Flexible Dispatch for Integrated Power and Gas Systems Considering Power-to-Gas and Demand Response

Abstract

:1. Introduction

2. Scheduling Flexibility and Demand Response Model

2.1. Scheduling Flexibility for Grid-Connected Wind Power

2.1.1. Adjustable Capacity Supply

2.1.2. Adjustable Capacity Demand

2.2. Demand Response Model

3. Flexible Economic Dispatch Model

3.1. Modeling for the Power System (The Main Problem of Unit Commitment and Adjustable Capacity Allocation)

3.1.1. Objective Function of Main Problem

3.1.2. Constraints

3.2. Modeling for the Power System (Adjustable Capacity Adequacy Test Sub-Problem)

3.2.1. Objective Function of Sub-Problem

3.2.2. Power System Constraints

3.3. Modeling for the Natural Gas System

3.3.1. Objective Function

3.3.2. Natural Gas System Constraints

3.4. Coupling Constraints of the IPGS

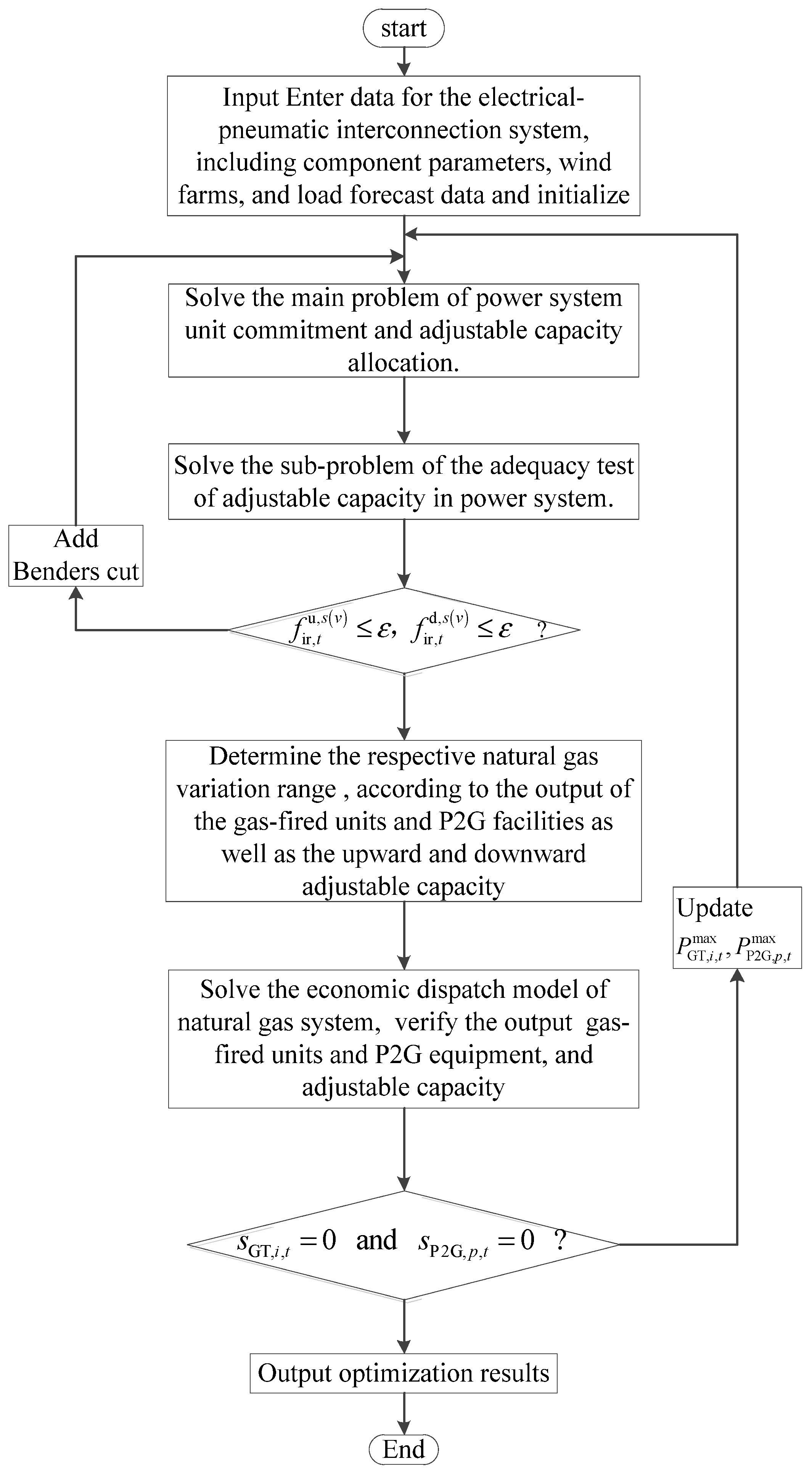

4. Solution Methodology

4.1. Flexible Economic Dispatch for the Power System

4.2. Economic Dispatch for the Gas System

4.3. Coordinated Optimization of Two Systems

4.3.1. Slack Variable for Gas-Fired Units

4.3.2. Slack Variable for P2G Facilities

5. Simulation Results

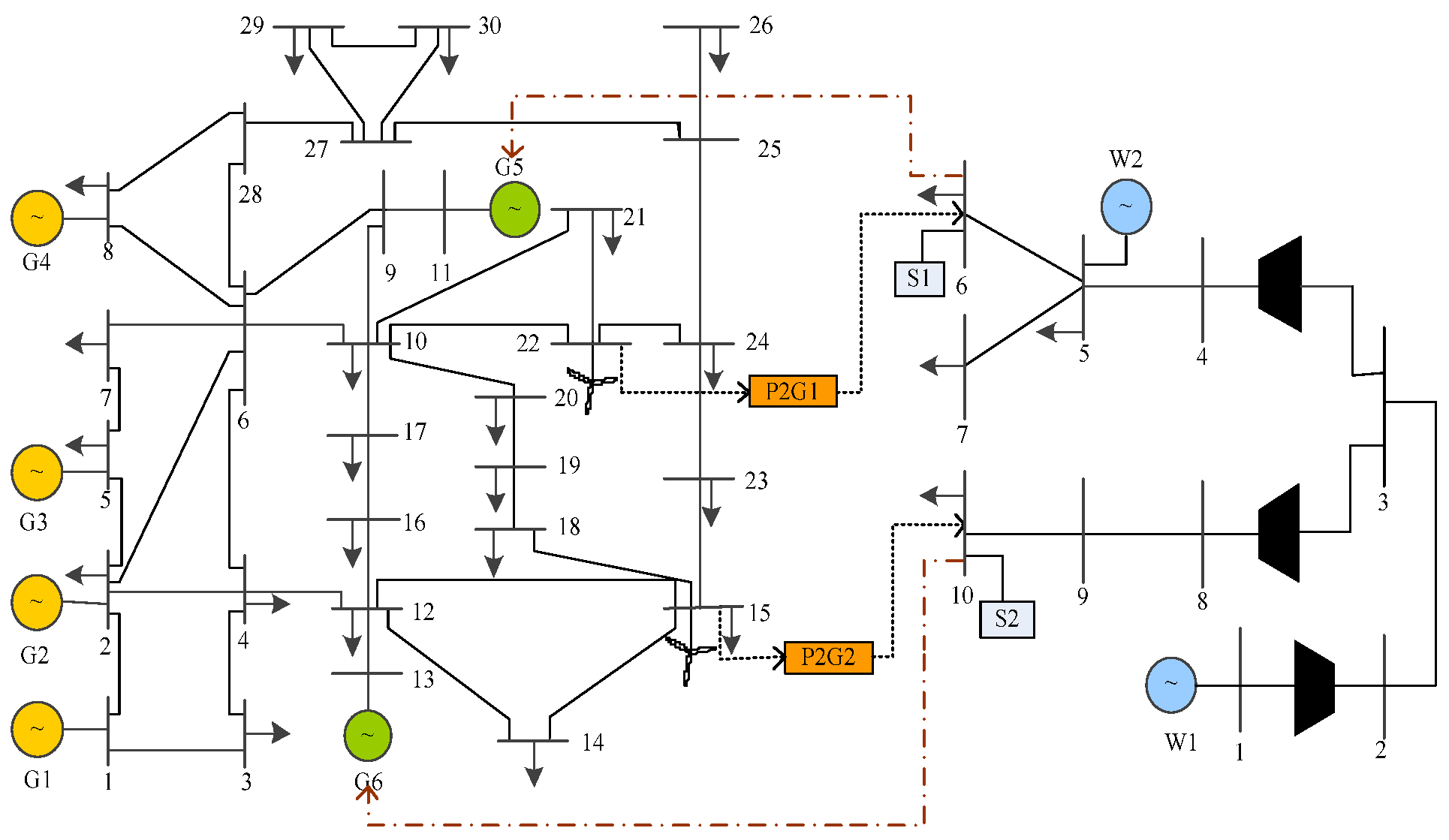

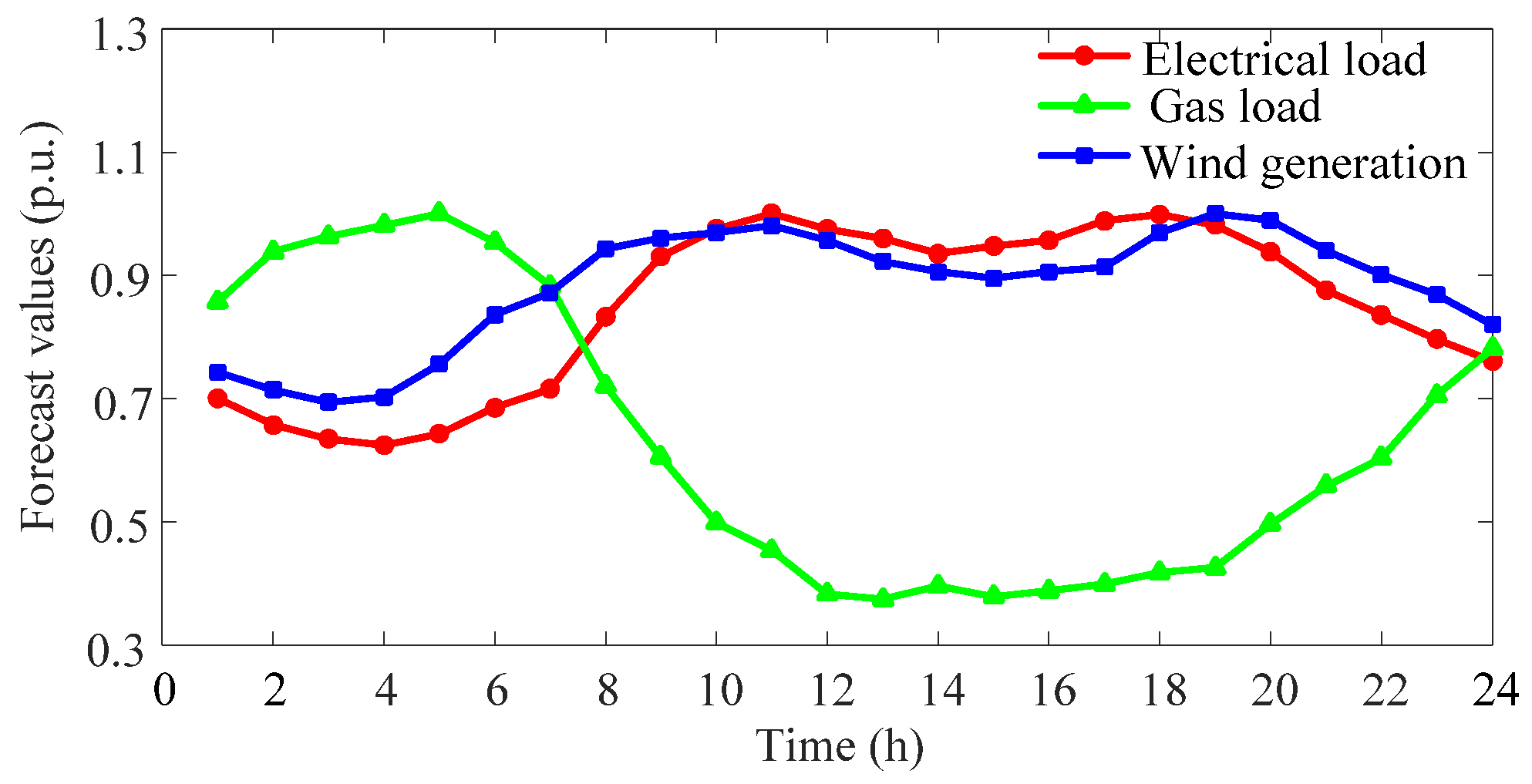

5.1. System Description and Data Source

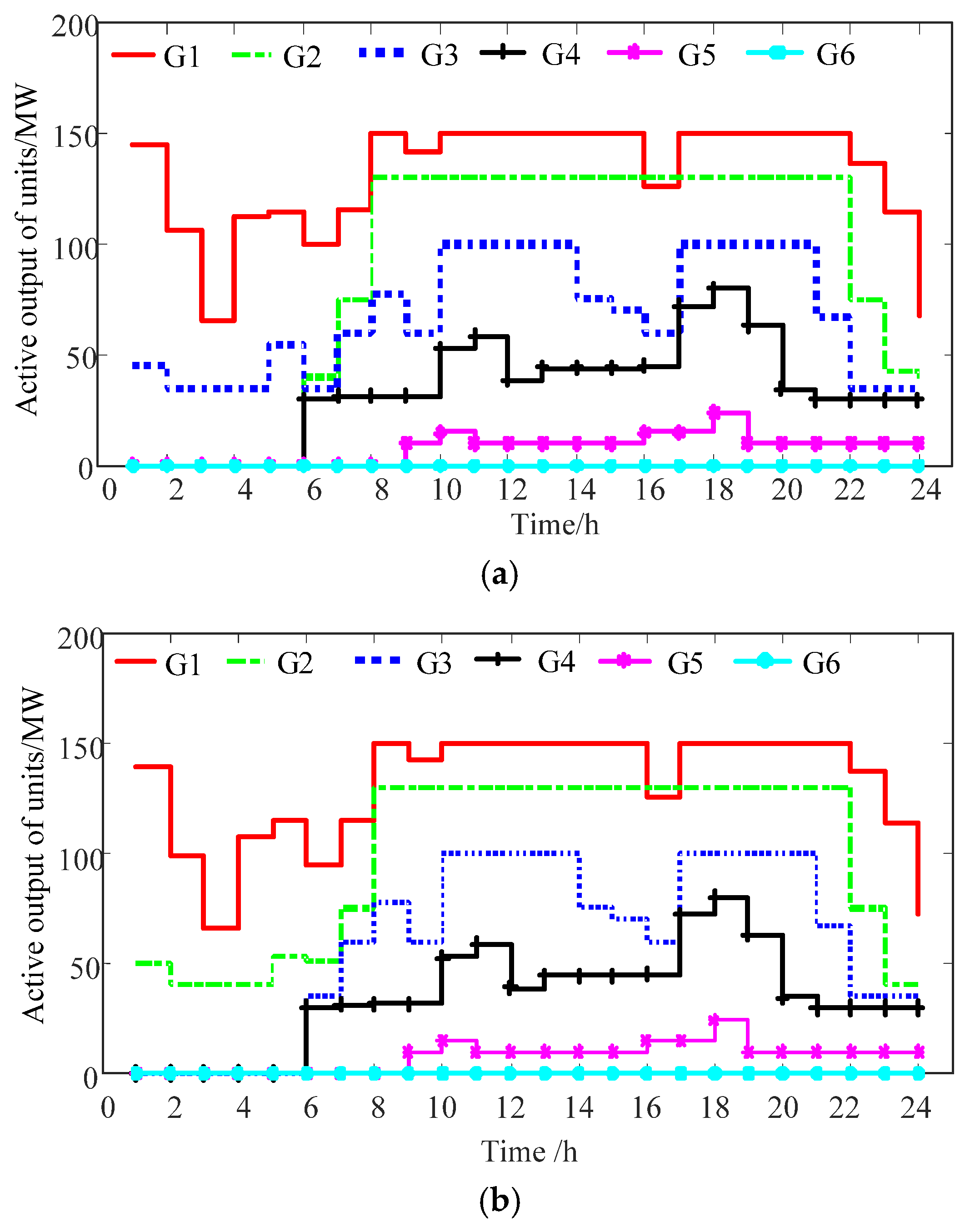

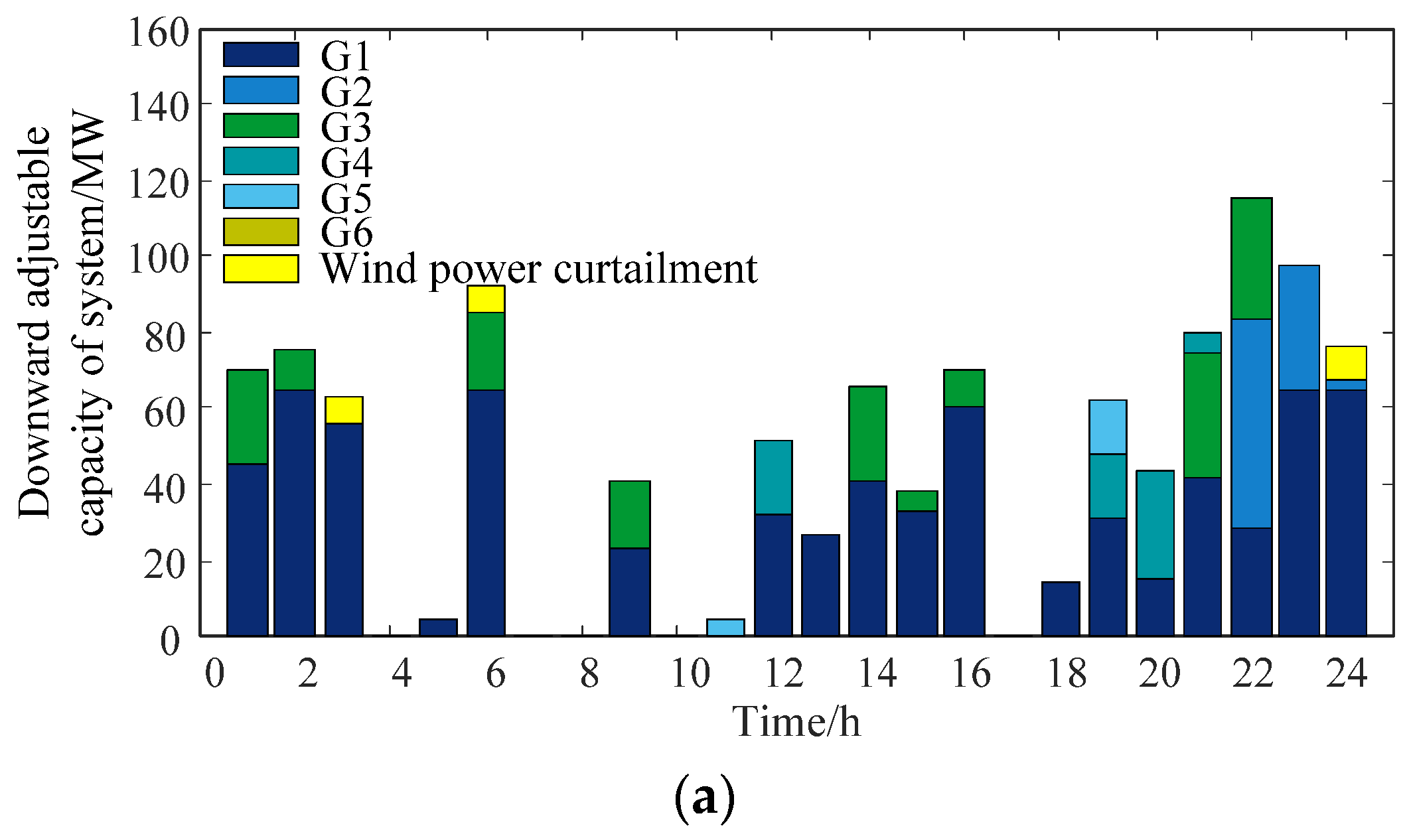

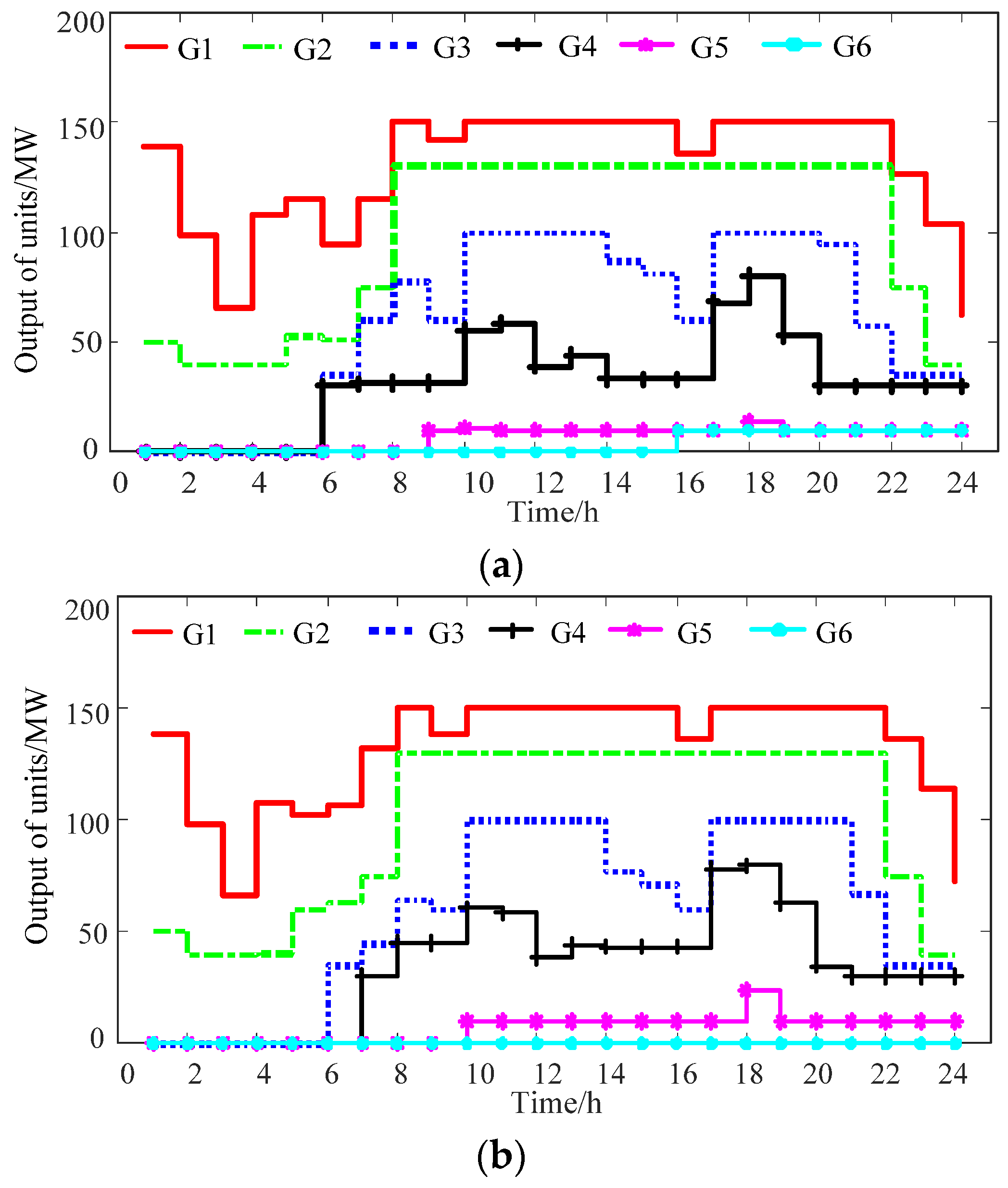

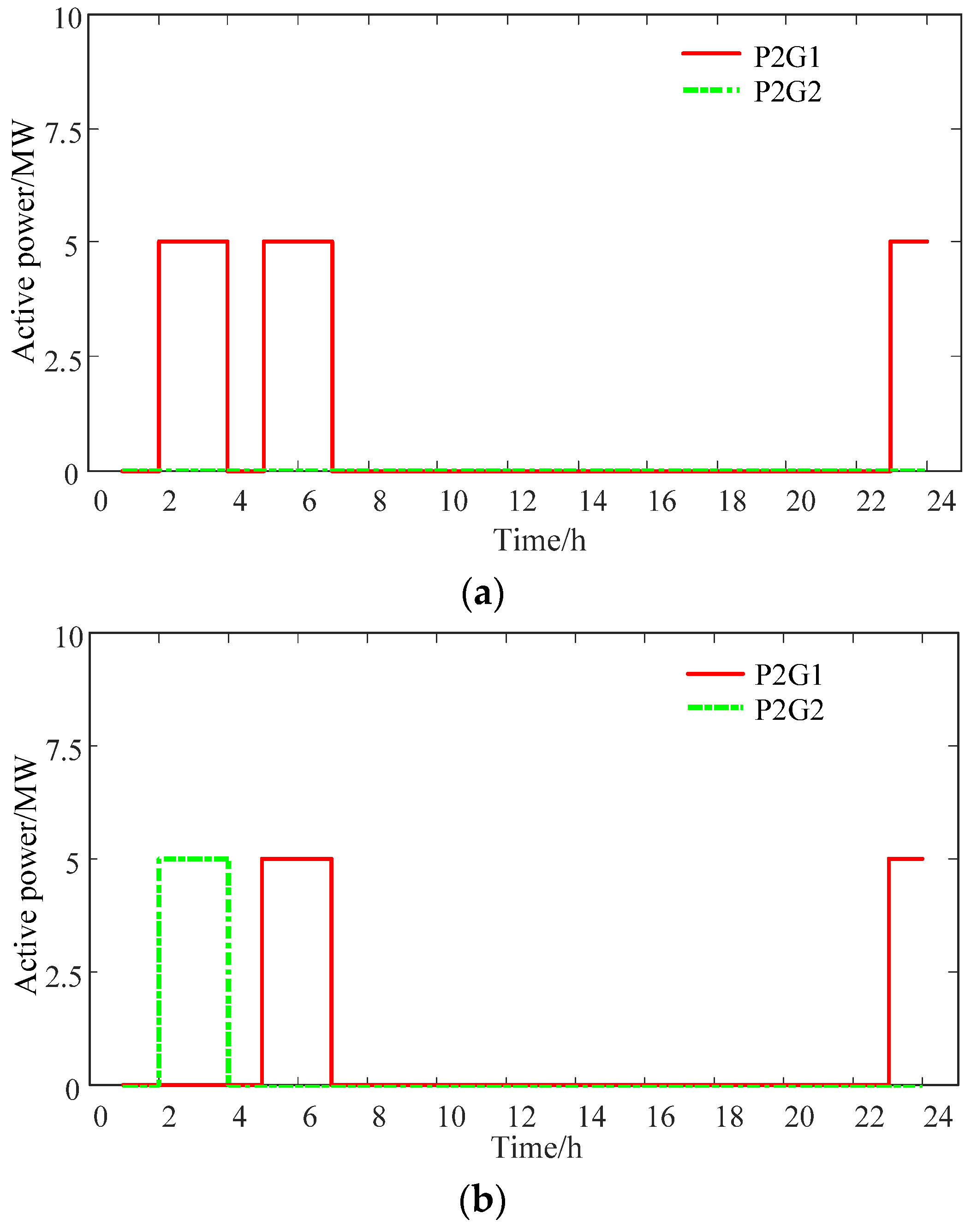

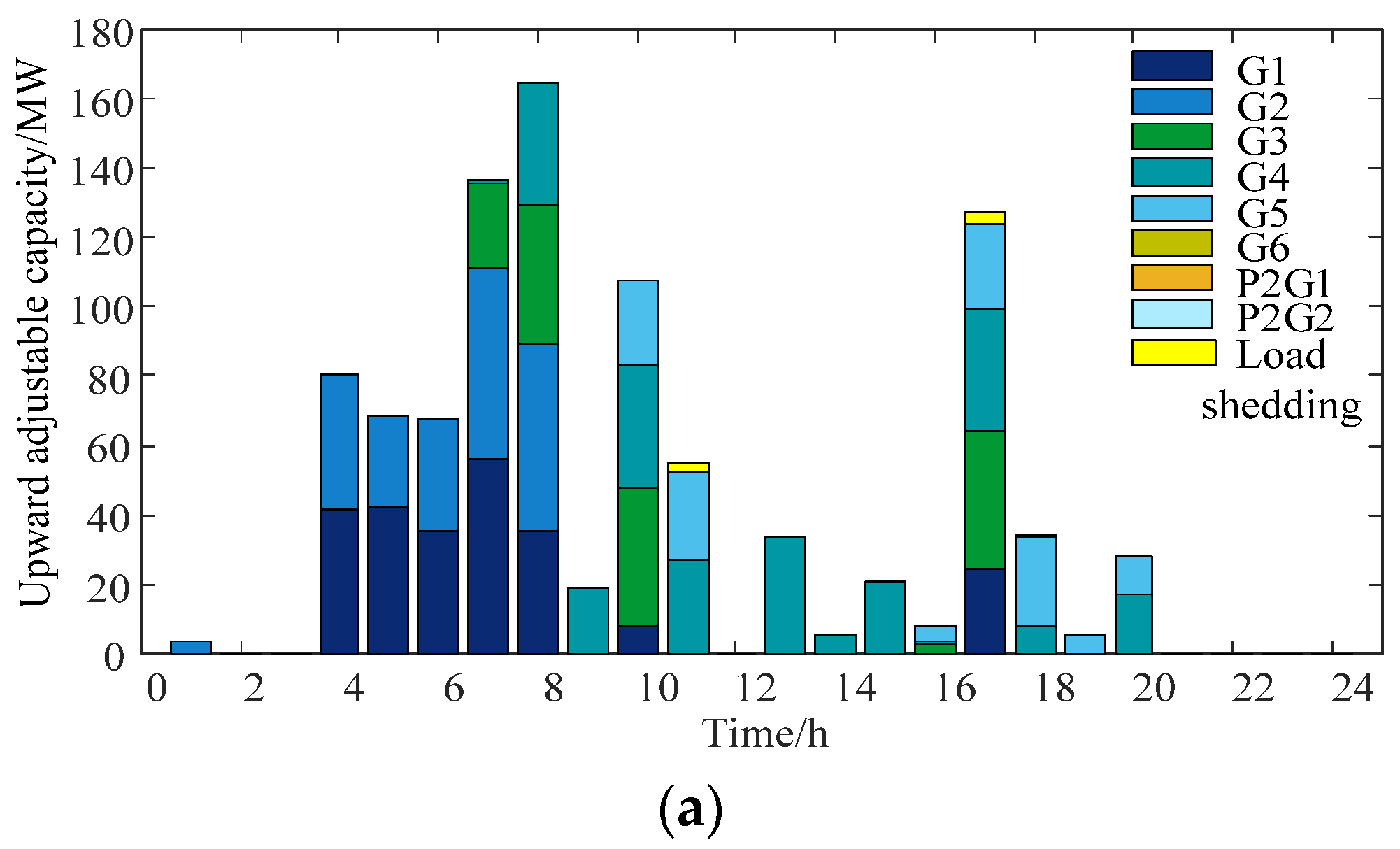

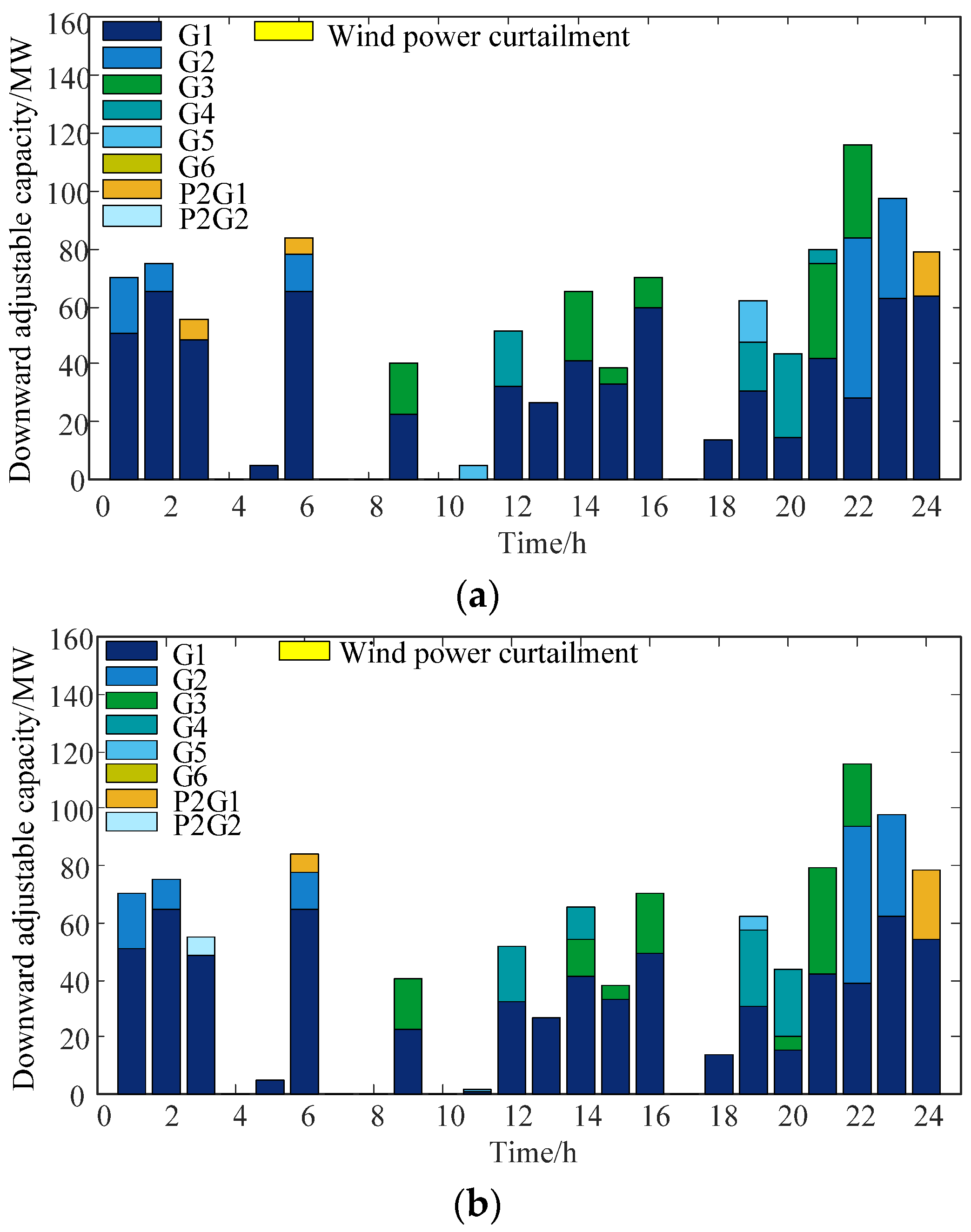

5.2. Analysis of the Impact of P2G on Flexible Economic Dispatch of Power System

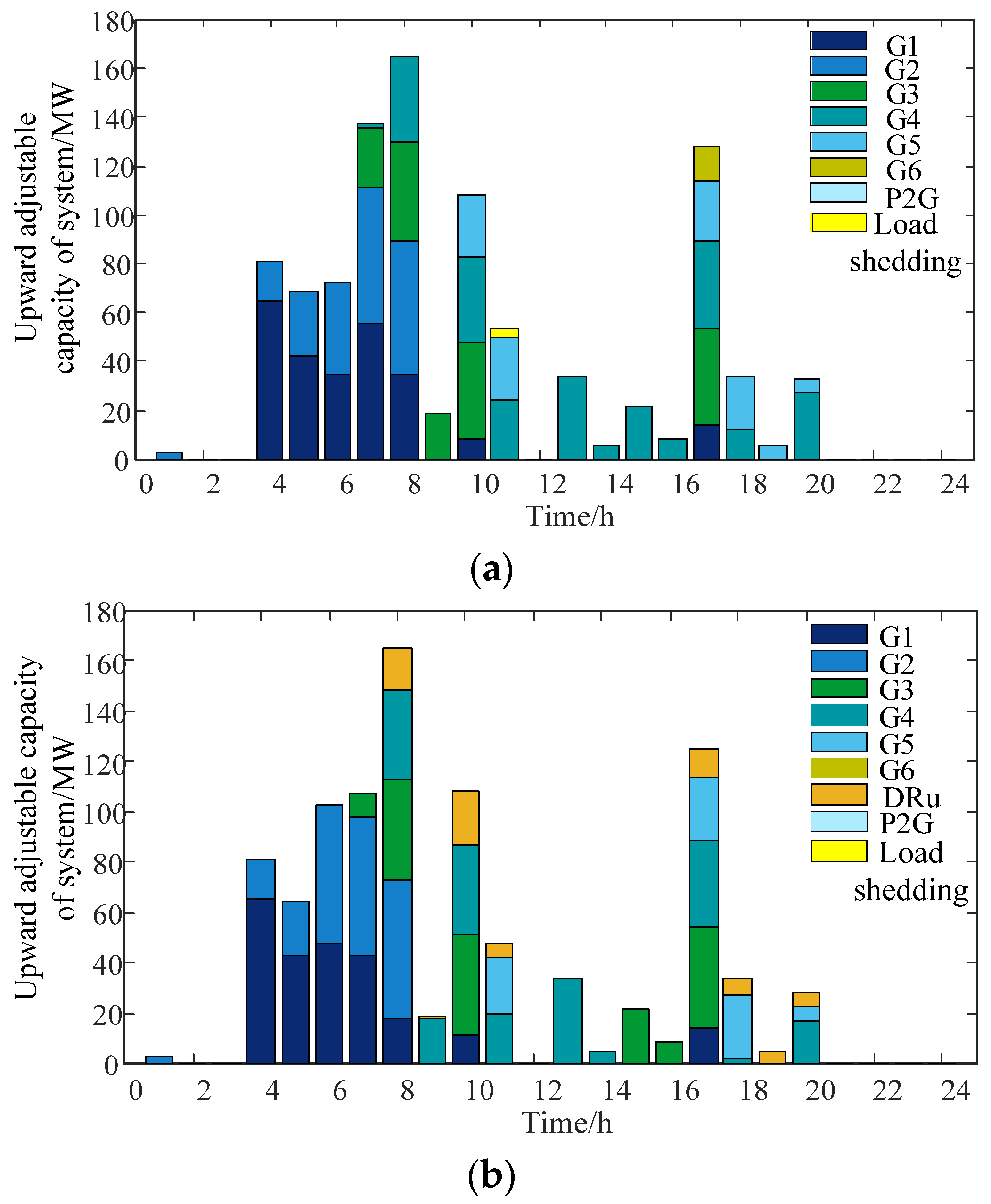

5.3. Analysis of Comprehensive Consideration of P2G Facilities and Demand Response

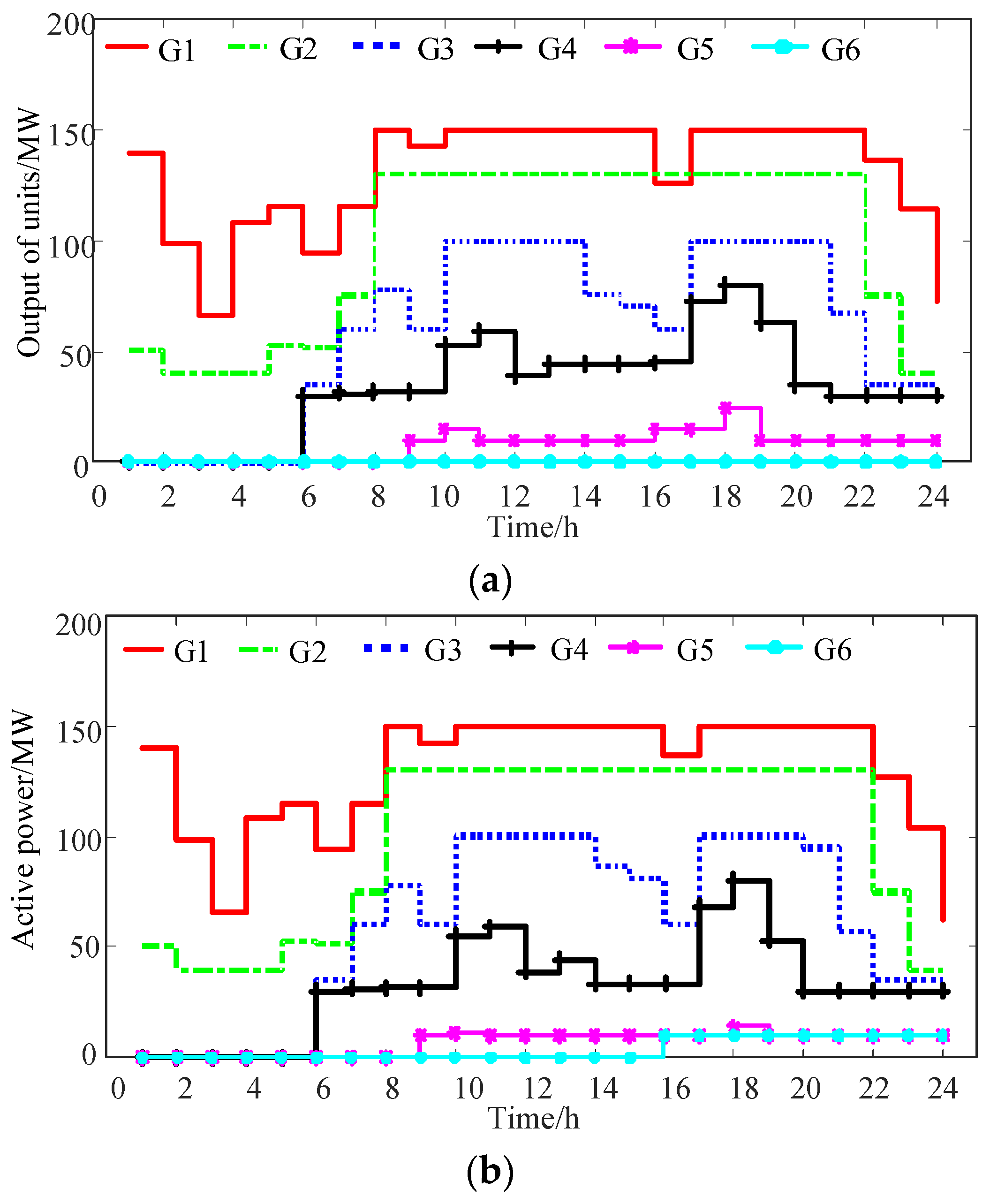

5.4. The Proposed Coordinated Optimization of IPGS

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Nomenclature

| A. Indexes and Sets | |

| i, p, k, m/q | Indices of units, P2G facilities, wind farms, demand response users. |

| l, b, t | Indices of branches, buses, and hours. |

| ΩG, ΩP2G, ΩW, ΩDR | Set of adjustable generator units, P2G facilities, wind farms, demand response users. |

| s | Wind power scenarios |

| B. Constants | |

| , | Max/Min output power of unit i at time t. |

| , | Max/Min power consumption of P2G facility p at time t. |

| , | Max/Min load reduction of demand response user m at time t. |

| Power flow limits of branch l. | |

| , | Up/Down ramp rate of unit i. |

| , | Start-up/shutdown cost of unit i. |

| , | Min on/off time of unit i. |

| Matrix relating node injections to power flow on transmission lines. | |

| Min interval of regulation time of the demand response user m. | |

| Continuously unregulated time of the demand response user m at the initial moment. | |

| Max regulation time of the demand response user m. | |

| Max response number of the demand response user m. | |

| , | Wind power curtailment cost and load shedding cost. |

| , | Upward and downward adjustable capacity allocation costs of conventional units. |

| , | Upward and downward adjustable capacity allocation costs of P2G facility. |

| , | Upward and downward adjustable capacity allocation costs of demand response. |

| , , | Operation cost of gas well w, P2G facility p, storage facility s. |

| Penalty cost of non-served gas loads. | |

| , | Max/Min gas injection of gas well w. |

| , | Max/Min pressure of gas node i. |

| , | Max/Min pressure ratio of the compressor c. |

| , | Max/Min gas storage capacity of the storage facility s. |

| Scheduling period interval. | |

| A constant depending on the characteristics of pipeline, such as temperature, length, diameter, and friction factor. | |

| A constant related to the characteristics of pipeline. | |

| , , | Heat consumption coefficients of the gas-fired unit. |

| σ | Conversion factor for electric power and heat. |

| ƞ | Conversion efficiency of the P2G facility. |

| C. Variables | |

| , , | Commitment Statuses of unit i, P2G facility p, demand response user m at time t. |

| , , | Dispatch of unit i, P2G facility p, demand response user m at time t. |

| Dispatch of gas-fired unit i at time t. | |

| , | Upward and downward adjustable capacity of conventional units. |

| , | Upward and downward adjustable capacity of P2G facility. |

| , | Upward and downward adjustable capacity of demand response. |

| , | Start-stop status variable of generator units. |

| , | On/off time counter of unit i at time t. |

| , , | Adjustable capacity provided by the units, P2G facilities, demand response at time t. |

| , | Called upward and downward adjustable capacity of P2G facility. |

| , | P2G called cost. |

| Start-stop status variable of P2G facility. | |

| , | Upward and downward climbing rate of P2G facility. |

| , | j-level response capacity, price of demand response user m. |

| Dispatch of wind farm k at time t. | |

| Wind power curtailment of wind farm k at time t. | |

| Cumulative unregulated time of the demand response user m. | |

| , , | Natural gas flow from gas well w, P2G facility p, storage facility s. |

| Non-served gas loads caused by the gas-fired unit i at time t. | |

| Pressure of gas node i at time t. | |

| Average flow of pipeline ij at time t. | |

| , | Inflow/outflow of gas pipeline ij at time t. |

| , | Inflow/outflow of storage facility s at time t. |

| Linepack of pipeline ij at time t. | |

| , | Pressure of the incoming node m, the out-coming node n of the compressor c. |

| Gas storage capacity of the storage facility s at time t. | |

| Gas load of node b at time t. | |

| Gas flow consumed by the gas-fired unit i at time t. | |

| Max injection flow of P2G facility p at time t. | |

| , , , , , | 6 dual variables of Benders cut. |

| D. Functions | |

| f(Pi,t) | Production cost of the coal-fired unit i at time t. |

| W(PGT,i,t) | Gas purchase cost of the gas-fired unit i at time t. |

Appendix A

| Units | Maximum Output (MW) | Minimum Output (MW) | Upward/Downward Ramping Rate (MW·h−1) | Units Type |

|---|---|---|---|---|

| G1 | 150 | 50 | 65 | Coal-fired |

| G2 | 130 | 40 | 55 | Coal-fired |

| G3 | 100 | 35 | 40 | Coal-fired |

| G4 | 80 | 30 | 35 | Coal-fired |

| G5 | 40 | 10 | 25 | Gas-fired |

| G6 | 40 | 10 | 25 | Gas-fired |

| Index | Node No | Min Output (kcf/h) | Max Output (kcf/h) | Gas Price ($/kcf/) |

|---|---|---|---|---|

| W1 | 1 | 2000 | 8000 | 1.018 |

| W2 | 5 | 1000 | 3000 | 1.223 |

| Index | Node No | Max Input (kcf/h) | Max Output (kcf/h) | Capacity (kcf) | Gas Price ($/kcf/) |

|---|---|---|---|---|---|

| S1 | 6 | 400 | 300 | 1000 | 1.287 |

| S2 | 10 | 600 | 400 | 1500 | 1.321 |

| Type | Capacity (%) | Price ($/MWh) | RI h | RT h | N times | ||||

|---|---|---|---|---|---|---|---|---|---|

| 1 | 2 | 3 | 1 | 2 | 3 | ||||

| DRu1 | 3 | 7 | 9 | 18 | 20 | 22 | 2 | 5 | 3 |

| DRu2 | 3 | 5 | 6 | 20 | 22 | 24 | 2 | 4 | 3 |

| DRd1 | 3 | 6 | 5 | 21 | 23 | 25 | 2 | 4 | 3 |

| DRd2 | 2 | 4 | 3 | 22 | 24 | 26 | 2 | 3 | 3 |

References

- Han, D.; Li, T.; Feng, S.; Shi, Z. Does Renewable Energy Consumption Successfully Promote the Green Transformation of China’s Industry? Energies 2020, 13, 229. [Google Scholar] [CrossRef] [Green Version]

- Zhang, Y.; Wang, J.; Ding, T.; Wang, X. Conditional value at risk-based stochastic unit commitment considering the uncertainty of wind power generation. IET Gener. Transm. Distrib. 2018, 12, 482–489. [Google Scholar] [CrossRef]

- China National Energy Administration. Wind Power Grid-Connected Operation in 2017. 2018. Available online: http://www.nea.gov.cn/2018-02/01/c_136942234.htm (accessed on 1 February 2018).

- Mohamed, O.; Khalil, A. Progress in Modeling and Control of Gas Turbine Power Generation Systems: A Survey. Energies 2020, 13, 2358. [Google Scholar] [CrossRef]

- Scheller, F.; Burkhardt, R.; Schwarzeit, R.; McKenna, R.; Bruckner, T. Competition between simultaneous demand-side flexibility options: The case of community electricity storage systems. Appl. Energy 2020, 269, 114969. [Google Scholar] [CrossRef]

- Clegg, S.; Mancarella, P. Storing renewables in the gas Network: Modelling of power-to-gas seasonal storage flexibility in low–carbonpower systems. IET Gener. Transm. Distrib. 2016, 10, 566–575. [Google Scholar] [CrossRef]

- Li, Y.; Liu, W.; Shahidehpour, M.; Wen, F.; Wang, K.; Huang, Y. Optimal Operation Strategy for Integrated Natural Gas Generating Unit and Power-to-Gas Conversion Facilities. IEEE Trans. Sustain. Energy 2018, 9, 1870–1879. [Google Scholar] [CrossRef]

- Faridpak, B.; Farrokhifar, M.; Murzakhanov, I.; Safari, A. A series multi-step approach for operation Co-optimization of integrated power and natural gas systems. Energy 2020, 204, 117897. [Google Scholar] [CrossRef]

- Farrokhifar, M.; Nie, Y.; Pozo, D. Energy systems planning: A survey on models for integrated power and natural gas networks coordination. Appl. Energy 2020, 262, 114567. [Google Scholar] [CrossRef]

- Liu, J.; Sun, W.; Yan, J. Effect of P2G on Flexibility in Integrated Power-Natural Gas-Heating Energy Systems with Gas Storage. Energies 2021, 14, 196. [Google Scholar] [CrossRef]

- Zhang, W.; Liu, R.; Yang, X. Study on Operating Strategy of Electric—Gas Combined System Considering the Improvement of Dispatchability. Energies 2019, 12, 4584. [Google Scholar] [CrossRef] [Green Version]

- Aldarajee, A.H.M.; Hosseinian, S.H.; Vahidi, B.; Dehghan, S. Security constrained multi-objective bi-directional integrated electricity and natural gas co-expansion planning considering multiple uncertainties of wind energy and system demand. IET Renew. Power Gener. 2020, 14, 1395–1404. [Google Scholar] [CrossRef]

- He, C.; Wu, L.; Liu, T.; Wei, W.; Wang, C. Co-optimization scheduling of interdependent power and gas systems with electricity and gas uncertainties. Energy 2018, 159, 1003–1015. [Google Scholar] [CrossRef]

- Zhang, Y.; Huang, Z.; Shu, S.; Zheng, F.; Lin, J. Cooperative Scheduling for Integrated Electricity and Natural Gas Systems Considering Gas Flow Transient Characteristics and Source—Load Uncertainties. Energy Technol. 2020, 8, 201901098. [Google Scholar] [CrossRef]

- Karamdel, S.; Moghaddam, M.P. Robust expansion co-planning of electricity and natural gas infrastructures for multi energy-hub systems with high penetration of renewable energy sources. IET Renew. Power Gener. 2019, 13, 2287–2297. [Google Scholar] [CrossRef]

- Fang, X.; Cui, H.; Yuan, H.; Tan, J.; Jiang, T. Distributionally-robust chance constrained and interval optimization for integrated electricity and natural gas systems optimal power flow with wind uncertainties. Appl. Energy 2019, 252, 113420. [Google Scholar] [CrossRef]

- Chen, J.; Lin, Z.; Ren, J.; Zhang, W.; Zhou, Y.; Zhang, Y. Distributed multi-scenario optimal sizing of integrated electricity and gas system based on ADMM. Int. J. Electr. Power Energy Syst. 2020, 117, 105675. [Google Scholar] [CrossRef]

- Osi adacz, A.J.; Isoli, N. Multi-Objective Optimization of Gas Pipeline Networks. Energies 2020, 13, 5141. [Google Scholar] [CrossRef]

- Tan, C.; Geng, S.; Tan, Z.; Wang, G.; Pu, L.; Guo, X. Integrated energy system—Hydrogen natural gas hybrid energy storage system optimization model based on cooperative game under carbon neutrality. J. Energy Storage 2021, 38, 102539. [Google Scholar] [CrossRef]

- Xi, Y.; Fang, J.; Chen, Z.; Zeng, Q.; Lund, H. Optimal coordination of flexible resources in the gas-heat-electricity integrated energy system. Energy 2021, 223, 119729. [Google Scholar] [CrossRef]

- Zhang, B.; Hu, W.; Cao, D.; Huang, Q.; Chen, Z.; Blaabjerg, F. Economical operation strategy of an integrated energy system with wind power and power to gas technology—A DRL-based approach. IET Renew. Power Gener. 2021, 14, 3292–3299. [Google Scholar] [CrossRef]

- Wang, S.; Yuan, S. Interval optimization for integrated electrical and natural-gas systems with power to gas considering uncertainties. Int. J. Electr. Power Energy Syst. 2020, 119, 105906. [Google Scholar] [CrossRef]

- Chen, Z.; Zhang, Y.; Ji, T.; Li, C.; Xu, Z.; Cai, Z. Economic dispatch model for wind power integrated system considering the dispatchability of power to gas. IET Gener. Transm. Distrib. 2019, 13, 1535–1544. [Google Scholar] [CrossRef]

- Liu, J.; Sun, W.; Harrison, G.P. The economic and environmental impact of power to hydrogen/power to methane facilities on hybrid power-natural gas energy systems. Int. J. Hydrog. Energy 2020, 45, 20200–20209. [Google Scholar] [CrossRef]

- Zhang, Y.; Huang, Z.; Zheng, F.; Zhou, R.; An, X.; Li, Y. Interval optimization based coordination scheduling of gas—Electricity coupled system considering wind power uncertainty, dynamic process of natural gas flow and demand response management. Energy Rep. 2020, 6, 216–227. [Google Scholar] [CrossRef]

- Li, P.; Wang, Z.; Wang, J.; Yang, W.; Guo, T.; Yin, Y. Two-stage optimal operation of integrated energy system considering multiple uncertainties and integrated demand response. Energy 2021, 225, 120256. [Google Scholar] [CrossRef]

- Kou, X.; Li, F.; Dong, J.; Starke, M.; Munk, J.; Xue, Y.; Olama, M.; Zandi, H. A Scalable and Distributed Algorithm for Managing Residential Demand Response Programs using Alternating Direction Method of Multipliers (ADMM). IEEE Trans. Smart Grid 2020, 11, 4871–4882. [Google Scholar] [CrossRef]

- He, C.; Zhang, X.; Liu, T.; Wu, L. Distributionally Robust Scheduling of Integrated Gas-Electricity Systems with Demand Response. IEEE Trans. Power Syst. 2019, 34, 3791–3803. [Google Scholar] [CrossRef]

- Rakipour, D.; Barati, H. Probabilistic optimization in operation of energy hub with participation of renewable energy resources and demand response. Energy 2019, 173, 384–399. [Google Scholar] [CrossRef]

- Subramanya, K.; Nagaraj, M.S. Optimization of Demand Side Management and DG Placement in the Distribution System with Demand Response. Int. J. Eng. Adv. Technol. 2020, 10, 407–414. [Google Scholar]

- Wang, C.; Chen, S.; Mei, S.; Chen, R.; Yu, H. Optimal Scheduling for Integrated Energy System Considering Scheduling Elasticity of Electric and Thermal Loads. IEEE Access 2020, 8, 202933–202945. [Google Scholar] [CrossRef]

- Ming, H.; Xie, L.; Campi, M.C.; Garatti, S.; Kumar, P.R. Scenario-Based Economic Dispatch with Uncertain Demand Response. IEEE Trans. Smart Grid 2019, 10, 1858–1868. [Google Scholar] [CrossRef] [Green Version]

- Ju, L.; Tan, Z.; Yuan, J.; Tan, Q.; Li, H.; Dong, F. A bi-level stochastic scheduling optimization model for a virtual power plant connected to a wind–photovoltaic–energy storage system considering the uncertainty and demand response. Appl. Energy. 2016, 171, 184–199. [Google Scholar] [CrossRef] [Green Version]

- Wang, C.; Wang, Z.; Hou, Y.; Ma, K. Dynamic game-based maintenance scheduling of integrated electric and natural gas grids with a bilevel approach. IEEE Trans. Power Syst. 2018, 33, 4958–4971. [Google Scholar] [CrossRef] [Green Version]

- He, C.; Wu, L.; Liu, T.; Shahidehpour, M. Robust co-optimization scheduling of electricity and natural gas systems via ADMM. IEEE Trans. Sustain. Energy 2017, 8, 658–670. [Google Scholar] [CrossRef]

- Power System Test Case Archive. Available online: http://labs.ece.uw.edu/pstca (accessed on 30 August 1993).

- Wu, S.; Rios-Mercado, R.Z.; Boyd, E.A.; Scott, L.R. Model relaxations for the fuel cost minimization of steady-state gas pipeline networks. Math. Comput. Model. 2000, 31, 197–220. [Google Scholar] [CrossRef]

| Case1 | Case2 | |

|---|---|---|

| Units generating cost/$ | 184,212 | 183,606 |

| P2G operating costs/$ | — | 2400 |

| Wind power curtailment cost/$ | 11,695 | 0 |

| Load shedding cost/$ | 7480 | 7480 |

| Units adjustable capacity allocation cost/$ | 33,722 | 33,272 |

| P2G adjustable capacity allocation cost/$ | — | 500 |

| Total cost/$ | 237,109 | 227,259 |

| Case3 | Case4 | |

|---|---|---|

| Units generating cost/$ | 190,393 | 181,665 |

| P2G operating costs/$ | 2400 | 1600 |

| Wind power curtailment cost/$ | 0 | 0 |

| Load shedding cost/$ | 4300 | 170 |

| Units adjustable capacity allocation cost/$ | 33,295 | 31,008 |

| P2G adjustable capacity allocation cost/$ | 687 | 308 |

| Demand response adjustable capacity Allocation cost/$ | — | 1398 |

| Total cost/$ | 231,075 | 216,151 |

| Separate Optimization | Coordinated Optimization | |

|---|---|---|

| Units generating cost/$ | 227,259 | 190,393 |

| P2G operating costs/$ | 2400 | 2400 |

| Wind power curtailment cost/$ | 0 | 0 |

| Load shedding cost/$ | 7480 | 4300 |

| Units adjustable capacity allocation cost/$ | 33,272 | 33,295 |

| P2G adjustable capacity allocation cost/$ | 500 | 687 |

| Total cost of power system/$ | 270,912 | 231,075 |

| Load reduction of natural gas system/kcf | 368 | 0 |

| Excess natural gas from P2G/kcf | 36 | 0 |

| Total cost of gas system/$ | 320,656 | 244,687 |

| Cost of IPGS/$ | 547,916 | 475,763 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Duan, J.; Liu, F.; Yang, Y.; Jin, Z. Flexible Dispatch for Integrated Power and Gas Systems Considering Power-to-Gas and Demand Response. Energies 2021, 14, 5554. https://doi.org/10.3390/en14175554

Duan J, Liu F, Yang Y, Jin Z. Flexible Dispatch for Integrated Power and Gas Systems Considering Power-to-Gas and Demand Response. Energies. 2021; 14(17):5554. https://doi.org/10.3390/en14175554

Chicago/Turabian StyleDuan, Jiandong, Fan Liu, Yao Yang, and Zhuanting Jin. 2021. "Flexible Dispatch for Integrated Power and Gas Systems Considering Power-to-Gas and Demand Response" Energies 14, no. 17: 5554. https://doi.org/10.3390/en14175554

APA StyleDuan, J., Liu, F., Yang, Y., & Jin, Z. (2021). Flexible Dispatch for Integrated Power and Gas Systems Considering Power-to-Gas and Demand Response. Energies, 14(17), 5554. https://doi.org/10.3390/en14175554