Thermal Characterization of a New Bio-Based Insulation Material Containing Puffed Rice

Abstract

:1. Introduction

2. Materials and Methods

2.1. Material

2.2. Puffing Technique Methods

2.3. Fabrication of Insulation Material Sample

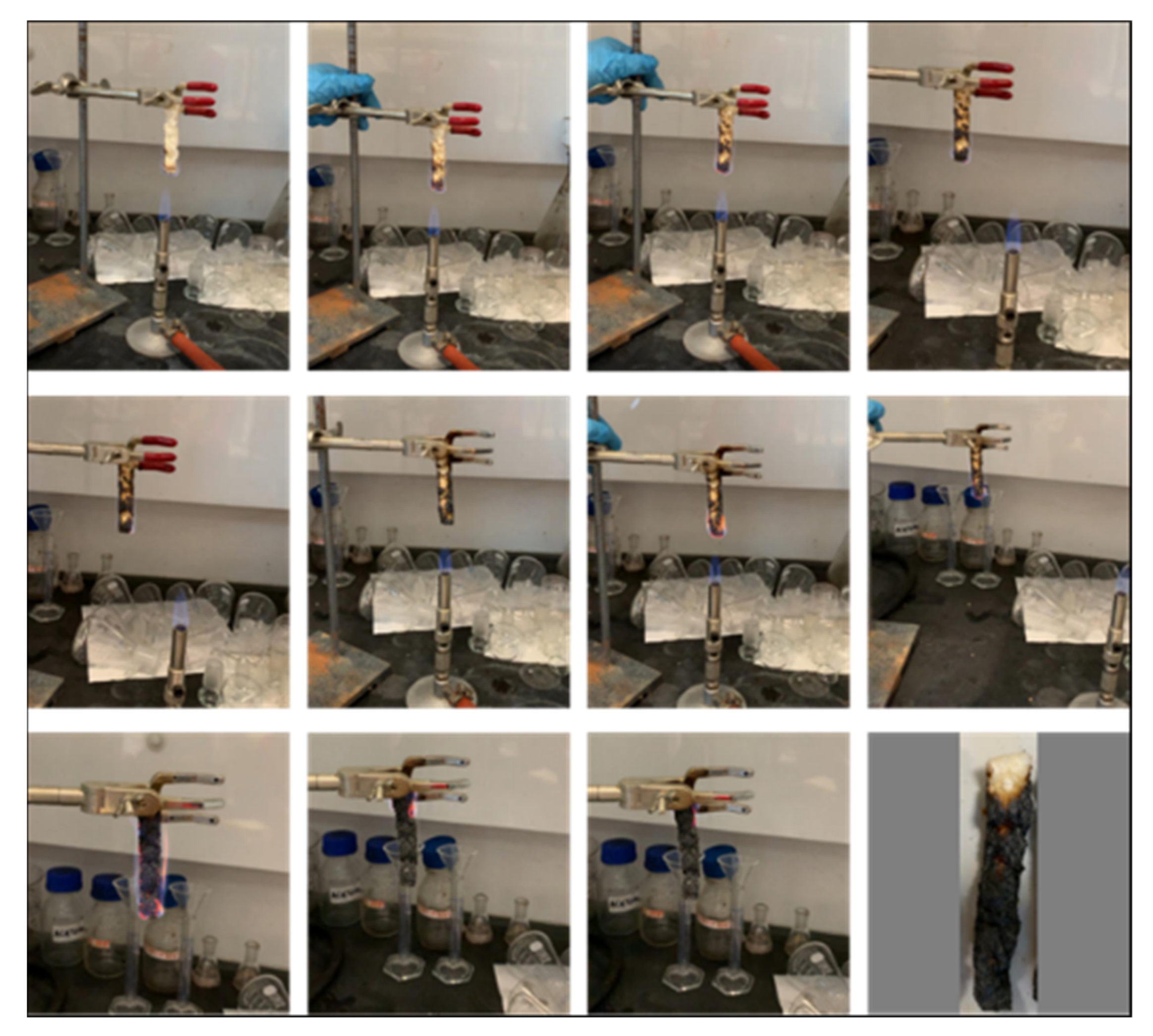

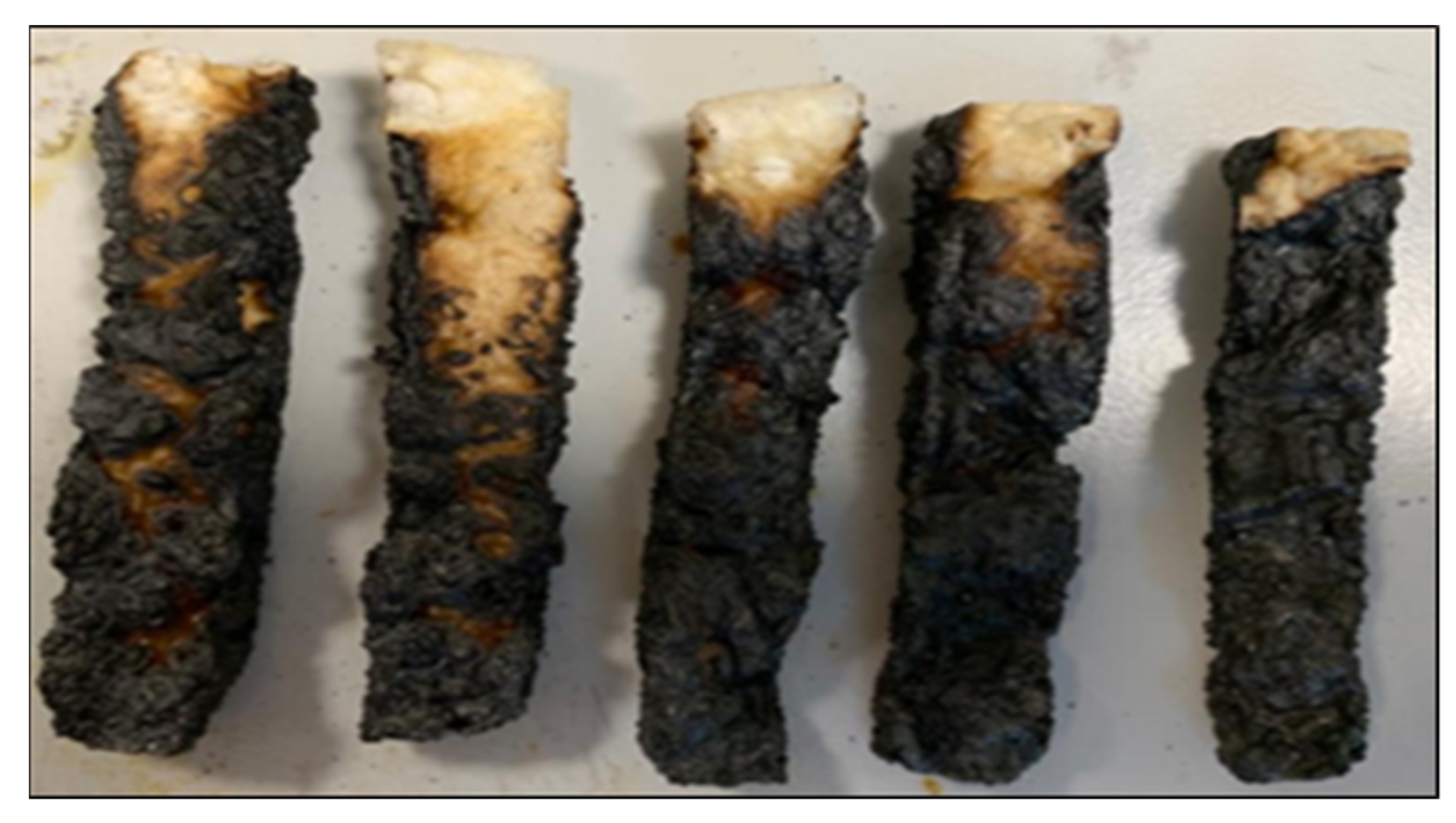

2.4. Fire Reaction Test

3. Results and Discussion

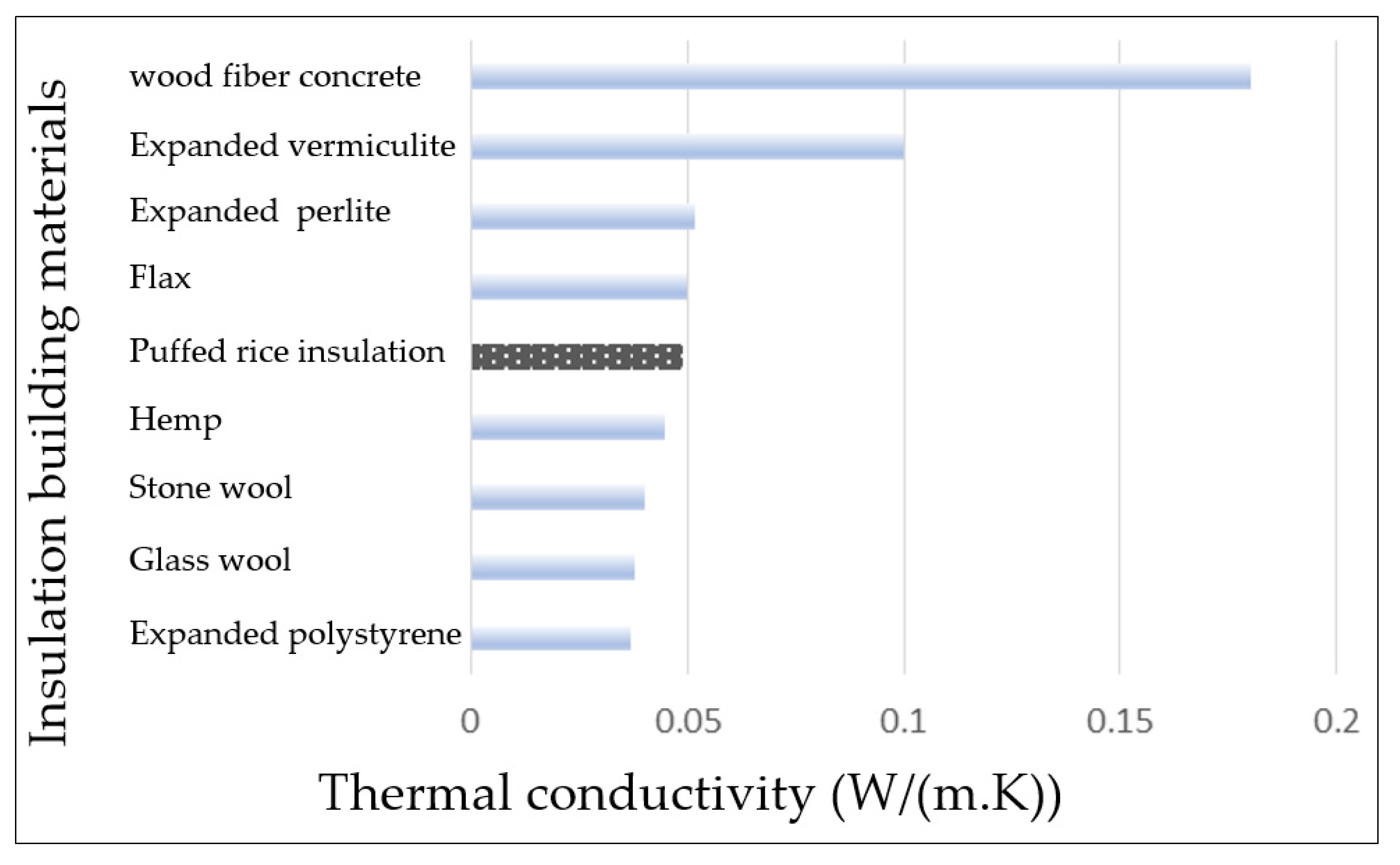

3.1. Screening Study

3.2. Applicable Experimental Range of Sample Weight, Temperature, and Moisture Level

3.3. Thermal Conductivity Test

3.4. Fire Reaction

4. Conclusions

5. Future Work

- An insulation board of size typically used in construction (1 m × 1 m) for instance could be evaluated under actual wall structure conditions.

- The environmental impact of the degradation of the rice insulation material composite, including humidity and thermal transmission, could be investigated.

- The mechanical properties of the sample, such as tensile strength, compressive strength, and shear strength, could be evaluated.

- The cost of large-scale production of the puffed rice insulation material needs to be estimated.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Dixon, G.; Abdel-Salam, T.; Kauffmann, P. Evaluation of the effectiveness of an energy efficiency program for new home construction in eastern North Carolina. Energy 2010, 35, 1491–1496. [Google Scholar] [CrossRef]

- EIA. Annual Energy Outlook; U.S. Energy Information Administration: Washington, DC, USA, 2017.

- IEA. World Energy Outlook; Clean Energy Ministerial: Paris, France, 2011. [Google Scholar]

- IEA. Clean Energy Progress Report; Clean Energy Ministerial: Paris, France, 2013. [Google Scholar]

- Ong, H.C.; Mahlia, T.M.I.; Masjuki, H.H. Ren Sust. Energy Rev. 2011, 15, 639–647. [Google Scholar]

- Patterson, M. What is energy efficiency?: Concepts, indicators and methodological issues. Energy Policy 1996, 24, 377–390. [Google Scholar] [CrossRef]

- Dubai, E. How to Save on Energy Consumption. UAE. Retrieved 18 May 2020. Available online: https://www.energydubai.com/energy-consumers/save-energy-consumption/ (accessed on 20 April 2021).

- Berde, P.A.; Bhavani, R.G. Investigation for reducing energy consumption for a university campus in Dubai using automation. In Proceedings of the 2015 IEEE Recent Advances in Intelligent Computational Systems (RAICS), Trivandrum, India, 10–12 December 2015; pp. 358–363. [Google Scholar]

- Majumder, A.; Canale, L.; Mastino, C.C.; Pacitto, A.; Frattolillo, A.; Dell’Isola, M. Thermal Characterization of Recycled Materials for Building Insulation. Energies 2021, 14, 3564. [Google Scholar] [CrossRef]

- Al-Homoud, M.S. Performance characteristics and practical applications of common building thermal insulation materials. Build. Environ. 2005, 40, 353–366. [Google Scholar] [CrossRef]

- Domínguez-Muñoz, F.; Anderson, B.; Cejudo-López, J.M.; Carrillo-Andrés, A. Uncertainty in the thermal conductivity of insulation materials. Energy Build. 2010, 42, 2159–2168. [Google Scholar] [CrossRef] [Green Version]

- Pinto, J.; Paiva, A.; Varum, H.; Costa, A.; Cruz, D.; Pereira, S.; Fernandes, L.; Tavares, P.; Agarwal, J. Corn’s cob as a potential ecological thermal insulation material. Energy Build. 2011, 43, 1985–1990. [Google Scholar] [CrossRef]

- Palumbo, M.; Lacasta, A.M.; Navarro, A.; Giraldo, M.P.; Lesar, B. Improvement of fire reaction and mould growth resistance of a new bio-based thermal insulation material. Constr. Build. Mater. 2017, 139, 531–539. [Google Scholar] [CrossRef] [Green Version]

- Schiavoni, S.; D’Alessandro, F.; Bianchi, F.; Asdrubali, F. Insulation materials for the building sector: A review and comparative analysis. Renew. Sustain. Energy Rev. 2016, 62, 988–1011. [Google Scholar] [CrossRef]

- Collet, F.; Prétot, S. Thermal conductivity of hemp concretes: Variation with formulation, density and water content. Constr. Build. Mater. 2014, 65, 612–619. [Google Scholar] [CrossRef] [Green Version]

- Stamyr, K.; Thelander, G.; Ernstgård, L.; Ahlner, J.; Johanson, G. Swedish forensic data 1992–2009 suggest hydrogen cyanide as an important cause of death in fire victims. Inhal. Toxicol. 2012, 24, 194–199. [Google Scholar] [CrossRef] [PubMed]

- European Committee for Standardization. Fire Classification of Construction Products and Building Elements—Part 1: Classification Using Data from Reaction to Fire Tests; British Standards Institution: London, UK, 2007. [Google Scholar]

- Asdrubali, F.; D’Alessandro, F.; Schiavoni, S. A review of unconventional sustainable building insulation materials. Sustain. Mater. Technol. 2015, 4, 1–17. [Google Scholar] [CrossRef]

- Dikmen, N.; Ozkan, S.T.E. Unconventional insulation materials. In Insulation Materials in Contexts of Sustainability; IntechOpen: London, UK, 2016. [Google Scholar] [CrossRef] [Green Version]

- Kuo, L. Wasted Rice in Asia Emits over 600 Million Tonnes of Greenhouse Gases a Year. 2013. Available online: https://qz.com/123456/wasted-rice-in-asia-emits-over-600-million-tonnes-of-greenhouse-gases-a-year/ (accessed on 12 September 2013).

- Chandrasekhar, P.R.; Chattopadhyay, P.K. Studies on microstructural changes of parboiled andpuffed rice. J. Food Process. Preserv. 1990, 14, 27–37. [Google Scholar] [CrossRef]

- Sumnu, G.; Datta, A.K.; Sahin, S.; Keskin, S.O.; Rakesh, V. Transport and related properties of breads baked using various heating modes. J. Food Eng. 2007, 78, 1382–1387. [Google Scholar] [CrossRef]

- Kaláb, M.; A Bowl of Rice and SEM. A Bowl of Rice and SEM. Infocus Mag.-Proc. R. Microsc. Soc. UK 2018, 1, 13–36. [Google Scholar]

- Laoutid, F.; Bonnaud, L.; Alexandre, M.; Lopez-Cuesta, J.-M.; Dubois, P. New prospects in flame retardant polymer materials: From fundamentals to nanocomposites. Mater. Sci. Eng. R Rep. 2009, 63, 100–125. [Google Scholar] [CrossRef]

| Insulation Materials | Thermal Conductivity W/(mK) | Density kg/m3 | Specific Heat kJ/(kgK) | Fire Classification | Water Resistance | Reference Number |

|---|---|---|---|---|---|---|

| Hemp | 0.038–0.060 | 20–90 | 1.6−1.7 | E | 1.0–2.0 | [14,15] |

| Straw | 0.038–0.067 | 50–150 | 0.6 | NA | NA | [14,15] |

| Flax | 0.038–0.075 | 20–100 | 1.4–1.6 | E | 1.0–2.0 | [14] |

| Wood fiber | 0.038–0.050 | 50–270 | 1.9–2.1 | E | 1–5 | [15] |

| Cotton stalk | 0.0585–0.0815 | 150–450 | NA | NA | NA | [14,18] |

| Corn cob | 0.10 | 171–334 | NA | NA | NA | [12,18] |

| sunflower | 0.0385–0.050 | 36–152 | NA | NA | NA | [12,18] |

| palm date fibers | 0.0475–0.072 | 187–389 | NA | NA | NA | [14,18] |

| Jute fiber | 0.038–0.055 | 35–100 | 2.3 | E | 1–2 | [14] |

| Kenaf | 0.034−0.043 | 30–180 | 1.6−1.7 | D-E | 1.2–2.3 | [14] |

| Coir fiber | 0.040–0.045 | 75–125 | 1.3–1.6 | D-Eb | 5.0–30 | [14] |

| Cork | 0.037–0.050 | 110–170 | 1.5–1.7 | E | 5–30 | [14] |

| Reeds | 0.045–0.056 | 13–190 | 1.2 | E | 1–2 | [14,18] |

| Bagasse | 0.046–0.055 | 70–350 | NA | NA | NA | [14,18] |

| Cattail | 0.0438–0.0606 | 200–400 | NA | NA | NA | [18] |

| Pineapple leaves | 0.035–0.042 | 178–232 | NA | NA | NA | [18] |

| Durian peel | 0.064–0.185 | 357–907 | NA | NA | NA | [14,18] |

| Rice hulls | 0.0464–0.566 | 154–168 | NA | NA | NA | [18] |

| Sansevieria fiber | 0.132 | 1410 | 1.52 | NA | NA | [18] |

| Temperature [°C] | Thermal Conductivity W/(mK) | |

|---|---|---|

| Bio-Insulation Material | Polystyrene | |

| 5 | 0.04156 | 0.03541 |

| 15 | 0.04473 | 0.03790 |

| 25 | 0.04672 | 0.03985 |

| 35 | 0.04834 | 0.04187 |

| 45 | 0.04971 | 0.04395 |

| Insulation Material | Burning Time (s) | Burning Drops | Material Vanishing |

|---|---|---|---|

| Puffed rice | 20 | No | No |

| Polystyrene | 6 | Yes | Yes |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Khoukhi, M.; Dar Saleh, A.; Hassan, A.; Abdelbaqi, S. Thermal Characterization of a New Bio-Based Insulation Material Containing Puffed Rice. Energies 2021, 14, 5700. https://doi.org/10.3390/en14185700

Khoukhi M, Dar Saleh A, Hassan A, Abdelbaqi S. Thermal Characterization of a New Bio-Based Insulation Material Containing Puffed Rice. Energies. 2021; 14(18):5700. https://doi.org/10.3390/en14185700

Chicago/Turabian StyleKhoukhi, Maatouk, Abeer Dar Saleh, Ahmed Hassan, and Shaimaa Abdelbaqi. 2021. "Thermal Characterization of a New Bio-Based Insulation Material Containing Puffed Rice" Energies 14, no. 18: 5700. https://doi.org/10.3390/en14185700

APA StyleKhoukhi, M., Dar Saleh, A., Hassan, A., & Abdelbaqi, S. (2021). Thermal Characterization of a New Bio-Based Insulation Material Containing Puffed Rice. Energies, 14(18), 5700. https://doi.org/10.3390/en14185700