Odour Nuisance at Municipal Waste Biogas Plants and the Effect of Feedstock Modification on the Circular Economy—A Review

Abstract

:1. Introduction

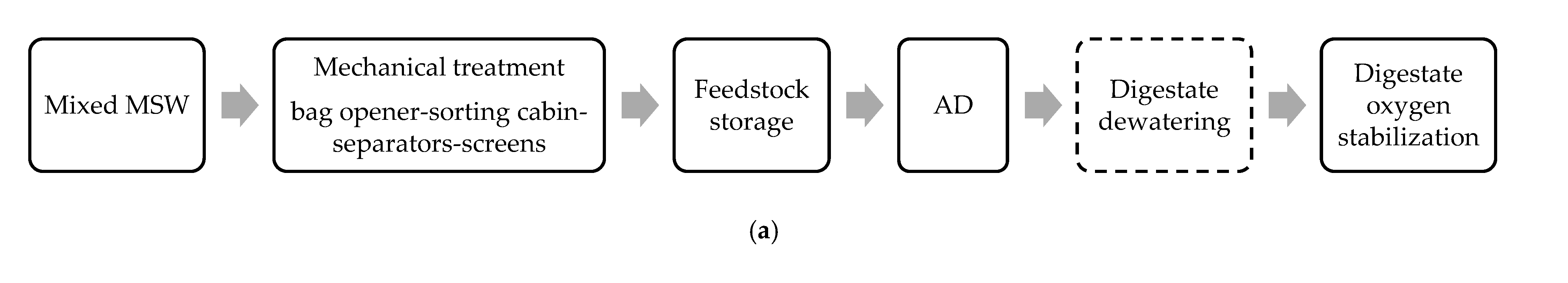

2. Municipal Waste Biogas Plants (MWBPs)

2.1. Anaerobic Digestion Process

2.2. Odour Nuisance of MWBPs

2.3. MWBPs in the CE

2.4. Feedstock for MWBPs

3. The Feedstock Modification to Reduce Odour Nuisance at MWBPs–Analysis, Discussion, Recommendations

4. Summary and Future Research Work

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| AD | Anaerobic digestion |

| BAT | Best available techniques |

| BW | Selectively collected biowaste |

| CE | Circular economy |

| cod | Odour concentration (ou/m3) |

| MSW | Municipal solid waste |

| MWBP | Municipal waste biogas plant |

| OFMSW | Organic fraction of municipal solid waste |

| SDGs | Sustainable development goals |

| VFAs | Volatile fatty acids |

| VOCs | Volatile organic compounds |

| WETs | Waste-to-energy technologies |

References

- Commission of European Communities. Closing the Loop—An EU Action Plan for the Circular Economy; Communication No. 614 (COM (2015), 614); Commission of European Communities: Brussels, Belgium, 2015; Available online: https://eur-lex.euopa.eu/resource.html?uri=cellar:8a8ef5e8-99a0-11e5-b3b7-01aa75ed71a1.0012.02/DOC_1&format=PDF (accessed on 20 November 2020).

- Commission of European Communities. Towards a Circular Economy: A Zero Waste Programme for Europe; Communication No. 398 (COM (2014), 398); Commission of European Communities: Brussels, Belgium, 2014; Available online: http://ec.europa.eu/environment/circular-economy/pdf/circular-economy-communication.pdf (accessed on 20 November 2020).

- Ellen MacArthur Foundation. Available online: https://ellenmacarthurfoundation.org/ (accessed on 2 October 2021).

- Kaza, S.; Yao, L.C.; Bhada-Tata, P.; Van Woerden, F. What a Waste 2.0; World Bank: Washington, DC, USA, 2018. [Google Scholar] [CrossRef]

- Wiśniewska, M.; Kulig, A.; Lelicińska-Serafin, K. The Use of Chemical Sensors to Monitor Odour Emissions at Municipal Waste Biogas Plants. Appl. Sci. 2021, 11, 3916. [Google Scholar] [CrossRef]

- Iqbal, A.; Liua, X.; Chen, G.-H. Municipal solid waste: Review of best practices in application of life cycle assessment and sustainable management techniques. Sci. Total. Environ. 2020, 729, 138622. [Google Scholar] [CrossRef]

- Zulkifli, A.A.; Yusoff, M.Z.M.; Abd Manaf, L.; Zakaria, M.R.; Roslan, A.M.; Ariffin, H.; Hassan, M.A. Assessment of Municipal Solid Waste Generation in Universiti Putra Malaysia and Its Potential for Green Energy Production. Sustainability 2019, 11, 3909. [Google Scholar] [CrossRef] [Green Version]

- The European Parliament and the Council of the European Union. Directive 2008/98/EC of the European Parliament and of the Council of 19 November 2008 on waste and repealing certain Directives. Off. J. Eur. Union 2008, 312, 3–30. [Google Scholar]

- The European Parliament and the Council of the European Union. Directive (EU) 2018/851 of the European Parliament and of the Council of 30 May 2018 amending Directive 2008/98/EC on waste. Off. J. Eur. Union 2018, 150, 109–140. [Google Scholar]

- United Nations. Resolution Adopted by the General Assembly on 25 September 2015, Transforming Our World: The 2030 Agenda for Sustainable Development; United Nations: Geneva, Switzerland, 2015. [Google Scholar]

- Kledyński, Z.; Bogdan, A.; Jackiewicz-Rek, W.; Lelicińska-Serafin, K.; Machowska, A.; Manczarski, P.; Masłowska, D.; Rolewicz-Kalińska, A.; Rucińska, J.; Szczygielski, T.; et al. Condition of Circular Economy in Poland. Arch. Civ. Eng. 2020, 66, 37–80. [Google Scholar] [CrossRef]

- Kuo, W.-C.; Lasek, J.; Słowik, K.; Głód, K.; Jagustyn, B.; Li, Y.H.; Cygan, A. Low-temperature pre-treatment of municipal solid waste for efficient application in combustion systems. Energy Convers. Manag. 2019, 196, 525–535. [Google Scholar] [CrossRef]

- Wiśniewska, M.; Lelicińska-Serafin, K. The Role and Effectiveness of the MBT Installation in Poland Based on Selected Examples. Civ. Environ. Eng. Rep. 2019, 29, 1–12. [Google Scholar] [CrossRef] [Green Version]

- Wienchol, P.; Szlęk, A.; Ditaranto, M. Waste-to-energy technology integrated with carbon capture—Challenges and opportunities. Energy 2020, 198, 117352. [Google Scholar] [CrossRef]

- Huttunen, S.; Manninen, K.; Leskinen, P. Combining biogas LCA reviews with stakeholder interviews to analyse life cycle impacts at a practical level. J. Clean. Prod. 2014, 80, 5–16. [Google Scholar] [CrossRef]

- Komakech, A.J.; Sundberg, C.; Jonsson, H.; Vinnerås, B. Life cycle assessment of biodegradable waste treatment systems for sub-Saharan African cities. Resour. Conserv. Recycl. 2015, 99, 100–110. [Google Scholar] [CrossRef]

- Jensen, M.B.; Møller, J.; Scheutz, C. Comparison of the organic waste management systems in the Danish–German border region using life cycle assessment (LCA). Waste Manag. 2016, 49, 491–504. [Google Scholar] [CrossRef]

- Bhatia, S.K.; Joo, H.S.; Yang, Y.H. Biowaste-to-bioenergy using biological methods—A mini-review. Energy Convers. Manag. 2018, 177, 640–660. [Google Scholar] [CrossRef]

- Margallo, M.; Ziegler-Rodriguez, K.; V’azquez-Rowe, I.; Aldaco, R.; Irabien, A.; Kahhat, R. Enhancing waste management strategies in Latin America under a holistic environmental assessment perspective: A review for policy support. Sci. Total Environ. 2019, 689, 1255–1275. [Google Scholar] [CrossRef]

- Brunner, P.H.; Rechberger, H. Waste to energy—Key element for sustainable waste management. Waste Manag. 2015, 37, 3–12. [Google Scholar] [CrossRef] [PubMed]

- Saveyn, H.; Eder, P. End-of-Waste Criteria for Biodegradable Waste Subjected to Biological Treatment (Compost & Digestate): Technical Proposals, JRC Scientific and Policy Reports; Publications Office of the European Union: Luxembourg, 2014. [Google Scholar]

- Das, S.; Lee, S.H.; Kumar, P.; Kim, K.H.; Lee, S.S.; Bhattacharya, S.S. Solid waste management: Scope and the challenge of sustainability. J. Clean. Prod. 2019, 228, 658–678. [Google Scholar] [CrossRef]

- Slorach, P.C.; Jeswani, H.K.; Cuéllar-Franca, R.; Azapagic, A. Environmental and economic implications of recovering resources from food waste in a circular economy. Sci. Total Environ. 2019, 693, 133516. [Google Scholar] [CrossRef]

- International Energy Agency. World Energy Outlook Special Report 2015: Energy and Climate Change; Final Report; OECD/IEA: Paris, France, 2015. [Google Scholar]

- United Nations Environment Programme. The Emissions Gap Report 2014: A UNEP Synthesis Report; Final Report; UNEP: Nairobi, Kenya, 2014. [Google Scholar]

- Rolewicz-Kalińska, A.; Lelicińska-Serafin, K.; Manczarski, P. The Circular Economy and Organic Fraction of Municipal Solid Waste Recycling Strategies. Energies 2020, 13, 4366. [Google Scholar] [CrossRef]

- Diamantis, V.; Eftaxias, A.; Stamatelatou, K.; Noutsopoulos, C.; Vlachokostas, C.; Aivasidis, A. Bioenergy in the era of circular economy: Anaerobic digestion technological solutions to produce biogas from lipid-rich wastes. Renew. Energy 2021, 168, 438–447. [Google Scholar] [CrossRef]

- Tisserant, A.; Pauliuk, S.; Merciai, S.; Schmidt, J.; Fry, J.; Wood, R.; Tukker, A. Solid Waste and the Circular Economy: A Global Analysis of Waste Treatment and Waste Footprints. J. Ind. Ecol. 2017, 21, 628–640. [Google Scholar] [CrossRef] [Green Version]

- Abad, V.; Avila, R.; Vicent, T.; Font, X. Promoting circular economy in the surroundings of an organic fraction of municipal solid waste anaerobic digestion treatment plant: Biogas production impact and economic factors. Bioresour. Technol. 2019, 283, 10–17. [Google Scholar] [CrossRef] [PubMed]

- Holm-Nielsen, J.B.; Al Seadi, T.; Oleskowicz-Popiel, P. The future of anaerobic digestion and biogas utilization. Bioresour. Technol. 2009, 100, 5478–5484. [Google Scholar] [CrossRef] [PubMed]

- Jędrczak, A. Biologiczne Przetwarzanie Odpadów (Biological Waste Treatment); PWN: Warszawa, Poland, 2008. (In Polish) [Google Scholar]

- Nizami, A.S.; Rehan, M.; Waqas, M.; Naqvi, M.; Ouda, O.K.M.; Shahzad, K.; Miandada, R.; Khand, M.Z.; Syamsiroe, M.; Ismaila, I.M.I.; et al. Waste biorefineries: Enabling circular economies in developing countries. Bioresour. Technol. 2017, 241, 1101–1117. [Google Scholar] [CrossRef]

- Tyagi, V.K.; Fdez-Güelfo, L.A.; Zhou, Y.; Álvarez-Gallego, C.J.; Garcia, L.I.R.; Ng, W.J. Anaerobic co-digestion of organic fraction of municipal solid waste (OFMSW): Progress and challenges. Renew. Sustain. Energy Rev. 2018, 93, 380–399. [Google Scholar] [CrossRef]

- Cardoen, D.; Joshi, P.; Diels, L.; Sarma, P.M.; Pant, D. Agriculture biomass in India: Part 1. Estimation and characterisation. Resour. Conserv. Recycl. 2015, 102, 39–48. [Google Scholar] [CrossRef]

- Cardoen, D.; Joshi, P.; Diels, L.; Sarma, P.M.; Pant, D. Agriculture biomass in India: Part 2. Post-harvest losses, cost and environmental impacts. Resour. Conserv. Recycl. 2015, 101, 143–153. [Google Scholar] [CrossRef]

- Farmanbordar, S.; Karimi, K.; Amiri, H. Municipal solid waste as a suitable substrate for butanol production as an advanced biofuel. Energy Convers. Manag. 2018, 157, 396–408. [Google Scholar] [CrossRef]

- Ravindran, R.; Jaiswal, A.K. Exploitation of food industry waste for high-value products. Trends Biotechnol. 2016, 34, 58–69. [Google Scholar] [CrossRef] [Green Version]

- Banks, C.J.; Chesshire, M.; Heaven, S.; Arnold, R. Anaerobic Digestion of Source-Segregated Domestic Food Waste: Performance Assessment by Mass and Energy Balance. Bioresour. Technol. 2011, 102, 612–620. [Google Scholar] [CrossRef] [Green Version]

- Di Maria, F.; Micale, C.; Morettini, E. Impact of the Pre-Collection Phase at Different Intensities of Source Segregation of Bio-Waste: An Italian Case Study. Waste Manag. 2016, 53, 12–21. [Google Scholar] [CrossRef]

- Seruga, P.; Krzywonos, M.; Seruga, A.; Niedźwiecki, Ł.; Pawlak-Kruczek, H.; Urbanowska, A. Anaerobic Digestion Performance: Separate Collected vs. Mechanical Segregated Organic Fractions of Municipal Solid Waste as Feedstock. Energies 2020, 13, 3768. [Google Scholar] [CrossRef]

- Lim, L.S.; Lee, L.H.; Wu, T.Y. Sustainability of Using Composting and Vermicomposting Technologies for Organic Solid Waste Biotransformation: Recent Overview, Greenhouse Gases Emissions and Economic Analysis. J. Clean. Prod. 2016, 111, 262–278. [Google Scholar] [CrossRef]

- Bölükba¸s, A.; Akinci, G. Solid Waste Composition and the Properties of Biodegradable Fractions in Izmir City, Turkey: An Investigation on the Influencing Factors. J. Environ. Health Sci. Eng. 2018, 16, 299–311. [Google Scholar] [CrossRef]

- Jędrczak, A. Composting and Fermentation of Biowaste—Advantages and Disadvantages of Processes. Civ. Environ. Eng. Rep. 2019, 28, 71–87. [Google Scholar] [CrossRef] [Green Version]

- Edjabou, M.E.; Jensen, M.B.; Götze, R.; Pivnenko, K.; Petersen, C.; Scheutz, C.; Astrup, T.F. Municipal solid waste composition: Sampling methodology, statistical analyses, and case study evaluation. Waste Manag. 2015, 36, 12–23. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Karak, T.; Bhagat, R.M.; Bhattacharyya, P. Municipal solid waste generation, composition, and management: The world scenario. Crit. Rev. Environ. Sci. Technol. 2012, 42, 1509–1630. [Google Scholar] [CrossRef]

- Chen, Y.-C. Effects of urbanisation on municipal solid waste composition. Waste Manag. 2018, 79, 828–836. [Google Scholar] [CrossRef] [PubMed]

- Khair, H.; Putri, C.N.; Dalimunthe, R.A.; Matsumoto, T. Examining of solid waste generation and community awareness between city center and suburban area in Medan City, Indonesia. IOP Conf. Ser. Mater. Sci. Eng. 2018, 309, 012050. [Google Scholar] [CrossRef]

- Gasification Technologies Council (GTC). Gasification: The Waste and Energy Solution; Gasification Technologies Council (GTC): Penwell, TX, USA, 2011. [Google Scholar]

- World Energy Council (WEC). World Energy Resources: Waste to Energy; World Energy Council: London, UK, 2013; Available online: https://www.worldenergy.org/wp-content/uploads/2013/10/WER_2013_7b_Waste_to_Energy.pdf (accessed on 2 December 2019).

- Mubeen, I.; Buekens, A. Chapter 14—Energy from Waste: Future Prospects Toward Sustainable Development. In Current Developments in Biotechnology and Bioengineering Waste Treatment Processes for Energy Generation; Elsevier: Amsterdam, The Netherlands, 2019; pp. 283–305. [Google Scholar] [CrossRef]

- Sun, L.; Liu, W.; Fujii, M.; Li, Z.; Ren, J.; Dou, Y. Chapter 1—An overview of waste-to-energy: Feedstocks, technologies and implementations. In Waste-to-Energy, Multi-Criteria Decision Analysis for Sustainability Assessment and Ranking; Academic Press: Cambridge, MA, USA, 2020; pp. 1–22. [Google Scholar] [CrossRef]

- Haarich, S. Bioeconomy Development in EU Regions: Mapping of EU Member States’/Regions’ Research and Innovation Plans & Strategies for Smart Specialisation (RIS3) on Bioeconomy; Publications Office of the European Union: Luxembourg, 2017. [Google Scholar]

- Zaleski, P.; Chawla, Y. Circular Economy in Poland: Profitability Analysis for Two Methods of Waste Processing in Small Municipalities. Energies 2020, 13, 5166. [Google Scholar] [CrossRef]

- WEC. World Energy Resources Waste to Energ. 2016. Available online: https://www.worldenergy.org/wp-content/uploads/2017/03/WEResources_Waste_to_Energy_2016.pdf (accessed on 30 September 2021).

- Khan, I.; Zobaidul, K. Waste-to-energy generation technologies and the developing economies: A multi-criteria analysis for sustainability assessment. Renew. Energy 2020, 150, 320–333. [Google Scholar] [CrossRef]

- Di Giacomo, G.; Gallifuoco, A.; Taglieri, L. Hydrothermal Carbonization of Mixed Biomass: Experimental Investigation for an Optimal Valorisation of Agrofood Wastes. In Proceedings of the 24th European Biomass Conference and Exibition (24th EUBCE), Amsterdam, The Netherlands, 6–9 June 2016; pp. 1252–1255. [Google Scholar] [CrossRef]

- Panigrahi, S.; Dubey, B.K. A Critical Review on Operating Parameters and Strategies to Improve the Biogas Yield From Anaerobic Digestion of Organic Fraction of Municipal Solid Waste. Renew. Energy 2019, 143, 779–797. [Google Scholar] [CrossRef]

- Carmo-Calado, L.; Hermoso-Orzáez, M.J.; Mota-Panizio, R.; Guilherme-Garcia, B.; Brito, P. Co-Combustion of Waste Tires and Plastic-Rubber Wastes with Biomass Technical and Environmental Analysis. Sustainability 2020, 12, 1036. [Google Scholar] [CrossRef] [Green Version]

- Kluska, J.; Ochnio, M.; Karda’s, D. Carbonization of Corncobs for the Preparation of Barbecue Charcoal and Combustion Characteristics of Corncob Char. Waste Manag. 2020, 105, 560–565. [Google Scholar] [CrossRef] [PubMed]

- Ruggeri, B.; Tommasi, T.; Sanfilippo, S. BioH2 & BioCH4 through Anaerobic Digestion: From Research to Full-Scale Applications; Springer: London, UK, 2015. [Google Scholar] [CrossRef]

- Agostini, F.; Sundberg, C.; Navia, R. Is biodegradable waste a porous environment? A review. Waste Manag. Res. 2012, 30, 1001–1015. [Google Scholar] [CrossRef]

- Achinas, S.; Achinas, V.; Euverink, G.J.W. A Technological Overview of Biogas Production from Biowaste. Engineering 2017, 3, 299–307. [Google Scholar] [CrossRef]

- Mirmohamadsadeghi, S.; Karimi, K.; Tabatabaei, M.; Aghbashlo, M. Biogas production from food wastes: A review on recent developments and future perspectives. Bioresour. Technol. Rep. 2019, 7, 100202. [Google Scholar] [CrossRef]

- Sharma, U.C. Energy from Municipal Solid Waste. In Environmental Science and Engineering Vol. 5 Solid Waste Management; Studium Press LLC: Delhi, India, 2019. [Google Scholar]

- Vanek, M.; Mitterpach, J.; Zacharova, A. Odour control in biogas plant. In Proceedings of the 15th International Multidisciplinary Scientific GeoConferences SGEM2015: Renewable Energy Sources and Clean Technologies, Albena Resort, Bulgaria, 16–25 June 2015; pp. 353–360. [Google Scholar]

- Jaimes-Estévez, J.; Zafra, G.; Martí-Herrero, J.; Pelaz, G.; Morán, A.; Puentes, A.; Gomez, C.; Castro, L.D.P.; Escalante Hernández, H. Psychrophilic Full Scale Tubular Digester Operating over Eight Years: Complete Performance Evaluation and Microbiological Population. Energies 2021, 14, 151. [Google Scholar] [CrossRef]

- United States Environmental Protection Agency. Available online: https://www.epa.gov/sites/default/files/2020-11/documents/agstar-operator-guidebook.pdf (accessed on 30 November 2020).

- Pilarski, G.; Kyncl, M.; Stegenta, S.; Piechota, G. Emission of Biogas from Sewage Sludge in Psychrophilic Conditions. Waste Biomass Valorization 2020, 11, 3579–3592. [Google Scholar] [CrossRef]

- Thi, N.B.D.; Kumor, G.; Liu, C.-Y. An overview of food waste management in developing countries: Current status and future perspectives. J. Environ. Manag. 2015, 157, 220–229. [Google Scholar] [CrossRef]

- Fagerström, A.; Al Seadi, T.; Rasi, S.; Briseid, T. The Role of Anaerobic Digestion and Biogas in the Circular Economy; Murphy, J.D., Ed.; IEA Bioenergy Task 37; IEA Bioenergy: Didcot, UK, 2018; Volume 8. [Google Scholar]

- Anderson, S. Samhällsnyttan Med Biogas—En Studie i Jönköpings Län; Energikontor Norra Småland: Stockholm, Sweden, 2016. [Google Scholar]

- Ardolino, F.; Parrillo, F.; Arena, U. Biowaste-to-biomethane or biowaste-to-energy? An LCA study on anaerobic digestion of organic waste. J. Clean. Prod. 2018, 174, 462–476. [Google Scholar] [CrossRef]

- Ardolino, F.; Arena, U. Biowaste-to-Biomethane: An LCA study on biogas and syngas roads. Waste Manag. 2019, 87, 441–453. [Google Scholar] [CrossRef]

- Barbera, E.; Menegon, S.; Banzato, D.; D’Alpaos, C.; Bertucco, A. From biogas to biomethane: A process simulation-based techno-economic comparison of different upgrading technologies in the Italian context. Renew. Energy 2019, 135, 663–673. [Google Scholar] [CrossRef]

- Ardolino, F.; Cardamone, G.F.; Parrillo, F.; Arena, U. Biogas-to-biomethane upgrading: A comparative review and assessment in a life cycle perspective. Renew. Sustain. Energy Rev. 2021, 139, 110588. [Google Scholar] [CrossRef]

- Rasi, S.; Veijanen, A.; Rintala, J. Trace compounds of biogas from different biogas production plants. Energy 2007, 32, 1375–1380. [Google Scholar] [CrossRef]

- Słupek, E.; Makoś, P.; Gębicki, J. Deodorization of model biogas by means of novel non-ionic deep eutectic solvent. Arch. Environ. Prot. 2020, 46, 41–46. [Google Scholar] [CrossRef]

- Piechota, G. Multi-step biogas quality improving by adsorptive packed column system as application to biomethane upgrading. J. Environ. Chem. Eng. 2021, 9, 105944. [Google Scholar] [CrossRef]

- McCarty, P.L. Anaerobic waste treatment fundamentals. Public Work 1964, 95, 9–12. [Google Scholar]

- Taricska, J.R.; Long, D.A.; Chen, J.P.; Hung, Y.T.; Zou, S.W. Anaerobic Digestion. In Biosolids Treatment Processes; Wang, L.K., Shammas, N.K., Hung, Y.T., Eds.; Handbook of Environmental Engineering; Humana Press: Totowa, NJ, USA, 2007; Volume 6. [Google Scholar] [CrossRef]

- Mihai, F.C.; Ingrao, C. Assessment of biowaste losses through unsound waste management practices in rural areas and the role of home composting. J. Clean. Prod. 2018, 172, 1631–1638. [Google Scholar] [CrossRef]

- Khalid, A.; Arshad, M.; Anjum, M.; Mahmood, T.; Dawson, L. The anaerobic digestion of solid organic waste. Waste Manag. 2011, 31, 1737–1744. [Google Scholar] [CrossRef]

- Mathew, A.K.; Bhui, I.; Banerjee, S.N.; Goswami, R.; Shome, A.; Chakraborty, A.K.; Balachandran, S.; Chaudhury, S. Biogas production from locally available aquatic weeds of Santiniketan through anaerobic digestion. Clean Technol. Environ. Policy 2015, 17, 1681–1688. [Google Scholar] [CrossRef]

- Lohani, S.P.; Havukainenm, J. Anaerobic Digestion: Factors Affecting Anaerobic Digestion Process. In Waste Bioremediation, Energy, Environment and Sustainability; Varjani, S.J., Gnansounou, E., Baskar, G., Pant, D., Zakaria, Z.A., Eds.; Springer Nature Singapore Pte Ltd.: Singapore, 2018; pp. 343–360. [Google Scholar] [CrossRef]

- Van Lier, J.B.; Sanz Martin, J.L.; Lettinga, G. Effect of temperature on the anaerobic thermophilic conversion of volatile fatty acids by dispersed and granular sludge. Water Res. 1996, 30, 199–207. [Google Scholar] [CrossRef]

- Abdelgadir, A.; Chen, X.; Liu, J.; Xie, X.; Zhang, J.; Zhang, K.; Wang, H.; Liu, N. Characteristics, process parameters, and inner components of anaerobic bioreactors. BioMed Res. Int. 2014, 2014, 841573. [Google Scholar] [CrossRef] [Green Version]

- Bendixen, H.J. Safeguards against pathogens in Danish biogas plants. Water Sci. Technol. 1994, 30, 171–180. [Google Scholar] [CrossRef]

- Smith, S.R.; Lang, N.L.; Cheung, K.H.M.; Spanoudaki, K. Factors controlling pathogen destruction during anaerobic digestion of biowastes. Waste Manag. 2005, 25, 417–425. [Google Scholar] [CrossRef]

- Appels, L.; Baeyens, J.; Degrève, J.; Dewil, R. Principles and potential of the anaerobic digestion of waste-activated sludge. Prog. Energy Combust. Sci. 2008, 34, 755–781. [Google Scholar] [CrossRef]

- Van Lier, J.B.; Mohmoud, N.; Zeeman, G. Anaerobic wastewater treatment. In Biological Wastewater Treatment, Principles, Modelling and Design; Henze, M., van Loosdrecht, M., Ekama, G.A., Brdjanovic, D., Eds.; IWA Publishing: London, UK, 2008; pp. 415–457. [Google Scholar]

- Hwang, M.H.; Jang, N.J.; Hyun, S.H.; Kim, I.S. Anaerobic bio-hydrogen production from ethanol fermentation: The role of pH. J. Biotechnol. 2004, 111, 297–309. [Google Scholar] [CrossRef] [PubMed]

- Patel, A.; Mahboubi, A.; Horváth, I.S.; Taherzadeh, M.J.; Rova, U.; Christakopoulos, P.; Matsakas, L. Volatile Fatty Acids (VFAs) Generated by Anaerobic Digestion Serve as Feedstock for Freshwater and Marine Oleaginous Microorganisms to Produce Biodiesel and Added-Value Compounds. Front. Microbiol. 2021, 12, 614612. [Google Scholar] [CrossRef]

- Tampio, E.A.; Blasco, L.; Vainio, M.M.; Kahala, M.M.; Rasi, S.E. Volatile fatty acids (VFAs) and methane from food waste and cow slurry: Comparison of biogas and VFA fermentation processes. GCB Bioenergy 2019, 11, 72–84. [Google Scholar] [CrossRef]

- Swiatkiewicz, J.; Slezak, R.; Krzystek, L.; Ledakowicz, S. Production of Volatile Fatty Acids in a Semi-Continuous Dark Fermentation of Kitchen Waste: Impact of Organic Loading Rate and Hydraulic Retention Time. Energies 2021, 14, 2993. [Google Scholar] [CrossRef]

- Lusk, P. Latest progress in anaerobic digestion. Biocycle 1999, 40, 52–54. [Google Scholar]

- Rajeshwari, K.V.; Balakrishnan, M.; Kansal, A.; Lata, K.; Kishore, V.V.N. State-of-the-art of anaerobic digestion technology for industrial wastewater treatment. Renew. Sustain. Energy Rev. 2000, 4, 135–156. [Google Scholar] [CrossRef]

- Weiland, P. Stand und Perspektiven der Biogasnutzung und -erzeugung in Deutschland. In Gülzower Fachgespräche: Band 15: Energetische Nutzung von Biogas: Stand der Technik und Optimierungspotenzial; Fachagentur Nachwachsende Rohstoffe e. V. (Hrsg.): Gülzow, Germany, 2000. [Google Scholar]

- Fujishima, S.; Miyahara, T.; Noike, T. Effect of moisture content on anaerobic digestion of dewatered sludge: Ammonia inhibition to carbohydrate removal and methane production. Water Sci. Technol. 2000, 41, 119–127. [Google Scholar] [CrossRef]

- Kim, S.I.; Kim, H.D.; Hyun, H.S. Effect of particle size and sodium ion concentration on anaerobic thermophilic food waste digestion. Water Sci. Technol. 2000, 41, 67–73. [Google Scholar] [CrossRef] [PubMed]

- Liu, Y.; Tay, J. State of the art of biogranulation technology for wastewater treatment. Biotechnol. Adv. 2004, 22, 533–563. [Google Scholar] [CrossRef] [PubMed]

- Halalsheh, M.; Koppes, J.; Den Elzen, J.; Zeeman, G.; Fayyad, M.; Lettinga, G. Effect of SRT and temperature on biological conversions and the related scum-forming potential. Water Res. 2005, 39, 2475–2482. [Google Scholar] [CrossRef] [PubMed]

- Batstone, D.J.; Keller, J.; Angelidaki, R.I.; Kalyuzhnyi, S.V.; Pavlostathis, S.G.; Rozzi, A.; Sanders, W.T.M.; Siegrist, H.; Vavilin, V.A. Anaerobic Digestion Model No. 1 (ADM1); IWA Publishing: London, UK, 2002. [Google Scholar]

- Speece, R.E. Anaerobic Biotechnology for Industrial Wastewaters; Archae Press: Nashville, TN, USA, 1996. [Google Scholar]

- Arceivala, S.J.; Asolekar, S.R. Wastewater Treatment for Pollution Control and Reuse; Tata McGraw-Hill: New Delhi, India, 2007. [Google Scholar]

- Foxon, K.M.; Brouckaert, C.J.; Remigi, E.; Buckley, C.A. The anaerobic baffled reactor: An appropriate technology for onsite sanitation. Water SA 2006, 30, 44–50. [Google Scholar] [CrossRef]

- Fidaleo, M.; Laveccio, R. Kinetic study of enzymatic urea hydrolysis in the pH range of 4–9. Chem. Biochem. Eng. 2003, 17, 311–318. [Google Scholar]

- Fotidis, I.A.; Karakashev, D.; Kotsopoulos, T.A.; Martzopoulos, G.G.; Angelidaki, I. Effect of ammonium and acetate on methanogenic pathwayand methanogenic community composition. FEMS Microbiol. Ecol. 2013, 83, 38–48. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Kadam, P.C.; Boone, D.R. Influence of pH on ammonia accumulation and toxicity in halophilic, Methylotrophic Methanogens. Appl. Environ. Microbiol. 1996, 62, 4486–4492. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Shanmugam, P.; Horan, N.J. Simple and rapid methods to evaluate methane potential and biomass yield for a range of mixed solid wastes. Bioresour. Technol. 2008, 100, 471–474. [Google Scholar] [CrossRef]

- Chen, Y.; Cheng, J.J.; Creamer, K.S. Inhibition of anaerobic digestion process: A review. Bioresour. Technol. 2008, 99, 4044–4064. [Google Scholar] [CrossRef]

- McKeown, M.R.; Hughes, D.; Collins, G.; Mahony, T.; O’Flaherty, V. Low-temperature anaerobic digestion for wastewater treatment. Curr. Opin. Biotechnol. 2012, 23, 444–451. [Google Scholar] [CrossRef]

- Xia, A.; Cheng, J.; Murphy, D.J. Innovation in biological production and upgrading of methane and hydrogen for use as gaseous transport biofuel. Biotechnol. Adv. 2016, 34, 451–472. [Google Scholar] [CrossRef]

- Monnet, F. An Introduction to Anaerobic Digestion of Organic Wastes. 2003. Available online: http://www.remade.org.uk/media/9102/an-introduction-to-anaerobic-digestion-nov2003.pdf (accessed on 1 September 2021).

- Khanal, S.K. Anaerobic Biotechnology for Bioenergy Production: Principles and Applications; Wiley-Blackwell: Ames, IA, USA, 2008. [Google Scholar]

- Colón, J.; Cadena, E.; Pognani, M.; Barrena, R.; Sánchez, A.; Font, X.; Artola, A. Determination of the energy and environmental burdens associated with the biological treatment of source-separated municipal solid wastes. Energy Environ. Sci. 2012, 5, 5731–5741. [Google Scholar] [CrossRef] [Green Version]

- Atelge, M.R.; Krisa, D.; Kumar, G.; Eskicioglu, C.; Nguyen, D.D.; Chang, S.W.; Atabani, A.E.; Al-Muhtaseb, A.H.; Unalan, S. Biogas Production from Organic Waste: Recent Progress and Perspectives. Waste Biomass Valorization 2018, 11, 1019–1040. [Google Scholar] [CrossRef]

- Turan, N.G.; Akdemir, A.; Ergun, O.N. Emission of Volatile Organic Compounds during Composting of Poultry Litter. Water Air Soil Pollut. 2007, 184, 177–182. [Google Scholar] [CrossRef]

- Sironi, S.; Capelli, L.; Céntola, P.; Del Rosso, R. Development of a system for the continuous monitoring of odors from a composting plant: Focus on training, data processing and results validation, methods. Sens. Actuators B Chem. 2007, 124, 336–346. [Google Scholar] [CrossRef]

- Font, X.; Artola, A.; Sánchez, A. Detection, composition and treatment of volatile organic compounds from waste treatment plants. Sensors 2011, 11, 4043–4059. [Google Scholar] [CrossRef] [Green Version]

- Wiśniewska, M.; Kulig, A.; Lelicińska-Serafin, K. The importance of the microclimatic conditions inside and outside of plant buildings in odorants emission at municipal waste biogas installations. Energies 2020, 13, 6463. [Google Scholar] [CrossRef]

- Rincón, C.A.; De Guardia, A.; Couvert, A.; Le Roux, S.; Soutrel, I.; Daumoin, M.; Benoist, J.C. Chemical and odor characterisation of gas emissions released during composting of solid wastes and digestates. J. Environ. Manag. 2019, 233, 39–53. [Google Scholar] [CrossRef]

- Zheng, G.; Liu, J.; Shao, Z.; Chen, T. Emission characteristics and health risk assessment of VOCs from a food waste anaerobic digestion plant: A case study of Suzhou, China. Environ. Pollut. 2020, 257, 113546. [Google Scholar] [CrossRef]

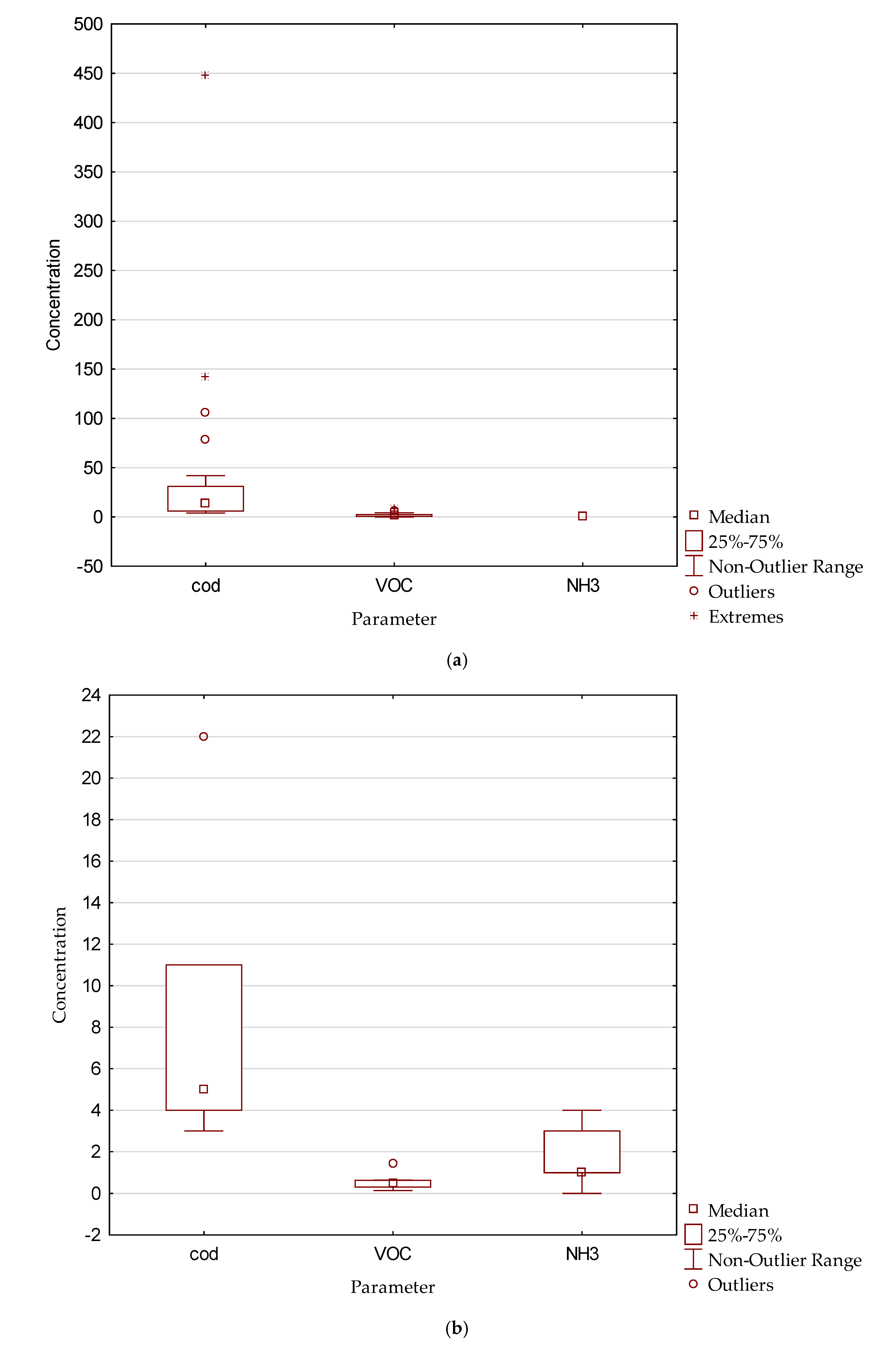

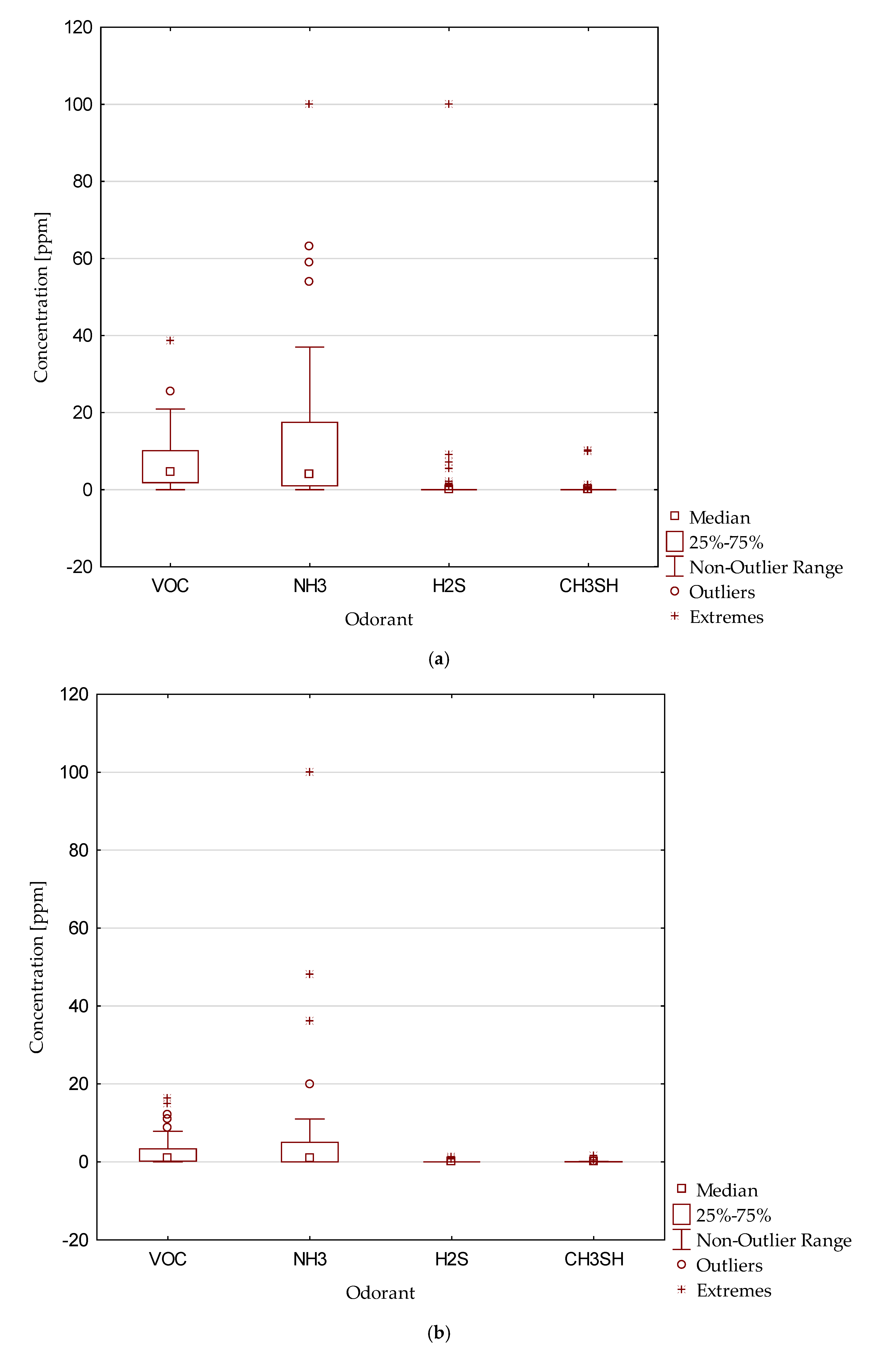

- Wiśniewska, M.; Kulig, A.; Lelicińska-Serafin, K. The Impact of Technological Processes on Odorant Emissions at Municipal Waste Biogas Plants. Sustainability 2020, 12, 5457. [Google Scholar] [CrossRef]

- Wiśniewska, M.; Kulig, A.; Lelicińska-Serafin, K. Odour Emissions of Municipal Waste Biogas Plants—Impact of Technological Factors, Air Temperature and Humidity. Appl. Sci. 2020, 10, 1093. [Google Scholar] [CrossRef] [Green Version]

- Fang, J.; Zhang, H.; Yang, N.; Shao, L.; He, P. Gaseous pollutants emitted from a mechanical biological treatment plant for municipal solid waste: Odor assessment and photochemical reactivity. J. Air Waste Manag. Assoc. 2013, 63, 1287–1297. [Google Scholar] [CrossRef]

- Tsai, C.-J.; Chen, M.-L.; Ye, A.-D.; Chou, M.-S.; Shen, S.-H.; Mao, I.-F. The relationship of odor concentration and the critical components emitted from food waste composting plants. Atmos. Environ. 2008, 42, 8246–8251. [Google Scholar] [CrossRef]

- Komilis, D.P.; Ham, R.K.; Park, J.K. Emission of volatile organic compounds during composting of municipal solid wastes. Water Res. 2004, 38, 1707–1714. [Google Scholar] [CrossRef]

- Scaglia, B.; Orzi, V.; Artola, A.; Font, X.; Davoli, E.; Sanchez, A.; Adani, F. Odours and volatile organic compounds emitted from municipal solid waste at different stage of decomposition and relationship with biological stability. Bioresour. Technol. 2011, 102, 4638–4645. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- IARC. IARC Monographs: On the Evaluation of Carcinogenic Risks to Humans. Volume 120: Benzene. 2018. Available online: http://publications.iarc.fr/Book-And-Report-Series/Iarc-Monographs-On-The-Identification-Of-Carcinogenic-Hazards-To-Humans/Benzene-2018 (accessed on 1 September 2021).

- ATSDR. Toxicological Profile for Xylene. Agency for Toxic Substances and Disease Registry, Department of Health and Human Services, Public Health Service, USA. 2007. Available online: https://www.atsdr.cdc.gov/toxprofiles/tp71.pdf (accessed on 1 September 2021).

- ATSDR. Toxicological Profile for Ethylbenzene. Agency for Toxic Substances and Disease Registry, Department of Health and Human Services, Public Health Service, USA. 2010. Available online: https://www.atsdr.cdc.gov/toxprofiles/tp110.pdf (accessed on 1 September 2021).

- ATSDR. Toxicological Profile for Toluene. Agency for Toxic Substances and Disease Registry, Department of Health and Human Services, Public Health Service, USA. 2017. Available online: https://www.atsdr.cdc.gov/toxprofiles/tp56.pdf (accessed on 1 September 2021).

- Bolden, A.L.; Kwiatkowski, C.F.; Colborn, T. New loot at BTEX: Are ambient levels a problem? Environ. Sci. Technol. 2015, 49, 5261–5276. [Google Scholar] [CrossRef] [PubMed]

- Uchida, Y.; Nakatsuka, H.; Ukai, H. Symptoms and signs in workers exposed predominantly to xylenes. Int. Arch. Occup. Environ. Health. 1993, 64, 597–605. [Google Scholar] [CrossRef]

- Byliński, H.; Barczak, R.J.; Gębicki, J.; Namieśnik, J. Monitoring of odors emitted from stabilised dewatered sludge subjected to aging using proton transfer reaction–mass spectrometry. Environ. Sci. Pollut. Res. 2019, 26, 5500–5513. [Google Scholar] [CrossRef] [Green Version]

- Costa, J.A.V.; de Morais, M.G. The role of biochemical engineering in the production of biofuels from microalgae. Bioresour. Technol. 2011, 102, 2–9. [Google Scholar] [CrossRef]

- World Health Organization. Guidelines for Air Quality; WHO: Geneva, Switzerland, 2000. [Google Scholar]

- Wiśniewska, M.; Kulig, A.; Lelicińska-Serafin, K. Olfactometric testing as a method for assessing odour nuisance of biogas plants processing municipal waste. Arch. Environ. Prot. 2020, 46, 60–68. [Google Scholar] [CrossRef]

- EUR—Lex. Commission Implementing Decision (EU) 2018/1147 of 10 August 2018 Establishing Best Available Techniques (BAT) Conclusions for Waste Treatment, under Directive 2010/75/EU of the European Parliament and of the Council. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?toc=OJ:L:2018:208:TOC&uri=uriserv:OJ.L_.2018.208.01.0038.01.ENG (accessed on 17 August 2018).

- Umberto, A. Process and technological aspects of municipal solid waste gasification. Rev. Waste Manag. 2012, 32, 625–639. [Google Scholar] [CrossRef]

- Kamuk, B.; Haukohl, J. ISWA Guidelines: Waste to Energy in Low and Middle Income Countries. 2013. Available online: https://www.iswa.org/index.php?eID¼tx_iswaknowledgebase_download&documentUid¼3252 (accessed on 1 September 2021).

- WEC. World Energy Resources, Waste to Energy. World Energy Council: London, UK, 2013. [CrossRef]

- Santoyo-Castelazo, E.; Azapagic, A. Sustainability assessment of energy systems: Integrating environmental, economic and social aspects. J. Clean. Prod. 2014, 80, 119–138. [Google Scholar] [CrossRef]

- Astrup, T.F.; Tonini, D.; Turconi, R.; Boldrin, A. Life cycle assessment of thermal Waste-to-Energy technologies: Review and recommendations. Waste Manag. 2015, 37, 104–115. [Google Scholar] [CrossRef] [Green Version]

- Jeswani, H.K.; Azapagic, A. Assessing the environmental sustainability of energy recovery from municipal solid waste in the UK. Waste Manag. 2016, 50, 346–363. [Google Scholar] [CrossRef]

- Kumar, A.; Samadder, S.R. A review on technological options of waste to energy for effective management of municipal solid waste. Waste Manag. 2017, 69, 407–422. [Google Scholar] [CrossRef] [PubMed]

- Dong, J.; Tang, Y.; Nzihou, A.; Chi, Y.; Weiss-Hortala, E.; Ni, M. Life cycle assessment of pyrolysis, gasification and incineration waste-to-energy technologies: Theoretical analysis and case study of commercial plants. Sci. Total Environ. 2018, 626, 744–753. [Google Scholar] [CrossRef]

- Zhou, Z.; Tang, Y.; Chi, Y.; Ni, M.; Buekens, A. Waste-to-energy: A review of life cycle assessment and its extension methods. Waste Manag. Res. 2018, 36, 3–16. [Google Scholar] [CrossRef] [PubMed]

- Ng, H.S.; Kee, P.E.; Yim, H.S.; Chen, P.T.; Wei, Y.H.; Lan, J.C.W. Recent advances on the sustainable approaches for conversion and reutilization of food wastes to valuable bioproducts. Bioresour. Technol. 2020, 302, 122889. [Google Scholar] [CrossRef] [PubMed]

- Cottafava, D.; Ritzen, M. Circularity indicator for residential buildings: Addressing the gap between embodied impacts and design aspects. Resour. Conserv. Recycl. 2021, 164, 105120. [Google Scholar] [CrossRef]

- Mazur-Wierzbicka, E. Towards Circular Economy—A Comparative Analysis of the Countries of the European Union. Resources 2021, 10, 49. [Google Scholar] [CrossRef]

- Padilla-Rivera, A.; Carmo, B.B.T.; Arcese, G.; Merveille, N. Social circular economy indicators: Selection through fuzzy delphi method. Sustain. Prod. Consum. 2021, 26, 101–110. [Google Scholar] [CrossRef]

- Haupt, M.; Hellweg, S. Measuring the environmental sustainability of a circular economy. Environ. Sustain. Indic. 2019, 1–2, 100005. [Google Scholar] [CrossRef]

- Hoornweg, D.; Bhada-Tata, P. What a Waste: A Global Review of Solid Waste Management; World Bank: Washington, DC, USA, 2012. [Google Scholar]

- Rajaeifara, M.A.; Ghanavati, H.; Dashti, B.B.; Heijungs, R.; Aghbashlo, M.; Tabatabaei, M. Electricity generation and GHG emission reduction potentials through different municipal solid waste management technologies: A comparative review. Renew. Sustain. Energy Rev. 2017, 79, 414–439. [Google Scholar] [CrossRef]

- Shirzad, M.; Panahi, H.K.S.; Dasht, B.B.; Rajaeifar, M.A.; Aghbashlo, M.; Tabatabaei, M. A comprehensive review on electricity generation and GHG emission reduction potentials through anaerobic digestion of agricultural and livestock/slaughterhouse wastes in Iran. Renew. Sustain. Energy Rev. 2019, 111, 571–594. [Google Scholar] [CrossRef]

- Schlegelmilch, M.; Streese, J.; Biedermann, W.; Herold, T.; Stegmann, R. Odour control at biowaste composting facilities. Waste Manag. 2005, 25, 917–927. [Google Scholar] [CrossRef]

- Wojnarowska, M.; Sołtysik, M.; Turek, P.; Szakiel, J. Odour Nuisance as a Consequence of Preparation for Circular Economy. Eur. Res. Stud. J. 2020, 23, 128–142. [Google Scholar] [CrossRef] [Green Version]

- Rodríguez-Navas, C.; Forteza, R.; Cerdà, V. Use of thermal desorption-gas chromatography-mass spectrometry (TD-GC-MS) on identification of odorant emission focus by volatile organic compounds characterisation. Chemosphere 2012, 89, 1426–1436. [Google Scholar] [CrossRef]

- World Health Organization. Circular Economy and Health: Opportunities and Risks. 2018. Available online: https://www.euro.who.int/__data/assets/pdf_file/0004/374917/Circular-Economy_EN_WHO_web_august-2018.pdf (accessed on 1 September 2021).

- Nikonorova, M.; Imoniana, J.O.; Stankeviciene, J. Analysis of social dimension and well-being in the context of circular economy. Int. J. Glob. Warm. 2020, 21, 3. [Google Scholar] [CrossRef]

- Adani, F.; Tambone, F.; Gotti, A. Biostabilization of municipal solid waste. Waste Manag. 2004, 24, 775–783. [Google Scholar] [CrossRef]

- Titta, G.; Viviani, G.; Sabella, D. Biostabilization and Biodrying of Municipal Solid Waste. In Proceedings of the Eleventh International Waste Management and Landfill Symposium, Cagliari, Sardinia, Italy, 1–5 October 2007; pp. 1085–1086. [Google Scholar]

- Velis, C.A.; Longhurst, P.J.; Drew, G.H.; Smith, R.; Pollard, S.J.T. Biodrying for mechanical–biological treatment of wastes: A review of process science and engineering. Bioresour. Technol. 2009, 100, 2747–2761. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Jędrczak, A.; Suchowska-Kisielewicz, M. A comparison of waste stability indices for mechanical-biological waste treatment and composting plant. Int. J. Environ. Res. Public Health 2018, 15, 2585. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Gliniak, M.; Grabowski, Ł.; Wołosiewicz-Głąb, M.; Polek, D. Influence of ozone aeration on toxic metal content and oxygen activity in green waste compost. J. Ecol. Eng. 2017, 18, 90–94. [Google Scholar] [CrossRef]

- Voberková, S.; Vaverková, M.D.; Burešová, A.; Adamcová, D.; Vršanská, M.; Kynický, J.; Brtnický, M.; Adam, V. Effect of inoculation with white-rot fungi and fungal consortium on the composting efficiency of municipal solid waste. Waste Manag. 2017, 61, 157–164. [Google Scholar] [CrossRef] [PubMed]

- Żygadło, M.; Dębicka, M. The mechanical-biological treatment (MBT) of waste under polish law. Struct. Environ. 2014, 6, 37–42. [Google Scholar]

- Vaverková, M.D.; Elbl, J.; Voběrková, S.; Koda, E.; Adamcová, D.; Gusiatin, Z.M.; Rahman, A.A.; Radziemska, M.; Mazur, Z. Composting versus mechanical–biological treatment: Does it really make a difference in the final product parameters and maturity. Waste Manag. 2020, 106, 173–183. [Google Scholar] [CrossRef]

- Kasiński, S.; Slota, M.; Markowski, M.; Kamińska, A. Municipal solid waste stabilisation in a reactor with an integrated active and passive aeration system. Waste Manag. 2016, 50, 31–38. [Google Scholar] [CrossRef]

- Fourti, O. The maturity tests during the composting of municipal solid wastes. Resour. Conserv. Recycl. 2013, 72, 43–49. [Google Scholar] [CrossRef]

- Cesaro, A.; Belgiorno, V.; Guida, M. Compost from organic solid waste: Quality assessment and European regulations for its sustainable use. Resour. Conserv. Recycl. 2015, 94, 72–79. [Google Scholar] [CrossRef]

- Pavlas, M.; Dvořáček, J.; Pitschke, T.; Peche, R. Biowaste treatment and waste-to-energy-environmental benefits. Energies 2020, 13, 1994. [Google Scholar] [CrossRef] [Green Version]

- Garfi, M.; Gelman, P.; Comas, J.; Carrasco, W.; Ferrer, I. Agricultural reuse of the digestate from low-cost tubular digesters in rural Andean communities. Waste Manag. 2011, 31, 2584–2589. [Google Scholar] [CrossRef]

- Koszel, M.; Lorencowicz, E. Agricultural use of biogas digestate as a replacement fertilisers. Agric. Agric. Sci. Procedia 2015, 7, 119–124. [Google Scholar] [CrossRef] [Green Version]

- Czekała, W.; Lewicki, A.; Pochwatka, P.; Czekała, A.; Wojcieszak, D.; Jóźwiakowski, K.; Waliszewska, H. Digestate management in polish farms as an element of the nutrient cycle. J. Clean. Prod. 2020, 242, 1184545. [Google Scholar] [CrossRef]

- O-Thong, S.; Boe, K.; Angelidaki, I. Thermophilic anaerobic codigestion of oil palm empty fruit bunches with palm oil mill effluent for efficient biogas production. Appl. Energy 2012, 93, 648–654. [Google Scholar] [CrossRef]

- Borowski, S.; Domański, J.; Weatherley, L. Anaerobic co-digestion of swine and poultry manure with municipal sewage sludge. Waste Manag. 2014, 34, 513–521. [Google Scholar] [CrossRef]

- Zhang, C.; Xiao, G.; Peng, L.; Su, H.; Tan, T. The anaerobic co-digestion of food waste and cattle manure. Bioresour. Technol. 2013, 129, 170–176. [Google Scholar] [CrossRef]

- Wei, Y.; Li, X.; Yu, L.; Zou, D.; Yuan, H. Mesophilic anaerobic codigestion of cattle manure and corn stover with biological and chemical pre-treatment. Bioresour. Technol. 2015, 198, 431–436. [Google Scholar] [CrossRef]

- Kougias, P.G.; Kotsopoulos, T.A.; Martzopoulos, G.G. Effect of feedstock composition and organic loading rate during the mesophilic co-digestion of olive mill wastewater and swine manure. Renew. Energy 2014, 69, 202–207. [Google Scholar] [CrossRef]

- Hartmann, H.; Angelidaki, I.; Ahring, B.K. Co-digestion of the organic fraction of municipal waste with other waste types. In Biomethanization of the Organic Fraction of Municipal Solid Wastes; IWA Publishing: London, UK, 2002. [Google Scholar]

- Heo, N.H.; Park, S.C.; Lee, J.S.; Kang, H.; Park, D.H. Single-Stage Anaerobic Codigestion for Mixture Wastes of Simulated Korean Food Waste and Waste Activated Sludge. In Biotechnology for Fuels and Chemicals; Davison, B.H., Lee, J.W., Finkelstein, M., McMillan, J.D., Eds.; Humana Press: Totowa, NJ, USA, 2003; pp. 567–579. ISBN 978-1-4612-6592-4. [Google Scholar]

- Sosnowski, P.; Wieczorek, A.; Ledakowicz, S. Anaerobic co-digestion of sewage sludge and organic fraction of municipal solid wastes. Adv. Environ. Res. 2003, 7, 609–616. [Google Scholar] [CrossRef]

- Heo, N.H.; Park, S.C.; Kang, H. Effects of Mixture Ratio and Hydraulic Retention Time on Single-Stage Anaerobic Co-digestion of Food Waste and Waste Activated Sludge. J. Environ. Sci. Health Part A 2004, 39, 1739–1756. [Google Scholar] [CrossRef] [PubMed]

- Sosnowski, P.; Klepacz-Smolka, A.; Kaczorek, K.; Ledakowicz, S. Kinetic investigations of methane cofermentation of sewage sludge and organic fraction of municipal solid wastes. Bioresour. Technol. 2008, 99, 5731–5737. [Google Scholar] [CrossRef] [PubMed]

- Tsapekos, P.; Kougias, P.G.; Treu, L.; Campanaro, S.; Angelidaki, I. Process performance and comparative metagenomic analysis during co-digestion of manure and lignocellulosic biomass for biogas production. Appl. Energy 2017, 185, 126–135. [Google Scholar] [CrossRef]

- Liu, C.; Li, H.; Zhang, Y.; Liu, C. Improve biogas production from loworganic-content sludge through high-solids anaerobic co-digestion with food waste. Bioresour. Technol. 2016, 219, 252–260. [Google Scholar] [CrossRef] [PubMed]

- Mata-Alvarez, J.; Dosta, J.; Macé, S.; Astals, S. Codigestion of solid wastes: A review of its uses and perspectives including modeling. Crit. Rev. Biotechnol. 2011, 31, 99–111. [Google Scholar] [CrossRef] [PubMed]

- Tsapekos, P.; Kougias, P.G.; Angelidaki, I. Anaerobic mono- and codigestion of mechanically pretreated meadow grass for biogas production. Energy Fuels 2015, 29, 4005–4010. [Google Scholar] [CrossRef]

- Søndergaard, M.M.; Fotidis, I.A.; Kovalovszki, A.; Angelidaki, I. Anaerobic co-digestion of agricultural byproducts with manure for enhanced biogas production. Energy Fuels 2015, 29, 8088–8094. [Google Scholar] [CrossRef] [Green Version]

- Dennehy, C.; Lawlor, P.G.; Gardiner, G.E.; Jiang, Y.; Cormican, P.; McCabe, M.S.; Zhan, X. Process stability and microbial community composition in pig manure and food waste anaerobic co-digesters operated at low HRTs. Front. Environ. Sci. Eng. 2017, 11, 4. [Google Scholar] [CrossRef]

- De Baere, L.; Mattheeuws, B.; Anaerobic Digestion of the Organic Fraction of Municipal Solid Waste in Europe. Anaerobic Digestion of the Organic Fraction of Municipal Solid Waste in Europe—Status, Experience and Prospects. Available online: https://www.ows.be/wp-content/uploads/2013/02/Anaerobic-digestion-of-the-organic-fraction-of-MSW-in-Europe.pdf (accessed on 1 September 2021).

- Stucki, M.; Jungbluth, N.; Leuenberger, M. Life Cycle Assessment of Biogas Production from Different Substrates; Final Report; Federal Department of Environment, Transport, Energy and Communications, Federal Office of Energy: Bern, Switzerland, 2011. [Google Scholar]

- Sustainable Energy Authority of Ireland. Gas Yields Table; Sustainable Energy Authority of Ireland: Dublin, Ireland, 2002. [Google Scholar]

- Conti, C.; Guarino, M.; Bacenetti, J. Measurements techniques and models to assess odor annoyance: A review. Environ. Int. 2020, 134, 105261. [Google Scholar] [CrossRef]

- Toledo, M.; Gutiérrez, M.; Siles, J.; Martín, M. Full-scale composting of sewage sludge and market waste: Stability monitoring and odor dispersion modeling. Environ. Res. 2018, 167, 739–750. [Google Scholar] [CrossRef]

- Toledo, M.; Gutiérrez, M.; Siles, J.; Martín, M. Odor mapping of an urban waste management plant: Chemometric approach and correlation between physico-chemical, respirometric and olfactometric variables. J. Clean. Prod. 2019, 210, 1098–1108. [Google Scholar] [CrossRef]

- Kamaruddin, M.A.; Yusoff, M.S.; Aziz, H.A.; Hung, Y.-T. Sustainable treatment of landfill leachate. Appl. Water Sci. 2015, 5, 113–126. [Google Scholar] [CrossRef]

- Gao, J.; Oloibiri, V.; Chys, M.; Audenaert, W.; Decostere, B.; He, Y.; Van Langenhove, H.; Demeestere, K.; Van Hulle, S.W.H. The present status of landfill leachate treatment and its development trend from a technological point of view. Rev. Environ. Sci. Biotechnol. 2015, 14, 93–122. [Google Scholar] [CrossRef]

- Yuan, M.; Chen, Y.; Tsai, J.; Chang, C. Ammonia removal from ammonia-rich wastewater. Process. Saf. Environ. Prot. 2016, 102, 777–785. [Google Scholar] [CrossRef]

- Wang, D.; Liu, D.; Tao, L.; Li, Z. The impact on the effects of leachate concentrates recirculation for different fill age waste. J. Mater. Cycles Waste Manag. 2016, 19, 1211–1219. [Google Scholar] [CrossRef]

- Hashisho, J.; El-Fadel, M. Membrane bioreactor technology for leachate treatment at solid waste landfills. Rev. Environ. Sci. Bio/Technol. 2016, 15, 441–463. [Google Scholar] [CrossRef]

- Wiśniewska, M.; Szyłak-Szydłowski, M. The Air and Sewage Pollutants from Biological Waste Treatment. Processes 2021, 9, 250. [Google Scholar] [CrossRef]

- Stretton-Maycock, D.; Merrington, G. The Use and Application to Land of MBT Compost-Like Output—Review of Current European Practice in Relation to Environmental Protection; Environment Agency: Bristol, UK, 2009. [Google Scholar]

- Jamal, M.; Szefler, A.; Kelly, C.; Bond, N. Commercial and Household Food Waste Separation Behaviour and the Role of Local Authority: A Case Study. Int. J. Recycl. Org. Waste Agric. 2019, 8, 281–290. [Google Scholar] [CrossRef] [Green Version]

| Chemical Compound | Average Ambient Air Concentration (μg/m3) |

|---|---|

| Acetone | 0.5–125 |

| Acrolein | 15 |

| Carbon disulphide | 10–1500 |

| Hydrogen sulphide | 0–15 |

| Isophorone | no data |

| Styrene | 1.0–20 |

| Tetrachloroethylene | 1–5 |

| Toluene | 5–150 |

| Location/Odour Source | Fermentation Preparation | Digestate Dewatering | ||||||

|---|---|---|---|---|---|---|---|---|

| cod (ou/m3) | CVOC (ppm) | CH2S (ppm) | CDMS (ppm) | cod (ou/m3) | CVOC (ppm) | CH2S (ppm) | CDMS (ppm) | |

| Jarocin | 16 ÷ 78 | 0.20 ÷ 0.53 | 0.279 | 0.360 | 142 ÷ 448 | 0.82 ÷ 1.30 | 0.406 | 1.317 |

| Tychy | 4 ÷ 22 | 1.37 ÷ 1.94 | 0.860 | <0.001 | 31 ÷ 42 | 1.20 ÷ 1.83 | 0.114 | <0.001 |

| Promnik | 5 ÷ 11 | 1.06 ÷ 5.71 | 0.007 | 0.624 | 8 ÷ 42 | 2.65 ÷ 6.41 | 0.267 | 0.997 |

| Stalowa Wola | 16 ÷ 31 | 2.35 ÷ 2.38 | <0.001 | 0.009 | 16 ÷ 31 | 0.20 ÷ 2.13 | <0.001 | 0.022 |

| Wólka Rokicka | 22 ÷ 42 | 1.30 ÷ 1.40 | <0.001 | 0.026 | - | - | - | - |

| Biała Podlaska | 4 ÷ 5 | 0.50 ÷ 0.63 | <0.001 | 0.002 | - | - | - | - |

| Waste Storage | Emission from the Hall of Waste Storage | Digestate Dewatering | Emission from the Hall of Digestate Dewatering | Oxygen Stabilisation of Digestate | ||||||

|---|---|---|---|---|---|---|---|---|---|---|

| CNH3 (ppm) | CVOC (ppm) | ENH3 (kg/h) | EVOC (kg/h) | EH2S (kg/h) | CNH3 (ppm) | CVOC (ppm) | ENH3 (kg/h) | EVOC (kg/h) | CNH3 (ppm) | CVOC (ppm) |

| 2–8 | 4.42–19.79 | 0.23–0.44 | 0.15–0.42 | 0.02–0.25 | 1–12 | 2.07–6.27 | 0.004–0.04 | 0.03–0.17 | 0–7 | 0.08–2.47 |

| No | Environmental Indicators |

|---|---|

| 1 | Land use |

| 2 | Water use |

| 3 | Pollutant generation |

| 4 | Life cycle of CO2 emission |

| 5 | Overall emissions |

| 6 | SOx emissions |

| 7 | NOx emissions |

| 8 | Particulate matters |

| 9 | Ash |

| 10 | Noise |

| 11 | Dust |

| 12 | Odour |

| 13 | Litter |

| Location | Feedstock | Annual Biogas Plant Capacity (Mg/a) | Fermentation | Digestate Stabilisation |

|---|---|---|---|---|

| Jarocin | OFMSW | 15,000 | Horizontal reactor with one paddle agitator; thermophilic, semi-dry dynamic fermentation | Digestate dewatering followed by two-step oxygen stabilisation |

| Tychy | OFMSW | 30,000 | Two separate horizontal reactors, each with four agitators; mesophilic, dry dynamic fermentation | |

| Promnik | OFMSW | 30,000 | ||

| Stalowa Wola | OFMSW | 15,000 | Horizontal reactor with four agitators; mesophilic, dry dynamic fermentation | |

| Wólka Rokicka | OFMSW | 20,000 | Seven open-feed reactors; thermophilic, dry static (garage) fermentation | One-step oxygen stabilisation |

| Biała Podlaska | BW | 20,000 | Two separate horizontal reactors, each with one paddle agitator; thermophilic, semi-dry dynamic fermentation |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wiśniewska, M.; Kulig, A.; Lelicińska-Serafin, K. Odour Nuisance at Municipal Waste Biogas Plants and the Effect of Feedstock Modification on the Circular Economy—A Review. Energies 2021, 14, 6470. https://doi.org/10.3390/en14206470

Wiśniewska M, Kulig A, Lelicińska-Serafin K. Odour Nuisance at Municipal Waste Biogas Plants and the Effect of Feedstock Modification on the Circular Economy—A Review. Energies. 2021; 14(20):6470. https://doi.org/10.3390/en14206470

Chicago/Turabian StyleWiśniewska, Marta, Andrzej Kulig, and Krystyna Lelicińska-Serafin. 2021. "Odour Nuisance at Municipal Waste Biogas Plants and the Effect of Feedstock Modification on the Circular Economy—A Review" Energies 14, no. 20: 6470. https://doi.org/10.3390/en14206470

APA StyleWiśniewska, M., Kulig, A., & Lelicińska-Serafin, K. (2021). Odour Nuisance at Municipal Waste Biogas Plants and the Effect of Feedstock Modification on the Circular Economy—A Review. Energies, 14(20), 6470. https://doi.org/10.3390/en14206470