Abstract

Biodiesel is a renewable energy source which is gaining prominence as an alternative fuel over fossil diesel for different applications. Due to their higher viscosity and lower volatility, biodiesels are blended with diesel in various proportions. B20 blends are viable and sustainable solutions in diesel engines with acceptable engine performance as they can replace 20% fossil fuel usage. Biodiesel blends are slightly viscous as compared with diesel and can be used in common rail direct injection (CRDI) engines which provide high pressure injection using an electronic control unit (ECU) with fuel flexibility. In view of this, B20 blends of three biodiesels derived from cashew nutshell (CHNOB (B20)), jackfruit seed (JACKSOB (B20)), and Jamun seed (JAMNSOB (B20)) oils are used in a modified single-cylinder high-pressure-assisted CRDI diesel engine. At a BP of 5.2 kW, for JAMNSOB (B20) operation, BTE, NOx, and PP increased 4.04%, 0.56%, and 5.4%, respectively, and smoke, HC, CO, ID, and CD decreased 5.12%, 6.25%, 2.75%, 5.15%, and 6.25%, respectively, as compared with jackfruit B20 operation.

1. Introduction

Environmental degradation is one of the major concerns associated with continued usage of fossil fuels in internal combustion (IC) engines. Further, scarcity and high cost of fossil fuels is adding to these renewed concerns. This has compelled researchers to look for alternative and renewable fuels that can adequately address the above drawbacks [1,2,3]. Compression ignition (CI) engines are highly efficient and rugged but have major disadvantages that include higher smoke and NOx emissions [4,5]. Simultaneous reduction of both these emissions is a major issue and several studies have reported different methods of controlling these emissions [6,7,8,9], which have included fuel modification, optimization of engine configuration, and operating parameters that have an impact on engine combustion characteristics [10,11]. The B20 biodiesel blend is one such option which partially substitutes for the diesel usage and addresses the drawbacks of higher diesel engine emissions [12,13]. Utilization of B20 blends in CRDI diesel engines with optimized injection parameters can significantly improve engine performance [14]. In addition, injecting biodiesel blends with split and multiple injection modes, can further reduce smoke and NOx emissions simultaneously.

Venkatesan et al. [15] studied engine performance analysis using five different blends of CNS (cashew nutshell) and Jatropha biodiesels with diesel in varied proportions. Engine performance with CSO10 showed higher BTE and lower specific fuel consumption (SFC) as well as low emissions, except for NOx. Pandian et al. [16] studied engine performance analysis using CNS and hexanol in varied proportions. The use of hexanol in biodiesel resulted in lower emissions of CO, HC, and smoke at all the loads tested and enhanced BTE. Thanigaivelan and Loganathan [17] studied emission and performance analysis of a diesel engine operated at 1500 rpm fueled with CNSL blends. Lower HRR and peak pressures and an increment in emission patterns were registered, except NOx emissions. Prasad et al. [18] reviewed the feasibility of CNSL as a biodiesel with different characteristics considering different fuel blends. Santhanakrishnan and Jose [19] studied emission and performance analysis of a diesel engine fueled with CNSL blends in different volume fractions. Among all the blends used, the B20 blend exhibited overall improved engine characteristics, while higher emissions were obtained as compared with diesel alone as fuel. Jagadish et al. [20] utilized methanol and CNSO in the preparation of biodiesel blends and studied emission and performance characteristics of an engine at various loads. The B20 blend exhibited improved performance characteristics with lower engine-out emissions. Loganathan et al. [21] investigated the feasibility of diethyl ester-hydrogen-diesel-cashew nutshell blends by varying their proportions with B20 blends in direct injection diesel engines at a constant 1500 rpm. The BTE of a diesel engine improved while CO and HC emissions were reduced with increased NOx emisssions with the addition of H2 in CNSLB20 blends. In addition, 6 lpm H2-CNSLB20 with diethyl ether (6%) blends showed a decrement of 43% and 50% in HC and CO emissions, respectively, as compared with CNSLB20 blends. Loganathan et al. [22] utilized hydrogen with CNS oil blends for improved engine performance and reduced emissions of HC and CO. For a reduction in NOx emissions, 10% EGR was utilized. At full load conditions, an increment in BTE reductions in NOx, HC, and CO emissions were observed. By utilizing EGR, a decrement in NOx emissions of 26% was observed. Singh and Sandhu [23] studied the emission, performance, and combustion characteristics of a CRDI engine fueled with various blends of argemone biodiesel in varied proportions at different engine load conditions. The B10 and B20 blends showed improved combustion attributes such as CP and HRR associated with higher BTE and lower BSFC at partial and heavy loads. Higher ignition delay was not observed with up to 20% blends, and higher exhaust gas temperature and lower brake thermal efficiency were observed with the blends AB30 and AB50, respectively. Kamil Duda et al. [24] studied diesel engine performance using animal origin-based biofuels. Further, engine performance results were compared with conventional blends of rapeseed oil methyl esters used in a medium-duty, turbocharged-CRDI-diesel engine, at varied speeds and full load. Single pulse for 3000 rpm and multipulse injection for 1500 RPM strategies were utilized. The rate of pressure rise was found to be maximum for biofuels as compared with mineral diesel operation. Heat release rate and combustion rates were higher for S75 and T75 than mineral diesel R75. The T75 biodiesel minerals were found to be far better than mineral fuels. An increase of 6.6% in NOx emission was observed. Dharmarajaa et al. [25] studied the emission characteristics of a DI engine powered with rice husk holding 16–20% crude oil. Ignition delay at higher loads increased vaporization rate for B20 biodiesel blends due to their higher cetane number and resulted into higher BTE. HC and CO2 emissions decreased, while NOx emissions increased for both B20 and B30 blends at a constant CR of 17:5:1. Jorge Calder et al. [26] studied the emission and performance characteristics of a two-cylinder DI diesel engine at varied engine speeds powered with biodiesel-diesel blends using recycled expanded polystyrene (EPS). As compared with diesel, EPS-dissolved B50 with or without acetone emitted much lower NOx emissions. Tayari et al. [27] studied the feasibility of three feedstocks of Eruca sativa (ES), waste cooking oil (WCO), and microalgae chlorella vulgaris for diesel engine applications. GC-MS and FTIR analysis of the oils were carried out and assessed as per ASTM D6751 standards. ES and WCO contained FAME of methyl oleic (C18:1) with 28.3 and 38 wt%, respectively. MCV biodiesel produced lower engine power and higher BSFC. An increase in NOx emissions with MCV biodiesel and a decrease in NOxemissions with WCO biodiesel were observed as compared with pure biodiesel. Decreased CO and HC emissions were found for these fuel combinations. Nabi et al. [28] studied the performance characteristics of a diesel engine powered with macadamia and waste cooking (WCO) oil-based biodiesel blends and reported that a fuel oxygen wt% of 3.35 must be maintained in the blends considered for improved engine performance. Decreased HC and CO emissions, whereas increased NOx emissions, based on the fuel engine analysis, were observed. Shameer and Ramesh [29] studied the performance characteristics of a CI engine by considering different fuel combinations of AFO20, WCO20, CMO20, and D100. Higher peak cylinder pressure and lower heat release rates were reported, based on the engine tests conducted. Higher NOx emissions for CMO20 (7.52%), AFO20 (10.352%), and WCO20 (16.405%) were found accordingly. For blends of camphor oil and diesel oil, NOx emissions were reduced by 43.8%. The camphor oil blends showed overall improved results due to their comparatively lower viscosity. Ozer Can et al. [30] studied the characteristics of a DI diesel engine at different loads powered with blends of canola biodiesel. Due to early combustion timings, lower ignition delays occurred for all the loads considered. The BSFC increased to 6.56%, while the BTE decreased to 4.2% at 20% lighter loads. The blends used in the engine released higher NOx emissions, medium levels of CO2, and lower HC and CO emissions at all the loads considered. Pimenidou et al. [31] reported on the emission and performance characteristics of a diesel engine powered with nanosized CZAl (cerium-zircorium-aluminium) infused with waste cooking oil and tallow origin biodiesels. Increases in BSFC and decreases in BTE at all the loads were observed for the biodiesels. For the nano-biodiesel blends, HC was drastically reduced and NOx and CO emissions were considerably reduced. Zhang et al. [32] considered blends of hydrogenated catalytic biodiesel (HCB) derived from waste cooking oil and China’s gasoline at different ratios. Gasoline compression ignition (GCI) engines are gaining more attention due to their high thermal efficiency and lower harmful emissions. However, GCI engines powered with pure gasoline exhibit poor combustion stability at lower loads and high pressures at higher loads, and therefore HCB has been blended with China’s 95 Gasoline at different ratios to determine the combustion and emission behavior of GCI engines. When the HCB blend increases, the ignition performance is improved, and the combustion rate is decreased. NOx, CO, and HC emissions were reduced, as the PM increased for the tested engine. Simsek et al. [33] reported on the performance and exhaust emissions of a DI engine powered with different biodiesel blends of canola, safflower, and waste oils. Increased BTE was reported for a BD75 blend as compared with BD100 blends of the respective biodiesel combination. Further, the engine exhibited a decrement in EGT and emission patterns, while increased NOx emissions were observed. Yasar et al. [34] reported on the significance of different properties of algae oil viz, such as higher cetane number, lower cold filter plugging point (CFPP), and higher saturated fatty acids, and its suitability for diesel engine applications as compared with cottonseed oil. Wang et al. [35] studied the effect of injection timing (IT), injection pressure (IP), and compression ratio (CR) on the combustion, performance, and emission characteristics of a diesel engine powered with pumpkin seed oil methyl ester and reported optimized parameters for lower emissions emanating from the diesel engines. Vijay Kumar et al. [36] studied the effect of different nozzle geometries on the combustion and emission characteristics of a CI engine powered with mahua methyl ester (MME). The nozzle geometry was optimized for improved engine performance, combustion rates, and lower emissions, except NOx emissions.

Daniel Romeo Kamta Legue et al. [37] concentrated on the impacts of engine loads of 50%, 75%, and 100%, as well as heat loss models on cylinder pressure fluctuation. Heat loss through the cylinder wall was more apparent during diffusion combustion. Under identical testing circumstances, the cylinder pressure, while using B100, was estimated at 89 bars, which was approximately 3.3 percent higher than that using D100. It was also observed that by adjusting ignition delay, the issue of high pressure linked with the use of biodiesels in engines could be addressed. When utilizing D100 and B100 at full load, the net heat release rate was approximately the same. The heat release rate of D100 was greater than that of B100 at low loads. J. Monsalve-Serrano et al. [38] concentrated on adopting alternative combustion ideas that used cleaner fuels than diesel, and offered a potential approach for increasing future powertrain efficiency and emissions. The methane–diesel dual-fuel concept offered a significant solution for compression ignition engines, since by using a low-carbon methane fuel, which is a major component of natural gas, as the principal fuel, it lowered CO2 emissions considerably as compared with traditional liquid fuels. Other problems, such as increased total hydrocarbon (THC) and CO emissions, have been discovered, in low load circumstances. To address this problem, the impacts of several engine management parameters (i.e., rail pressure, pilot amount, start of injection, and premixed ratio) on efficiency and emissions using a one-dimensional spray model were observed. Belgiorno et al. [39] studied diesel combustion and the development of innovative combustion systems capable of improving CO2 and NOx-Soot trade-offs such as specific bowl design. Di Blasio et al. [40] investigated innovative fuel injection systems and demonstrated their efficiencies as strategies in the historical trend of improving heavy diesel performance and emission formation. According to E. G. Varuvel et al. [41], NOx emissions increase as engine load increases because more fuel is used to generate the necessary power, which raises the combustion temperature. Diesel engine running resulted in the highest NOx emissions at all loads. However, as compared with diesel, engine running with biodiesels resulted in the lowest NOx emissions at all loads. Despite the presence of oxygen in the fuel structure, decreased emissions are due to a lower premixed burning rate, which tends to delay the heat release rate, resulting in a lower combustion temperature. For all fuels, smoke opacity rises with increased engine load, with diesel-fueled engines having the lowest opacity. The rise in emissions is related to a lack of atomization and a propensity to create mixtures. For traditional compression ignition engines, there is a trade-off between NOx and smoke emissions. Increased smoke emissions come from oxygen shortage in the combustion chamber, while increased NOx emissions result from oxygen enrichment, resulting in a trade-off between NOx and smoke emissions.

From the extensive literature review on sustained utilization of biodiesel blends, we found that most studies focused on convention mechanical fuel injection systems and adopted a few hundred injection pressures. Further utilization of Jamun seed oil and jackfruit seed oil-derived biodiesel and their blends for diesel engine applications has not been investigated in depth. Finally, the use of high pressure-assisted CRDI engine performance fueled with cashew nutshell, Jamun, and jackfruit seed-based biodiesel and their blends has rarely been reported.

The objective of the present study is to evaluate the performance of a modified CRDI diesel engine powered with B20 blends of cashew nutshell, Jamun seed, and jackfruit seed oils with diesel. The biodiesel blends are injected very close to top dead centre (TDC) with high injection pressures (1000 bar) using an electronic control unit (ECU). The novelty of this study is that it basically involves injection of B20 biodiesel blends at optimized injection pressures and injection timings to simultaneously address smoke and NOx emissions of conventional diesel engines.

2. Materials and Methods

2.1. Fuel Properties

The fuels chosen for diesel engine applications should have a significant impact on ensuring higher engine efficiency and lower emissions. Cashew nutshell, jackfruit seed, and Jamun seed oils are nonedible, and can be effectively used as feasible fuels for diesel engine utilization.

The weight of the Jamun fruit is about from 10.88 to 7.10 gm and the weight of the seed is about from 1.85 to 1.43 gm. The seed and fruit both contain polyphenol in higher quantity, in addition to tannin and anthocyanin. Cashew nut shells can be used as biodiesel feedstock. The cashew nutshell has a soft honeycomb texture and is about 0.3 cm thick. It consists of 3 layers, i.e., endocarp, epicarp, and mesocarp. The shell oil is present in the mesocarp, which is made of natural resin. The liquid oil extracted from cashew nutshell oil (CNSO) is a dark viscous brown reddish liquid. Cashew nutshells are dried to decrease the moisture content before extracting the oil. CNSO consists of 10% cardol and 90% anacardic acid. Jackfruit contains yellow colored edible bulbs, and the seeds are 2–4 cm in length and 2.5 cm in diameter. A complete fruit consists of almost 400–500 seeds which are utilized for extraction of nonedible oils. Table 1 and Table 2 show the fatty acid compositions of these oils and their respective biodiesels. The properties of diesel, CHNOB (B20), JAMNSOB (B20), and JACKSOB (B20) are shown in Table 3.

Table 1.

Fatty acid compositions of nonedible oils [42].

Table 2.

Fatty acid compositions of biodiesel [42].

Table 3.

Properties of diesel, CHNOB (B20), JAMNSOB (B20), and JACKSOB B20 [42].

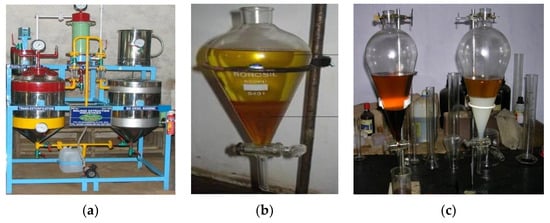

Biodiesels from the three biomass feedstocks selected are prepared by the transesterification process. The setup used for biodiesel production is shown in Figure 1.

Figure 1.

Biodiesel production process: (a) Setup for BDF production; (b) separation of glycerin from BDF; (c) dissolved catalyst removal from BDF [42].

2.2. Experimental Setup

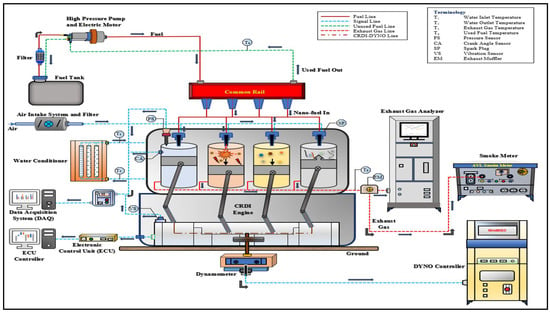

The experimental investigations were carried out on a TV1 Kirloskar make 1-cylinder 4-stroke diesel engine with a displacement volume of 660 cc. The overhead valves are arranged on an open-type combustion chamber. At a rated engine speed of 1500 rpm and compression ratio (CR) of 17.5, 5.2 kW power is obtained. An Eddy current dynamometer was used for the engine loading. The existing diesel engine was modified to operate in CRDI mode which injects pilot fuels at high injection pressures of 1200 bar with single and multiple fuel injection capabilities. The ECU-enabled CRDI mode allowed fuel injection at different injection timings (ITs) with fuel injection flexibility. A pressure transducer (piezo electric pressure transducer) was fixed on the cylinder head for measuring in-cylinder pressure having a resolution of 0.145 mV/kPa (PCB Piezotronics, Model-HSM 111A22). AVL smoke metre and an exhaust gas analyser were used to measure different emissions. All the readings were recorded after the engine attained steady state condition. Figure 2 shows the CRDI experimental setup used for the investigation.

Figure 2.

Schematic view of the experimental test rig (adapted from [43], Elsevier, Amsterdam, The Netherlands, 2021).

Figure 3 shows both a conventional 3-hole nozzle with 0.3 mm orifices which is replaced by a 6-hole CRDI injector with 0.18 mm orifices.

Figure 3.

(a) Conventional injector [44], (b) CRDI injector [43].

Figure 4 shows the CRDI engine test rig used in the study with the ECU (electronic control unit) facility. Figure 5 shows a pressure gauge used for recording the fuel IOP.

Figure 4.

(a) CRDI system integrated CI engine; (b) ECU facilitated CRDI injectors [42].

Figure 5.

Pressure gauge for recording fuel IOP [42].

2.2.1. Heat Release Rate (HRR)

The HRR of the fuel induces changes in temperature inside the cylinder and gas pressure, which has a significant impact on engine power output, emissions, and fuel economy [45]. The heat release rate, Equation (1) at each crank angle is determined using the first law equation, as given below. Energy can be transformed from one form to another but can be neither created nor destroyed. In the current study, 100 cycles of pressure crank angle history are collected and the averaged pressure at each crank angle is used for the HRR calculation:

where is the apparent heat release rate (J), is the ratio of specific heats V is the instantaneous volume of the cylinder (m3), P is the cylinder pressure (bar), and is the heat transfer to the wall (J).

2.2.2. Ignition Delay and Combustion Duration

From the HRR graphs, the start of combustion is estimated. Due to the unexpected high premixed heat release, the slope abruptly rises at the point of ignition. The point where 90% of the heat is released is considered to be combustion termination. Ignition delay corresponds to the crank angle from the start of injection to when the ignition starts.

3. Results

In this section, the diesel engine performance operated on the B20 blends of CHNOB, JAMNSOB, and JACKSOB with diesel are investigated.

3.1. Analysis of Uncertainty

The error analysis of the experimental data is calculated by using systematic calculations. The overall uncertainty is calculated using the following equation:

where y is the specific factor which depends on the parameter xi and Uy is the level of uncertainties or variation in y.

Overall uncertainty =

3.2. Effect of Blends on CRDI Engine Performance

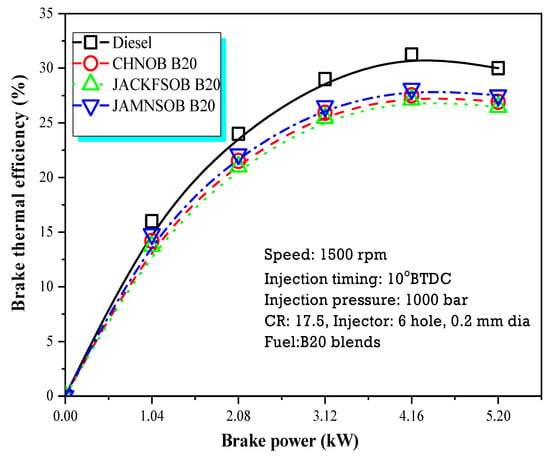

Brake Thermal Efficiency

Figure 6 illustrates the variation of BTE with BP. BTE increases for the blends as the load increases. Compared to all considered blends, JAMNSOB (B20) exhibited good performance followed by JACKSOB (B20) and CHNOB (B20). The reasons could be due to variations in the properties of the respective biodiesel added to diesel. The BTE of the JAMNSOB (B20) blend is almost closer to standard diesel operation. However, petro diesel showed the highest brake thermal efficiency as compared with all blends tested, due to variations in the fuel properties.

Figure 6.

Variation of BTE vs. BP.

3.3. Effect of Blends on CRDI Engine Emissions

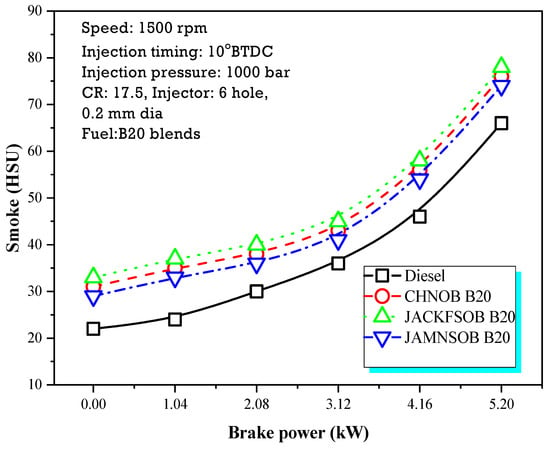

3.3.1. Smoke Emission (SE)

Figure 7 illustrates the variation of smoke vs. BP. As the load increases, emissions also increase, which may be attributed to higher fuel injection with substantial fuel droplet and the associated nonuniform combination of air and fuel mixtures, as well as oxidation. As compared with biodiesel blends, diesel engines often produce less smoke, because of the importance of FFA in biodiesel and the fact that it has a lower oxidation rate. Among all the considered biodiesels, JAMNSOB (B20) performed well as compared with the other B20 blends of CHNOB and JACKSOB. The common properties of diesel (80%) and the respective biodiesels (20%) in the blends determine the patterns of the smoke behavior, as shown in Figure 7.

Figure 7.

Variation of SE vs. BP.

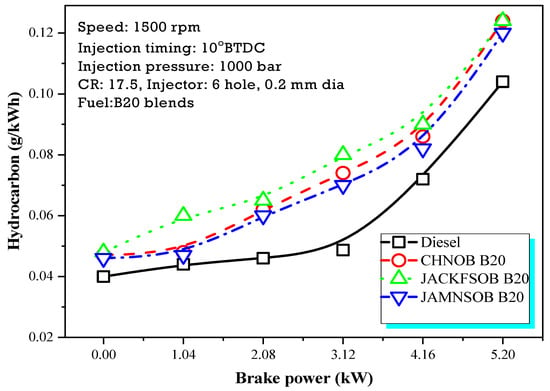

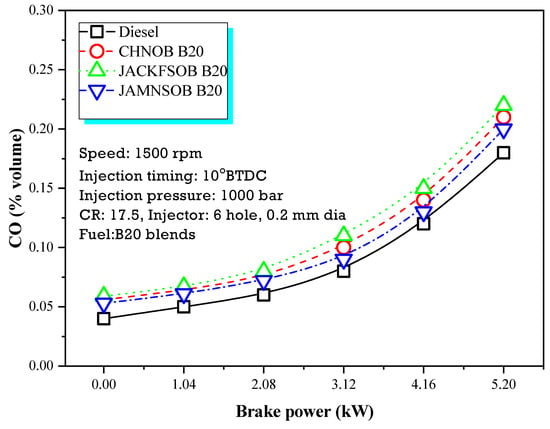

3.3.2. HC Emissions (HCE) and CO Emissions (COE)

Figure 8 and Figure 9 illustrate the variation of HC with BP and the variation of CO with BP. As the load increases, UBHC and CO emissions are also increased. As compared with diesel fuel, biodiesels exhibit more HC and CO emissions. The UBHC and CO emissions increase with increased quantity of biodiesel in the blend. Diesel being common, the properties of the respective biodiesels determine the variation in the HC and CO emission patterns [46]. Later, the presence of moisture in the blends retards the combustion. Among the considered biodiesels, JAMNSOB (B20) emissions are less (which is more similar to conventional fuel) as compared with CHNOB (B20) and JACKSOB (B20). This could be attributed to higher wall impingement and lower BTE obtained with these fuel combinations as compared with JAMUNSOB (B20). In addition, better mixing rates and speedy chemical reactions due to the use of a six-hole fuel injector creates a leaner mixture which assists in self-ignition [47,48,49].

Figure 8.

Variation of HCE vs. BP.

Figure 9.

Variation of COE vs. BP.

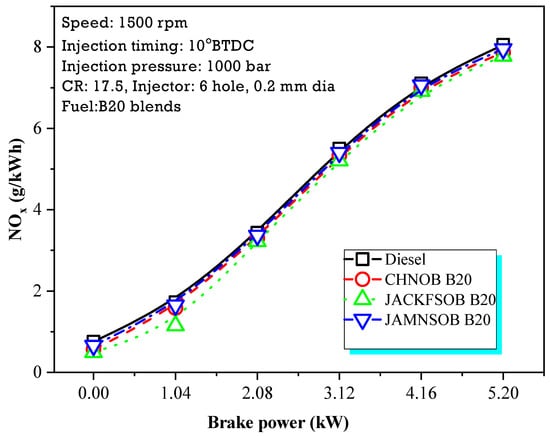

3.3.3. NOx Emissions

Figure 10 illustrates the variations in the NOx emissions of CRDI engine with BP obtained for the various loads. The NOx emissions increase as the load increases. However, the blends resulted in decreased NOx emissions due to improper burning and reduced premixed combustion phase. Further, the presence of moisture in the blends, lower heating value, and poor combustion due to higher viscosity retard the combustion leading to reduced combustion temperature, this in turn lowers the NOx emissions as compared with diesel operation [50,51,52]. JAMNSOB (B20) operation exhibits higher NOx emissions as compared with other biodiesel blends. The main reasons for the NOx emissions are higher in-cylinder gas temperatures, oxygen availability, and residual time during combustion of these B20 blends. The oxygen content is higher in pure biodiesel (B100). For the B20 blends of the respective biodiesel’s tested, the volume of the biodiesel contributes only 20% in the blend. Further, the diesel combustion involves higher premixed combustion peaks as compared with their counterpart biodiesel blends. The higher in-cylinder temperatures associated with higher cetane numbers of diesel fuel as compared with biodiesel blends contribute to higher NOx emissions [42].

Figure 10.

Variation of NOx emissions vs. BP.

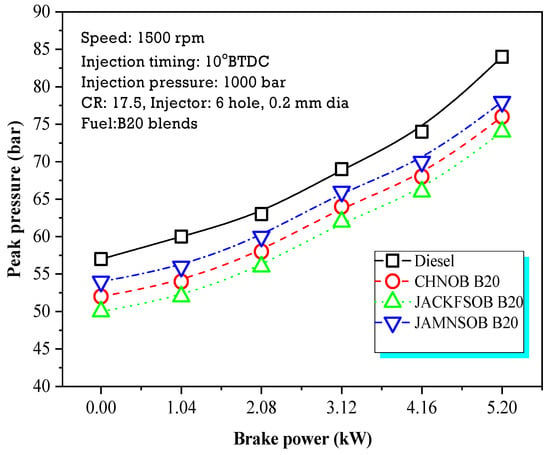

3.4. Effect of Blends on CRDI Engine Combustion Parameters

Figure 11 shows the variation in peak pressure (PP) of the CRDI diesel engine with different fuel combinations. PP increases with an increase in load as more pilot fuel is injected. Among the considered biodiesels, JAMNSOB (B20) shows higher PP as compared with CHNOB (B20) and JACKSOB (B20).

Figure 11.

Variation of PP vs. BP.

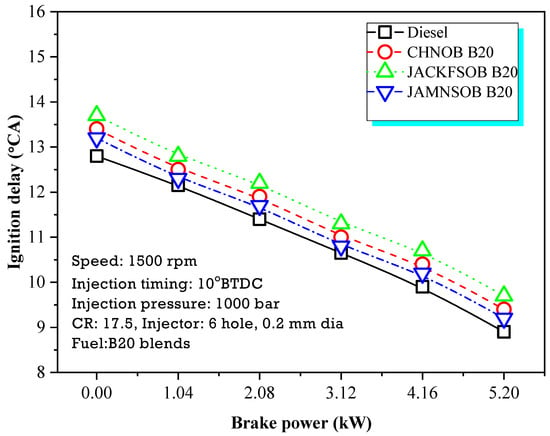

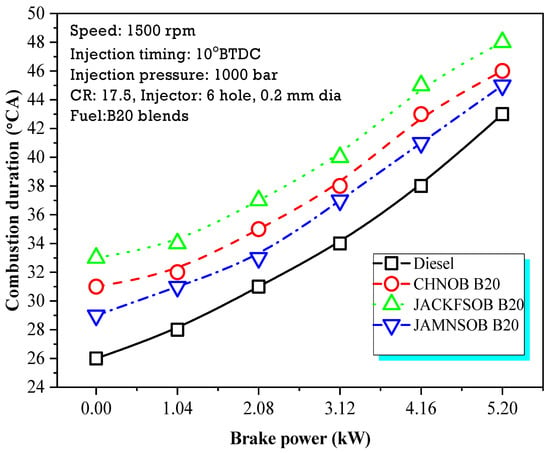

Figure 12 and Figure 13 show the variations of ID and CD, respectively, with BP for the considered biodiesel blends. The ID is observed to decrease as the biodiesel content increases. For the no-load condition, the delay period is found be maximum because of the lower in-cylinder temperatures. Among the considered biodiesels, JACKSOB biodiesel shows higher ID and CD as compared with diesel and the other B20 blends due to a decreased mixing rate and reduced chemical kinetics for biodiesel operation, followed by CHNOB (B20) and JAMNSOB (B20). However, diesel operation that resulted in less ID as compared with B20 blends may be attributed to better mixing rates and speedy chemical reactions due to the use of a 6-hole fuel injector which creates a leaner mixture which assists in self-ignition. JAMNSOB (B20) shows lower ID and CD as compared with other biodiesels but higher than conventional diesel fuel [42].

Figure 12.

Variation of ID vs. BP.

Figure 13.

Variation of CD vs. BP.

CRDI engine fueled with JAMNSOB (B20) exhibited overall good engine characteristics in all aspects.

3.5. Variation of In-Cylinder Pressure and Heat Release Rate with Crank Angle

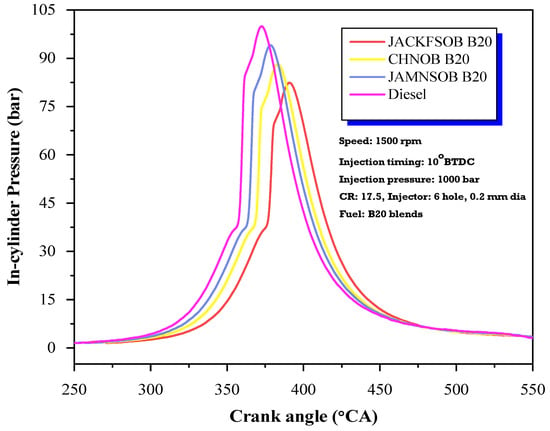

3.5.1. In-Cylinder Pressure

Figure 14 shows the variation of in-cylinder pressure versus crank angle for JAMNSOB (B20) with diesel at 80% load condition. The cylinder pressure is determined by the rate of combustion and the type of fuel used during the unregulated combustion period. The delay period has a major impact on the unregulated combustion process. Due to the fast mixing of fuel particles with air and the higher heat release rate during the rapid combustion process, higher cylinder pressure is obtained for diesel followed by JAMUNSOB (B20), JACKFSNOB (B20), and CHNOB (B20).

Figure 14.

Variation of CP vs. CA.

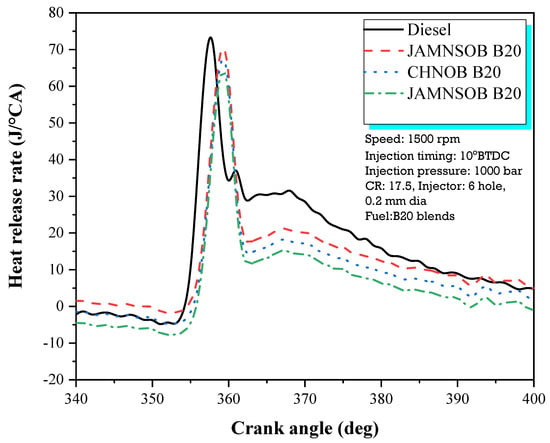

3.5.2. Heat Release Rate

Figure 15 presents the HRR for the JAMNSOB (B20) blend with diesel at 80% load condition. The HRR is found, as explained in the section on experimental setup. For diesel engines, the premixed burning process is crucial. Therefore, the JAMNSOB (B20) blend has a better thermal quality than other diesel blends. As compared with diesel activity, the diffusion combustion process shown by the second peak is higher for JAMNSOB (B20). This effect with biodiesel is due to incomplete combustion caused by the higher viscosity of biodiesel blends and reduced air entrainment and air-fuel mixing rates [53,54,55,56,57]. This results in lower fuel and air mixing during a delay period leading to lower rapid combustion phase with biodiesel. Higher combustion rates are observed for biodiesel during the later stages, and lead to higher exhaust temperatures and lower thermal efficiency.

Figure 15.

Variation of HRR vs. CA.

4. Conclusions

The application of B20 blends in a CRDI engine shows that the properties of the respective B20 blends can significantly influence the overall characteristics which are influenced by respective fuel properties.

- ➢

- From the experimental investigations, for high viscous fuel B20 blend operations, it is observed that biodiesel blend B20 operation results in improved performance with lower emissions.

- ➢

- Among the biodiesel blends, JAMUNSOB (B20) and JACKFSNOB (B20) show improved performance as compared with CHNOB (B20).

- ➢

- As compared with diesel fuel, BDFs exhibited lower NOx emissions, but higher HC, CO, and smoke emissions.

- ➢

- Among all the considered BDFs, JAMNSOB (B20) exhibited good performance in all aspects with lower emissions.

- ➢

- At a BP of 1.04 kW, for Jamun seed B20 operation, BTE, NOx, and PP increased by 8.01%, 2.4%, 7.69%, respectively, and smoke, HC, CO, ID, and CD decreased by 10.81%, 13.79%, 8.9%, 3.9%, and 8.8%, respectively, as compared with jackfruit B20 operation.

- ➢

- At a BP of 2.08 kW, for Jamun seed B20 operation, BTE, NOx, and PP increased by 5.33%, 1.2%, and 5.45%, respectively, and smoke, HC, CO, ID, and CD decreased by 10%, 12.129%, 7.69%, 4.0%, and 10.80%, respectively, as compared with jackfruit B20 operation.

- ➢

- At a BP of 3.12 kW, for Jamun seed B20 operation, BTE, NOx, and PP increased by 4.20%, 0.7%, and 6.45%, respectively, and smoke, HC, CO, ID, and CD decreased by 9.3%, 10.26%, 8.8%, 4.4%, and 7.5%, respectively, as compared with jackfruit B20 operation.

- ➢

- At a BP of 4.16 kW, for Jamun seed B20 operation, BTE, NOx, and PP increased by 3.68%, 0.5%, and 6.06%, respectively, and smoke, HC, CO, ID, and CD decreased by 7.14%, 8.8%, 4.05%, 4.6%, and 6.66%, respectively, as compared with jackfruit B20 operation.

- ➢

- Ø At a BP of 5.2 kW, for Jamun seed B20 operation, BTE, NOx, and PP increased by 4.04%, 0.56%, and 5.4%, respectively, and smoke, HC, CO, ID, and CD decreased by 5.12%, 6.25%, 2.75%, 5.15%, and 6.25%, as compared with jackfruit B20 operation.

5. Future Scope

Research and industry are working on conventional diesel combustion and developing innovative combustion systems to improve CO2 and NOx-Soot trade-offs such as specific bowl design, innovative fuel injection systems, and the injection strategy. In addition, in the future, friction losses and energy balance can be compared to a baseline. The use of ducted fuel injection (DFI) in a CI engine may improve the combustion phenomenon.

Author Contributions

Conceptualization, K.M.V.R.T., N.R.B. and P.I.P.; methodology, K.M.V.R.T. and N.R.B.; software, M.E.M.S.; validation, M.E.M.S.; formal analysis, K.M.V.R.T., N.R.B. and M.E.M.S.; investigation, K.M.V.R.T., N.R.B. and M.E.M.S.; resources, N.R.B.; writing—original draft preparation, K.M.V.R.T. and N.R.B.; writing—review and editing, A.A., N.H. and C.A.S.; supervision, P.I.P., K.V.K.R. and N.R.B.; project administration, P.I.P., K.V.K.R. and N.R.B.; funding acquisition, A.A., N.H. and C.A.S. All authors have read and agreed to the published version of the manuscript.

Funding

Deanship of Scientific Research, Research Group Program Grant No. R.G.P.1/104/42, King Khalid University, Saudi Arabia.

Institutional Review Board Statement

Not Applicable.

Informed Consent Statement

Not Applicable.

Acknowledgments

The authors extend their appreciation to the Deanship of Scientific Research at King Khalid University, Saudi Arabia for funding this work through the Research Group Program under grant no. R.G.P.1/104/42.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Wategave, S.; Banapurmath, N.; Sawant, M.; Soudagar, M.E.M.; Mujtaba, M.; Afzal, A.; Basha, J.S.; Alazwari, M.A.; Safaei, M.R.; Elfasakhany, A. Clean combustion and emissions strategy using reactivity controlled compression ignition (RCCI) mode engine powered with CNG-Karanja biodiesel. J. Taiwan Inst. Chem. Eng. 2021, 124, 116–131. [Google Scholar] [CrossRef]

- Sateesh, K.A.; Yaliwal, V.S.; Soudagar, M.E.M.; Banapurmath, N.R.; Fayaz, H.; Safaei, M.R.; Elfasakhany, A.; El-Seesy, A.I. Utilization of biodiesel/Al2O3 nanoparticles for combustion behavior enhancement of a diesel engine operated on dual fuel mode. J. Therm. Anal. Calorim. 2021. [Google Scholar] [CrossRef]

- Mujtaba, M.A.; Kalam, M.A.; Masjuki, H.H.; Razzaq, L.; Khan, H.M.; Soudagar, M.E.M.; Gul, M.; Ahmed, W.; Raju, V.D.; Kumar, R.; et al. Development of empirical correlations for density and viscosity estimation of ternary biodiesel blends. Renew. Energy 2021, 179, 1447–1457. [Google Scholar] [CrossRef]

- Mueller, C.J.; Boehman, A.L.; Martin, G.C. An experimental investigation of the origin of increased NOx emissions when fueling a heavy-duty compression-ignition engine with soy biodiesel. SAE Int. J. Fuels Lubr. 2009, 2, 789–816. [Google Scholar] [CrossRef] [Green Version]

- Venu, H.; Raju, V.D.; Lingesan, S.; Soudagar, M.E.M. Influence of Al2O3nano additives in ternary fuel (diesel-biodiesel-ethanol) blends operated in a single cylinder diesel engine: Performance, Combustion and Emission Characteristics. Energy 2021, 215, 119091. [Google Scholar] [CrossRef]

- Prasad, K.B.; Raju, V.D.; Shaik, A.A.; Gopidesi, R.K.; Reddy, M.B.S.S.; Soudagar, M.E.M.; Mujtaba, M.A. Impact of injection timings and exhaust gas recirculation rates on the characteristics of diesel engine operated with neat tamarind biodiesel. Energy Sources Part A Recovery Util. Environ. Eff. 2021, 1–19. [Google Scholar] [CrossRef]

- Mujtaba, M.; Kalam, M.; Masjuki, H.; Gul, M.; Soudagar, M.E.M.; Ong, H.C.; Ahmed, W.; Atabani, A.; Razzaq, L.; Yusoff, M. Comparative study of nanoparticles and alcoholic fuel additives-biodiesel-diesel blend for performance and emission improvements. Fuel 2020, 279, 118434. [Google Scholar] [CrossRef]

- El-Seesy, A.I.; Hassan, H.; Ibraheem, L.; He, Z.; Soudagar, M.E.M. Combustion, emission, and phase stability features of a diesel engine fueled by Jatropha/ethanol blends and n-butanol as co-solvent. Int. J. Green Energy 2020, 17, 793–804. [Google Scholar] [CrossRef]

- Dimitrakopoulos, N.; Belgiorno, G.; Tunér, M.; Tunestål, P.; Di Blasio, G. Effect of EGR routing on efficiency and emissions of a PPC engine. Appl. Therm. Eng. 2019, 152, 742–750. [Google Scholar] [CrossRef]

- Afzal, A.; Soudagar, M.E.M.; Belhocine, A.; Kareemullah, M.; Hossain, N.; Alshahrani, S.; Saleel, C.A.; Subbiah, R.; Qureshi, F.; Mujtaba, M.A. Thermal Performance of Compression Ignition Engine Using High Content Biodiesels: A Comparative Study with Diesel Fuel. Sustainability 2021, 13, 7688. [Google Scholar] [CrossRef]

- Gavhane, R.S.; Kate, A.M.; Pawar, A.; Safaei, M.R.; Soudagar, M.E.M.; Abbas, M.M.; Ali, H.M.; Banapurmath, N.R.; Goodarzi, M.; Badruddin, I.A. Effect of Zinc Oxide Nano-Additives and Soybean Biodiesel at Varying Loads and Compression Ratios on VCR Diesel Engine Characteristics. Symmetry 2020, 12, 1042. [Google Scholar] [CrossRef]

- Harari, P.; Banapurmath, N.; Yaliwal, V.; Khan, T.Y.; Soudagar, M.E.M.; Sajjan, A. Experimental studies on performance and emission characteristics of reactivity controlled compression ignition (RCCI) engine operated with gasoline and Thevetia Peruviana biodiesel. Renew. Energy 2020, 160, 865–875. [Google Scholar] [CrossRef]

- Mujtaba, M.; Masjuki, H.; Kalam, M.; Ong, H.C.; Gul, M.; Farooq, M.; Soudagar, M.E.M.; Ahmed, W.; Harith, M.; Yusoff, M. Ultrasound-assisted process optimization and tribological characteristics of biodiesel from palm-sesame oil via response surface methodology and extreme learning machine-Cuckoo search. Renew. Energy 2020, 158, 202–214. [Google Scholar] [CrossRef]

- Soudagar, M.E.M.; Banapurmath, N.R.; Afzal, A.; Hossain, N.; Abbas, M.M.; Haniffa, M.A.C.M.; Naik, B.; Ahmed, W.; Nizamuddin, S.; Mubarak, N.M. Study of diesel engine characteristics by adding nanosized zinc oxide and diethyl ether additives in Mahua biodiesel–diesel fuel blend. Sci. Rep. 2020, 10, 15326. [Google Scholar] [CrossRef]

- Venkatesan, K. Experimental investigation on performance of cashew nut shell pyrolysed oil blend with bio diesel and diesel. Int. J. Chem. Sci. 2016, 14, 2918–2926. [Google Scholar]

- Pandian, A.K.; Munuswamy, D.B.; Radhakrishanan, S.; Devarajan, Y.; Ramakrishnan, R.B.B.; Nagappan, B. Emission and performance analysis of a diesel engine burning cashew nut shell oil bio diesel mixed with hexanol. Pet. Sci. 2018, 15, 176–184. [Google Scholar] [CrossRef] [Green Version]

- Thanigaivelan, V.; Loganathan, M. Investigational Analysis of Performance Characteristics and Emission of Cashew Nut Shell Biodiesel on Di Diesel Engine. Int. J. Adv. Res. Eng. Technol. 2019, 10, 10. [Google Scholar] [CrossRef]

- Raghavendra Prasada, S. A Review on CNSL Biodiesel as an Alternative fuel for Diesel Engine. Int. J. Sci. Res. 2014, 3, 2028–2038. [Google Scholar]

- Santhanakrishnan, S.; Jose, S. Performance and Emission Evaluation of a Diesel Engine Fuelled with Cashew Nut Shell Oil Blends. In Advanced Materials Research; Trans Tech Publications Ltd.: Stafa-Zurich, Switzerland, 2014; pp. 893–899. [Google Scholar]

- Jagadish, D. Effect of fuel injection pressure on performance of constant-speed diesel engine fuelled with biofuel mixtures. Biofuels 2017, 8, 537–541. [Google Scholar] [CrossRef]

- Loganathan, M.; Madhavan, V.; Balasubramanian, K.A.; Thanigaivelan, V.; Vikneswaran, M.; Anbarasu, A. Investigation on the effect of diethyl ether with hydrogen-enriched cashew nut shell (CNS) biodiesel in direct injection (DI) diesel engine. Fuel 2020, 277, 118165. [Google Scholar] [CrossRef]

- Loganathan, M.; Thanigaivelan, V.; Madhavan, V.; Anbarasu, A.; Velmurugan, A. The synergetic effect between hydrogen addition and EGR on cashew nut shell liquid biofuel-diesel operated engine. Fuel 2020, 266, 117004. [Google Scholar] [CrossRef]

- Singh, M.; Sandhu, S.S. Performance, emission and combustion characteristics of multi-cylinder CRDI engine fueled with argemone biodiesel/diesel blends. Fuel 2020, 265, 117024. [Google Scholar] [CrossRef]

- Duda, K.; Wierzbicki, S.; Śmieja, M.; Mikulski, M. Comparison of performance and emissions of a CRDI diesel engine fuelled with biodiesel of different origin. Fuel 2018, 212, 202–222. [Google Scholar] [CrossRef]

- Dharmaraja, J.; Nguyen, D.D.; Shobana, S.; Saratale, G.D.; Arvindnarayan, S.; Atabani, A.; Chang, S.W.; Kumar, G. Engine performance, emission and bio characteristics of rice bran oil derived biodiesel blends. Fuel 2019, 239, 153–161. [Google Scholar] [CrossRef]

- Calder, J.; Roy, M.M.; Wang, W. Performance and emissions of a diesel engine fueled by biodiesel-diesel blends with recycled expanded polystyrene and fuel stabilizing additive. Energy 2018, 149, 204–212. [Google Scholar] [CrossRef]

- Tayari, S.; Abedi, R.; Rahi, A. Comparative assessment of engine performance and emissions fueled with three different biodiesel generations. Renew. Energy 2020, 147, 1058–1069. [Google Scholar] [CrossRef]

- Nabi, M.N.; Rasul, M.; Anwar, M.; Mullins, B. Energy, exergy, performance, emission and combustion characteristics of diesel engine using new series of non-edible biodiesels. Renew. Energy 2019, 140, 647–657. [Google Scholar] [CrossRef]

- Shameer, P.M.; Ramesh, K. Experimental evaluation on performance, combustion behavior and influence of in-cylinder temperature on NOx emission in a DI diesel engine using thermal imager for various alternate fuel blends. Energy 2017, 118, 1334–1344. [Google Scholar] [CrossRef]

- Can, Ö.; Öztürk, E.; Yücesu, H.S. Combustion and exhaust emissions of canola biodiesel blends in a single cylinder DI diesel engine. Renew. Energy 2017, 109, 73–82. [Google Scholar] [CrossRef]

- Cheng, L.-H.; Yeh, C.-F.; Tsai, K.-C.; Lee, P.-F.; Tseng, T.-P.; Huang, L.-J.; Yeh, S.-H.; Hsu, H.-T.; Lin, C.-H.; Lai, C.-H. Effect of pool fire scale of heavy fuel oil on the characteristics of PAH emissions. Fuel 2019, 235, 933–943. [Google Scholar] [CrossRef]

- Zhang, Y.; Li, Z.; Tamilselvan, P.; Jiang, C.; He, Z.; Zhong, W.; Qian, Y.; Wang, Q.; Lu, X. Experimental study of combustion and emission characteristics of gasoline compression ignition (GCI) engines fueled by gasoline-hydrogenated catalytic biodiesel blends. Energy 2019, 187, 115931. [Google Scholar] [CrossRef]

- Simsek, S. Effects of biodiesel obtained from Canola, sefflower oils and waste oils on the engine performance and exhaust emissions. Fuel 2020, 265, 117026. [Google Scholar] [CrossRef]

- Yaşar, F. Comparision of fuel properties of biodiesel fuels produced from different oils to determine the most suitable feedstock type. Fuel 2020, 264, 116817. [Google Scholar] [CrossRef]

- Wang, S.; Karthickeyan, V.; Sivakumar, E.; Lakshmikandan, M. Experimental investigation on pumpkin seed oil methyl ester blend in diesel engine with various injection pressure, injection timing and compression ratio. Fuel 2020, 264, 116868. [Google Scholar] [CrossRef]

- Kumar, M.V.; Babu, A.V.; Kumar, P.R. Experimental investigation on the effects of diesel and mahua biodiesel blended fuel in direct injection diesel engine modified by nozzle orifice diameters. Renew. Energy 2018, 119, 388–399. [Google Scholar] [CrossRef]

- Kamta Legue, D.R.; Ayissi, Z.M.; Babikir, M.H.; Obounou, M.; Ekobena Fouda, H.P. Experimental and Simulation of Diesel Engine Fueled with Biodiesel with Variations in Heat Loss Model. Energies 2021, 14, 1622. [Google Scholar] [CrossRef]

- Monsalve-Serrano, J.; Belgiorno, G.; Di Blasio, G.; Guzmán-Mendoza, M. 1D simulation and experimental analysis on the effects of the injection parameters in methane–diesel dual-fuel combustion. Energies 2020, 13, 3734. [Google Scholar] [CrossRef]

- Belgiorno, G.; Boscolo, A.; Dileo, G.; Numidi, F.; Pesce, F.C.; Vassallo, A.; Ianniello, R.; Beatrice, C.; Di Blasio, G. Experimental study of additive-manufacturing-enabled innovative diesel combustion bowl features for achieving ultra-low emissions and high efficiency. SAE Int. J. Adv. Curr. Pract. Mobil. 2020, 3, 672–684. [Google Scholar] [CrossRef]

- Blasio, G.D.; Vassallo, A.; Pesce, F.C.; Beatrice, C.; Belgiorno, G.; Avolio, G. The Key Role of Advanced, Flexible Fuel Injection Systems to Match the Future CO₂ Targets in an Ultra-Light Mid-Size Diesel Engine. SAE Int. J. Engines 2019, 12, 129–144. [Google Scholar] [CrossRef]

- Varuvel, E.G.; Sonthalia, A.; Subramanian, T.; Aloui, F. NOx-smoke trade-off characteristics of minor vegetable oil blends synergy with oxygenate in a commercial CI engine. Environ. Sci. Pollut. Res. 2018, 25, 35715–35724. [Google Scholar] [CrossRef]

- Teja, K.M.V.R.; Prasad, P.I.; Reddy, K.V.K.; Banapurmath, N.R.; Soudagar, M.E.M.; Khan, T.M.Y.; Badruddin, I.A. Influence of Combustion Chamber Shapes and Nozzle Geometry on Performance, Emission, and Combustion Characteristics of CRDI Engine Powered with Biodiesel Blends. Sustainability 2021, 13, 9613. [Google Scholar] [CrossRef]

- Soudagar, M.E.M.; Mujtaba, M.; Safaei, M.R.; Afzal, A.; Ahmed, W.; Banapurmath, N.; Hossain, N.; Bashir, S.; Badruddin, I.A.; Goodarzi, M. Effect of Sr@ ZnO nanoparticles and Ricinus communis biodiesel-diesel fuel blends on modified CRDI diesel engine characteristics. Energy 2021, 215, 119094. [Google Scholar] [CrossRef]

- Akkoli, K.; Banapurmath, N.; Shivashimpi, M.; Soudagar, M.E.M.; Badruddin, I.A.; Alazwari, M.A.; Yaliwal, V.; Mujtaba, M.; Akram, N.; Goodarzi, M. Effect of injection parameters and producer gas derived from redgram stalk on the performance and emission characteristics of a diesel engine. Alex. Eng. J. 2021, 60, 3133–3142. [Google Scholar] [CrossRef]

- Soudagar, M.E.M.; Nik-Ghazali, N.-N.; Kalam, M.; Badruddin, I.A.; Banapurmath, N.; Khan, T.Y.; Bashir, M.N.; Akram, N.; Farade, R.; Afzal, A. The effects of graphene oxide nanoparticle additive stably dispersed in dairy scum oil biodiesel-diesel fuel blend on CI engine: Performance, emission and combustion characteristics. Fuel 2019, 257, 116015. [Google Scholar] [CrossRef]

- Soudagar, M.E.M.; Khan, H.M.; Khan, T.; Razzaq, L.; Asif, T.; Mujtaba, M.; Hussain, A.; Farooq, M.; Ahmed, W.; Shahapurkar, K. Experimental Analysis of Engine Performance and Exhaust Pollutant on a Single-Cylinder Diesel Engine Operated Using Moringa Oleifera Biodiesel. Appl. Sci. 2021, 11, 7071. [Google Scholar] [CrossRef]

- Blasio, G.D.; Bonura, G.; Frusteri, F.; Beatrice, C.; Cannilla, C.; Viscardi, M. Experimental characterization of diesel combustion using glycerol derived ethers mixtures. SAE Int. J. Fuels Lubr. 2013, 6, 940–950. [Google Scholar] [CrossRef]

- Nilsen, C.W.; Biles, D.E.; Yraguen, B.F.; Mueller, C.J. Ducted Fuel Injection vs. Conventional Diesel Combustion: Extending the Load Range in an Optical Engine with a Four-Orifice Fuel Injector. SAE Int. J. Engines 2021, 14, 47–58. [Google Scholar] [CrossRef]

- Nilsen, C.W.; Biles, D.E.; Mueller, C.J. Using ducted fuel injection to attenuate soot formation in a mixing-controlled compression ignition engine. SAE Int. J. Engines 2019, 12, 309–322. [Google Scholar] [CrossRef]

- Soudagar, M.E.M.; Afzal, A.; Safaei, M.R.; Manokar, A.M.; EL-Seesy, A.I.; Mujtaba, M.; Samuel, O.D.; Badruddin, I.A.; Ahmed, W.; Shahapurkar, K. Investigation on the effect of cottonseed oil blended with different percentages of octanol and suspended MWCNT nanoparticles on diesel engine characteristics. J. Therm. Anal. Calorim. 2020, 1–18. [Google Scholar] [CrossRef]

- Khan, H.; Kareemullah, M.; Ravi, H.; Rehman, K.F.; Kumar, R.H.; Afzal, A.; Soudagar, M.E.M.; Fayaz, H. Combined effect of synthesized waste milk scum oil methyl ester and ethanol fuel blend on the diesel engine characteristics. J. Inst. Eng. Ser. C 2020, 101, 947–962. [Google Scholar] [CrossRef]

- Soudagar, M.; Afzal, A.; Kareemullah, M. Waste coconut oil methyl ester with and without additives as an alternative fuel in diesel engine at two different injection pressures. Energy Sources Part A Recovery Util. Environ. Eff. 2020. [Google Scholar] [CrossRef]

- Fayaz, H.; Mujtaba, M.; Soudagar, M.E.M.; Razzaq, L.; Nawaz, S.; Nawaz, M.A.; Farooq, M.; Afzal, A.; Ahmed, W.; Khan, T.Y. Collective effect of ternary nano fuel blends on the diesel engine performance and emissions characteristics. Fuel 2021, 293, 120420. [Google Scholar] [CrossRef]

- Kareemullah, M.; Afzal, A.; Rehman, K.F.; Vishwanath, K.C.; Khan, H.; Soudagar, M.E.M.; Kaladgi, A.R. Preparation and physicochemical properties evaluation of epoxidized neem oil-based bio-lubricant. Aust. J. Mech. Eng. 2021, 1–10. [Google Scholar] [CrossRef]

- Keerthi Kumar, N.; Banapurmath, N.; Chandrashekar, T.; Jatadhara, G.; Soudagar, M.E.M.; Anqi, A.E.; Mujtaba, M.; Goodarzi, M.; Elfasakhany, A.; Siddiqui, M.I.H. Effect of Parameters Behavior of Simarouba Methyl Ester Operated Diesel Engine. Energies 2021, 14, 4973. [Google Scholar] [CrossRef]

- Usman, M.; Hussain, H.; Riaz, F.; Irshad, M.; Bashir, R.; Shah, M.H.; Zafar, A.A.; Bashir, U.; Kalam, M.; Mujtaba, M. Artificial Neural Network Led Optimization of Oxyhydrogen Hybridized Diesel Operated Engine. Sustainability 2021, 13, 9373. [Google Scholar] [CrossRef]

- Aneeque, M.; Alshahrani, S.; Kareemullah, M.; Afzal, A.; Saleel, C.A.; Soudagar, M.E.M.; Hossain, N.; Subbiah, R.; Ahmed, M.H. The Combined Effect of Alcohols and Calophyllum inophyllum Biodiesel Using Response Surface Methodology Optimization. Sustainability 2021, 13, 7345. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).