 2020, 208, 106512. [Google Scholar] [CrossRef]

- Vodička, M.; Hrdlička, J.; Skopec, P. Experimental study of the NOx reduction through the staged oxygen supply in the oxy-fuel combustion in a 30 kWth bubbling fluidized bed. Fuel 2021, 286, 119343. [Google Scholar] [CrossRef]

- Song, G.L.; Yang, X.T.; Yang, Z.; Xiao, Y. Experimental study on ultra-low initial NOx emission characteristics of Shenmu coal and char in a high temperature CFB with post-combustion. J. Energy Inst. 2021, 94, 310–318. [Google Scholar] [CrossRef]

- Guo, Q.; Wang, Q.H.; Lu, X.F.; Li, J.B.; Xu, J. Numerical study on gas flow characteristics in three parallel separators of a large-scale CFB boiler. Proc. CSEE 2019, 39, 3851–3858. [Google Scholar]

- Wang, W. Numerical Simulation of the SNCR Denitration Process in a Circulating Fluidized Bed; Southeast University: Nanjing, China, 2016. [Google Scholar]

| Item | Unit | Value (BMCR) |

|---|---|---|

| Superheat steam flow rate | t/h | 1100 |

| Superheated steam pressure | MPa | 17.4 |

| Superheated steam temperature | °C | 541 |

| Reheat steam pressure | MPa | 3.87 |

| Reheat steam temperature | °C | 541 |

| Water feed temperature | °C | 282 |

| Item | Sensor Type | Range | Precision (Based on Measured Values) |

|---|---|---|---|

| Ecom-J2KN type analyzer | |||

| O2 | Electrochemical | 0–21% | 0.2% |

| CO1 | Electrochemical | 0–10,000 ppm | 5% |

| NO | Electrochemical | 0–5000 ppm | 5% |

| NO2 | Electrochemical | 0–1000 ppm | 5% |

| SO2 | Electrochemical | 0–5000 ppm | 5% |

| Testo 350 type analyzer | |||

| O2 | Electrochemical | 0–25% | 0.8% |

| CO1 | Electrochemical | 0–10,000 ppm | 10% |

| NO | Electrochemical | 0–4000 ppm | 5% |

| NO2 | Electrochemical | 0–500 ppm | 5% |

| SO22 | Electrochemical | 0–5000 ppm | 5% |

| Item | Unit | Dilute Phase | #A-Y | #B-Y | #C-Y |

|---|---|---|---|---|---|

| Load | MW | 270 | 270 | 266 | 268 |

| Coal feed rate | t/h | 151 | 151 | 146 | 150 |

| PA flow rate | kNm3/h | 507 | 507 | 487 | 499 |

| SA flow rate | kNm3/h | 310 | 310 | 299 | 302 |

| Bed pressure | kPa | 7.41 | 7.43 | 7.68 | 7.69 |

| Bed temperature | °C | 918 | 920 | 930 | 937 |

| Cyclone inlet temperature | °C | 932 | 931 | 984 | 975 |

| Cyclone outlet temperature | °C | 882 | 882 | 942 | 933 |

| Economizer O2 | Vol.-% | 3.93 | 3.93 | 4.17 | 4.06 |

| Item | Unit | #A-X | #B-X | #C-X |

|---|---|---|---|---|

| Load | MW | 280 | 279 | 264 |

| Coal feed rate | t/h | 170 | 162 | 136 |

| PA flow rate | kNm3/h | 532 | 539 | 458 |

| SA flow rate | kNm3/h | 319 | 318 | 287 |

| Bed pressure | kPa | 8.12 | 8.21 | 7.54 |

| Bed temperature | °C | 936 | 955 | 933 |

| Cyclone inlet temperature | °C | 932 | 962 | 952 |

| Cyclone outlet temperature | °C | 898 | 914 | 940 |

| O2 | Vol.-% | 4.26 | 4.15 | 3.78 |

| Coal | Value |

|---|---|

| Proximate analysis (wt%, air dry basis) | |

| Ash | 42.33 |

| Fixed carbon | 49.22 |

| Moisture | 8.8 |

| Volatiles | 8.45 |

| Lower heating value (MJ/kg) | 16.31 |

| Ultimate analysis (wt%, air dry basis) | |

| C | 52.28 |

| H | 2.69 |

| O | 1.51 |

| N | 0.52 |

| Stotal | 0.67 |

| Item | Unit | Before Optimization | After Optimization |

|---|---|---|---|

| Urea solution flowrate in #A | m3/h | 2.800 | 2.535 |

| Urea solution flowrate in #B | m3/h | 2.694 | 1.982 |

| Urea solution flowrate in #C | m3/h | 2.601 | 2.307 |

| NH3 escape | ppm | 8.39 | / |

| Stack NOx emission | mg/m3 | 44.93 | 47.49 |

| O2 | % | 6.29 | 6.06 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yan, J.; Lu, X.; Zhang, C.; Li, Q.; Wang, J.; Liu, S.; Zheng, X.; Fan, X. An Experimental Study on the Characteristics of NOx Distributions at the SNCR Inlets of a Large-Scale CFB Boiler. Energies 2021, 14, 1267. https://doi.org/10.3390/en14051267

Yan J, Lu X, Zhang C, Li Q, Wang J, Liu S, Zheng X, Fan X. An Experimental Study on the Characteristics of NOx Distributions at the SNCR Inlets of a Large-Scale CFB Boiler. Energies. 2021; 14(5):1267. https://doi.org/10.3390/en14051267

Chicago/Turabian StyleYan, Jin, Xiaofeng Lu, Changfei Zhang, Qianjun Li, Jinping Wang, Shirong Liu, Xiong Zheng, and Xuchen Fan. 2021. "An Experimental Study on the Characteristics of NOx Distributions at the SNCR Inlets of a Large-Scale CFB Boiler" Energies 14, no. 5: 1267. https://doi.org/10.3390/en14051267

APA StyleYan, J., Lu, X., Zhang, C., Li, Q., Wang, J., Liu, S., Zheng, X., & Fan, X. (2021). An Experimental Study on the Characteristics of NOx Distributions at the SNCR Inlets of a Large-Scale CFB Boiler. Energies, 14(5), 1267. https://doi.org/10.3390/en14051267