Seismic Response Analysis of Tunnel through Fault Considering Dynamic Interaction between Rock Mass and Fault

Abstract

:1. Introduction

2. Seismic Deterioration Effect of Contact Interface

2.1. Influencing Factors for the Seismic Deterioration of Contact Interface

2.2. Calculation Formula for the Vibration Deterioration Coefficient

3. Contact Conditions and Contact States

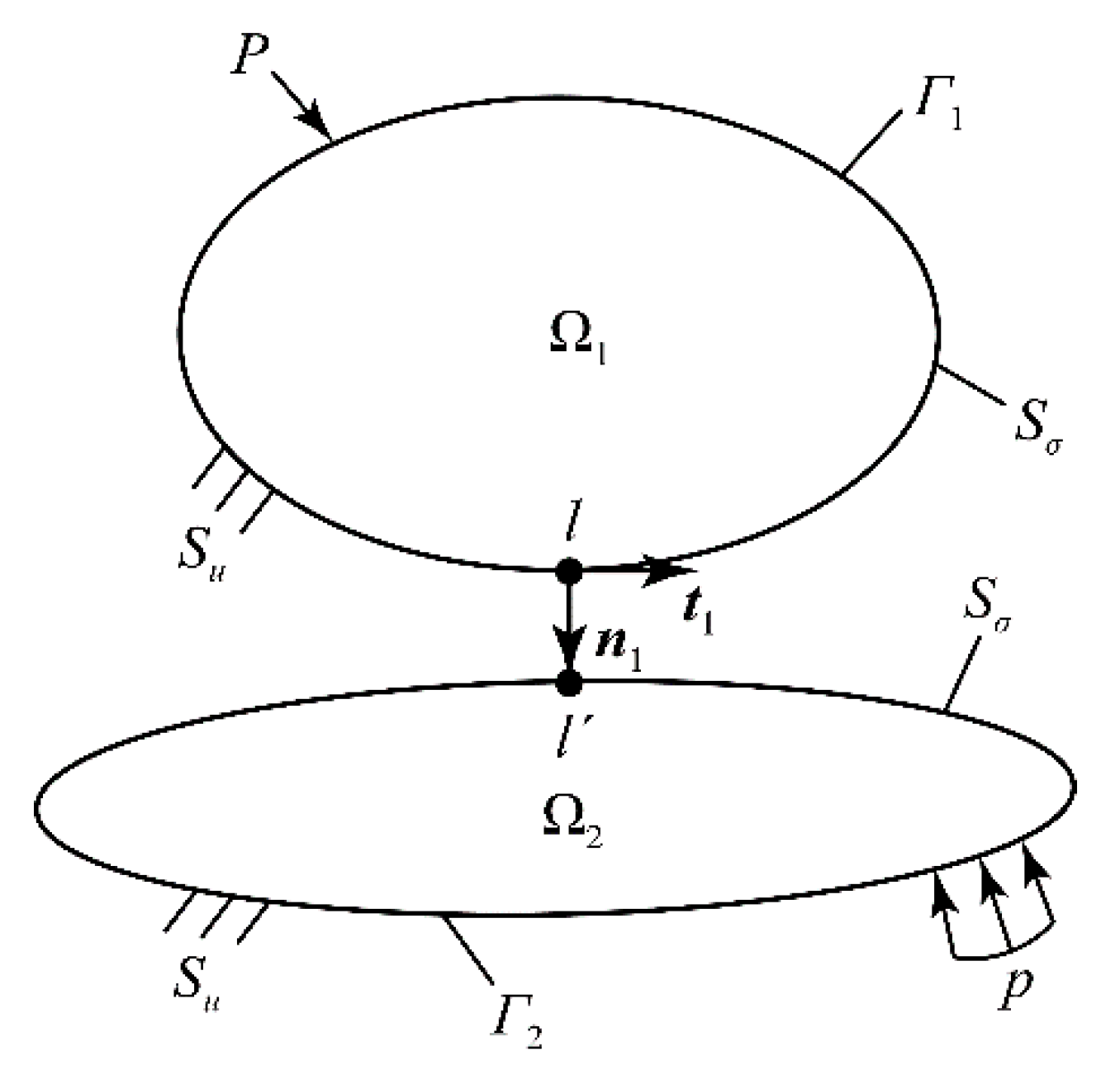

3.1. Contact Conditions

- (1)

- Contact Displacement Conditions

- (2)

- Contact Force Conditions

3.2. Contact States

- (1)

- Bond Contact State

- (2)

- Separation State

- (3)

- Sliding Contact State

- (4)

- Static Contact State

4. Dynamic Contact Analysis Method for Rock Mass and Fault

4.1. Fundamental Theory of the Dynamic Contact Force Method

4.2. Solving for the Contact Force and Judging of the Contact State

- (1)

- Point-to-Point Contact Type

- (2)

- Point-to-Surface Contact Type

4.3. Calculation Flow of the Improved Dynamic Contact Force Method

5. Verification of the Method

6. Engineering Case Study

6.1. Engineering Profiles and Calculation Model

6.2. Calculation Conditions

6.3. Analysis of Calculation Results

6.3.1. Relative Movement and Seismic Deterioration Analysis of the Contact Interface

6.3.2. Displacement Analysis of the Lining

6.3.3. Stress and Damage Analysis of the Lining

6.4. Discussion

6.4.1. Influences of Fault Thickness on Seismic Response of the Lining

6.4.2. Influences of Fault Dip Angle on Seismic Response of the Lining

7. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Huang, J.Q.; Zhao, M.; Du, X.L. Non-linear seismic responses of tunnels within normal fault ground under obliquely incident P waves. Tunn. Undergr. Space Technol. 2017, 61, 26–39. [Google Scholar] [CrossRef]

- Wang, Z.Z.; Zhang, Z. Seismic damage classification and risk assessment of mountain tunnels with a validation for the 2008 Wenchuan earthquake. Soil Dyn. Earthq. Eng. 2013, 45, 45–55. [Google Scholar] [CrossRef]

- Yan, G.M.; Gao, B.; Shen, Y.S.; Zheng, Q.; Fan, K.X.; Huang, H.F. Shaking table test on seismic performances of newly designed joints for mountain tunnels crossing faults. Adv. Struct. Eng. 2020, 23, 248–262. [Google Scholar] [CrossRef]

- Shen, Y.S.; Gao, B.; Yang, X.M.; Tao, S.J. Seismic damage mechanism and dynamic deformation characteristic analysis of mountain tunnel after Wenchuan earthquake. Eng. Geol. 2014, 180, 85–98. [Google Scholar] [CrossRef]

- Li, T.B. Damage to mountain tunnels related to the Wenchuan earthquake and some suggestions for aseismic tunnel construction. Bull. Eng. Geol. Environ. 2012, 71, 297–308. [Google Scholar] [CrossRef]

- Yu, H.T.; Chen, J.T.; Bobet, A.; Yuan, Y. Damage observation and assessment of the Longxi tunnel during the Wenchuan earthquake. Tunn. Undergr. Space Technol. 2016, 54, 102–116. [Google Scholar] [CrossRef]

- Fang, L.; Jiang, S.P.; Lin, Z.; Wang, F.Q. Shaking table model test study of tunnel through fault. Rock Soil Mech. 2011, 32, 2709–2713. [Google Scholar]

- Liu, Y.; Gao, F. Experimental study on the dynamic characteristics of a tunnel-crossing fault using a shake-table test. J. Vib. Shock. 2016, 35, 160–165. [Google Scholar]

- Fan, L.; Chen, J.L.; Peng, S.Q.; Qi, B.X.; Zhou, Q.W.; Wang, F. Seismic response of tunnel under normal fault slips by shaking table test technique. J. Cent. South. Univ. 2020, 27, 1306–1319. [Google Scholar] [CrossRef]

- Li, L.; He, C.; Geng, P.; Cao, D.J. Analysis of seismic dynamic responses of tunnel through fault zone in high earthquake intensity area. J. Chongqing Univ. Nat. Sci. Ed. 2012, 35, 92–98. [Google Scholar]

- Yang, Z.H.; Lan, H.X.; Zhang, Y.S.; Gao, X.; Li, L.P. Nonlinear dynamic failure process of tunnel-fault system in response to strong seismic event. J. Asian Earth Sci. 2013, 64, 125–135. [Google Scholar] [CrossRef]

- Ardeshiri-Lajimi, S.; Yazdani, M.; Langroudi, A.A. Control of fault lay-out on seismic design of large underground caverns. Tunn. Undergr. Space Technol. 2015, 50, 305–316. [Google Scholar] [CrossRef]

- Liu, J.B.; Sharan, S.K. Analysis of dynamic contact of cracks in viscoelastic media. Comput. Methods Appl. Mech. Eng. 1995, 121, 187–200. [Google Scholar] [CrossRef]

- Yang, Y.; Chen, J.T.; Xiao, M. Analysis of seismic damage of underground powerhouse structure of hydropower plants based on dynamic contact force method. Shock. Vib. 2014, 2014, 1–13. [Google Scholar] [CrossRef]

- Zhou, H.; Xiao, M.; Yang, Y.; Liu, G.Q. Seismic response analysis method for lining structure in underground cavern of hydropower station. KSCE J. Civ. Eng. 2019, 23, 1236–1247. [Google Scholar] [CrossRef]

- Hutson, R.W.; Dowding, C.H. Joint asperity degradation during cyclic shear. Int. J. Rock Mech. Min. Sci. 1990, 27, 109–119. [Google Scholar] [CrossRef]

- Hou, D.; Rong, G.; Yang, J.; Zhou, C.B.; Peng, J.; Wang, X.J. A new shear strength criterion of rock joints based on cyclic shear experiment. Eur. J. Environ. Civ. Eng. 2016, 20, 180–198. [Google Scholar] [CrossRef]

- Yang, Z.Y.; Di, C.C.; Yen, K.C. The effect of asperity order on the roughness of rock joints. Int. J. Rock Mech. Min. Sci. 2001, 38, 745–752. [Google Scholar] [CrossRef]

- Ni, W.D.; Tang, H.M.; Liu, X.; Wu, Y.P. Dynamic stability analysis of rock slope considering vibration deterioration of structural planes under seismic loading. Chin. J. Rock Mech. Eng. 2013, 32, 492–500. [Google Scholar]

- Crawford, A.M.; Curran, J.H. The influence of shear velocity on the frictional resistance of rock discontinuities. Int. J. Rock Mech. Min. Sci. 1981, 18, 505–515. [Google Scholar] [CrossRef]

- Wang, Z.; Gu, L.L.; Shen, M.R.; Zhang, F.; Zhang, G.K.; Deng, S.X. Influence of shear rate on the shear strength of discontinuities with different joint roughness coefficients. Geotech. Test. J. 2020, 43, 683–700. [Google Scholar] [CrossRef]

- Lee, H.S.; Park, Y.J.; Cho, T.F.; You, K.H. Influence of asperity degradation on the mechanical behavior of rough rock joints under cyclic shear loading. Int. J. Rock Mech. Min. Sci. 2001, 38, 967–980. [Google Scholar] [CrossRef]

- Li, H.B.; Feng, H.P.; Liu, B. Study on strength behaviors of rock joints under different shearing deformation velocities. Chin. J. Rock Mech. Eng. 2006, 25, 2435–2440. [Google Scholar]

- Wang, F.J.; Cheng, J.G.; Yao, Z.H.; Huang, C.J.; Kou, Z.J. A new contact algorithm for numerical simulation of structure crashworthiness. Eng. Mech. 2002, 19, 130–134. [Google Scholar]

- Zhang, L.H.; Liu, T.Y.; Li, Q.B.; Chen, T. Modified dynamic contact force method under reciprocating load. Eng. Mech. 2014, 31, 8–14. [Google Scholar]

- Zhang, Z.G.; Xiao, M.; Chen, J.T. Simulation of earthquake disaster process of large-scale underground caverns using three-dimensional dynamic finite element method. Chin. J. Rock Mech. Eng. 2011, 30, 509–523. [Google Scholar]

| Case | Initial Displacement | Initial Velocity | Vertical Load | Horizontal Load | Friction Coefficient |

|---|---|---|---|---|---|

| 1 | 0 | 0 | −30 | 24 t | 0.4 |

| 2 | 0 | −20 | −25 | 20 | 0.4 |

| Material | Elastic Modulus (GPa) | Poisson Ratio | Internal Friction Angle (°) | Cohesive Force (MPa) | Tensile Strength (MPa) | Compressive Strength (MPa) | Density (g∙cm−3) |

|---|---|---|---|---|---|---|---|

| Fault | 0.3 | 0.33 | 24.2 | 0.1 | 0.50 | 10.0 | 2.0 |

| Lining | 30.0 | 0.17 | 46.0 | 2.0 | 1.43 | 12.7 | 2.5 |

| Rock | 5.0 | 0.29 | 35.0 | 0.6 | 1.30 | 40.0 | 2.7 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, G.; Zhang, Y.; Ren, J.; Xiao, M. Seismic Response Analysis of Tunnel through Fault Considering Dynamic Interaction between Rock Mass and Fault. Energies 2021, 14, 6700. https://doi.org/10.3390/en14206700

Liu G, Zhang Y, Ren J, Xiao M. Seismic Response Analysis of Tunnel through Fault Considering Dynamic Interaction between Rock Mass and Fault. Energies. 2021; 14(20):6700. https://doi.org/10.3390/en14206700

Chicago/Turabian StyleLiu, Guoqing, Yanhong Zhang, Junqing Ren, and Ming Xiao. 2021. "Seismic Response Analysis of Tunnel through Fault Considering Dynamic Interaction between Rock Mass and Fault" Energies 14, no. 20: 6700. https://doi.org/10.3390/en14206700

APA StyleLiu, G., Zhang, Y., Ren, J., & Xiao, M. (2021). Seismic Response Analysis of Tunnel through Fault Considering Dynamic Interaction between Rock Mass and Fault. Energies, 14(20), 6700. https://doi.org/10.3390/en14206700