Performance Analysis of Modular Multilevel Converter and Modular Multilevel Series Converter under Variable-Frequency Operation Regarding Submodule-Capacitor Voltage Ripple

Abstract

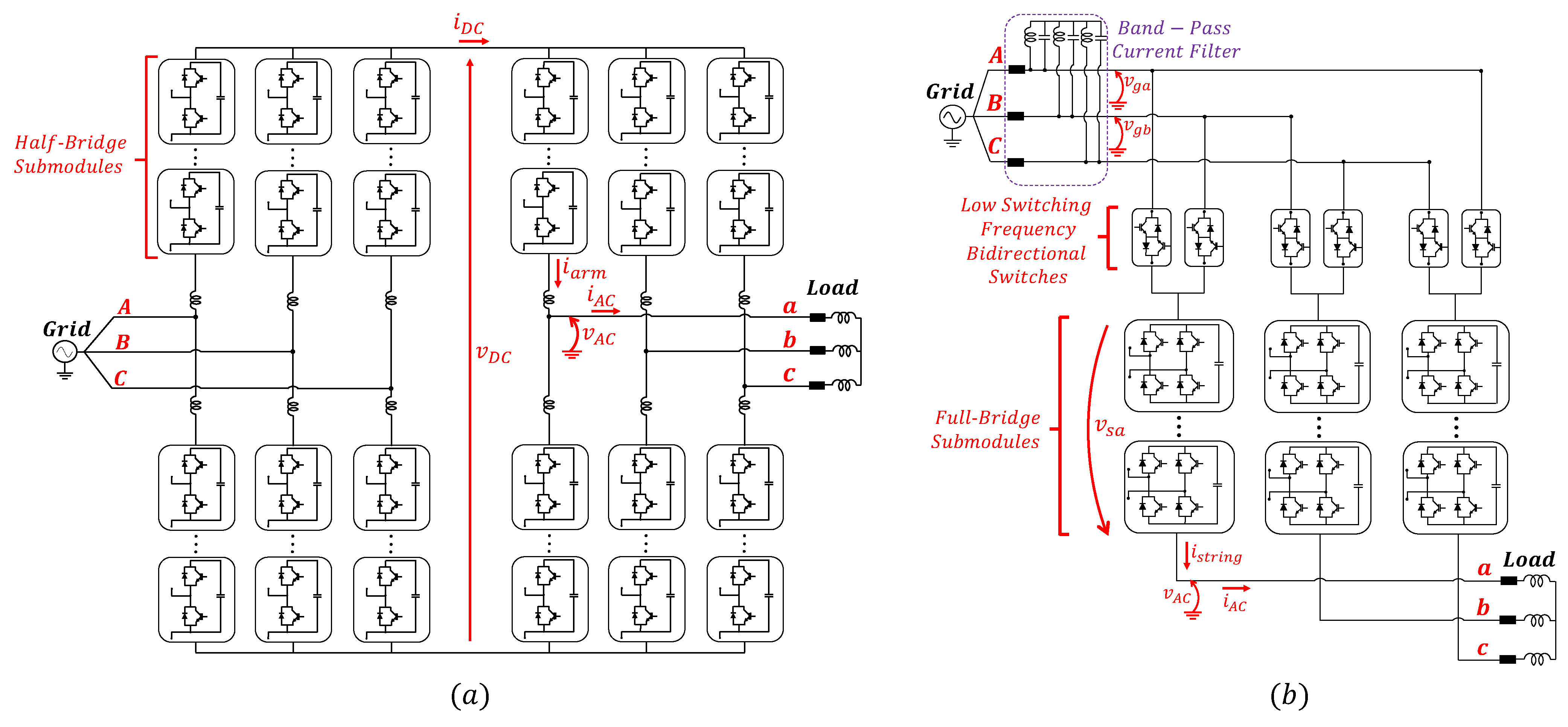

1. Introduction

2. Analytical Description of Submodule-Capacitor Voltage Ripple

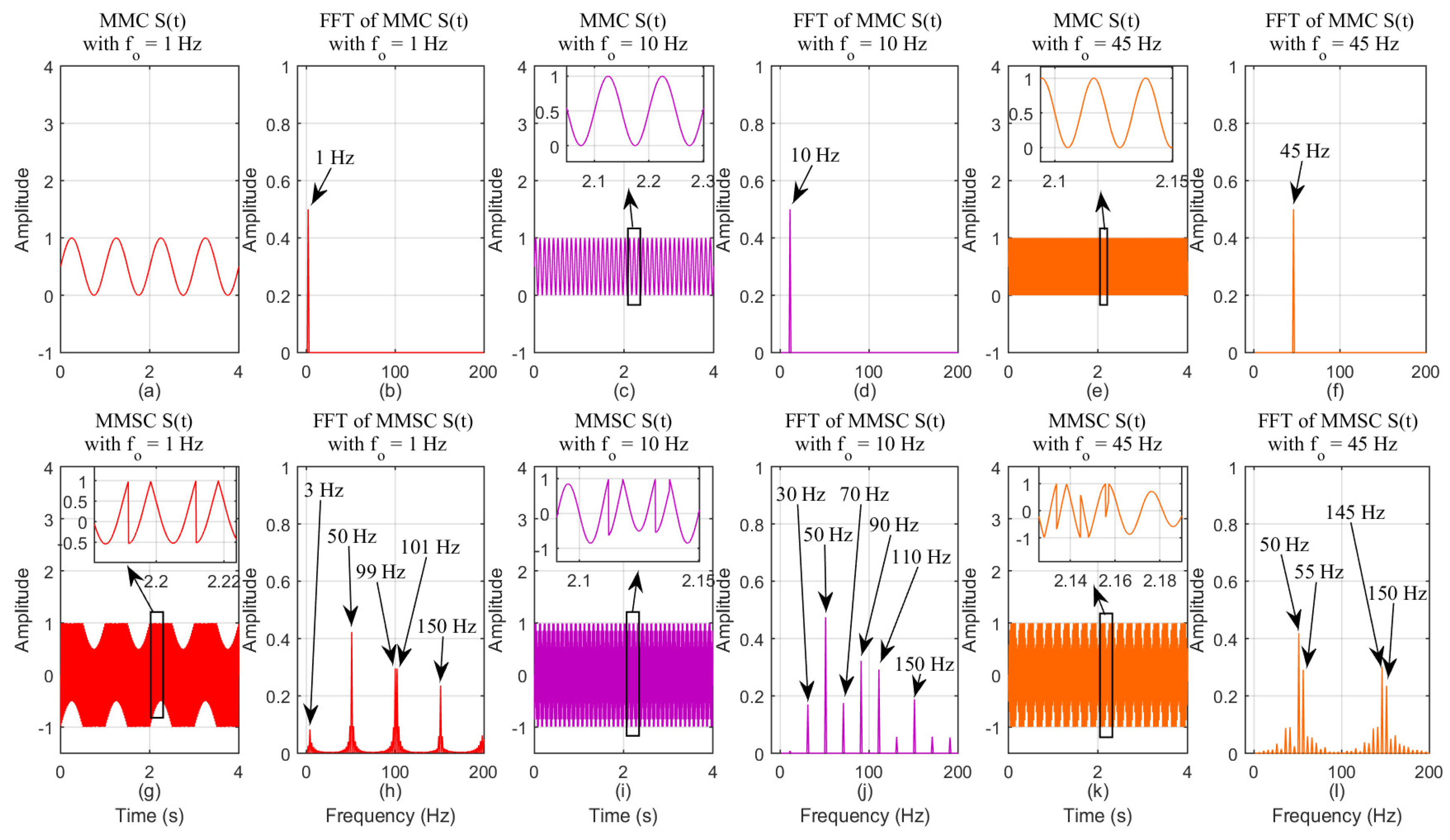

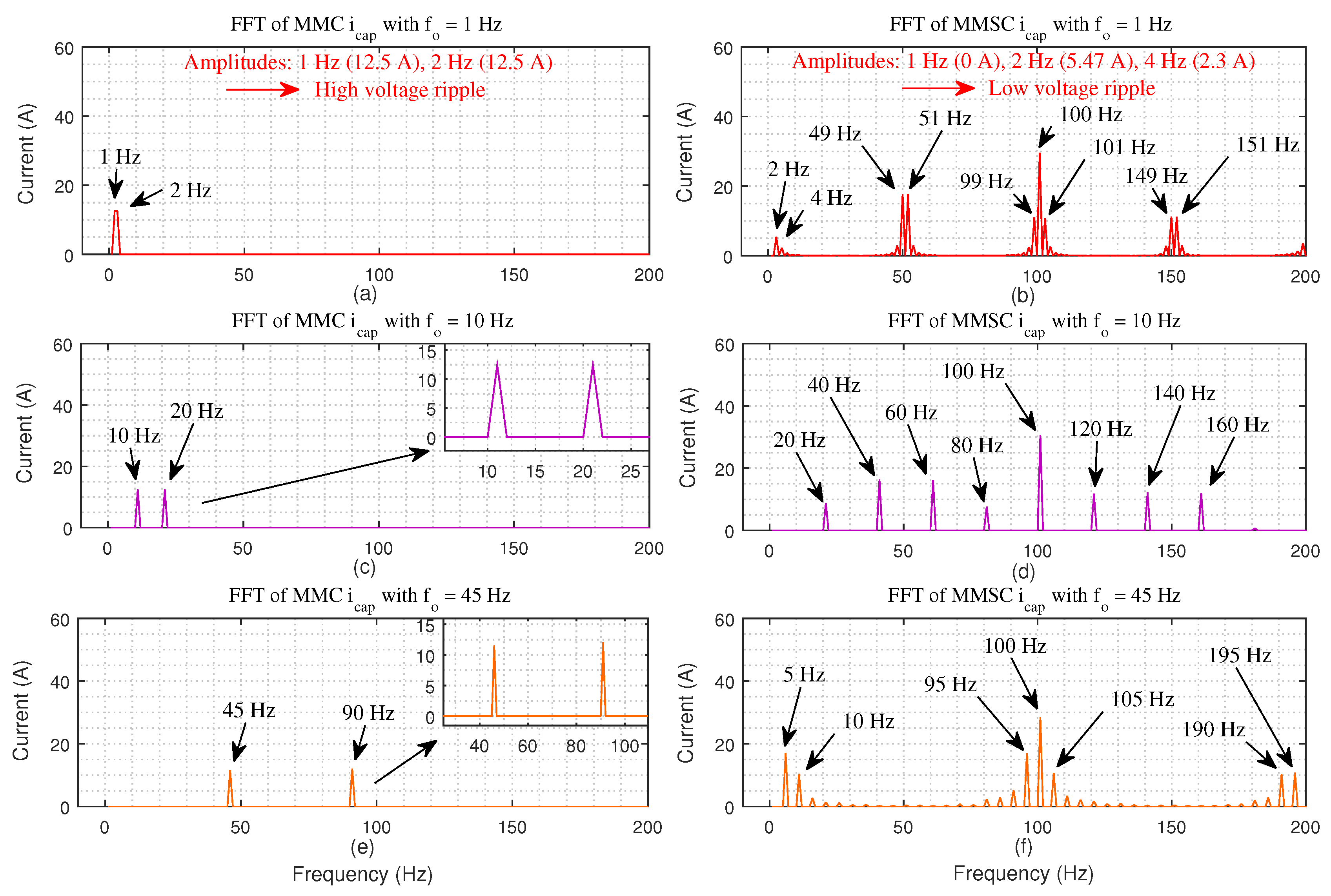

2.1. MMC

2.2. MMSC

3. Simulation Results

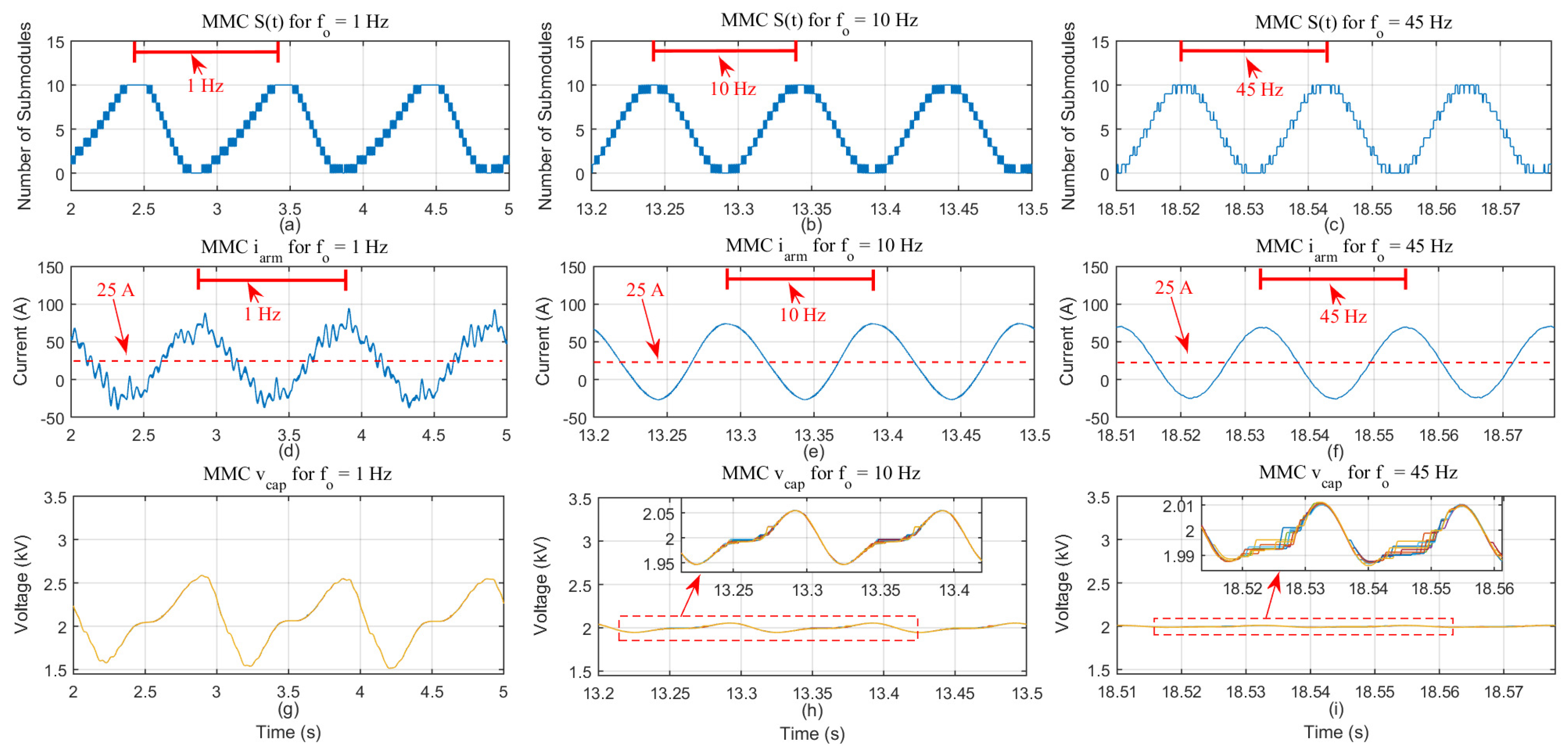

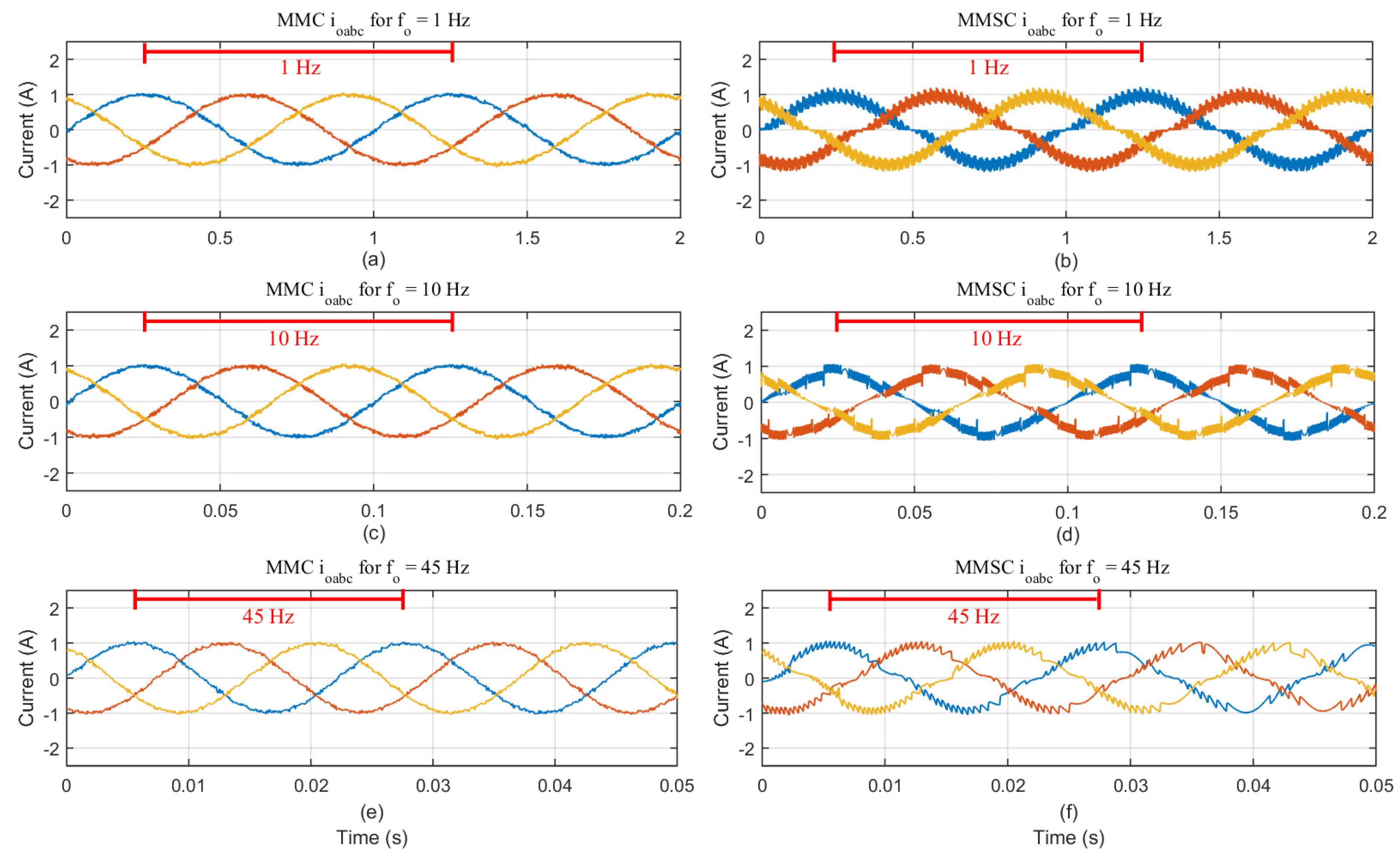

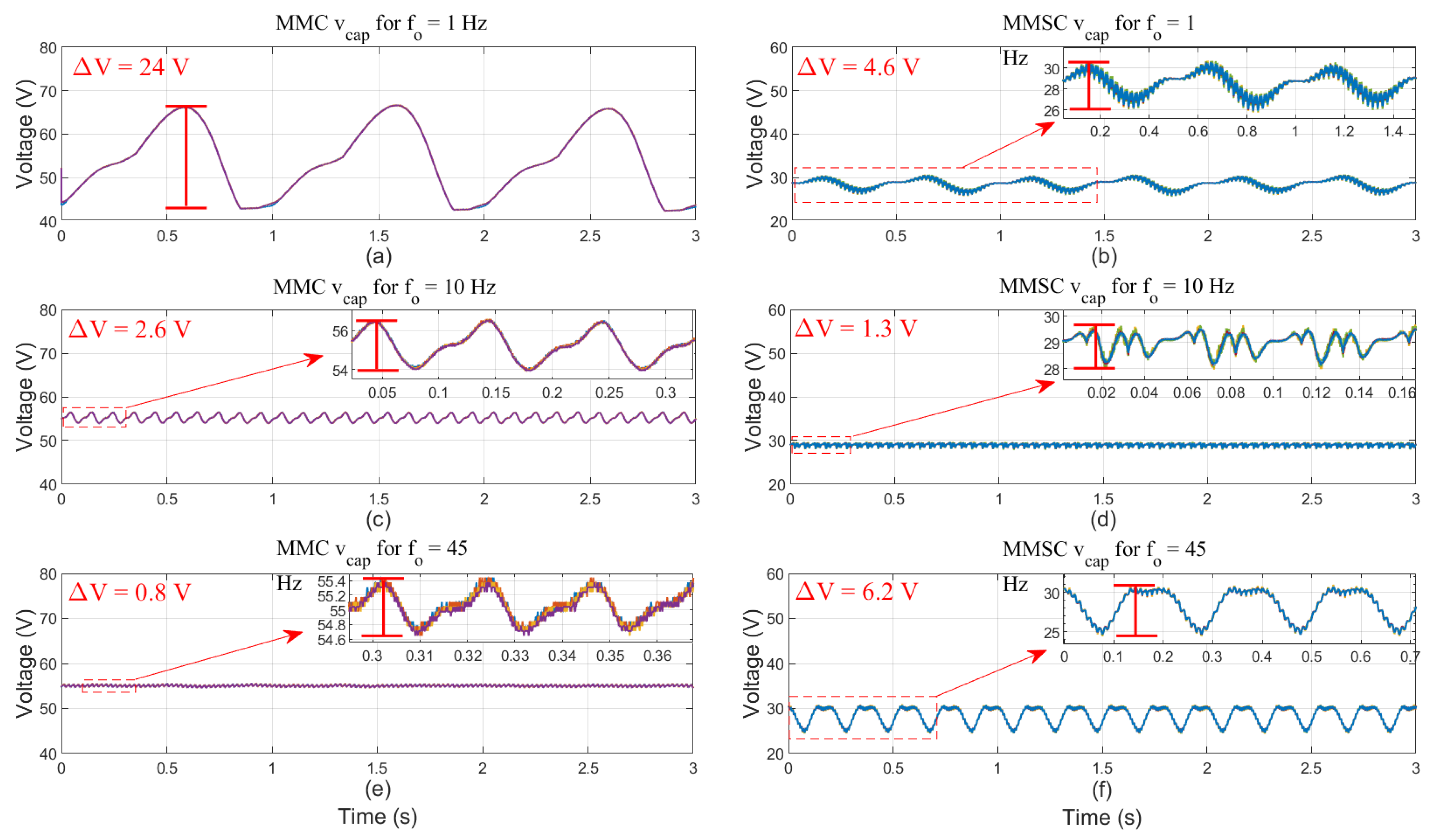

3.1. MMC

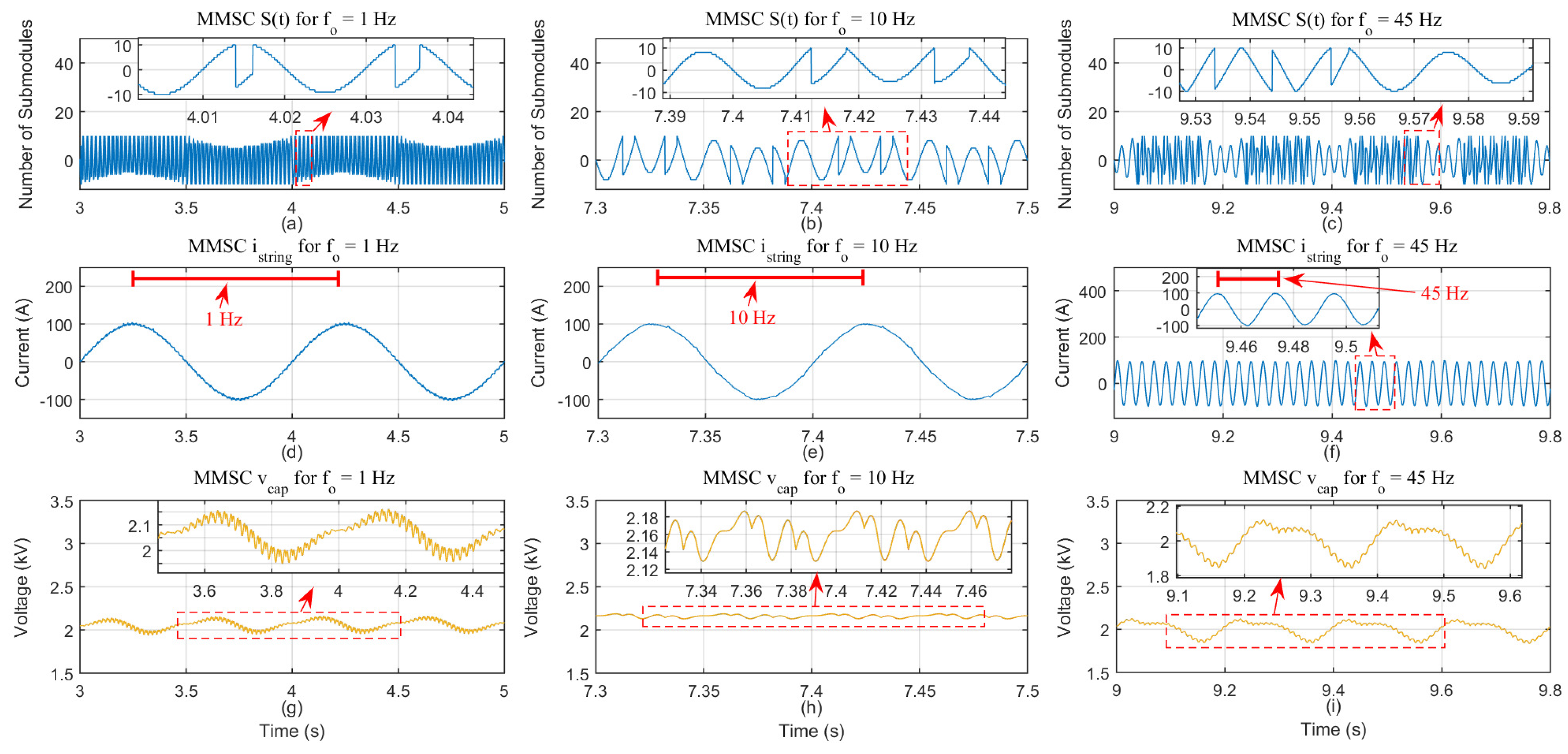

3.2. MMSC

4. Experimental Results

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Diaz, M.; Cárdenas, R.; Espinoza, M.; Mora, A.; Wheeler, P. Modelling and control of the modular multilevel matrix converter and its application to wind energy conversion systems. In Proceedings of the IECON 2016—42nd Annual Conference of the IEEE Industrial Electronics Society, Florence, Italy, 23–26 October 2016. [Google Scholar] [CrossRef]

- Diaz, M.; Cardenas, R.; Espinoza, M.; Rojas, F.; Mora, A.; Clare, J.C.; Wheeler, P. Control of Wind Energy Conversion Systems Based on the Modular Multilevel Matrix Converter. IEEE Trans. Ind. Electron. 2017, 64. [Google Scholar] [CrossRef]

- Fichaux, N.; Beurskens, J.; Jensen, P.H.; Wilkes, J.; Frandsen, S.; Sorensen, J.D.; Eecen, P.; Malamatenios, C.; Gomez, J.A.; Hemmelmann, J.; et al. UPWIND—Design Limits and Solutions for Very Large Wind Turbines; Technical Report; The European Wind Energy Association: Brussels, Belgium, 2011. [Google Scholar]

- Madariaga, A.; Martín, J.L.; Zamora, I.; Martínez De Alegría, I.; Ceballos, S. Technological trends in electric topologies for offshore wind power plants. Renew. Sustain. Energy Rev. 2013, 24, 32–44. [Google Scholar] [CrossRef]

- Iversen, T.M.; Gjerde, S.S.; Undeland, T. Multilevel converters for a 10 MW, 100 kV transformer-less offshore wind generator system. In Proceedings of the 2013 15th European Conference on Power Electronics and Applications, EPE 2013, Lille, France, 2–6 September 2013; pp. 1–10. [Google Scholar] [CrossRef]

- Basić, M.; Silva, P.C.O.; Dujić, D. High Power Electronics Innovation Perspectives for Pumped Storage Power Plants. In Proceedings of the Hydro, Gdansk, Poland, 15–17 October 2018; Available online: https://www.semanticscholar.org/paper/High-Power-Electronics-Innovation-Perspectives-for-Basi%C4%87-Silva/df0908790e65a6137de2a1827629b82736d12ebe (accessed on 18 January 2021).

- Vasiladiotis, M.; Baumann, R.; Häderli, C.; Steinke, J. IGCT-based Direct AC/AC Modular Multilevel Converters for Pumped Hydro Storage Plants. In Proceedings of the 2018 IEEE Energy Conversion Congress and Exposition (ECCE), Portland, OR, USA, 23–27 September 2018. [Google Scholar]

- Steimer, P.K.; Senturk, O.; Aubert, S.; Linder, S. Converter-fed synchronous machine for pumped hydro storage plants. In Proceedings of the 2014 IEEE Energy Conversion Congress and Exposition, ECCE 2014, Pittsburgh, PA, USA, 14–18 September 2014; pp. 4561–4567. [Google Scholar] [CrossRef]

- Korn, A.J.; Winkelnkemper, M.; Steimer, P. Low output frequency operation of the Modular Multi-Level Converter. In Proceedings of the 2010 IEEE Energy Conversion Congress and Exposition, ECCE 2010, Atlanta, GA, USA, 12–16 September 2010; pp. 3993–3997. [Google Scholar] [CrossRef]

- Hagiwara, M.; Hasegawa, I.; Akagi, H. Start-up and low-speed operation of an electric motor driven by a modular multilevel cascade inverter. IEEE Trans. Ind. Appl. 2013, 49, 1556–1565. [Google Scholar] [CrossRef]

- Antonopoulos, A.; Ängquist, L.; Norrga, S.; Ilves, K.; Harnefors, L.; Nee, H.P. Modular multilevel converter AC motor drives with constant torque from zero to nominal speed. IEEE Trans. Ind. Appl. 2014, 50, 1982–1993. [Google Scholar] [CrossRef]

- Okazaki, Y.; Hagiwara, M.; Akagi, H. A speed-sensorless start-up method of an induction motor driven by a modular multilevel cascade inverter (MMCI-DSCC). IEEE Trans. Ind. Appl. 2014, 50, 2671–2680. [Google Scholar] [CrossRef]

- Soares, M.; Watanabe, E.H. MMC Applied to Pumped Hydro Storage using a Differentiable Approximation of a Square Wave as Common-Mode Voltage during Low-Frequency Operation. In Proceedings of the 2020 IEEE 21st Workshop on Control and Modeling for Power Electronics, COMPEL 2020, Aalborg, Denmark, 9–12 November 2020. [Google Scholar] [CrossRef]

- Du, S.; Dekka, A.; Wu, B.; Zargari, N. Modular Multilevel Converters Analysis, Control and Applications; Wiley: Hoboken, NJ, USA, 2018. [Google Scholar]

- Hammond, P.W. A new approach to enhance power quality for medium voltage AC drives. IEEE Trans. Ind. Appl. 1997, 33, 202–208. [Google Scholar] [CrossRef]

- Kawamura, W.; Hagiwara, M.; Akagi, H. Control and experiment of a modular multilevel cascade converter based on triple-star bridge cells. IEEE Trans. Ind. Appl. 2014, 50, 3536–3548. [Google Scholar] [CrossRef]

- Fan, B.; Wang, K.; Wheeler, P.; Gu, C.; Li, Y. A Branch Current Reallocation Based Energy Balancing Strategy for the Modular Multilevel Matrix Converter Operating Around Equal Frequency. IEEE Trans. Power Electron. 2018, 33, 1105–1117. [Google Scholar] [CrossRef]

- Kawamura, W.; Chen, K.L.; Hagiwara, M.; Akagi, H. A Low-Speed, High-Torque Motor Drive Using a Modular Multilevel Cascade Converter Based on Triple-Star Bridge Cells (MMCC-TSBC). IEEE Trans. Ind. Appl. 2015, 51, 3965–3974. [Google Scholar] [CrossRef]

- Fan, B.; Wang, K.; Wheeler, P.; Gu, C.; Li, Y. An Optimal Full Frequency Control Strategy for the Modular Multilevel Matrix Converter Based on Predictive Control. IEEE Trans. Power Electron. 2018, 33, 6608–6621. [Google Scholar] [CrossRef]

- Diab, M.S.; Massoud, A.M.; Ahmed, S.; Williams, B.W. A Dual Modular Multilevel Converter With High-Frequency Magnetic Links Between Submodules for MV Open-End Stator Winding Machine Drives. IEEE Trans. Power Electron. 2018, 33, 5142–5159. [Google Scholar] [CrossRef]

- Thitichaiworakorn, N.; Hagiwara, M.; Akagi, H. A Medium-Voltage Large Wind Turbine Generation System Using an AC/AC Modular Multilevel Cascade Converter. IEEE J. Emerg. Sel. Top. Power Electron. 2016, 4, 534–546. [Google Scholar] [CrossRef]

- Gontijo, G.; Wang, S.; Kerekes, T.; Teodorescu, R. New AC–AC Modular Multilevel Converter Solution for Medium-Voltage Machine-Drive Applications: Modular Multilevel Series Converter. Energies 2020, 13, 3664. [Google Scholar] [CrossRef]

| Peak-To-Peak Voltage () | |

|---|---|

| 1 Hz | 1 kV |

| 10 Hz | 0.1 kV |

| 45 Hz | 0.02 kV |

| Hz | ||

| Harmonic Component | Hz | Hz |

| Voltage Peak Value | 392 V | 184.5 V |

| Current Peak Value | 12.32 A | 11.6 A |

| Hz | ||

| Harmonic Component | Hz | Hz |

| Voltage Peak Value | 38 V | 17.8 V |

| Current Peak Value | 11.94 A | 11.18 A |

| Hz | ||

| Harmonic Component | Hz | Hz |

| Voltage Peak Value | 9.6 V | 4.2 V |

| Current Peak Value | 13.57 A | 11.88 A |

| Peak-To-Peak Voltage () | |

|---|---|

| 1 Hz | 0.2 kV |

| 10 Hz | 0.06 kV |

| 45 Hz | 0.28 kV |

| Hz | ||

| Harmonic Component | Hz | Hz |

| Voltage Peak Value | 69.7 V | 18.4 V |

| Current Peak Value | 4.38 A | 2.31 A |

| Hz | ||

| Harmonic Component | Hz | Hz |

| Voltage Peak Value | 13 V | 13 V |

| Current Peak Value | 8.17 A | 16.34 A |

| Hz | ||

| Harmonic Component | Hz | Hz |

| Voltage Peak Value | 105.5 V | 42 V |

| Current Peak Value | 16.57 A | 13.19 A |

| MMC | MMSC | |

|---|---|---|

| Peak-To-Peak Voltage () | Peak-To-Peak Voltage () | |

| 1 Hz | 24 V | 4.6 V |

| 10 Hz | 2.6 V | 1.3 V |

| 45 Hz | 0.8 V | 6.2 V |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gontijo, G.; Wang, S.; Kerekes, T.; Teodorescu, R. Performance Analysis of Modular Multilevel Converter and Modular Multilevel Series Converter under Variable-Frequency Operation Regarding Submodule-Capacitor Voltage Ripple. Energies 2021, 14, 776. https://doi.org/10.3390/en14030776

Gontijo G, Wang S, Kerekes T, Teodorescu R. Performance Analysis of Modular Multilevel Converter and Modular Multilevel Series Converter under Variable-Frequency Operation Regarding Submodule-Capacitor Voltage Ripple. Energies. 2021; 14(3):776. https://doi.org/10.3390/en14030776

Chicago/Turabian StyleGontijo, Gustavo, Songda Wang, Tamas Kerekes, and Remus Teodorescu. 2021. "Performance Analysis of Modular Multilevel Converter and Modular Multilevel Series Converter under Variable-Frequency Operation Regarding Submodule-Capacitor Voltage Ripple" Energies 14, no. 3: 776. https://doi.org/10.3390/en14030776

APA StyleGontijo, G., Wang, S., Kerekes, T., & Teodorescu, R. (2021). Performance Analysis of Modular Multilevel Converter and Modular Multilevel Series Converter under Variable-Frequency Operation Regarding Submodule-Capacitor Voltage Ripple. Energies, 14(3), 776. https://doi.org/10.3390/en14030776