A Review on Management of End of Life Tires (ELTs) and Alternative Uses of Textile Fibers

Abstract

1. Introduction

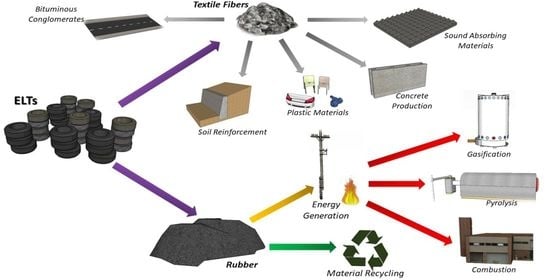

2. Composition of ELTs

2.1. Rubber, Steel Wire and Textile Fibers

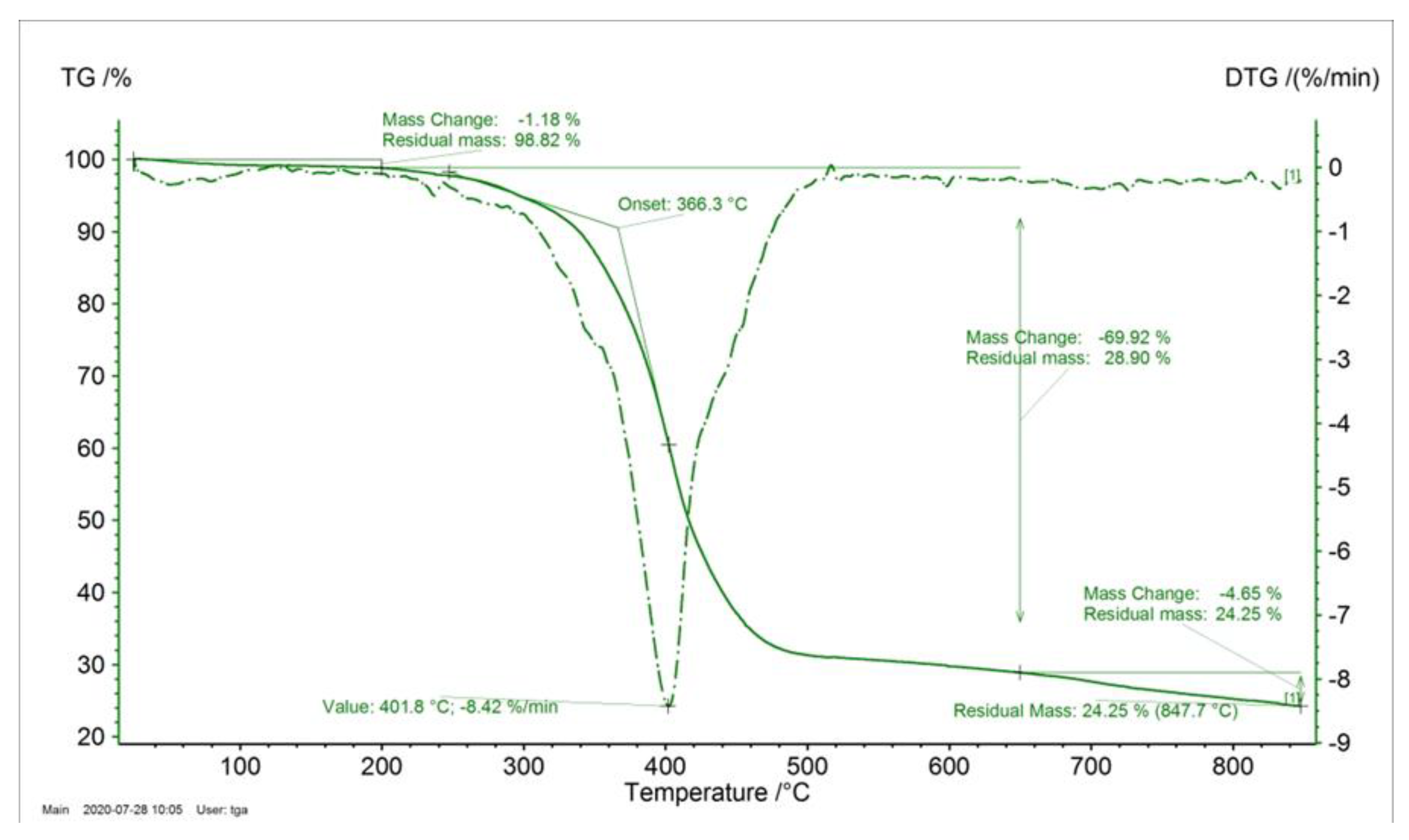

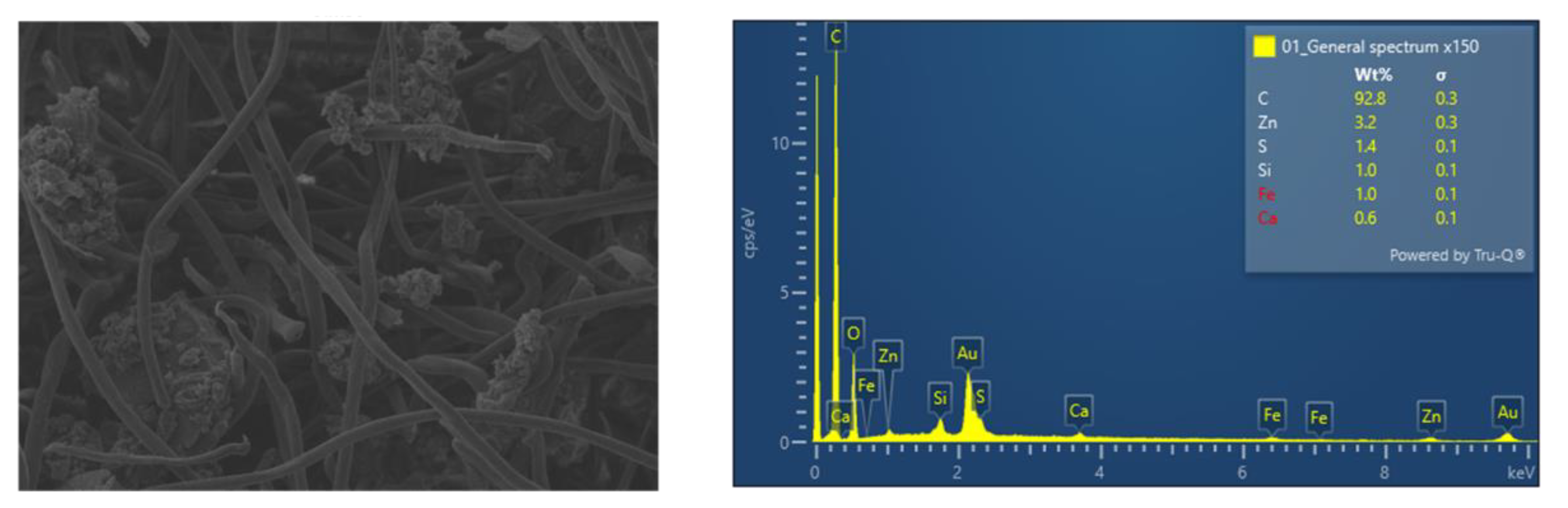

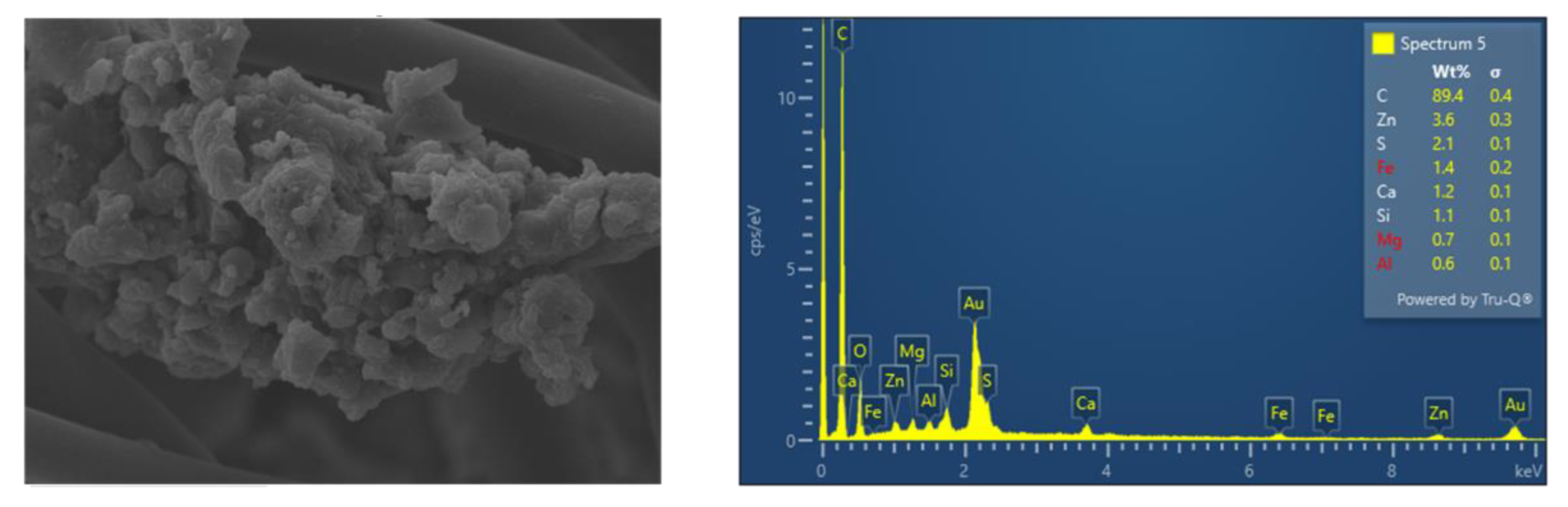

Chemical Characterization of Textile Fibers

3. Management of ELTs

3.1. Energy Generation

3.1.1. Combustion

3.1.2. Pyrolysis

3.1.3. Gasification

3.2. Material Recycling

Civil Engineering Uses

4. Alternative Uses and Opportunities for the Use of Textile Fibers

4.1. Sound Absorbing Materials

4.2. Bituminous Conglomerates

4.3. Concrete Production

4.4. Plastic Materials

4.5. Soil Reinforcement

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

References

- Pellegrino, C.; Faleschini, F.; Meyer, C. Recycled materials in concrete. In Developments in the Formulation and Reinforcement of Concrete, 2nd ed.; Mindess, S., Ed.; Series in Civil and Structural Engineering; Woodhead Publishing: Cambridge, UK, 2019; pp. 19–54. [Google Scholar]

- Selbes, M.; Yilmaza, O.; Khan, A.A.; Karanfil, T. Leaching of DOC, DN, and inorganic constituents from scrap tires. Chemosphere 2015, 139, 617–623. [Google Scholar] [CrossRef]

- Oikonomou, N.; Mavridou, S. Chapter: The use of waste tire rubber in civil engineering works. In Sustainability of Construction Materials; Khatib, J.M., Ed.; Series in Civil and Structural Engineering; Woodhead Publishing: Cambridge, UK, 2009; pp. 213–238. [Google Scholar]

- ETRMA—The ETRMA Statistics Report Edition 2015. Available online: https://www.etrma.org/wp-content/uploads/2019/09/20151214-statistics-booklet-2015-final2.pdf (accessed on 23 November 2020).

- Communication from the Commission to the European Parliament, the Council, the European Economic and Social Committee and the Committee of the Regions Closing the Loop—An EU Action Plan for the Circular Economy COM/2015/0614 Final. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=CELEX%3A52015DC0614 (accessed on 2 December 2020).

- Decision No 1386/2013/EU of the European Parliament and of the Council of 20 November 2013 on a General Union Environment Action Programme to 2020 ‘Living Well, within the Limits of Our Planet’ Text with EEA Relevance. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=CELEX%3A32013D1386 (accessed on 22 November 2020).

- Directive 2000/53/EC of the European Parliament and of the Council of 18 September 2000 on End-of Life Vehicles—Commission Statements. Available online: https://eur-lex.europa.eu/legal-content/EN/ALL/?uri=CELEX%3A32000L0053 (accessed on 23 November 2020).

- European Commission—Guide to Cost-Benefit Analysis of Investment Projects. Available online: https://ec.europa.eu/regional_policy/en/information/publications/guides/2014/guide-to-cost-benefit-analysis-of-investment-projects-for-cohesion-policy-2014-2020 (accessed on 4 December 2020).

- Directive 2008/98/EC of the European Parliament and of the Council of 19 November 2008 on Waste and Repealing Certain Directives (Text with EEA Relevance). Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=celex%3A32008L0098 (accessed on 22 November 2020).

- Directive 2009/28/EC of the European Parliament and of the Council of 23 April 2009 on the Promotion of the Use of Energy from Renewable Sources and Amending and Subsequently Repealing Directives 2001/77/EC and 2003/30/EC (Text with EEA Relevance). Available online: https://eur-lex.europa.eu/legal-content/EN/ALL/?uri=CELEX%3A32009L0028 (accessed on 22 November 2020).

- Council Directive 75/442/EEC of 15 July 1975 on Waste Council Regulation 259/93/EEC. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=CELEX%3A31975L0442 (accessed on 18 November 2020).

- Council Regulation (EEC) No 259/93 of 1 February 1993 on the Supervision and Control of Shipments of Waste within, into and out of the European Community. Available online: https://eur-lex.europa.eu/legal-content/EN/ALL/?uri=celex:31993R0259 (accessed on 18 November 2020).

- Council Directive 1999/31/EC of 26 April 1999 on the Landfill of Waste. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=CELEX%3A31999L0031 (accessed on 22 November 2020).

- 2000/532/EC: Commission Decision of 3 May 2000 Replacing Decision 94/3/EC Establishing a List of Wastes Pursuant to Article 1(a) of Council Directive 75/442/EEC on Waste and Council Decision 94/904/EC Establishing a List of Hazardous Waste Pursuant to Article 1(4) of Council Directive 91/689/EEC on Hazardous Waste (Notified under Document Number C(2000) 1147) (Text with EEA Relevance). Available online: https://eur-lex.europa.eu/legal-content/EN/ALL/?uri=celex%3A32000D0532 (accessed on 25 November 2020).

- Directive 2000/76/EC of the European Parliament and of the Council of 4 December 2000 on the Incineration of Waste. Available online: https://eur-lex.europa.eu/legal-content/en/TXT/?uri=CELEX:32000L0076 (accessed on 22 November 2020).

- 2001/118/EC: Commission Decision of 16 January 2001 Amending Decision 2000/532/EC as Regards the List of Wastes (Text with EEA Relevance) (Notified under Document Number C (2001) 108). Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=celex%3A32001D0118 (accessed on 25 November 2020).

- COM (2005) 666 Final Communication from the Commission to the Council, the European Parliament, the European Economic and Social Committee and the Committee of The Regions: Taking Sustainable Use of Resources Forward: A Thematic Strategy on the Prevention and Recycling of Waste. Available online: https://ec.europa.eu/transparency/regdoc/?fuseaction=list&coteId=1&year=2005&number=666&language=EN (accessed on 18 November 2020).

- CEN/TS 14243. Materials Produced from End of Life Tyres—Specification of Categories Based on Their Dimension(s) and Impurities and Methods for Determining Their Dimension(s) and Impurities; European Committee for Standardization—CEN: Brussels, Belgium, 2010. [Google Scholar]

- Directive (EU) 2018/851 of the European Parliament and of the Council of 30 May 2018 Amending Directive 2008/98/EC on Waste (Text with EEA Relevance). Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=uriserv:OJ.L_.2018.150.01.0109.01.ENG&toc=OJ:L:2018:150:TOC (accessed on 3 December 2020).

- ETRMA—End of Life Tyres Management—Europe 2018 Status. Available online: https://www.etrma.org/wp-content/uploads/2020/09/Copy-of-ELT-Data-2018-002.pdf (accessed on 23 November 2020).

- EURIC—Environmental Benefits—Tyre Recycling—Infill Artificial Turf. Available online: https://www.euric-aisbl.eu/position-papers/item/396-press-release-environmental-benefits-tyre-recycling-infill-artificial-turf (accessed on 24 November 2020).

- Hylands, K.N.; Shulman, V. Civil Engineering Applications of Tires; Viridis Report VR 5; TRL Limited: Crowthorne, UK, 2003. [Google Scholar]

- Pehlken, A.; Essadiqi, E. Scrap Tire Recycling in Canada—A Reference for All Parties Involved in the Tire Recycling Industry on the Options Available for End-Of-Life OTR and Passenger Tires from an Economic and Environmental Perspective; MTL 2005-08 (CF), CANMET-Materials Technology Laboratory: Hamilton, ON, Canada, 2005. [Google Scholar]

- Sienkiewicz, M.; Kucinska-Lipka, J.; Janik, H.; Balas, A. Progress in used tyres management in the European Union: A review. Waste Manag. 2012, 32, 1742–1751. [Google Scholar] [CrossRef] [PubMed]

- Landi, D.; Vitali, S.; Germani, M. Environmental analysis of different end of life scenarios of tires textile fibers. Procedia CIRP 2016, 48, 508–513. [Google Scholar] [CrossRef]

- Vamvouka, D.; Chatib, N.E.; Sfakiotakis, S.I. Measurements of ignition point and combustion characteristics of biomass fuels and their blends with lignite. In Proceedings of the 5th European Combustion Meeting, London, UK, 28–30 June 2011. [Google Scholar]

- ETRMA—End of Life Tyres ELTs—A Valuable Source with Growing Potential—2011. Available online: https://www.etrma.org/wp-content/uploads/2019/09/brochure-elt-2011-final.pdf (accessed on 25 November 2020).

- Rogoff, M.J. Chapter 3—Collection Approaches. In Solid Waste Recycling and Processing: Planning of Solid Waste Recycling Facilities and Programs, 2nd ed.; Elsevier: Oxfordshire, UK, 2014; pp. 19–42. [Google Scholar]

- ETRMA—Circular Economy. Available online: https://www.etrma.org/key-topics/circular-economy/ (accessed on 2 December 2020).

- Winternitz, K.; Heggie, M.; Baird, J. Extended producer responsibility for waste tyres in the EU: Lessons learnt from three case studies—Belgium, Italy and the Netherlands. Waste Manag. 2019, 89, 386–396. [Google Scholar] [CrossRef] [PubMed]

- Ferronato, N.; Torretta, V. Waste Mismanagement in Developing Countries: A Review of Global Issues. Int. J. Environ. Res. Public Health 2019, 16, 1060. [Google Scholar] [CrossRef]

- EPA—Energy Recovery from Waste. Available online: https://archive.epa.gov/epawaste/nonhaz/municipal/web/html/index-11.html (accessed on 3 December 2020).

- Global Recycling—Tire Recycling Riding on. Available online: https://global-recycling.info/archives/2883 (accessed on 21 November 2020).

- Neuwahl, F.; Cusano, G.; Gómez Benavides, J.; Holbrook, S.; Roudier, S. Best Available Techniques (BAT) Reference Document for Waste Incineration: Industrial Emissions Directive 2010/75/EU (Integrated Pollution Prevention and Control); EUR 29971 EN; European Union: Luxembourg, 2019. [Google Scholar]

- Ecoelastika Annual Report—2019. Available online: https://www.ecoelastika.gr/news/annual_report_2019_EN/ (accessed on 2 December 2020).

- Spitz, N.; Bar-Ziv, E.; Korytnyi, E.; Saveliev, R. Review, Examination and Comparison of Alternatives for Thermochemical Conversion of Municipal Solid Waste and Scrap Tires; Laboratory of Clean Combustion, Ben-Gurion University, Unit of Solid Waste, Israel Ministry for Environmental Protection: Beer Sheva, Israel, 2012. [Google Scholar]

- Williams, P.T. Pyrolysis of waste tyres: A review. Waste Manag. 2013, 33, 1714–1728. [Google Scholar] [CrossRef]

- Martinez, J.D.; Puy, N.; Murillo, R.; Garcia, T.; Navarro, M.V.; Mastral, A.M. Waste tyre pyrolysis—A review. Renew. Sustain. Energy Rev. 2013, 23, 179–213. [Google Scholar] [CrossRef]

- Muzenda, E. A comparative review of waste tyre pyrolysis, gasification and liquefaction (PGL) processes. In Proceedings of the International Conference on Chemical Engineering Advanced Computational Technologies, Pretoria, South Africa, 24–25 November 2014; pp. 1–6. [Google Scholar]

- Williams, P.T.; Besler, S.; Taylor, D.T. The pyrolysis of scrap automotive tyres: The influence of temperature and heating rate on product composition. Fuel 1990, 69, 1474–1482. [Google Scholar] [CrossRef]

- Laresgoiti, M.F.; Caballero, B.M.; De Marco, I.; Torres, A.; Cabrero, M.A.; Chomon, M.J.J. Characterization of the liquid products obtained in tire pyrolysis. J. Anal. Appl. Pyrolysis 2004, 71, 917–934. [Google Scholar] [CrossRef]

- Torretta, V.; Rada, E.C.; Ragazzi, M.; Trulli, E.; Istrate, I.A.; Cioca, L.I. Treatment and disposal of tyres: Two EU approaches. A review. Waste Manag. 2015, 45, 152–160. [Google Scholar] [CrossRef]

- Diez, C.; Martinez, O.; Calvo, L.F.; Cara, J.; Morán, A. Pyrolysis of tires. Influence of the final temperature of the process on emissions and the calorific value of the products recovered. Waste Manag. 2004, 24, 463–469. [Google Scholar] [CrossRef] [PubMed]

- Ruwona, W.; Danha, G.; Muzenda, E. A Review on Material and Energy Recovery from Waste Tyres. Procedia Manuf. 2019, 35, 216–222. [Google Scholar] [CrossRef]

- Juaidi, A.; Assad, M.; Salameh, T.; Agugliaro, F.M.; Khaldi, R. Energy Recovery from Waste Tires Using Pyrolysis: Palestine as Case of Study. Energies 2020, 13, 1817. [Google Scholar]

- Lopez, F.A.; Centeno, T.A.; Alguacil, F.J.; Lobato, B. Distillation of granulated scrap tires in a pilot plant. J. Hazard. Mater. 2011, 190, 285–292. [Google Scholar] [CrossRef]

- Amari, T.; Themelis, N.J.; Wernick, I.K. Resource recovery from used rubber tires. Resour. Policy 1999, 25, 179–188. [Google Scholar] [CrossRef]

- Samolada, M.C.; Zabaniotou, A. Potential application of pyrolysis for the effective valorisation of the end of life tires in Greece. Environ. Dev. 2012, 4, 73–87. [Google Scholar] [CrossRef]

- Labaki, M.; Jeguirim, M. Thermochemical conversion of waste tyres-a review. Environ. Sci. Pollut. Res. 2017, 24, 9962–9992. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Y.; Wu, C.; Nahil, M.A.; Williams, P. Pyrolysis-catalytic reforming/gasification of waste tires for production of carbon nanotubes and hydrogen. Energy Fuels 2015, 29, 3328–3334. [Google Scholar] [CrossRef]

- Portofino, S.; Donatelli, A.; Iovane, P.; Innella, C.; Civita, R.; Martino, M.; Matera, M.C.; Russo, A.; Cornacchia, G.; Galvagno, S. Steam gasification of waste tyre: Influence of process temperature on yield and product composition. Waste Manag. 2013, 33, 672–678. [Google Scholar] [CrossRef]

- Lopez, F.A.; Centeno, T.A.; Alguacil, F.J.; Lobato, B.; Lopez-Delgado, A.; Fermoso, J. Gasification of the char derived from distillation of granulated scrap tyres. Waste Manag. 2012, 32, 743–752. [Google Scholar] [CrossRef]

- Xiao, G.; Ni, M.J.; Chi, Y.; Cen, K.-F. Low-temperature gasification of waste tire in a fluidized bed. Energy Convers. Manag. 2008, 49, 2078–2082. [Google Scholar] [CrossRef]

- Landi, D.; Marconi, M.; Meo, I.; Germani, M. Reuse scenarios of tires textile fibers: An environmental evaluation. Procedia Manuf. 2018, 21, 329–336. [Google Scholar] [CrossRef]

- Lopez, F.A.; Centeno, T.A.; Rodriquez, O.; Alguacil, F.J. Preparation and characterization of activated carbon from the char produced in the thermolysis of granulated scrap tyres. J. Air Waste Manag. Assoc. 2013, 63, 534–544. [Google Scholar] [CrossRef]

- Januszewicz, K.; Kazimierski, P.; Suchocki, T.; Kardaś, D.; Lewandowski, W.; Klugmann-Radziemska, E.; Łuczak, J. Waste Rubber Pyrolysis: Product Yields and Limonene Concentration. Materials 2020, 13, 4435. [Google Scholar] [CrossRef]

- Kuznetsov, G.V.; Syrodoy, S.V.; Purin, M.V.; Zenkov, A.V.; Gvozdyakov, D.V.; Larionov, K.B. Justification of the possibility of car tires recycling as part of coal-water composites. J. Environ. Chem. Eng. 2021, 9, 104741. [Google Scholar] [CrossRef]

- Medina, N.F.; Flores-Medina, D.; Hernandez-Olivares, F. Influence of fibers partially coated with rubber from tire recycling as aggregate on the acoustical properties of rubberized concrete. Constr. Build. Mater. 2016, 129, 25–36. [Google Scholar] [CrossRef]

- Helleur, R.; Popovic, N.; Ikura, M.; Stanciulescu, M.; Liu, D. Characterization and potential applications of pyrolytic char from ablative pyrolysis of used tires. J. Anal. Appl. Pyrolysis 2001, 58, 813–824. [Google Scholar] [CrossRef]

- Chan, O.S.; Cheung, W.H.; McKay, G. Preparation and characterisation of demineralised tyre derived activated carbon. Carbon 2011, 49, 4674–4687. [Google Scholar] [CrossRef]

- Adhikari, J.; Das, A.; Sinha, T.; Saha, P.; Kim, J.K. Chapter 1: Grinding of Waste Rubber. In Rubber Recycling: Challenges and Developments; Kim, J.K., Saha, P., Thomas, S., Haponiuk, J.T., Aswathi, K.M., Eds.; Royal Society of Chemistry: London, UK, 2018; pp. 1–23. [Google Scholar]

- Corinaldesi, V.; Donnini, J. Waste rubber aggregates. In New Trends in Eco-Efficient and Recycled Concrete; de Brito, J., Agrela, F., Eds.; Woodhead Publishing Series in Civil and Structural Engineering: Cambridge, UK, 2019; pp. 87–119. [Google Scholar]

- Li, X.; Xu, X.; Liu, Z. Cryogenic grinding performance of scrap tire rubber by devulcanization treatment with ScCO2. Powder Technol. 2020, 374, 609–617. [Google Scholar] [CrossRef]

- Fernandez, A.M.; Barriocanal, C.; Alvarez, R. Pyrolysis of a waste from the grinding of scrap tyres. J. Hazard. Mater. 2012, 203, 236–243. [Google Scholar] [CrossRef]

- ASTM D6270-20. Standard Practice for Use of Scrap Tires in Civil Engineering Applications; ASTM International: West Conshohocken, PA, USA, 2020. [Google Scholar]

- BSI-PAS 107. Specification for the Manufacture and Storage of Size Reduced Tyre Materials. Publicly Available Standards; BSI British Standards Institution: London, UK, 2012. [Google Scholar]

- UNEP—Revised Technical Guidelines for the Environmentally Sound Management of Used and Waste Pneumatic Tyres. Available online: https://www.informea.org/en/revised-technical-guidelines-environmentally-sound-management-used-and-waste-pneumatic-tyres (accessed on 2 December 2020).

- CalRecycle—Tire-Derived Aggregate (TDA). Available online: https://www.calrecycle.ca.gov/tires/greenroads/tda (accessed on 19 November 2020).

- Simm, J.D.; Wallis, M. Sustainable re-use of tyres in port, coastal and river engineering. In Guidance for Planning, Implementation and Maintenance; Project Report; DTI/Environment Agency; HR Wallingford: Wallingford, UK, 2004. [Google Scholar]

- Simalti, A.; Singh, A.P. Comparative study on performance of manufactured steel fiber and shredded tire recycled steel fiber reinforced self-consolidating concrete. Constr. Build. Mater. 2021, 266, 121102. [Google Scholar] [CrossRef]

- Tischmak, D.; Marcato, W. Investigation of Best Options for Using Scrap Tires in Highway Noise Barriers; Report No. CDOT-2011-8; Colorado Department of Transportation dtd Applied Research and Innovation Branch: Denver, CO, USA, 2011.

- Kader, M.A.; Abdel-wehabb, S.M.; Helala, M.A.; Hassan, H.H. Evaluation of thermal insulation and mechanical properties of waste rubber/natural rubber composite. HBRC J. 2012, 8, 69–74. [Google Scholar] [CrossRef]

- Romero-Flores, M.; Becerra-Lucatero, L.M.; Salmón-Folgueras, R.; Lopez-Salinas, J.S.; Bremer-Bremer, M.H.; Montesinos-Castellanos, A. Thermal performance of scrap tire blocks as roof insulator. Energy Build. 2017, 149, 384–390. [Google Scholar] [CrossRef]

- Zakaria, F.; Radwan, M.A.; Sadek, M.; Elazab, H. Insulating material based on shredded used tires and inexpensive polymers for different roofs. Int. J. Eng. Technol. 2018, 7, 1983–1988. [Google Scholar] [CrossRef]

- Siddique, R.; Naik, T.R. Properties of concrete containing scrap-tire rubber—An overview. Waste Manag. 2004, 24, 563–569. [Google Scholar] [CrossRef] [PubMed]

- Pelisser, F.; Zavarise, N.; Longo, T.A.; Bernardin, A.M. Concrete made with recycled tire rubber: Effect of alkaline activation and silica fume addition. J. Clean. Prod. 2011, 19, 757–763. [Google Scholar] [CrossRef]

- Perez, G.; Coma, J.; Solé, C.; Castell, A.; Cabeza, L.F. Green roofs as passive system for energy savings when using rubber crumbs as drainage layer. Energy Procedia 2012, 30, 452–460. [Google Scholar] [CrossRef]

- Azmi, A.A.; Al Bakri Abdullah, M.M.; Ruzaidi, C.M.; Sandu, A.V.; Kamarudin, H. A Review—Manufacturing on Rubberized Concrete Filled Recycled Tire Rubber. Key Eng. Mater. 2015, 660, 249–253. [Google Scholar] [CrossRef]

- Aslani, F. Mechanical properties of waste tire rubber concrete. J. Mater. Civ. Eng. 2016, 28, 04015152. [Google Scholar] [CrossRef]

- Mushunje, K.; Otieno, M.; Ballim, Y. A review of Waste Tyre Rubber as an Alternative Concrete Consituent Material. MATEC Web Conf. 2018, 199, 11003. [Google Scholar] [CrossRef]

- Valente, M.; Sibai, A. Rubber/crete: Mechanical properties of scrap to reuse tire-derived rubber in concrete; A review. J. Appl. Biomater. Funct. Mater. 2019, 17, 2280800019835486. [Google Scholar] [CrossRef] [PubMed]

- Zanetti, M.C.; Fiore, S.; Ruffino, B.; Santagata, E.; Dalmazzo, D.; Lanotte, M. Characterization of crumb rubber from end-of-life tyres for paving applications. Waste Manag. 2015, 45, 161–170. [Google Scholar] [CrossRef] [PubMed]

- Lo Pesti, D. Recycled Tyre Rubber Modified Bitumens for road asphalt mixtures: A literature review. Constr. Build. Mater. 2013, 49, 863–881. [Google Scholar] [CrossRef]

- Issa, Y. Effect of Adding Waste Tires Rubber to Asphalt Mix. Int. J. Sci. Res. Innov. Technol. 2016, 3, 62–67. [Google Scholar]

- Wulandari, P.S.; Tjandra, D. Use of Crumb Rubber as an Additive in Asphalt Concrete Mixture. Procedia Eng. 2017, 171, 1384–1389. [Google Scholar] [CrossRef]

- Qudah, A.A.; Rahim, M.A.; Ghazaly, Z.M.; Mashaan, N.S.; Koting, S.; Napiah, M.; Omar, W.M.S.W.; Issa, Y. Effect of Aged Crumb Rubber Bitumen on Performance Dense Graded Mix in Malaysia. Int. J. Civ. Eng. Technol. 2018, 9, 1356–1369. [Google Scholar]

- Malarvizhi, G.; Senthil, N.; Kamaraj, C. A study on Recycling of crumb rubber and low density polyethylene blend on stone matrix asphalt. Int. J. Sci. Res. Publ. 2012, 2, 10. [Google Scholar]

- Thomas, B.S.; Gupta, R.C. A comprehensive review on the applications of waste tire rubber in cement concrete. Renew. Sustain. Energy Rev. 2016, 54, 1323–1333. [Google Scholar] [CrossRef]

- Gesser, H.D.; Goswami, H.D. Aerogels and Related Porous Materials. Chem. Rev. 1989, 89, 765–788. [Google Scholar] [CrossRef]

- Thai, Q.B.; Siang, T.E.; Le, D.K.; Shah, W.A.; Phan-Thien, N.; Duong, H.M. Advanced fabrication and multi-properties of rubber aerogels from car tire waste. Coll. Surf. 2019, 577, 702–708. [Google Scholar] [CrossRef]

- Maderuelo-Sanz, R.; Nadal-Gisbert, A.V.; Crespo-Amorós, J.E.; Parres-García, F. A novel sound absorber with recycled fibers coming from end of life tires (ELTs). Appl. Acoust. 2012, 73, 402–408. [Google Scholar] [CrossRef]

- Jimenez-Espadafor, F.J.; Villanueva, J.A.B.; García, M.T.; Trujillo, E.C.; Blanco, A.M. Optimal design of acoustic material from tire fluff. Mater. Des. 2011, 32, 3608–3616. [Google Scholar] [CrossRef]

- Xiang, S.; Baoshan, H. Recycling of waste tire rubber in asphalt and portland cement concrete: An overview. Constr. Build. Mater. 2014, 67, 217–224. [Google Scholar]

- Bignozzi, M.C.; Saccani, A.; Sandrolini, F. New polymer mortars containing polymeric wastes. Part 2. Dynamic mechanical and dielectric behaviour. Compos. Part A Appl. Sci. Manuf. 2002, 33, 205–211. [Google Scholar] [CrossRef]

- Bocci, E.; Prosperi, E. Recycling of reclaimed fibers from end-of-life tires in hot mix asphalt. J. Traffic Transp. Eng. 2020, 7, 678–687. [Google Scholar] [CrossRef]

- Landi, D.; Gigli, S.; Germani, M.; Marconi, M. Investigating the feasibility of a reuse scenario for textile fibres recovered from end-of-life tyres. Waste Manag. 2018, 75, 187–204. [Google Scholar] [CrossRef]

- Ganjian, E.; Khorami, M.; Maghsoudi, A.A. Scrap-tyre rubber replacement for aggregate and filler in concrete. Constr. Build. Mater. 2009, 23, 1828–1836. [Google Scholar] [CrossRef]

- Hernandez-Olivares, F.; Barluenga, G.; Bollati, M.; Witoszek, B. Static and dynamic behaviour of recycled tyre rubber filled concrete. Cem. Concr. Res. 2002, 32, 1587–1596. [Google Scholar] [CrossRef]

- Sang Son, K.; Hajirasouliha, I.; Pilakoutas, K. Strength and deformability of waste tyre rubber-filled reinforced concrete columns. Constr. Build. Mater. 2011, 25, 218–226. [Google Scholar]

- Aiello, M.A.; Leuzzi, F. Waste tyre rubberized concrete, properties at fresh and hardened state. Waste Manag. 2010, 30, 1696–1704. [Google Scholar] [CrossRef]

- Oikonomou, N.; Eskioglou, P.; Mavridou, S. Study of concrete kerb units modified with tire rubber. In Proceedings of the 4th International Conference on Bituminous Mixtures and Pavements, Thessaloniki, Greece, 19–20 April 2007; pp. 465–477. [Google Scholar]

- Oikonomou, N.; Mavridou, S. Rubcrete—Rubberized Portland Cement Concrete. Chapter 8: Rubcrete—Rubberized portland cement concrete. In Progress in Sustainable Development Research; Lopez, R.A., Ed.; Nova Science Publishers: New York, NY, USA, 2008; pp. 201–214. [Google Scholar]

- Pacheco-Torgal, F.; Ding, Y.; Jalali, S. Properties and durability of concrete containing polymeric wastes (tyre rubber and polyethylene terephthalate bottles): An overview. Constr. Build. Mater. 2012, 30, 714–724. [Google Scholar] [CrossRef]

- El-Gammal, A.; Abdel-Gawad, A.K.; El-Sherbini, Y.; Shalaby, A. Compressive strength of concrete utilizing waste tire rubber. J. Emerg. Trends Eng. Appl. Sci. 2010, 1, 96–99. [Google Scholar]

- Zhang, Y.M.; Chen, X.S.; Chen, B.; Sun, W. Dry shrinkage, frost resistance and permeability of rubber included concrete. Key Eng. Mater. 2006, 302, 120–124. [Google Scholar] [CrossRef]

- Malaiskinie, J.; Nagrockinie, G.; Skripkiunas, G. Possibilities to Use Textile Cord Waste from Used Tires for Concrete. J. Environ. Eng. Landsc. Manag. 2015, 23, 183–191. [Google Scholar] [CrossRef]

- Chen, M.; Zhong, H.; Zhang, M. Flexural fatigue behaviour of recycled tyre polymer fibre reinforced concrete. Cem. Concr. Compos. 2020, 105, 103441. [Google Scholar] [CrossRef]

- Serdar, Μ.; Baričević, A.; Lakušić, S.; Bjegović, D. Special purpose concrete products from waste tyre recyclates. Građevinar 2013, 65, 793–801. [Google Scholar]

- Chen, M.; Chen, W.; Zhong, H.; Chi, D.; Wang, Y.; Zhang, M. Experimental study on dynamic compressive behaviour of recycled tyre polymer fibre reinforced concrete. Cem. Concr. Compos. 2019, 98, 95–112. [Google Scholar] [CrossRef]

- Oikonomou, N.; Mavridou, S. Utilization of textile fibres from worn automobile tires in cement based mortars. Glob. Nest J. 2011, 13, 176–181. [Google Scholar]

- Czvikovszky, T.; Hargitai, H. Electron Beam Surface Modifications in Reinforcing and Recycling of Polymers. Nucl. Instrum. Methods Phys. Res. B 1997, 131, 300–304. [Google Scholar] [CrossRef]

- Marconi, Μ.; Landi, D.; Meo, I.; Germani, M. Reuse of tires textile fibers in plastic compounds: Is this scenario environmentally sustainable? Procedia CIRP 2018, 69, 944–949. [Google Scholar] [CrossRef]

- Mucsi, G.; Szenczi, A.; Nagy, S. Fiber reinforced geopolymer from synergetic utilization of fly ash and waste tire. J. Clean. Prod. 2018, 178, 429–440. [Google Scholar] [CrossRef]

- Abbaspour, M.; Aflaki, E.; Nejad, F.M. Reuse of waste tire textile fibers as soil reinforcement. J. Clean. Prod. 2019, 207, 1059–1071. [Google Scholar] [CrossRef]

| Year | Title—Reference | Content |

|---|---|---|

| 1975 | Council Directive 75/442/EEC (modified by Directive 2008/98/EC) [11] | ELTs characterized as non-hazardous wastes |

| 1993 | Council Regulation (EEC) No 259/93 [12] | Shipments of wastes—Supervision & Control (code: 4012 20 Used pneumatic tires) |

| 1999 | Council Directive 1999/31/EC [13] | Prohibition of tires disposed in landfills (whole tires 2003-shredded tires 2006) |

| 2000 | Commission Decision 2000/532/EC [14] | End-of-life vehicles are coded as “16 01 03” |

| 2000 | Directive 2000/76/EC [15] | Specific emission standards for the cement industry with effect from 2002. |

| 2000 | Directive 2000/53/EC [7] | Recovery of 85% of vehicles to be disposed off, with effect from 2006, with compulsory removal of tires from the vehicle |

| 2001 | Commission Decision 2001/118/EC [16] | ELTS classification code 16.01.03, (from 1 January 2002) |

| 2005 | COM (2005) 666 [17] | Features the need for additional actions in order to determine the optimal environmental options and targets for wastes. Includes the principle of producer responsibility |

| 2008 | Directive 2008/98/EC [9] | Basic principles of waste management (“the polluter pays” & “waste management hierarchy”). Introduces the waste end principle. |

| 2009 | Directive 2009/28/EC [10] | Mandating the levels of renewable energy use within the European Union from 2009 to 2021 |

| 2010 | CEN TS 14,243 “Materials produced from end of life tires—Specification of categories based on their dimension(s) and impurities, and methods for determining their dimension(s) and impurities” [18] | Characterization of the materials resulting from ELTs in terms of dimensions and impurities including sampling and testing methods. |

| 2018 | Directive EU 2018/851 [19] | Amendments to Directive 2008/98/EC on waste (incl. legislation for treatment of waste) |

| Composition | Passenger Cars | Trucks |

|---|---|---|

| Rubber | 47% | 45% |

| Carbon Black | 21.5% | 22% |

| Steel | 16.5% | 25% |

| Fiber | 5.5% | 0% |

| Zinc Oxide | 1% | 2% |

| Additives | 7.5% | 5% |

| Distribution | Total Quantity | Rubber | Textile Fiber |

|---|---|---|---|

| 1000 μm | 76.4–91% | 0.5–11.8% | 64.6–92.6% |

| 1000–800 μm | 0.3–6.3% | 0.3–6.3% | >0.1% |

| 800–500 μm | 0.7–7.9% | 0.7–7.9% | - |

| 500–250 μm | 0.6–5.8% | 0.6–5.7% | >0.3% |

| <250 μm | 1.9–5.6% | 1.5–5.2% | >0.4% |

| Total | 7–35.2% | 64.7–93% | |

| Moisture (wt.%, a.r) (CEN/TS 15414-1) | Proximate Analysis (w.t%, db) (EN 15414-3, 15402 & 15403) | Ultimate Analysis (wt.% db) (EN 15407, 15408 & ASTM D 516) | NCV, d.b. (MJ/kg) (EN 15400) | GCV, d.b. (MJ/kg) (EN 15400) | ||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Volatiles | Ash | C | H | N | S | Cl | O * | |||

| 1.3 | 72.3 | 7.1 | 79.34 | 7.75 | 0.64 | 1.12 | 0.11 | 11.04 | 31.75 | 33.39 |

| Concentrations (ppm, d.b. ash) (EN 15410 & 15411) | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Cd | Cr | Cu | Mn | Ni | Pb | Zn | Co | |||||

| 3.62 | 37.44 | 4251.06 | 315.2 | 7.08 | 267.34 | 192,732.72 | 1851.24 | |||||

| Al | Ca | Fe | K | Mg | Na | Si | ||||||

| 6821.1 | 51,245.91 | 45,707.05 | 8747.28 | 9450.78 | 6365.88 | 79,624.45 | ||||||

| Ash Melting Behavior (CEN/TR 15404) | ||||

|---|---|---|---|---|

| Initial Temperature | Shrinkage (ST) | Deformation (DT) | Hemisphere (HT) | Flow (FT) |

| 400 °C | 732 °C | 1060 °C | 1151 °C | 1164 °C |

|  |  |  |  |

| Application | Source | ||||

|---|---|---|---|---|---|

| Whole Car Tire | Whole Truck Tire | Mixed Whole Tires | Truck Tire Tread | All Types | |

| Artificial Reefs | x | ||||

| Bridge Abutments | x | x | |||

| Concrete Construction Additives | x | ||||

| Construction Bales | x | x | |||

| Culvert Drainage Beds | x | x | |||

| Embankments | x | x | x | ||

| Insulation | x | x | |||

| Landfill Drainage Layer | x | x | |||

| Slope Stabilization | x | x | |||

| Temporary Roads | x | x | |||

| Thermal Insulation | x | x | x | ||

| Collision Barriers | x | ||||

| Lightweight Fill | x | x | x | ||

| Noise Barriers | x | x | x | ||

| Equestrian Tracks | x | x | x | ||

| Soccer/Hockey Pitches | x | x | |||

| Indoor Safety Flooring | x | x | |||

| Playground Surfaces | x | x | |||

| Asphalt Additives | x | ||||

| Asphalt Rubber | x | x | |||

| Coatings | x | x | |||

| Expansion Joints | x | x | |||

| Road Furniture | x | ||||

| Sealants | x | ||||

| Surfacing | x | x | x | ||

| Train & Tram Rail Beds | x | x | |||

| Wearing Course | x | x | |||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Grammelis, P.; Margaritis, N.; Dallas, P.; Rakopoulos, D.; Mavrias, G. A Review on Management of End of Life Tires (ELTs) and Alternative Uses of Textile Fibers. Energies 2021, 14, 571. https://doi.org/10.3390/en14030571

Grammelis P, Margaritis N, Dallas P, Rakopoulos D, Mavrias G. A Review on Management of End of Life Tires (ELTs) and Alternative Uses of Textile Fibers. Energies. 2021; 14(3):571. https://doi.org/10.3390/en14030571

Chicago/Turabian StyleGrammelis, Panagiotis, Nikolaos Margaritis, Petros Dallas, Dimitrios Rakopoulos, and Georgios Mavrias. 2021. "A Review on Management of End of Life Tires (ELTs) and Alternative Uses of Textile Fibers" Energies 14, no. 3: 571. https://doi.org/10.3390/en14030571

APA StyleGrammelis, P., Margaritis, N., Dallas, P., Rakopoulos, D., & Mavrias, G. (2021). A Review on Management of End of Life Tires (ELTs) and Alternative Uses of Textile Fibers. Energies, 14(3), 571. https://doi.org/10.3390/en14030571