Implications of Nonlinear Material Parameters on the Dielectric Loss under Harmonic Distorted Voltages

Abstract

1. Introduction

2. Dielectric Properties

2.1. Conductivity

2.2. Polarisation

3. Dielectric Losses under Distorted Voltage Waveforms

4. Methods

4.1. Samples

4.2. Procedure

4.2.1. DC Conductivity

4.2.2. AC Dielectric Properties

4.2.3. Dielectric Loss under Harmonic Distorted Voltages

4.3. Setup

5. Results

5.1. DC Conductivity

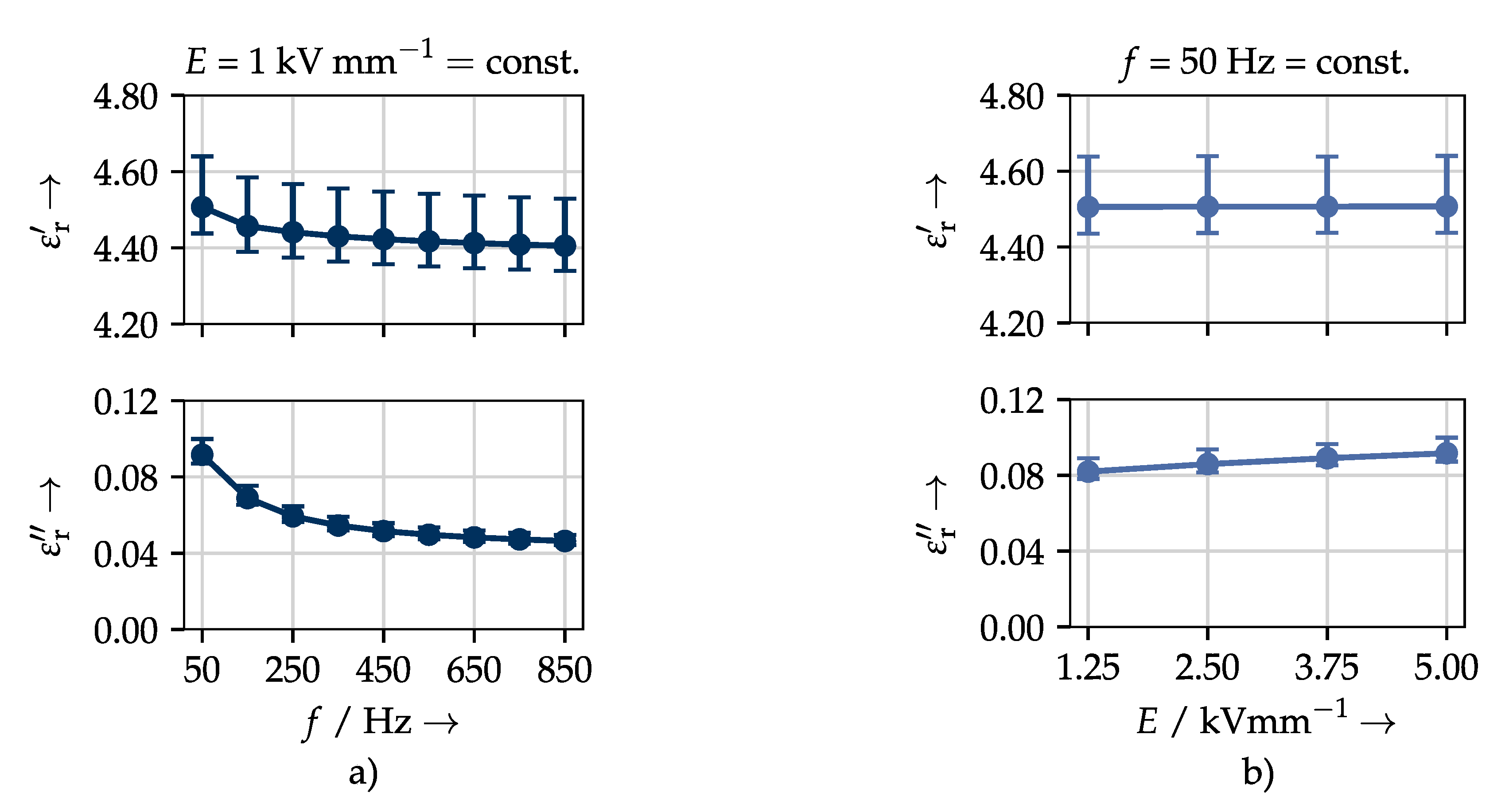

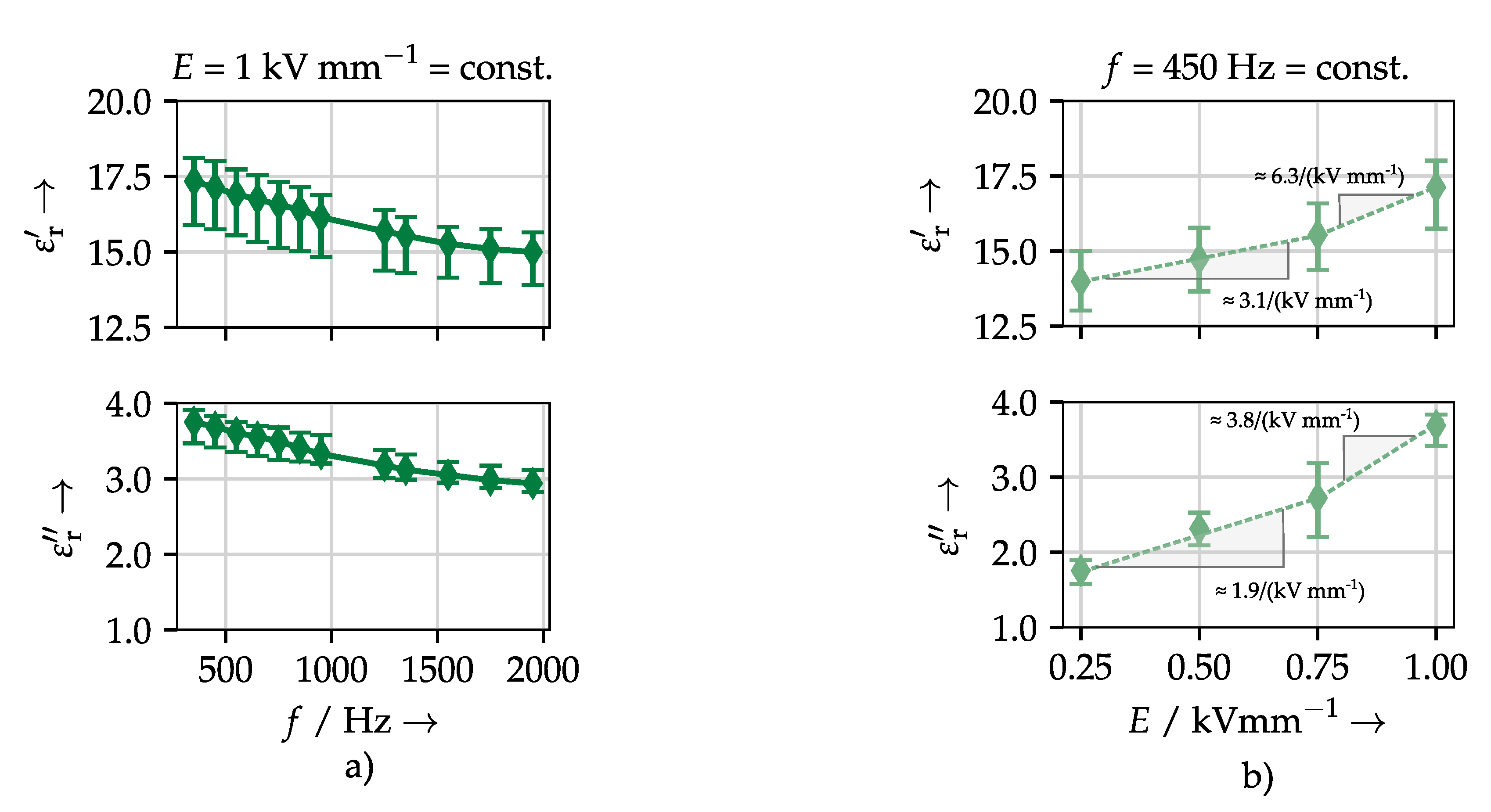

5.2. AC Dielectric Properties

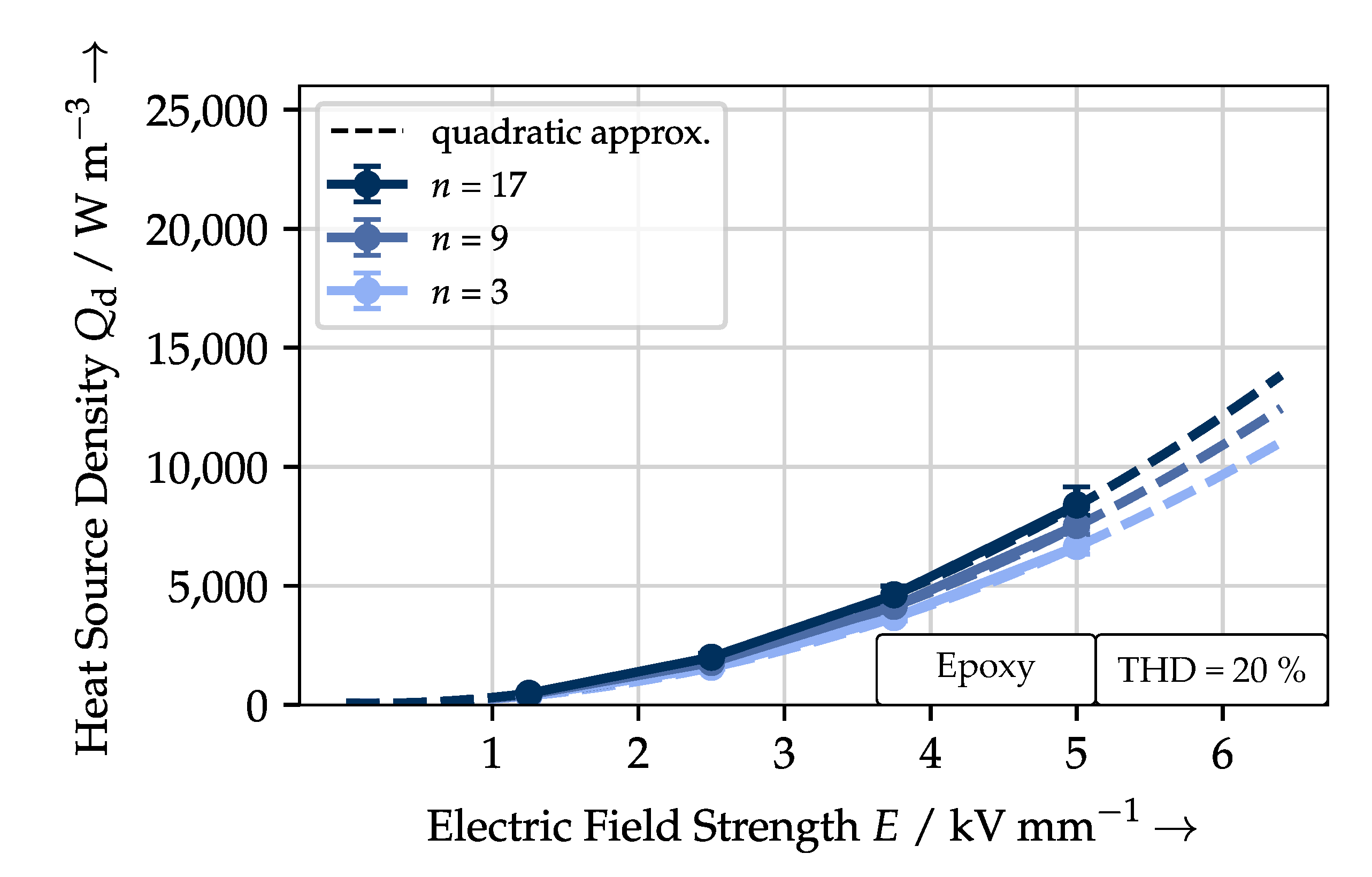

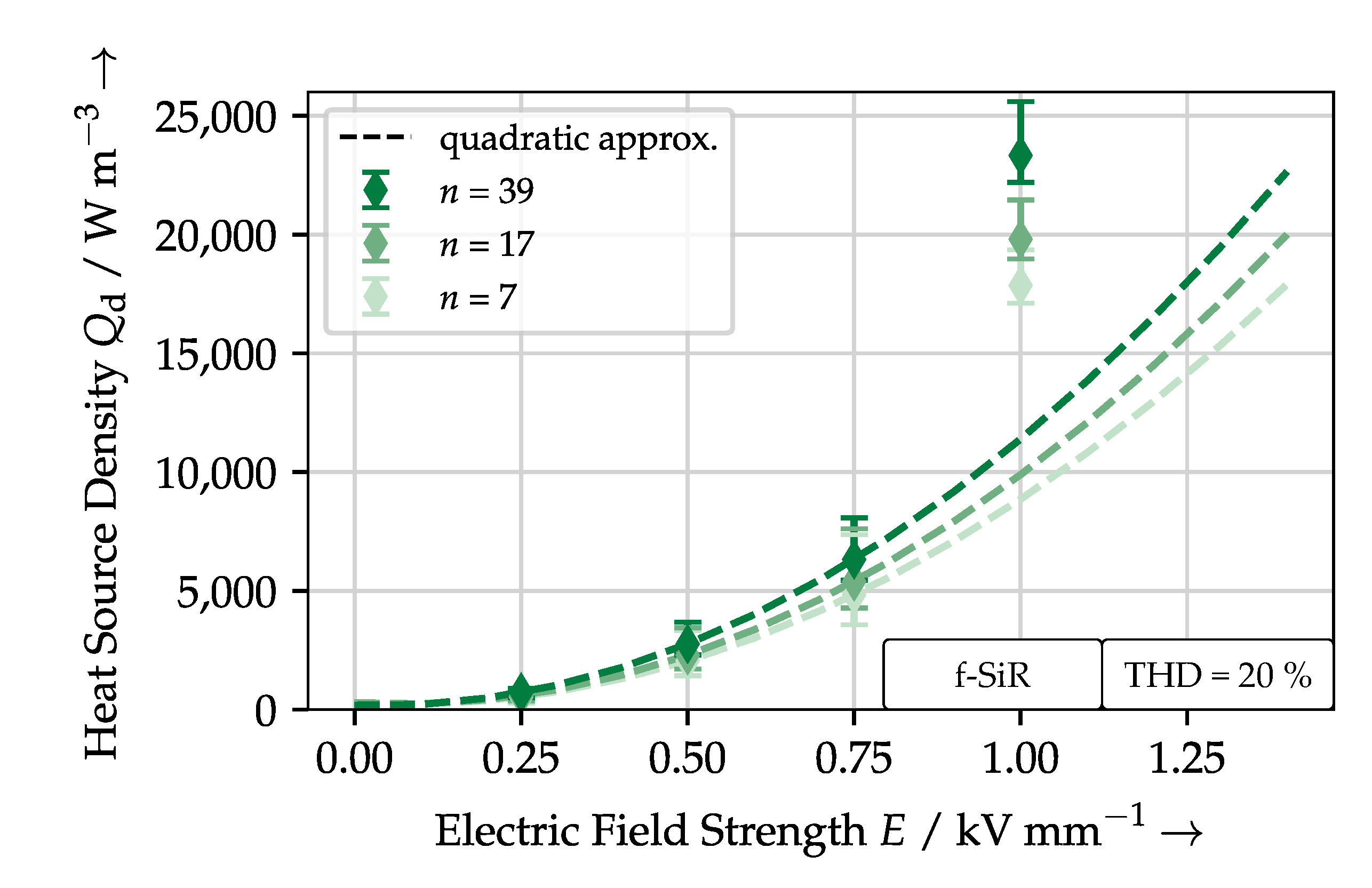

5.3. Dielectric Loss under Harmonic Distorted Voltage

6. Discussion

7. Conclusions

- A method to directly quantify the dielectric losses under harmonic distorted voltage waveforms is introduced;

- The dielectric properties of epoxy polymer are weakly dependent on the electrical field strength (linear behaviour), while strongly changing with increasing frequency;

- The dissipated heat of the epoxy polymer due to the dielectric losses as a result of harmonic distortion can be calculated via linear extrapolation with sufficient accuracy;

- The f-SiR exhibits a significant field dependency: the complex permittivity increases with the electric field strength;

- The complex permittivity of the f-SiR becomes nonlinear above an electric field strength threshold value;

- The nonlinearity leads to a sharp increase of the measured dielectric loss above the threshold;

- The estimation of the dielectric losses based on the linear superposition of several frequency components (Equation (11)) is valid for linear materials, but invalid for materials with nonlinear field dependence;

- Generally, advanced models for dielectric loss dissipation are necessary in order to incorporate the multiple dependencies on frequency, electric field strength and temperature.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Espin-Delgado, A.; Letha, S.S.; Rönnberg, S.K.; Bollen, M.H.J. Failure of MV Cable Terminations Due to Supraharmonic Voltages: A Risk Indicator. IEEE Open J. Ind. Appl. 2020, 1, 42–51. [Google Scholar] [CrossRef]

- Temma, H.; Ishiguro, F.; Toki, N.; Iyoda, I.; Paserba, J.J. Clarification and Measurements of High Frequency Harmonic Resonance by a Voltage Sourced Converter. IEEE Trans. Power Deliv. 2005, 20, 450–457. [Google Scholar]

- Rönnberg, S.K.; Bollen, M.H.J.; Amaris, H.; Chang, G.W.; Gu, I.Y.H.; Kocewiak, Ł.H.; Meyer, J.; Olofsson, M.; Ribeiro, P.F.; Desmet, J. On Waveform Distortion in the Frequency Range of 2 kHz–150 kHz—Review and Research Challenges. Electr. Power Syst. Res. 2017, 150, 1–10. [Google Scholar]

- Birle, M.; Leu, C. Dielectric Heating in Insulating Materials at High DC and AC Voltages Superimposed by High Frequency High Voltages. In Proceedings of the 18th International Symposium on High Voltage Engingeering (ISH 2013), Seoul, Korea, 25–30 August 2013. [Google Scholar]

- Sonerud, B.; Bengtsson, T.; Blennow, J.; Gubanski, S. Dielectric Heating in Insulating Materials Subjected to Voltage Waveforms with High Harmonic Content. IEEE Trans. Dielectr. Electr. Insul. 2009, 16, 926–933. [Google Scholar] [CrossRef]

- Florkowski, M.; Florkowska, B.; Zydroń, P. High Voltage Harmonics Induced Modifications of PD Phase-Resolved Patterns. Arch. Electr. Eng. 2018, 67, 231–246. [Google Scholar] [CrossRef]

- Florkowski, M.; Blaszczyk, P.; Klimczak, P. Partial Discharges in Insulation Systems Subjected to Multilevel Converters. In Proceedings of the 2016 IEEE International Power Modulator and High Voltage Conference (IPMHVC), San Francisco, CA, USA, 5–9 July 2016; pp. 320–324. [Google Scholar] [CrossRef]

- Fabiani, D.; Montanari, G. The Effect of Voltage Distortion on Ageing Acceleration of Insulation Systems under Partial Discharge Activity. IEEE Electr. Insul. Mag. 2001, 17, 24–33. [Google Scholar] [CrossRef]

- Bengtsson, T.; Dijkhuizen, F.; Ming, L.; Sahlen, F.; Liljestrand, L.; Bormann, D.; Papazyan, R.; Dahlgren, M. Repetitive Fast Voltage Stresses-Causes and Effects. IEEE Electr. Insul. Mag. 2009, 25, 26–39. [Google Scholar] [CrossRef]

- Paulsson, L.; Ekehov, B.; Halen, S.; Larsson, T.; Palmqvist, L.; Edris, A.A.; Kidd, D.; Keri, A.; Mehraban, B. High-Frequency Impacts in a Converter-Based Back-to-Back Tie; The Eagle Pass Installation. IEEE Trans. Power Deliv. 2003, 18, 1410–1415. [Google Scholar] [CrossRef]

- Kao, K.C. Dielectric Phenomena in Solids—With Emphasis on Physical Concepts of Electronic Processes; Elsevier Academic Press: San Diego, CA, USA, 2004. [Google Scholar]

- Guillod, T.; Faerber, R.; Rothmund, D.; Krismer, F.; Franck, C.M.; Kolar, J.W. Dielectric Losses in Dry-Type Insulation of Medium-Voltage Power Electronic Converters. IEEE J. Emerg. Sel. Top. Power Electron. 2019, 2716–2732. [Google Scholar] [CrossRef]

- Färber, R. Endurance of Polymeric Insulation under Mixed-Frequency Medium-Voltage Stress. Ph.D. Thesis, ETH Zurich, Zurich, Switzerland, 2019. [Google Scholar]

- Birle, M. Beanspruchung von Polymeren durch höherfrequente Anteile einer Mischspannung. Ph.D. Thesis, Shaker, Aachen, Germany, 2015. [Google Scholar]

- Bärsch, R.; Kindesberger, J. Nichtlineare dielektrische Funktionseigenschaften von Dielektrika. In Werkstoffe mit Nichtlinearen Dielektrischen Eigenschaften; VDE-Verlag GmbH: Stuttgart, Germany, 2008; Volume 110, pp. 7–33. [Google Scholar]

- Zaengl, W. Dielectric Spectroscopy in Time and Frequency Domain for HV Power Equipment. I. Theoretical Considerations. IEEE Electr. Insul. Mag. 2003, 19, 5–19. [Google Scholar] [CrossRef]

- Bartnikas, R.; Eichhorn, R. (Eds.) Engineering Dielectrics Volume IIA Electrical Properties of Solid Insulating Materials: Molecular Structure and Electrical Behavior; ASTM International: West Conshohocken, PA, USA, 1983. [Google Scholar] [CrossRef]

- Menczel, J.D.; Prime, R.B. Thermal Analysis of Polymers, 1st ed.; John Wiley & Sons, Ltd.: Hoboken, NJ, USA, 2009. [Google Scholar] [CrossRef]

- Blythe, A.R.; Blythe, T.; Bloor, D. Electrical Properties of Polymers; Cambridge University Press: Cambridge, UK, 2005. [Google Scholar]

- Han, Y.; Li, S.; Min, D. Nonlinear Conduction and Surface Potential Decay of Epoxy/SiC Nanocomposites. IEEE Trans. Dielectr. Electr. Insul. 2017, 24, 3154–3164. [Google Scholar] [CrossRef]

- Guillod, T. Modeling and Design of Medium-Frequency Transformers for Future Medium-Voltage Power Electronics Interfaces. Ph.D. Thesis, ETH Zurich, Zurich, Switzerland, 2018. [Google Scholar]

- Martensson, E. Modelling Electrical Properties of Composite Materials. Ph.D. Thesis, Kungl Tekniska Högskolan, Stockholm, Sweden, 2003. [Google Scholar]

- Christen, T.; Donzel, L.; Greuter, F. Nonlinear Resistive Electric Field Grading Part 1: Theory and Simulation. IEEE Electr. Insul. Mag. 2010, 26, 47–59. [Google Scholar] [CrossRef]

- Hinrichsen, V.; Küchler, A. Grundlagen der Feldsteuerung. In Feldsteuernde Isoliersysteme: Werkstoffe, Design, Prüfung und Simulation; VDE Verlag: Berlin, Germany, 2011. [Google Scholar]

- Kremer, F.; Schönhals, A. (Eds.) Broadband Dielectric Spectroscopy; Springer: Berlin/Heidelberg, Germany, 2003. [Google Scholar] [CrossRef]

- Kahle, M. Elektrische Isoliertechnik; Springer-Verlag: Berlin/Heidelberg, Germany, 1989. [Google Scholar]

- Linde, T.; Backhaus, K. Comparison of Dielectric Loss Measuring Methods on Epoxy Samples under Harmonic Distorted Voltages; VDE-Hochspannungstechnik; VDE e.V.: Berlin, Germany, 2020. [Google Scholar]

- DIN EN IEC 62631-2-1:2018—Dielectric and Resistive Properties of Solid Insulating Materials—Part 2-1: Relative Permittivity and Dissipation Factor—Technical Frequencies (0.1 Hz to 10 MHz)—AC Methods; Technical Report; Beuth Verlag: Berlin, Germany, 2018.

- Loh, J.T.; Kornhuber, S. Influence of Harmonic Distorted Voltages on the Power Loss of Functionally Filled Silicone Elastomers. In VDE-Hochspannungstechnik; VDE e.V.: Berlin, Germany, 2020. [Google Scholar]

- Faerber, R.; Franck, C.M. Modular Arbitrary Waveform Dielectric Spectrometer for Aging Diagnostics of Recessed Specimens. In Proceedings of the 2016 IEEE Conference on Electrical Insulation and Dielectric Phenomena (CEIDP), Toronto, ON, Canada, 16–19 October 2016; pp. 763–767. [Google Scholar] [CrossRef]

- Sonerud, B.; Bengtsson, T.; Blennow, J.; Gubanski, S. Dielectric Response Measurements Utilizing Non-Sinusoidal Waveforms. In Proceedings of the IEEE Conference on Electrical Insulation and Dielectric Phenomena (CEIDP), Kansas, MO, USA, 15–18 October 2006. [Google Scholar] [CrossRef]

- Winter, H.J. Dielektrische Eigenschaften von Silikonelastomeren Als Isolierstoffe. ETG-Fachber 2003, 93, 29–35. [Google Scholar]

- Oesterheld, J. Dielektrisches Verhalten von Silikongummi-Isolierungen Bei Hohen Elektrischen Feldstärken. Ph.D. Thesis, TU Dresden, Dresden, Germany, 1994. [Google Scholar]

| Epoxy | f-SiR | ||

|---|---|---|---|

| Filler | 67% quartz flour | ferroelectric particles | |

| Thickness | mm | AC: (3.9 ± 0.1) | (1 ± 0.05) |

| DC: (1 ± 0.1) | (1 ± 0.05) | ||

| Effective volume | (7.65 ± 0.2) | (1.92 ± 0.1) | |

| Vacuum capacitance | (4.4 ± 0.1) | (17.7 ± 0.9) |

| Section | Measured Quantity | Voltage | Parameter | Epoxy | f-SiR | |

|---|---|---|---|---|---|---|

| Section 5.1 | DC | E | kV mm−1 | 1 | 0.25 … 1 | |

| Section 5.2 | and | AC | E | kV mm−1 | 1.25 … 5 | 0.25 … 1 |

| sinusoidal | f | Hz | 50 … 850 | 350 … 1950 | ||

| Section 5.3 | AC | E | kV mm−1 | 1.25 … 5 | 0.25 … 1 | |

| distorted | n | 1 … 17 | 7 …39 | |||

| THD | % | 5 … 20 | 10 … 20 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Linde, T.; Loh, J.T.; Kornhuber, S.; Backhaus, K.; Schlegel, S.; Großmann, S. Implications of Nonlinear Material Parameters on the Dielectric Loss under Harmonic Distorted Voltages. Energies 2021, 14, 663. https://doi.org/10.3390/en14030663

Linde T, Loh JT, Kornhuber S, Backhaus K, Schlegel S, Großmann S. Implications of Nonlinear Material Parameters on the Dielectric Loss under Harmonic Distorted Voltages. Energies. 2021; 14(3):663. https://doi.org/10.3390/en14030663

Chicago/Turabian StyleLinde, Thomas, Jun Ting Loh, Stefan Kornhuber, Karsten Backhaus, Stephan Schlegel, and Steffen Großmann. 2021. "Implications of Nonlinear Material Parameters on the Dielectric Loss under Harmonic Distorted Voltages" Energies 14, no. 3: 663. https://doi.org/10.3390/en14030663

APA StyleLinde, T., Loh, J. T., Kornhuber, S., Backhaus, K., Schlegel, S., & Großmann, S. (2021). Implications of Nonlinear Material Parameters on the Dielectric Loss under Harmonic Distorted Voltages. Energies, 14(3), 663. https://doi.org/10.3390/en14030663