Experimental Study on Infrared Temperature Characteristics and Failure Modes of Marble with Prefabricated Holes under Uniaxial Compression

Abstract

1. Introduction

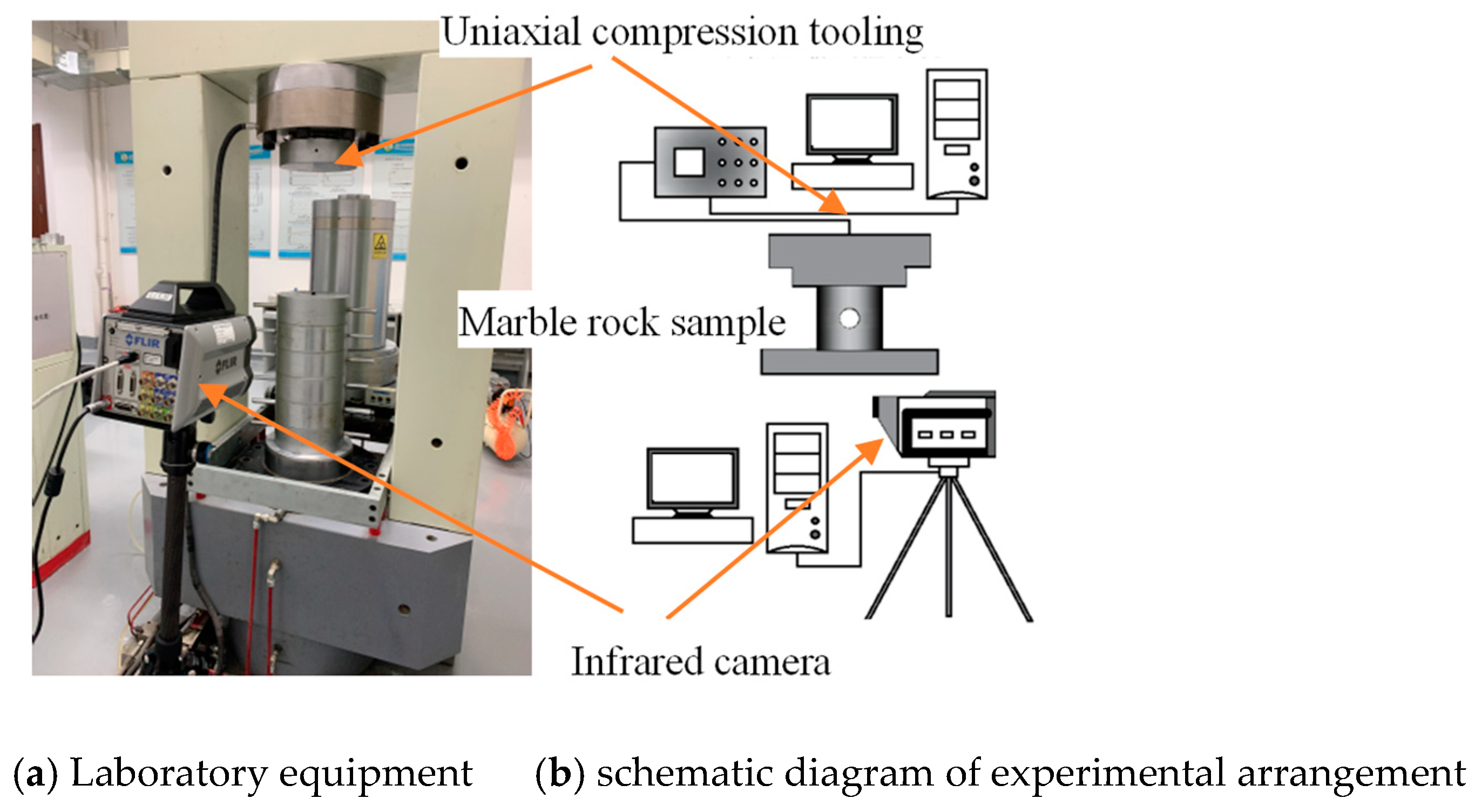

2. Experimental

2.1. Testing Machine

2.2. Testing Program

2.3. Principle of Infrared Thermal Imaging

3. Analysis of Experimental Results

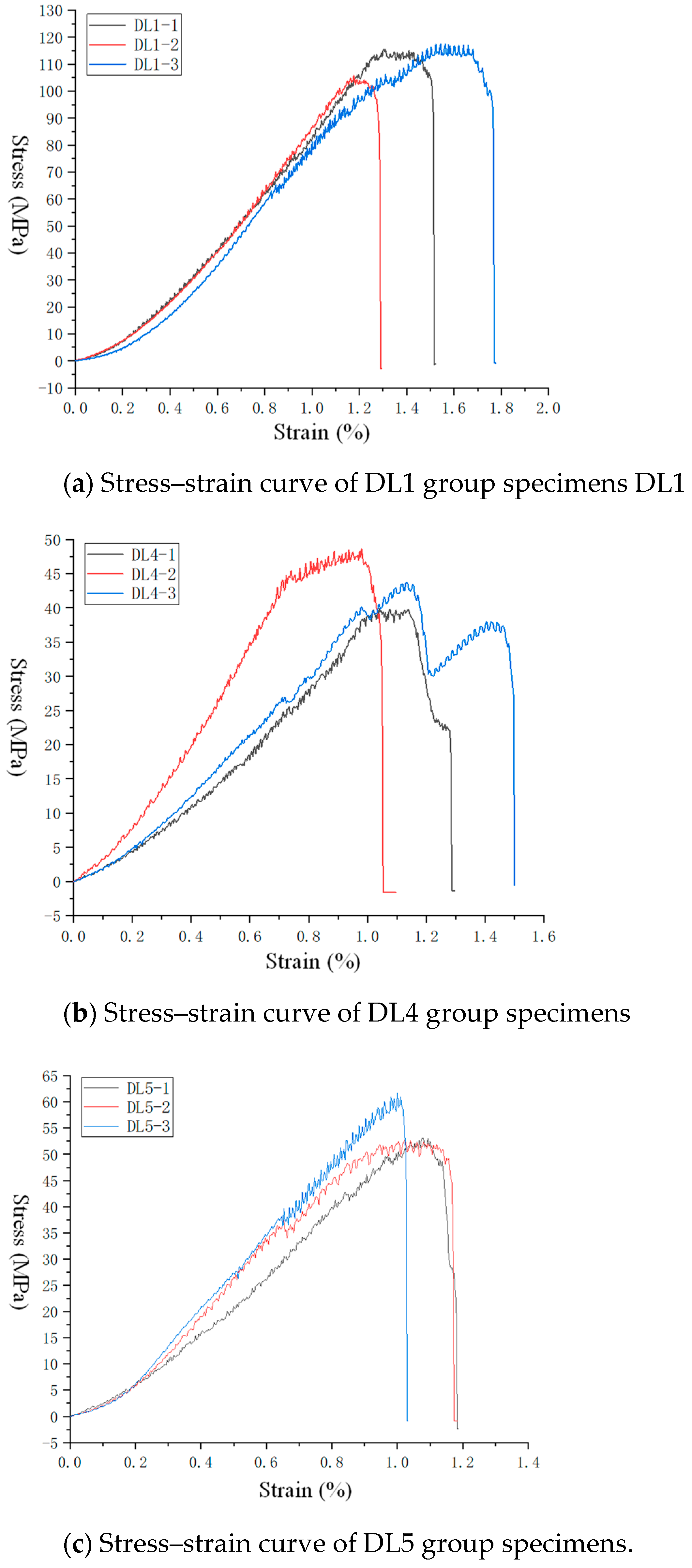

3.1. Stress–Strain Curve

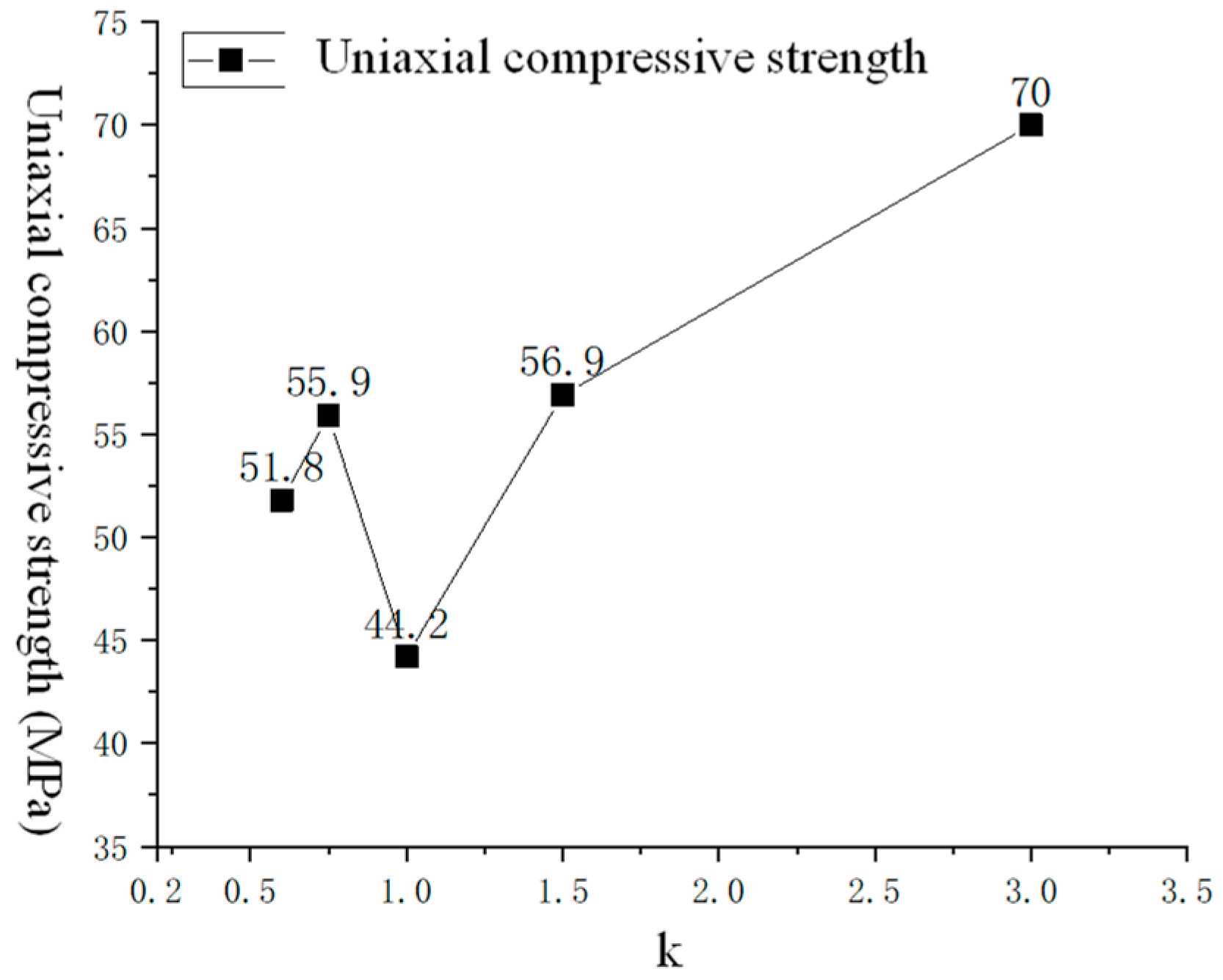

3.2. Strength Analysis

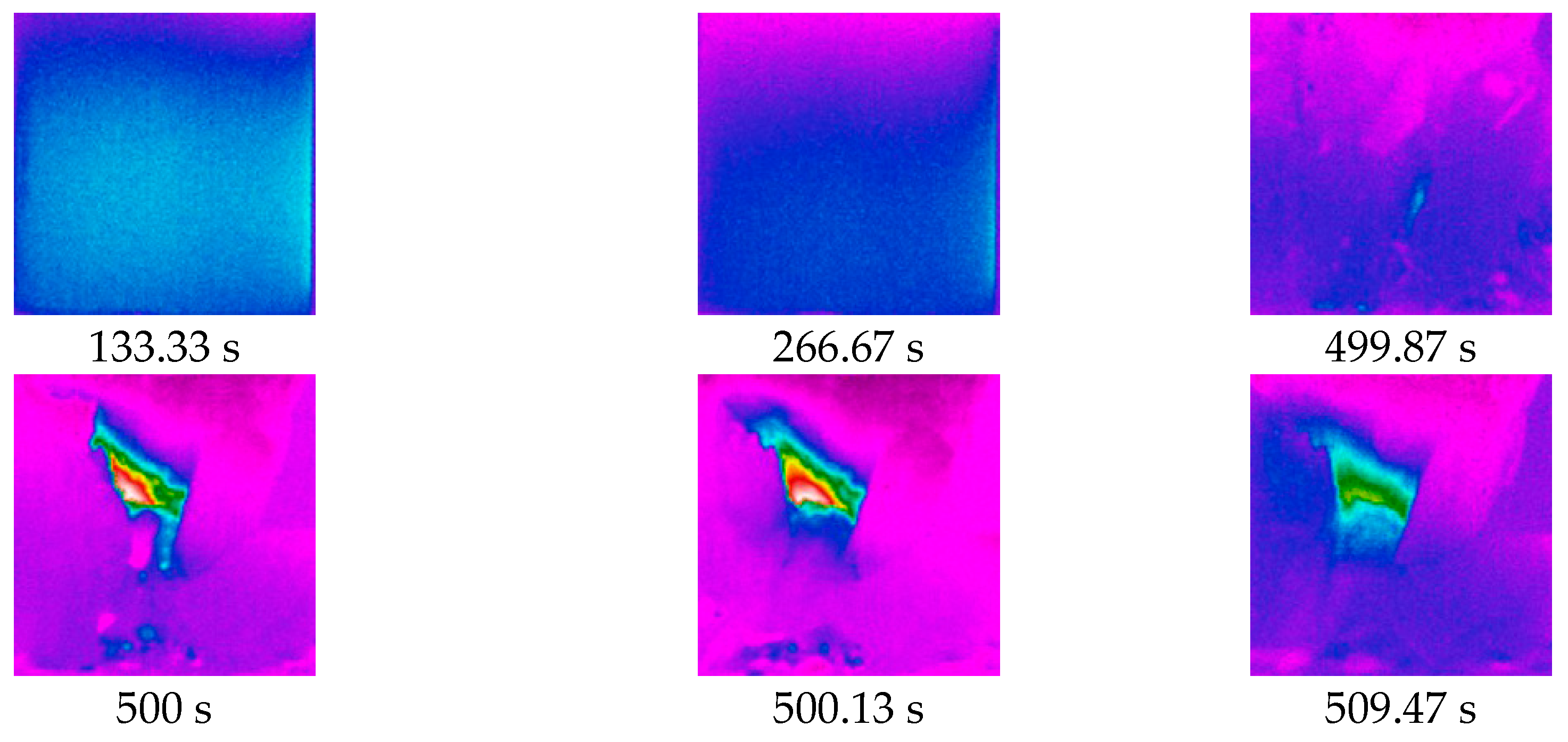

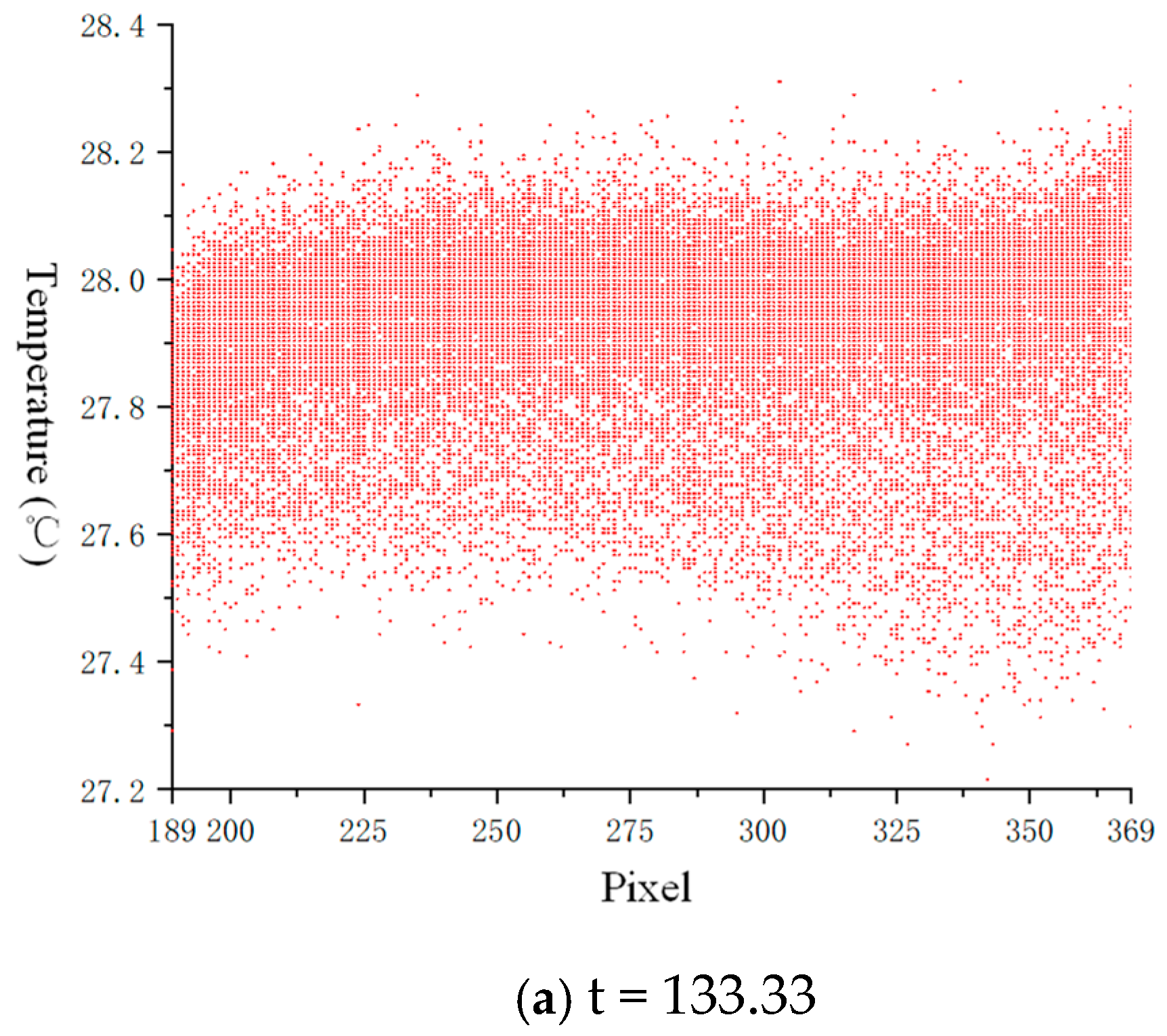

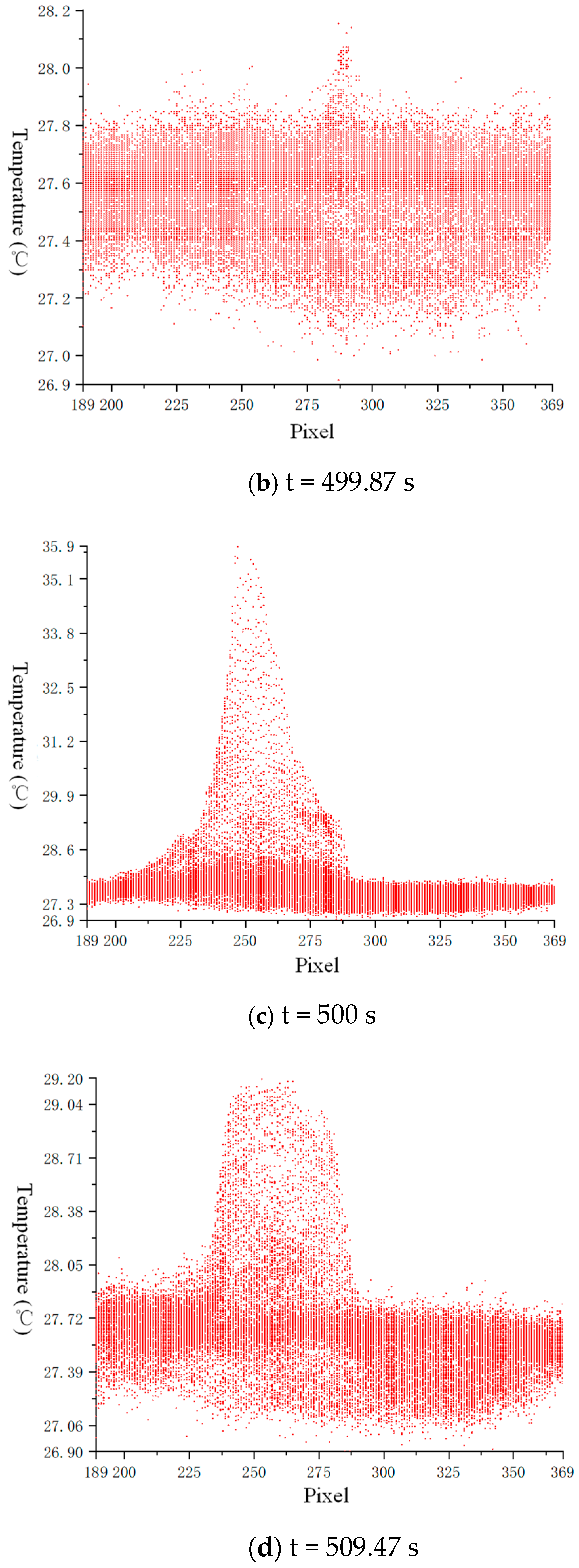

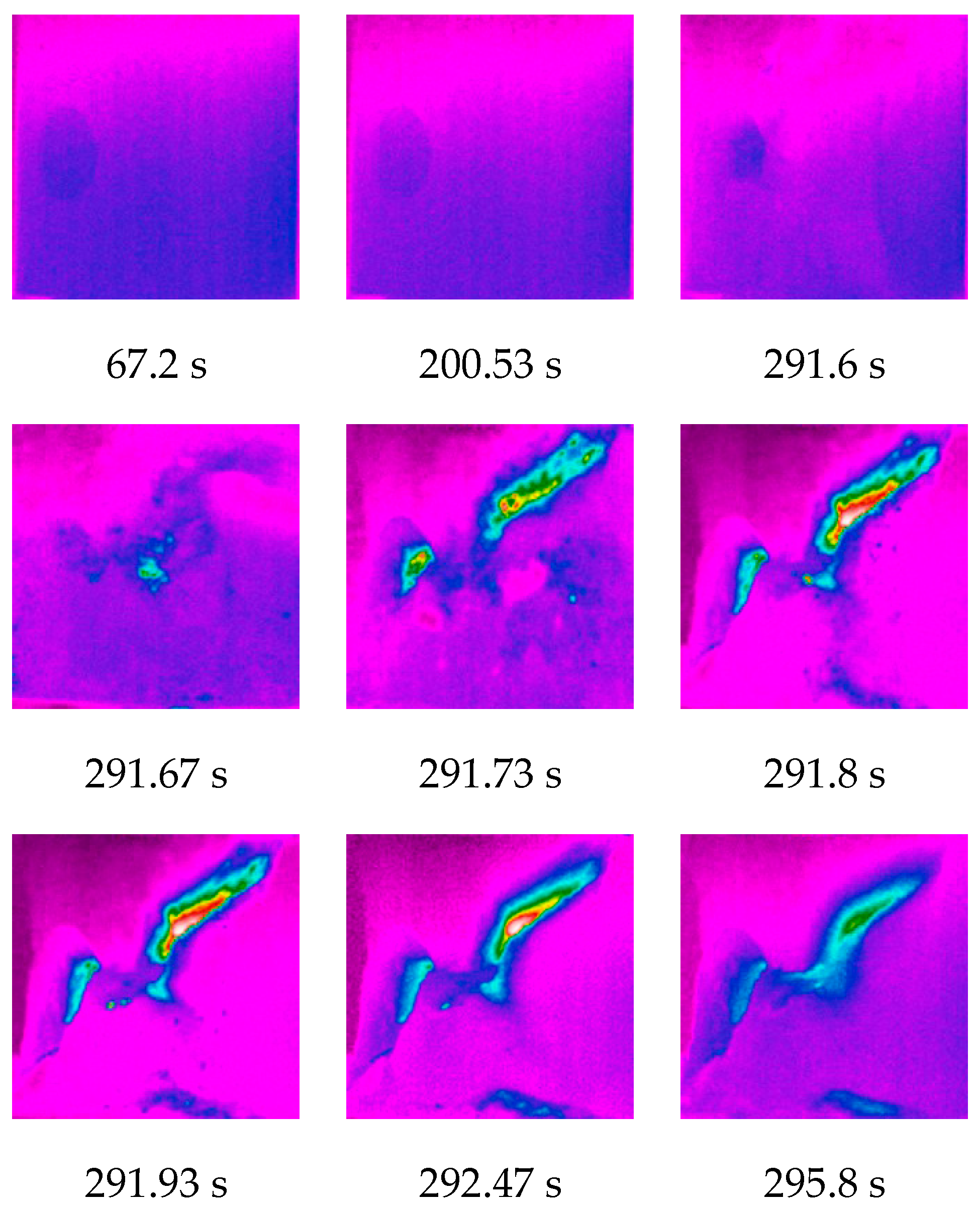

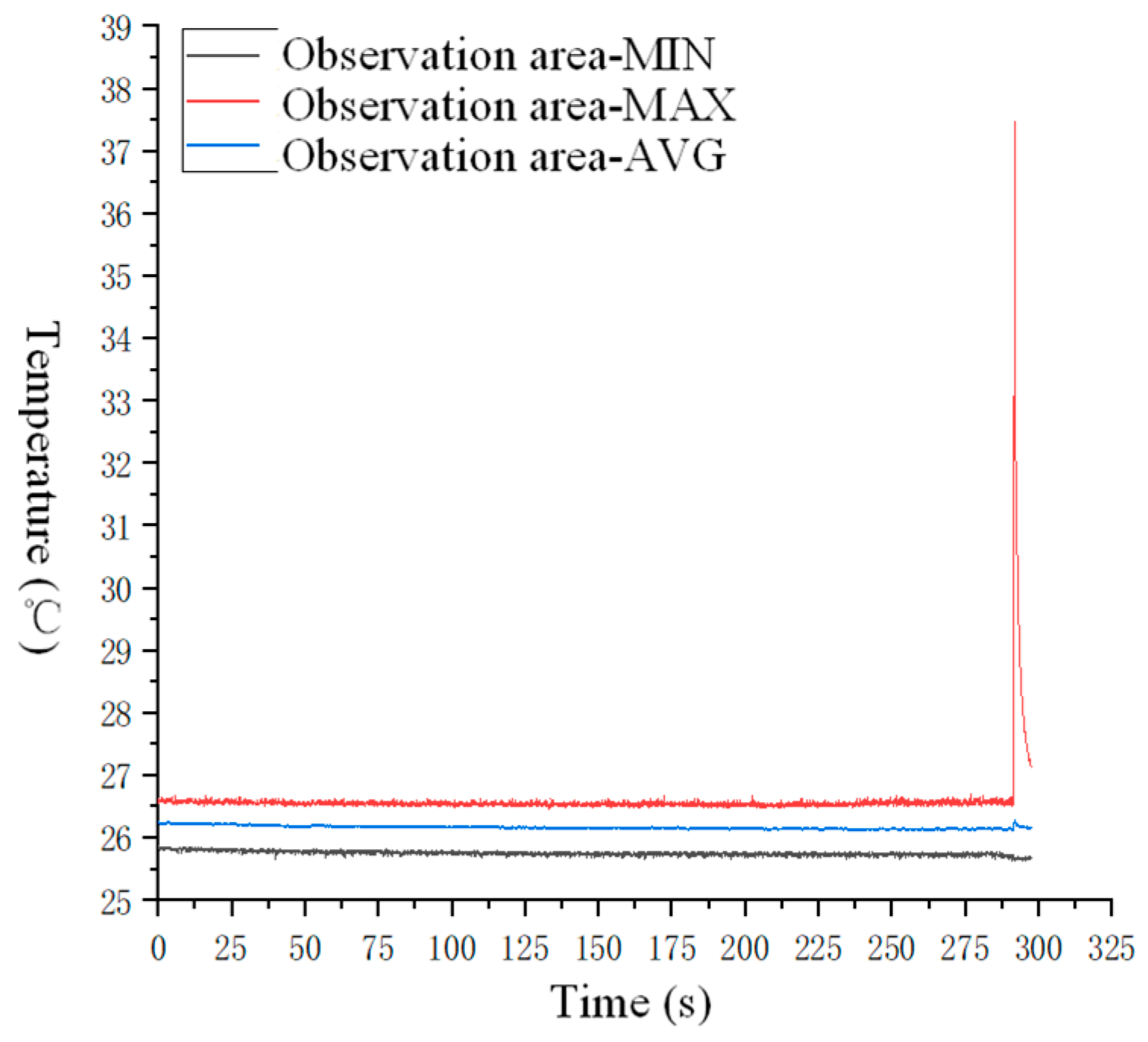

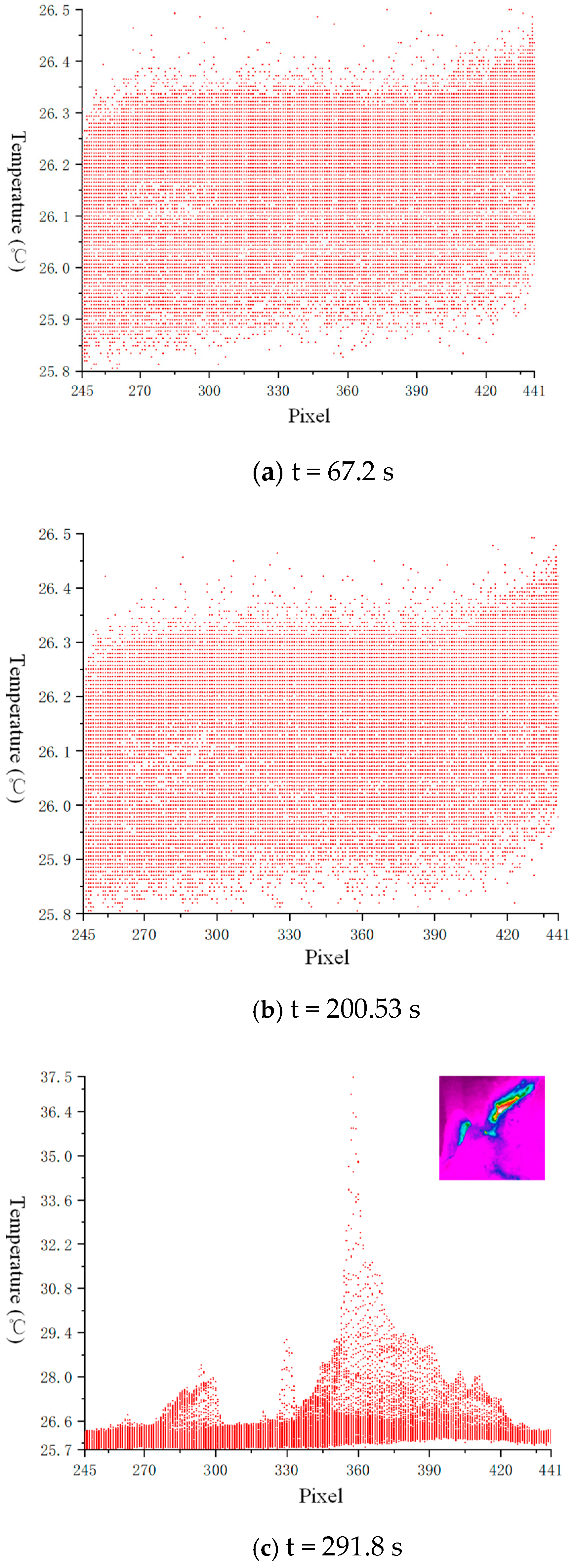

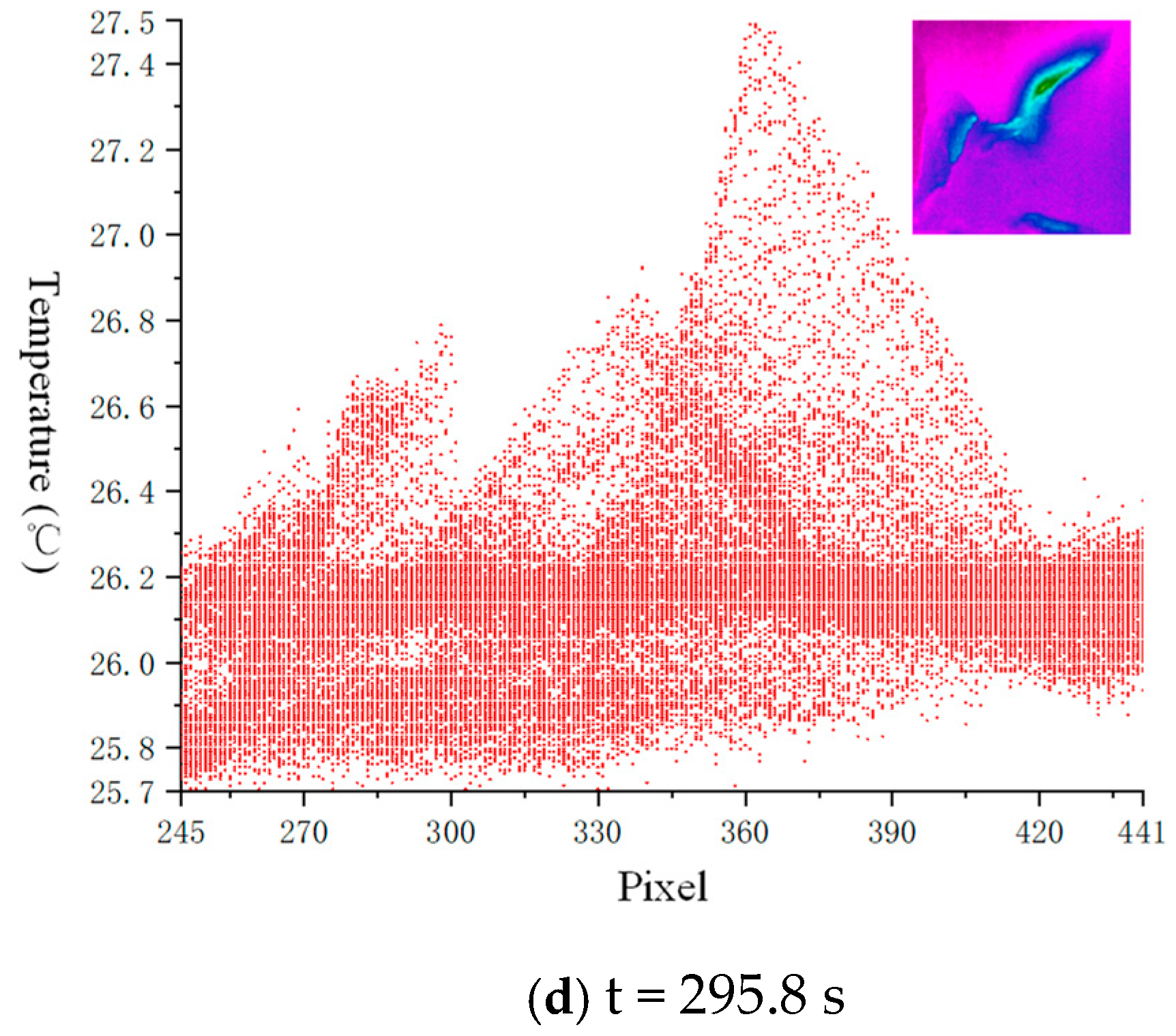

4. Evolution Characteristics of Temperature Field

4.1. Analysis of Infrared Results of Typical Specimens

4.2. Temperature Change Trend Analysis

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Huon, V.; Cousin, B.; Wattrisse, B.; Maisonneuve, O. Investigating the thermo-mechanical behaviour of cementitious materials using image processing techniques. Cem. Concr. Res. 2009, 39, 529–536. [Google Scholar] [CrossRef]

- Ma, S.-P.; Wang, L.-G.; Zhao, Y.-H. Experimental study on deformation field evolution during failure procedure of a rock borehole structure. Yantu Lixue (Rock Soil Mech.) 2006, 27, 1082–1086. [Google Scholar]

- Yong, R.; Ye, J.; Li, B.; Du, S. Determining the maximum sampling interval in rock joint roughness measurements using Fourier series. Int. J. Rock Mech. Min. Sci. 2018, 101, 78–88. [Google Scholar] [CrossRef]

- He, M.; Miao, J.; Feng, J. Rock burst process of limestone and its acoustic emission characteristics under true-triaxial unloading conditions. Int. J. Rock Mech. Min. Sci. 2010, 47, 286–298. [Google Scholar] [CrossRef]

- Li, A.; Zhang, R.; Ai, T.; Gao, M.; Zhang, Z.; Jing, X. Acoustic emission space-time evolution rules and failure precursors of granite under uniaxial compression. Chin. J. Geotech. Eng. 2016, 38, 306–311. [Google Scholar]

- Yang, S.-Q.; Tian, W.-L.; Huang, Y.-H.; Ma, Z.-G.; Fan, L.-F.; Wu, Z.-J. Experimental and discrete element modeling on cracking behavior of sandstone containing a single oval flaw under uniaxial compression. Eng. Fract. Mech. 2018, 194, 154–174. [Google Scholar] [CrossRef]

- Li, S.; Li, T.; Wang, G.; Bai, S. CT real-time scanning tests on rock specimens with artificial initial crack under uniaxial conditions. Yanshilixue Yu Gongcheng Xuebao/Chin. J. Rock Mech. Eng. 2007, 26, 484–492. [Google Scholar]

- Sun, X.; Li, X.; Zheng, B.; He, J.; Mao, T. Study on the progressive fracturing in soil and rock mixture under uniaxial compression conditions by CT scanning. Eng. Geol. 2020, 279, 105884. [Google Scholar] [CrossRef]

- Wang, Y.; Xiao, Y.; Hou, Z.; Li, C.; Wei, X. In situ X-ray computed tomography (CT) investigation of crack damage evolution for cemented paste backfill with marble waste block admixture under uniaxial deformation. Arab. J. Geosci. 2020, 13, 1–16. [Google Scholar] [CrossRef]

- Brand, B.T.; Roswell, G.A. Laboratory investigation of the electrodynamics of rock fracture. Nature 1986, 321, 488–492. [Google Scholar]

- Luong, M. Infrared thermographic scanning of fatigue in metals. Nucl. Eng. Des. 1995, 158, 363–376. [Google Scholar] [CrossRef]

- Luong, M.P. Infrared Thermography of Macrostructural Aspects of Thermoplasticity. Micro-and Macrostructural Aspects of Thermoplasticity; Springer: Dordrecht, The Netherlands, 2006; pp. 437–446. [Google Scholar]

- Luong, M.P.; Parganin, D.; Loizeau, J. Infrared Thermography of Thermomechanical Couplings in Solids. In Iutam Symposium on Advanced Optical Methods and Applications in Solid Mechanics; Springer: Berlin/Heidelberg, Germany, 2000; Volume 82, pp. 297–304. [Google Scholar]

- Shanjun, L.; Lixin, W.; Huanping, W.; Yuhua, W.; Tao, C.; Guohua, L. Quantitative study on the thermal infrared radiation of dark mineral rock in condition of uniaxial loading. Chin. J. Rock Mech. Eng. 2002, 21, 1585–1589. [Google Scholar]

- Shan-jun, L.; Li-xin, W.; Chuan-ying, W.; Daqing, G.; Yuhua, W. Remote sensing-rock mechanics (VIII): TIR omens of rock fracturing. Chin. J. Rock Mech. Eng. 2004, 23, 1621–1627. [Google Scholar]

- Shanjun, L.; Lixin, W.; Yuhua, W.; Yongqiang, L. Remote sensing-rock mechanics (V)—Analysis on the factors affecting thermal infrared radiation in process of rock viscosity sliding. Chin. J. Rock Mech. Eng. 2004, 23, 730–735. [Google Scholar]

- Liu, S.-J.; Wu, L.-X.; Zhang, Y.-B. Temporal-spatial evolution features of infrared thermal images before rock failure. J. Northeast. Univ. Nat. Sci 2009, 30, 1034–1038. [Google Scholar]

- Wu, L.; Liu, S.; Wu, Y.; Li, Y. Remote sensing-rock mechanics (II)—Laws of thermalinfrared radiation from viscosity-sliding of bi-shearedfaults and its meanings for tectonic earthquake omens. Chin. J. Rock Mech. Eng. 2004, 23, 192–198. [Google Scholar]

- Lixin, W.; Shanjun, L.; Yunhua, W. Remote-sensing-rock mechanics (IV)—Laws of thermal infrared radiation from compressively-sheared fracturing of rock and its meanings for earthquake omens. Chin. J. Rock Mech. Eng. 2004, 23, 539–544. [Google Scholar]

- Gong, W.; Peng, Y.; Sun, X.; He, M.; Zhao, S.; Chen, H.; Xie, T. Enhancement of low-contrast thermograms for detecting the stressed tunnel in horizontally stratified rocks. Int. J. Rock Mech. Min. Sci. 2015, 74, 69–80. [Google Scholar] [CrossRef]

- Gong, W.; Peng, Y.; He, M.; Wang, J. Thermal image and spectral characterization of roadway failure process in geologically 45° inclined rocks. Tunn. Undergr. Space Technol. 2015, 49, 156–173. [Google Scholar] [CrossRef]

- Gong, W.; Peng, Y.; He, M.; Xie, T.; Zhao, S. An overview of the thermography-based experimental studies on roadway excavation in stratified rock masses at CUMTB. Int. J. Min. Sci. Technol. 2015, 25, 333–345. [Google Scholar] [CrossRef]

- Zhang, Y.-b.; Liu, S. Thermal radiation temperature field variation of hole rock in loading process. Rock Soil Mech. 2011, 32, 1013–1017. [Google Scholar]

- Zhang, Y.; Wu, W.; Yao, X.; Liang, P.; Tian, B.; Huang, Y.; Liang, J. Acoustic emission-infrared characteristics and damage evolution of granite under uniaxial compression. Rock Soil Mech 2020, 41, 139–146. [Google Scholar]

- Wu, X.; Gao, X.; Liu, X.; Zhao, K. Abnormality of infrared temperature mutation in the process of saturated siltstone failure. J. China Coal Soc. 2015, 40, 328–336. [Google Scholar]

- Wu, X.; Gao, X.; Zhao, K.; Liu, J.; Liu, X. Abnormality of transient infrared temperature field (ITF) in the process of rock failure. Chin. J. Rock Mech. Eng. 2016, 35, 1578–1594. [Google Scholar]

- Ma, L.; Zhang, Y.; Sun, H.; Wang, S.; Najeem, A. Experimental study on dependence of infrared radiation on stress for coal fracturing process. J. China Coal Soc. 2017, 42, 140–147. [Google Scholar]

- Ma, L.; Zhang, D.; Guo, X.; Sun, H.; Najeem, A.; Zhang, Y. Characteristics on the variance of differential infrared image sequence during coal failures under uniaxial loading. Chin. J. Rock Mech. Eng. 2017, 36, 3927–3934. [Google Scholar]

- Zhou, Z.; Chang, Y.; Cai, X. Experimental study of infrared radiation effects of rock with different loading rates. J. Cent. South Univ. (Sci. Technol.) 2019, 50, 1127–1134. [Google Scholar]

- Ma, J.; Niu, X.; Liu, X.; Wang, Y.; Wen, T.; Zhang, J. Thermal Infrared Imagery Integrated with Terrestrial Laser Scanning and Particle Tracking Velocimetry for Characterization of Landslide Model Failure. Sensors 2019, 20, 219. [Google Scholar] [CrossRef]

- Teena, M.; Manickavasagan, A. Thermal Infrared Imaging. In Imaging with Electromagnetic Spectrum; Manickavasagan, A., Jayasuriya, H., Eds.; Springer: Berlin/Heidelberg, Germany, 2014; pp. 147–173. [Google Scholar]

- Mujtaba, B.; De Lima, J.L.M.P. Laboratory testing of a new thermal tracer for infrared-based PTV technique for shallow overland flows. Catena 2018, 169, 69–79. [Google Scholar] [CrossRef]

- Morello, R. Potentialities and limitations of thermography to assess landslide risk. Measurement 2018, 116, 658–668. [Google Scholar] [CrossRef]

- Sobrino, J.A.; Del Frate, F.; Drusch, M.; Jimenez, J.C.; Manunta, P.; Regan, A. Review of Thermal Infrared Applications and Requirements for Future High-Resolution Sensors. IEEE Trans. Geosci. Remote. Sens. 2016, 54, 2963–2972. [Google Scholar] [CrossRef]

- Frodella, W.; Gigli, G.; Morelli, S.; Lombardi, L.; Casagli, N. Landslide Mapping and Characterization through Infrared Thermography (IRT): Suggestions for a Methodological Approach from Some Case Studies. Remote Sens. 2017, 9, 1281. [Google Scholar] [CrossRef]

- Xu, B.; Dong, S.; Yin, S.; Li, S.; Xu, Y.; Dai, Z. Analysis of Crack Initiation and Propagation Thresholds of Inclined Cracks under High-Pressure Grouting in Ordovician Limestone. Energies 2021, 14, 360. [Google Scholar] [CrossRef]

- Wang, Y.; Tang, J.; Dai, Z.; Yi, T. Experimental study on mechanical properties and failure modes of low-strength rock samples containing different fissures under uniaxial compression. Eng. Fract. Mech. 2018, 197, 1–20. [Google Scholar] [CrossRef]

- Yang, S.; Huang, Y.; Jing, H.; Liu, X. Discrete element modeling on fracture coalescence behavior of red sandstone containing two unparallel fissures under uniaxial compression. Eng. Geol. 2014, 178, 28–48. [Google Scholar] [CrossRef]

- Shi, G.; Yang, X.; Yu, H.; Zhu, C. Acoustic emission characteristics of creep fracture evolution in double-fracture fine sandstone under uniaxial compression. Eng. Fract. Mech. 2019, 210, 13–28. [Google Scholar] [CrossRef]

- Li, Z.; Liu, S.; Ren, W.; Fang, J.; Zhu, Q.; Dun, Z. Multiscale Laboratory Study and Numerical Analysis of Water-Weakening Effect on Shale. Adv. Mater. Sci. Eng. 2020, 2020, 1–14. [Google Scholar] [CrossRef]

- Meng, Q.; Wang, H.; Cai, M.; Xu, W.; Zhuang, X.; Rabczuk, T. Three-dimensional mesoscale computational modeling of soil-rock mixtures with concave particles. Eng. Geol. 2020, 277, 105802. [Google Scholar] [CrossRef]

- Wang, Y.; Zhang, B.; Gao, S.; Li, C. Investigation on the effect of freeze-thaw on fracture mode classification in marble subjected to multi-level cyclic loads. Theor. Appl. Fract. Mech. 2021, 111, 102847. [Google Scholar] [CrossRef]

- Li, Z.; Liu, H.; Dun, Z.; Ren, L.; Fang, J. Grouting effect on rock fracture using shear and seepage assessment. Constr. Build. Mater. 2020, 242, 118131. [Google Scholar] [CrossRef]

- Meng, Q.-X.; Wang, H.; Xu, W.-Y.; Chen, Y.-L. Numerical homogenization study on the effects of columnar jointed structure on the mechanical properties of rock mass. Int. J. Rock Mech. Min. Sci. 2019, 124, 104127. [Google Scholar] [CrossRef]

| Number | Picture | Schematic Diagram | k (a/b) | Uniaxial Compressive Strength (MPa) | Difference Value (MPa) | Average UCS (MPa) |

|---|---|---|---|---|---|---|

| DL1-1 |  |  | — | 116.5 | 3.2 | 113.3 |

| DL1-2 | 105.8 | −7.5 | ||||

| DL1-3 | 117.5 | 4.2 | ||||

| DL2-1 |  |  | 3 | 78.9 | 8.9 | 70.0 |

| DL2-2 | 63.7 | −6.3 | ||||

| DL2-3 | 67.5 | −2.5 | ||||

| DL3-1 |  |  | 1.5 | 61.8 | 4.9 | 56.9 |

| DL3-2 | 51.7 | −5.2 | ||||

| DL3-3 | 57.4 | 0.5 | ||||

| DL4-1 |  |  | 1 | 40 | −4.2 | 44.2 |

| DL4-2 | 48.9 | 4.7 | ||||

| DL4-3 | 43.7 | −0.5 | ||||

| DL5-1 |  |  | 0.75 | 53.2 | −2.7 | 55.9 |

| DL5-2 | 52.9 | −3 | ||||

| DL5-3 | 61.7 | 5.8 | ||||

| DL6-1 |  |  | 0.6 | 57.8 | 6 | 51.8 |

| DL6-2 | 50.6 | −1.2 | ||||

| DL6-3 | 47.1 | −4.7 |

| Number | Picture | Loading Stage | Brittle Failure Stage | ||||||

|---|---|---|---|---|---|---|---|---|---|

| △tmin (°C) | △tmax (°C) | △tavg (°C) | tavg (°C) | △tmin (°C) | △tmax (°C) | △tavg (°C) | tavg (°C) | ||

| DL1-1 |  | −0.36 | −0.39 | −0.37 | −0.29 | −0.15 | 6.51 | 0.16 | 0.12 |

| DL1-2 | −0.23 | −0.43 | −0.29 | −0.13 | 5.82 | 0.17 | |||

| DL1-3 | −0.67 | −0.58 | −0.63 | −0.2 | 7.70 | 0.19 | |||

| DL2-1 |  | −0.24 | −0.22 | −0.23 | −0.11 | 2.44 | 0.14 | ||

| DL2-2 | −0.27 | −0.16 | −0.25 | −0.09 | 3.35 | 0.12 | |||

| DL2-3 | −0.31 | −0.27 | −0.29 | −0.15 | 4.76 | 0.11 | |||

| DL3-1 |  | −0.49 | −0.42 | −0.47 | −0.12 | 5.23 | 0.13 | ||

| DL3-2 | −0.34 | −0.32 | −0.33 | −0.07 | 1.64 | 0.07 | |||

| DL3-3 | −0.11 | −0.11 | −0.11 | −0.08 | 1.68 | 0.05 | |||

| DL3-1 |  | −0.47 | −0.43 | −0.46 | −0.11 | 2.31 | 0.08 | ||

| DL3-2 | −0.39 | −0.33 | −0.37 | −0.14 | 5.76 | 0.14 | |||

| DL3-3 | −0.33 | −0.29 | −0.32 | −0.09 | 6.33 | 0.15 | |||

| DL5-1 |  | −0.18 | −0.17 | −0.17 | −0.13 | 3.21 | 0.09 | ||

| DL5-2 | −0.23 | −0.21 | −0.22 | −0.08 | 4.57 | 0.10 | |||

| DL5-3 | −0.12 | −0.10 | −0.10 | −0.1 | 10.96 | 0.19 | |||

| DL6-1 |  | −0.23 | −0.17 | −0.21 | −0.14 | 2.34 | 0.09 | ||

| DL6-2 | −0.09 | −0.07 | −0.08 | −0.09 | 1.57 | 0.08 | |||

| DL6-3 | −0.35 | −0.30 | −0.33 | −0.07 | 2.11 | 0.06 | |||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Peng, Y.; Lin, Q.; He, M.; Zhu, C.; Zhang, H.; Guo, P. Experimental Study on Infrared Temperature Characteristics and Failure Modes of Marble with Prefabricated Holes under Uniaxial Compression. Energies 2021, 14, 713. https://doi.org/10.3390/en14030713

Peng Y, Lin Q, He M, Zhu C, Zhang H, Guo P. Experimental Study on Infrared Temperature Characteristics and Failure Modes of Marble with Prefabricated Holes under Uniaxial Compression. Energies. 2021; 14(3):713. https://doi.org/10.3390/en14030713

Chicago/Turabian StylePeng, Yanyan, Qunchao Lin, Manchao He, Chun Zhu, Haijiang Zhang, and Pengfei Guo. 2021. "Experimental Study on Infrared Temperature Characteristics and Failure Modes of Marble with Prefabricated Holes under Uniaxial Compression" Energies 14, no. 3: 713. https://doi.org/10.3390/en14030713

APA StylePeng, Y., Lin, Q., He, M., Zhu, C., Zhang, H., & Guo, P. (2021). Experimental Study on Infrared Temperature Characteristics and Failure Modes of Marble with Prefabricated Holes under Uniaxial Compression. Energies, 14(3), 713. https://doi.org/10.3390/en14030713