Combined Use of Solar and Biomass Energy for Sustainable and Cost-Effective Low-Temperature Drying of Food Processing Residues on Industrial-Scale

Abstract

1. Introduction

2. Materials and Methods

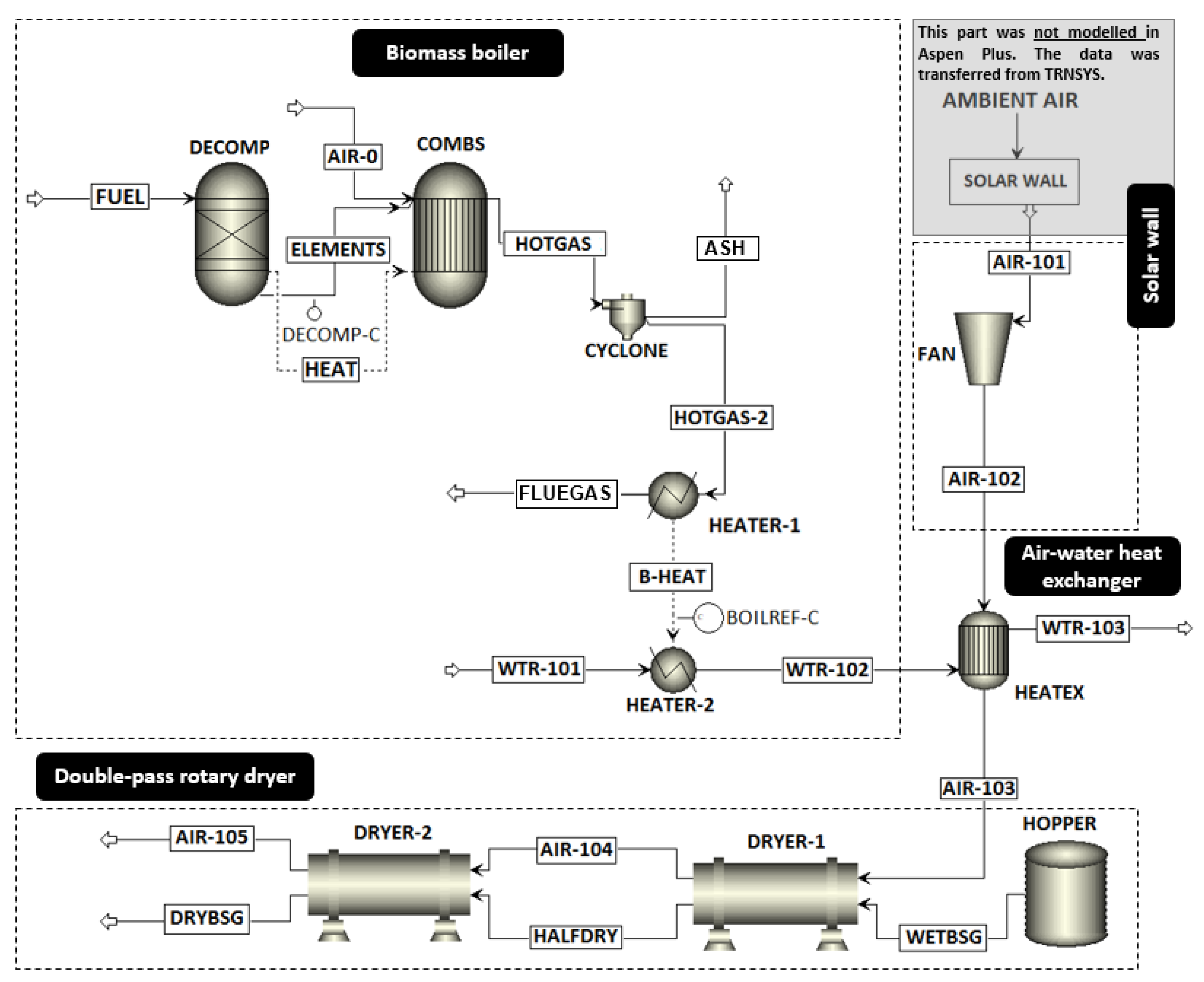

2.1. Process Description

2.2. Aspen Plus Modelling

- Dimensions: length and diameter of each pass is 9 m, and 1.5 m, respectively.

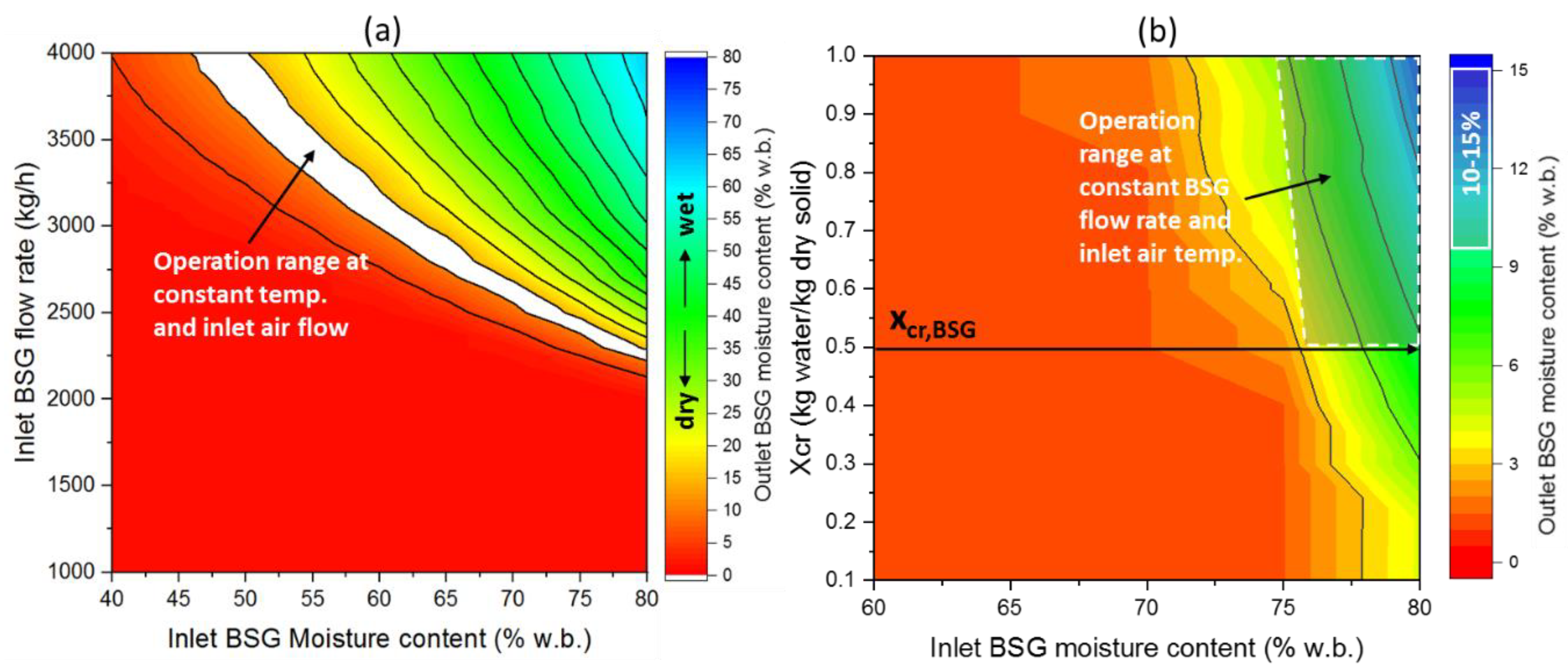

- Information on the drying curve, critical (Xcr), and equilibrium (Xeq) moisture of the material, as well as heat and mass transfer coefficients to develop a model based on drying kinetics, can be found elsewhere [29]. In this study, Xcr is defined as critical moisture at which further evaporation is mass-transfer limited with a constant drying rate. It was set to 0.8 kgwater/kgdry solid considering the critical moisture of food and sludge-like materials being between 0.4–0.8 kgwater/kgdry solid [30]. The equilibrium moisture Xeq, defined as the moisture at which the remaining moisture in the solid is in equilibrium with the moisture with the surrounding atmosphere. It was set to 0.015 kgwater/kgdry solid [31].

- The main assumptions in the dryer model can be summarized as follows:

- The dryer is adiabatic (no heat losses) [32].

- Drying gas and the solids passing through the dryer are considered as plug flow. Thus, complex solid material flow characteristics in the rotary dryer were neglected [33].

- Ideal mixing of the particles inside the dryer in a lateral direction was assumed [32].

- The moisture and temperature are spatially constant in each particle [32].

- A co-current gas flow was considered for drying of heat-sensitive products with higher drying rates [33].

- In total, wet BSG material of 20,000 tons per year was set as the target amount.

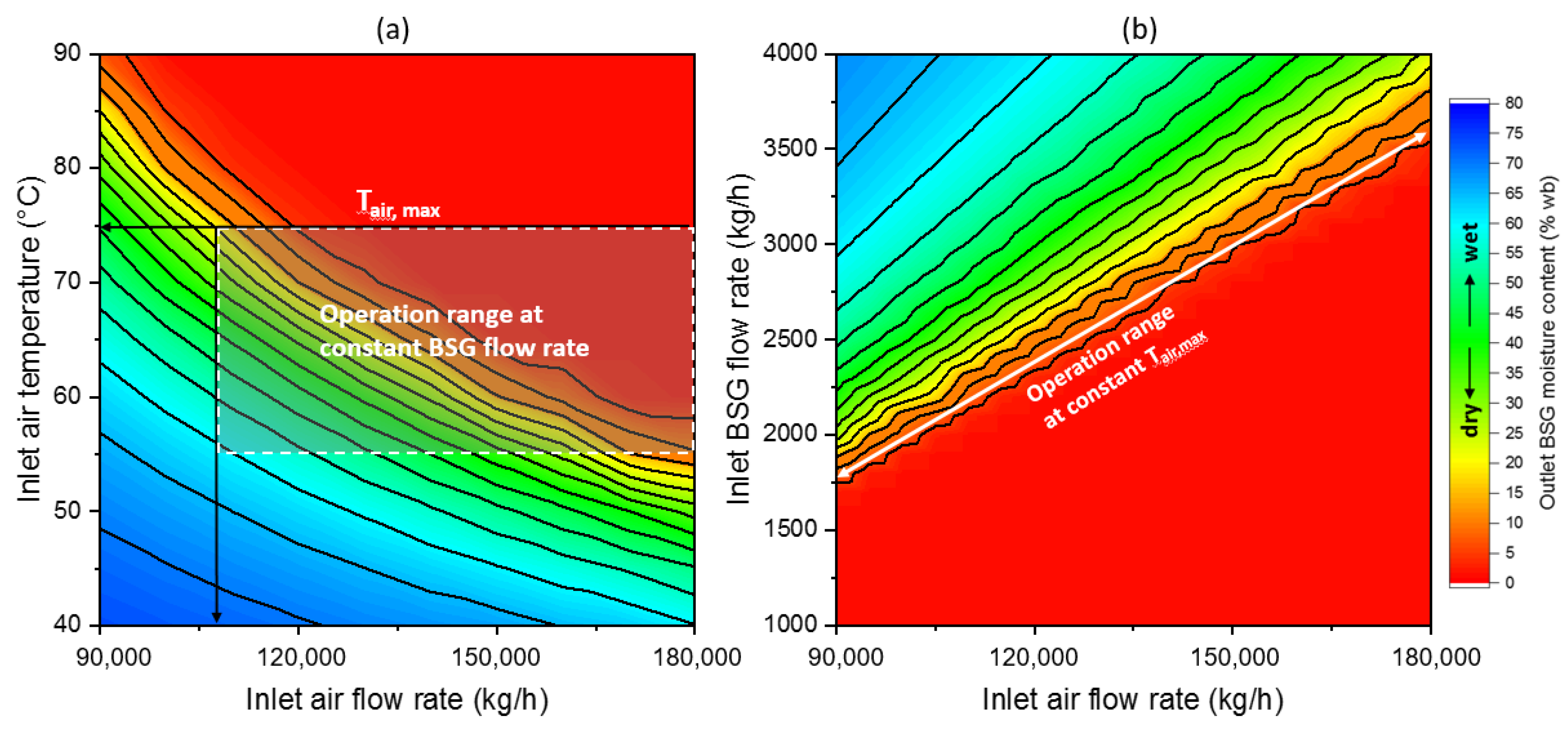

- (a)

- A constant BSG flow rate at the dryer inlet.

- (b)

- A constant air inlet temperature of 75 °C.

2.3. Parameter Variation and Weather Data Selection for the Aspen Plus Simulations

2.4. Techno-Economic Analysis

- -

- Isenthalpic drying process with constant moisture of the BSG of 0.8 kg/kg at the inlet and 0.15 kg/kg at the outlet of the dryer.

- -

- No thermal capacities of the plant equipment were considered.

- -

- Maximum air humidity at the dryer outlet was set to 75%.

- -

- The inlet air temperature into the dryer was kept constant at a maximum of 75 °C while the maximum inlet air flow rate within the system was limited to 180,000 m3/h.

- -

- Technical limitations of the dryer and drying process (e.g., rotational speed, residence time, and equilibrium moisture) were not considered.

- -

- The calculations were based on the control strategy b in which inlet air temperature into the dryer was kept constant at 75 °C as done in Aspen Plus simulations (cf. Section 3.1).

- -

- The dryer design was assumed to be the same in all cases, while the capacities of the renewable heat sources (i.e., SW area and boiler capacity) were varied. The maximum input flow rate of the wet BSG material into the dryer is set to 4.0 t/h.

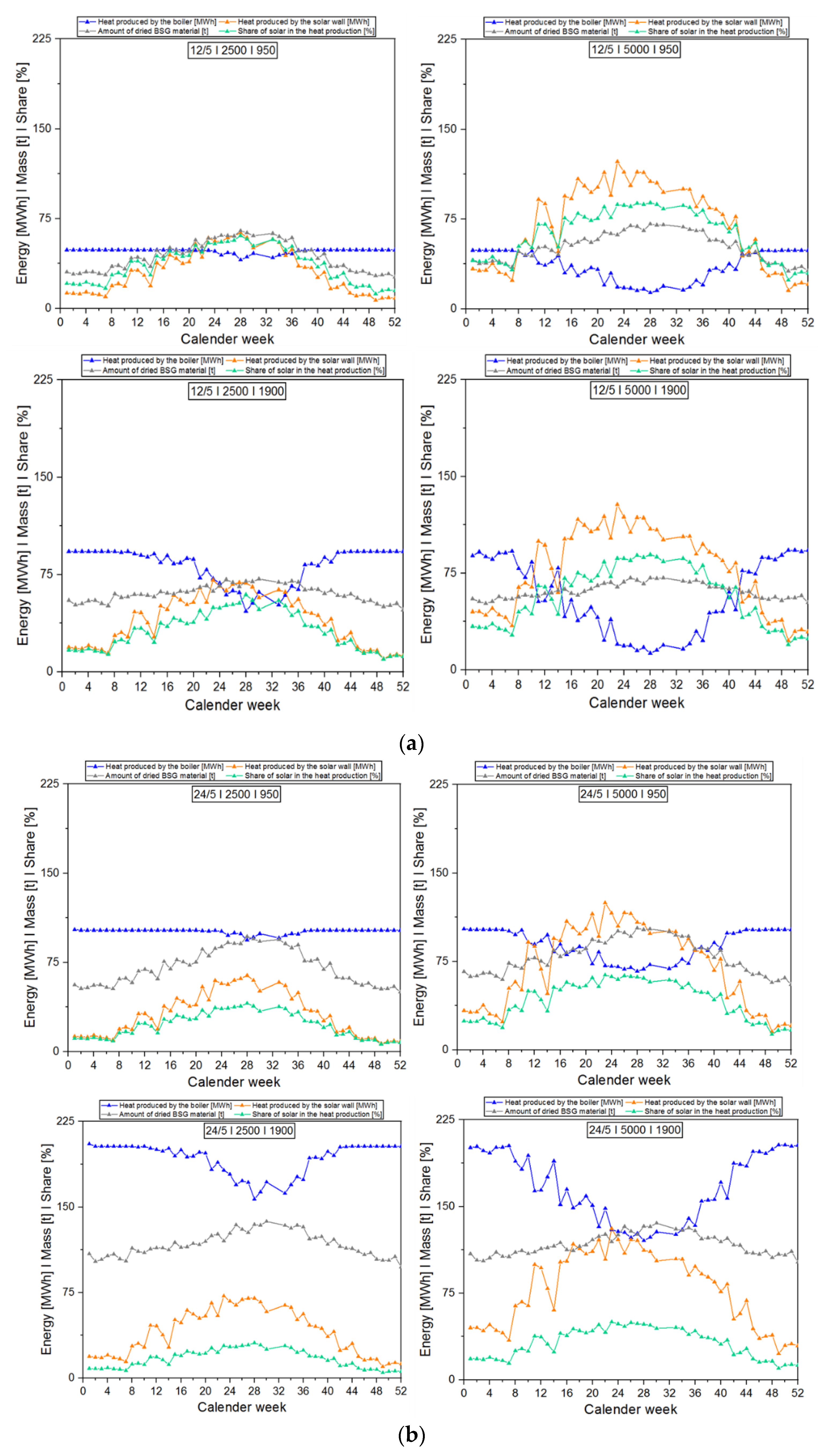

- -

- For a better comparison, the calculations were performed based on two operational strategies; 12 h/day and five days per week, as well as 24 h/day and five days per week. These will be shortly referred to as 12/5 and 24/5 within the text, respectively. The plant was operated between 9:00–17:00 in case of the operational strategy 12/5.

- -

- “Reference design” refers to the plant configuration with 2500 m2 SW area and 950 kW boiler, unless otherwise is indicated in the text.

- -

- The calendar weeks 31 and 32 were planned for yearly maintenance; therefore, no plant operation occurred during this period in all scenarios.

3. Results and Discussion

3.1. The Operational Boundaries of Drying Process

3.2. Comparison of Monthly Heat Production Based On Different Plant Set-Ups and Operational Strategies

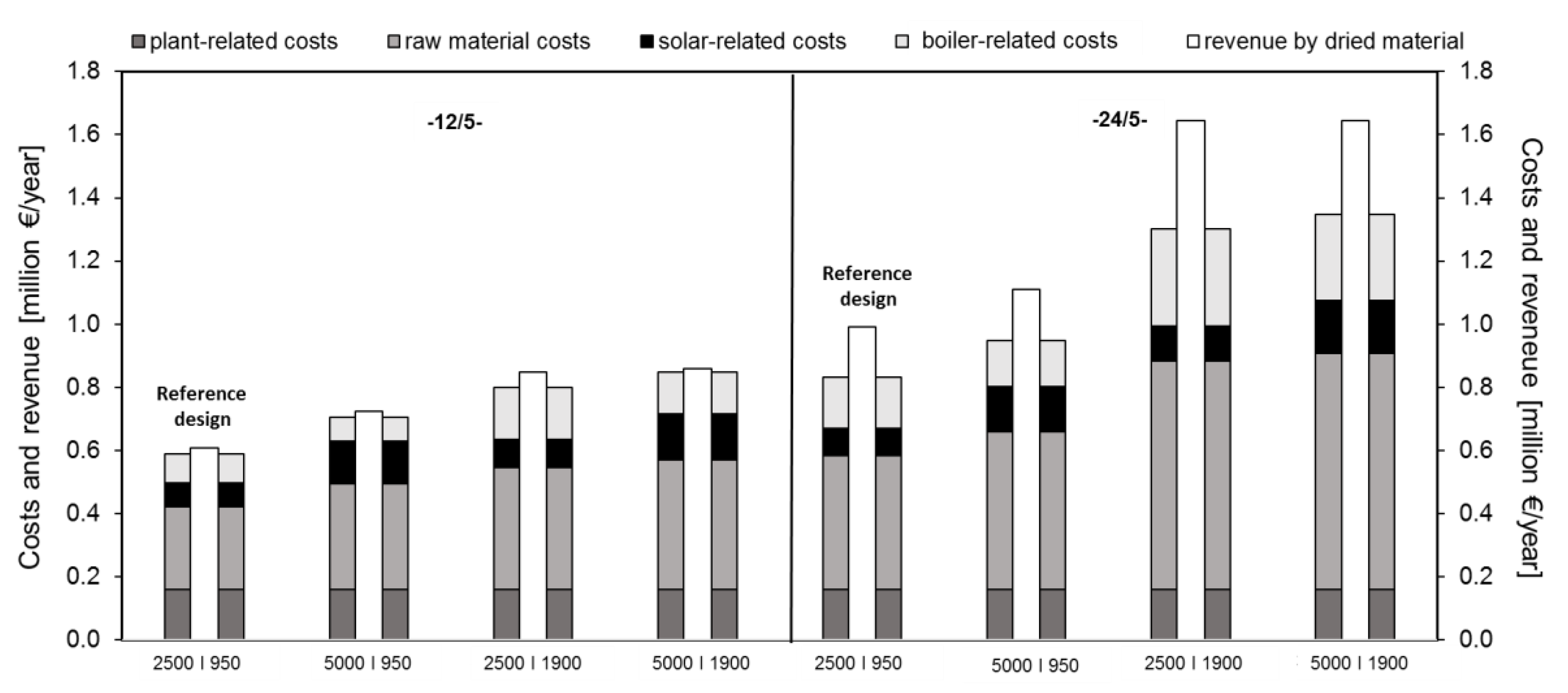

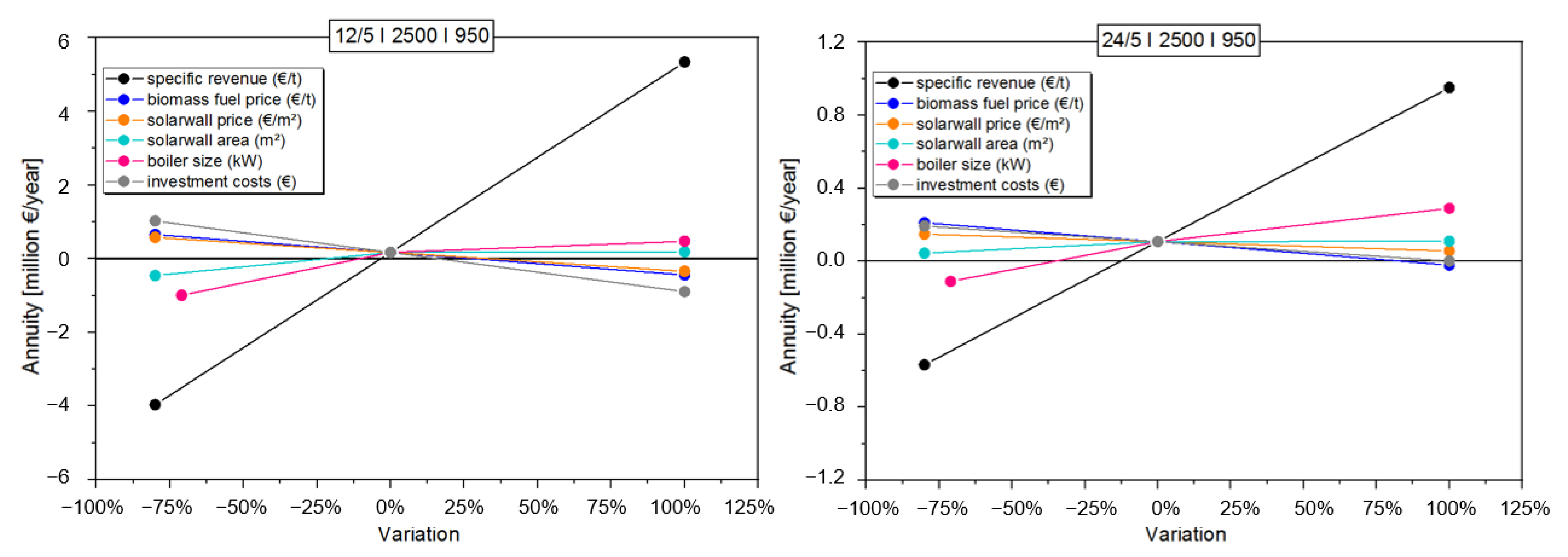

3.3. The Cost Optimization of the Renewable Drying Process

- -

- The raw material costs refer to BSG costs.

- -

- The plant-related costs include capital costs for the plant (dryer and other auxiliary units), personal costs as well as maintenance costs.

- -

- The solar-related costs refer to capital costs of SW, electricity costs for pumping air as well as maintenance costs.

- -

- Boiler-related costs refer to capital costs for the boiler, fuel costs, ash disposal costs, as well as maintenance costs.

4. Summary and Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| a.r. | As received |

| BSG | Brewery spent grain |

| calc. | Calculated |

| D | Day |

| GHG | Greenhouse gas emissions |

| N | Night |

| NTU | Number of transfer units |

| PENG-ROB | Peng–Robinson cubic equation of state |

| SW | Solar wall |

| w.b. | Wet basis |

| 12/5 | 12 h per day, five days per week |

| 24/5 | 24 h per day, five days per week |

| Nomenclature | |

| Ta | Cold air temperature, °C |

| RH | Air humidity, % |

| Density of dry air, kg/m3 | |

| Saturation vapor pressure, kPa | |

| Partial water vapor pressure | |

| Absolute humidity, kgw/kga | |

| Absolute humidity, | |

| Heat capacity, | |

| Enthalpy of moist air, kJ/kg | |

| Sloped radiation, W/m2 | |

| Mass flow, kg/h | |

| Required boiler heat, kW | |

| Psol | Solar power, kW |

| Hot air temperature, °C | |

| Removed water per kg of air, kgw/kga | |

| Amount of evaporated water, | |

| Dried BSG material, |

References

- Goula, A.M.; Lazarides, H.N. Integrated processes can turn industrial food waste into valuable food by-products and/or ingredients: The cases of olive mill and pomegranate wastes. J. Food Eng. 2015, 167, 45–50. [Google Scholar] [CrossRef]

- European Commission. Food Waste. Available online: https://ec.europa.eu/food/safety/food_waste_en (accessed on 7 January 2020).

- Zabaniotou, A.; Kamaterou, P. Food waste valorization advocating Circular Bioeconomy—A critical review of potentialities and perspectives of spent coffee grounds biorefinery. J. Clean. Prod. 2019, 211, 1553–1566. [Google Scholar] [CrossRef]

- Mirabella, N.; Castellani, V.; Sala, S. Current options for the valorization of food manufacturing waste: A review. J. Clean. Prod. 2014, 65, 28–41. [Google Scholar] [CrossRef]

- Imbert, E. Food waste valorization options: Opportunities from the bioeconomy. Open Agric. 2017, 2, 195–204. [Google Scholar] [CrossRef]

- European Commission. Directive 2008/98/EC on Waste (Waste Framework Directive). Available online: https://ec.europa.eu/environment/waste/framework/ (accessed on 28 January 2020).

- European Commission. Internal Market, Industry, Entrepreneurship and SMEs: Food and Drink Industry. Available online: https://ec.europa.eu/growth/sectors/food_en (accessed on 19 May 2020).

- European Commission (EC). Closing the Loop—An EU Action Plan for the Circular Economy. 2015. Available online: https://eur-lex.europa.eu/resource.html?uri=cellar:8a8ef5e8-99a0-11e5-b3b7-01aa75ed71a1.0012.02/DOC_1&format=PDF (accessed on 19 May 2019).

- Hnin, K.K.; Zhang, M.; Mujumdar, A.S.; Zhu, Y. Emerging food drying technologies with energy-saving characteristics: A review. Dry. Technol. 2018, 37, 1465–1480. [Google Scholar] [CrossRef]

- Belessiotis, V.; Delyannis, E. Solar drying. Sol. Energy 2011, 85, 1665–1691. [Google Scholar] [CrossRef]

- Bassetti, M.C.; Consoli, D.; Manente, G.; Lazzaretto, A. Design and off-design models of a hybrid geothermal-solar power plant enhanced by a thermal storage. Renew. Energy 2018, 128, 460–472. [Google Scholar] [CrossRef]

- Yoo, J.Y.; Kim, H.J.; Woo, E.J.; Park, C.J. On Solar Energy Utilization for Drying Technology. Int. J. Environ. Sci. Dev. 2017, 8, 305–311. [Google Scholar] [CrossRef]

- Madhlopa, A.; Ngwalo, G. Solar dryer with thermal storage and biomass-backup heater. Sol. Energy 2007, 81, 449–462. [Google Scholar] [CrossRef]

- Okoroigwe, E.C.; Ndu, E.C. Comparative evaluation of the performance of an improved solar-biomass hybrid dryer. J. Energy South. Afr. 2017, 26, 38. [Google Scholar] [CrossRef]

- Amer, B.; Hossain, M.; Gottschalk, K. Design and performance evaluation of a new hybrid solar dryer for banana. Energy Convers. Manag. 2010, 51, 813–820. [Google Scholar] [CrossRef]

- Tonui, K.; Mutai, E.; Mutuli, D.; Mbuge, D.; Too, K. Design and Evaluation of Solar Grain Dryer with a Back-up Heater. Res. J. Appl. Sci. Eng. Technol. 2014, 7, 3036–3043. [Google Scholar] [CrossRef]

- Neba, F.A.; Nono, Y.J. Modeling and simulated design: A novel model and software of a solar-biomass hybrid dryer. Comput. Chem. Eng. 2017, 104, 128–140. [Google Scholar] [CrossRef]

- Sonthikun, S.; Chairat, P.; Fardsin, K.; Kirirat, P.; Kumar, A.; Tekasakul, P. Computational fluid dynamic analysis of innovative design of solar-biomass hybrid dryer: An experimental validation. Renew. Energy 2016, 92, 185–191. [Google Scholar] [CrossRef]

- Dhanushkodi, S.; Vincent, H.W.; Sudhakar, K. Design and thermal performance of the solar biomass hybrid dryer for cashew drying. Facta Univ. Ser. Mech. Eng. 2014, 12, 277–288. [Google Scholar]

- Hao, W.; Liu, S.; Mi, B.; Lai, Y. Mathematical Modeling and Performance Analysis of a New Hybrid Solar Dryer of Lemon Slices for Controlling Drying Temperature. Energies 2020, 13, 350. [Google Scholar] [CrossRef]

- Yuwana, Y.; Sidebang, B. Performance Testing of the Hybrid Solar-Biomass Per. J. Mod. Eng. Res. 2016, 6, 63–68. [Google Scholar]

- Genskow, L.R. Dryer scale-up methodology for the process industries. Dry. Technol. 1994, 12, 47–58. [Google Scholar] [CrossRef]

- Di Fraia, S.; Figaj, R.D.; Massarotti, N.; Vanoli, L. An integrated system for sewage sludge drying through solar energy and a combined heat and power unit fuelled by biogas. Energy Convers. Manag. 2018, 171, 587–603. [Google Scholar] [CrossRef]

- Çepelioğullar, M.Ö.; Zeng, T. Challenges and Opportunities of Modeling Biomass Gasification in Aspen Plus: A Review. Chem. Eng. Technol. 2020, 43, 1674–1689. [Google Scholar] [CrossRef]

- Aspen Technology Inc. Aspen Plus Physical Property System: Physical Property Models and Methods; Aspen Technology Inc.: Cambridge MA, USA, 2001. [Google Scholar]

- Meteotest, A.G. Meteonorm Features. Available online: https://meteonorm.com/en/meteonorm-features (accessed on 20 January 2021).

- Amos, W.A.; Report on Biomass Drying Technology. Natl. Renew. Energy Lab. 1998. Available online: https://www.nrel.gov/docs/fy99osti/25885.pdf (accessed on 20 January 2021).

- Hosseinabadi, H.Z.; Layeghi, M.; Berthold, D.; Doosthosseini, K.; Shahhosseini, S. Mathematical Modeling the Drying of Poplar Wood Particles in a Closed-Loop Triple Pass Rotary Dryer. Dry. Technol. 2013, 32, 55–67. [Google Scholar] [CrossRef]

- Han, J.; Choi, Y.; Kim, J. Development of the Process Model and Optimal Drying Conditions of Biomass Power Plants. ACS Omega 2020, 5, 2811–2818. [Google Scholar] [CrossRef] [PubMed]

- Mujumdar, A.S.; Devastin, S. Guide to Industrial Drying: Principles, Equipment and New Developments. Chapter 1: Fundamental Principles of Drying; Colour Publications Pvt. Limited: Mumbai, India, 2005. [Google Scholar]

- Texas AgriLife Research and Center. Equilibrium Moisture Content (EMC) Calculator. Available online: https://beaumont.tamu.edu/EMCCalculator/default.aspx.EMCCalculator (accessed on 2 November 2020).

- Aspen Plus Inc. Aspen Plus V 10.0-Help: Convective Dryer—Model; Aspen Technology Inc.: Cambridge, MA, USA.

- Delele, M.A.; Weigler, F.; Mellmann, J. Advances in the Application of a Rotary Dryer for Drying of Agricultural Products: A Review. Dry. Technol. 2014, 33, 541–558. [Google Scholar] [CrossRef]

- Land, C.M.V. Drying in the Process Industry; Wiley: Hoboken, NJ, USA, 2011. [Google Scholar]

- Perry, R.H.; Green, D.W.; Maloney, J.O. Perry’s Chemical Engineers’ Handbook, 7th ed.; McGraw-Hill: New York, NY, USA, 1984. [Google Scholar]

- Hui, H.Y.; Clary, C.; Frid, M.M.; Fasina, O.O.; Noomhorm, A.; Welti-Chanes, J. Food Drying Science and Technology. Microbiology, Chemistry, Applications; DEStech Publications Inc.: Lancaster, Pennsylvania, PA, USA, 2008. [Google Scholar]

- Verein Deutscher Ingeniure. VDI 2067—Economic Efficiency of Building Installations. Fundamentals and Economic Calculation; Verein Deutscher Ingeniure: Düsseldorf, Germany, 2012. [Google Scholar]

- Stroem, L.; Desai, D.; Hoadley, A. Superheated steam drying of Brewer’s spent grain in a rotary drum. Adv. Powder Technol. 2009, 20, 240–244. [Google Scholar] [CrossRef]

- Freire, F.B.; Vieira, G.N.A.; Freire, J.T.; Mujumdar, A.S. Trends in Modeling and Sensing Approaches for Drying Control. Dry. Technol. 2014, 32, 1524–1532. [Google Scholar] [CrossRef]

- Tsotsas, E.; Metzger, T.; Gnielinski, V.; Schlünder, E.U. Ullmann’s Encyclopedia of Industrial Chemistry. Drying of Solid Materials; Wiley-VCH Verlag GmbH & Co. KgaA: Weinheim, Germany, 2012. [Google Scholar]

- Slim, R.; Zoughaib, A.; Clodic, D. Modeling of a solar and heat pump sludge drying system. Int. J. Refrig. 2008, 31, 1156–1168. [Google Scholar] [CrossRef]

- Lamidi, R.O.; Jiang, L.; Pathare, P.B.; Wang, Y.; Roskilly, A. Recent advances in sustainable drying of agricultural produce: A review. Appl. Energy 2019, 367–385. [Google Scholar] [CrossRef]

- ÖKOTHERM Biomasse-Heizanlagen. Available online: https://www.oeko-therm.net/de/produkte-service-oekotherm/compact-biomasse-heizanlagen (accessed on 20 January 2021).

| Proximate Analysis (Dry, wt.%) | BSG | Fuel |

|---|---|---|

| Volatiles | 80.6 | 80 |

| Ash | 4.4 | 0.6 |

| Fixed C (by difference) | 15.3 | 19.4 |

| Ultimate Analysis (Dry, wt.%) | ||

| C | 50.9 | 51 |

| H | 6.5 | 6.3 |

| O (by difference) | 38.4 | 42.5 |

| N | 3.9 | 0.11 |

| S | 0.3 | 0.008 |

| Process Specifications in the Model | |

|---|---|

| Total SW area (m2) | 2500 |

| Max. humid air flow rate (m3/ h) | 180,000 |

| Max. inlet air temperature (°C) | 75 |

| Material to be dried (tons/year) | ~20,000 |

| Inlet moisture of BSG (wt.%, a.r.) | 80 |

| Outlet moisture of BSG (wt.%, w.b.) | 10–15 |

| Inlet BSG temperature (°C) | 25 |

| Each dryer length (m) | 9 |

| Each dryer diameter (m) | 1.5 |

| Total residence time of both passes (min) | 45 |

| Xcr (kgwater/kgdry solid) | 0.8 |

| Xequ (kgwater/kgdry solid) | 0.015 |

| NTU (-) | 2 |

| Thermal output boiler (kW) | 950 |

| Physical property method | PENG-ROB |

| Dryer model | Convective |

| Heat exchanger model | Shortcut |

| Heat exchanger type | Water-air |

| Boiler model | RYield, RGibbs and heater blocks |

| Reference Days | Codes | Ambient Air Temperature (°C) | Absolute Humidity (kg/kg) |

|---|---|---|---|

| 9 January/night | 0901N | 2.8 | 0.0037 |

| 9 January/day | 0901D | 4.4 | 0.0039 |

| 11 July/night | 1107N | 22.0 | 0.0085 |

| 11 July/day | 1107D | 28.0 | 0.0086 |

| 10 October/night | 1010N | 16.6 | 0.0078 |

| 10 October/day | 1010D | 22.0 | 0.0090 |

| Description | Unit | Notes/Equations | No. |

|---|---|---|---|

| (1) | |||

| Saturation vapor pressure, | kPa | (2) | |

| Partial water vapor pressure, | kPa | (3) | |

| Absolute humidity, | kgw/kga | (4) | |

| Absolute humidity, | (5) | ||

| Heat capacity, | (6) | ||

| Enthalpy of moist air, | (7) | ||

| Required boiler heat, | kW | (8) | |

| Solar power, | kW | (9) | |

| SW efficiency †) | % | (10) | |

| Hot air temp., | °C | (11) | |

| Relative humidity of hot air, RH | % | (12) | |

| Removed water per kg of air, | (13) | ||

| Evaporated water mass flow, | (14) | ||

| Dried BSG material, | (15) | ||

| † The used balancing function was developed using the Solar Keymark certificate of the SW. | |||

| Cost Parameters | Unit | Value | Specific Costs | Unit | Value |

|---|---|---|---|---|---|

| Mixed interest rate, q | % | 3.00 | Electricity price (net) | ct/kWh | 12 |

| Observation period, T | years | 20 | Wet BSG material | €/t | 35 |

| Yearly price increase | % | 2.00 | Biomass fuel price | €/t | 70 |

| Other Parameters | Unit | Value | Ash disposal | €/t | 8 |

| Energy demand for fans | kW/(m3/s) | 1.5 | Dried BSG material | €/t | 235 |

| Lower heating value of fuel | MWh/tw.b. | 4.3 | Total investment costs * | k€ | 2800 |

| Reference Day | Heat from the Biomass Boiler (kW) | Heat from the SW (kW) | AIR-103 (kg/h) | WETBSG (kg/h) |

|---|---|---|---|---|

| 0901N | 855 | 0 | 42,148 | 940 |

| 0901D | 855 | 353 | 60,856 | 1340 |

| 1107N | 855 | 0 | 57,416 | 1199 |

| 1107D | 662 | 2084 | 180,000 | 3734 |

| 1010N | 855 | 0 | 52,143 | 1084 |

| 1010D | 855 | 782 | 112,600 | 2310 |

| Operational Strategy and Plant Design * | Heat Provided by Boiler (MWh/a) | Heat Provided by SW (MWh/a) | Total Annual Heat [MWh/a] | Solar Share (%) | Annually Dried Wet BSG (t/a) | Annual Operational Hours of the Boiler (h/a) | Annual Operational Hours of the SW (h/a) | Annual Income (€/a) |

|---|---|---|---|---|---|---|---|---|

| 12/5|2500|950 | 2410 | 1552 | 3962 | 39.1 | 6284 | 3012 | 2912 | 17,452 |

| 12/5|5000|950 | 1801 | 3482 | 5283 | 65.9 | 8035 | 2416 | 2912 | 19,012 |

| 12/5|2500|1900 | 4138 | 1976 | 6114 | 32.3 | 9247 | 2973 | 2912 | 48,016 |

| 12/5|5000|1900 | 2872 | 3883 | 6755 | 57.4 | 9879 | 2351 | 2912 | 10,838 |

| 24/5|2500|950 | 5080 | 1564 | 6644 | 23.5 | 10,204 | 6024 | 3321 | 160,786 |

| 24/5|5000|950 | 4472 | 3507 | 7978 | 44.0 | 11,977 | 5428 | 3321 | 163,451 |

| 24/5|2500|1900 | 9681 | 1994 | 11,675 | 17.1 | 17,383 | 5985 | 3321 | 342,815 |

| 24/5|5000|1900 | 8399 | 3920 | 12,319 | 31.8 | 17,972 | 5372 | 3321 | 294,869 |

| Revenue from Dried BSG Material (€/t) | Biomass Fuel Price (€/t) | SW Price (€/m2) | SW Area (m2) | Boiler Capacity (kW) | Total Investment Costs (€/a) | ||

|---|---|---|---|---|---|---|---|

| Variations | Min (−80%) | 40 | 18 | 56 | 500 | 275 * | 300,000 |

| Max (+100) | 400 | 180 | 560 | 5000 | 1900 | 3,000,000 | |

| Standard | Standard | 200 | 70 | 280 | 2500 | 950 | 1,500,000 |

| Break-even point | 12/5 | 193 | 90 | 375 | 3352 | 810 | 1,745,052 |

| 24/5 | 174 | 129 | 872 | 7789 | 580 | 3,021,526 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mutlu, Ö.Ç.; Büchner, D.; Theurich, S.; Zeng, T. Combined Use of Solar and Biomass Energy for Sustainable and Cost-Effective Low-Temperature Drying of Food Processing Residues on Industrial-Scale. Energies 2021, 14, 561. https://doi.org/10.3390/en14030561

Mutlu ÖÇ, Büchner D, Theurich S, Zeng T. Combined Use of Solar and Biomass Energy for Sustainable and Cost-Effective Low-Temperature Drying of Food Processing Residues on Industrial-Scale. Energies. 2021; 14(3):561. https://doi.org/10.3390/en14030561

Chicago/Turabian StyleMutlu, Özge Çepelioğullar, Daniel Büchner, Steffi Theurich, and Thomas Zeng. 2021. "Combined Use of Solar and Biomass Energy for Sustainable and Cost-Effective Low-Temperature Drying of Food Processing Residues on Industrial-Scale" Energies 14, no. 3: 561. https://doi.org/10.3390/en14030561

APA StyleMutlu, Ö. Ç., Büchner, D., Theurich, S., & Zeng, T. (2021). Combined Use of Solar and Biomass Energy for Sustainable and Cost-Effective Low-Temperature Drying of Food Processing Residues on Industrial-Scale. Energies, 14(3), 561. https://doi.org/10.3390/en14030561