Data-Driven Prognostics of the SOFC System Based on Dynamic Neural Network Models

Abstract

1. Introduction

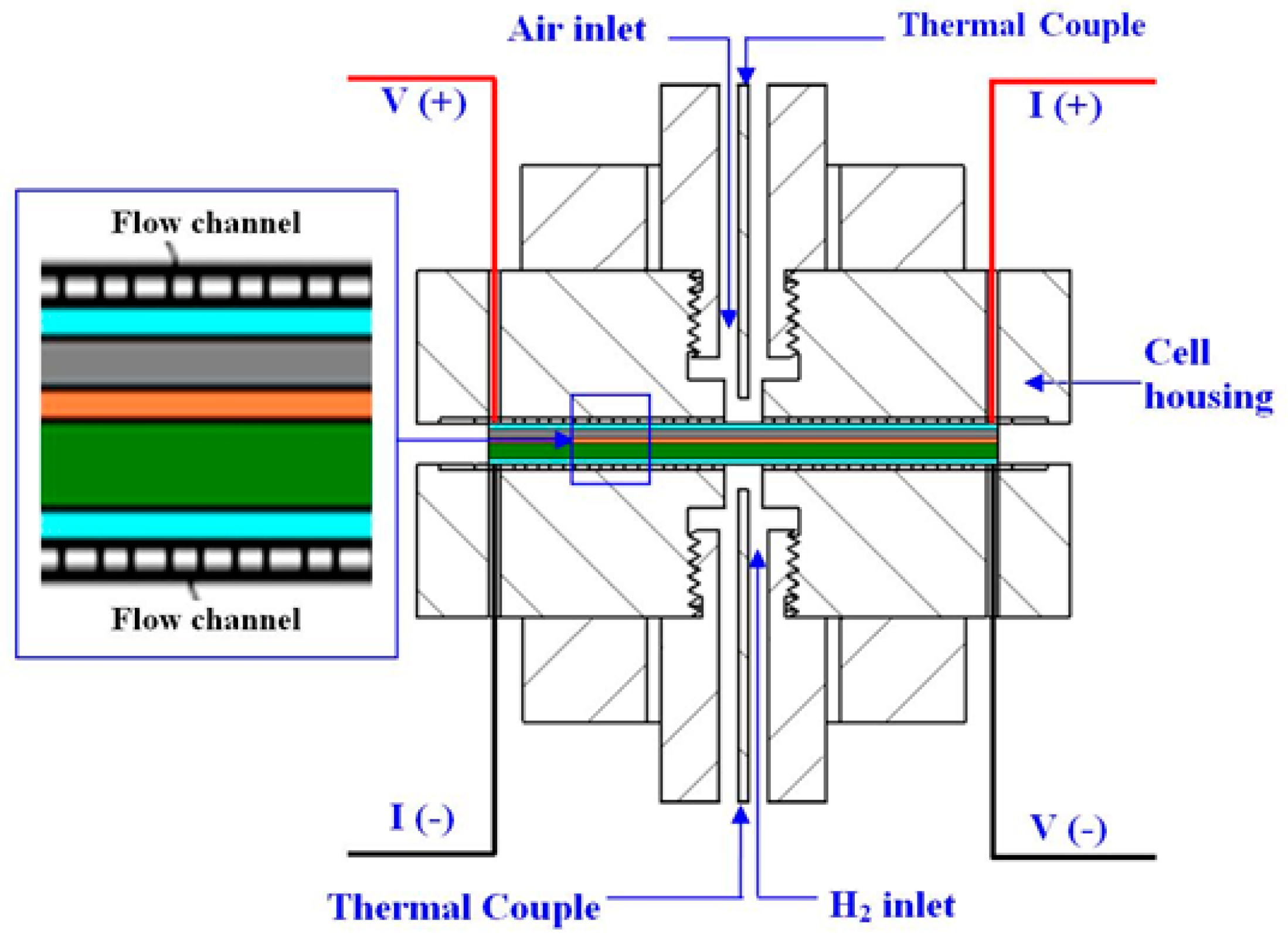

2. Experiment Setting and Data Implementation

3. Considered Theory

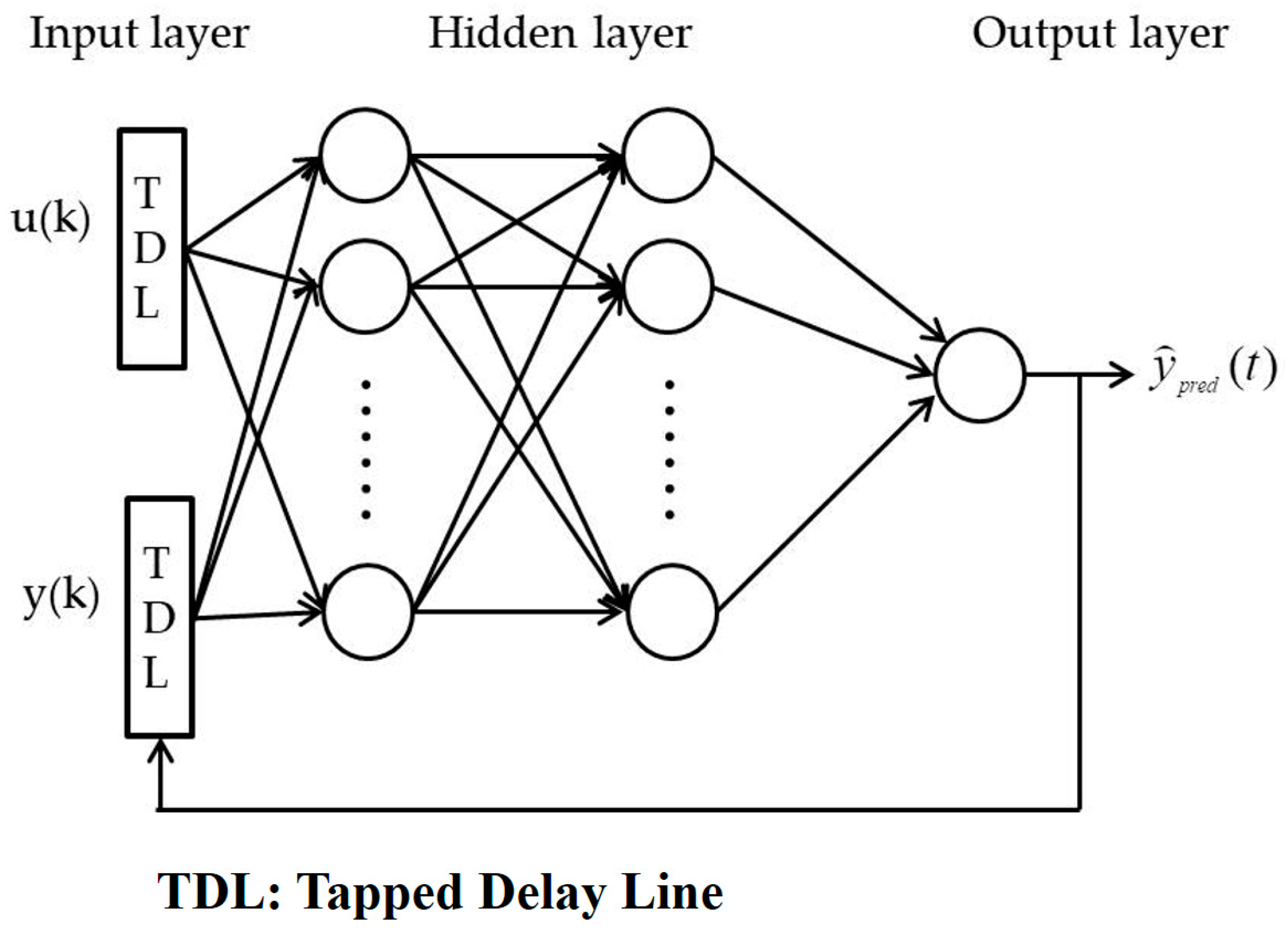

3.1. Model Development

- (1)

- The B polynomial is related to the control signal.

- (2)

- The A polynomial is related to the output of the measurement.

- (3)

- The is related to the simulated outputs from the past u(k), associated with the C polynomial.

- (4)

- The predicted errors are associated with the D polynomial.

3.2. Learning with Backpropagation (BP) Method

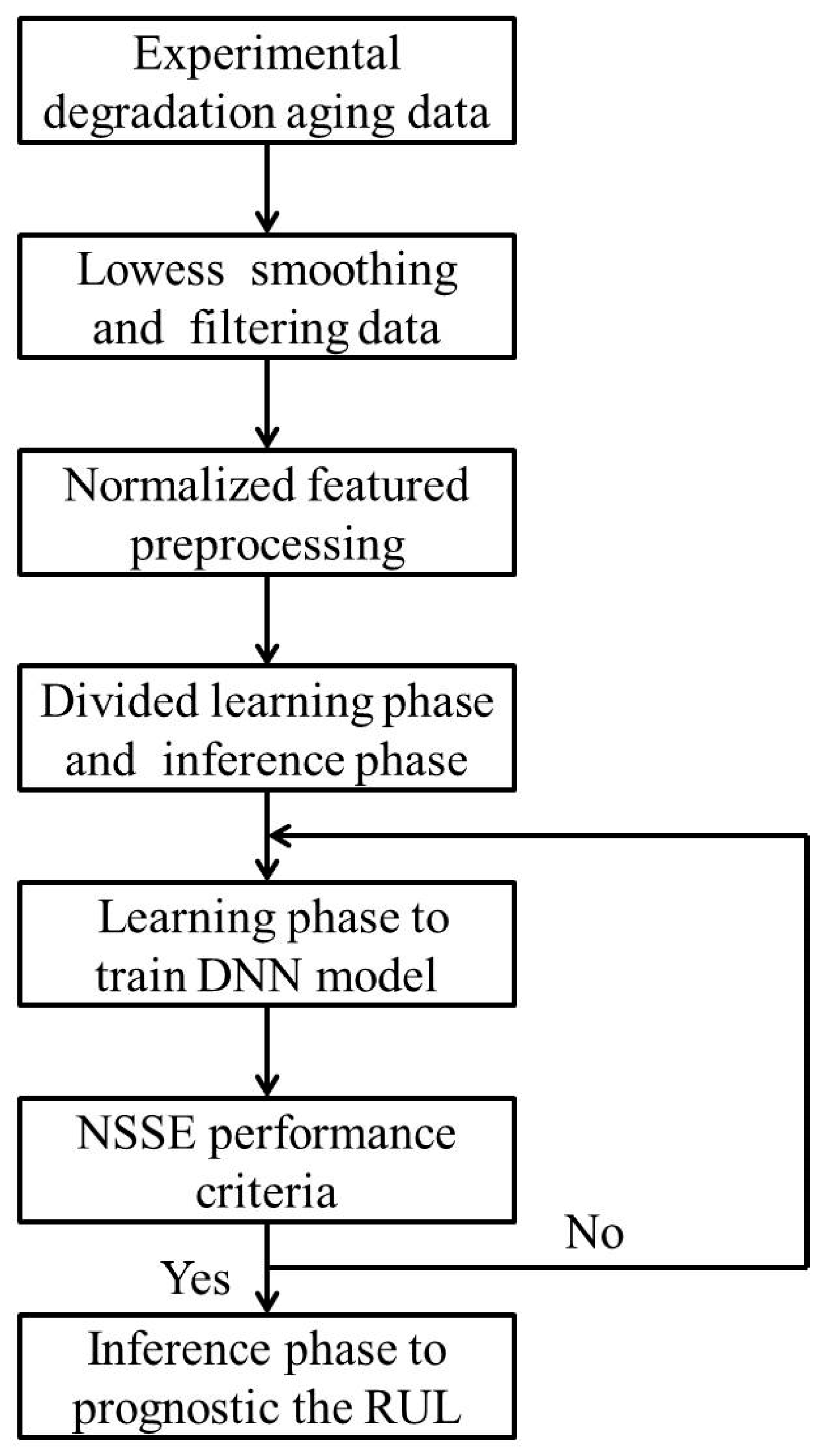

4. Prognostic Framework Based on DNN Methods

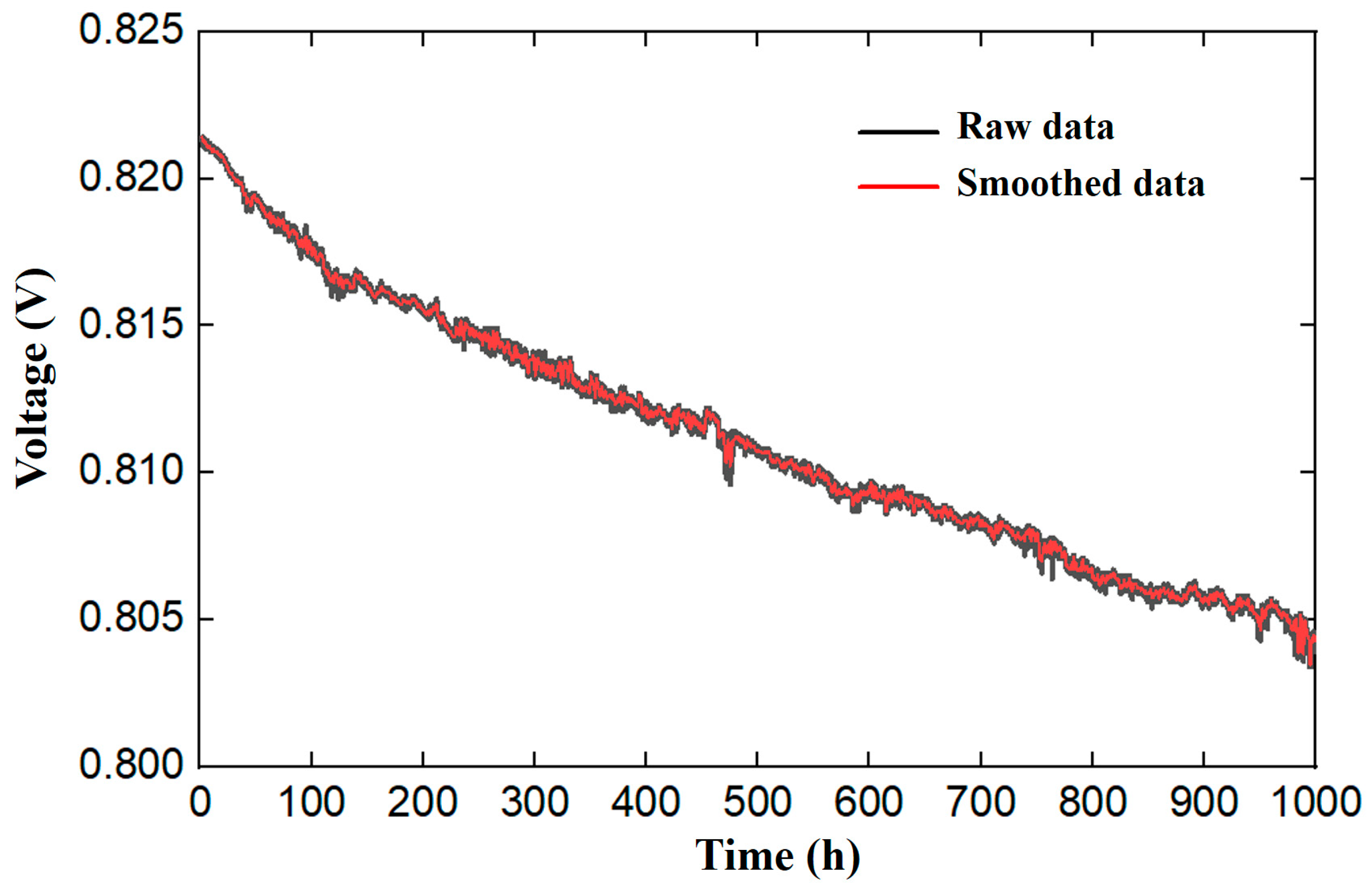

4.1. Experimental Raw Data Preprocessing

4.2. Feature Extraction of Neural Network Structures

4.3. Performance Evaluation Criteria

5. Results and Discussion

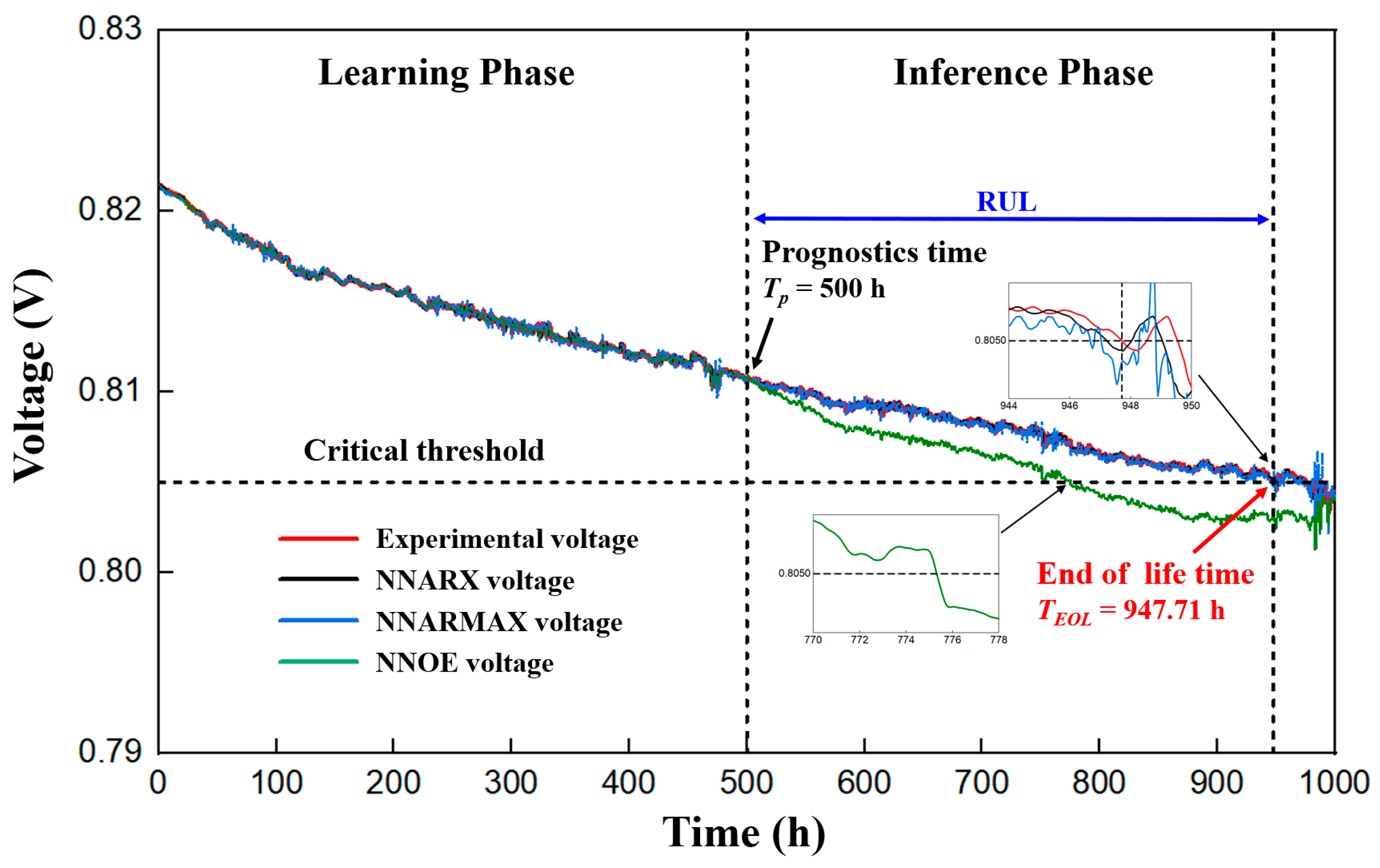

5.1. Comparison of Performance Degradation Prediction

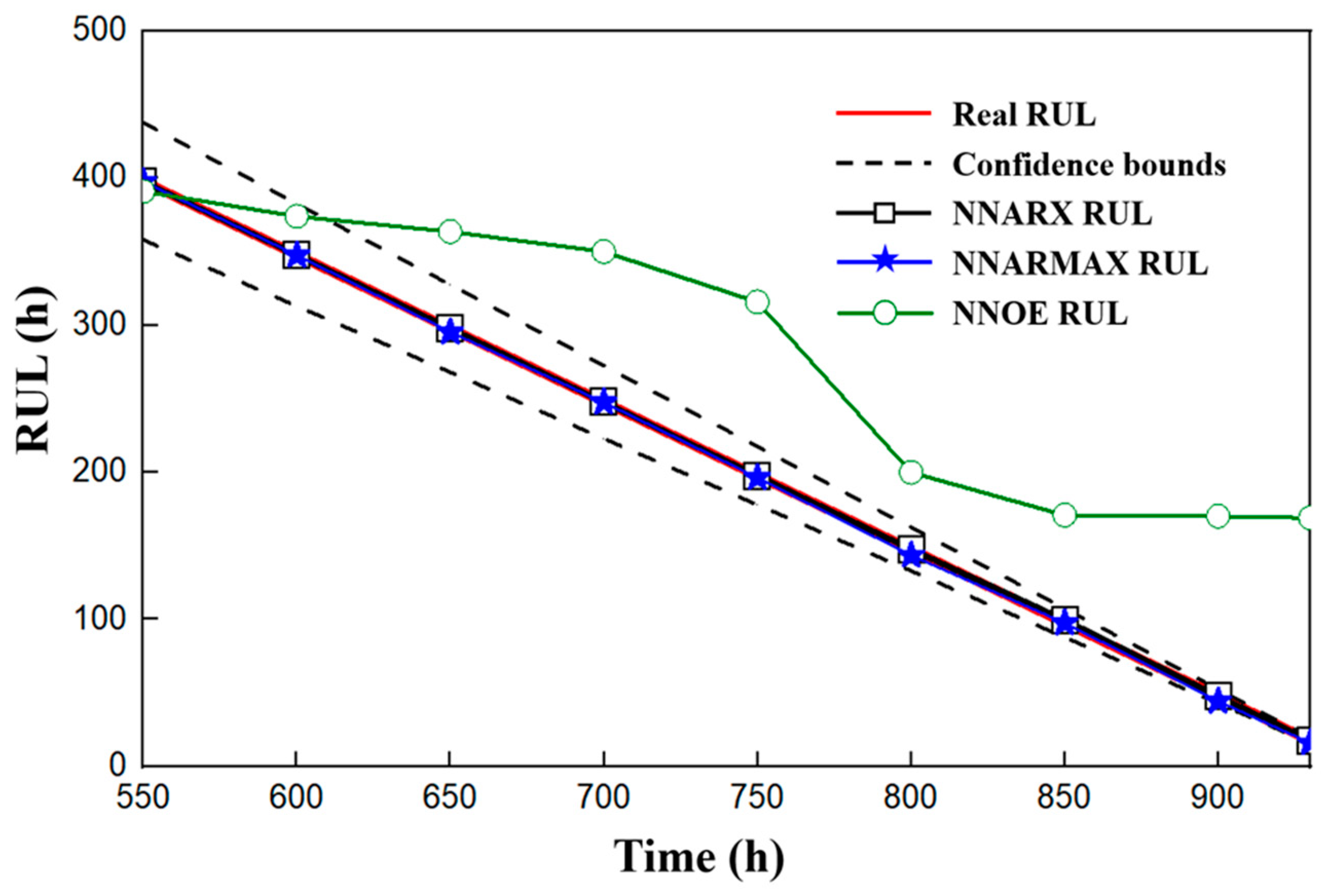

5.2. Remaining Useful Lifetime Inference

6. Conclusions

- (1)

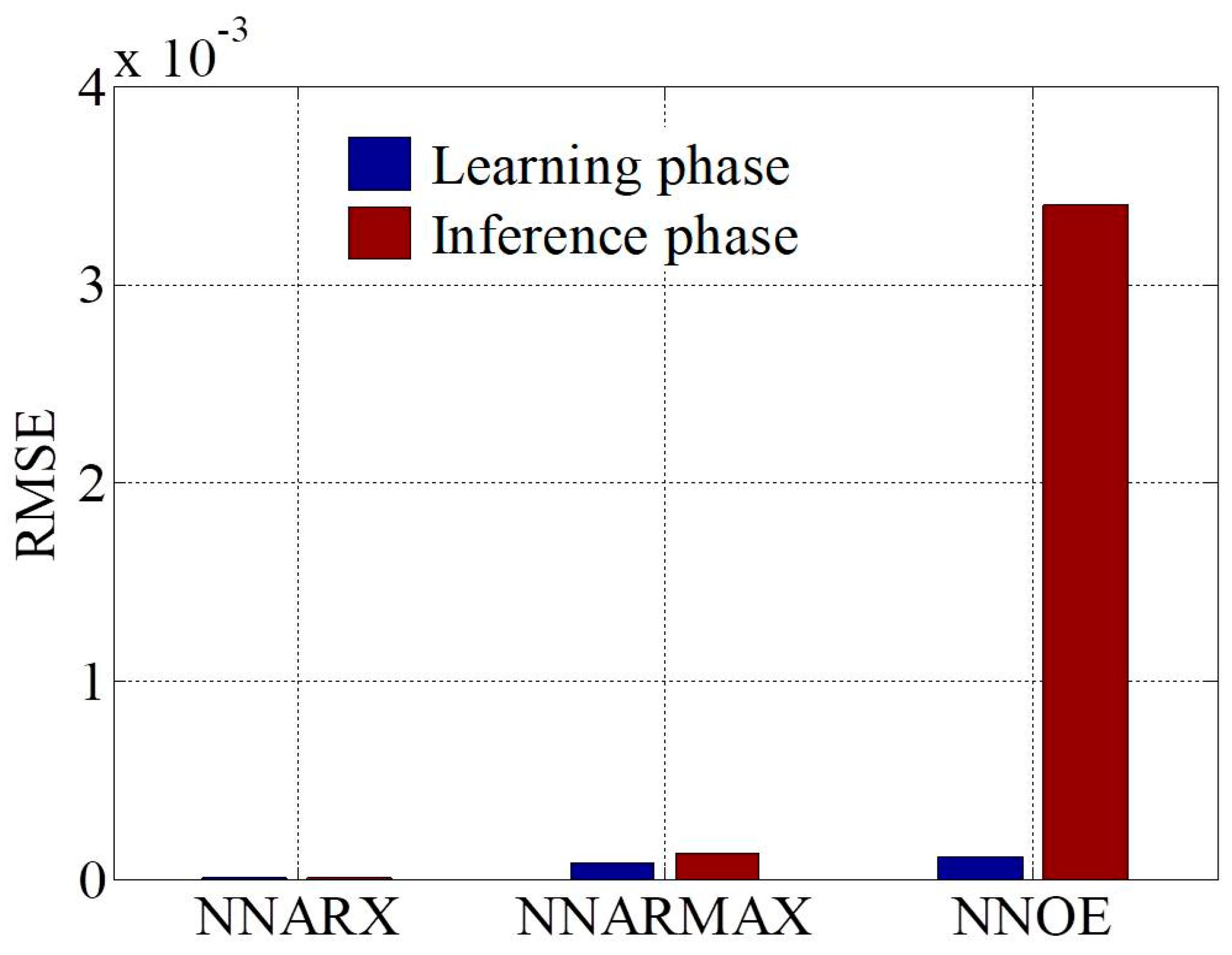

- In the learning phase, the proposed models can efficiently capture the degradation trend of the SOFC performance. During the inference phase, the NNARX model provides higher (and more accurate) prognostic performances than the other NNARMAX and NNOE models.

- (2)

- In the DNN model structures, the NNARX model has low values of RMSE and MAE due to parallel structure in a series. Although both NNARMAX and NNOE are parallel structures, the computation form of the NNARX model is stable, leading to better prognostics accuracy than the NNOE model.

- (3)

- The results of the RUL estimation demonstrate that both NNARX and NNARMAX models not only agree very well with the actual RUL values, but also “fall into” the confidence intervals. Although the NNOE model has a deviation from the real RUL values, its predicted tendency is still qualitatively consistent with experimental data.

- (4)

- Comparing the results with previous prognostic methods from the open literature, the proposed methods of the DNN models present better performances.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Saebea, D.; Authayanun, S.; Patcharavorachot, Y. Performance analysis of direct steam reforming of methane in SOFC with SDC-based electrolyte. Energy Rep. 2020, 6, 391–396. [Google Scholar] [CrossRef]

- Xu, H.; Ma, J.; Tan, P.; Chen, B.; Wu, Z.; Zhang, Y.; Wang, H.; Xuan, J.; Ni, M. Towards online optimization of solid oxide fuel cell performance: Combining deep learning with multi-physics simulation. Energy AI 2020, 1, 1–11. [Google Scholar] [CrossRef]

- Lanzini, A.; Ferrero, D.; Papurello, D.; Santarelli, M. Reporting Degradation from Different Fuel Contaminants in Ni-anode SOFCs. Fuel Cells 2017, 17, 423–433. [Google Scholar] [CrossRef]

- Faro, M.L.; Antonucci, V.; Antonucci, P.; Aricò, A. Fuel flexibility: A key challenge for SOFC technology. Fuel 2012, 102, 554–559. [Google Scholar] [CrossRef]

- Zhang, L.; Lin, J.; Liu, B.; Zhang, Z.; Yan, X.; Wei, M. A review on deep learning applications in prognostics and health management. IEEE Access 2019, 7, 162415–162438. [Google Scholar] [CrossRef]

- Chen, K.; Laghrouche, S.; Djerdir, A. Proton exchange membrane fuel cell prognostics using genetic algorithm and extreme learning machine. Fuel Cells 2020, 20, 263–271. [Google Scholar] [CrossRef]

- Lecoeuche, S.; Lalot, S. Prediction of the daily performance of solar collectors. Int. Commun. Heat Mass Transf. 2005, 32, 603–611. [Google Scholar] [CrossRef]

- Perera, A.T.D.; Wickramasinghe, P.; Nik, V.M.; Scartezzini, J.L. Introducing reinforcement learning to the energy system design process. Appl. Energy 2020, 262, 114580. [Google Scholar] [CrossRef]

- Huang, Q.A.; Hui, R.; Wang, B.; Zhang, J. A review of AC impedance modeling and validation in SOFC diagnosis. Electrochim. Acta 2007, 52, 8144–8164. [Google Scholar] [CrossRef]

- Kakac, S.; Pramuanjaroenkij, A.; Zhou, X.Y. A review of numerical modeling of solid oxide fuel cells. Int. J. Hydrogen Energy 2007, 32, 761–786. [Google Scholar] [CrossRef]

- Hajimolana, S.A.; Hussain, M.A.; Daud, W.A.W.; Soroush, M.; Shamiri, A. Mathematical modeling of solid oxide fuel cells: A review. Renew. Sustain. Energy Rev. 2011, 15, 1893–1917. [Google Scholar] [CrossRef]

- Seborg, D.E.; Mellichamp, D.A.; Edgar, T.F.; Doyle, F.J., III. Process Dynamics and Control; John Wiley & Sons: Hoboken, NJ, USA, 2010. [Google Scholar]

- Wang, K.; Hissel, C.; Péra, M.C.; Steiner, N.; Marra, D.; Sorrentino, M.; Pianese, C.; Monteverde, M.; Cardone, P.; Saarinen, J. A review on solid oxide fuel cell models. Int. J. Hydrogen Energy 2011, 36, 7212–7228. [Google Scholar] [CrossRef]

- Song, C.; Lee, S.; Gu, B.; Chang, I.; Cho, G.Y.; Baek, F.D.; Cha, S.W. A Study of Anode-Supported Solid Oxide Fuel Cell Modeling and Optimization Using Neural Network and Multi-Armed Bandit Algorithm. Energies 2020, 13, 1621. [Google Scholar] [CrossRef]

- Cheng, S.J.; Liu, J.J. Nonlinear modeling and identification of proton exchange membrane fuel cell (PEMFC). Int. J. Hydrogen Energy 2015, 40, 9452–9461. [Google Scholar] [CrossRef]

- He, Y.J.; Ma, Z.F. A Data-Driven Gaussian Process Regression Model for Two-Chamber Microbial Fuel Cells. Fuel Cells 2016, 16, 365–376. [Google Scholar] [CrossRef]

- Wang, X.; Balakrishnan, N.; Guo, B. Residual life estimation based on a generalized Wiener degradation process. Reliab. Eng. Syst. Saf. 2014, 124, 13–23. [Google Scholar] [CrossRef]

- Wu, X.; Ye, Q. Fault diagnosis and prognostic of solid oxide fuel cells. J. Power Sources 2016, 321, 47–56. [Google Scholar] [CrossRef]

- Bressel, M.; Hilairet, M.; Hissel, D.; Bouamama, B.Q. Extended Kalman filter for prognostic of proton exchange membrane fuel cell. Appl. Energy 2016, 164, 220–227. [Google Scholar] [CrossRef]

- Fathy, A.; Rezk, H.; Ramadan, H.S.M. Recent moth-flame optimizer for enhanced solid oxide fuel cell output power via optimal parameters extraction process. Energy 2020, 207, 118326. [Google Scholar] [CrossRef]

- Milewski, J.; Świrski, K. Modelling the SOFC behaviours by artificial neural network. Int. J. Hydrogen Energy 2009, 34, 5546–5553. [Google Scholar] [CrossRef]

- Bai, H.; Liu, C.; Breaz, E.; Gao, F. Artificial neural network aided real-time simulation of electric traction system. Energy AI 2020, 1, 100010. [Google Scholar] [CrossRef]

- Sinha, N.K.; Gupta, M.M.; Rao, D.H. Dynamic Neural Networks: An Overview. In Proceedings of the IEEE International Conference on Industrial Technology 2000, Goa, India, 19–22 January 2000; pp. 491–495. [Google Scholar]

- Lang, K.J.; Waibel, A.H.; Hinton, G.E. A Time-Delay Neural Network Architecture from Isolated Word Recognition. Neural Netw. 1990, 3, 23–44. [Google Scholar] [CrossRef]

- Gupta, M.M.; Rao, D.H. Neural Units with Applications to the Control of Unknown Nonlinear Systems. J. Intell. Fuzzy Syst. 1993, 1, 73–92. [Google Scholar] [CrossRef]

- Lee, D.; Lin, J.K.; Tsai, C.H.; Wu, S.H.; Cheng, Y.N.; Lee, R.Y. Analysis of Long-Term and Thermal Cycling Tests for a Commercial Solid Oxide Fuel Cell. J. Electrochem. Energy 2017, 14, 041002. [Google Scholar] [CrossRef]

- Tsai, C.H.; Hwang, C.S.; Chang, C.L.; Yang, S.F.; Cheng, S.W.; Shie, Z.Y.C.; Hwang, T.J.; Lee, R.Y. Performance and long term durability of metal-supported solid oxide fuel cells. J. Ceram. Soc. Jpn. 2015, 123, 205–212. [Google Scholar] [CrossRef][Green Version]

- Cheng, Y.N.; Cheng, S.W.; Lee, R.Y. The Comparisons of Electrical Performance and Impedance Spectrum for Two Commercial Cells. J. Fuel Cell Sci. Technol. 2014, 11, 051002–051006. [Google Scholar] [CrossRef]

- Jouin, M.; Bressel, M.; Morando, S.; Gouriveau, R.; Hissel, G.; Péra, M.C.; Zerhouni, N.; Jemei, S.; Hilairet, M.; Bouamama, B.O. Estimating the end-of-life of PEM fuel cells: Guidelines and metrics. Appl. Energy 2016, 177, 87–97. [Google Scholar] [CrossRef]

- Lyu, J.; Zhang, J. BP neural network prediction model for suicide attempt among Chinese rural residents. J. Affect. Disord. 2019, 246, 465–473. [Google Scholar] [CrossRef] [PubMed]

- Cheng, S.J.; Lin, J.K. Performance Prediction Model of Solid Oxide Fuel Cell System Based on Neural Network Autoregressive with External Input Method. Processes 2020, 8, 828. [Google Scholar] [CrossRef]

- Kimmel, R.K.; Booth, D.E.; Booth, S.E. The analysis of outlying data points by robust Locally Weighted Scatter Plot Smooth: A model for the identification of problem banks. Int. J. Oper. Res. 2010, 7, 1–15. [Google Scholar] [CrossRef]

- Beale, M.H.; Hagan, M.T.; Demuth, H.B. Users’ Guide for the Neural Network Toolbox for MATLAB; The Mathworks: Natica, MA, USA, 2017. [Google Scholar]

- Liu, H.; Chen, J.; Hou, M.; Shao, Z.; Su, H. Data-based short-term prognostics for proton exchange membrane fuel cells. Int. J. Hydrogen Energy 2017, 42, 20791–20808. [Google Scholar] [CrossRef]

- Song, S.; Xiong, X.; Wu, X.; Xue, X. Modeling the SOFC by BP neural network algorithm Modeling the SOFC by BP neural network algorithm. Int. J. Hydrogen Energy 2021, 46, 20065–20071. [Google Scholar] [CrossRef]

- Nakajo, A.; Mueller, F.; Brouwer, J.; Favrat, D. Mechanical reliability and durability of SOFC stacks. Part II: Modelling of mechanical failures during ageing and cycling. Int. J. Hydrogen Energy 2012, 37, 9269–9286. [Google Scholar] [CrossRef]

- Colombo, K.W.E.; Kharton, V.V.; Berto, F.; Paltrinieri, N. Mathematical modeling and simulation of hydrogen-fueled solid oxide fuel cell system for micro-grid applications-Effect of failure and degradation on transient performance. Energy 2020, 202, 117752. [Google Scholar] [CrossRef]

- I.S. Organization. Condition Monitoring and Diagnostics of Machinery-Prognostics—Part 1: General Guidelines; Technical Report ISO 13381-1; ISO: Geneva, Switzerland, 2004; pp. 1–20. [Google Scholar]

- Mosallam, A.; Medjaher, K.; Zerhouni, N. Data-driven prognostic method based on Bayesian approaches for direct remaining useful life prediction. J. Intell. Manuf. 2016, 27, 1037–1048. [Google Scholar] [CrossRef]

| Layer | Composition/Thickness |

|---|---|

| Anode composition | NiO/YSZ (12m) |

| Anode support | NiO/YSZ (500m) |

| Cathode composition | LSC (20–30m) |

| Electrolyte composition | YSZ (3m) |

| Dynamic Neural Unit | ||||||

|---|---|---|---|---|---|---|

| Model | Hidden Number (hn) | Output Order (na) | Input Order (nb) | Noise Order (nc) | Time Delay (nk) | NSSE |

| NNARX | 10 | 5 | 5 | None | 1 | 1.32 × 10−10 |

| NNARMAX | 10 | 5 | 5 | 1 | 1 | 3.43 × 10−7 |

| NNOE | 10 | 5 | 5 | None | 1 | 6.56 × 10−5 |

| RMSE | MAE | |||

|---|---|---|---|---|

| Model | Learning Phase | Inference Phase | Learning Phase | Inference Phase |

| NNARX | 1.58 × 10−6 | 1.86 × 10−6 | 9.30 × 10−7 | 9.44 × 10−7 |

| NNARMAX | 8.19 × 10−5 | 1.23 × 10−4 | 5.83 × 10−5 | 8.05 × 10−5 |

| NNOE | 1.11 × 10−4 | 3.40 × 10−3 | 8.80 × 10−5 | 3.02 × 10−3 |

| Method | RMSE | MAE |

|---|---|---|

| NNARX | ||

| NNARMAX | ||

| NNOE | ||

| Backpropagation (BP) [35] | 0.0032 | 0.0769 |

| Support vector machine (SVM) [35] | 0.4492 | 0.2998 |

| Random forest (RF) [35] | 0.524 | 0.3598 |

| Models | RUL_prognostic | AE | RE | PA |

|---|---|---|---|---|

| NNARX | 447.19 | 0.52 | 0.12% | 99.88% |

| NNARMAX | 447.04 | 0.67 | 0.15% | 99.85% |

| NNOE | 275.81 | 171.9 | 38.40% | 61.6% |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cheng, S.-J.; Li, W.-K.; Chang, T.-J.; Hsu, C.-H. Data-Driven Prognostics of the SOFC System Based on Dynamic Neural Network Models. Energies 2021, 14, 5841. https://doi.org/10.3390/en14185841

Cheng S-J, Li W-K, Chang T-J, Hsu C-H. Data-Driven Prognostics of the SOFC System Based on Dynamic Neural Network Models. Energies. 2021; 14(18):5841. https://doi.org/10.3390/en14185841

Chicago/Turabian StyleCheng, Shan-Jen, Wen-Ken Li, Te-Jen Chang, and Chang-Hung Hsu. 2021. "Data-Driven Prognostics of the SOFC System Based on Dynamic Neural Network Models" Energies 14, no. 18: 5841. https://doi.org/10.3390/en14185841

APA StyleCheng, S.-J., Li, W.-K., Chang, T.-J., & Hsu, C.-H. (2021). Data-Driven Prognostics of the SOFC System Based on Dynamic Neural Network Models. Energies, 14(18), 5841. https://doi.org/10.3390/en14185841