Numerical Investigation of the Turbulent Flame Propagation in Dual Fuel Engines by Means of Large Eddy Simulation

Abstract

:1. Introduction

2. Computational Method

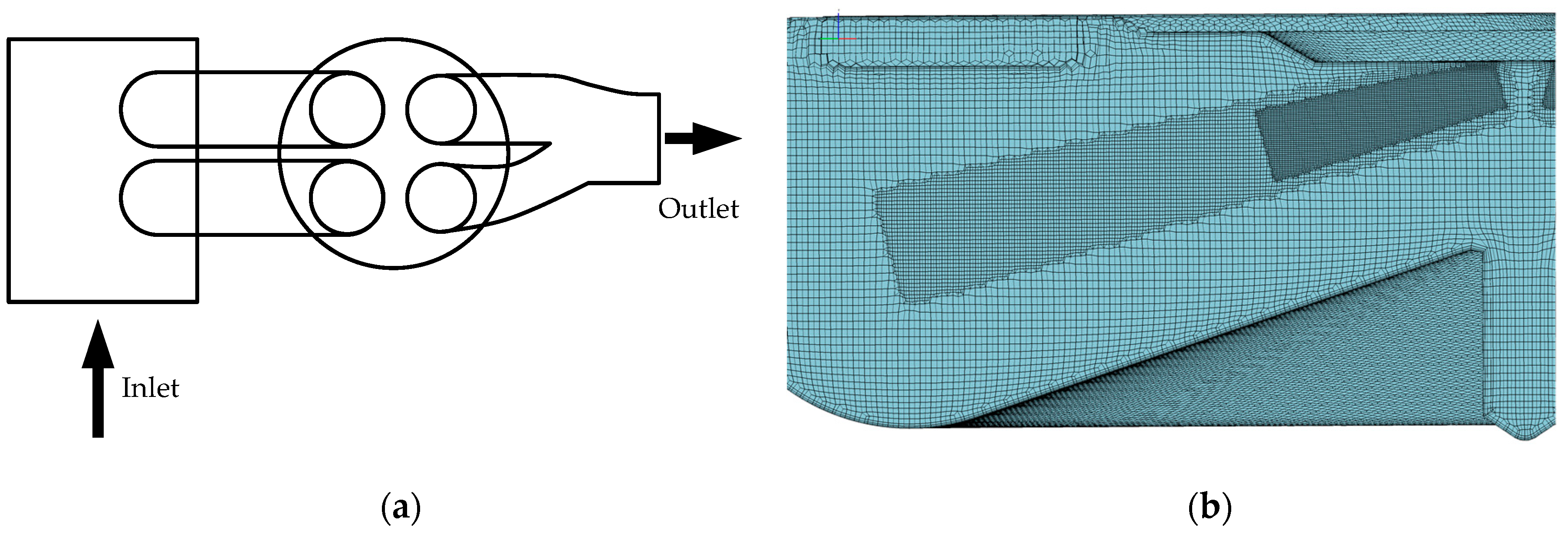

2.1. Mesh Generation

2.2. Numerical Setup

2.3. Injection of the Pilot Fuel

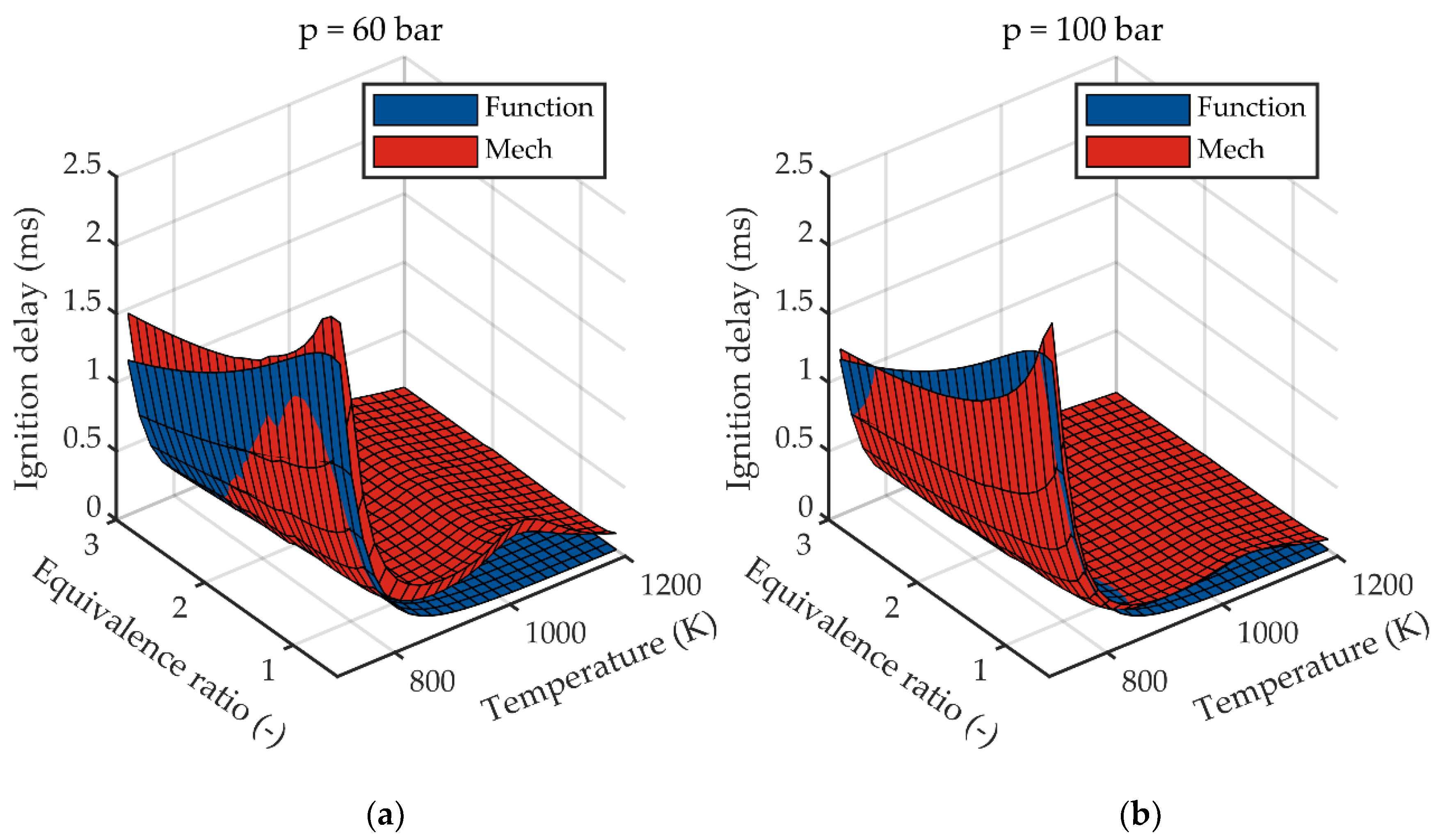

2.4. Combustion Model

3. Model Validation

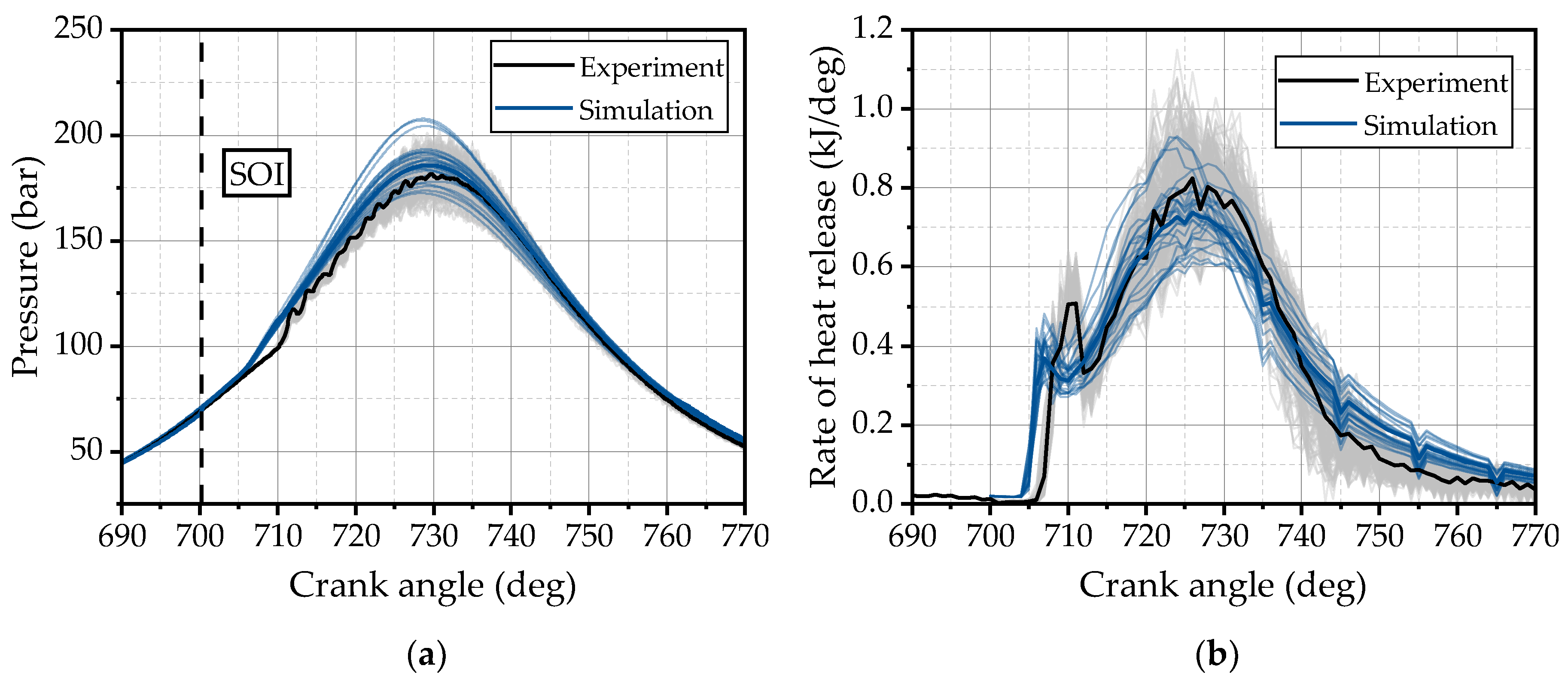

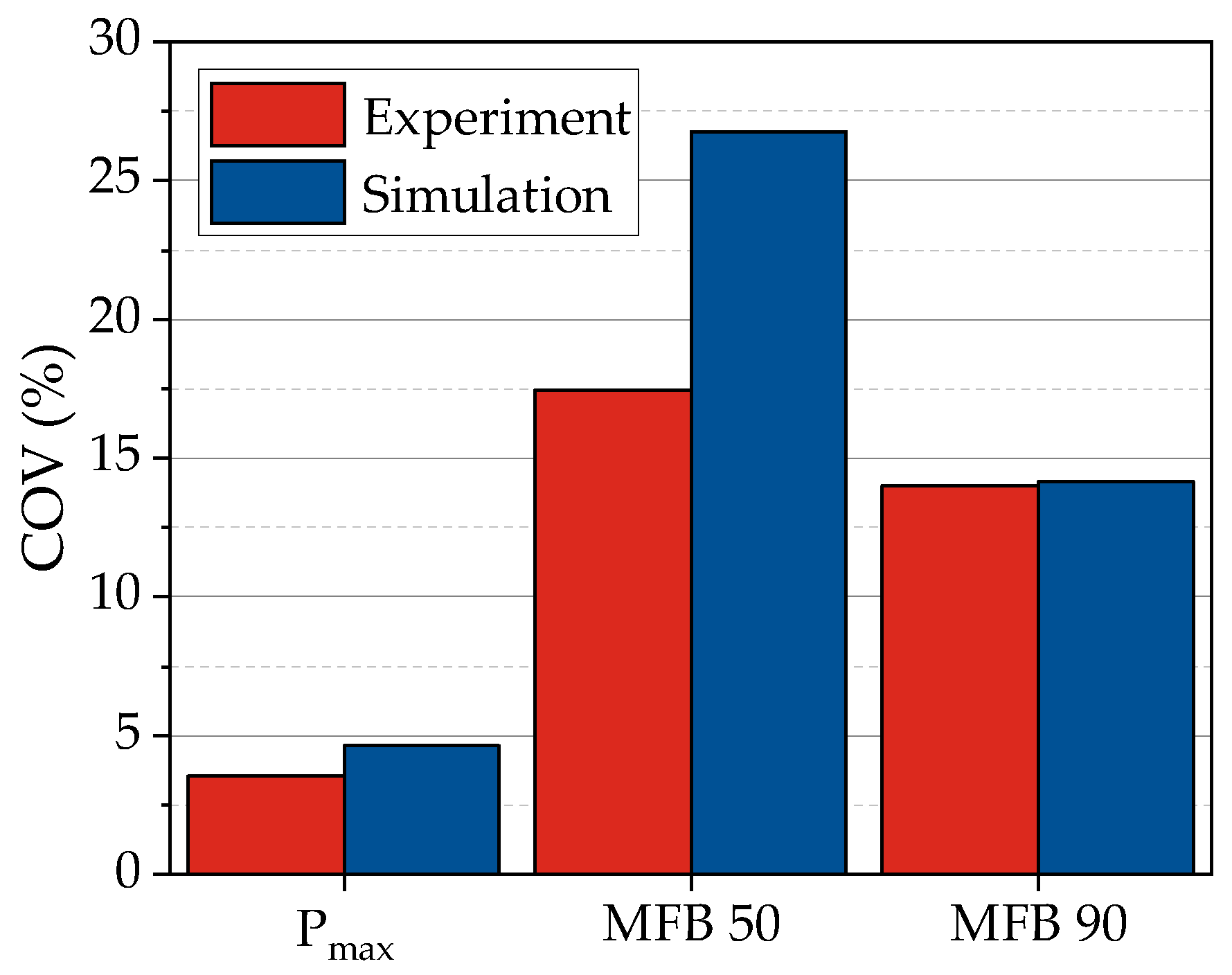

3.1. Evaluation of the Combustion Process

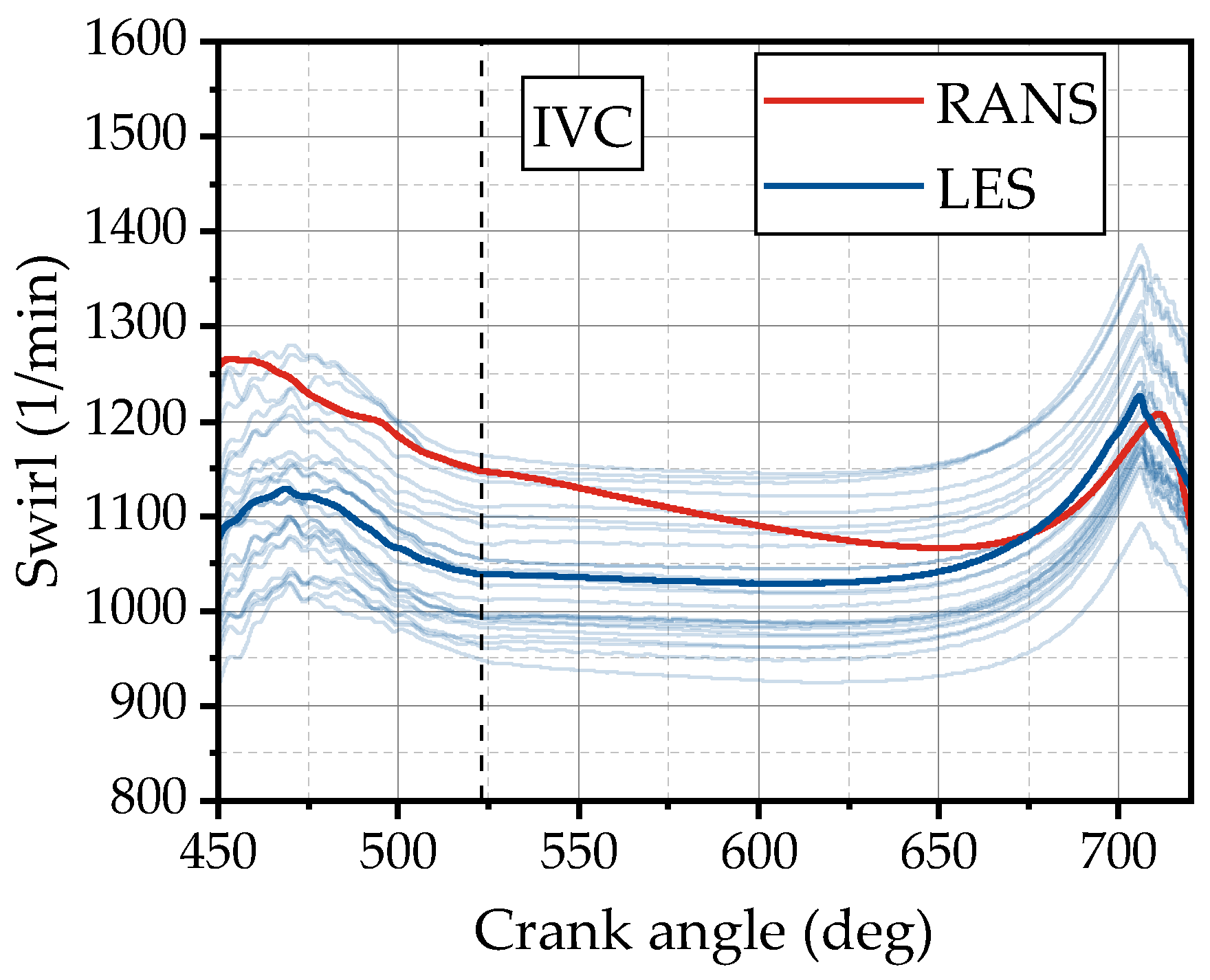

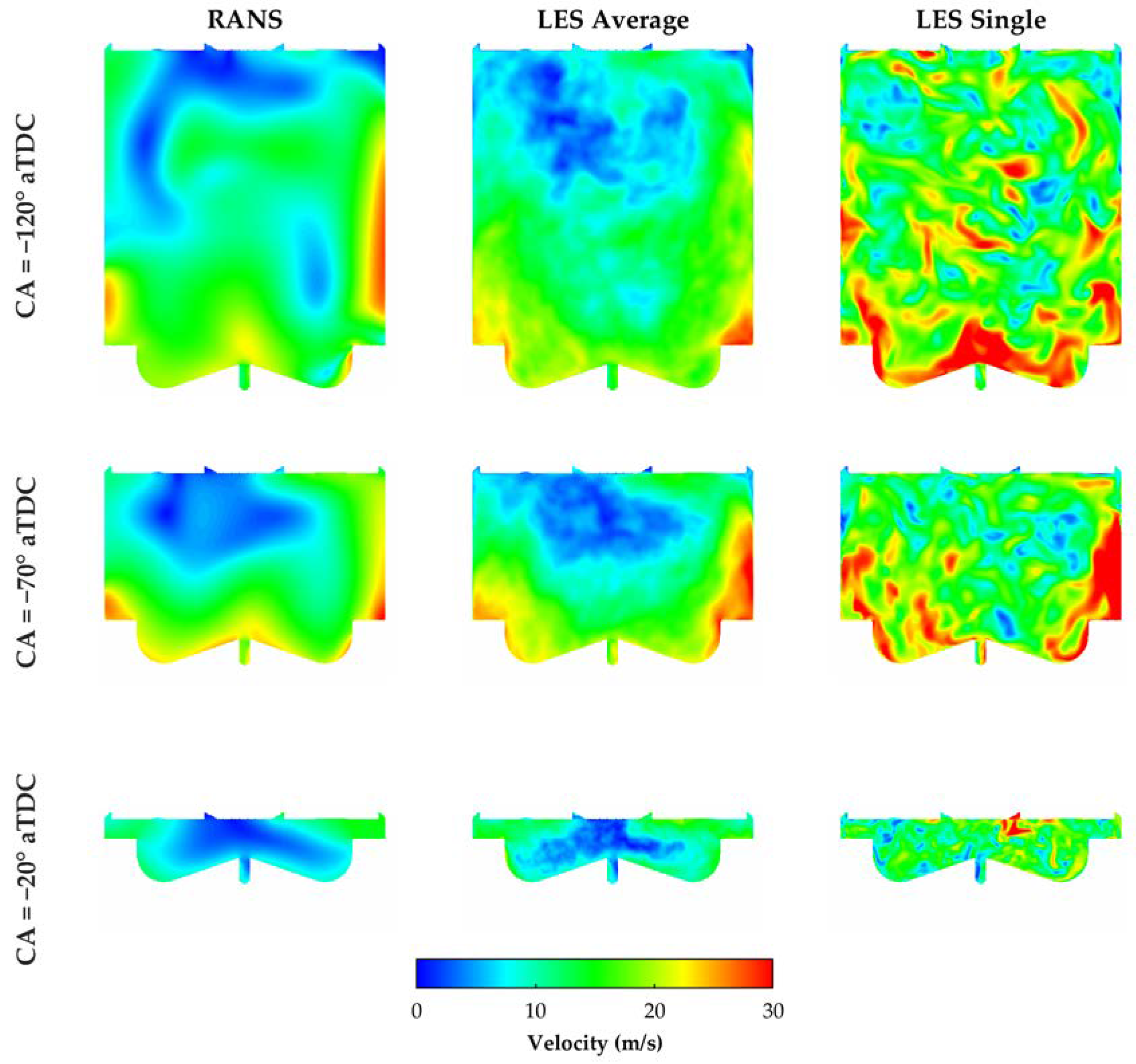

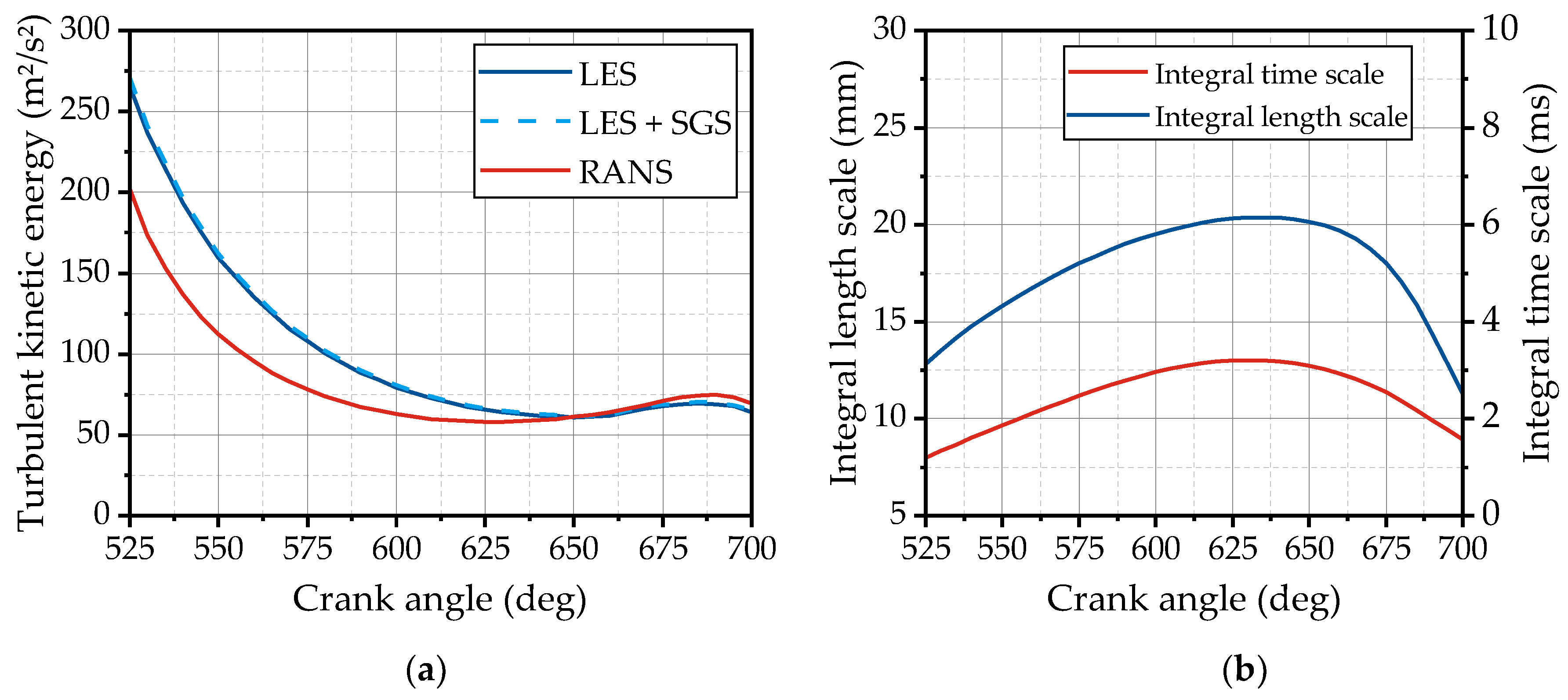

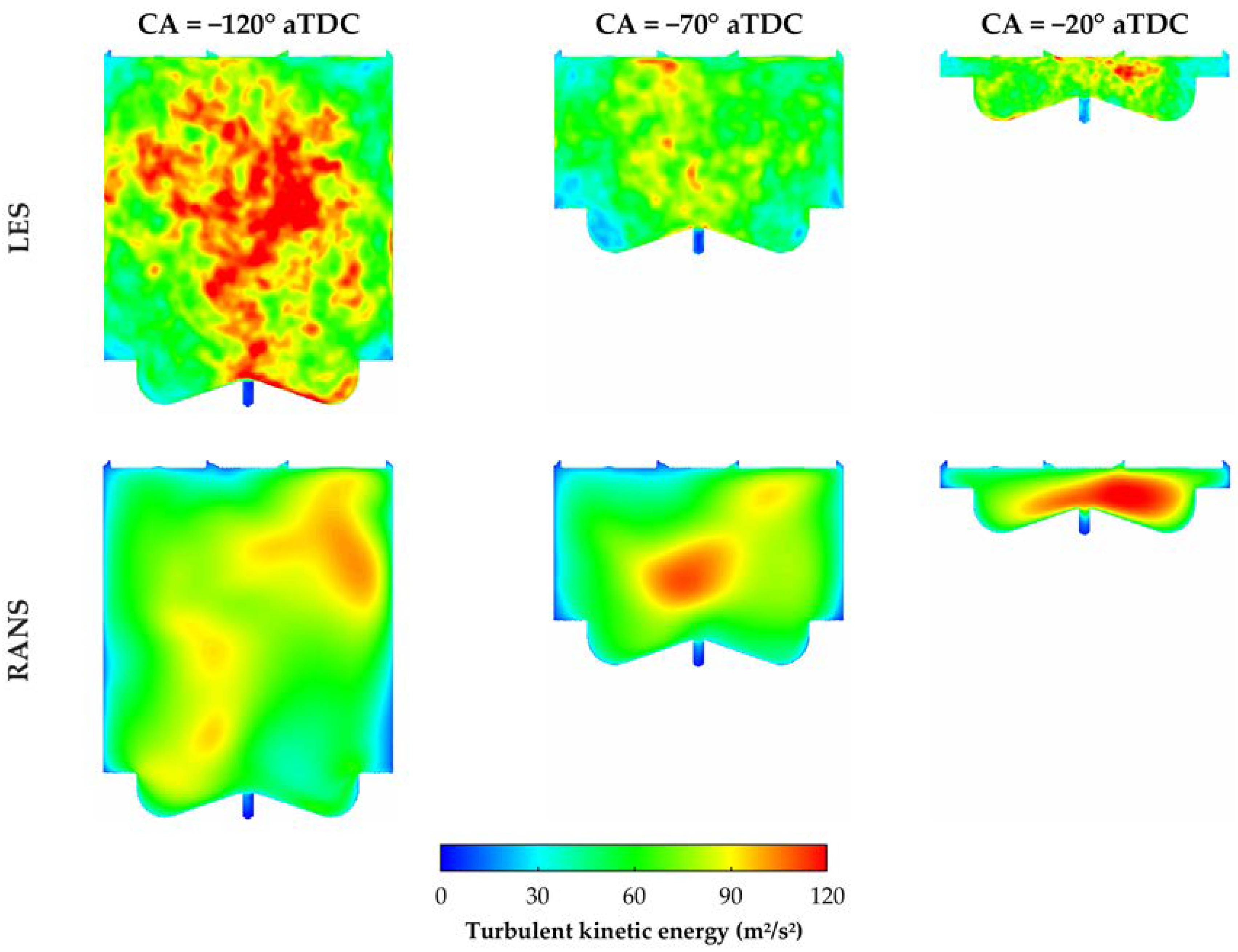

3.2. Evaluation of the Flow Field

4. Results

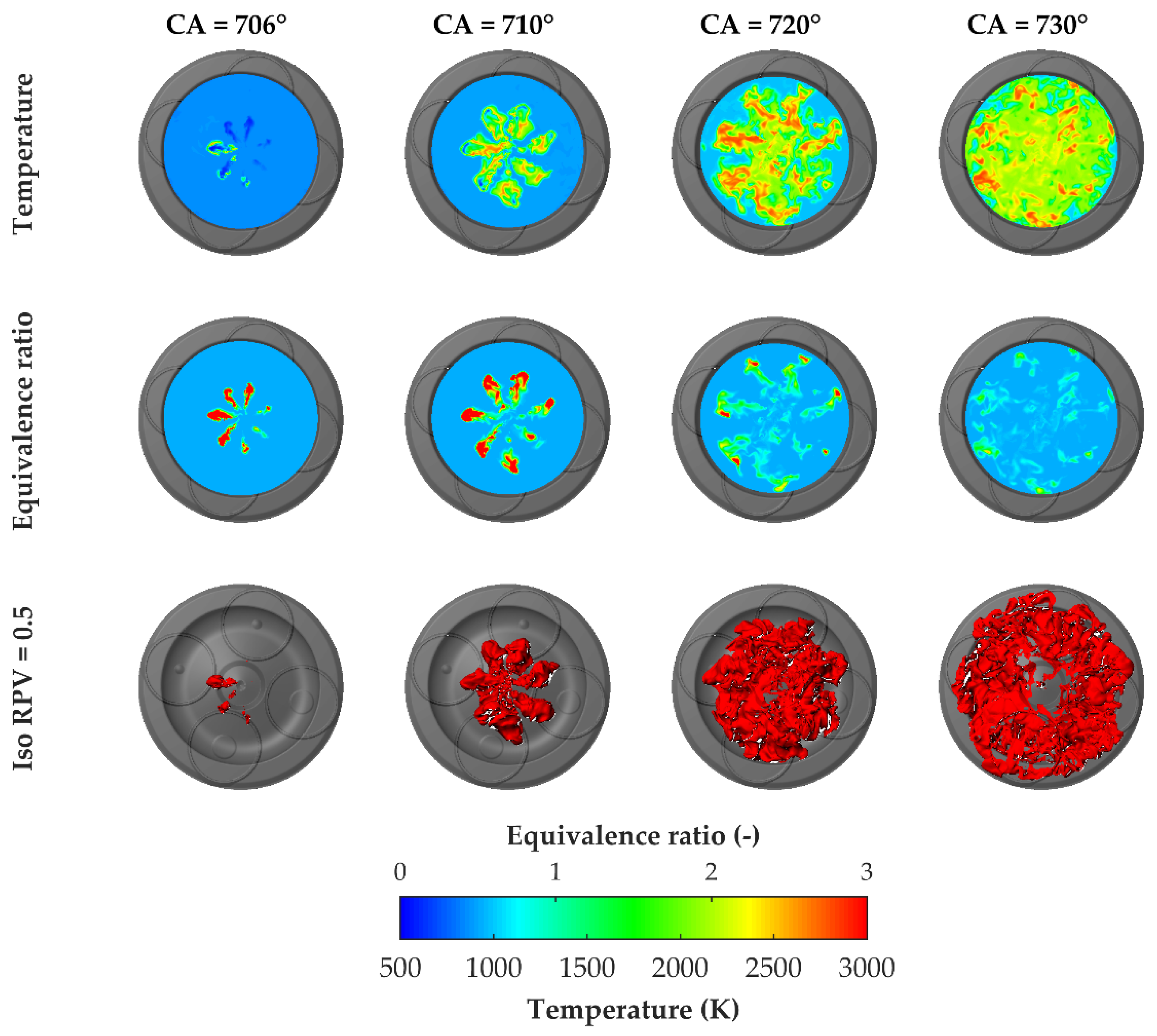

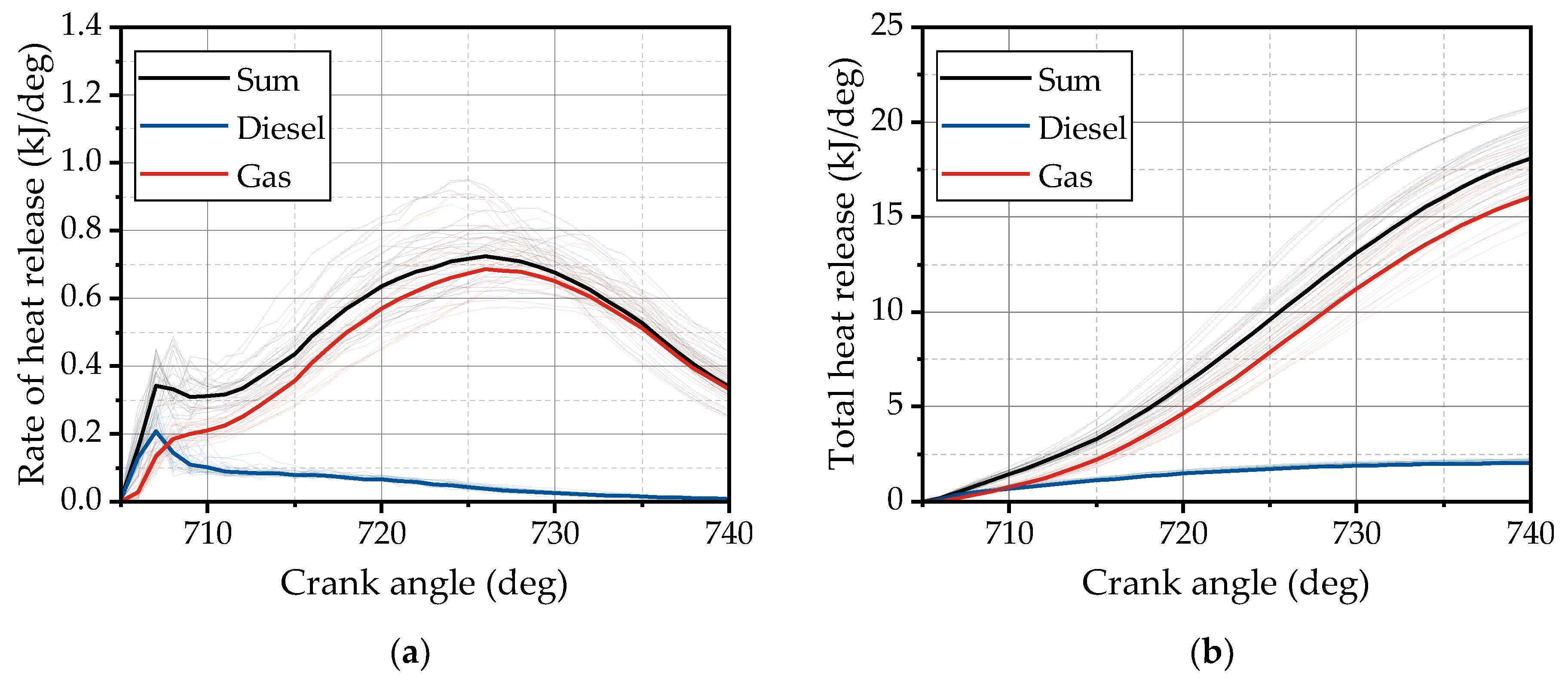

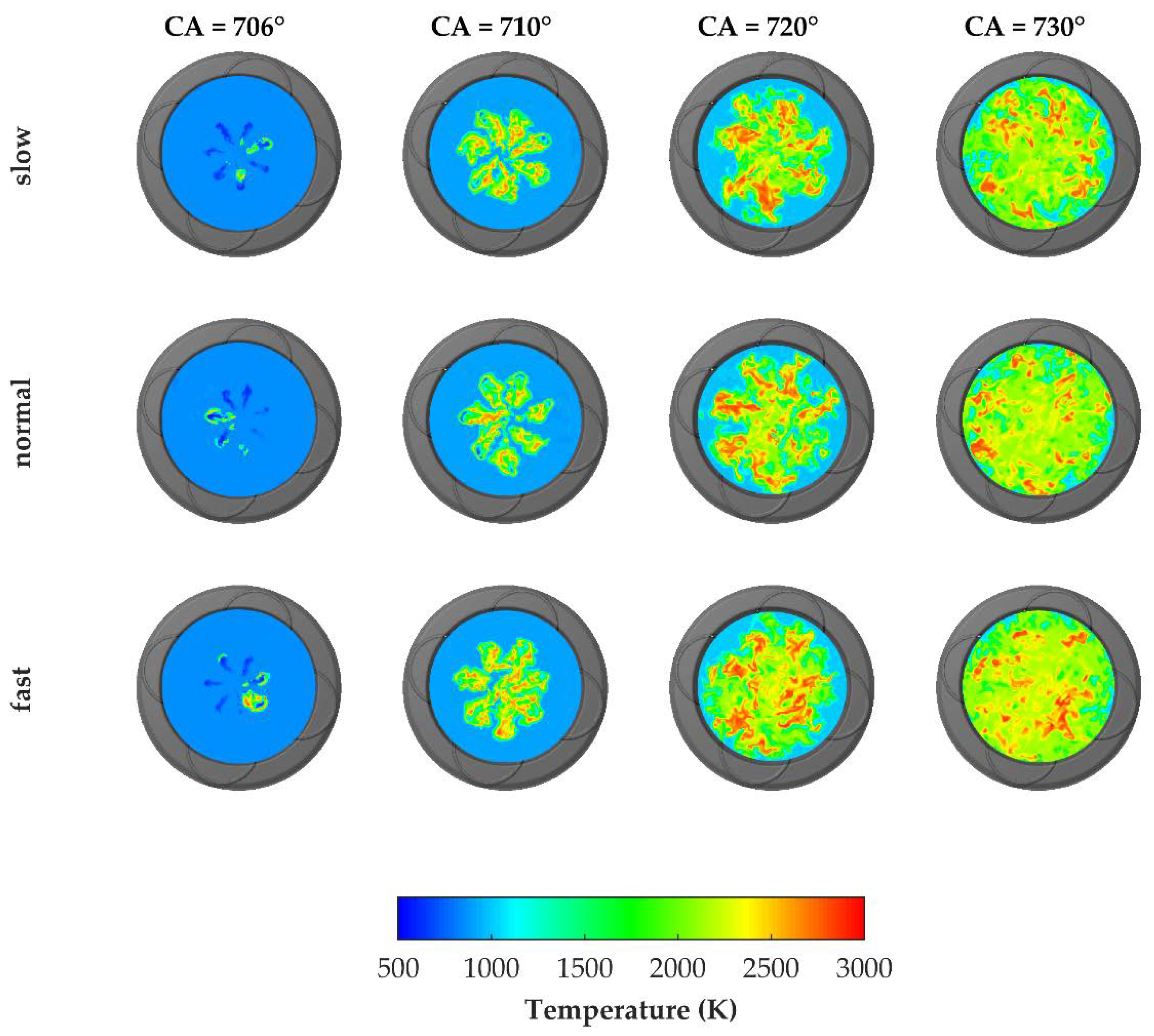

4.1. Dual Fuel Combustion

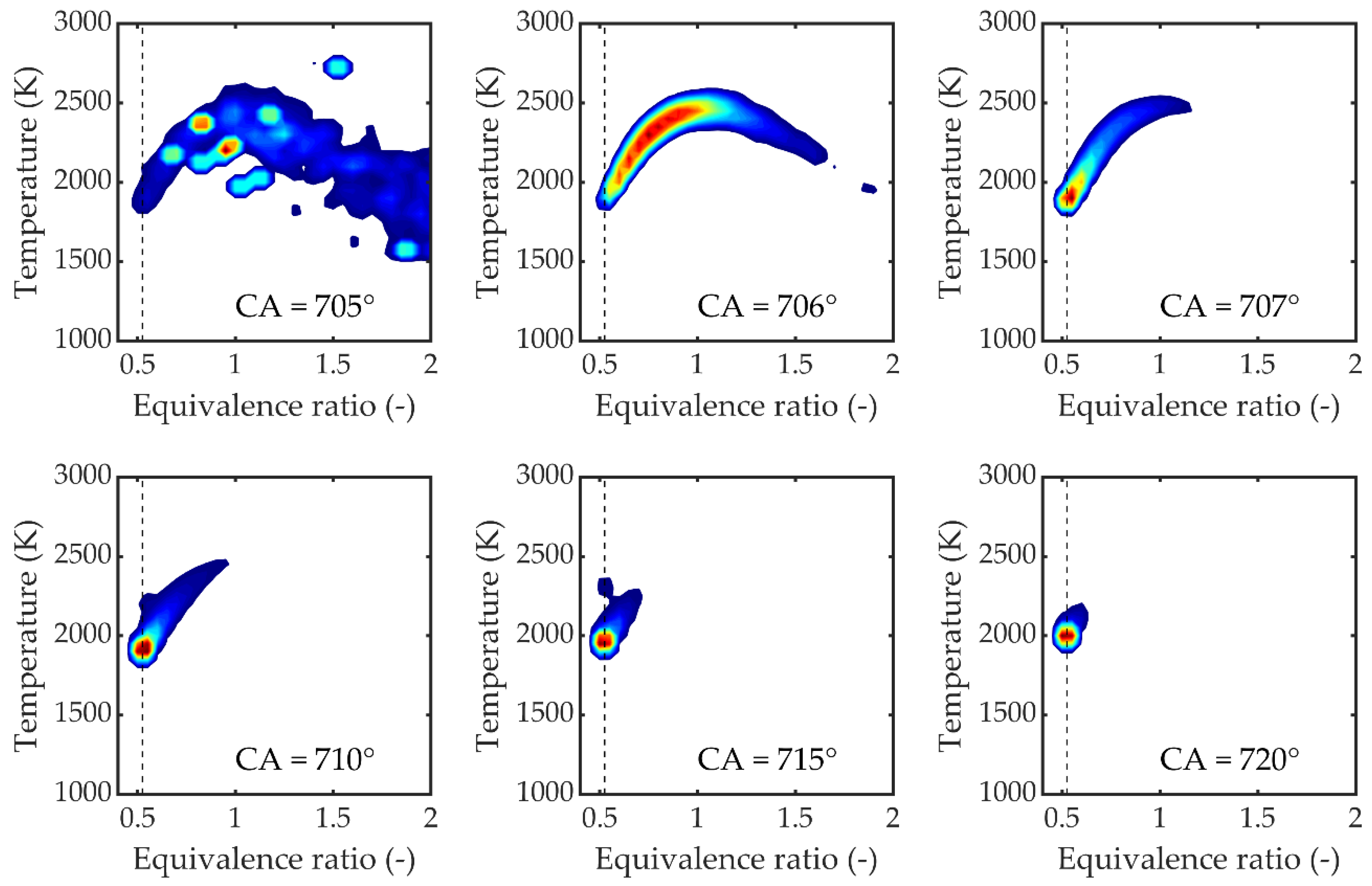

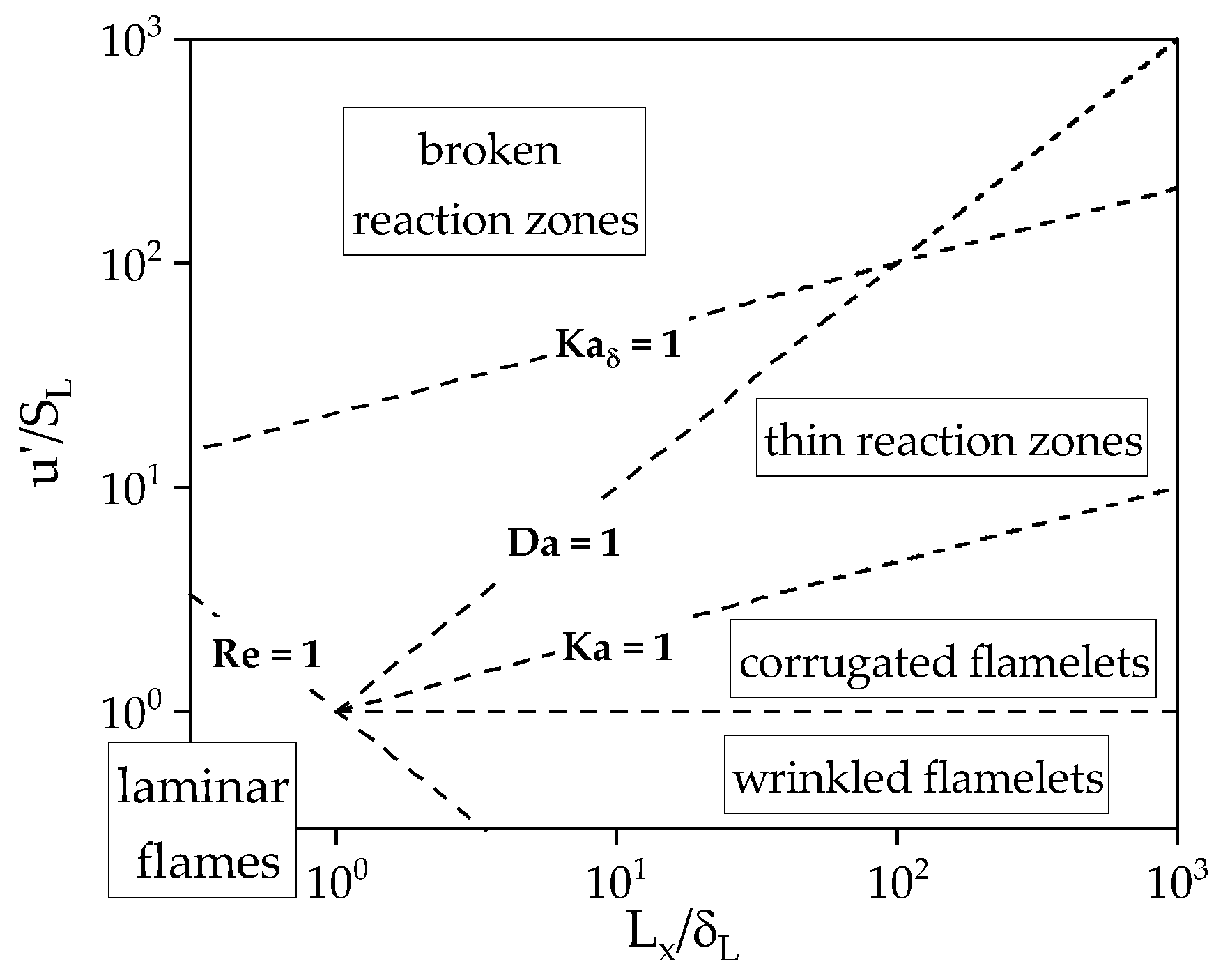

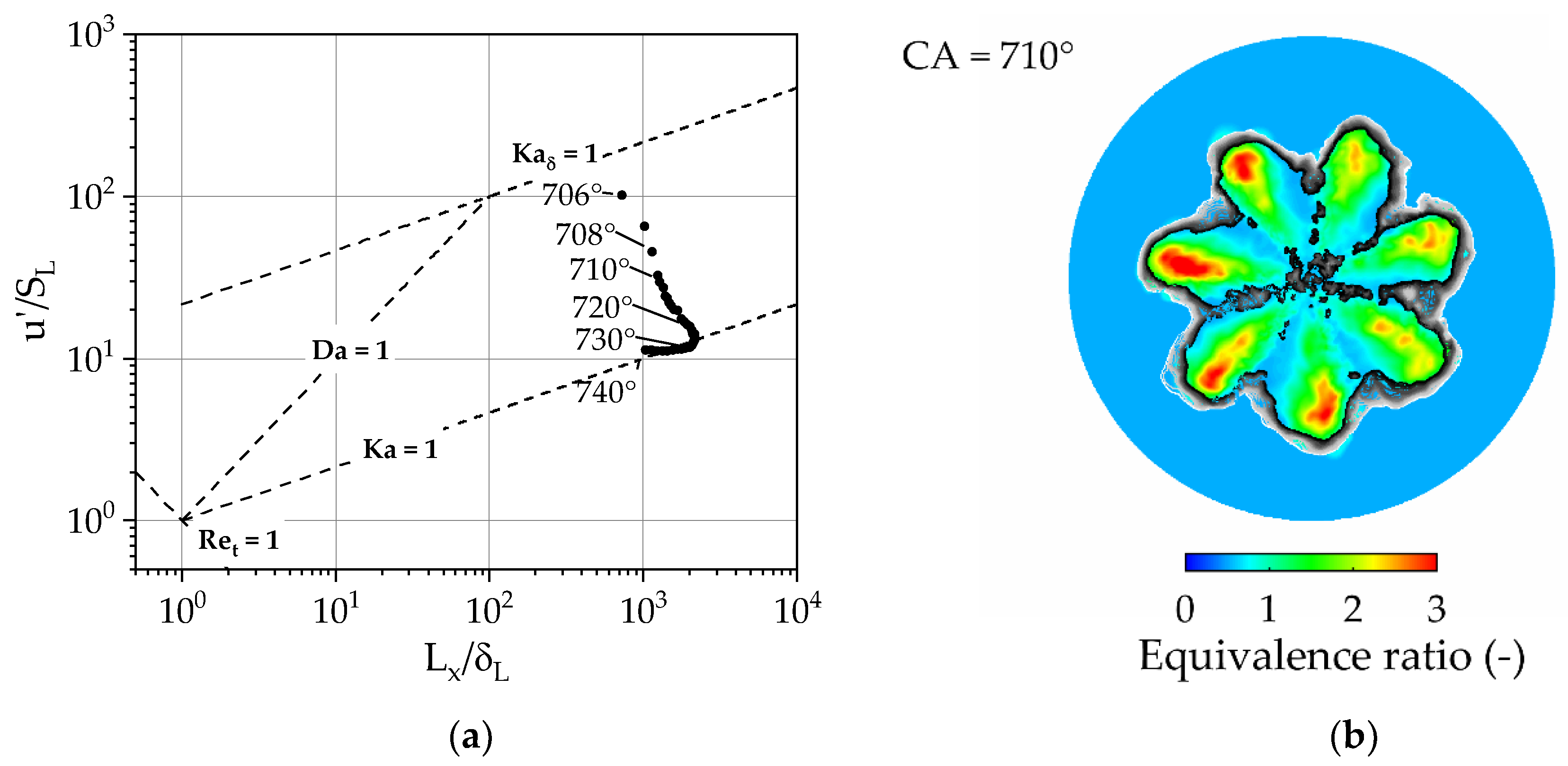

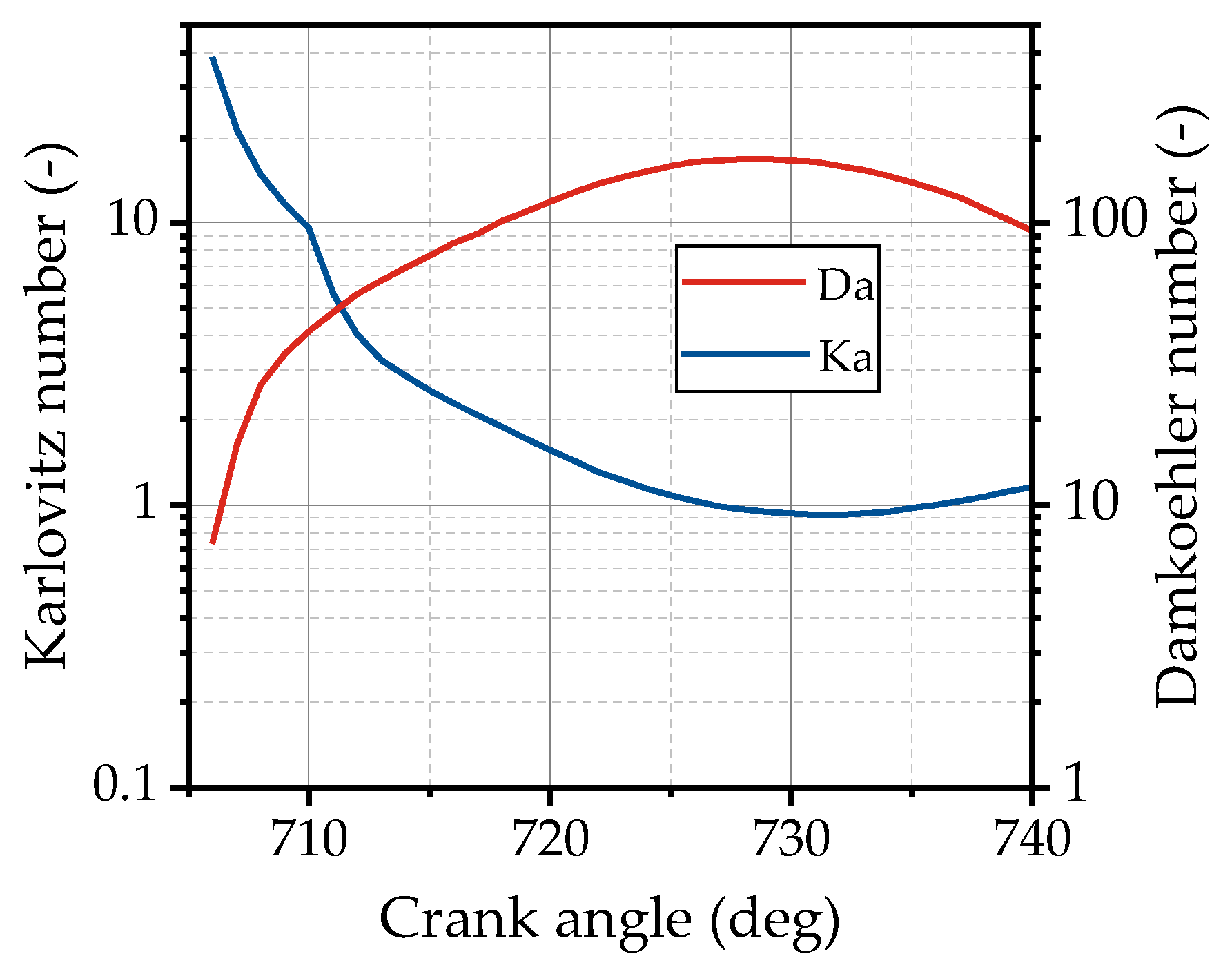

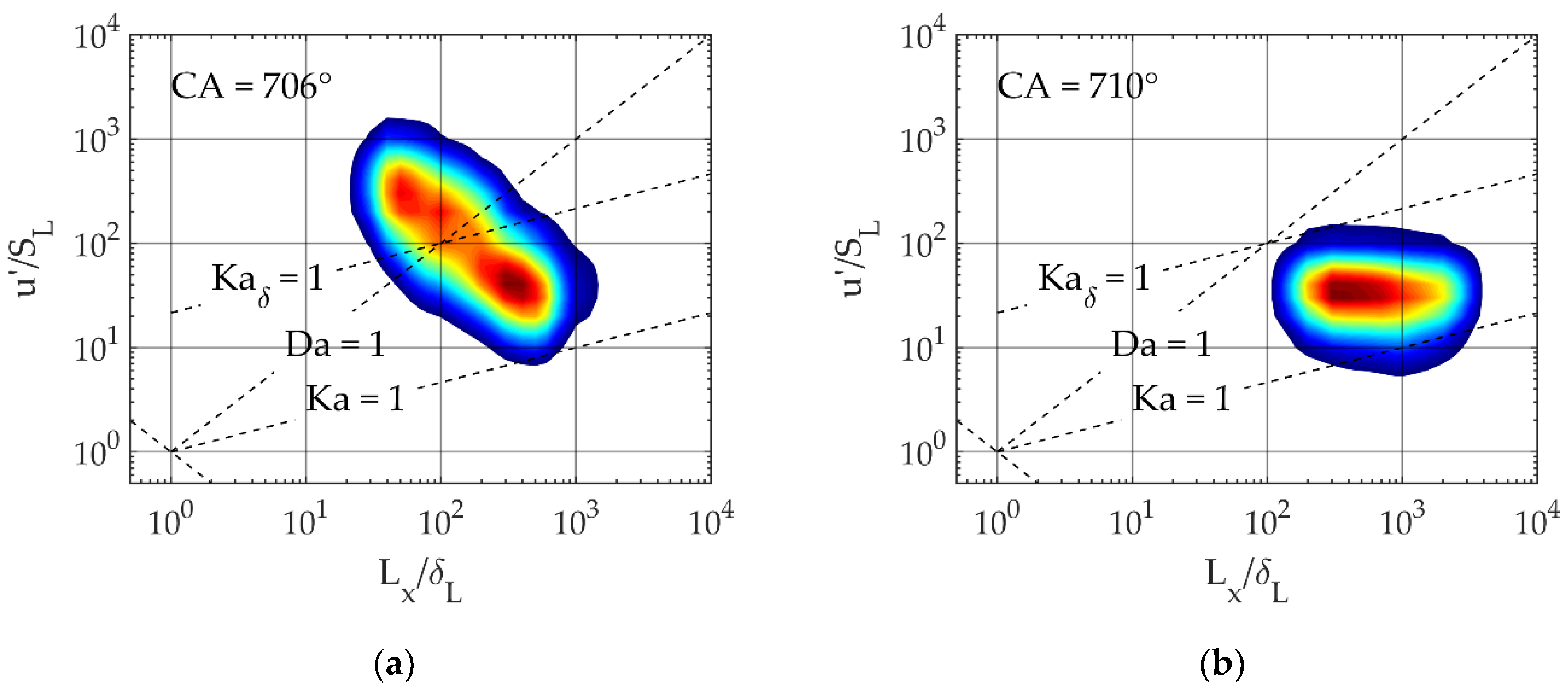

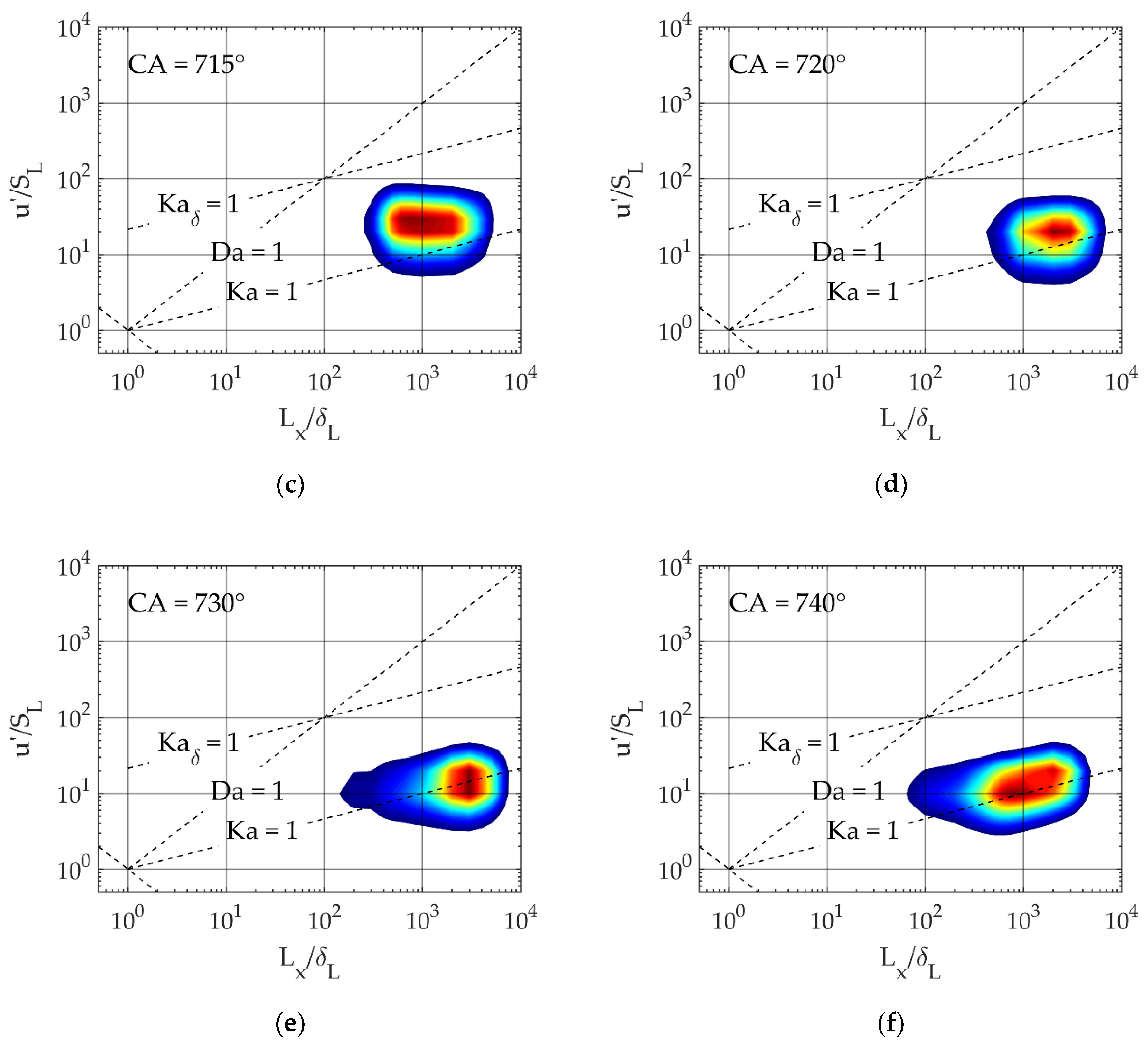

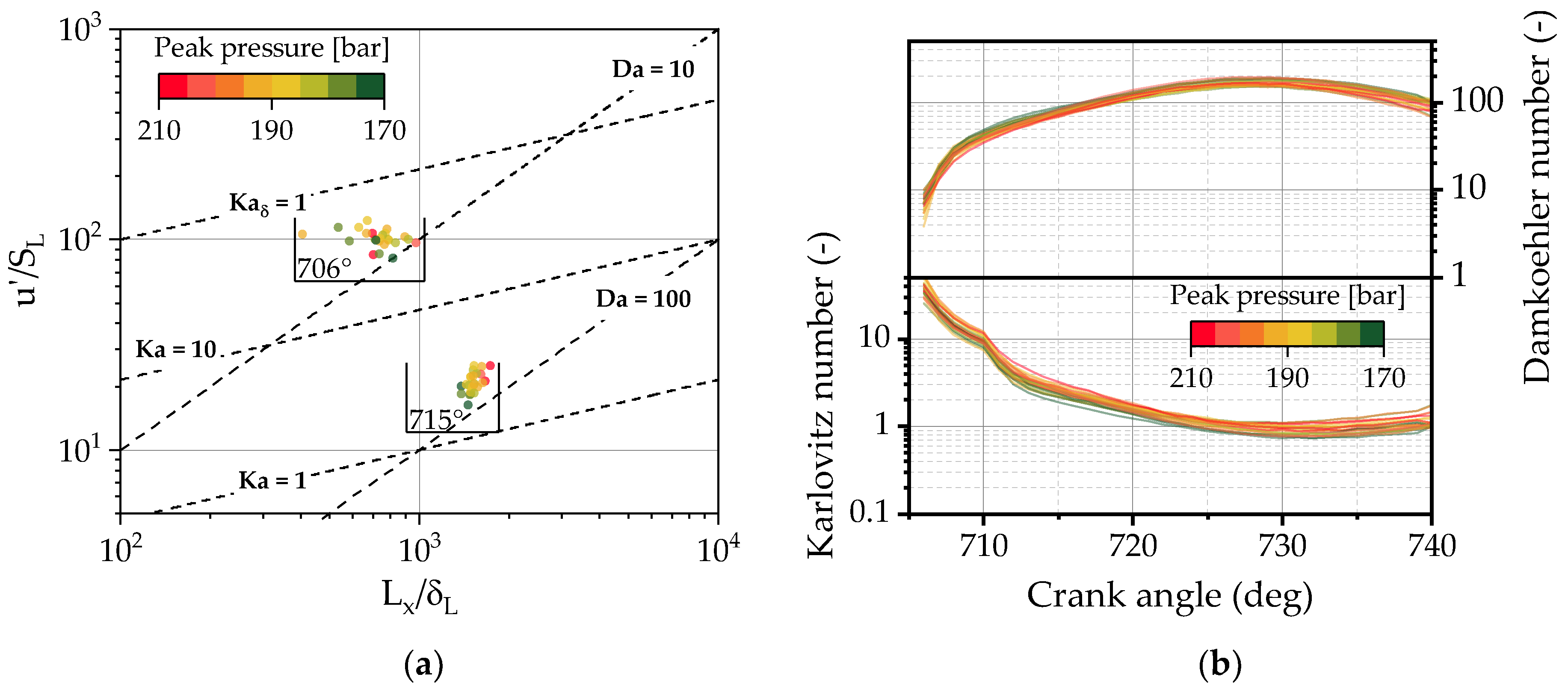

4.2. Analysis of Combustion Regimes

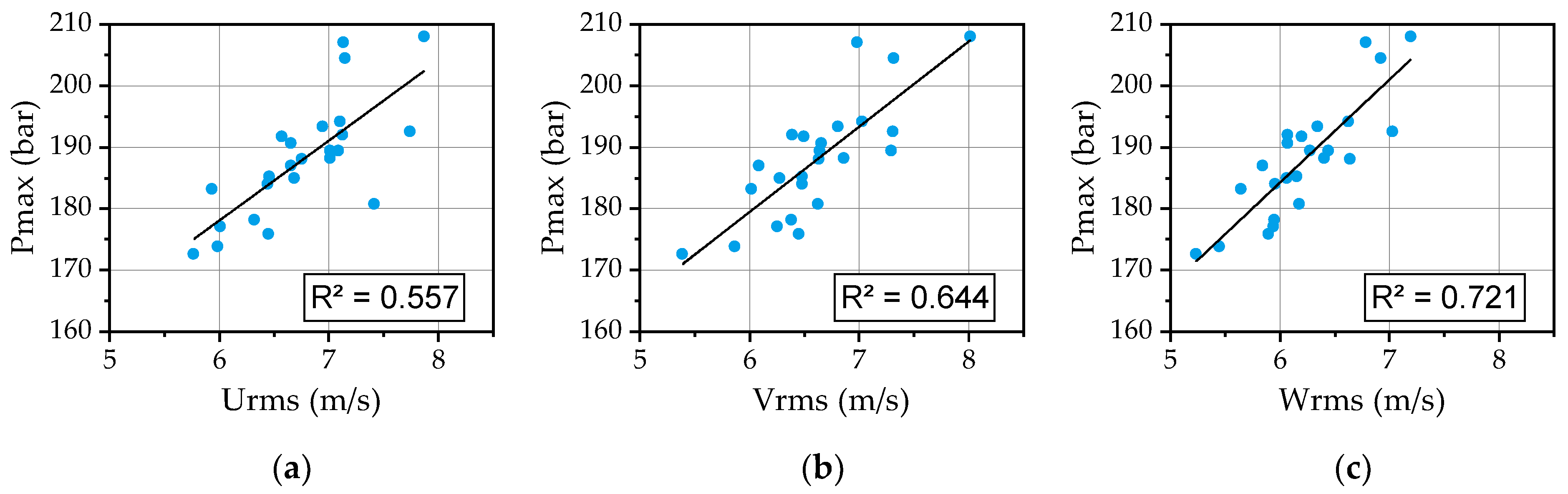

4.3. Cycle-to-Cycle Variations

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| BDC | Bottom Dead Center |

| CA | Crank Angle |

| CCV | Cycle-to-Cycle Variation |

| CFD | Computational Fluid Dynamics |

| COV | Coefficient of Variation |

| LES | Large Eddy Simulation |

| DF | Dual Fuel |

| DIGE | Diesel Ignited Gas Engine |

| ECA | Emission Controlled Area |

| ECFM | Extended Coherent Flame Model |

| IMO | International Maritime Organization |

| IVC | Intake Valve Close |

| MFB | Mass Fraction Burnt |

| RANS | Reynolds-Averaged Navier–Stokes |

| RPV | Reaction Progress Variable |

| RMS | Root Mean Square |

| SGS | Subgrid-scale |

| TCI | Turbulence Chemistry Interaction |

| TDC | Top Dead Center |

Nomenclature

| A | Area |

| B0,1 | Wave model constants |

| Cd | Drag coefficient |

| D | Destruction term |

| Da | Damkoehler number |

| FD | Drag force |

| Ka, Kaδ | Karlovitz number |

| Lx | Turbulent length scale |

| P | Pressure |

| P1,2,3 | Production terms |

| r | Radius |

| Re | Reynolds number |

| s | Flame speed |

| Sc | Schmidt number |

| U, u, V, v, W | Velocity |

| u’ | Turbulent fluctuation intensity |

| V | Volume |

| x | Distance |

| y | Mass fraction |

| δ | Flame thickness |

| η | Kolmogorov length |

| Λ | Wave length |

| μ | Viscosity |

| ρ | Density |

| Σ | Flame surface density |

| σ | Standard deviation |

| τ | Time scale |

| Ω | Growth rate |

| ω | Reaction rate |

Subscripts

| d | Droplet |

| F | Fuel |

| g | Gas |

| i | Coordinate direction (x, y, z) |

| K | Kolmogorov |

| L | Laminar |

| l | Liquid |

| p | Parent droplet |

| T | Turbulent |

| u | Unburnt |

References

- International Maritime Organization. Resolution MEPC.176(58)—Revised MARPOL Annex VI; International Maritime Organization: London, UK, 2008; (MEPC.176(58)). [Google Scholar]

- Schlemmer-Kelling, U. Agenda 2030—mega trends in the large-bore marine engine business. In Proceedings of the Heavy-Duty-, On- and Off-Highway Engines Conference, Augsburg, Germany, 28–29 November 2017. [Google Scholar] [CrossRef]

- van Basshuysen, R. Natural Gas and Renewable Methane for Powertrains: Future Strategies for a Climate-Neutral Mobility, 1st ed.; Springer: Berlin/Heidelberg, Germany, 2016; ISBN 9783319232256. [Google Scholar]

- Karim, G.A. Dual-Fuel Diesel Engines; CRC Press: Boca Raton, FL, USA; London, UK; New York, NY, USA, 2015; ISBN 9781498703086. [Google Scholar]

- Baufeld, T.; Mohr, H.; Phillipp, H. Future Perspectives and technical Challenges for large-bore Dual-Fuel Engines. In Proceedings of the Dessau Gas Engine Conference, Dessau-Roßlau, Germany, 21–22 March 2013. [Google Scholar]

- Senghass, C.; Willmann, M.; Koch, H.-J. Simplified L’Orange fuel injection system for Dual Fuel applications. In Proceedings of the CIMAC Congress 2016, Helsinki, Finland, 6–9 June 2016. [Google Scholar]

- Königsson, F. On Combustion in the CNG-Diesel Dual Fuel Engine; Industrial Engineering and Management, KTH Royal Institute of Technology: Stockholm, Sweden, 2014; ISBN 978-91-7595-243-7. [Google Scholar]

- Frühhaber, J.; Peter, A.; Schuh, S.; Lauer, T.; Wensing, M.; Winter, F.; Priesching, P.; Pachler, K. Modeling the Pilot Injection and the Ignition Process of a Dual Fuel Injector with Experimental Data from a Combustion Chamber Using Detailed Reaction Kinetics. In SAE Technical Paper 2018-01-1724; SAE International: Warrendale, PA, USA, 2017. [Google Scholar] [CrossRef]

- Kahila, H.; Wehrfritz, A.; Kaario, O.; Vuorinen, V. Large-eddy simulation of dual-fuel ignition: Diesel spray injection into a lean methane-air mixture. Combust. Flame 2019, 199, 131–151. [Google Scholar] [CrossRef]

- Zhao, W.; Zhou, L.; Liu, Z.; Qi, J.; Lu, Z.; Wei, H.; Shu, G. Numerical Study on the Combustion Process of n-heptane Spray Flame in Methane Environment Using Large Eddy Simulation. Combust. Sci. Technol. 2021, 193, 142–166. [Google Scholar] [CrossRef]

- Demosthenous, E.; Borghesi, G.; Mastorakos, E.; Cant, R.S. Direct Numerical Simulations of premixed methane flame initiation by pilot n-heptane spray autoignition. Combust. Flame 2016, 163, 122–137. [Google Scholar] [CrossRef] [Green Version]

- Tekgül, B.; Kahila, H.; Kaario, O.; Vuorinen, V. Large-eddy simulation of dual-fuel spray ignition at different ambient temperatures. Combust. Flame 2020, 215, 51–65. [Google Scholar] [CrossRef]

- Ratzke, A.; Dinkelacker, F. Modellierung der Flammenausbreitung und des Flammenlöschens im Gasmotor; PZH-Verlag: Garbsen, Germany, 2013. [Google Scholar]

- Hockett, A.; Hampson, G.; Marchese, A.J. Development and Validation of a Reduced Chemical Kinetic Mechanism for Computational Fluid Dynamics Simulations of Natural Gas/Diesel Dual-Fuel Engines. Energy Fuels 2016, 30, 2414–2427. [Google Scholar] [CrossRef]

- Frankl, S.; Gleis, S.; Wachtmeister, G. Interpretation of Ignition and Combustion in a Full-Optical High-Pressure-Dual-Fuel (HPDF) Engine using 3D-CFD Methods. In Proceedings of the 29th CIMAC World Congress on Combustion Engine, Meeting the Future of Combustion Engines, Vancouver, BC, Canada, 10–14 June 2019. [Google Scholar]

- Li, Y.; Li, H.; Guo, H.; Li, Y.; Yao, M. A numerical investigation on methane combustion and emissions from a natural gas-diesel dual fuel engine using CFD model. Appl. Energy 2017, 205, 153–162. [Google Scholar] [CrossRef]

- Wijeyakulasuriya, S.; Jupudi, R.S.; Givler, S.; Primus, R.J.; Klingbeil, A.E.; Raju, M.; Raman, A. Multidimensional Modeling and Validation of Dual-Fuel Combustion in a Large Bore Medium Speed Diesel Engine. In Proceedings of the ASME 2015 Internal Combustion Engine Division Fall Technical Conference, Houston, TX, USA, 8–11 November 2015; The American Society of Mechanical Engineers: New York, NY, USA, 2016. ISBN 978-0-7918-5727-. [Google Scholar]

- Wang, H.; Gan, H.; Theotokatos, G. Parametric investigation of pre-injection on the combustion, knocking and emissions behaviour of a large marine four-stroke dual-fuel engine. Fuel 2020, 281, 118744. [Google Scholar] [CrossRef]

- Andree, S.; Goryntsev, D.; Theile, M.; Henke, B.; Schleef, K.; Nocke, J.; Tap, F.; Buchholz, B.; Hassel, E. Numerical Simulation of a Large Bore Dual Fuel Marine Engine Using Tabulated Detailed Reaction Mechanisms. In Proceedings of the ASME 2019 Internal Combustion Engine Division Fall Technical Conference, Chicago, IL, USA, 20–23 October 2019. [Google Scholar]

- Eder, L.; Kiesling, C.; Priesching, P.; Pirker, G.; Wimmer, A. Multidimensional Modeling of Injection and Combustion Phenomena in a Diesel Ignited Gas Engine. In SAE Technical Paper 2017-01-0559; SAE International: Warrendale, PA, USA, 2017. [Google Scholar] [CrossRef]

- Decan, G.; Lucchini, T.; D’Errico, G.; Verhelst, S. A novel technique for detailed and time-efficient combustion modeling of fumigated dual-fuel internal combustion engines. Appl. Therm. Eng. 2020, 174, 115224. [Google Scholar] [CrossRef]

- Ameen, M.M.; Yang, X.; Kuo, T.-W.; Som, S. Parallel methodology to capture cyclic variability in motored engines. Int. J. Engine Res. 2017, 18, 366–377. [Google Scholar] [CrossRef]

- Fontanesi, S.; Paltrinieri, S.; Tiberi, A.; D’Adamo, A. LES Multi-cycle Analysis of a High Performance GDI Engine. In SAE Technical Paper Series; SAE 2013 World Congress & Exhibition, APR. 16, 2013; SAE International400 Commonwealth Drive: Warrendale, PA, USA, 2013. [Google Scholar]

- Goryntsev, D.; Sadiki, A.; Klein, M.; Janicka, J. Large eddy simulation based analysis of the effects of cycle-to-cycle variations on air–fuel mixing in realistic DISI IC-engines. Proc. Combust. Inst. 2009, 32, 2759–2766. [Google Scholar] [CrossRef]

- Vermorel, O.; Richard, S.; Colin, O.; Angelberger, C.; Benkenida, A.; Veynante, D. Towards the understanding of cyclic variability in a spark ignited engine using multi-cycle LES. Combust. Flame 2009, 156, 1525–1541. [Google Scholar] [CrossRef]

- Schmitt, M.; Hu, R.; Wright, Y.M.; Soltic, P.; Boulouchos, K. Multiple Cycle LES Simulations of a Direct Injection Natural Gas Engine. Flow Turbul. Combust. 2015, 95, 645–668. [Google Scholar] [CrossRef]

- Pope, S.B. Turbulent Flows; Cambridge University Press: Cambridge, NY, USA, 2000; ISBN 1316179478. [Google Scholar]

- Rutland, C.J. Large-eddy simulations for internal combustion engines—A review. Int. J. Engine Res. 2011, 12, 421–451. [Google Scholar] [CrossRef] [Green Version]

- Kobayashi, H.; Ham, F.; Wu, X. Application of a local SGS model based on coherent structures to complex geometries. Int. J. Heat Fluid Flow 2008, 29, 640–653. [Google Scholar] [CrossRef]

- Hanjalić, K.; Popovac, M.; Hadžiabdić, M. A robust near-wall elliptic-relaxation eddy-viscosity turbulence model for CFD. Int. J. Heat Fluid Flow 2004, 25, 1047–1051. [Google Scholar] [CrossRef]

- Stiesch, G. Modeling Engine Spray and Combustion Processes; Springer: Berlin/Heidelberg, Germany, 2003; ISBN 9783662087909. [Google Scholar]

- Liu, A.B.; Mather, D.; Reitz, R.D. Modeling the Effects of Drop Drag and Breakup on Fuel Sprays. SAE Trans. 1993, 102, 83–95. [Google Scholar]

- Dukowicz, J.K. Quasi-Steady Droplet Phase Change in the Presence of Convection; United States. 1979. Available online: http://inis.iaea.org/search/search.aspx?orig_q=RN:11517838 (accessed on 18 June 2021).

- Lauer, T.; Frühhaber, J. Towards a Predictive Simulation of Turbulent Combustion?—An Assessment for Large Internal Combustion Engines. Energies 2021, 14, 43. [Google Scholar] [CrossRef]

- van Pham, C.; Choi, J.-H.; Rho, B.-S.; Kim, J.-S.; Park, K.; Park, S.-K.; van Le, V.; Lee, W.-J. A Numerical Study on the Combustion Process and Emission Characteristics of a Natural Gas-Diesel Dual-Fuel Marine Engine at Full Load. Energies 2021, 14, 1342. [Google Scholar] [CrossRef]

- AVL List GmbH. Combustion Module—AVL FIRE; Version 2018.1; AVL List GmbH: Graz, Austria, 2018. [Google Scholar]

- Srna, A.; Bolla, M.; Wright, Y.M.; Herrmann, K.; Bombach, R.; Pandurangi, S.S.; Boulouchos, K.; Bruneaux, G. Effect of methane on pilot-fuel auto-ignition in dual-fuel engines. Proc. Combust. Inst. 2019, 37, 4741–4749. [Google Scholar] [CrossRef]

- Schuh, S.; Frühhaber, J.; Lauer, T.; Winter, F. A Novel Dual Fuel Reaction Mechanism for Ignition in Natural Gas–Diesel Combustion. Energies 2019, 12, 4396. [Google Scholar] [CrossRef] [Green Version]

- Ritzke, J.; Andree, S.; Theile, M.; Henke, B.; Schleef, K.; Nocke, J.; Hassel, E. Simulation of a Dual-Fuel Large Marine Engines using combined 0/1-D and 3-D Approaches. In Proceedings of the CIMAC Congress, Helsinki, Finland, 6–9 June 2016. [Google Scholar]

- Colin, O.; Benkenida, A.; Angelberger, C. 3d Modeling of Mixing, Ignition and Combustion Phenomena in Highly Stratified Gasoline Engines. Oil Gas Sci. Technol.—Rev. IFP 2003, 58, 47–62. [Google Scholar] [CrossRef] [Green Version]

- Heywood, J.B. Internal Combustion Engine Fundamentals; McGraw-Hill: New York, NY, USA, 1988; ISBN 007028637X. [Google Scholar]

- Enaux, B.; Granet, V.; Vermorel, O.; Lacour, C.; Thobois, L.; Dugué, V.; Poinsot, T. Large Eddy Simulation of a Motored Single-Cylinder Piston Engine: Numerical Strategies and Validation. Flow Turbul. Combust 2011, 86, 153–177. [Google Scholar] [CrossRef]

- Brußies, E. Simulation der Zylinderinnenströmung eines Zweiventil-Dieselmotors mit einem Skalenauflösenden Turbulenzmodell; Technical University of Darmstadt: Darmstadt, Germany, 2014. [Google Scholar]

- Catania, A.E.; Mittica, A. Extraction Techniques and Analysis of Turbulence Quantities from In-Cylinder Velocity Data. J. Eng. Gas Turbines Power 1989, 111, 466–478. [Google Scholar] [CrossRef]

- Liu, Z.; Karim, G.A. Simulation of combustion processes in gas-fuelled diesel engines. Proc. Inst. Mech. Eng. Part A J. Power Energy 1997, 211, 159–169. [Google Scholar] [CrossRef]

- Ahmad, Z.; Kaario, O.; Qiang, C.; Vuorinen, V.; Larmi, M. A parametric investigation of diesel/methane dual-fuel combustion progression/stages in a heavy-duty optical engine. Appl. Energy 2019, 251, 113191. [Google Scholar] [CrossRef]

- PETERS, N. The turbulent burning velocity for large-scale and small-scale turbulence. J. Fluid Mech. 1999, 384, 107–132. [Google Scholar] [CrossRef]

- Linse, D.; Hasse, C.; Durst, B. An experimental and numerical investigation of turbulent flame propagation and flame structure in a turbo-charged direct injection gasoline engine. Combust. Theory Model. 2009, 13, 167–188. [Google Scholar] [CrossRef]

| Bore | 170 mm |

| Stroke | 210 mm |

| Displacement | 4960 cm³ |

| Compression ratio | 13.25 |

| Engine speed (rpm) | 1800 |

| Mean effective pressure (bar) | 19.5 |

| Energetic diesel share | 5% |

| Equivalence ratio gas mixture | 0.55 |

| EGR rate | 0.5% |

| Injection pressure (bar) | 1000 |

| Start of injection (deg) | −20 aTDC |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Frühhaber, J.; Lauer, T. Numerical Investigation of the Turbulent Flame Propagation in Dual Fuel Engines by Means of Large Eddy Simulation. Energies 2021, 14, 5036. https://doi.org/10.3390/en14165036

Frühhaber J, Lauer T. Numerical Investigation of the Turbulent Flame Propagation in Dual Fuel Engines by Means of Large Eddy Simulation. Energies. 2021; 14(16):5036. https://doi.org/10.3390/en14165036

Chicago/Turabian StyleFrühhaber, Jens, and Thomas Lauer. 2021. "Numerical Investigation of the Turbulent Flame Propagation in Dual Fuel Engines by Means of Large Eddy Simulation" Energies 14, no. 16: 5036. https://doi.org/10.3390/en14165036

APA StyleFrühhaber, J., & Lauer, T. (2021). Numerical Investigation of the Turbulent Flame Propagation in Dual Fuel Engines by Means of Large Eddy Simulation. Energies, 14(16), 5036. https://doi.org/10.3390/en14165036