Addressing European Ocean Energy Challenge: The DTOceanPlus Structured Innovation Tool for Concept Creation and Selection

Abstract

:1. Introduction

1.1. Background

1.1.1. Structured Innovation Best Practice

1.1.2. Ocean Energy Current Practice

1.2. Goal

- QFD defines the innovation problem, represents the voice of the customer, identifies trade-offs in the system, and makes immediate objective assessment visible and useful.

- TRIZ generates potential solutions to the contradictions to meet the user requirements.

- FMEA improves understanding of technical risk during the development process and offers risk mitigation and cost reduction opportunities.

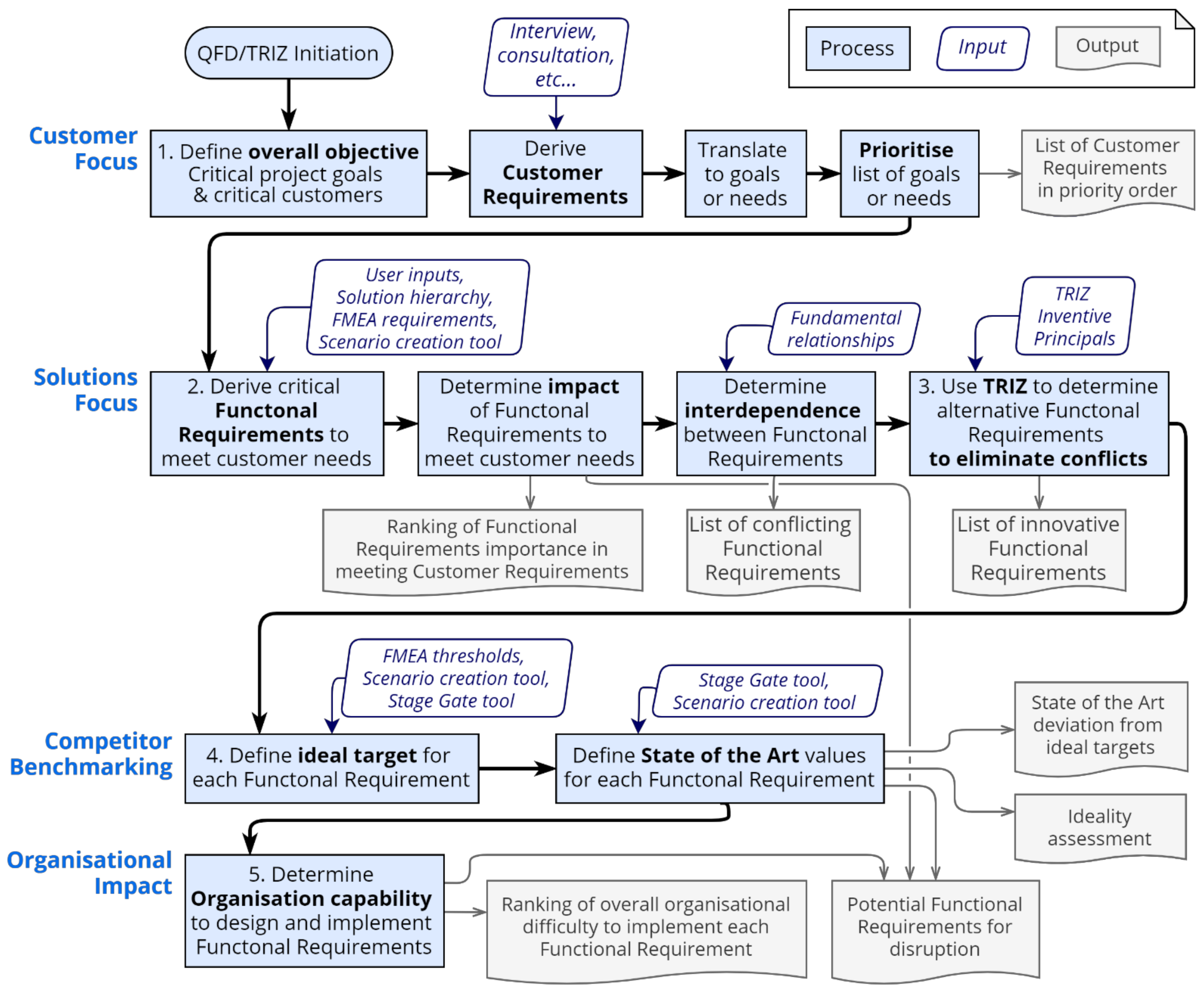

2. DTOceanPlus Structured Innovation Methodology

2.1. Main Structured Innovation Methodology (QFD/TRIZ)

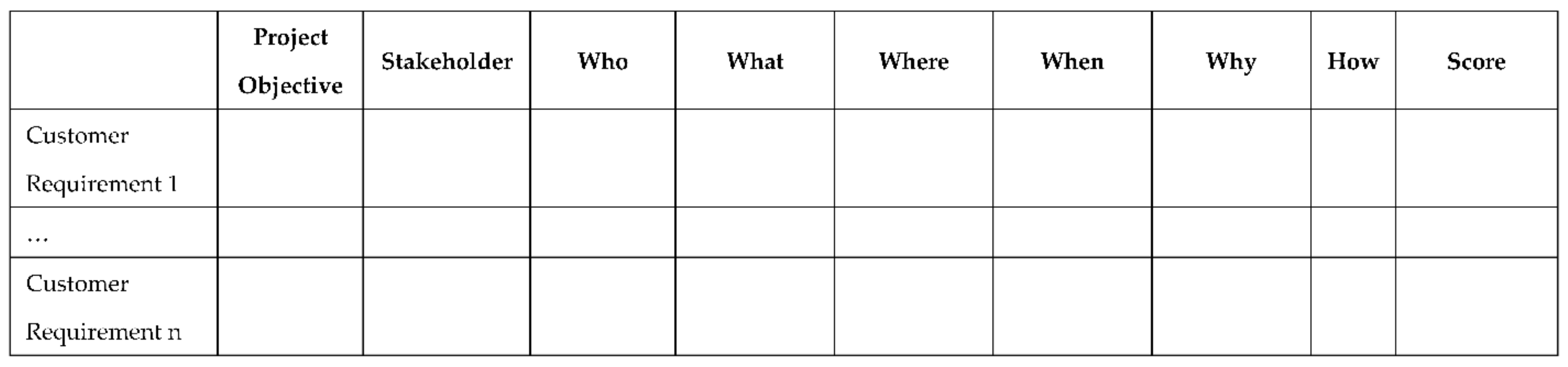

2.1.1. Definition of Overall Objective and Customer Requirements

- Why is the project or the specific features desirable?

- Who are the current or future potential users?

- What are the most important business goals and future targets?

- What are the most problematic products, processes, services, applications?

- What are the current constraints? E.g., financial, technological, operational, environmental? Are there any alternatives?

- Which markets or customers are the most critical?

- Where is the process or product currently used? (Application, sector, potential future uses).

- When and how is the product or service used?

- What are the current state-of-the-art technologies?

- “Wave energy converter with an LCOE of EUR 70/MWh”; since the scenario creation tool requires the user to define a target LCOE for their wave energy technology, which could be used for as a customer requirement in the Structured Innovation tool.

- “Safe to operate”; since the scenario creation tool uses a default breakdown for operation and maintenance costs, the user may reduce or increase these when using the tool, which would allow them to enter the Structured Innovation tool with an understanding of how important this parameter is to their overall project objectives.

- “Low environmental impact”; although this is not explored in the scenario creation tool, since the user will have generated several attractive scenarios, they could then enter the SI tool with some attractive scenarios and add in the important environmental impact consideration. This would ensure their attractive scenarios take this into account in their next stages of development in the Structured Innovation tool.

2.1.2. Definition of Functional Requirements

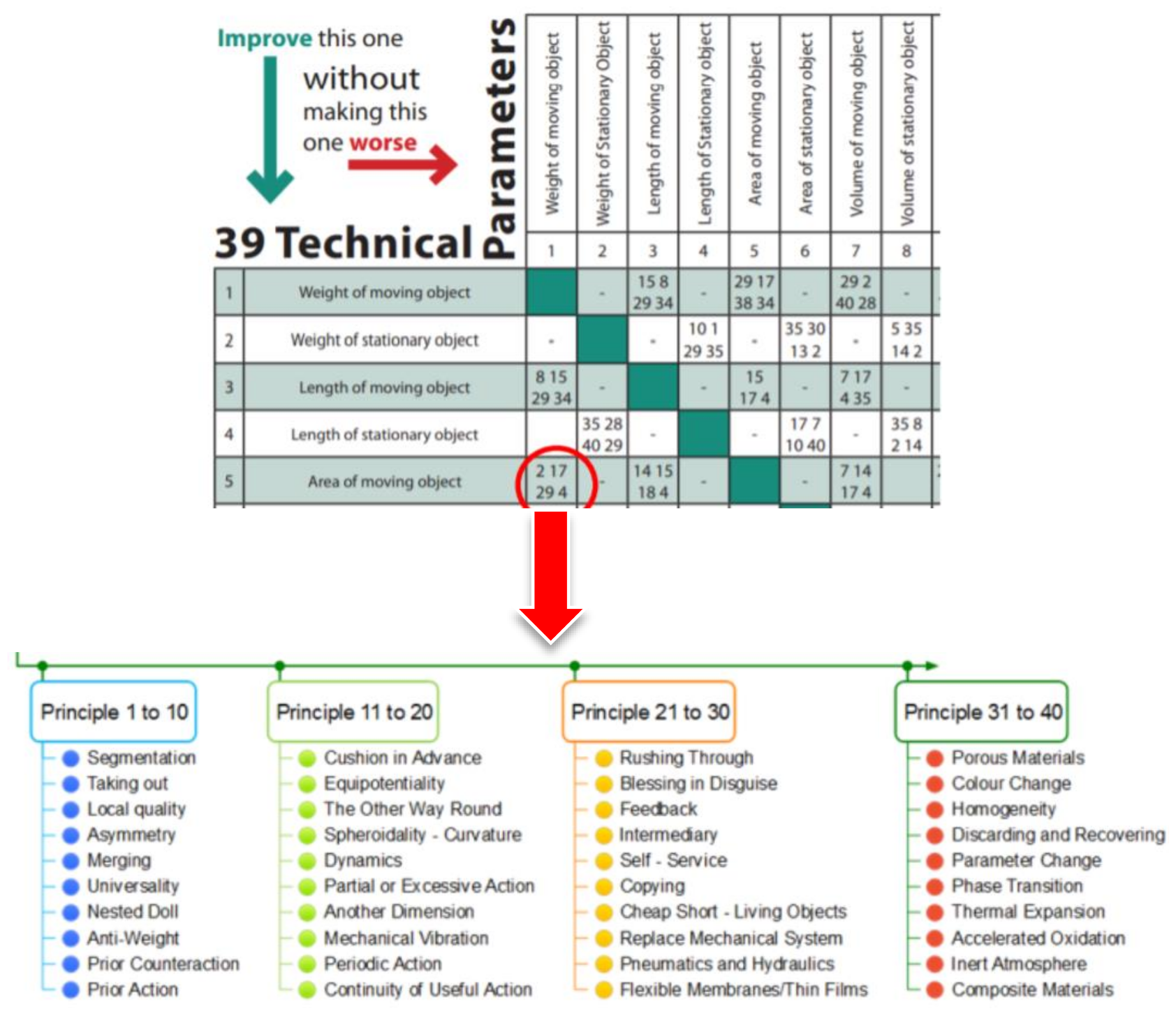

2.1.3. Solving Conflicts Using TRIZ Library

- Inventive Principle #13—The other way round suggests inverting “the action(s) used to solve the problem; make movable parts (or external environment) fixed, or fixed parts movable; or the object (or process) upside down” [32]. This principle is already implemented in most floating substructures, for example, where moorings are either in tension or not, depending on the need for stability or repairs. If the project objective is to optimise the layout of devices and power cabling architecture for a tidal array, the designers could explore ways to apply these principles for the different operation cases (e.g., buoyant nacelles, tensegrity foundations, etc.).

- Inventive Principle #1—Segmentation suggests “increasing the degree of an object’s segmentation by dividing an object into independent parts, making an object sectional, or increasing the degree of an object’s segmentation” [32,33]. The electrical architecture for tidal energy devices varies from device to device (e.g., different voltages, variable frequency output), encouraging segmentation or modular arrangement of device hubs. Applying this principle can enable modular manufacture and quick assembly and disconnection for servicing [54].

- Inventive Principle #35—Transformation of an object’s physical and chemical states entails “changing an object’s physical state to a gas, liquid, or solid; changing pressure or other physical parameters; changing the concentration or consistency; changing the degree of flexibility or changing temperature” [32,33]. For example, this principle has been investigated in the design of deformable blades, which are being investigated for tidal turbines to improve reliability [55].

- Inventive Principle #6 Multifunctionality or universality: For instance, when designing the physical structure of a wave energy device, one of the most important factors of the design is to maximise energy capture by considering interfaces that are intended to be joined (e.g., grouting a drilled anchor) and interfaces of those intended to be joined and unjointed as required (e.g., replacing components in maintenance). This principle suggests making parts of the design perform multiple functions or eliminating the need for other parts [56].

- Inventive Principle #35 Parameter change: refers to the ability to change physical state, concentration or density, flexibility, temperature, volume, or pressure. For instance, design devices adaptable to various sea states (e.g., ability for turret moorings to adapt and adjust to different directions and alter natural frequency by changing wetted surfaces).

2.1.4. Competitor Benchmarking and Ideality Assessment

- Defining Ideal Targets and the State-of-the-Art

- Assessing Ideality

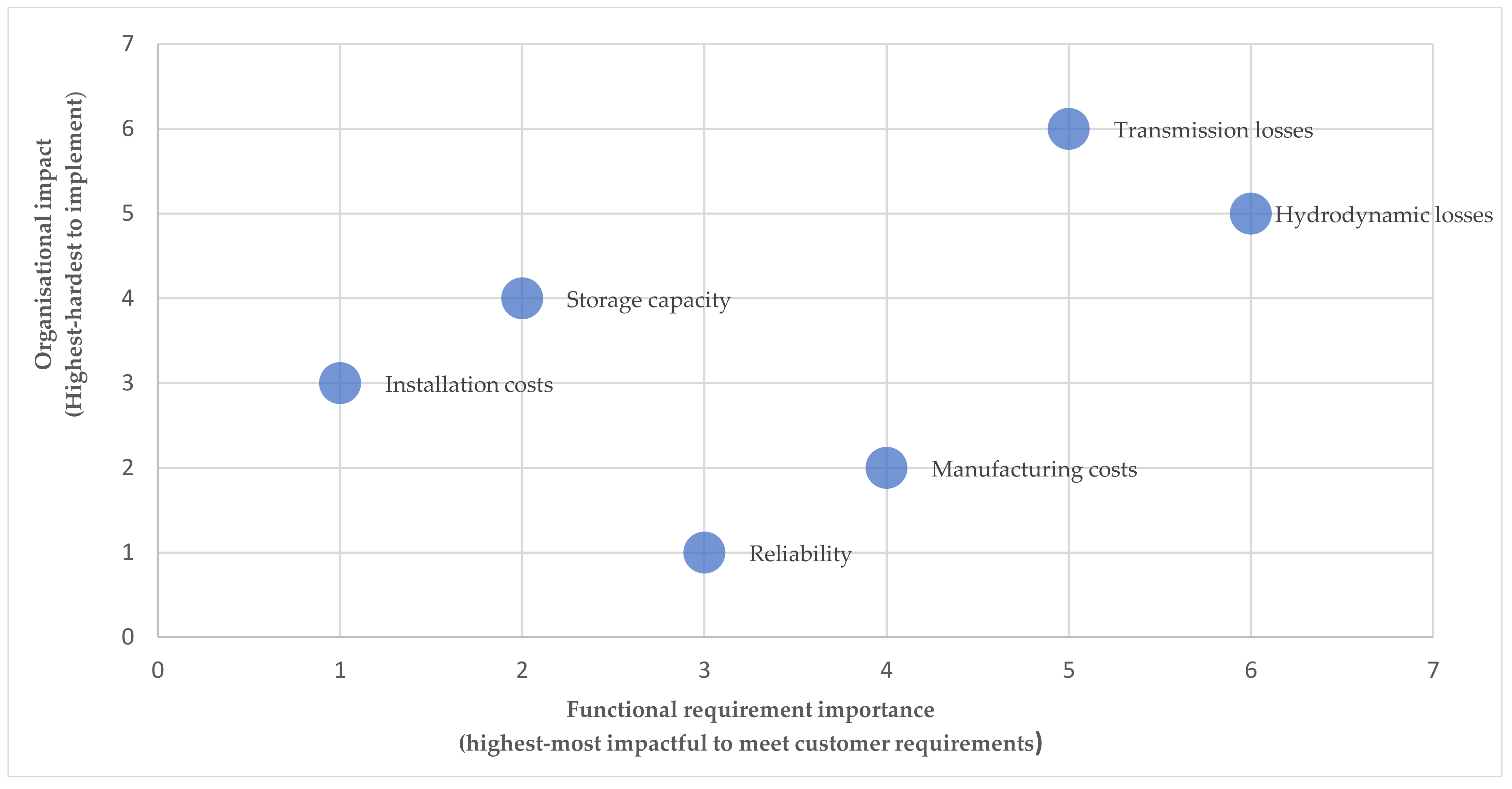

2.1.5. Organisational Impact Assessment

2.1.6. Proposed Critical Functional Requirements for Further Assessment

- Customer requirements (and importance) to define the innovation design space.

- Functional requirements, with measurable target values, to meet or exceed the customer requirements.

- Interactions between functional requirements.

- The organisational effort to engineer and deliver such requirements at or beyond the target set.

- Benchmarking of competing state-of-the-art designs (leading-edge technology or design data, including the newest ideas or concepts across the sector) to understand the extent to which each of the proposed functional requirement targets has been met elsewhere.

- The importance of the customer requirements.

- The functional requirements that would be most likely to disrupt the market.

- The organisational effort to engineer and deliver these requirements (i.e., to secure the skills, resources, supply, finance, etc., required to deliver).

- Repeat the TRIZ process to consider and compare two or more potential innovative approaches to meeting the defined requirements.

- Assess the technical risks associated with the selected functional requirements using FMEA.

- Use the Design and Assessment tools of the DTOceanPlus suite to develop detailed designs for the concepts created in this Structured Innovation tool and then assess their potential deployment to specific sites.

2.2. Additional Methodological Modules and Interactions

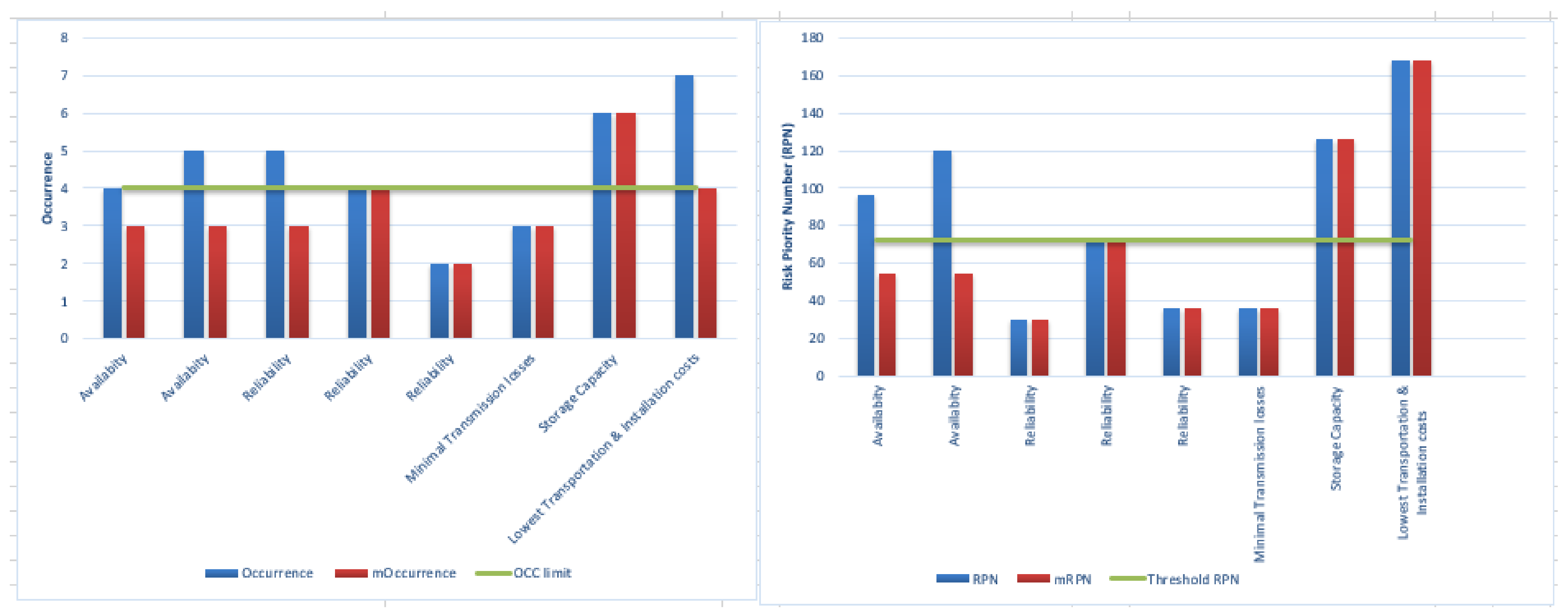

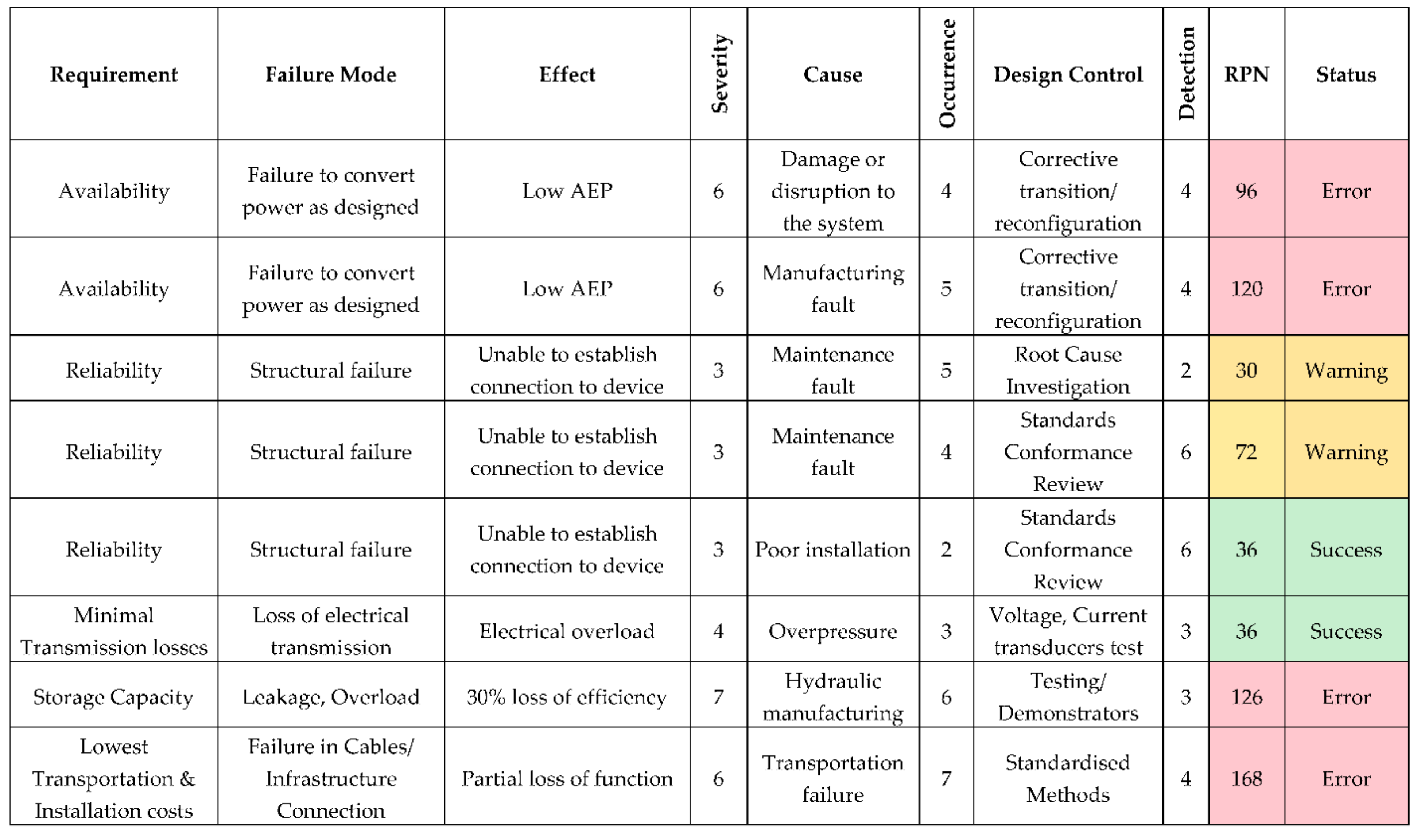

2.2.1. Risk Mitigation Using FMEA

2.2.2. Solution Hierarchy

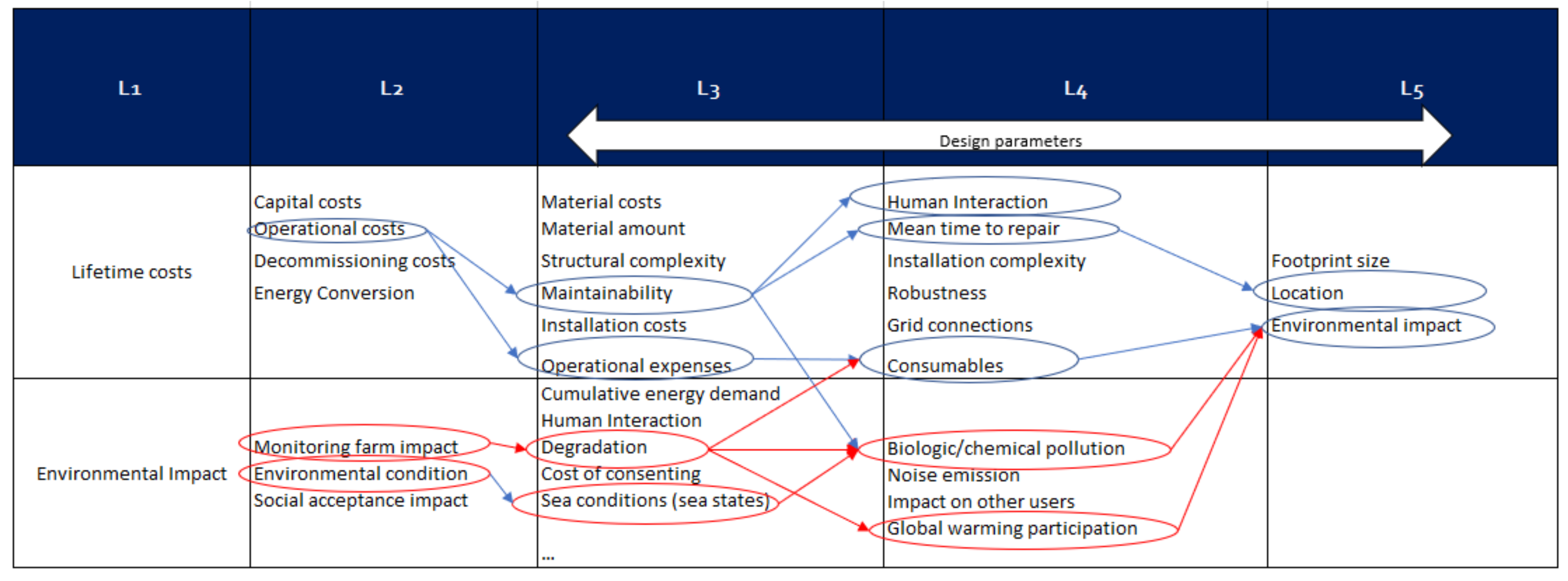

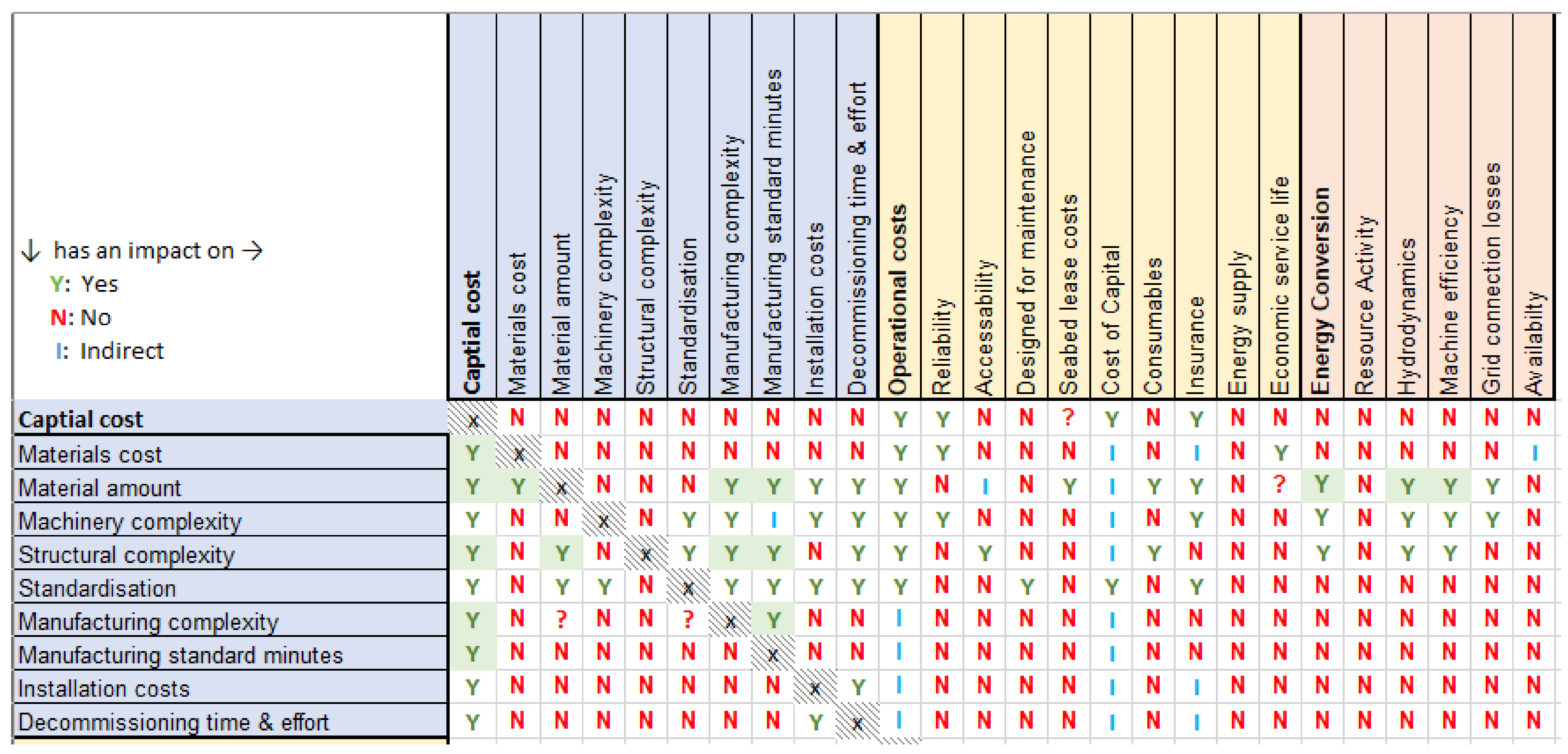

2.2.3. Fundamental Relationships

3. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Ocean Energy Europe. 2030 Ocean Energy Vision—Industry Analysis of Future Deployments, Costs and Supply Chains. 2020. Available online: https://www.oceanenergy-europe.eu/wp-content/uploads/2020/10/OEE_2030_Ocean_Energy_Vision.pdf (accessed on 7 April 2021).

- EMODnet. European Marine Observation and Data Network, European Commission. Available online: https://www.emodnet-humanactivities.eu/view-data.php (accessed on 31 August 2021).

- Corsatea, T.; Magagna, D. Overview of European Innovation Activities in Marine Energy Technology; Publications Office of the European Union: Luxembourg, 2014. [Google Scholar]

- Tunga, I.; Yates, M.; Vyas, A.; Briggs, S.; Eraut, N.; Ruiz-Minguela, P.; Salcedo, F.; Noble, R.; Hodges, J.; Marques, M.; et al. Developing Ocean Energy Standards for Business Management Models in Ocean Energy; DTOceanPlus: Bilbao, Spain, 2021. [Google Scholar]

- CorPower Ocean. Clean Energy from Our Oceans, CorPower Ocean. Available online: https://www.corpowerocean.com/about-us/ (accessed on 4 September 2021).

- Bombora. Learn More about Bombora, Bombora Wave. Available online: https://bomborawave.com/about-us/ (accessed on 4 September 2021).

- Wave Energy Scotland. Wave Energy Scotland-Driving the Development of Wave Energy Technology in Scotland. Available online: https://www.waveenergyscotland.co.uk/ (accessed on 4 September 2021).

- Orbital Marine Power. Turning the Tide on Climate Change, Orbital Marine Power. Available online: https://orbitalmarine.com/ (accessed on 4 September 2021).

- Nova Innovation. Tidal Energy—Transforming the Power of Our Seas into Clean, Predictable Energy, Nova Innovation. Available online: https://www.novainnovation.com/ (accessed on 4 September 2021).

- ITEG. Integrating Tidal Energy into the European Grid, Interreg North-West Europe. Available online: https://www.nweurope.eu/projects/project-search/iteg-integrating-tidal-energy-into-the-european-grid/ (accessed on 4 September 2021).

- EnFAIT. Enabling Future Arrays in Tidal. Available online: https://www.enfait.eu/partners/ (accessed on 4 September 2021).

- Junginger, M.; Louwen, A. Technological Learning in the Transition to a Low Carbon Energy System, Conceptual Issues, Empirical Findings, and Use in Energy Modelling; Elsevier: Amsterdam, The Netherlands, 2020. [Google Scholar]

- Noble, R.; Kerr, P.; Talukdar, S.; Cantarero, V.M.; Jeffrey, H.; Ruiz-Minguela, P.; Grispiani, L.; Tunga, I.; Hodges, J.; Henderson, J.; et al. Feasibility and Cost-Benefit Analysis- Deliverable D8.3; DTOceanPlus: Bilbao, Spain, 2021. [Google Scholar]

- Kerr, P.; Noble, D.; Hodges, J.; Jeffrey, H. Implementing Radical Innovation in Renewable Energy Experience Curves. Energies 2021, 14, 2364. [Google Scholar] [CrossRef]

- Chesbrough, H.W. Open Innovation: The New Imperative for Creating and Profiting from Technology; Harvard Business School Press: Boston, MA, USA, 2003. [Google Scholar]

- Tunga, I.; Bradley, S.; Eraut, N.; Bowick, L.; Noble, D.; Henderson, J. Technical Requirement for the Implementation of Structured Innovation in Ocean Energy Systems; DTOceanPlus: Bilbao, Spain, 2019. [Google Scholar]

- Tritle, G.; Scriven, E.; Fusfeld, A. Resolving uncertainty in R&D portfolios. Res. Technol. Manag. 2000, 43, 47–50. [Google Scholar]

- Rahnejat, H.; Zairi, M. The “QFD/FMEA interface”. Eur. J. Innov. Manag. 1998, 1, 18. [Google Scholar]

- Bergeon, S. Strategic CDI and Parent Process with Quick QFD. In Proceedings of the SSO (Strategic Standards Office), QFD/MRO (Market Research Office) Conference, Dearborn, MI, USA, 11 March 1996. [Google Scholar]

- Sullivan, L.P. "Quality Function Deployment," Quality Progress; American Society for Quality Control: Milwaukee, WI, USA, 1986; Volume 19, pp. 39–50. [Google Scholar]

- Mazur, G. Lifestyle QFD: Incorporating Emotional Appeal in Product Development. In Proceedings of the 17th Symposium on Quality Function Deployment, Portland, OR, USA, 17 September 2005. [Google Scholar]

- Hsu-Shih, S.; Chen, S.H. A conceptual design of a mobile healthcare device- an application of three-stage QFD with ANP and TRIZ. Int. J. Oper. Res. 2013, 10, 80–91. [Google Scholar]

- Osbon, A.F. How to "Think Up"; McGraw-Hill Company Inc.: New York, NY, USA; London, UK, 1942. [Google Scholar]

- Wikipedia, the Free Encyclopedia. Systematic Inventive Thinking. Available online: https://en.wikipedia.org/wiki/Systematic_inventive_thinking (accessed on 27 October 2020).

- Mumford, M.D. Where have we been, where are we going? Taking stock in creativity research. Creat. Res. J. 2003, 15, 107–120. [Google Scholar]

- Runco, M.A. Creativity. Annu. Rev. Psychol. 2004, 55, 657–687. [Google Scholar] [CrossRef] [PubMed]

- Kaufman, J.C.; Sternberg, R.J. The Cambridge Handbook of Creativity Second Edition; Cambridge University Press: Cambridge, UK, 2019. [Google Scholar]

- Sternberg, R.J. Handbook of Creativity; Cambridge University Press: Cambridge, UK, 1999. [Google Scholar]

- Runco, M. Creativity—Theories and Themes: Research, Development and Practice, 2nd ed.; Elsevier Academic Press: Cambridge, MA, USA, 2014. [Google Scholar]

- Tunga, I. Developing Market Strategies for the Next Generation of Offshore Wind Farms. Ph.D. Thesis, University of Edinburgh, Edinburgh, UK, 2019. [Google Scholar]

- Deliverable 3.1: State-of-the-Art Assessment and Specification of Data requizrements for Electrical System Architectures. Available online: https://www.dtoceanplus.eu/content/download/2522/file/DTO_WP3_ECD_D3.1v2.0.pdf (accessed on 11 August 2021).

- Gadd, K. TRIZ for Engineers: Enabling Inventive Problem Solving: Enabling Inventive Problem Solving; John Wiley & Sons, Ltd: Chichester, UK, 2011. [Google Scholar]

- Haines-Gadd, L. TRIZ for Dummies Chee; John Wiley &Sons, Ltd: Chichester, UK, 2016. [Google Scholar]

- Bloggs, K. The Selection and Application of Design Methodologies for the Design of Bone Tissue Scaffolds. Ph.D. Thesis, Cranfield University, Cranfield, UK, 2013. [Google Scholar]

- Kiran, D. Quality Function Deployment. In Multi Criteria Decision Analysis for Supporting the Selection of Engineering Materials in Product Design, 2nd ed.; Butterworth Heinemann: Oxford, UK, 2016. [Google Scholar]

- ODI. Management Techniques: Structured Innovation. 2009. Available online: https://www.odi.org/publications/5220-management-techniques-structured-innovation (accessed on 1 August 2019).

- Kiran, D.R. Chapter 30: Quality Function Deployment. In Total Quality Management: Key Concepts and Case Studies; Butterworth Heinemann: Oxford, UK, 2017; pp. 425–437. [Google Scholar]

- Weber, J.; Laird, D. Structured Innovation of High-Performance Wave Energy Converter Technology. In Proceedings of the 2015 European Wave and Tidal Energy Conference, Nantes, France, 6 September 2015. [Google Scholar]

- Weber, J.; Roberts, J. Structured Innovation. Available online: https://www.energy.gov/sites/prod/files/2017/07/f35/Structured-innovation-web.pdf (accessed on 11 August 2021).

- Fitzgerald, J.; Bolund, B. Technology Readiness for Wave Energy Projects: ESB and Vattenfall classification system. In ICOE; Ocean Energy Systems: Dublin, Ireland, 2012. [Google Scholar]

- Wave Energy Scotland. Project SEAWEED, WES. Available online: http://www.waveenergyscotland.co.uk/strategic-activity/strategic-activity-2/structured-innovation/project-seaweed-1/ (accessed on 21 May 2021).

- OREC. TiPTORS Design for Reliability Methodology: Phase 1 Summary Report; Offshore Renewable Energy Catapult: Glasgow, UK, 2015. [Google Scholar]

- ETI. Tidal Energy: Insights into Tidal Stream Energy; The Energy Technologies Institute: Loughborough, UK, 2015. [Google Scholar]

- ETI. An ETI Perspective: The Role of Tidal Energy in a Future UK Low Carbon Energy System; The Energy Technologies Institute: Loughborough, UK, 2017. [Google Scholar]

- DTOceanPlus. Providing Advanced Design Tools for Ocean Energy Systems Innovation, Development and Deployment, France Energies Marine. 2021. Available online: https://www.dtoceanplus.eu (accessed on 14 September 2021).

- Tunga, I.; Abrahams, M.; Khan, H.; Tatlock, B. D3.2—Structured Innovation Design Tool—Alpha Version; DTOceanPlus: Basque, Spain, 2020. [Google Scholar]

- DTOceanPlus Consortium. DTOceanPlus-GitLab. 31 August 2021. Available online: https://gitlab.com/dtoceanplus (accessed on 1 September 2021).

- DTOceanPlus. Overall DTOceanPlus Documentation; Tecnalia: Bilbao, Spain, 2021. [Google Scholar]

- Noble, D.; Nambiar, A.; Bloise-Thomaz, T.; Jeffrey, H.; Nava, V.; Fay, F.-X.; Ruiz-Minguela, P.; Touzon, I.; Mendia, J.L.; Tunga, I.; et al. Deliverable 2.2. Functional Requirements and Metrics of 2nd Generation Design Tools; DTOceanPlus: Bilbao, Spain, 2018. [Google Scholar]

- Roberts, O.; Henderson, J.; Garcia-Teruel, A.; Noble, D.; Jeffrey, H. Bringing structure to the wave energy innovation process with the development of a techno-economic tool. 2021, in press. [Google Scholar]

- BEIS. Electricity Generation Costs 2020; Department for Business, Energy & Industrial Strategy: London, UK, 2020. [Google Scholar]

- QFD Institute. The Official Source for QFD, Quality Function Deployment, QFDI. 2020. Available online: http://www.qfdi.org/ (accessed on 13 December 2020).

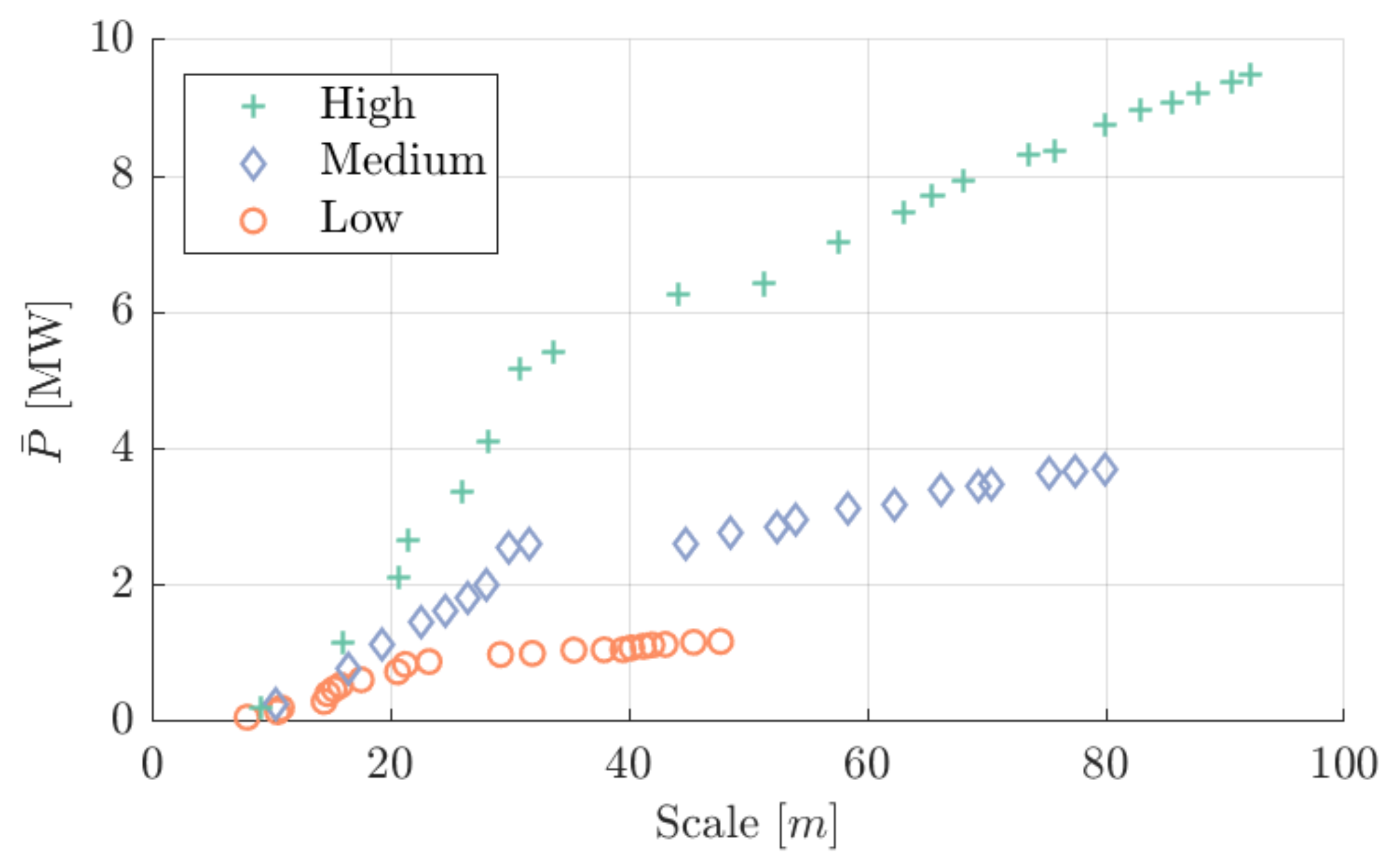

- Garcia-Teruel, A.; Roberts, O.; Noble, D.R.; Henderson, J.; Jeffrey, H. Design limits for wave energy converters based on the relationship on power and volume obtained through multi-objective optimisation. 2021, in press. [Google Scholar]

- OREC. Marine Energy Electrical Architecture; Offshore Renewables Energy Catapult: Glasgow, UK, 2015. [Google Scholar]

- The University of Edinburgh. Bio-Inspired Morphing Blades for Wind and Tidal Turbines, School of Engineering. 2021. Available online: https://www.eng.ed.ac.uk/studying/postgraduate/research/phd/bio-inspired-morphing-blades-wind-and-tidal-turbines (accessed on 11 August 2021).

- SANDIA. Systems Engineering Applied to the Development of a Wave Energy Farm; Sandia National Laboratories: Livermore, CA, USA, 2017. [Google Scholar]

- Hill, C.; Neary, V.S.; Gunawan, B.; Guala, M.; Sotiropoulos, F. "U.S. Department of Energy Reference Model Program RM1: Experimental Results," Wind and Water Power Technologies Program; Office of Energy Efficiency and Renewable Energy, US Department of Energy: Washington, DC, USA, 2014.

- Arabian-Hoseynabadi, H.; Oraee, H.; Tavner, P. Failure Modes and Effect Analysis (FMEA) for Wind Turbines. Int. J. Electr. Power Energy Syst. 2010, 32, 817–824. [Google Scholar] [CrossRef] [Green Version]

- Garcia-Teruel, A.; DuPont, B.; Forehand, D. Hull geometry optimisation of wave energy converters: On the choice of the objective functions and the optimisation formulation. Appl. Energy 2021, 298, 117153. [Google Scholar] [CrossRef]

- Garcia-Teruel, A. Geometry Optimisation of Wave Energy Converters; The University of Edinburgh: Edinburgh, UK, 2019. [Google Scholar]

| Objective | Customer Requirements | Importance (10—Most, 1—Least) |

|---|---|---|

| Optimal layout of devices and power cabling architecture for a tidal array | Annual Energy Production | 10 |

| Capital Costs | 9 | |

| The flexibility of energy supply | 8 | |

| Availability | 7 |

| Objective | Customer Requirements | Importance (10—Most, 1—Least) |

|---|---|---|

| Produces electrical energy from the energy in ocean waves by exploiting wave energy to result in an attractive and achievable business case Maximise power capture and minimise cost in reasonable potential sites | Lowest lifetime cost | 10 |

| Low risk of investment | 9 | |

| Safe to operate | 8 |

| Functional Requirements | Hydrodynamic Losses | Transmission Losses | Storage Capacity | Manufacturing Costs | Installation Costs | Reliability | QA Check Ranking (Total) | |

|---|---|---|---|---|---|---|---|---|

| Customer Requirements | ||||||||

| Annual energy production | High | High | Low | None | None | Low | 2nd (20) | |

| Capital costs | High | Medium | Low | High | High | None | 1st (32) | |

| Flexibility of energy supply | None | Low | High | Medium | None | Medium | 3rd (18) | |

| Availability | None | None | Low | Low | None | High | 4th (11) | |

| Functional requirement importance to meet customer requirements (Highest—most impactful solution) | 1st (6) | 2nd (5) | 5th (2) | 3rd (4) | 7th (1) | 4th (3) | ||

| Functional Requirements | CAPEX | Resource Level | Scale | Efficiency | QA Check Ranking (Total) | |

|---|---|---|---|---|---|---|

| Customer Requirements | ||||||

| Direction of improvement | Lower | Higher | Lower | Higher | ||

| Lowest lifetime cost | High | Medium | High | High | 1st (31) | |

| Minimal commercial risks | High | Medium | Medium | High | 2nd (26) | |

| Safe to operate | High | Medium | Low | Medium | 3rd (18) | |

| Functional requirement importance tomeet customer requirements(Highest—most impactful solution) | 1st (4) | 4th (1) | 3rd (2) | 2nd (3) | ||

| Functional Requirements | Hydrodynamic Losses | Transmission Losses | Storage Capacity | Manufacturing Costs | Installation Costs | Reliability | |

|---|---|---|---|---|---|---|---|

| Functional Requirements | |||||||

| Hydrodynamic losses | +Low | None | −Low | −Medium | +High | ||

| Transmission losses | +Low | None | +Low | +Low | +Medium | ||

| Storage capacity | None | None | +High | +Low | +High | ||

| Manufacturing costs | −Low | +Low | +High | +High | None | ||

| Installation costs | −Medium | +Low | +Low | +High | None | ||

| Reliability | +High | +Medium | +High | None | None | ||

| Functional Requirements | CAPEX | Resource Level | Scale | Efficiency | Sum of Conflicts | Worst Conflict | |

|---|---|---|---|---|---|---|---|

| Functional Requirements | |||||||

| CAPEX | +Medium | −High | −Medium | −13 | 2nd | ||

| Resource level | +Medium | −High | +Medium | −9 | 3rd | ||

| Scale | −High | −High | −Low | −19 | 1st | ||

| Efficiency | −Medium | +Medium | −Low | −5 | 4th | ||

| Functional Requirements | TRIZ Contradiction Parameter | TRIZ Inventive Principles Suggested | |

|---|---|---|---|

| Function to Improve | Reliability | 27—Reliability | 13—The other way round 35—Physical or chemical properties 1—Segmentation |

| Undesired result (conflicting function) | Manufacturing costs | 36—Complexity of device |

| Functional Requirements | TRIZ Contradiction Parameter | TRIZ Inventive Principles Suggested | |

|---|---|---|---|

| Function to Improve | Capital cost to power ratio | 21—Power | 35—Parameter change 6—Multifunctionality 38—Accelerate oxidation |

| Undesired result (conflicting function) | Scale | 7—Volume of moving object |

| Functional Requirements | Hydrodynamic Losses | Transmission Losses | Storage Capacity | Manufacturing Costs | Installation Costs | Reliability |

|---|---|---|---|---|---|---|

| Direction of Improvement | Down | Down | Up | Down | Down | Up |

| Target (ideal) values | 5 | 2 | 1 | 500,000 | 670,000 | 20 |

| Target units | % | % | MWh | M EUR | M EUR | years |

| SoTA Examples | ||||||

| RM1 (pure star configuration) | 10 | 8.7 | 0 | 500,000 | 1,000,000 | 18.0 |

| RM1 (DTOv2—star-radial) | 10 | 8.0 | 0 | 462,000 | 924,000 | 14.0 |

| RM1 (Compact config + storage) | 12 | 4.0 | 0.5 | 848,000 | 924,000 | 14.0 |

| Functional Requirements | Hydrodynamic Losses | Transmission Losses | Storage Capacity | Manufacturing Costs | Installation Costs | Reliability | |

|---|---|---|---|---|---|---|---|

| SoTA Examples | |||||||

| RM1 (pure star configuration) | −100% | −74% | −100% | 0% | −49% | −10% | |

| RM1 (DTOv2 star-radial) | −100% | −60% | −100% | 8% | −38% | −30% | |

| RM1 (Compact config + storage) | −140% | 20% | −50% | −70% | −38% | −30% | |

| Functional Requirements | Hydrodynamic Losses | Transmission Losses | Storage Capacity | Manufacturing Costs | Installation Costs | Reliability | |

|---|---|---|---|---|---|---|---|

| State-of-the-Art | |||||||

| Engineering difficulty to meet target | 5 | 5 | 3 | 1 | 2 | 1 | |

| Difficulty to deliver (make, obtain/procure) | 2 | 5 | 4 | 3 | 4 | 2 | |

| Overall organisational impact ranking (high= hardest to implement) | 5 | 6 | 4 | 2 | 3 | 1 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tunga, I.; Garcia-Teruel, A.; Noble, D.R.; Henderson, J. Addressing European Ocean Energy Challenge: The DTOceanPlus Structured Innovation Tool for Concept Creation and Selection. Energies 2021, 14, 5988. https://doi.org/10.3390/en14185988

Tunga I, Garcia-Teruel A, Noble DR, Henderson J. Addressing European Ocean Energy Challenge: The DTOceanPlus Structured Innovation Tool for Concept Creation and Selection. Energies. 2021; 14(18):5988. https://doi.org/10.3390/en14185988

Chicago/Turabian StyleTunga, Inès, Anna Garcia-Teruel, Donald R. Noble, and Jillian Henderson. 2021. "Addressing European Ocean Energy Challenge: The DTOceanPlus Structured Innovation Tool for Concept Creation and Selection" Energies 14, no. 18: 5988. https://doi.org/10.3390/en14185988

APA StyleTunga, I., Garcia-Teruel, A., Noble, D. R., & Henderson, J. (2021). Addressing European Ocean Energy Challenge: The DTOceanPlus Structured Innovation Tool for Concept Creation and Selection. Energies, 14(18), 5988. https://doi.org/10.3390/en14185988