Assessment of Cumulative Energy Needs for Chosen Technologies of Cattle Feeding in Barns with Conventional (CFS) and Automated Feeding Systems (AFS)

Abstract

:1. Introduction

- Mixing cattle feed ingredients in a stationary mixer, robot feeding and feed pushing to make it better accessible to animals;

- Filling the loading devices with fodder, mixing, feeding the animals with a robot. The robot runs along a rail along the feed corridor and moves the forage towards the animals.

- III.

- Transporting silage and loading the “feed kitchen”; filling the robot with feed, mixing in the robot, feeding with the robot, and feed pushing [13].

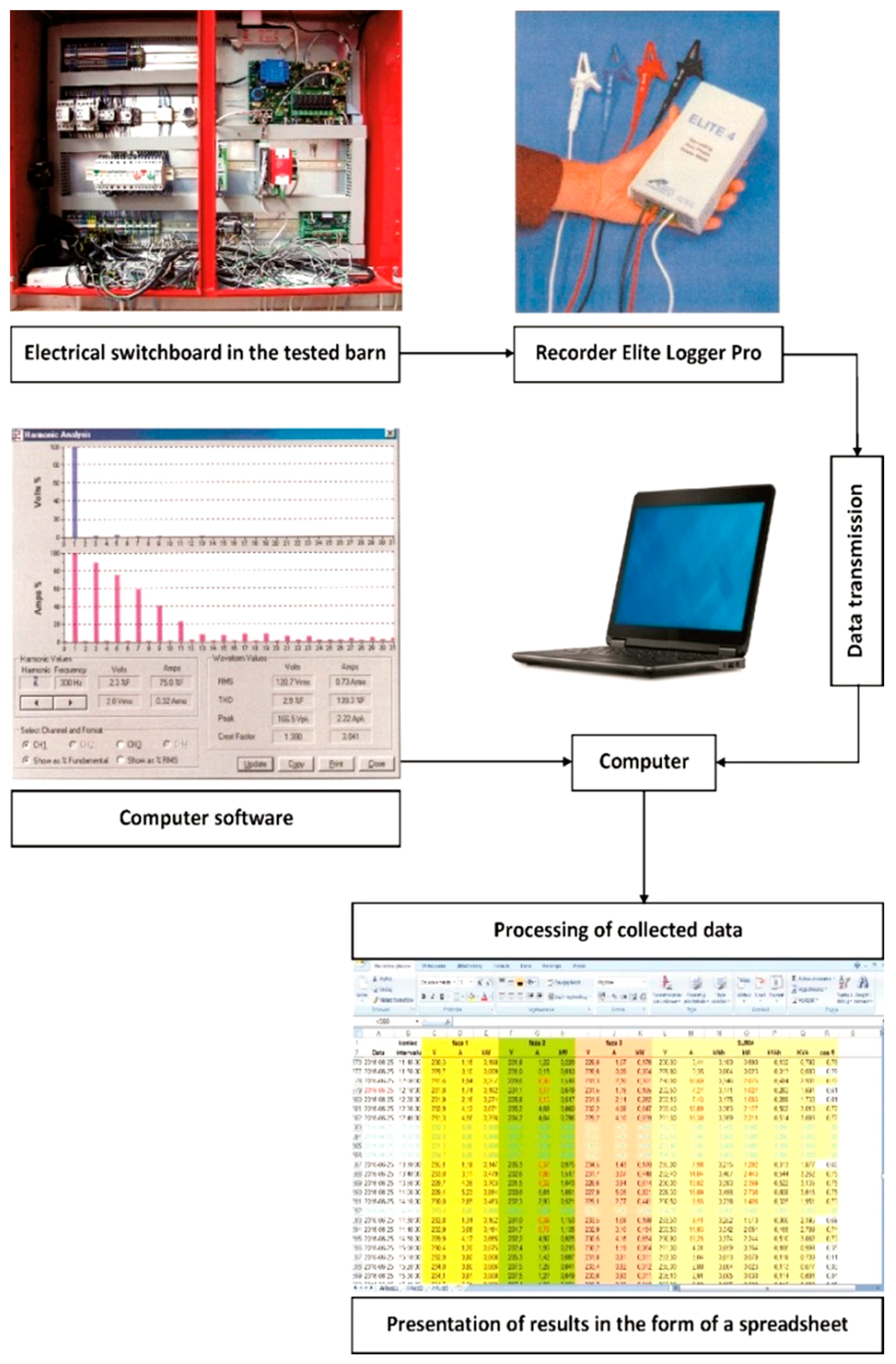

2. Materials and Methods

Cumulative Energy Intensity Calculation

3. Results

4. Discussion

5. Conclusions

- The automated feed mixing and feeding technologies recorded the lowest cumulative human labor energy intensities compared with conventional mixing and feeding technologies (CFS1 to CFS2);

- The high level of automation of the preparation and feeding of fodder for four technologies in the nutrition of both dairy and beef cattle guarantees low labor demand, which is of key importance for agricultural producers due to the increasing labor costs and difficulties in finding labor;

- The lowest energy inputs were found in a group of farms equipped with automated feed mixing and feeding equipment (from AFS1 to ASF4), but which, when combined with a high cumulative energy intensity of machinery and equipment, resulted in the total highest value of cumulative energy intensity for feed mixing and feeding in that technology group;

- A practical conclusion for scientists and agricultural producers, resulting from the research on cumulative energy consumption, is much lower (39.3%) total electric and mechanical energy inputs for robotic feed preparation and feeding technologies compared to simple conventional technologies;

- Carrying out an LCA in the longer term will allow for a comprehensive assessment of the impact of modern technologies on cattle nutrition, which will contribute to future articles;

- The dependence of electrical energy consumption on the LU density may show the economic approach of energy consumption in cattle breeding. According to the statistical analysis supported by a post-hoc test (e.g., Duncan), it turned out that the significance level in the dependence test was low—under 0.05. Three groups were presented, in which groups I and II, LU numbers were the same, in distinction to group III. The cases of the dependence of cumulative energy intensities for various feed mixing and feeding technologies on LU numbers had no differences in all of the homogenous groups.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

References

- Todde, G.; Murgia, L.; Caria, M.; Pazzona, A. A Comprehensive Energy Analysis and Related Carbon Footprint of Dairy Farms. Part 1: Direct Energy Requirements. Energies 2018, 11, 451. [Google Scholar] [CrossRef] [Green Version]

- Todde, G.; Caria., M.; Gambella., F.; Pazzona., A. Energy and Carbon Impact of Precision Livestock Farming Technologies Implementation in the Milk Chain: From Dairy Farm to Cheese Factory. Agriculture 2017, 7, 79. [Google Scholar] [CrossRef] [Green Version]

- Eurostat 2020. Available online: https://ec.europa.eu/eurostat/statistics-explained/index.php?title=Milk_and_milk_product_statistics (accessed on 12 August 2021).

- Borusiewicz, A.; Majchrzak, M.; Romaniuk, W. Monograph. In Robotization of Cattle Feeding Taking into Account Energy Expenditure and Renewable Energy Sources in Modern Cowsheds; Higher School of Agribusiness in Lomza: Lomza, Poland, 2018; p. 171. ISBN 978-83-947669-3-1. [Google Scholar]

- Berebeć, A.K.; Feledyn-Szewczyk, B.; Thalmann, C.; Wyss, R.; Grenz, J.; Kopiński, J.; Stalenga, J.; Radzikowski, P. Assessing the Sustainability Performance of Organic and Low-Input Conventional Farms from Eastern Poland with the RISE Indicator System. Sustainability 2018, 10, 1792. [Google Scholar] [CrossRef] [Green Version]

- Rokochinskiy, A.; Frolenkova, N.; Turcheniuk, V.; Volk, P.; Prykhodko, N.; Tykhenko, R.; Openko, I. The variability of natural and climatic conditions in investment projects in the field of nature management. J. Water Land Dev. 2021, 4, 48–54. [Google Scholar]

- Maria, V.C.; Riccardo, V. A land-based approach for climate change mitigation in the livestock sector. J. Clean. Prod. 2021, 283, 124622. [Google Scholar] [CrossRef]

- Wałowski, G. Multi-phase flow assessment for the fermentation process in mono-substrate reactor with skeleton bed. J. Water Land Dev. 2019, 42, 150–156. [Google Scholar] [CrossRef] [Green Version]

- Konieczna, A.; Kamil, R.; Monika, R.; Damian, Ś.; Michał, R. Energy Efficiency of Maize Production Technology: Evidence from Polish Farms. Energies 2021, 14, 170. [Google Scholar] [CrossRef]

- Konieczna, A.; Kamil, R.; Kinga, B.; Emilia, G. GHG and NH3 Emissions vs. Energy Efficiency of Maize Production Technology: Evidence from Polish Farms: A Further Study. Energies 2021, 14, 5574. [Google Scholar] [CrossRef]

- Wójcicki, Z. Metodyka badania energochłonności produkcji rolniczej. Problemy Inżynierii Rolniczej. Z. 2015, 4, 17–29. [Google Scholar]

- Tangorra, F.M.; Calcante, A. Energy consumption and technical-economic analysis of an automatic feeding system for dairy farms: Results from a field test. J. Agric. Eng. 2018, 49, 228–232. [Google Scholar] [CrossRef]

- Oberschätzl-Kopp, R.; Haidn, B. Automatische Fütterungssysteme für Rinder—Technik, Leistung, Planungshinweise; DLG-Merkblatt 398; DLG International: Cherry Hill, NJ, USA; Frankfurt am Main, Germany, 2018; p. 20. Available online: https://www.dlg.org/fileadmin/downloads/landwirtschaft/themen/publikationen/merkblaetter/dlg-merkblatt_398.pdf (accessed on 5 December 2021).

- Belle, Z.; Andre, G.; Pompe, J.C.A.M. Effect of automatic feeding of total mixed rations on the diurnal visiting pattern of dairy cows to an automatic milking system. Biosyst. Eng. 2012, 111, 33–39. [Google Scholar] [CrossRef]

- Oberschätzl, R.; Haidn, B.; Neiber, J.; Neser, S. Automatic feeding systems for cattle—A study of the energy consumption of the techniques. Environmentally Friendly Agriculture and Forestry for Future Generations. In Proceedings of the XXXVI CIOSTA & CIGR Section V Conference, Saint Petersburg, Russia, 26–28 May 2015; p. 966. [Google Scholar]

- Calcante, A.; Oberti, R. A Technical-Economic Comparison between Conventional Tillage and Conservative Techniques in Paddy-Rice Production Practice in Northern Italy. Agronomy 2019, 9, 886. [Google Scholar] [CrossRef] [Green Version]

- Muzalewski. Zasady Doboru Maszyn Rolniczych. Kryteria Oceny Racjonalności Doboru oraz Wykorzystania Wybranych Maszyn i Urządzeń Rolniczych w Ramach Programu Rozwoju Obszarów Wiejskich (PROW 2007–2013) Pod Kątem Działania Modernizacja Gospodarstw Rolnych; Instytut Technologiczno-Przyrodniczy: Warsaw, Poland, 2008; p. 92. ISBN 978-83-89806-21-5. [Google Scholar]

- Grothmann, A.; Nydegger, F. Landtechnik im Alpenraum. Available online: https://docplayer.org/113517161-Landtechnik-im-alpenraum.html (accessed on 5 December 2021).

- Grothmann, A.; Nydegger, F. Robotertechnik für den Füttertisch. Available online: https://docplayer.org/20426533-Robotertechnik-fuer-den-futtertisch.html (accessed on 5 December 2021).

- Dobek, T.; Inżynieria, R. Energy Effectiveness of Edible Potato Production in the Selected Farmsteads. Inżynieria Rol. 2006, 10, 239–246. [Google Scholar]

- Romaniuk, W.; Borek, K.; Borusiewicz, A.; Mazur, K.; Wardal, W. Analysis of Technological Solutions for Stanchion Barns for Dairy Cattle; High School of Agribusiness in Lomza: Łomża, Poland, 2018; p. 260. ISBN 978-83-947669-4-8. [Google Scholar]

- Roman, K.; Michał, R.; Dominika, S.; Jan, S.; Emilia, G. Evaluation of Physical and Chemical Parameters According to Energetic Willow (Salix viminalis L.) Cultivation. Energies 2021, 14, 2968. [Google Scholar] [CrossRef]

- Vaculík, P.; Smejtkova, A. Assessment of selected parameters of automatic and conventional equipment used in cattle feeding. Agron. Res. 2019, 17, 879–889. [Google Scholar] [CrossRef]

- Mantoam, E.J.; Romanelli, T.L.; Gimenez, L.M. Energy demand and greenhouse gases emissions in the life cycle of tractors. Biosyst. Eng. 2016, 151, 158–170. [Google Scholar] [CrossRef]

| Power Supply Method | Voltage | Equipment Requirements | Advantages | Disadvantages |

|---|---|---|---|---|

| Conducting bus bar | 48 V and 400 V | Water splash protection | Safe power supply from the rail, can be easily expanded, can overcome inclinations | Costly rail power-supply technology |

| Power-supply wire | 400 V | - | Safe device power-supply with electrical energy | Limited robot mobility on curves |

| Battery | 12 V | Battery charging time about 6 h·day−1 | High battery capacity, simple technology | Long battery charging time |

| Number of LU | Investments | Block Cutter | Feed Selector with a Dispenser | Mixer Unit | Self-Propelled Feed Selector | Robot |

|---|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | 5 | 6 | 7 |

| 30 | Investment costs (EUR) | 7000 | 10,000 | 30,000 | 35,000 | 125,000 |

| Period of use (years) | 17 | 17 | 17 | 12 | 17 | |

| Daily operation time (min) | 33 | 57 | 78 | 18 | 42 | |

| 50 | Investment costs (EUR) | 7000 | 15,000 | 35,000 | 35,000 | 125,000 |

| Period of use (years) | 15 | 15 | 15 | 10 | 15 | |

| Daily operation time (min) | 55 | 85 | 104 | 30 | 52 | |

| 80 | Investment costs (EUR) | 7000 | 20,000 | 40,000 | 35,000 | 125,000 |

| Period of use (years) | 10 | 10 | 10 | 7 | 12 | |

| Daily operation time (min) | 88 | 127 | 143 | 48 | 67 |

| Parameter | Coefficient | Unit |

|---|---|---|

| Human labor | 40.00 | MJ/mh |

| Fuels and energy carriers | ||

| Electrical energy | 13.60 | MJ/kwh |

| Diesel oil | 53.20 | MJ/kg |

| Petrol | 55.40 | MJ/kg |

| Black coal | 27.30 | MJ/kg |

| Liquid gas | 54.90 | MJ/kg |

| Others | ||

| Buildings and structures | 100.00 | MJ/m2 |

| Machinery and equipment | 110.00 | MJ/kg |

| Spare parts | 80.00 | MJ/kg |

| Technology | AFS1 | AFS2 | AFS3 | AFS4 | CF1 | CF2 | CF3 | CF4 | CF5 | CF6 |

|---|---|---|---|---|---|---|---|---|---|---|

| Province | Łódzkie | Mazowieckie | Mazowieckie | Dolnośląskie | Łódzkie | Mazowieckie | Mazowieckie | Łódzkie | Śląskie | Mazowieckie |

| Farm area (ha) | 65 | 70 | 36 | 320 | 70 | 55 | 145 | 48 | 2915 | 70 |

| Number of Livestock Units (LU) | 100 | 168 | 40 | 320 | 60 | 83 | 170 | 45 | 200 | 154 |

| Housing systems | Free-stall, boxed without litter | Free-stall, boxed %with litter | Stanchion, shallow bedding | Free-stall, boxed shallow bedding | Tied-up shallow bedding | Tied-up shallow bedding | Free-stall, boxed without litter | Tied-up, shallow bedding | Free-stall, boxed shallow bedding | Free-stall, boxed without litter |

| Feeding system | TMR feed robot | TMR feed robot | TMR feed robot | TMR robot | Feed robot and a feed wagon coupled with a tractor | Feed robot and a feed wagon coupled with a tractor | Feed wagon coupled with a tractor | Feed wagon coupled with a tractor | Self-propelled feed wagon | Feed wagon coupled with a tractor |

| Barn size/Cubic capacity [m3⋅LU−1] | 19.79 | 92.47 | 48.40 | 88.63 | 71.14 | 22.32 | 70.64 | 48.93 | 70.68 | 45.71 |

| Building development area [m2∙LU−1] | 6.24 | 13.05 | 9.43 | 13.00 | 14.12 | 6.12 | 12.43 | 13.06 | 10.97 | 11.72 |

| Feeding passage width (m) | 2.78 | 2.50 | 1.50 | 4.00 | 4.50 | 4.76 | 5.00 | 4.80 | 4.5 and 3.00 | 5.5 and 2.00 |

| Feeding passage area [m2∙LU−1] | 1.98 | 1.38 | 1.54 | 1.43 | 3.21 | 2.09 | 2.26 | 4.48 | 2.25 | 2.65 |

| Milk yield [L∙LU−1∙year−1] | Beef cattle | 10,500 | 9500 | 11,400 | 7700 | 7500 | 8500 | 7000 | 9500 | 8200 |

| Cattle Barn Number | Parameter | |||||||

|---|---|---|---|---|---|---|---|---|

| x1 | x2 | x3 | x4 | x5 | x6 | x7 | x8 | |

| 1 | 19.79 | 6.24 | 3.59 | 1.98 | 1.31 | 0.20 | 22.00 | 0.48 |

| 2 | 92.47 | 13.05 | 3.00 | 1.38 | 1.02 | 0.13 | 16.00 | 1.00 |

| 3 | 48.40 | 9.43 | 2.10 | 1.54 | 1.30 | 0.62 | 27.50 | 1.54 |

| 4 | 88.63 | 13.00 | 3.06 | 1.43 | 0.50 | 0.62 | 37.50 | 1.15 |

| 5 | 71.14 | 14.12 | 2.10 | 3.21 | 1.36 | 0.25 | 20.00 | - |

| 6 | 22.32 | 6.12 | 2.16 | 2.09 | 0.99 | 0.24 | 16.26 | - |

| 7 | 70.64 | 12.43 | 4.20 | 2.26 | 0.79 | 0.20 | 18.82 | - |

| 8 | 48.93 | 13.06 | 2.18 | 4.48 | 1.56 | 0.54 | 15.55 | - |

| 9 | 70.68 | 10.97 | 4.07 | 2.25 | 0.90 | 0.15 | 13.50 | - |

| 10 | 45.71 | 11.72 | 4.13 | 2.65 | 1.00 | 0.23 | 14.28 | - |

| Type of System | Feeding Line | Tractor/Feed Wagon Capacity [m3] | Tractor + Silage Selector or Self-Propelled Loader | Bowl Drinkers/ Chamber Drinkers/Calf Drink Dispensing Stations/Feed Stations |

|---|---|---|---|---|

| AFS1 | AFS Robot TMR Pellon Vol. 5 m3. Loader stations Pellon 2 × 8 m3, “Michał” concentrated feed silo 20 m3, liquid feed silo 3 m3), screw conveyer 8 m ø150, 3 kW, 16 t/h | Tractor/feed wagon capacity [m3] | Tractor + silage selector or self-propelled loader | Bowl drinkers/ chamber drinkers/calf drink dispensing stations/feed stations |

| AFS2 | AFS Robot TMR Pellon vol. 5 m3. Loading equipment 2 × 13 m3 and 1 × 8 m3, belt conveyer, 8 mineral-vitamin feed dispensers, “Michał” silos 2 × 8 m3 and 1 × 5 m3 Screw conveyer 8 m ø150. 3 kW. 16 t/h | N/A | Telehandler Deutz Fahr 75 kW | 15 bowl drinkers/calf drink dispensing station |

| AFS3 | AFS Robot TMR vol. 5 m3 of roughage mixer. Concentrated feed hopper, belt conveyor; “Michał” 25 m3 silo; screw conveyer 8 m ø150, 3 kW, 16 t/h | N/A | Telehandler JCB 55 kW | 8 chamber drinkers |

| AFS4 | AFS Robot Lely Vector TMR vol. 2 m3; 2 mineral-vitamin feed hoppers; roughage loading crane; 3 BIN 48 m3 silos with a bucket conveyor. 2 BIN 27 m3 silos; Pneumatic conveyer T420 15 kW 14 t/h | N/A | Tractor Valtra 65 kW Silage selector Strautmann Hydrofox | 40 bowl drinkers |

| CFS1 | Robot DeLaval FW200 for concentrated feeds for concentrated feeds. 15 m3 silo, screw conveyer 8 m, ø110. 1.5 kW. 7 t/h | N/A | Telehandler Manitou Maniscopic MLT1035L-LSU 74.5 kW | 4 bowl drinkers/10 chamber drinkers; 2 feed stations Lely Cosmix |

| CFS2 | Concentrated feed robot. Bin 2 × 7.5 m3 and 5 m3 silos; Screw conveyer 2.2 kW 8 m. ø140. 13 t/h | Massey Ferguson 3095 74.9 kW/vol. 9 m3 Sgariboldi | Tractor Ursus C 360 35 kW Front loader T261 | 32 bowl drinkers |

| CFS3 | Feed pusher robot Lely Juno 15, concentrated feed line: “Michał” silo, 14 m3 and 20 m3. Screw conveyer 1.5 kW with a charging hopper 4 m, ø16, 24 t/h | Zetor Proxima 60.3 kW/vol. 6 m3 WP6 | Tractor Farmtrac 675 DT 54 kW Jaw-type cutter WK085 | 99 bowl drinkers |

| CFS4 | Feeding with concentrated feeds: Silo Bin 12 m3, screw conveyer 2.2 kW with a charging hopper 4 m, ø140, 12 t/h | Zetor Proxima Plus 105. 74.3 kW/vol. 14 m3 RMH | Telehandler 55 kW JCB 525-60 | 7 bowl drinkers/4 chamber drinkers |

| CFS5 | Feeding with concentrated feeds: Silo DeLaval 12 m3 and 18 m, screw conveyer 1.5 kW with a charging hopper 6 m, ø160, 24 t/h | Fendt 308 C. 63 kW/vol. 6 m3 BEL-MIX T659 | Tractor Farmtrac 665 DT, 43 kW/ + silage jaw-type selector T385 | 31 bowl drinkers |

| CFS6 | Feeding with concentrated feeds: screw conveyer with a charging hopper 5, ø160, 1.5 kW, 24 t/h, Silos BIN 18 m3 | Self-propelled feed wagon R.M.H. Vol. 14 m3 with a milled selector VSL14 | N/A | 7 bowl drinkers/8 chamber drinkers 4 feed stations |

| New Holland T6.175. 128 kW /20 m3 Samasz Duo 2000 | Telehandler 54 kW Case FARMLIFT 525 | 17 bowl drinkers/2 chamber drinkers |

| Technology | Parameter | ||||||

|---|---|---|---|---|---|---|---|

| y1 | y2 | y3 | y4 | y5 | y6 | y7 | |

| AFS1 | 0.490 | 0.009 | 0.636 | 31,350.000 | 4.106 | 0.329 | 31,354.435 |

| AFS2 | 0.350 | 0.045 | 0.254 | 58,829.864 | 2.343 | 0.237 | 58,832.444 |

| AFS3 | 0.810 | 0.172 | 0.839 | 36,049.015 | 7.453 | 0.541 | 36,057.009 |

| AFS4 | 0.300 | 0.097 | 0.349 | 34,336.670 | 3.571 | 0.205 | 34,340.446 |

| CFS1 | 1.330 | 0.009 | 0.850 | 17,218.918 | 10.356 | 0.893 | 17,230.167 |

| CFS2 | 0.780 | 0.008 | 0.722 | 22,448.950 | 5.226 | 0.526 | 22,454.702 |

| CFS3 | 0.420 | 0.00047 | 0.459 | 17,836.376 | 3.173 | 0.284 | 17,839.833 |

| CFS4 | 2.270 | 0.00064 | 2.017 | 53,321.872 | 13.924 | 1.513 | 53,337.309 |

| CFS5 | 0.460 | 0.063 | 1.140 | 19,224.911 | 6.434 | 0.307 | 19,231.652 |

| CFS6 | 0.463 | 0.0002 | 0.665 | 18,670.059 | 4.312 | 0.309 | 18,674.68 |

| Technology No | Cumulative Energy Intensity | ||

|---|---|---|---|

| y4a | y4b | y4 | |

| AFS1 | 13,019.178 | 18,330.822 | 31,350.000 |

| AFS2 | 5596.869 | 53,232.995 | 58,829.864 |

| AFS3 | 15,625.029 | 20,423.986 | 36,049.015 |

| AFS4 | 1670.484 | 32,666.186 | 34,336.670 |

| CFS1 | 3765.616 | 13,453.301 | 17,218.918 |

| CFS2 | 7436.352 | 15,012.598 | 22,448.950 |

| CFS3 | 3280.987 | 14,555.389 | 17,836.376 |

| CFS4 | 10,747.686 | 42,574.186 | 53,321.872 |

| CFS5 | 0.000 | 19,224.911 | 19,224.911 |

| CFS6 | 2400.000 | 16,270.059 | 18,670.059 |

| LU Range | Average Value of Electrical Energy Consumption | Homogeneous Groups | |

|---|---|---|---|

| I | II | ||

| I | 673.936 | X | |

| II | 950.825 | X | |

| III | 8028.783 | X | |

| Regression Equation | t-Student Value | Level of Probability | Coefficient of Regression r | Coefficient of Determination r2 |

|---|---|---|---|---|

| Rzee = 33.18∙LU − 2222.29 | 3.76 | α < 0.01 | 0.80 | 0.64 |

| Rnr = 0.014∙Rkzpp + 222.34 | 3.43 | α < 0.01 | 0.77 | 0.60 |

| ETech = 11,730,000 − 3920 | 3.30 | α < 0.01 | 0.06 | 0.01 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wardal, W.J.; Mazur, K.E.; Roman, K.; Roman, M.; Majchrzak, M. Assessment of Cumulative Energy Needs for Chosen Technologies of Cattle Feeding in Barns with Conventional (CFS) and Automated Feeding Systems (AFS). Energies 2021, 14, 8584. https://doi.org/10.3390/en14248584

Wardal WJ, Mazur KE, Roman K, Roman M, Majchrzak M. Assessment of Cumulative Energy Needs for Chosen Technologies of Cattle Feeding in Barns with Conventional (CFS) and Automated Feeding Systems (AFS). Energies. 2021; 14(24):8584. https://doi.org/10.3390/en14248584

Chicago/Turabian StyleWardal, Witold Jan, Kamila Ewelina Mazur, Kamil Roman, Michał Roman, and Marcin Majchrzak. 2021. "Assessment of Cumulative Energy Needs for Chosen Technologies of Cattle Feeding in Barns with Conventional (CFS) and Automated Feeding Systems (AFS)" Energies 14, no. 24: 8584. https://doi.org/10.3390/en14248584

APA StyleWardal, W. J., Mazur, K. E., Roman, K., Roman, M., & Majchrzak, M. (2021). Assessment of Cumulative Energy Needs for Chosen Technologies of Cattle Feeding in Barns with Conventional (CFS) and Automated Feeding Systems (AFS). Energies, 14(24), 8584. https://doi.org/10.3390/en14248584