A Systematic Review on Predicting and Forecasting the Electrical Energy Consumption in the Manufacturing Industry

Abstract

1. Introduction

2. Related Work

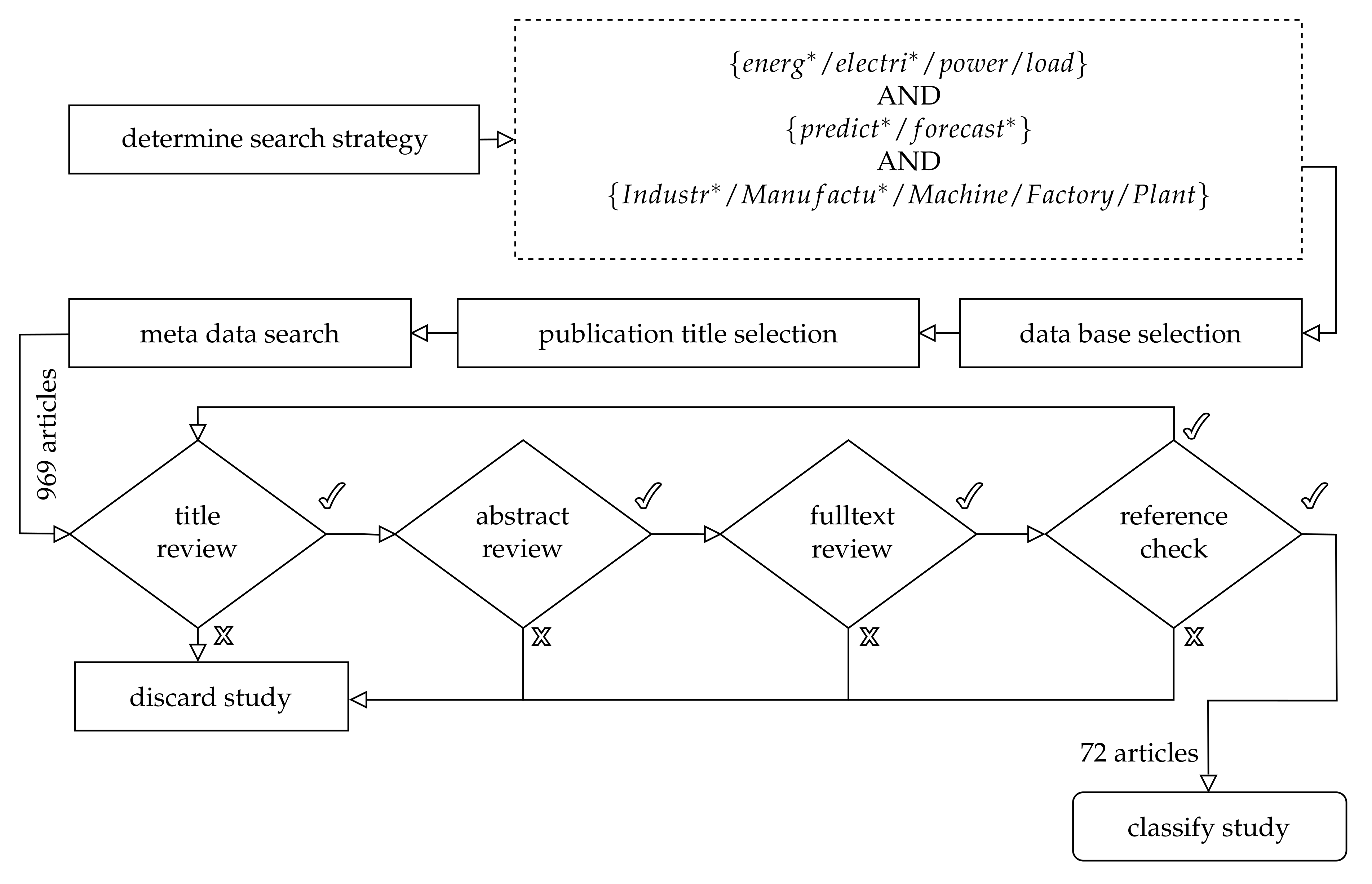

3. Methodology for Systematic Literature Review

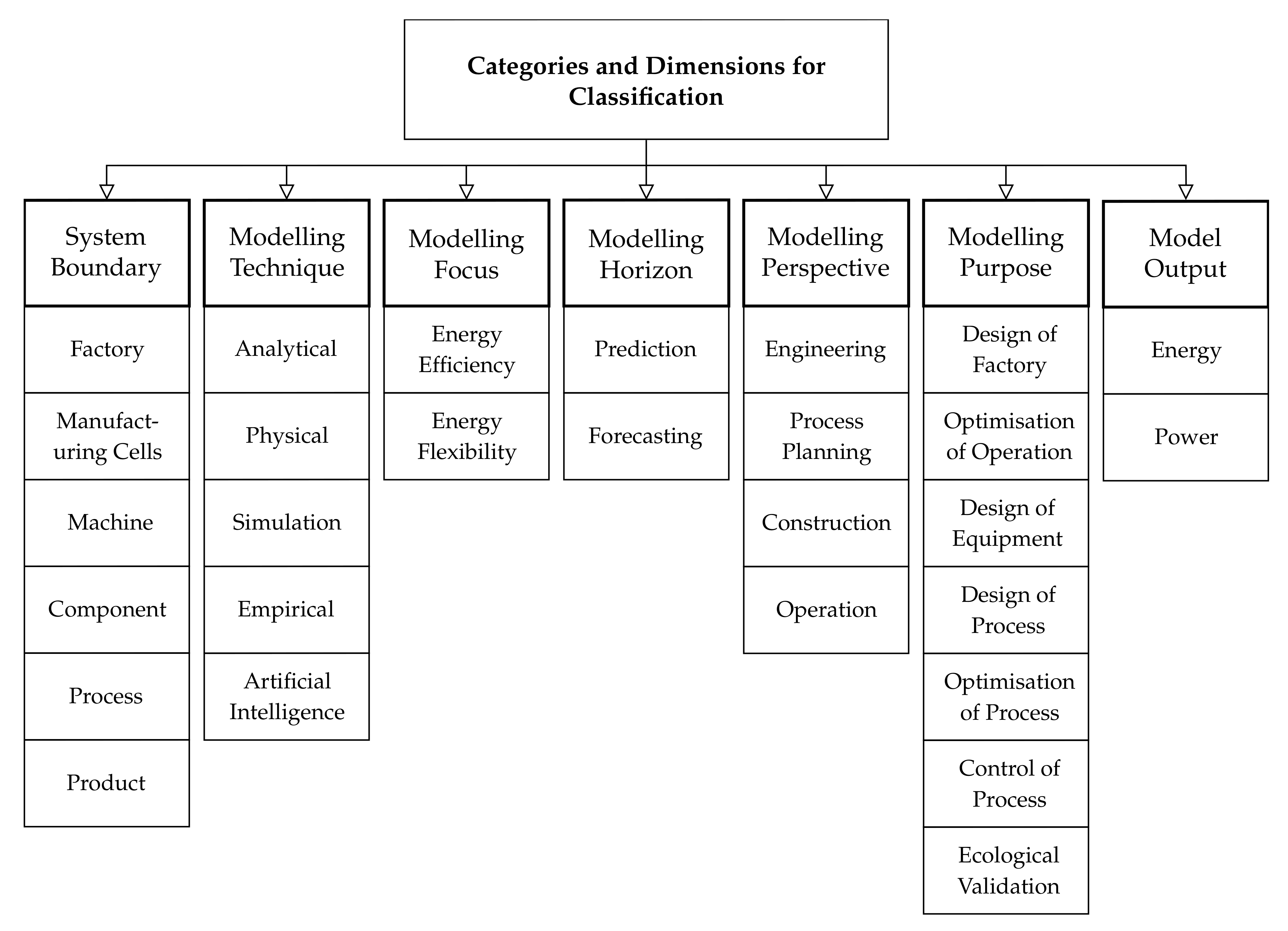

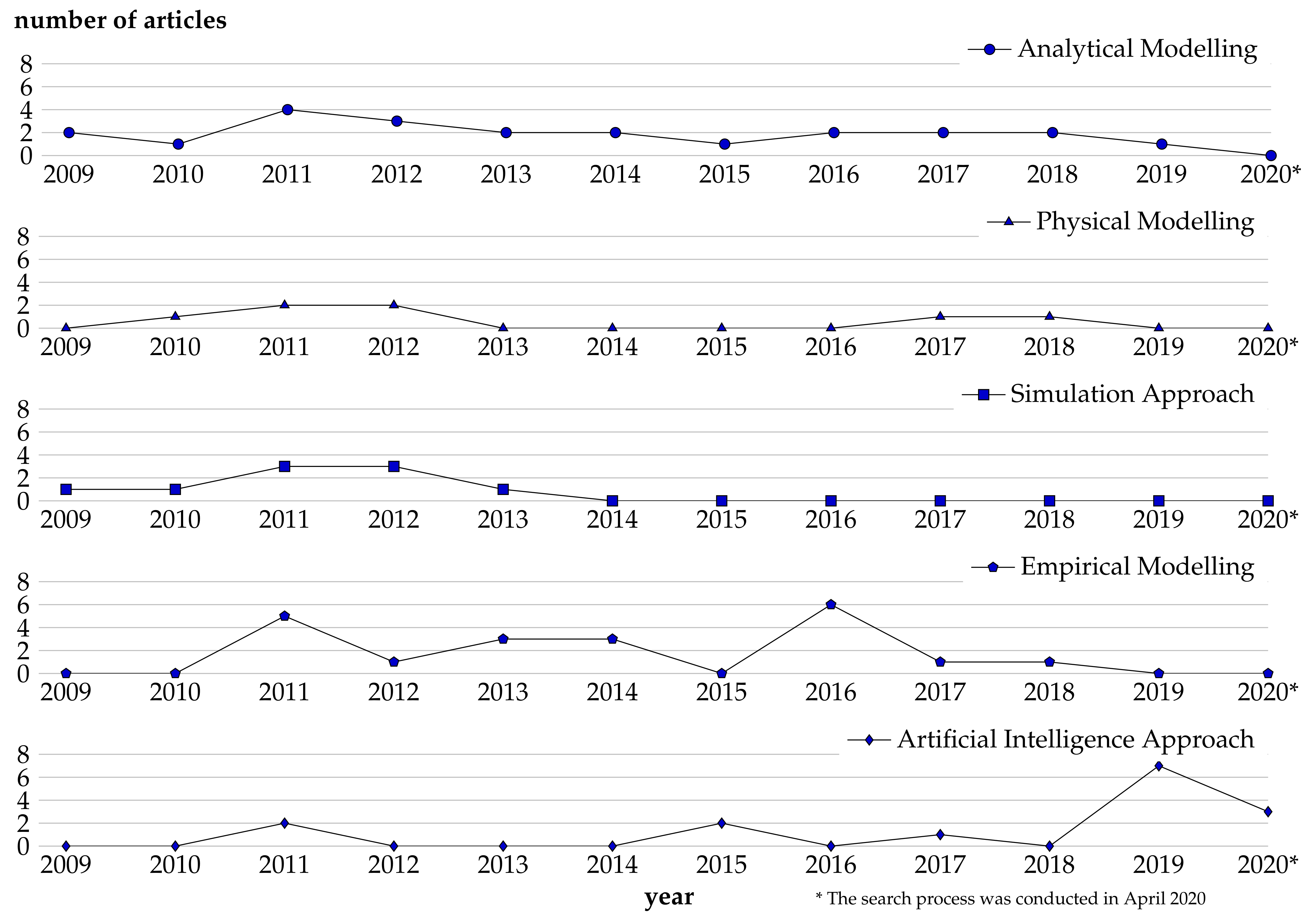

4. Classification Scheme

4.1. System Boundary

- Factory: An energy model for factory-level demand is being developed.

- Manufacturing cell: An energy model is developed for a manufacturing cell containing several production machines.

- Machine: A machine-level energy model is developed.

- Component: An energy model of individual components of a production machine is developed.

- Process: An energy model for a specific process is developed.

- Product: An energy model is developed for the energy embedded in a product.

4.2. Modelling Technique

- Analytical modelling: Theoretical analysis of the research question is conducted. In terms of energy models, the analytical procedure refers to the decomposition of the energy consumption. Different functions and areas are defined, which are usually represented by an average energy demand.

- Physical modelling: Fundamental physical relationships are described by mathematical equations.

- Simulation approaches: Physical models are solved numerically with simulation tools.

- Empirical modelling: Empirical research is performed via the systematic evaluation of experiences. Empirical models often use statistical methods, which require an explicit mathematical representation for the problem under consideration.

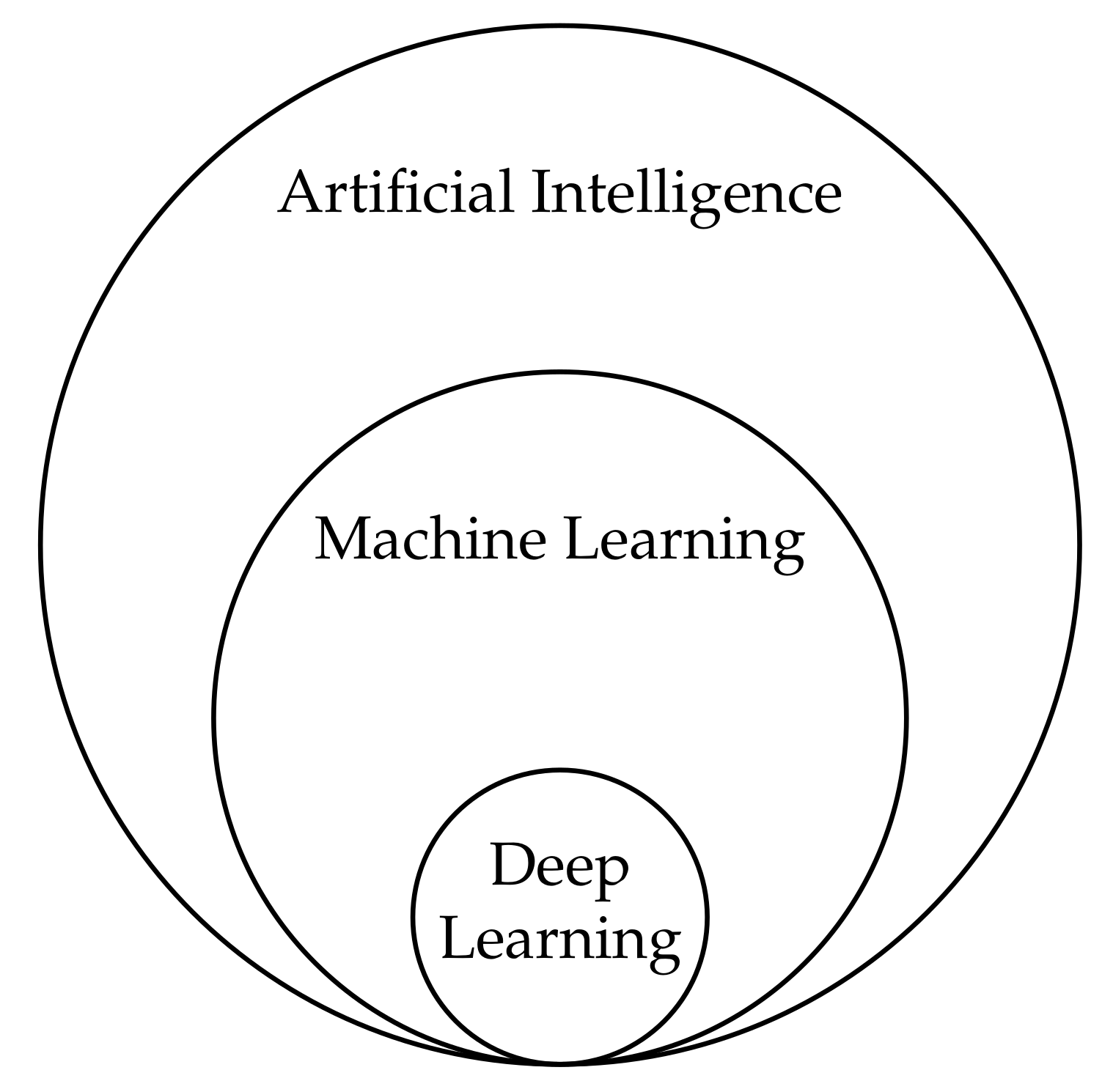

- Artificial Intelligence (AI) approaches: Many different approaches are summarised under the term Artificial Intelligence (AI). In general the term Artificial Intelligence (AI) encompasses three related concepts, which are illustrated in Figure 3. The broadest concept Artificial Intelligence (AI) encompasses the two sub-fields Machine Learning (ML) and Deep Learning (DL), while Deep Learning (DL) is again a sub-field of Machine Learning (ML). Artificial Intelligence (AI) is the study of “intelligent agents”, which refers to any device that perceives its environment and, acting on that basis, carries out actions that maximise the chances of success for a given objective. Machine Learning (ML) is a collection of data-driven algorithms that can learn form data without being explicitly programmed. Deep Learning (DL) refers to the study of Artifical Neural Networks and related machine learning algorithms that contain more than one hidden layer, also known as deep neural networks [12].

4.3. Modelling Focus

4.4. Modelling Horizon

- Prediction: Is the process to predict an unknown value from known inputs. In the case of energy modelling, this means that the available observations at time t of a time series are used to predict the output (energy or load) at time t.

- Forecasting: Is a procedure for making statements about the future. For energy modelling, this means that future values t + x of a time series are estimated based on current and/or past information at time t [16].

4.5. Modelling Perspective

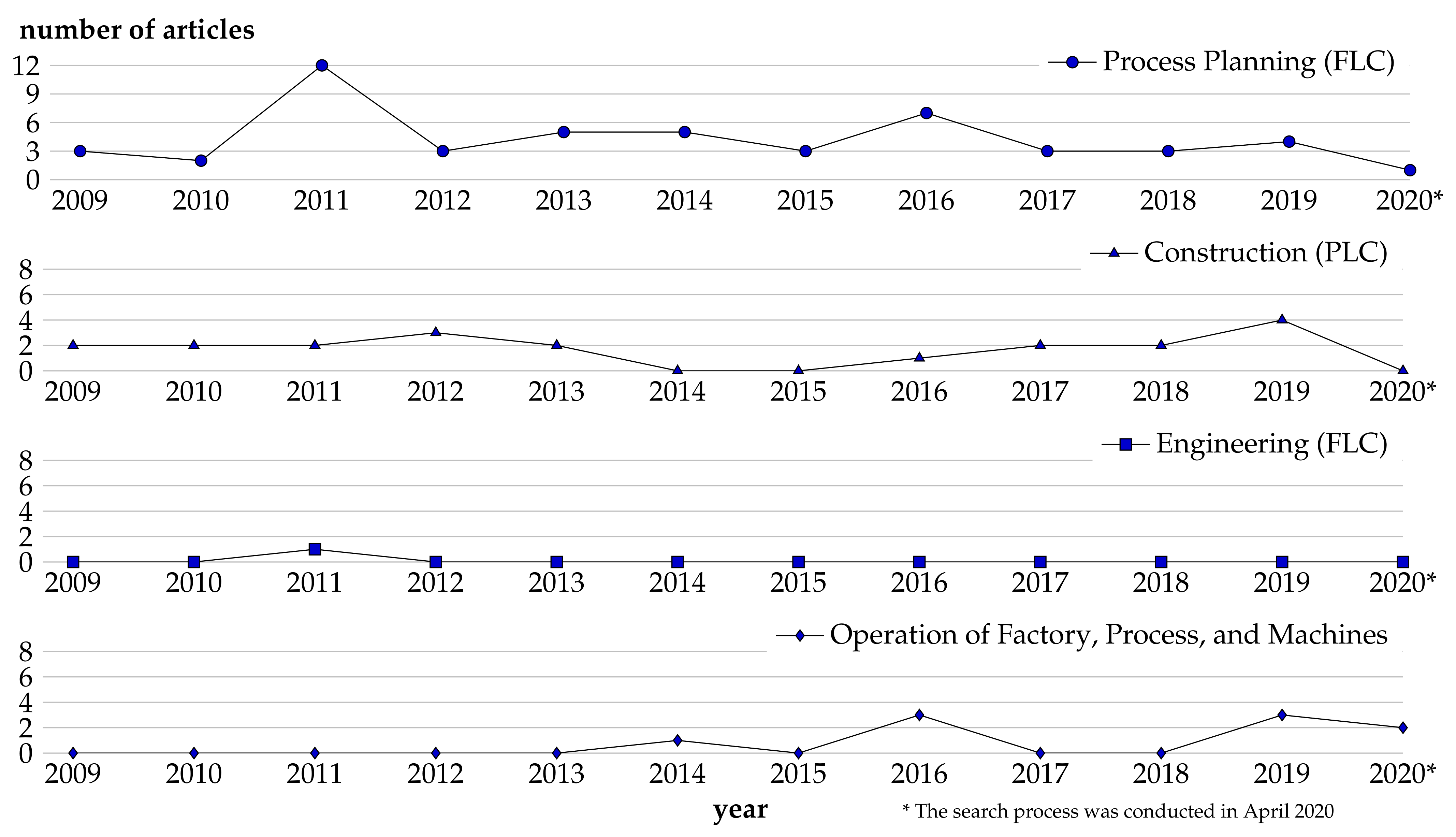

- Engineering (within the Factory Life Cycle (FLC)): Energy models are applied to plan the electrical energy grid of a new factory.

- Process Planning (within the Factory Life Cycle (FLC)): Designing and optimising manufacturing processes in regards to energy consumption is the objective to use energy models in this phase.

- Construction (within the Product Life Cycle (PLC)): Energy models are used to design products that are energy efficient in their production.

- Operation (within the Factory Life Cycle (FLC) and Product Life Cycle (PLC)): The operation phase is where the actual production takes place. Energy models are deployed to optimise the operation in regards to one of the two above mentioned focuses (Energy Efficiency or Flexibility). The optimisation of the operation phase can be distinguished in the operation on factory, machine and process level.

4.6. Modelling Purpose

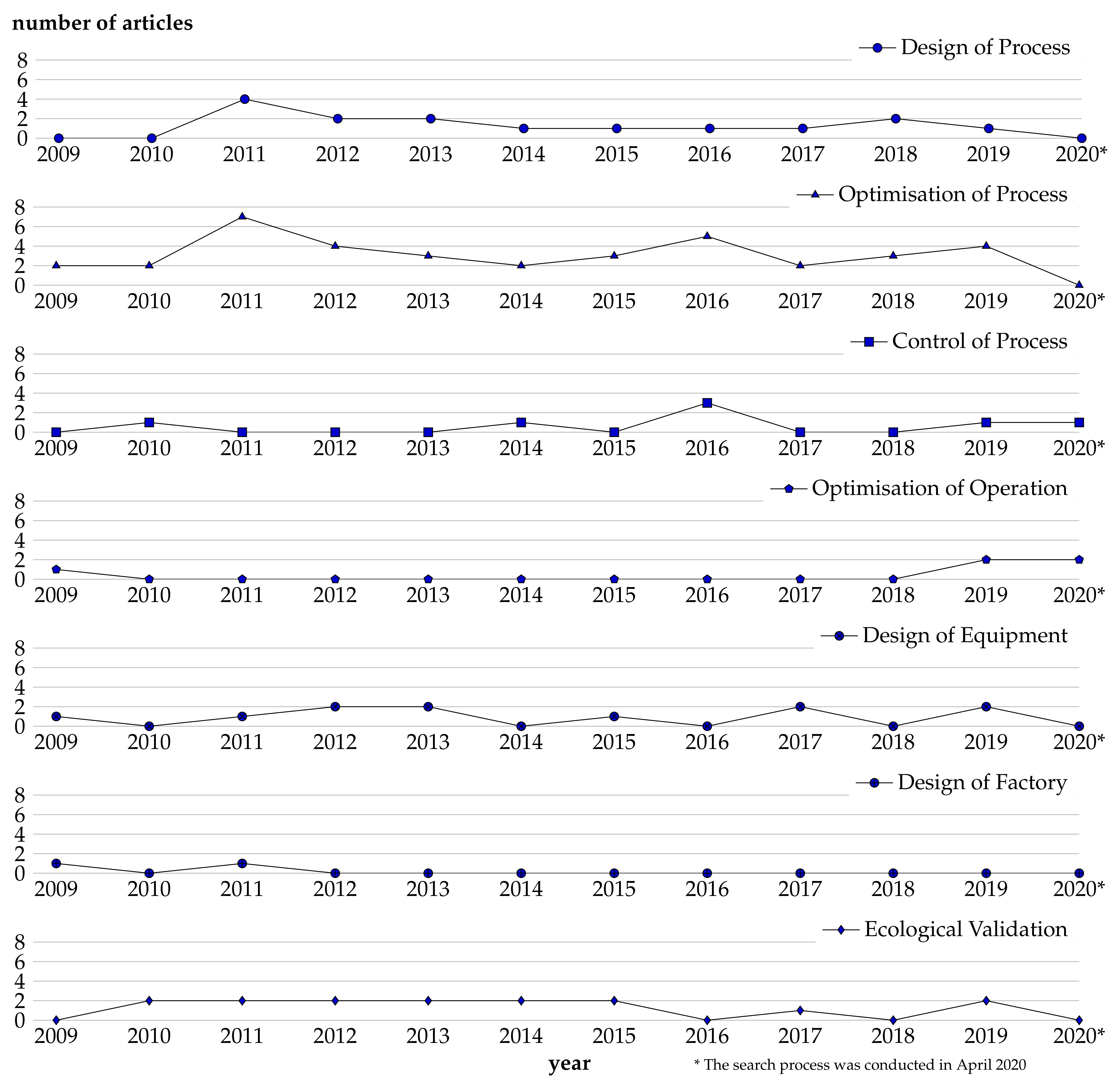

- Design of Factory: The objective is to design the electrical grid of a new factory.

- Optimisation of operation: The operation phase is optimised with respect to different objectives.

- Design of Equipment: The objective is to configure production machines in an energy efficient way.

- Design of Process: Energy models are utilised to design energy efficient production processes.

- Optimisation of Process: The process is optimised in regards to the the most energy efficient process parameters.

- Control of Process: The objective is to control the process in regards to predictive maintenance (tool wear), anomaly detection or energy consumption allowance.

- Ecological Validation: Energy models are used for a life cycle assessment.

4.7. Model Output

- Load: In technical usage, load is the power taken up by a plant or machine, where the power is the quotient of the work performed in a period of time and the period of time [17].

- Energy consumption or Specific Energy (SEC): “Energy consumption is the quantity of particular forms of energy consumed in order to cover energy demand under real conditions” [17] (p. 14). For the Specific Energy (SEC) the energy consumption is related to a suitable functional unit, where the functional unit may be cm3 or kg for instance [17].

5. Analysis and Synthesis

6. Conclusions

Author Contributions

Funding

Conflicts of Interest

Abbreviations

| CO2-eq | Carbon Dioxide Equivalents |

| AI | Artificial Intelligence |

| ANN | Artifical Neural Network |

| DL | Deep Learning |

| FLC | Factory Life Cycle |

| ML | Machine Learning |

| PLC | Product Life Cycle |

| SEC | Specific Energy |

References

- European Commission. The European Green Deal: Communication from the Commission to the European Parliament, the European Council, the Council, the European Economic and Social Comittee and the Committeee of the Regions; European Commission: Brussels, Belgium, 2019. [Google Scholar]

- Ritchie, H.; Roser, M. Emissions by Sector. Our World in Data. 2020. Available online: https://ourworldindata.org/emissions-by-sector#sector-by-sector-where-do-global-greenhouse-gas-emissions-come-from (accessed on 29 December 2020).

- International Energy Agency (IEA). Key World Energy Statistics 2020. Paris. 2020. Available online: https://www.iea.org/reports/key-world-energy-statistics-2020 (accessed on 29 December 2020).

- Hesselbach, J.; Herrmann, C.; Detzer, R.; Martin, L.; Thiede, S.; Ludemann, B. Energy efficiency through optimised coordination of production and technical building services. In LCE 2008: 15th CIRP International Conference on Life Cycle Engineering: Conference Proceedings; The University of New South Wales: Sydney, Australia, 2008; p. 624. [Google Scholar]

- International Energy Agency (IEA). Tracking Power. Paris. 2020. Available online: https://www.iea.org/reports/tracking-power-2020 (accessed on 29 December 2020).

- Beier, J. Simulation Approach towards Energy Flexible Manufacturing Systems; Sustainable Production, Life Cycle Engineering and Management; Springer International Publishing: Cham, Switzerland, 2017. [Google Scholar] [CrossRef]

- Zhao, G.Y.; Liu, Z.Y.; He, Y.; Cao, H.J.; Guo, Y.B. Energy consumption in machining: Classification, prediction, and reduction strategy. Energy 2017, 133, 142–157. [Google Scholar] [CrossRef]

- Reinhardt, H.; Bergmann, J.P.; Münnich, M.; Rein, D.; Putz, M. A survey on modeling and forecasting the energy consumption in discrete manufacturing. Procedia CIRP 2020, 90, 443–448. [Google Scholar] [CrossRef]

- Glock, C.H.; Hochrein, S. Purchasing Organization and Design: A literature review. Bus. Res. 2011, 4, 149–191. [Google Scholar] [CrossRef]

- Reynolds, N.; Simintiras, A.; Vlachou, E. International business negotiations. Int. Mark. Rev. 2003, 20, 231–261. [Google Scholar] [CrossRef]

- Westkämper, E. Digitales Engineering von Fabriken und Prozessen. In Schriftliche Fassung der Vorträge zum Fertigungstechnischen Kolloquium am 10 und 11 September in Stuttgart; [Tagungsband]; Ges. für Fertigungstechnik: Stuttgart, Germany, 2008; Volume 10, pp. 427–452. [Google Scholar]

- Ongsulee, P. Artificial intelligence, machine learning and deep learning. In Proceedings of the 2017 Fifteenth International Conference on ICT and Knowledge Engineering (ICT&KE), Bangkok, Thailand, 22–24 November 2017; pp. 1–6. [Google Scholar] [CrossRef]

- Goodfellow, I.; Bengio, Y.; Courville, A. Deep Learning; Adaptive Computation and Machine Learning; The MIT Press: Cambridge, MA, USA, 2016. [Google Scholar]

- ISO—International Organization for Standardization. ISO 14955-1—Machine Tools—Environmental Evaluation of Machine tools—Part 1: Design Methodology for Energy-Efficient Machine Tools; ISO: Geneva, Switzerland, 2017. [Google Scholar]

- VDI—Verein Deutscher Ingenieure e.V. VDI 5207 Blatt 1—Energieflexible Fabrik: Grundlagen; VDI: Düsseldorf, Germany, 2020. [Google Scholar]

- Box, G.E.P.; Jenkins, G.M.; Reinsel, G.C.; Ljung, G.M. Time Series Analysis: Forecasting and Control; John Wiley & Sons: Hoboken, NJ, USA, 2015. [Google Scholar]

- VDI—Verein Deutscher Ingenieure e.V. VDI 4661—Energiekenngrößen: Definitionen-Begriffe-Methodik; VDI: Düsseldorf, Germany, 2003. [Google Scholar]

- Spehr, J. On Hierarchical Models for Visual Recognition and Learning of Objects, Scenes, and Activities. Ph.D. Thesis, Universitätsbibliothek Braunschweig, Braunschweig, Germany, 2013. [Google Scholar] [CrossRef]

- Bhinge, R.; Park, J.; Law, K.H.; Dornfeld, D.A.; Helu, M.; Rachuri, S. Towards a generalized energy prediction model for machine tools. J. Manuf. Sci. Eng. 2017, 139. [Google Scholar] [CrossRef] [PubMed]

- Dietmair, A.; Verl, A. Energy consumption forecasting and optimisation for tool machines. Energy 2009, 62–67. [Google Scholar] [CrossRef]

- van Luttervelt, C.A.; Childs, T.; Jawahir, I.S.; Klocke, F.; Venuvinod, P.K.; Altintas, Y.; Armarego, E.; Dornfeld, D.; Grabec, I.; Leopold, J.; et al. Present Situation and Future Trends in Modelling of Machining Operations Progress Report of the CIRP Working Group ‘Modelling of Machining Operations’. CIRP Ann. 1998, 47, 587–626. [Google Scholar] [CrossRef]

- Hahn, H.; Meyer-Nieberg, S.; Pickl, S. Electric load forecasting methods: Tools for decision making. Eur. J. Oper. Res. 2009, 199, 902–907. [Google Scholar] [CrossRef]

- Walsh, T. Empirical methods in AI. AI Mag. 1998, 19, 121. [Google Scholar]

- Hong, T.; Fan, S. Probabilistic electric load forecasting: A tutorial review. Int. J. Forecast. 2016, 32, 914–938. [Google Scholar] [CrossRef]

- He, Y.; Wu, P.; Li, Y.; Wang, Y.; Tao, F.; Wang, Y. A generic energy prediction model of machine tools using deep learning algorithms. Appl. Energy 2020, 275. [Google Scholar] [CrossRef]

- Doreth, K. Einsatz Maschineller Lernverfahren zur Lebenszyklusbasierten Energieprognose für Werkzeugmaschinen; TEWISS: Garbsen, Germany, 2019. [Google Scholar]

- Kant, G.; Sangwan, K.S. Predictive Modeling for Power Consumption in Machining Using Artificial Intelligence Techniques. Procedia CIRP 2015, 26, 403–407. [Google Scholar] [CrossRef]

- Abele, E.; Eisele, C.; Schrems, S. Simulation of the Energy Consumption of Machine Tools for a Specific Production Task. In Leveraging Technology for a Sustainable World; Dornfeld, D.A., Linke, B.S., Eds.; Springer: Berlin/Heidelberg, Germany, 2012; Volume 143, pp. 233–237. [Google Scholar] [CrossRef]

- Abeykoon, C.; Kelly, A.L.; Brown, E.C.; Vera-Sorroche, J.; Coates, P.D.; Harkin-Jones, E.; Howell, K.B.; Deng, J.; Li, K.; Price, M. Investigation of the process energy demand in polymer extrusion: A brief review and an experimental study. Appl. Energy 2014, 136, 726–737. [Google Scholar] [CrossRef]

- Aramcharoen, A.; Mativenga, P.T. Critical factors in energy demand modelling for CNC milling and impact of toolpath strategy. J. Clean. Prod. 2014, 78, 63–74. [Google Scholar] [CrossRef]

- Avram, O.I.; Xirouchakis, P. Evaluating the use phase energy requirements of a machine tool system. J. Clean. Prod. 2011, 19, 699–711. [Google Scholar] [CrossRef]

- Balogun, V.A.; Mativenga, P.T. Modelling of direct energy requirements in mechanical machining processes. J. Clean. Prod. 2013, 41, 179–186. [Google Scholar] [CrossRef]

- Bi, Z.M.; Wang, L. Energy Modeling of Machine Tools for Optimization of Machine Setups. IEEE Trans. Autom. Sci. Eng. 2012, 9, 607–613. [Google Scholar] [CrossRef]

- Bi, Z.M.; Wang, L. Optimization of machining processes from the perspective of energy consumption: A case study. J. Manuf. Syst. 2012, 31, 420–428. [Google Scholar] [CrossRef]

- Bornschlegl, M.; Bregulla, M.; Franke, J. Methods-Energy Measurement—An approach for sustainable energy planning of manufacturing technologies. J. Clean. Prod. 2016, 135, 644–656. [Google Scholar] [CrossRef]

- Braun, S.; Heisel, U. Simulation and prediction of process-oriented energy consumption of machine tools. In Leveraging Technology for a Sustainable World; Springer: Berlin/Heidelberg, Germany, 2012; pp. 245–250. [Google Scholar]

- Budinoff, H.; Bhinge, R.; Dornfeld, D. A material-general energy prediction model for milling machine tools. In Proceedings of the 2016 International Symposium on Flexible Automation (ISFA), Cleveland, OH, USA, 1–3 August 2016; pp. 161–164. [Google Scholar]

- Diaz, N.; Choi, S.; Helu, M.; Chen, Y.; Jayanathan, S.; Yasui, Y.; Kong, D.; Pavanaskar, S.; Dornfeld, D. Machine tool design and operation strategies for green manufacturing. Proceedings of 4th CIRP International Conference on High Performance Cutting, Gifu, Japan, 24–26 October 2010. [Google Scholar]

- Diaz, N.; Redelsheimer, E.; Dornfeld, D. Energy Consumption Characterization and Reduction Strategies for Milling Machine Tool Use. In Glocalized Solutions for Sustainability in Manufacturing; Hesselbach, J., Herrmann, C.S., Eds.; Springer: Berlin/Heidelberg, Germany; New York, NY, USA, 2011; Volume 53, pp. 263–267. [Google Scholar] [CrossRef]

- Dietmair, A.; Verl, A. A generic energy consumption model for decision making and energy efficiency optimisation in manufacturing. Int. J. Sustain. Eng. 2009, 2, 123–133. [Google Scholar] [CrossRef]

- Dietrich, B.; Walther, J.; Weigold, M.; Abele, E. Machine learning based very short term load forecasting of machine tools. Appl. Energy 2020, 276, 115440. [Google Scholar] [CrossRef]

- Doreth, K.; Henjes, J.; Kroening, S. Approach to Forecast Energy Consumption of Machine Tools within the Design Phase. Adv. Mater. Res. 2013, 769, 278–284. [Google Scholar] [CrossRef]

- Draganescu, F.; Gheorghe, M.; Doicin, C.V. Models of machine tool efficiency and specific consumed energy. J. Mater. Process. Technol. 2003, 141, 9–15. [Google Scholar] [CrossRef]

- Feng, M.; Hua, Z.; Hon, K.K.B. A Qualitative Model for Predicting Energy Consumption of Rapid Prototyping Processes—A Case of Fused Deposition Modeling Processe. IEEE Access 2019, 7, 184825–184831. [Google Scholar] [CrossRef]

- Goldhahn, L.; Pietschmann, C.; Eckardt, R. Process for the machine specific analysis and modeling of the technology based energetical demand forecasts. Procedia CIRP 2018, 77, 405–408. [Google Scholar] [CrossRef]

- Gutowski, T.; Dahmus, J.; Thiriez, A. Electrical energy requirements for manufacturing processes. In Proceedings of the 13th CIRP International Conference on Life Cycle Engineering, Leuven, Belgium, 31 May–2 June 2006; Volume 31, pp. 623–638. [Google Scholar]

- Al-Hazza, M.H.F.; Adesta, E.Y.; Ali, A.M.; Agusman, D.; Supr, M.Y. Energy Cost Modeling for High Speed Hard Turning. J. Appl. Sci. 2011, 11, 2578–2584. [Google Scholar] [CrossRef]

- He, Y.; Liu, B.; Zhang, X.; Gao, H.; Liu, X. A modeling method of task-oriented energy consumption for machining manufacturing system. J. Clean. Prod. 2012, 23, 167–174. [Google Scholar] [CrossRef]

- He, Y.; Liu, F.; Wu, T.; Zhong, F.P.; Peng, B. Analysis and estimation of energy consumption for numerical control machining. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2012, 226, 255–266. [Google Scholar] [CrossRef]

- Herrmann, C.; Thiede, S. Process chain simulation to foster energy efficiency in manufacturing. CIRP J. Manuf. Sci. Technol. 2009, 1, 221–229. [Google Scholar] [CrossRef]

- Huang, J.; Liu, F.; Xie, J. A method for determining the energy consumption of machine tools in the spindle start-up process before machining. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2016, 230, 1639–1649. [Google Scholar] [CrossRef]

- Imani Asrai, R.; Newman, S.T.; Nassehi, A. A mechanistic model of energy consumption in milling. Int. J. Prod. Res. 2018, 56, 642–659. [Google Scholar] [CrossRef]

- Jia, S.; Tang, R.; Lv, J.; Zhang, Z.; Yuan, Q. Energy modeling for variable material removal rate machining process: An end face turning case. Int. J. Adv. Manuf. Technol. 2016, 85, 2805–2818. [Google Scholar] [CrossRef]

- Kant, G.; Sangwan, K.S. Predictive Modelling for Energy Consumption in Machining Using Artificial Neural Network. Procedia CIRP 2015, 37, 205–210. [Google Scholar] [CrossRef]

- Kara, S.; Li, W. Unit process energy consumption models for material removal processes. CIRP Ann. 2011, 60, 37–40. [Google Scholar] [CrossRef]

- Kong, D.; Choi, S.; Yasui, Y.; Pavanaskar, S.; Dornfeld, D.; Wright, P. Software-based tool path evaluation for environmental sustainability. J. Manuf. Syst. 2011, 30, 241–247. [Google Scholar] [CrossRef]

- Larek, R.; Brinksmeier, E.; Meyer, D.; Pawletta, T.; Hagendorf, O. A discrete-event simulation approach to predict power consumption in machining processes. Prod. Eng. 2011, 5, 575. [Google Scholar] [CrossRef]

- Li, L.; Yan, J.; Xing, Z. Energy requirements evaluation of milling machines based on thermal equilibrium and empirical modelling. J. Clean. Prod. 2013, 52, 113–121. [Google Scholar] [CrossRef]

- Li, W.; Kara, S. An empirical model for predicting energy consumption of manufacturing processes: A case of turning process. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2011, 225, 1636–1646. [Google Scholar] [CrossRef]

- Li, Y.; He, Y.; Wang, Y.; Wang, Y.; Yan, P.; Lin, S. A modeling method for hybrid energy behaviors in flexible machining systems. Energy 2015, 86, 164–174. [Google Scholar] [CrossRef]

- Li, Y.; He, Y.; Wang, Y.; Yan, P.; Liu, X. A framework for characterising energy consumption of machining manufacturing systems. Int. J. Prod. Res. 2014, 52, 314–325. [Google Scholar] [CrossRef]

- Liu, Z.Y.; Guo, Y.B.; Sealy, M.P.; Liu, Z.Q. Energy consumption and process sustainability of hard milling with tool wear progression. J. Mater. Process. Technol. 2016, 229, 305–312. [Google Scholar] [CrossRef]

- Lv, J.; Tang, R.; Jia, S. Therblig-based energy supply modeling of computer numerical control machine tools. J. Clean. Prod. 2014, 65, 168–177. [Google Scholar] [CrossRef]

- Lv, J.; Tang, R.; Tang, W.; Liu, Y.; Zhang, Y.; Jia, S. An investigation into reducing the spindle acceleration energy consumption of machine tools. J. Clean. Prod. 2017, 143, 794–803. [Google Scholar] [CrossRef]

- Mori, M.; Fujishima, M.; Inamasu, Y.; Oda, Y. A study on energy efficiency improvement for machine tools. CIRP Ann. 2011, 60, 145–148. [Google Scholar] [CrossRef]

- Mose, C.; Weinert, N. Evaluation of Process Chains for an Overall Optimization of Manufacturing Energy Efficiency. In Advances in Sustainable and Competitive Manufacturing Systems; Azevedo, A., Ed.; Lecture Notes in Mechanical Engineering; Springer: Cham, Switzerland, 2013; pp. 1639–1651. [Google Scholar]

- Munoz, A.A.; Sheng, P. An analytical approach for determining the environmental impact of machining processes. J. Mater. Process. Technol. 1995, 53, 736–758. [Google Scholar] [CrossRef]

- Peng, T.; Xu, X. An interoperable energy consumption analysis system for CNC machining. J. Clean. Prod. 2017, 140, 1828–1841. [Google Scholar] [CrossRef]

- Quintana, G.; Ciurana, J.; Ribatallada, J. Modelling Power Consumption in Ball-End Milling Operations. Mater. Manuf. Process. 2011, 26, 746–756. [Google Scholar] [CrossRef]

- Rahimifard, S.; Seow, Y.; Childs, T. Minimising Embodied Product Energy to support energy efficient manufacturing. CIRP Ann. 2010, 59, 25–28. [Google Scholar] [CrossRef]

- Rajemi, M.F.; Mativenga, P.T.; Aramcharoen, A. Sustainable machining: Selection of optimum turning conditions based on minimum energy considerations. J. Clean. Prod. 2010, 18, 1059–1065. [Google Scholar] [CrossRef]

- Rief, M. Vorhersagemodell für den Energiebedarf bei der Spanenden Bearbeitung für eine Energieeffiziente Prozessgestaltung; Shaker: Magdeburg, Germany, 2012. [Google Scholar]

- Sato, R.; Shirase, K.; Hayashi, A. Energy Consumption of Feed Drive Systems Based on Workpiece Setting Position in Five-Axis Machining Center. J. Manuf. Sci. Eng. 2018, 140, 25. [Google Scholar] [CrossRef]

- Sealy, M.P.; Liu, Z.Y.; Zhang, D.; Guo, Y.B.; Liu, Z.Q. Energy consumption and modeling in precision hard milling. J. Clean. Prod. 2016, 135, 1591–1601. [Google Scholar] [CrossRef]

- Seow, Y.; Rahimifard, S. A framework for modelling energy consumption within manufacturing systems. CIRP J. Manuf. Sci. Technol. 2011, 4, 258–264. [Google Scholar] [CrossRef]

- Seow, Y.; Rahimifard, S.; Woolley, E. Simulation of energy consumption in the manufacture of a product. Int. J. Comput. Integr. Manuf. 2013, 26, 663–680. [Google Scholar] [CrossRef]

- Shang, Z.; Gao, D.; Jiang, Z.; Lu, Y. Towards less energy intensive heavy-duty machine tools: Power consumption characteristics and energy-saving strategies. Energy 2019, 178, 263–276. [Google Scholar] [CrossRef]

- Shao, H.; Wang, H.L.; Zhao, X.M. A cutting power model for tool wear monitoring in milling. Int. J. Mach. Tools Manuf. 2004, 44, 1503–1509. [Google Scholar] [CrossRef]

- Shin, S.J.; Kim, Y.M.; Meilanitasari, P. A Holonic-Based Self-Learning Mechanism for Energy-Predictive Planning in Machining Processes. Processes 2019, 7, 739–766. [Google Scholar] [CrossRef]

- Sossenheimer, J.; Walther, J.; Fleddermann, J.; Abele, E. A Sensor Reduced Machine Learning Approach for Condition-based Energy Monitoring for Machine Tools. Procedia CIRP 2019, 81, 570–575. [Google Scholar] [CrossRef]

- Sossenheimer, J.; Vetter, O.; Abele, E.; Weigold, M. Hybrid virtual energy metering points—A low-cost energy monitoring approach for production systems based on offline trained prediction models. Procedia CIRP 2020, 93, 1269–1274. [Google Scholar] [CrossRef]

- Su, C.L. Load Estimation in Industrial Power Systems for Expansion Planning. IEEE Trans. Ind. Appl. 2011, 47, 2311–2323. [Google Scholar] [CrossRef]

- Teiwes, H.; Blume, S.; Herrmann, C.; Rössinger, M.; Thiede, S. Energy load profile analysis on machine level. Procedia CIRP 2018, 69, 271–276. [Google Scholar] [CrossRef]

- Verl, A.; Abele, E.; Heisel, U.; Dietmair, A.; Eberspächer, P.; Rahäuser, R.; Schrems, S.; Braun, S. Modular Modeling of Energy Consumption for Monitoring and Control. In Glocalized Solutions for Sustainability in Manufacturing; Hesselbach, J., Herrmann, C.S., Eds.; Springer: Berlin/Heidelberg, Germany; New York, NY, USA, 2011; Volume 28, pp. 341–346. [Google Scholar] [CrossRef]

- Walther, J.; Spanier, D.; Panten, N.; Abele, E. Very short-term load forecasting on factory level—A machine learning approach. Procedia CIRP 2019, 80, 705–710. [Google Scholar] [CrossRef]

- Walther, J.; Dietrich, B.; Abele, E. Generic Machine Learning Approach for very short term load forecasting of production machines. In Proceedings of the International Conference on Applied Energy 2019, Västerås, Sweden, 12–15 August 2019. [Google Scholar]

- Wang, L.; He, Y.; Li, Y.; Wang, Y.; Liu, C.; Liu, X.; Wang, Y. Modeling and analysis of specific cutting energy of whirling milling process based on cutting parameters. Procedia CIRP 2019, 80, 56–61. [Google Scholar] [CrossRef]

- Weinert, N.; Chiotellis, S.; Seliger, G. Methodology for planning and operating energy-efficient production systems. CIRP Ann. 2011, 60, 41–44. [Google Scholar] [CrossRef]

- Wu, Z.; Hobgood, M.; Wolf, M. Energy Mapping and Optimization in Rough Machining of Impellers. In International Manufacturing Science and Engineering Conference; The American Society of Mechanical Engineers: New York, NY, USA, 2016. [Google Scholar] [CrossRef]

- Yi, L.; Krenkel, N.; Aurich, J.C. An energy model of machine tools for selective laser melting. Procedia CIRP 2018, 78, 67–72. [Google Scholar] [CrossRef]

- Yi, L.; Gläßner, C.; Krenkel, N.; Aurich, J.C. Energy simulation of the fused deposition modeling process using machine learning approach. Procedia CIRP 2019, 86, 216–221. [Google Scholar] [CrossRef]

- Yoon, H.S.; Lee, J.Y.; Kim, M.S.; Ahn, S.H. Empirical power-consumption model for material removal in three-axis milling. J. Clean. Prod. 2014, 78, 54–62. [Google Scholar] [CrossRef]

- Yoon, H.S.; Moon, J.S.; Pham, M.Q.; Lee, G.B.; Ahn, S.H. Control of machining parameters for energy and cost savings in micro-scale drilling of PCBs. J. Clean. Prod. 2013, 54, 41–48. [Google Scholar] [CrossRef]

- Zhou, X.; Liu, F.; Cai, W. An energy-consumption model for establishing energy-consumption allowance of a workpiece in a machining system. J. Clean. Prod. 2016, 135, 1580–1590. [Google Scholar] [CrossRef]

- Wang, H.; Lei, Z.; Zhang, X.; Zhou, B.; Peng, J. A review of deep learning for renewable energy forecasting. Energy Convers. Manag. 2019, 198, 111799. [Google Scholar] [CrossRef]

- Chen, C.; Liu, Y.; Kumar, M.; Qin, J. Energy Consumption Modelling Using Deep Learning Technique—A Case Study of EAF. Procedia CIRP 2018, 72, 1063–1068. [Google Scholar] [CrossRef]

- Bianchi, F.M.; Maiorino, E.; Kampffmeyer, M.C.; Rizzi, A.; Jenssen, R. Recurrent Neural Networks for Short-Term Load Forecasting: An Overview and Comparative Analysis; Springer: Cham, Switzerland, 2017. [Google Scholar]

- Fan, C.; Xiao, F.; Zhao, Y. A short-term building cooling load prediction method using deep learning algorithms. Appl. Energy 2017, 195, 222–233. [Google Scholar] [CrossRef]

| Data Base | Publication Titles |

|---|---|

| Science Direct | Procedia CIRP |

| Applied Energy | |

| Energy | |

| International Journal of Machine Tools and Manufacture | |

| International Journal of Mechanical Science | |

| IEEE Xplore | IEEE Access |

| IEEE Transactions on Sustainable Energy | |

| IEEE Transactions on Industry Applications | |

| IET Renewable Power Generation | |

| IEEE Transactions on Components, Packaging and Manufacturing Technology | |

| IEEE Transactions on Industrial Informatics | |

| OCLC Worldcat | No journal restriction possible |

| Dimension | System Boundary | Technique | Focus | Time | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Approach from | Product | Process | Component | Machine | Manufacturing Cells | Factory | Analytical | Physical Modelling | Simulation | Empirical | Artificial Intelligence | Energy Efficiency | Energy Flexibility | Prediction | Forecast | |

| Number of Articles | 4 | 5 | 6 | 50 | 8 | 4 | 19 | 9 | 9 | 22 | 15 | 69 | 3 | 69 | 3 | |

| Abele et al. [28] | • | • | • | • | ||||||||||||

| Abeykoon et al. [29] | • | • | • | • | ||||||||||||

| Aramcharoen and Mativenga [30] | • | • | • | • | ||||||||||||

| Avram and Xirouchakis [31] | • | • | • | • | ||||||||||||

| Balogun and Mativenga [32] | • | • | • | • | ||||||||||||

| Bhinge et al. [19] | • | • | • | • | ||||||||||||

| Bi and Wang [33] | • | • | • | • | ||||||||||||

| Bi and Wang [34] | • | • | • | • | ||||||||||||

| Bornschlegl et al. [35] | • | • | • | • | ||||||||||||

| Braun and Heisel [36] | • | • | • | • | ||||||||||||

| Budinoff et al. [37] | • | • | • | • | ||||||||||||

| Diaz et al. [38] | • | • | • | • | ||||||||||||

| Diaz et al. [39] | • | • | • | • | ||||||||||||

| Dietmair and Verl [20] | • | • | • | • | ||||||||||||

| Dietmair and Verl [40] | • | • | • | • | • | • | ||||||||||

| Dietrich et al. [41] | • | • | • | • | ||||||||||||

| Doreth [26] | • | • | • | • | ||||||||||||

| Doreth et al. [42] | • | • | • | • | ||||||||||||

| Draganescu et al. [43] | • | • | • | • | ||||||||||||

| Feng et al. [44] | • | • | • | • | ||||||||||||

| Goldhahn et al. [45] | • | • | • | • | ||||||||||||

| Gutowski et al. [46] | • | • | • | • | ||||||||||||

| Al-Hazza et al. [47] | • | • | • | • | ||||||||||||

| He et al. [48] | • | • | • | • | ||||||||||||

| He et al. [49] | • | • | • | • | ||||||||||||

| He et al. [25] | • | • | • | • | ||||||||||||

| Herrmann and Thiede [50] | • | • | • | • | ||||||||||||

| Huang et al. [51] | • | • | • | • | ||||||||||||

| Imani Asrai et al. [52] | • | • | • | • | ||||||||||||

| Jia et al. [53] | • | • | • | • | ||||||||||||

| Kant and Sangwan [27] | • | • | • | • | • | |||||||||||

| Kant and Sangwan [54] | • | • | • | • | • | |||||||||||

| Kara and Li [55] | • | • | • | • | ||||||||||||

| Kong et al. [56] | • | • | • | • | ||||||||||||

| Larek et al. [57] | • | • | • | • | ||||||||||||

| Li et al. [58] | • | • | • | • | ||||||||||||

| Li and Kara [59] | • | • | • | • | ||||||||||||

| Li et al. [60] | • | • | • | • | ||||||||||||

| Li et al. [61] | • | • | • | • | ||||||||||||

| Li et al. [62] | • | • | • | • | ||||||||||||

| Li et al. [63] | • | • | • | • | ||||||||||||

| Li et al. [64] | • | • | • | • | ||||||||||||

| Mori et al. [65] | • | • | • | • | ||||||||||||

| Mose and Weinert [66] | • | • | • | • | ||||||||||||

| Munoz and Sheng [67] | • | • | • | • | ||||||||||||

| Peng and Xu [68] | • | • | • | • | • | |||||||||||

| Quintana et al. [69] | • | • | • | • | • | |||||||||||

| Rahimifard et al. [70] | • | • | • | • | ||||||||||||

| Rajemi et al. [71] | • | • | • | • | ||||||||||||

| Rief [72] | • | • | • | • | ||||||||||||

| Sato et al. [73] | • | • | • | • | ||||||||||||

| Sealy et al. [74] | • | • | • | • | ||||||||||||

| Seow and Rahimifard [75] | • | • | • | • | • | |||||||||||

| Seow et al. [76] | • | • | • | • | ||||||||||||

| Shang et al. [77] | • | • | • | • | ||||||||||||

| Shao et al. [78] | • | • | • | • | ||||||||||||

| Shin et al. [79] | • | • | • | • | ||||||||||||

| Sossenheimer et al. [80] | • | • | • | • | ||||||||||||

| Sossenheimer et al. [81] | • | • | • | • | ||||||||||||

| Su [82] | • | • | • | • | ||||||||||||

| Teiwes et al. [83] | • | • | • | • | ||||||||||||

| Verl et al. [84] | • | • | • | • | ||||||||||||

| Walther et al. [85] | • | • | • | • | ||||||||||||

| Walther et al. [86] | • | • | • | • | ||||||||||||

| Wang et al. [87] | • | • | • | • | ||||||||||||

| Weinert et al. [88] | • | • | • | • | ||||||||||||

| Wu et al. [89] | • | • | • | • | ||||||||||||

| Yi et al. [90] | • | • | • | • | ||||||||||||

| Yi et al. [91] | • | • | • | • | ||||||||||||

| Yoon et al. [92] | • | • | • | • | ||||||||||||

| Yoon et al. [93] | • | • | • | • | ||||||||||||

| Zhou et al. [94] | • | • | • | • | ||||||||||||

| Dimension | Perspective | Modelling Purpose | Output | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Approah from | Process Planning (FLC) | Construction (PLC) | Engineering (FLC) | Operation of Factory | Operation of Machines | Operation of Process | Design of Processes | Optimisation of Processes | Control of Processes | Optimisation of Operation | Design of Equipment | Design of Factory | Ecological Validation | Energy/SEC | Power | |

| Number of Articles | 57 | 20 | 1 | 1 | 5 | 4 | 15 | 40 | 8 | 5 | 11 | 2 | 19 | 53 | 19 | |

| Abele et al. [28] | • | • | • | |||||||||||||

| Abeykoon et al. [29] | • | • | • | • | ||||||||||||

| Aramcharoen and Mativenga [30] | • | • | • | • | • | |||||||||||

| Avram and Xirouchakis [31] | • | • | • | • | ||||||||||||

| Balogun and Mativenga [32] | • | • | • | • | • | • | ||||||||||

| Bhinge et al. [19] | • | • | • | |||||||||||||

| Bi and Wang [33] | • | • | • | • | ||||||||||||

| Bi and Wang [34] | • | • | • | • | ||||||||||||

| Bornschlegl et al. [35] | • | • | • | • | ||||||||||||

| Braun and Heisel [36] | • | • | • | • | • | |||||||||||

| Budinoff et al. [37] | • | • | • | • | ||||||||||||

| Diaz et al. [38] | • | • | • | • | • | |||||||||||

| Diaz et al. [39] | • | • | • | |||||||||||||

| Dietmair and Verl [20] | • | • | • | • | • | |||||||||||

| Dietmair and Verl [40] | • | • | • | • | • | |||||||||||

| Dietrich et al. [41] | • | • | • | |||||||||||||

| Doreth [26] | • | • | • | • | ||||||||||||

| Doreth et al. [42] | • | • | • | |||||||||||||

| Draganescu et al. [43] | • | • | • | |||||||||||||

| Feng et al. [44] | • | • | • | • | ||||||||||||

| Goldhahn et al. [45] | • | • | • | |||||||||||||

| Gutowski et al. [46] | • | • | • | • | ||||||||||||

| Al-Hazza et al. [47] | • | • | • | |||||||||||||

| He et al. [48] | • | • | • | |||||||||||||

| He et al. [49] | • | • | • | |||||||||||||

| He et al. [25] | • | • | • | |||||||||||||

| Herrmann and Thiede [50] | • | • | • | |||||||||||||

| Huang et al. [51] | • | • | • | |||||||||||||

| Imani Asrai et al. [52] | • | • | • | |||||||||||||

| Jia et al. [53] | • | • | • | |||||||||||||

| Kant and Sangwan [27] | • | • | • | • | ||||||||||||

| Kant and Sangwan [54] | • | • | • | • | ||||||||||||

| Kara and Li [55] | • | • | • | |||||||||||||

| Kong et al. [56] | • | • | • | |||||||||||||

| Larek et al. [57] | • | • | • | • | • | • | ||||||||||

| Li et al. [58] | • | • | • | |||||||||||||

| Li and Kara [59] | • | • | • | |||||||||||||

| Li et al. [60] | • | • | • | • | ||||||||||||

| Li et al. [61] | • | • | • | |||||||||||||

| Li et al. [62] | • | • | • | • | • | |||||||||||

| Li et al. [63] | • | • | • | |||||||||||||

| Li et al. [64] | • | • | • | • | • | |||||||||||

| Mori et al. [65] | • | • | • | |||||||||||||

| Mose and Weinert [66] | • | • | • | |||||||||||||

| Munoz and Sheng [67] | • | • | • | • | ||||||||||||

| Peng and Xu [68] | • | • | • | • | • | • | ||||||||||

| Quintana et al. [69] | • | • | • | |||||||||||||

| Rahimifard et al. [70] | • | • | • | |||||||||||||

| Rajemi et al. [71] | • | • | • | • | ||||||||||||

| Rief [72] | • | • | • | |||||||||||||

| Sato et al. [73] | • | • | • | |||||||||||||

| Sealy et al. [74] | • | • | • | • | • | |||||||||||

| Seow and Rahimifard [75] | • | • | • | |||||||||||||

| Seow et al. [76] | • | • | • | |||||||||||||

| Shang et al. [77] | • | • | • | • | • | |||||||||||

| Shao et al. [78] | • | • | • | • | • | |||||||||||

| Shin et al. [79] | • | • | • | |||||||||||||

| Sossenheimer et al. [80] | • | • | • | |||||||||||||

| Sossenheimer et al. [81] | • | • | • | |||||||||||||

| Su [82] | • | • | • | |||||||||||||

| Teiwes et al. [83] | • | • | • | |||||||||||||

| Verl et al. [84] | • | • | • | |||||||||||||

| Walther et al. [85] | • | • | • | |||||||||||||

| Walther et al. [86] | • | • | • | |||||||||||||

| Wang et al. [87] | • | • | • | |||||||||||||

| Weinert et al. [88] | • | • | • | |||||||||||||

| Wu et al. [89] | • | • | • | |||||||||||||

| Yi et al. [90] | • | • | • | |||||||||||||

| Yi et al. [91] | • | • | • | • | ||||||||||||

| Yoon et al. [92] | • | • | • | |||||||||||||

| Yoon et al. [93] | • | • | • | |||||||||||||

| Zhou et al. [94] | • | • | • | |||||||||||||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Walther, J.; Weigold, M. A Systematic Review on Predicting and Forecasting the Electrical Energy Consumption in the Manufacturing Industry. Energies 2021, 14, 968. https://doi.org/10.3390/en14040968

Walther J, Weigold M. A Systematic Review on Predicting and Forecasting the Electrical Energy Consumption in the Manufacturing Industry. Energies. 2021; 14(4):968. https://doi.org/10.3390/en14040968

Chicago/Turabian StyleWalther, Jessica, and Matthias Weigold. 2021. "A Systematic Review on Predicting and Forecasting the Electrical Energy Consumption in the Manufacturing Industry" Energies 14, no. 4: 968. https://doi.org/10.3390/en14040968

APA StyleWalther, J., & Weigold, M. (2021). A Systematic Review on Predicting and Forecasting the Electrical Energy Consumption in the Manufacturing Industry. Energies, 14(4), 968. https://doi.org/10.3390/en14040968