Solid Fraction of Digestate from Biogas Plant as a Material for Pellets Production

Abstract

:1. Introduction

2. Materials and Methods

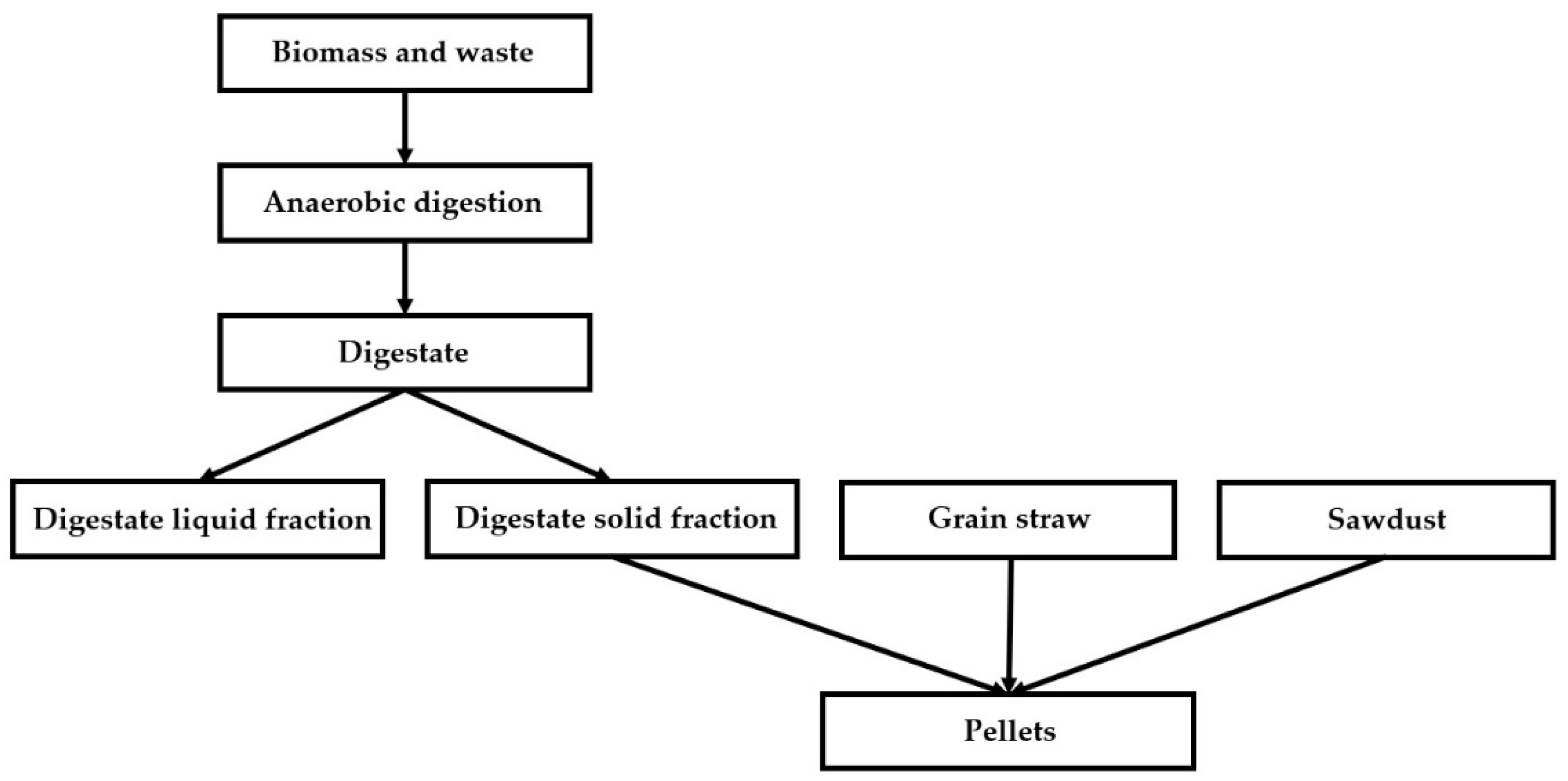

2.1. Substrates and Composition of Mixtures

2.2. Pellets Production

2.3. Methods

- Qas—combustion heat of the analyzed fuel (HHV) [kJ∙kg−1],

- C—calorimeter heat capacity [J∙°C−1],

- Dt—the overall temperature rise of the main period [°C],

- k—correction for environmental heat exchange [°C],

- c—correction sum for the additional heat effects [J],

- m—fuel sample mass [g].

- Qaw—calorific value of the analyzed fuel in the analytical state (LHV) [kJ∙kg−1],

- Qas—combustion heat of the analyzed fuel (HHV) [kJ∙kg−1],

- Wa—moisture content of test sample [%],

- Ha—hydrogen content of test sample [%].

3. Results and Discussion

3.1. Pellets Production and Physical Analysis

3.2. Higher and Lower Heating Value of Pellets

3.3. Economic Calculation of Solid Biofuels Production

4. Conclusions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| DM | Dry matter content [%] |

| DSF | Digestate solid fraction |

| HHV | Higher heating value [kJ·kg−1] |

| LHV | Lower heating value [kJ·kg−1] |

| MC | Moisture content [%] |

| Mg | Megagram, ton |

| MM | Mineral matter, ash content [% DM] |

| OM | Organic matter [% DM] |

References

- Kumar, B.; Bhardwaj, N.; Agrawal, K.; Verm, P.C. Current perspective on pretreatment technologies using lignocellulosic biomass: An emerging biorefinery concept. Fuel Process. Technol. 2020, 199, 106244. [Google Scholar] [CrossRef]

- Jastrzębski, K.; Kula, P. Emerging Technology for a Green, Sustainable Energy-Promising Materials for Hydrogen Storage, from Nanotubes to Graphene—A Review. Materials 2021, 14, 2499. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.; Zhi, Q. The Role of Green Finance in Environmental Protection: Two Aspects of Market Mechanism and Policies. Energy Procedia 2016, 104, 311–316. [Google Scholar] [CrossRef]

- Castells, B.; Amez, I.; Medic, L.; García-Torrent, J. Torrefaction influence on combustion kinetics of Malaysian oil palm wastes. Fuel Process. Technol. 2021, 218, 106843. [Google Scholar] [CrossRef]

- Styks, J.; Knapczyk, A.; Łapczyńska-Kordon, B. Effect of Compaction Pressure and Moisture Content on Post-Agglomeration Elastic Springback of Pellets. Materials 2021, 14, 879. [Google Scholar] [CrossRef] [PubMed]

- Williams, O.; Taylor, S.; Lester, E.; Kingman, S.; Giddings, D.; Eastwick, C. Applicability of Mechanical Tests for Biomass Pellet Characterisation for Bioenergy Applications. Materials 2018, 11, 1329. [Google Scholar] [CrossRef] [Green Version]

- Mack, R.; Kuptz, D.; Schön, C.; Hartmann, H. Combustion behavior and slagging tendencies of kaolin additivated agricultural pellets and of wood-straw pellet blends in a small-scale boiler. Biomass Bioenergy 2019, 125, 50–62. [Google Scholar] [CrossRef]

- Aghilinategh, M.; Barati, M.; Hamadanian, M. Supercritical methanol for one put biodiesel production from chlorella vulgaris microalgae in the presence of CaO/TiO2 nano-photocatalyst and subcritical water. Biomass Bioenergy 2019, 123, 34–40. [Google Scholar] [CrossRef]

- Padilla-Rivera, A.; Paredes, G.; Güereca, L.P. A systematic review of the sustainability assessment of bioenergy: The case of gaseous biofuels. Biomass Bioenergy 2019, 125, 79–94. [Google Scholar] [CrossRef]

- Cudjoe, D.; Han, M.S.; Nandiwardhana, A.P. Electricity generation using biogas from organic fraction of municipal solid waste generated in provinces of China: Techno-economic and environmental impact analysis. Fuel Process. Technol. 2020, 203, 106381. [Google Scholar] [CrossRef]

- Dach, J.; Koszela, K.; Boniecki, P.; Zaborowicz, M.; Lewicki, A.; Czekała, W.; Skwarcz, J.; Wei, Q.; Piekarska-Boniecka, H.; Białobrzewski, I. The use of neural modelling to estimate the methane production from slurry fermentation processes. Renew. Sustain. Energy Rev. 2016, 56, 603–610. [Google Scholar] [CrossRef]

- Dahunsi, S.O.; Adesulu-Dahunsi, A.T.; Osueke, C.O.; Lawal, A.I.; Olayanju, T.M.A.; Ojediran, J.O.; Izebere, J.O. Biogas generation from Sorghum bicolor stalk: Effect of pretreatment methods and economic feasibility. Energy Rep. 2019, 5, 584–593. [Google Scholar] [CrossRef]

- Decker, T.; Baumgardner, M.; Prapas, J.; Bradley, T. A mixed computational and experimental approach to improved biogas burner flame port design. Energy Sustain. Dev. 2018, 44, 37–46. [Google Scholar] [CrossRef]

- Mazurkiewicz, J.; Marczuk, A.; Pochwatka, P.; Kujawa, S. Maize Straw as a Valuable Energetic Material for Biogas Plant Feeding. Materials 2019, 12, 3848. [Google Scholar] [CrossRef] [Green Version]

- Gava, O.; Favilli, E.; Bartolini, F.; Brunori, G. Knowledge networks and their role in shaping the relations within the Agricultural Knowledge and Innovation System in the agroenergy sector. The case of biogas in Tuscany (Italy). J. Rural Stud. 2017, 56, 100–113. [Google Scholar] [CrossRef]

- Woźniak, M.; Ratajczak, I.; Wojcieszak, D.; Waśkiewicz, A.; Szentner, K.; Przybył, J.; Borysiak, S.; Goliński, P. Chemical and Structural Characterization of Maize Stover Fractions in Aspect of Its Possible Applications. Materials 2021, 14, 1527. [Google Scholar] [CrossRef] [PubMed]

- Nguyen, V.H.; Topno, S.; Balingbing, C.; Nguyen, V.C.N.; Röder, M.; Quilty, J.; Jamieson, C.; Thornley, P.; Gummert, M. Generating a positive energy balance from using rice straw for anaerobic digestion. Energy Rep. 2016, 2, 117–122. [Google Scholar] [CrossRef]

- Czekała, W.; Dach, J.; Dong, R.; Janczak, D.; Malińska, K.; Jóźwiakowski, K.; Smurzyńska, A.; Cieślik, M. Composting potential of the solid fraction of digested pulp produced by a biogas plant. Biosyst. Eng. 2017, 160, 25–29. [Google Scholar] [CrossRef]

- Lachman, J.; Baláš, M.; Lisý, M.; Lisá, M.; Milčák, P.; Elbl, P. An overview of slagging and fouling indicators and their applicability to biomass fuels. Fuel Process. Technol. 2021, 217, 106804. [Google Scholar] [CrossRef]

- Lindner, J.; Zielonka, S.; Oechsner, H.; Lemmer, A. Effects of mechanical treatment of digestate after anaerobic digestion on the degree of degradation. Bioresour. Technol. 2015, 178, 194–200. [Google Scholar] [CrossRef] [PubMed]

- Boni, M.R.; D’Amato, E.; Polettini, A.; Pomi, R.; Rossi, A. Effect of ultrasonication on anaerobic degradability of solid waste digestate. Waste Manag. 2016, 48, 209–217. [Google Scholar] [CrossRef] [PubMed]

- Maynaud, G.; Druilhe, C.; Daumoin, M.; Jimenez, J.; Patureau, D.; Torrijos, M.; Pourcher, A.M.; Wéry, N. Characterisation of the biodegradability of post-treated digestates via the chemical accessibility and complexity of organic matter. Bioresour. Technol. 2017, 231, 65–74. [Google Scholar] [CrossRef] [PubMed]

- Kataki, S.; Hazarika, S.; Baruah, D.C. Assessment of by-products of bioenergy systems (anaerobic digestion and gasification) as potential crop nutrient. Waste Manag. 2016, 59, 102–117. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Czekała, W.; Lewicki, A.; Pochwatka, P.; Czekała, A.; Wojcieszak, D.; Jóźwiakowski, K.; Waliszewska, H. Digestate management in Polish farms as an element of the nutrient cycle. J. Clean. Prod. 2020, 242, 118454. [Google Scholar] [CrossRef]

- Moreira, D.M.; Ferreira, V.; Resende, P.R.; Pinho, C. Determination of kinetic data through the fluidized bed combustion of chars made from vine and kiwi pruning wastes. Energy Rep. 2020, 6, 615–619. [Google Scholar] [CrossRef]

- Tan, M.; Luo, L.; Wu, Z.; Huang, Z.; Zhang, J.; Huang, J.; Yang, Y.; Zhang, X.; Li, H. Pelletization of Camellia oleifera Abel. shell after storage: Energy consumption and pellet properties. Fuel Process. Technol. 2020, 201, 106337. [Google Scholar] [CrossRef]

- Czekała, W.; Bartnikowska, S.; Dach, J.; Janczak, D.; Smurzyńska, A.; Kozłowski, K.; Bugała, A.; Lewicki, A.; Cieślik, M.; Typańska, D.; et al. The energy value and economic efficiency of solid biofuels produced from digestate and sawdust. Energy 2018, 159, 1118–1122. [Google Scholar] [CrossRef]

- Czekała, W. Biogas Production from Raw Digestate and its Fraction. J. Ecol. Eng. 2019, 20, 97–102. [Google Scholar] [CrossRef]

- Musatti, A.; Ficara, E.; Mapelli, C.; Sambusiti, C.; Rollini, M. Use of solid digestate for lignocellulolytic enzymes production through submerged fungal fermentation. J. Environ. Manag. 2016, 199, 1–6. [Google Scholar] [CrossRef]

- Lin, L.; Yang, L.; Xu, F.; Michel, F.C.; Li, Y. Comparison of solid-state anaerobic digestion and composting of yard trimmings with effluent from liquid anaerobic digestion. Bioresour. Technol. 2014, 169, 439–446. [Google Scholar] [CrossRef]

- Czekała, W.; Bartnikowska, S.; Lewicka, A.; Bugała, A.; Zbytek, Z.; Lewicki, A. Economic and energy efficiency of the solid biofuels produced from digested pulp. MATEC Web Conf. 2016, 60, 04005. [Google Scholar] [CrossRef]

- PN-81/G-04513 Polish Standard: Solid Fuels—Determination of Heat of Combustion and Calculation of Calorific Value; Polski Komitet Normalizacji: Miar i Jakości, Poland, 1981.

- PN-92/P-50092 Polish Standard: Raw Materials for the Paper Industry—Wood—Chemical Analysis; Polski Komitet Normalizacji: Miar i Jakości, Poland, 1992.

- Whittaker, C.; Shield, I. Factors affecting wood, energy grass and straw pellet durability—A review. Renew. Sustain. Energy Rev. 2017, 71, 1–11. [Google Scholar] [CrossRef]

- Strandberg, A.; Thyrela, M.; Skoglund, N.; Lestander, T.A.; Broström, M.; Backman, R. Biomass pellet combustion: Cavities and ash formation characterized by synchrotron X-ray micro-tomography. Fuel Process. Technol. 2018, 176, 211–220. [Google Scholar] [CrossRef] [Green Version]

- Peng, J.; Bi, X.T.; Lim, C.J.; Peng, H.; Kim, C.S.; Jia, D.; Zuo, H. Sawdust as an effective binder for making torrefied pellets. Appl. Energy 2015, 157, 491–498. [Google Scholar] [CrossRef]

- Ríos-Badrán, I.M.; Luzardo-Ocampo, I.; García-Trejo, J.F.; Santos-Cruz, J.; Gutiérrez-Antonio, C. Production and characterization of fuel pellets from rice husk and wheat straw. Renew. Energy 2020, 145, 500–507. [Google Scholar] [CrossRef]

- Stolarski, M.; Graban, Ł.; Szczukowski, S.; Tworkowski, J. Agricultural and forest biomass as feedstock in the manufacture of solid biofuels. Pol. J. Agron. 2010, 2, 67–72. Available online: https://www.iung.pl/PJA/wydane/2/PJA2_12.pdf (accessed on 13 July 2021).

- García, R.; Pizarro, C.; Lavín, A.G.; Bueno, J.L. Spanish biofuels heating value estimation, Part I: Ultimate analysis data. Fuel 2014, 117, 1130–1138. [Google Scholar] [CrossRef]

- García, R.; Pizarro, C.; Lavín, A.G.; Bueno, J.L. Spanish biofuels heating value estimation, Part II: Proximate analysis data. Fuel 2014, 117, 1139–1147. [Google Scholar] [CrossRef]

- Kratzeisen, M.; Starcevic, N.; Martinov, M.; Maurer, C.; Müller, J. Applicability of biogas digestate as solid fuel. Fuel 2010, 89, 2544–2548. [Google Scholar] [CrossRef]

| Name | % of the Fresh Matter | ||

|---|---|---|---|

| DSF | Grain Straw | Sawdust | |

| Blend 1 | 66.7 | 33.3 | - |

| Blend 2 | 66.7 | - | 33.3 |

| Blend 3 | 66.6 | 16.7 | 16.7 |

| DSF | 100.0 | - | - |

| Name | Parameters | |||

|---|---|---|---|---|

| MC [%] | MM [%] | HHV [kJ·kg−1 DM] | LHV [kJ·kg−1 DM] | |

| Blend 1 | 23.96 | 4.24 | 21,774 | 19,879 |

| Blend 2 | 20.06 | 3.62 | 21,562 | 19,777 |

| Blend 3 | 20.84 | 4.08 | 20,968 | 19,164 |

| DSF | 10.80 | 5.23 | 20,967 | 19,394 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Czekała, W. Solid Fraction of Digestate from Biogas Plant as a Material for Pellets Production. Energies 2021, 14, 5034. https://doi.org/10.3390/en14165034

Czekała W. Solid Fraction of Digestate from Biogas Plant as a Material for Pellets Production. Energies. 2021; 14(16):5034. https://doi.org/10.3390/en14165034

Chicago/Turabian StyleCzekała, Wojciech. 2021. "Solid Fraction of Digestate from Biogas Plant as a Material for Pellets Production" Energies 14, no. 16: 5034. https://doi.org/10.3390/en14165034

APA StyleCzekała, W. (2021). Solid Fraction of Digestate from Biogas Plant as a Material for Pellets Production. Energies, 14(16), 5034. https://doi.org/10.3390/en14165034