An In-Depth Life Cycle Assessment (LCA) of Lithium-Ion Battery for Climate Impact Mitigation Strategies

Abstract

:1. Introduction

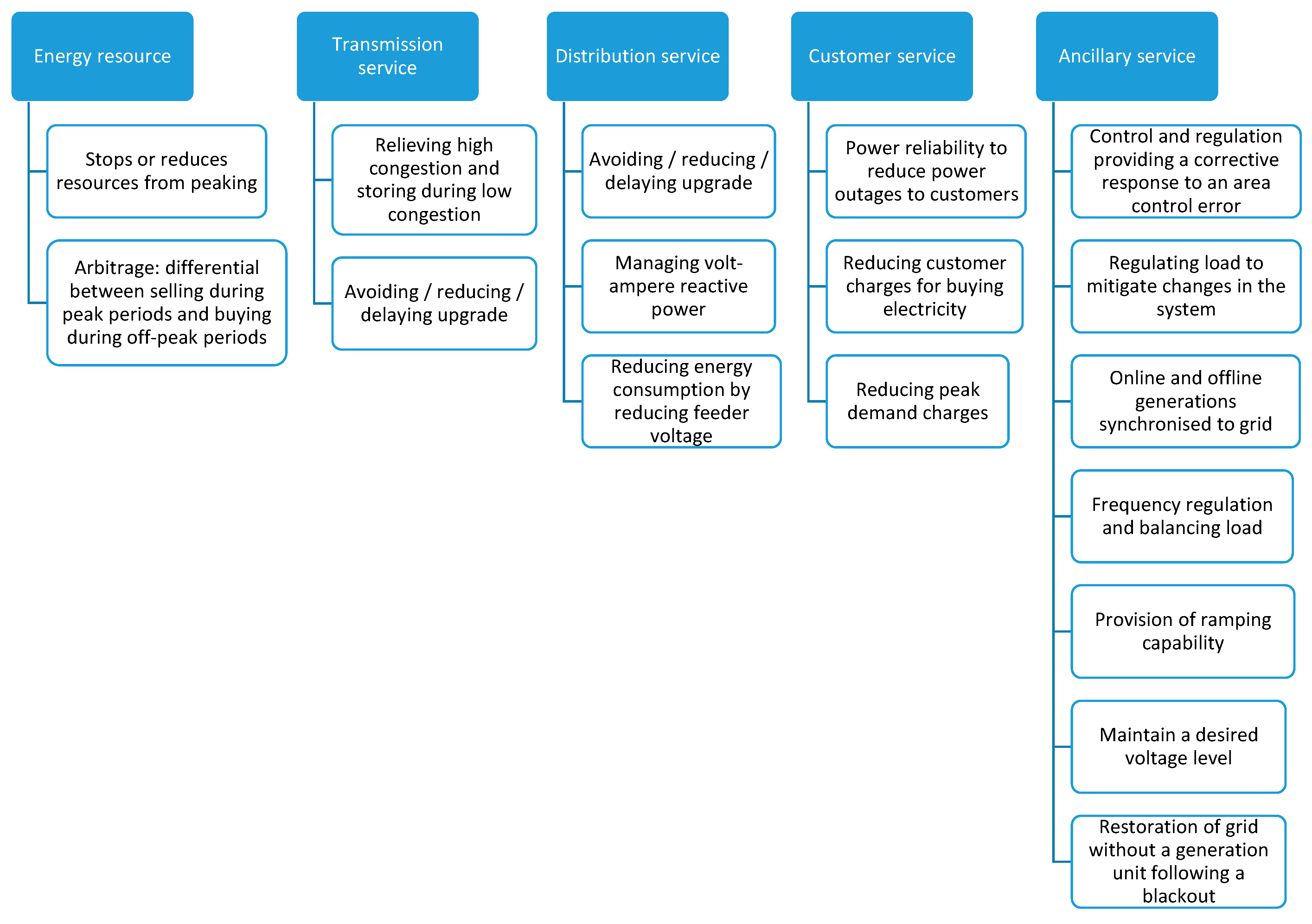

2. Literature Review for the Technical and Environmental Performances of BESS

3. Materials and Methods

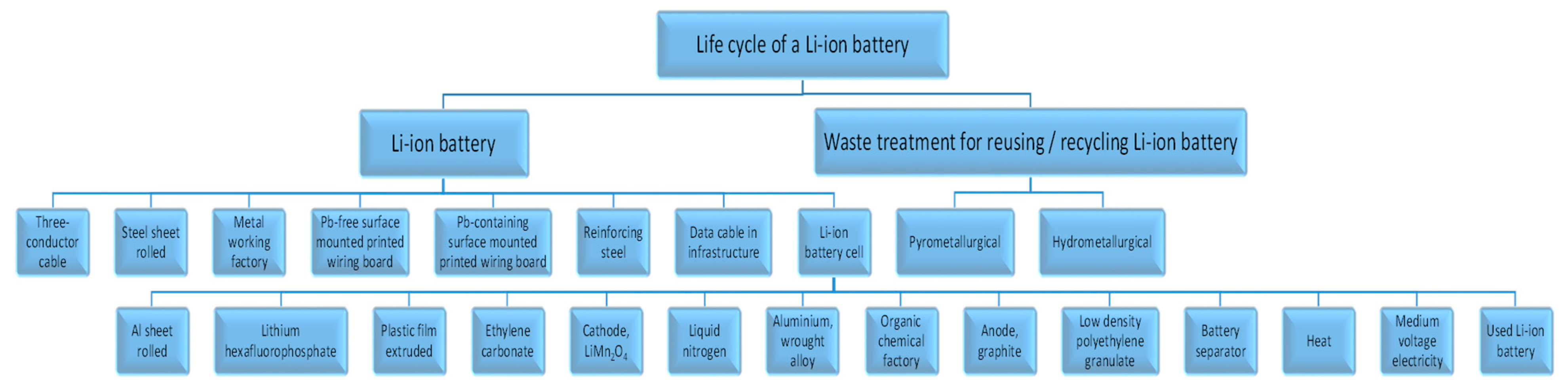

4. System Boundary and Life Cycle Inventory Analysis of BESS

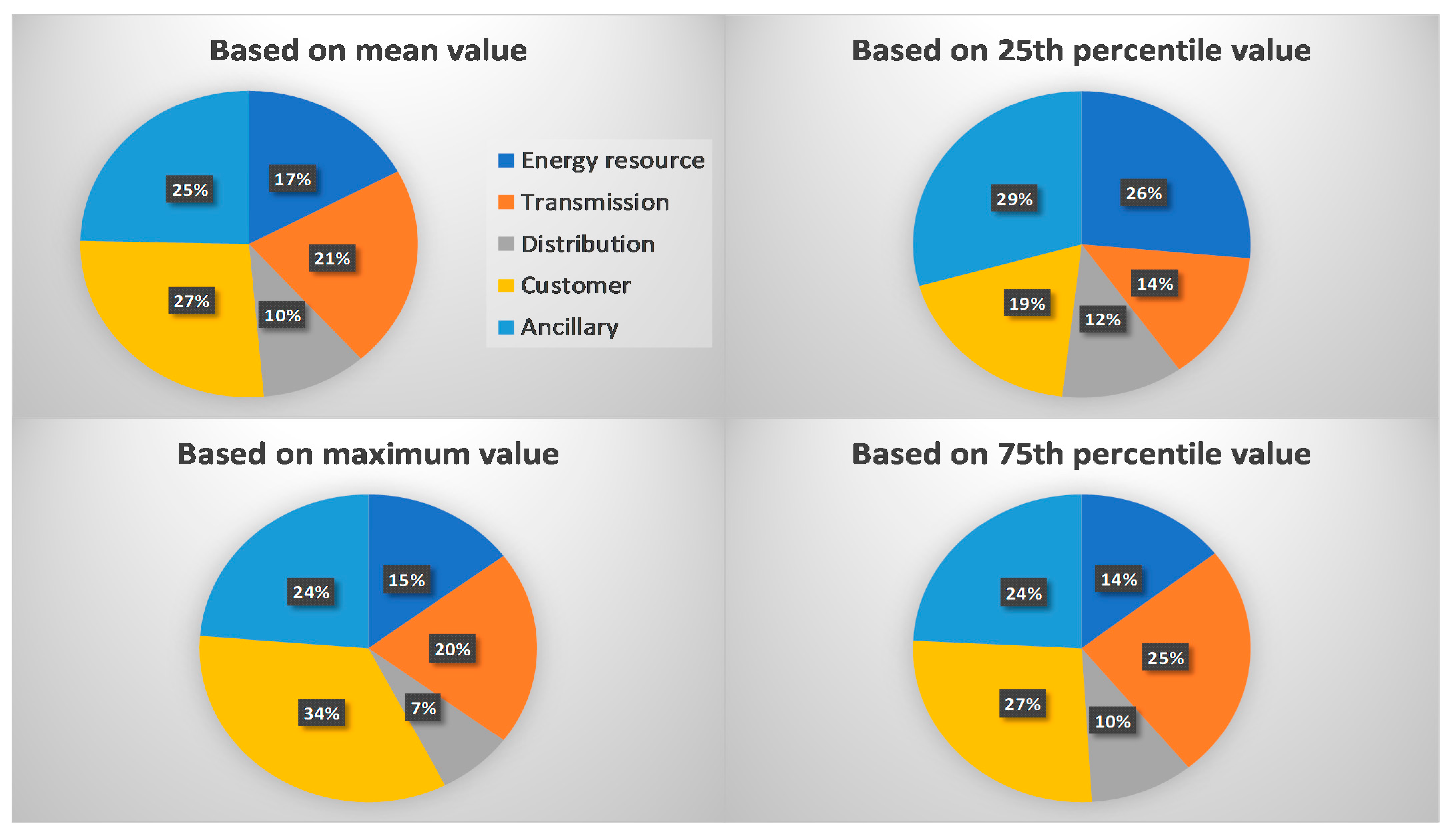

5. Results of LCA of BESS and BESS-Connected Renewable Energy Systems

5.1. Overall GWP Analysis of BESS

- Allocation at the point of substitution: 6.7 kg CO2 eq per kg of lithium-ion battery

- Cut-off: 8.1 kg CO2 eq per kg of lithium-ion battery

- Consequential: 1.7 kg CO2 eq per kg of lithium-ion battery

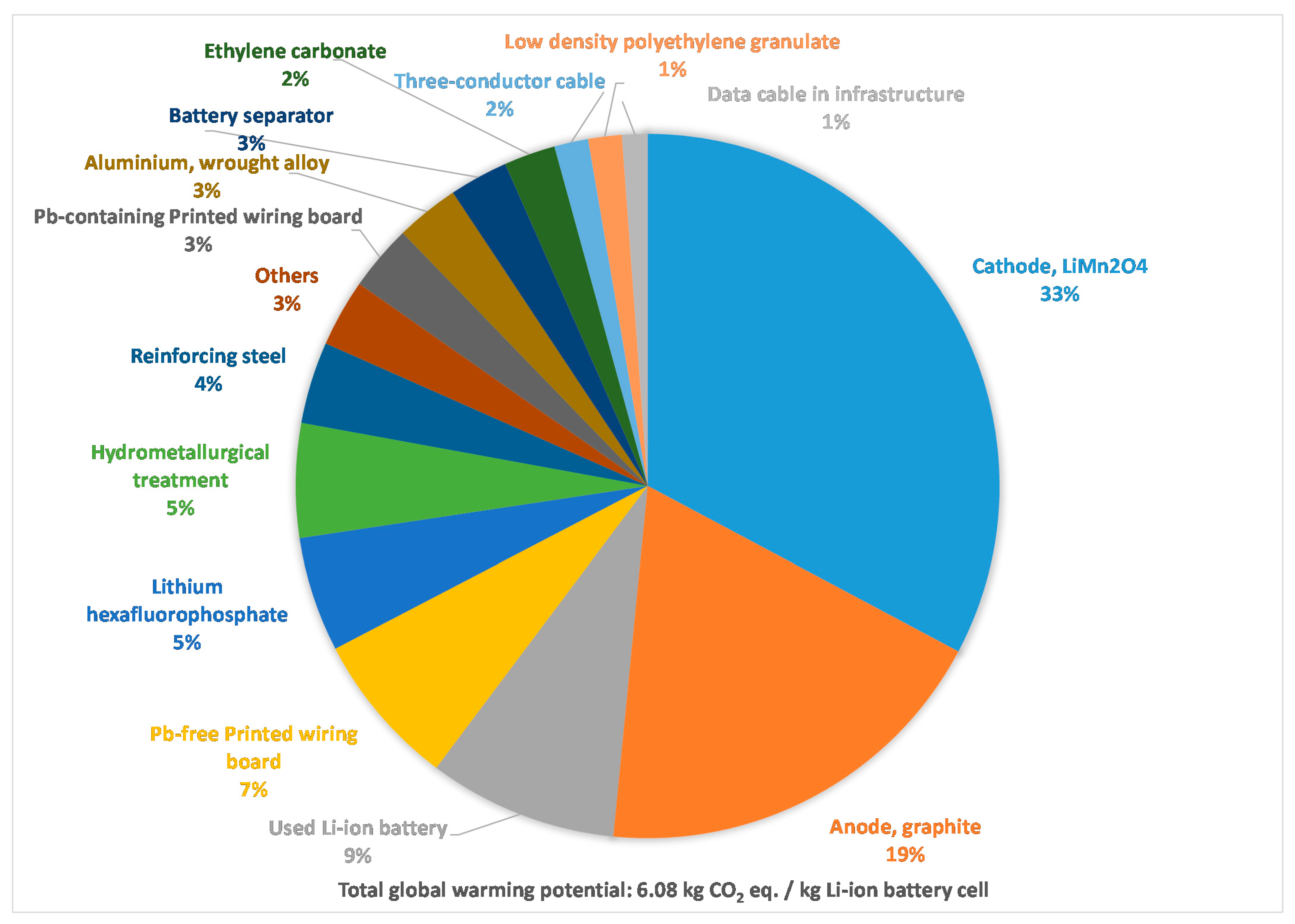

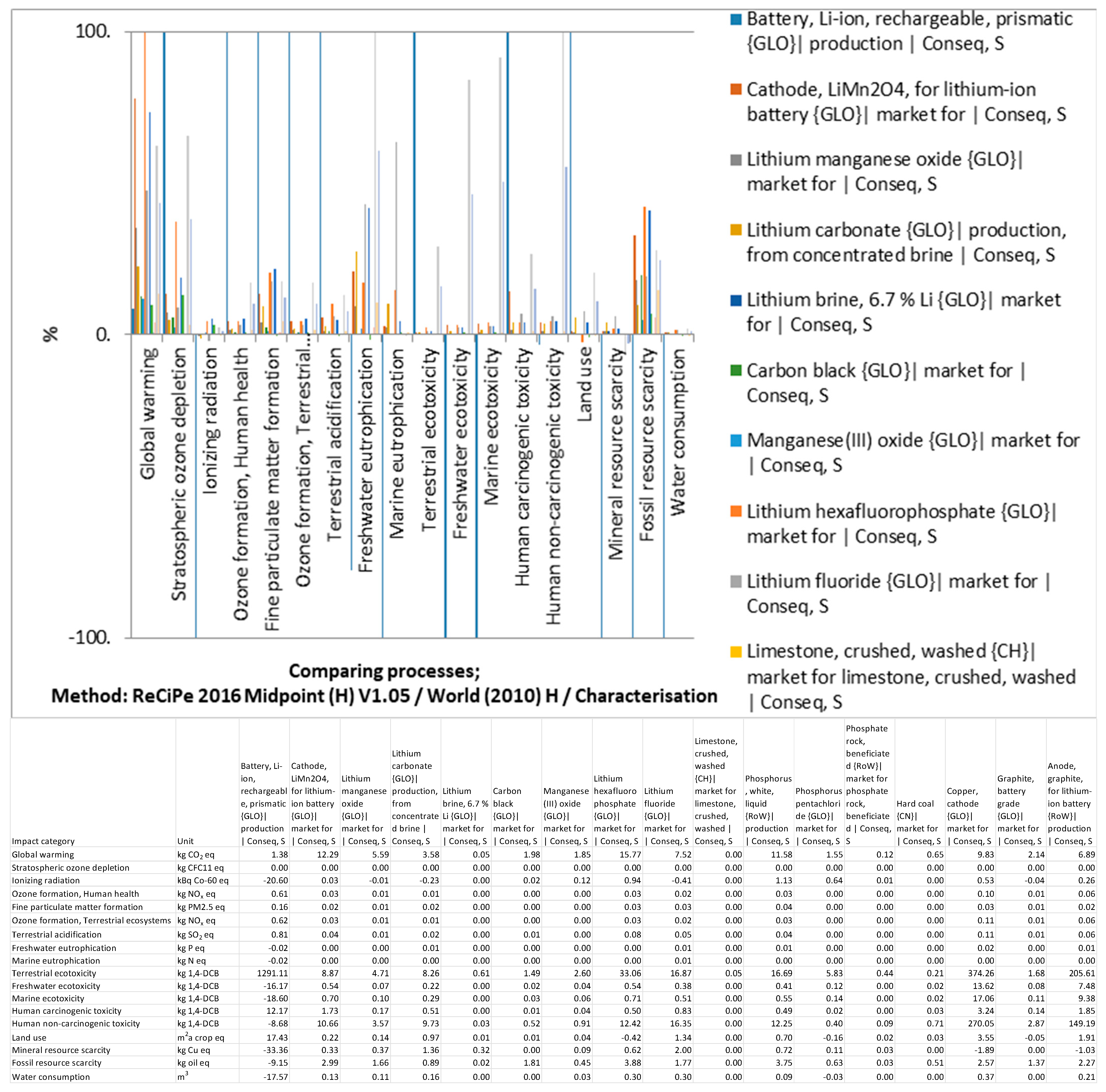

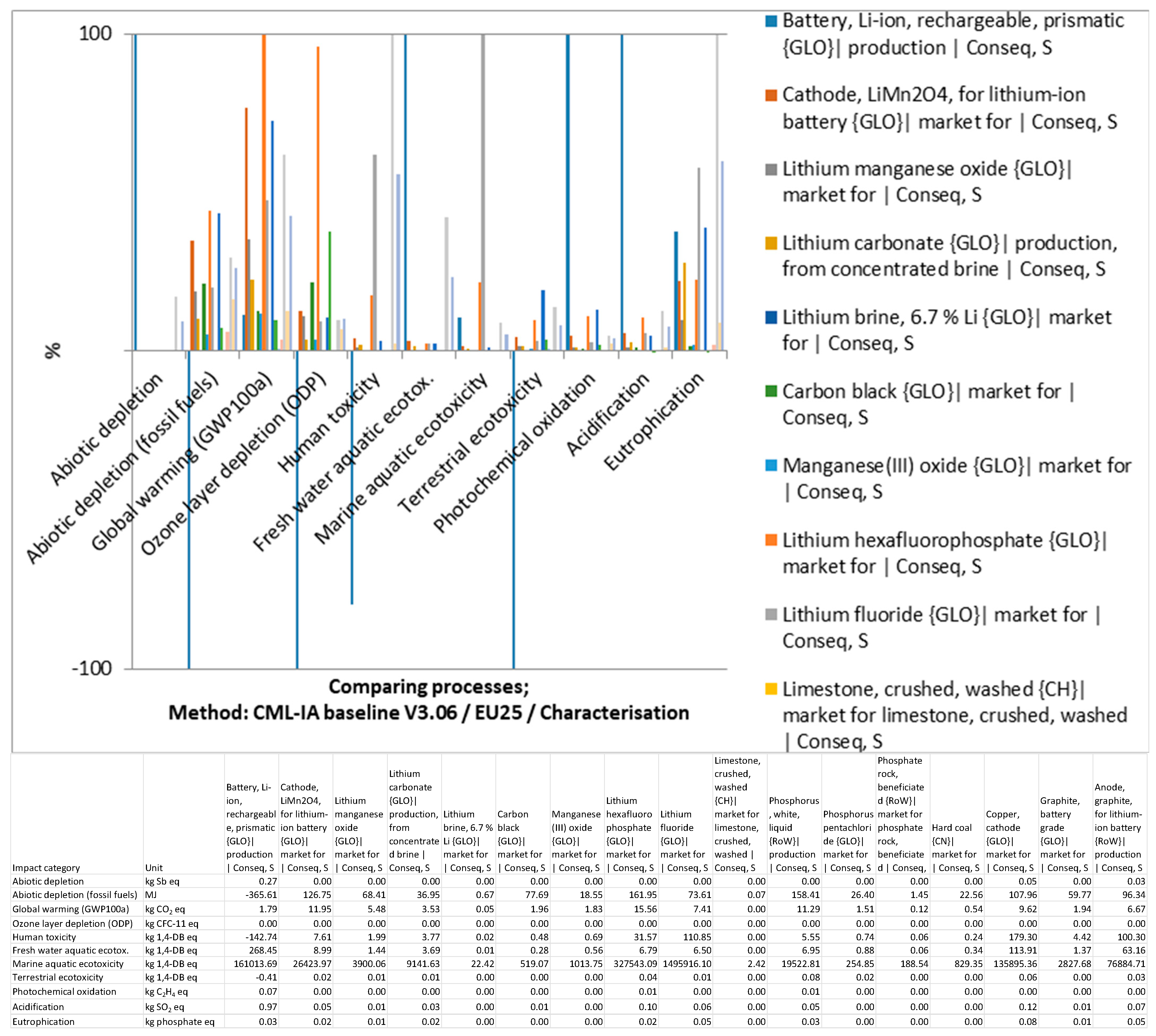

5.2. Hotspot Analysis of BESS Components

5.3. GWP Analysis of BESS-Connected Renewable Energy Systems

- (1)

- (2)

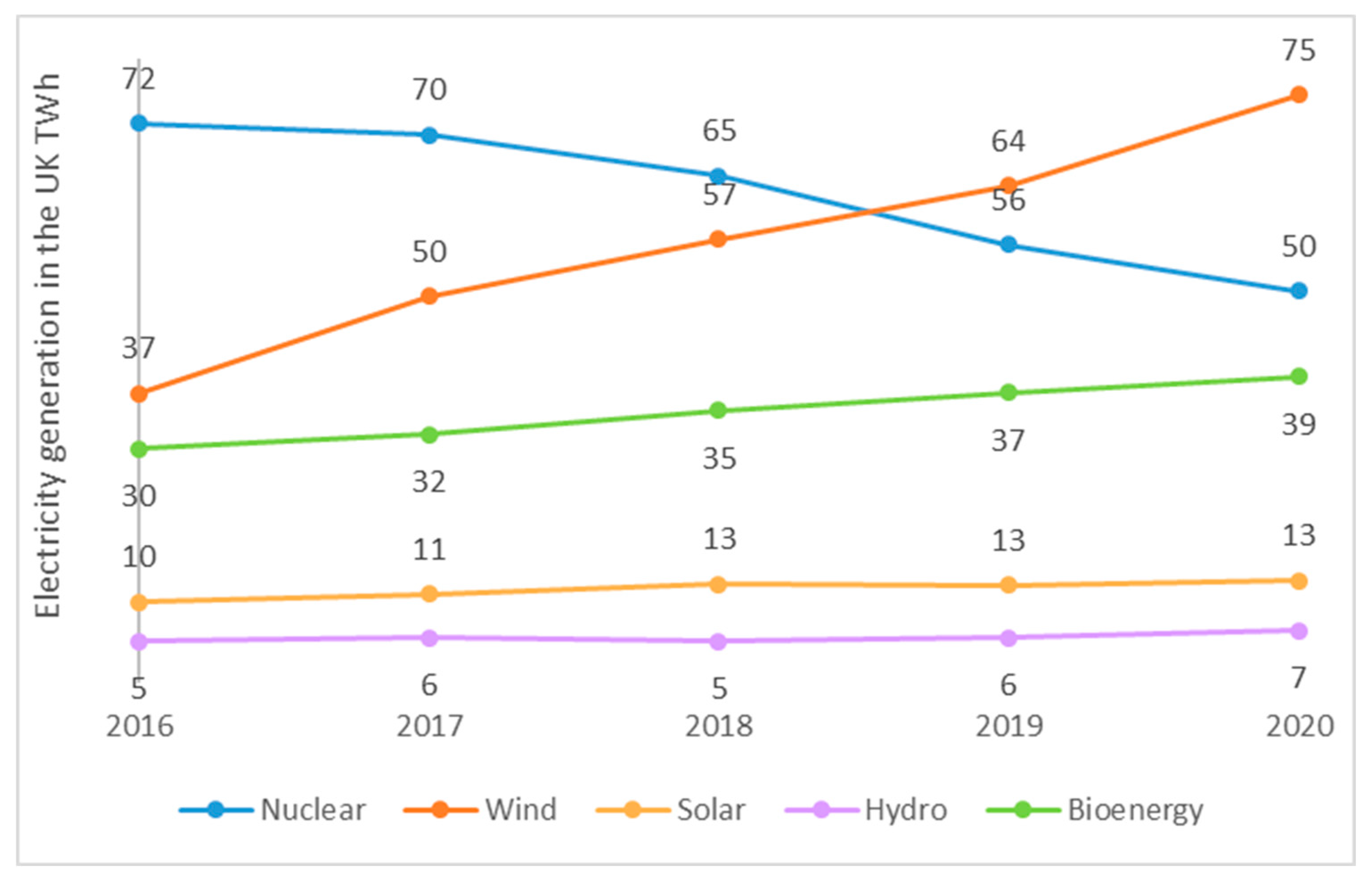

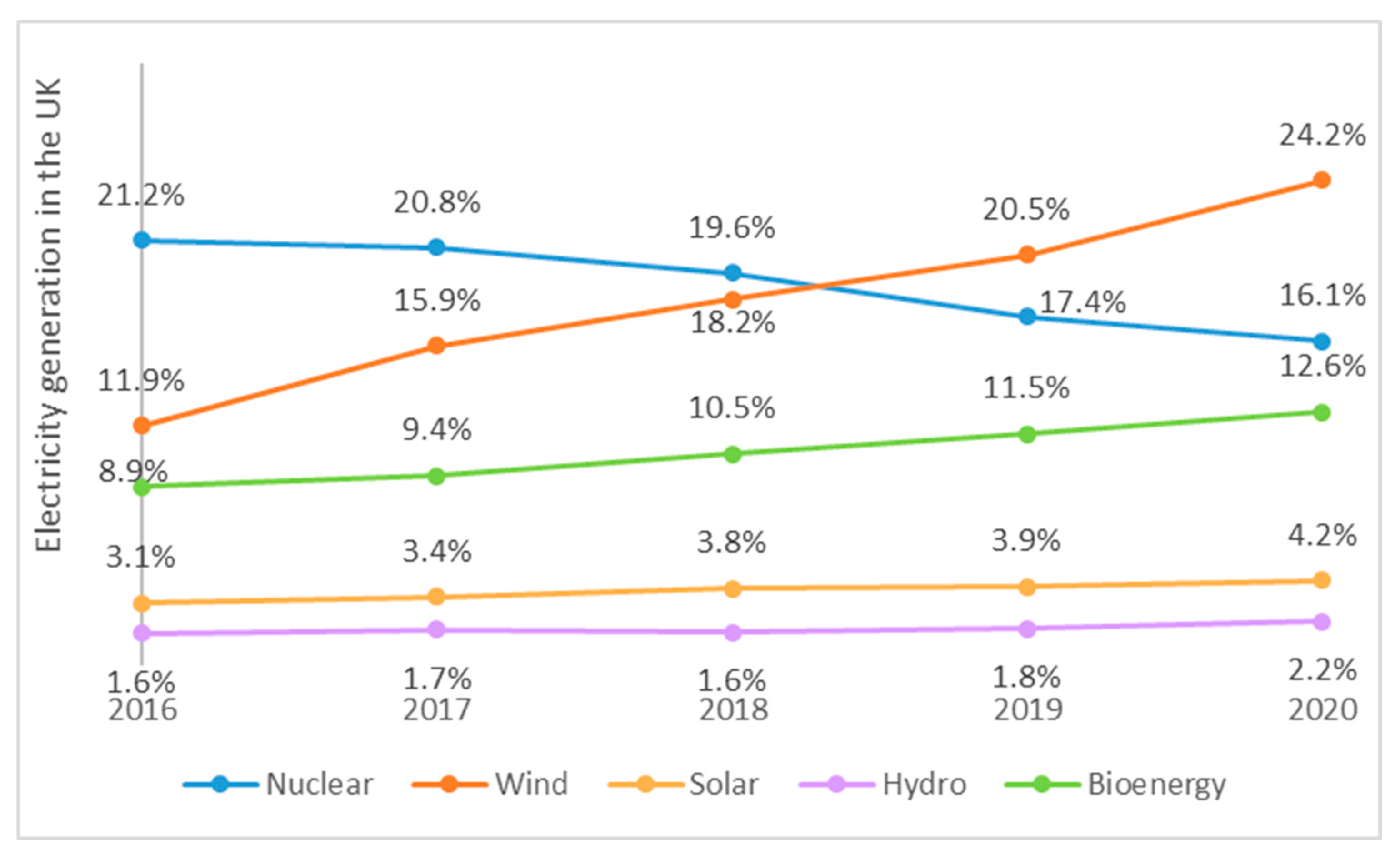

- The proportion of the UK electricity generation, present and forecasted, by resource (Table 2). In this case, the proportion of renewables (wind, solar and hydro) would increase to 56% and the proportion of gas would decrease to 18% by 2040 [34]. The contributions shown in Figure 9, are the actual values of the main resources. Thus, the total annual electricity generation in the UK can be obtained from the ratio between TWh and fractional contribution from a resource. Oil, other fossil resources and pumped storage with their aggregated contributions of less than 3% are not presented. The totals in Table 2 do not include their contributions.

- (3)

- The proportion of gas by the energy of the UK electricity generation is forecasted for the years 2025, 2030, 2035 and 2040 for a non-fossil electricity generation scenario by 2040 (Table 3). In this case, all other resource energy contributions are kept the same [34] thus reducing the totals to as shown in Table 3. The demand reduction is necessary in this case.

- (4)

- (5)

- The other life cycle environmental impact potentials, acidification potential (AP), eutrophication potential (EP) and fossil depletion potential (FDP) using the CML characterisation factors and photochemical oxidant creation potential or urban smog (POCP) using the ILCD characterisation factors of the above technologies in the UK (Table 4) [28].

6. Discussion

- Allocation at the point of substitution: 6.7 kg CO2 eq per kg of lithium-ion battery

- Cut-off: 8.1 kg CO2 eq per kg of lithium-ion battery

- Consequential: 1.7 kg CO2 eq per kg of lithium-ion battery

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- World Energy Outlook. 2018. Available online: https://www.iea.org/weo/ (accessed on 10 August 2021).

- Available online: https://assets.publishing.service.gov.uk/government/uploads/system/uploads/attachment_data/file/1006712/DUKES_5.6.xls (accessed on 10 August 2021).

- Gür, T.M. Review of electrical energy storage technologies, materials and systems: Challenges and prospects for large-scale grid storage. Energy Environ. Sci. 2018, 11, 2696–2767. [Google Scholar] [CrossRef]

- Mohamad, F.; Teh, J.; Lai, C.M.; Chen, L.R. Development of energy storage systems for power network reliability: A review. Energies 2018, 11, 2278. [Google Scholar] [CrossRef] [Green Version]

- Sabishchenko, O.; Rębilas, R.; Sczygiol, N.; Urbański, M. Ukraine energy sector management using hybrid renewable energy systems. Energies 2020, 13, 1776. [Google Scholar] [CrossRef] [Green Version]

- Balducci, P.J.; Alam, M.J.E.; Hardy, T.D.; Wu, D. Assigning value to energy storage systems at multiple points in an electrical grid. Energy Environ. Sci. 2018, 11, 1926–1944. [Google Scholar] [CrossRef] [Green Version]

- Hammond, G.P.; Hazeldine, T. Indicative energy technology assessment of advanced rechargeable batteries. Appl. Energy 2015, 138, 559–571. [Google Scholar] [CrossRef] [Green Version]

- Thomas, S.; Jung, H.; Kim, S.; Jun, B.; Lee, C.H.; Lee, S.U. Two-dimensional haeckelite h567: A promising high capacity and fast Li diffusion anode material for lithium-ion batteries. Carbon 2019, 148, 344–353. [Google Scholar] [CrossRef]

- Dunn, B.; Kamath, H.; Tarascon, J.M. Electrical energy storage for the grid: A battery of choices. Science 2011, 334, 928–935. [Google Scholar] [CrossRef] [Green Version]

- Denholm, P.; Kulcinski, G.L. Life cycle energy requirements and greenhouse gas emissions from large scale energy storage systems. Energy Conv. Manag. 2004, 45, 2153–2172. [Google Scholar] [CrossRef]

- Tolomeo, R.; De Feo, G.; Adami, R.; Sesti Osséo, L. Application of life cycle assessment to lithium ion batteries in the automotive sector. Sustainability 2020, 12, 4628. [Google Scholar] [CrossRef]

- Raugei, M.; Winfield, P. Prospective LCA of the production and EoL recycling of a novel type of Li-ion battery for electric vehicles. J. Clean. Prod. 2019, 213, 926–932. [Google Scholar] [CrossRef] [Green Version]

- Jones, C.; Gilbert, P.; Stamford, L. Assessing the climate change mitigation potential of stationary energy storage for electricity grid services. Environ. Sci. Technol. 2019, 54, 67–75. [Google Scholar] [CrossRef]

- McManus, M.C. Environmental consequences of the use of batteries in low carbon systems: The impact of battery production. Appl. Energy 2012, 93, 288–295. [Google Scholar] [CrossRef] [Green Version]

- Smith, L.; Ibn-Mohammed, T.; Astudillo, D.; Brown, S.; Reaney, I.M.; Koh, S.L. The Role of Cycle Life on the Environmental Impact of Li6.4La3Zr1.4Ta0.6O12 based Solid-State Batteries. Adv. Sustain. Syst. 2021, 5, 2000241. [Google Scholar] [CrossRef]

- Ahmadi, L.; Young, S.B.; Fowler, M.; Fraser, R.A.; Achachlouei, M.A. A cascaded life cycle: Reuse of electric vehicle lithium-ion battery packs in energy storage systems. Int. J. Life Cycle Assess. 2017, 22, 111–124. [Google Scholar] [CrossRef]

- Kamran, M.; Raugei, M.; Hutchinson, A. A dynamic material flow analysis of lithium-ion battery metals for electric vehicles and grid storage in the UK: Assessing the impact of shared mobility and end-of-life strategies. Resour. Conserv. Recycl. 2021, 167, 105412. [Google Scholar] [CrossRef]

- Zhao, S.; You, F. Comparative life-cycle assessment of Li-ion batteries through process-based and integrated hybrid approaches. ACS Sustain. Chem. Eng. 2019, 7, 5082–5094. [Google Scholar] [CrossRef]

- Yu, Y.; Chen, B.; Huang, K.; Wang, X.; Wang, D. Environmental impact assessment and end-of-life treatment policy analysis for Li-ion batteries and Ni-MH batteries. Int. J. Environ. Res. Pub. Health 2014, 11, 3185–3198. [Google Scholar] [CrossRef] [PubMed]

- Sadhukhan, J. Analysing Life Cycle Climate Change Impact Savings by Battery Energy Storage Systems in The UK. SME Voucher Project Thesis, The University of Surrey, Surrey, UK, 2019. [Google Scholar]

- Chowdhury, J.I.; Balta-Ozkan, N.; Goglio, P.; Hu, Y.; Varga, L.; McCabe, L. Techno-environmental analysis of battery storage for grid level energy services. Ren. Sustain. Energy Rev. 2020, 131, 110018. [Google Scholar] [CrossRef]

- ISO 14040: Environmental Management–Life Cycle Assessment–Principles and Framework; International Standard Organization: Geneva, Switzerland, 2006.

- ISO 14041: Environmental Management–Life Cycle Assessment–Goal and Scope Definition and Inventory Analysis; International Standard Organization: Geneva, Switzerland, 1998.

- ISO 14042: Environmental Management–Life Cycle Assessment–Life Cycle Impact Assessment; International Standard Organization: Geneva, Switzerland, 2000.

- ISO 14043: Environmental Management–Life Cycle Assessment–Life Cycle Interpretation; International Standard Organization: Geneva, Switzerland, 2000.

- ISO 14044: Environmental Management–Life Cycle Assessment–Requirements and Guidelines; International Standard Organization: Geneva, Switzerland, 2006.

- Sadhukhan, J.; Ng, K.S.; Martinez-Hernandez, E. Biorefineries and Chemical Processes: Design, Integration and Sustainability Analysis; Wiley: Chichester, UK, 2014; Available online: https://onlinelibrary.wiley.com/doi/book/10.1002/9781118698129 (accessed on 10 August 2021).

- Sadhukhan, J.; Sen, S.; Gadkari, S. The Mathematics of life cycle sustainability assessment. J. Clean. Prod. 2021, 309, 127457. [Google Scholar] [CrossRef]

- Shemfe, M.B.; Gadkari, S.; Sadhukhan, J. Social hotspot analysis and trade policy implications of the use of bioelectrochemical systems for resource recovery from wastewater. Sustainability 2018, 10, 3193. [Google Scholar] [CrossRef] [Green Version]

- Gadkari, S.; Beigi, B.H.M.; Aryal, N.; Sadhukhan, J. Microbial electrosynthesis: Is it sustainable for bioproduction of acetic acid? RSC Adv. 2021, 11, 9921–9932. [Google Scholar] [CrossRef]

- Gadkari, S.; Gu, S.; Sadhukhan, J. Two-dimensional mathematical model of an air-cathode microbial fuel cell with graphite fiber brush anode. J. Power Sourc. 2019, 441, 227145. [Google Scholar] [CrossRef]

- Sadhukhan, J.; Dugmore, T.I.; Matharu, A.; Martinez-Hernandez, E.; Aburto, J.; Rahman, P.K.; Lynch, J. Perspectives on “game changer” global challenges for sustainable 21st century: Plant-based diet, unavoidable food waste biorefining, and circular economy. Sustainability 2020, 12, 1976. [Google Scholar] [CrossRef] [Green Version]

- Sadhukhan, J.; Gadkari, S.; Martinez-Hernandez, E.; Ng, K.S.; Mobolaji, S.; Torres-Garcia, E.; Lynch, J. Novel macroalgae (seaweed) biorefinery systems for integrated chemical, protein, salt, nutrient and mineral extractions and environmental protection by green synthesis and life cycle sustainability assessments. Green Chem. 2019, 21, 2635–2655. [Google Scholar] [CrossRef]

- Available online: https://assets.publishing.service.gov.uk/government/uploads/system/uploads/attachment_data/file/931323/updated-energy-and-emissions-projections-2019.pdf (accessed on 10 August 2021).

| Basis: Li-Ion Battery | 1 | kg |

| * Battery cell, Li-ion | 0.8 | kg |

| Cable (data cable in infrastructure) | 0.37 | m |

| Cable (three-conductor cable) | 0.025 | m |

| Printed wiring board (Pb) | 0.001 | kg |

| Printed wiring board (Pb-free) | 0.002 | kg |

| Reinforcing steel | 0.15 | kg |

| Sheet rolling | 0.15 | kg |

| Electricity | 0.108 | kWh |

| Battery recycling (pyrometallurgical) | 0.5 | kg |

| Battery recycling (hydrometallurgical) | 0.5 | kg |

| Basis: Battery cell, Li-ion | 1 | kg |

| Aluminium, wrought alloy | 0.016 | kg |

| * Graphite anode | 0.4 | kg |

| Battery separator | 0.054 | kg |

| * Lithium-ion cathode | 0.33 | kg |

| Ethylene carbonate | 0.16 | kg |

| Plastic film extruded | 0.07 | kg |

| * Lithium hexafluorophosphate | 0.019 | kg |

| Liquid nitrogen | 0.01 | kg |

| Low density polyethylene | 0.07 | kg |

| Sheet rolling | 0.016 | kg |

| Electricity | 0.106 | kWh |

| Heat | 0.065 | MJ |

| Basis: Graphite anode | 1 | kg |

| Carbon black | 0.015855 | kg |

| Copper | 0.52414 | kg |

| Graphite | 0.49414 | kg |

| Latex | 0.018497 | kg |

| Sheet rolling | 0.52414 | kg |

| Sulfuric acid | 0.080763 | kg |

| Deionised water | 0.42369 | kg |

| Electricity | 0.002 | kWh |

| Heat | 1.2163 | MJ |

| Basis: Lithium-ion cathode | 1 | kg |

| Aluminium | 0.39 | kg |

| Carbon black | 0.026 | kg |

| * Lithium manganese oxide | 0.62 | kg |

| Sheet rolling | 0.39 | kg |

| Sodium hydroxide | 0.13 | kg |

| Deionised water | 0.2 | kg |

| Electricity | 0.002 | kWh |

| Heat | 0.65 | MJ |

| Basis: Lithium manganese oxide | 1 | kg |

| * Lithium carbonate | 0.21 | kg |

| Manganese(III) oxide | 0.92 | kg |

| Liquid nitrogen | 0.79 | kg |

| Liquid oxygen | 0.7 | kg |

| Deionised water | 3.4 | kg |

| Electricity | 0.005 | kWh |

| Heat | 15.3 | MJ |

| Basis: Lithium carbonate | 1 | kg |

| Activated bentonite | 0.014 | kg |

| Hydrochloric acid | 0.04 | kg |

| * Lithium brine, 6.7% Li | 4.2 | kg |

| Quicklime | 0.07 | kg |

| Soda ash | 2.12 | kg |

| Sodium hydroxide | 0.0002 | kg |

| Sulfuric acid | 0.025 | kg |

| Electricity | 0.6 | kWh |

| Heat | 2.96 | MJ |

| Basis: Lithium brine, 6.7% Li | 1 | kg |

| * Lithium | 0.0667 | kg |

| Heat | 0.1407 | MJ |

| Electricity | 0.00714 | kWh |

| Basis: Lithium hexafluorophosphate | 1 | kg |

| Hydrogen fluoride | 4.04 | kg |

| Hydrated lime | 7.44 | kg |

| Lithium fluoride | 0.2 | kg |

| Liquid nitrogen | 0.001 | kg |

| * Phosphorus pentachloride | 2 | kg |

| Water | 4.3 | kg |

| Electricity | 0.5 | kWh |

| Basis: Phosphorus pentachloride | 1 | kg |

| Liquid chlorine | 0.36 | kg |

| * Phosphorous chloride | 0.7 | kg |

| Electricity | 0.002 | kWh |

| Heat | 0.087 | MJ |

| Basis: Phosphorous chloride | 1 | kg |

| Liquid chlorine | 0.79 | kg |

| * Phosphorus, white, liquid | 0.226 | kg |

| Electricity | 0.333 | kWh |

| Basis: Phosphorus, white, liquid | 1 | kg |

| Hard coal | 1.25 | kg |

| Phosphate | 26.2931 | kg |

| Electricity | 13 | kWh |

| TWh Electricity Generation | 2016 | 2017 | 2018 | 2019 | 2020 | 2025 | 2030 | 2035 | 2040 |

|---|---|---|---|---|---|---|---|---|---|

| Coal | 31 | 23 | 17 | 7 | 6 | 0 | 0 | 0 | 0 |

| Gas | 143 | 137 | 131 | 132 | 111 | 80 | 73 | 68 | 65 |

| Nuclear | 72 | 70 | 65 | 56 | 50 | 56 | 65 | 70 | 80 |

| Hydro | 5 | 6 | 5 | 6 | 7 | 7 | 7 | 7 | 7 |

| Wind | 37 | 50 | 57 | 64 | 75 | 116 | 156 | 175 | 200 |

| Solar | 10 | 11 | 13 | 13 | 13 | 16 | 20 | 23 | 25 |

| Bioenergy | 30 | 32 | 35 | 37 | 39 | 39 | 39 | 39 | 39 |

| Total | 329 | 328 | 323 | 315 | 301 | 315 | 360 | 382 | 416 |

| TWh Electricity Generation | 2025 | 2030 | 2035 | 2040 |

|---|---|---|---|---|

| Gas | 80 | 44 | 9 | 0 |

| Total | 315 | 331 | 323 | 351 |

| Basis: 1 TWh Electricity Generation | Coal | Gas | Solar | Bioenergy | Wind | Nuclear | Hydro | |

|---|---|---|---|---|---|---|---|---|

| GWP | IPCC kt CO2 eq | 1057 | 514 | 76 | 62 | 21 | 12 | 4 |

| AP | CML kt SO2 eq | 7.13 | 0.3 | 0.44 | 1.34 | 0.23 | 0.06 | 0.02 |

| POCP | ILCD kt NMVOC eq | 3.13 | 0.59 | 0.3 | 1.75 | 0.11 | 0.05 | 0.02 |

| EP | CML kt phosphate eq | 2.19 | 0.08 | 0.18 | 0.46 | 0.11 | 0.05 | 0.01 |

| FDP | CML TWh | 3.32 | 2.12 | 0.24 | 0.21 | 0.06 | 0.04 | 0.01 |

| kt CO2 eq | 2016 | 2017 | 2018 | 2019 | 2020 | 2025 | 2030 | 2035 | 2040 |

|---|---|---|---|---|---|---|---|---|---|

| Coal | 32,417 | 23,815 | 17,791 | 7350 | 5818 | 0 | 0 | 0 | 0 |

| Gas | 73,685 | 70,287 | 67,586 | 67,813 | 57,276 | 41,120 | 37,522 | 34,952 | 33,410 |

| Bioenergy | 1864 | 1977 | 2168 | 2313 | 2437 | 2418 | 2418 | 2418 | 2418 |

| Wind | 780 | 1042 | 1195 | 1340 | 1583 | 2443 | 3282 | 3675 | 4200 |

| Solar | 790 | 871 | 963 | 956 | 1000 | 1250 | 1491 | 1733 | 1900 |

| Nuclear | 861 | 844 | 781 | 674 | 603 | 672 | 780 | 840 | 960 |

| Hydro | 21 | 24 | 22 | 23 | 27 | 28 | 28 | 28 | 28 |

| Total | 110,418 | 98,860 | 90,505 | 80,469 | 68,744 | 48,821 | 47,274 | 45,836 | 45,650 |

| kt CO2 eq TWh−1 | 336 | 301 | 280 | 256 | 228 | 155 | 131 | 120 | 110 |

| % GWP reduction based on the year 2000 | 46 | 52 | 56 | 61 | 66 | 76 | 77 | 78 | 78 |

| % GWP reduction based on the year 2020 | 29 | 31 | 33 | 34 | |||||

| % GWP reduction for zero-fossil electricity by 2040 based on 2000 | 76 | 84 | 92 | 94 | |||||

| % GWP reduction for zero-fossil electricity by 2040 based on 2020 | 29 | 53 | 77 | 82 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sadhukhan, J.; Christensen, M. An In-Depth Life Cycle Assessment (LCA) of Lithium-Ion Battery for Climate Impact Mitigation Strategies. Energies 2021, 14, 5555. https://doi.org/10.3390/en14175555

Sadhukhan J, Christensen M. An In-Depth Life Cycle Assessment (LCA) of Lithium-Ion Battery for Climate Impact Mitigation Strategies. Energies. 2021; 14(17):5555. https://doi.org/10.3390/en14175555

Chicago/Turabian StyleSadhukhan, Jhuma, and Mark Christensen. 2021. "An In-Depth Life Cycle Assessment (LCA) of Lithium-Ion Battery for Climate Impact Mitigation Strategies" Energies 14, no. 17: 5555. https://doi.org/10.3390/en14175555

APA StyleSadhukhan, J., & Christensen, M. (2021). An In-Depth Life Cycle Assessment (LCA) of Lithium-Ion Battery for Climate Impact Mitigation Strategies. Energies, 14(17), 5555. https://doi.org/10.3390/en14175555