Hot Compressed Water Pretreatment and Surfactant Effect on Enzymatic Hydrolysis Using Agave Bagasse

Abstract

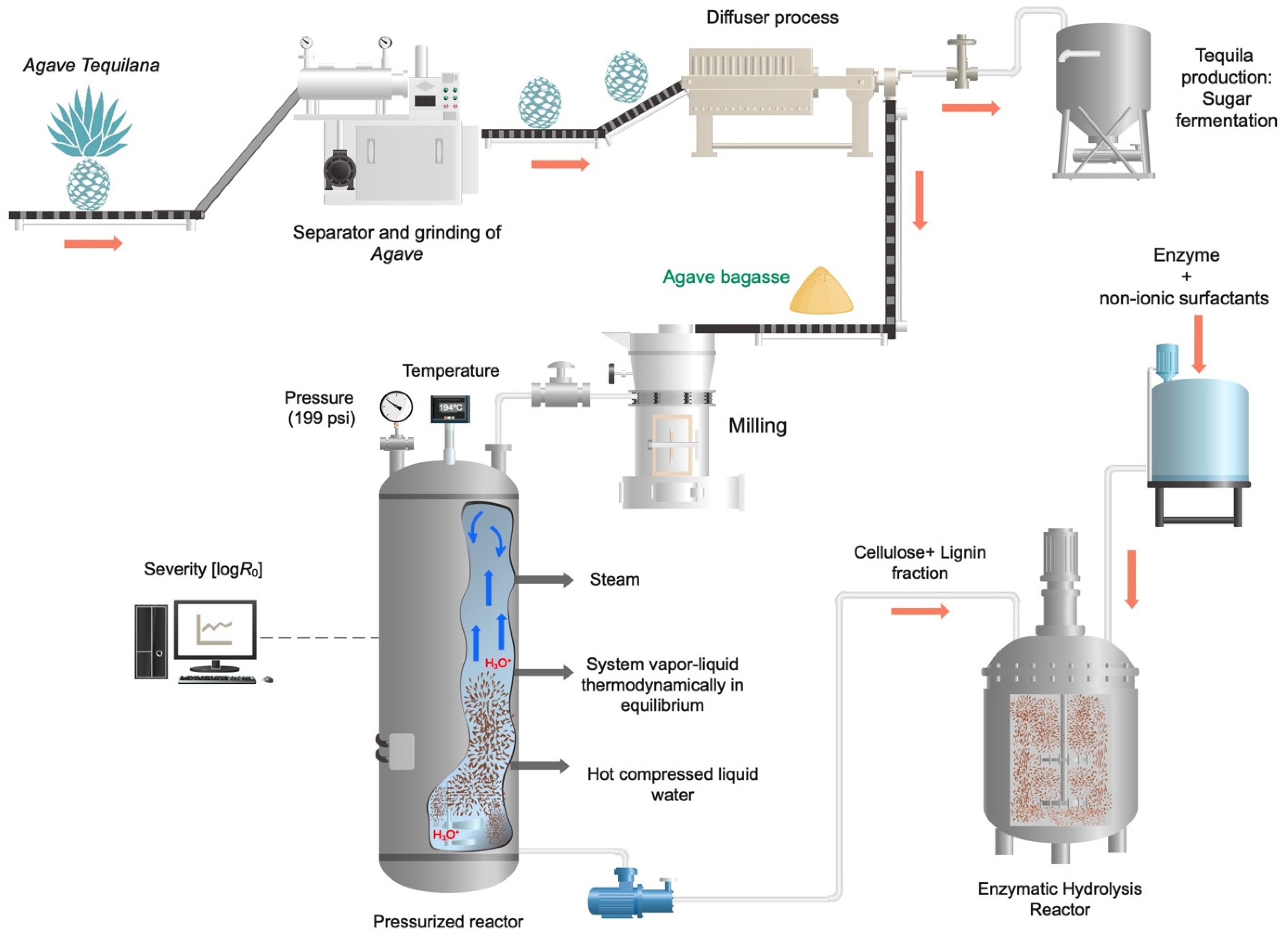

1. Introduction

2. Materials and Methods

2.1. Raw Material

2.2. Hot Compressed Water Pretreatment

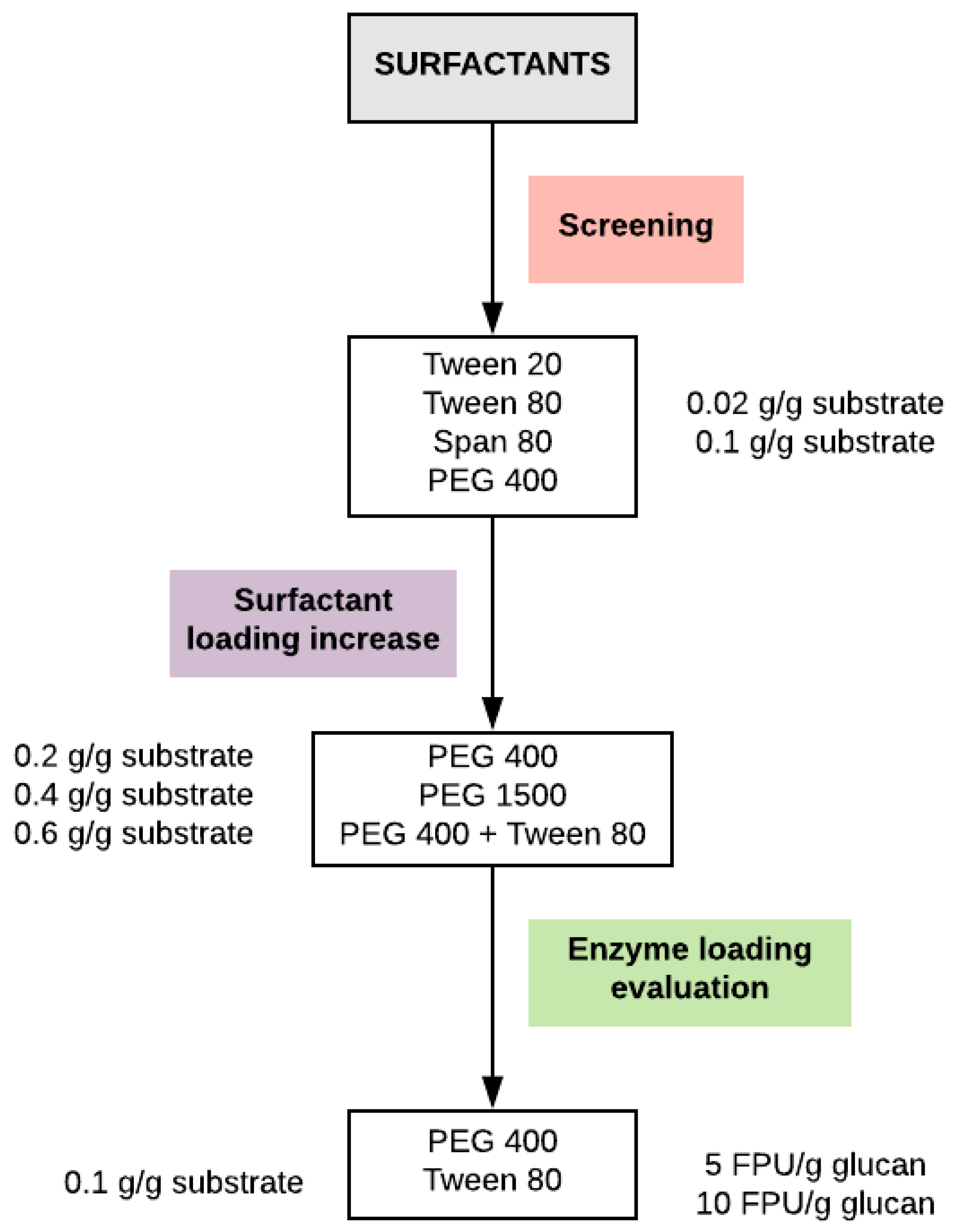

2.3. Evaluation of Surfactants Effects on Enzymatic Hydrolysis

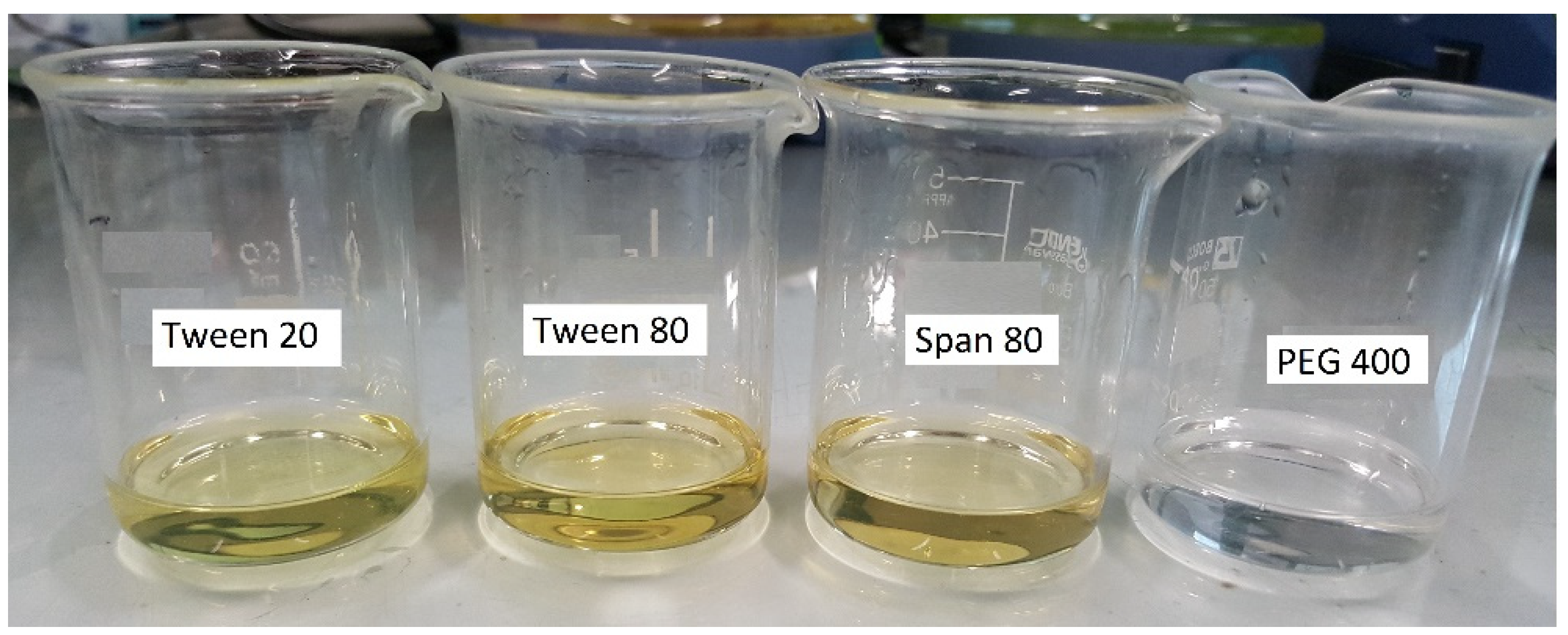

2.3.1. Surfactant Screening

2.3.2. Surfactant Loading

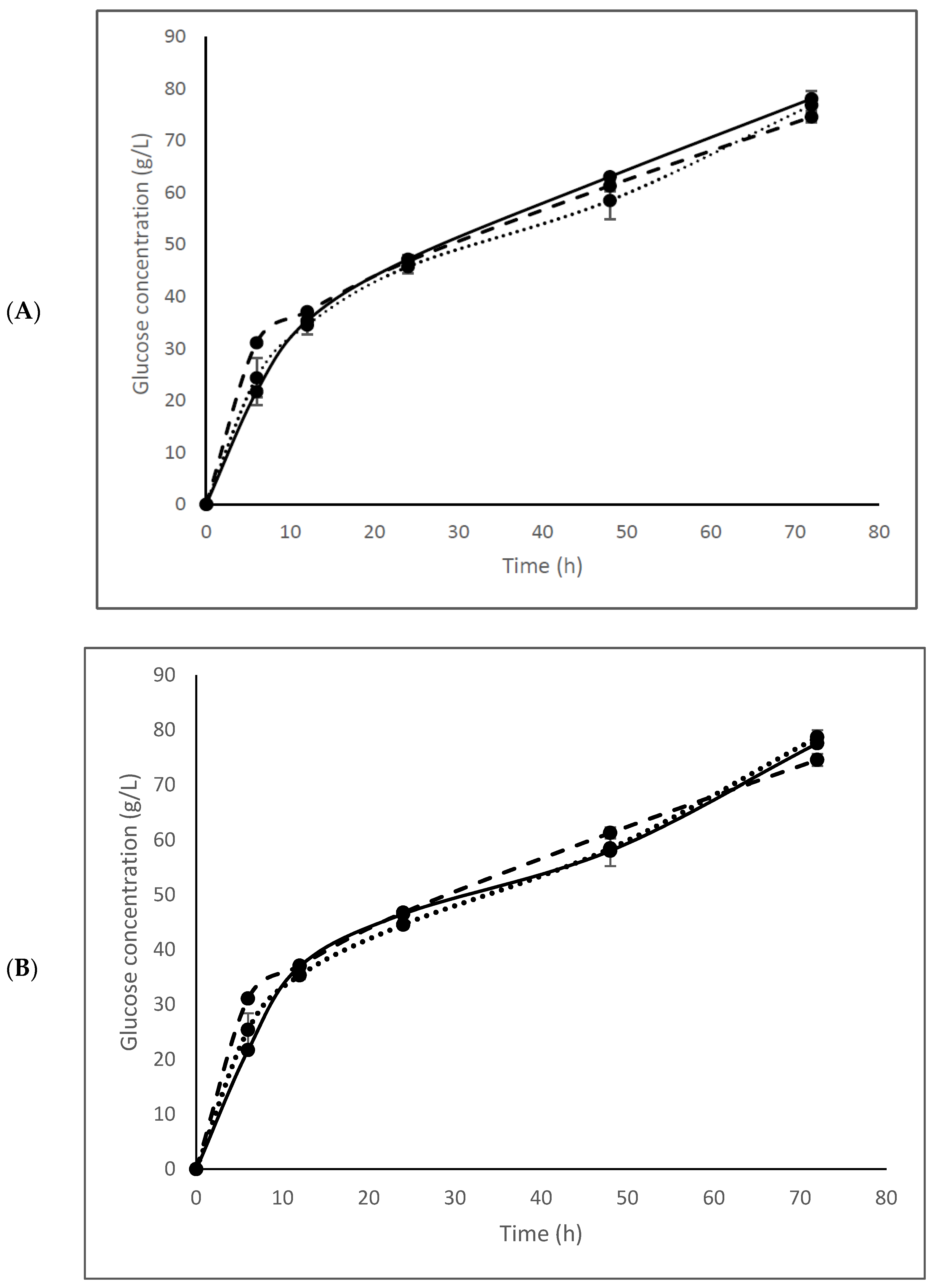

2.3.3. Enzyme Loading Evaluation

3. Results

3.1. Evaluation of Surfactants Effect on Enzymatic Hydrolysis

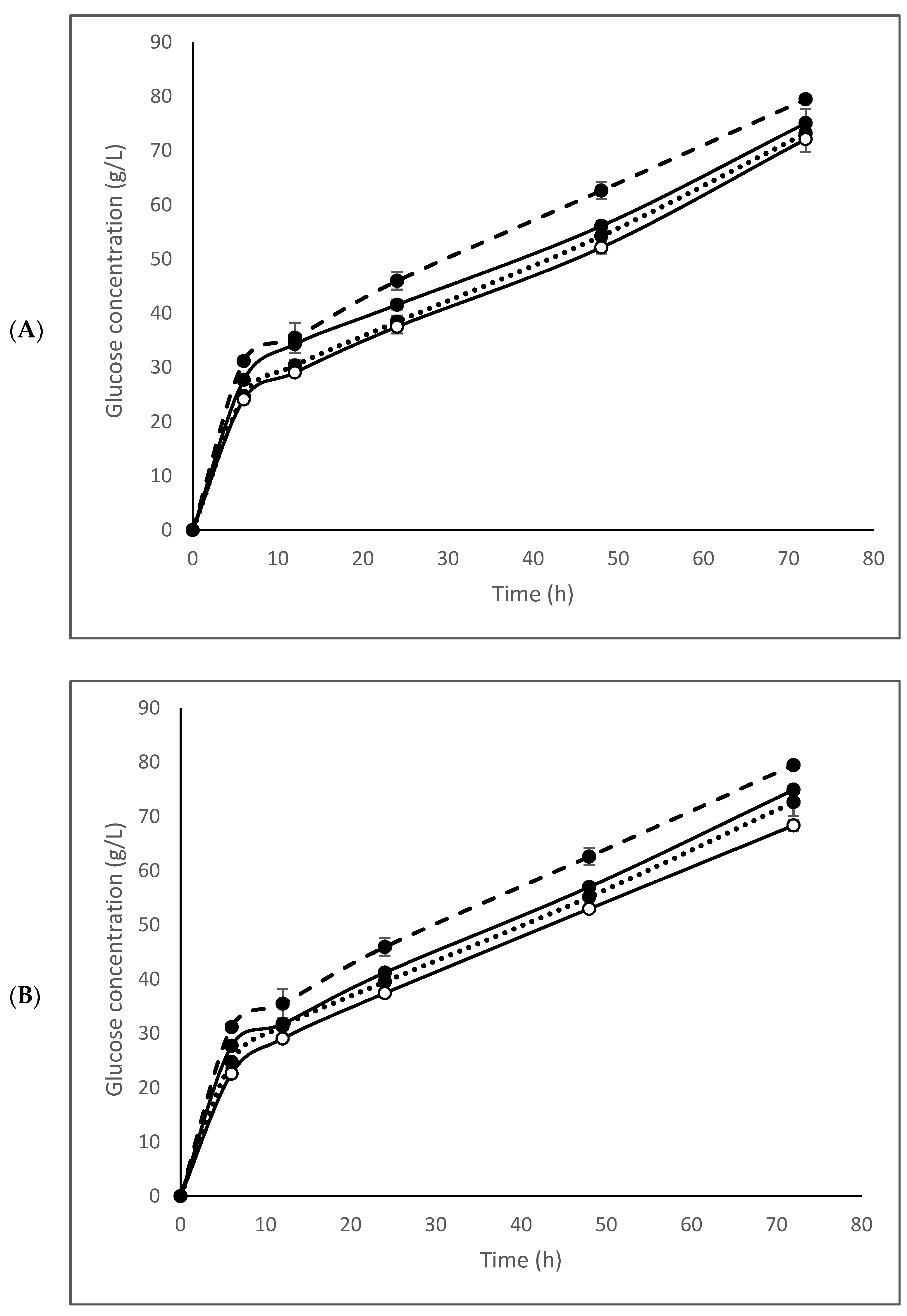

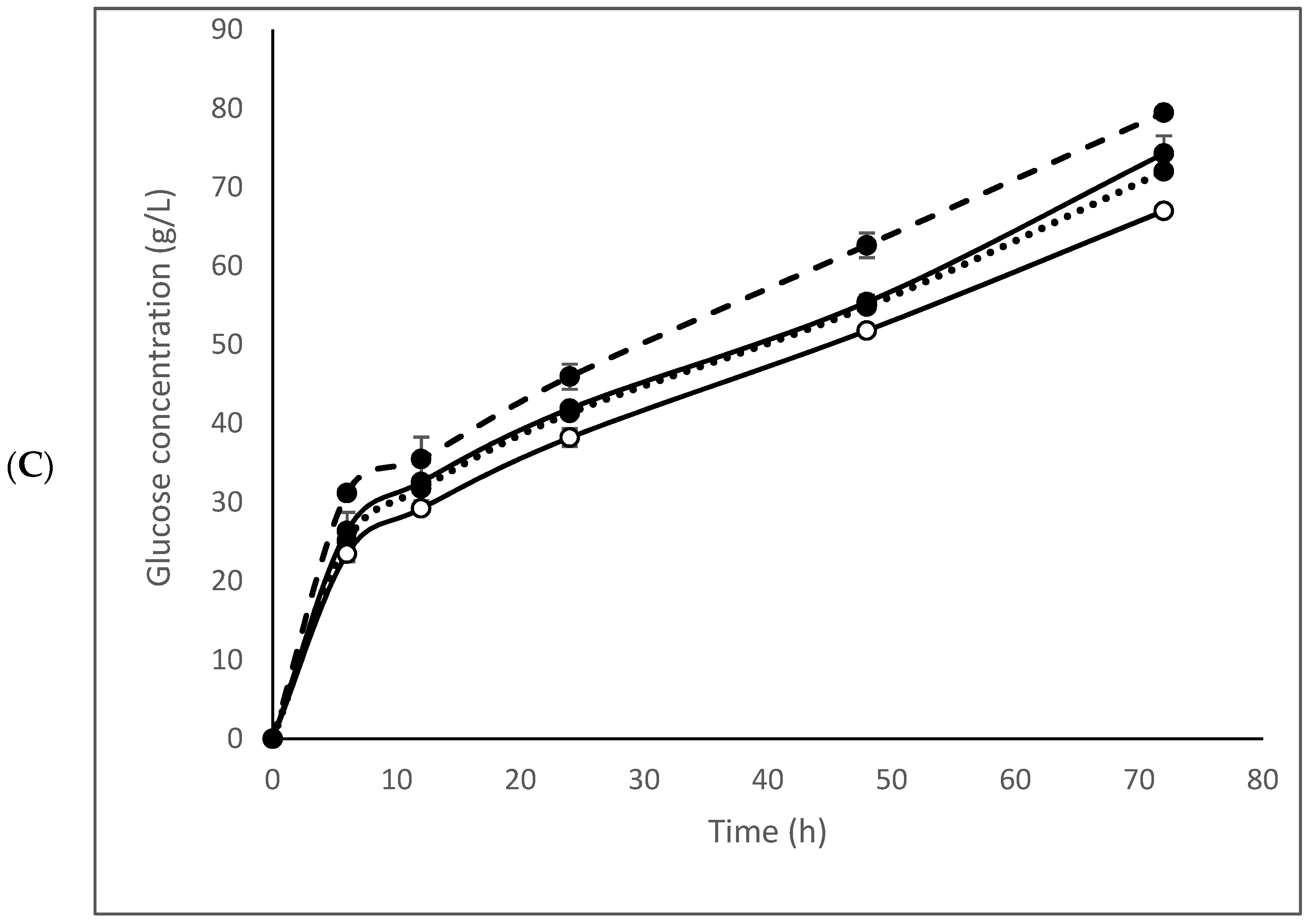

3.1.1. Surfactant Screening

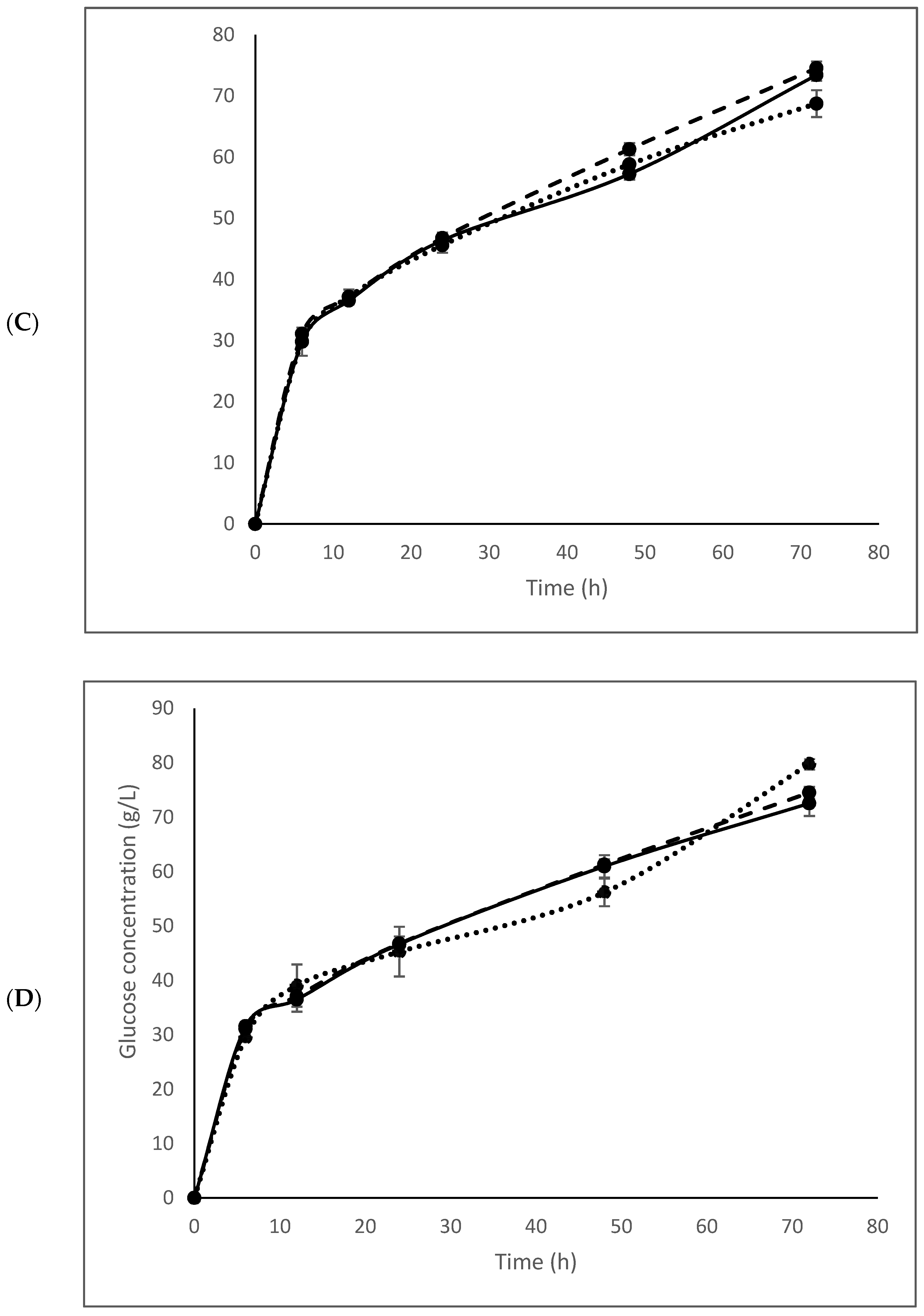

3.1.2. Surfactant Loading

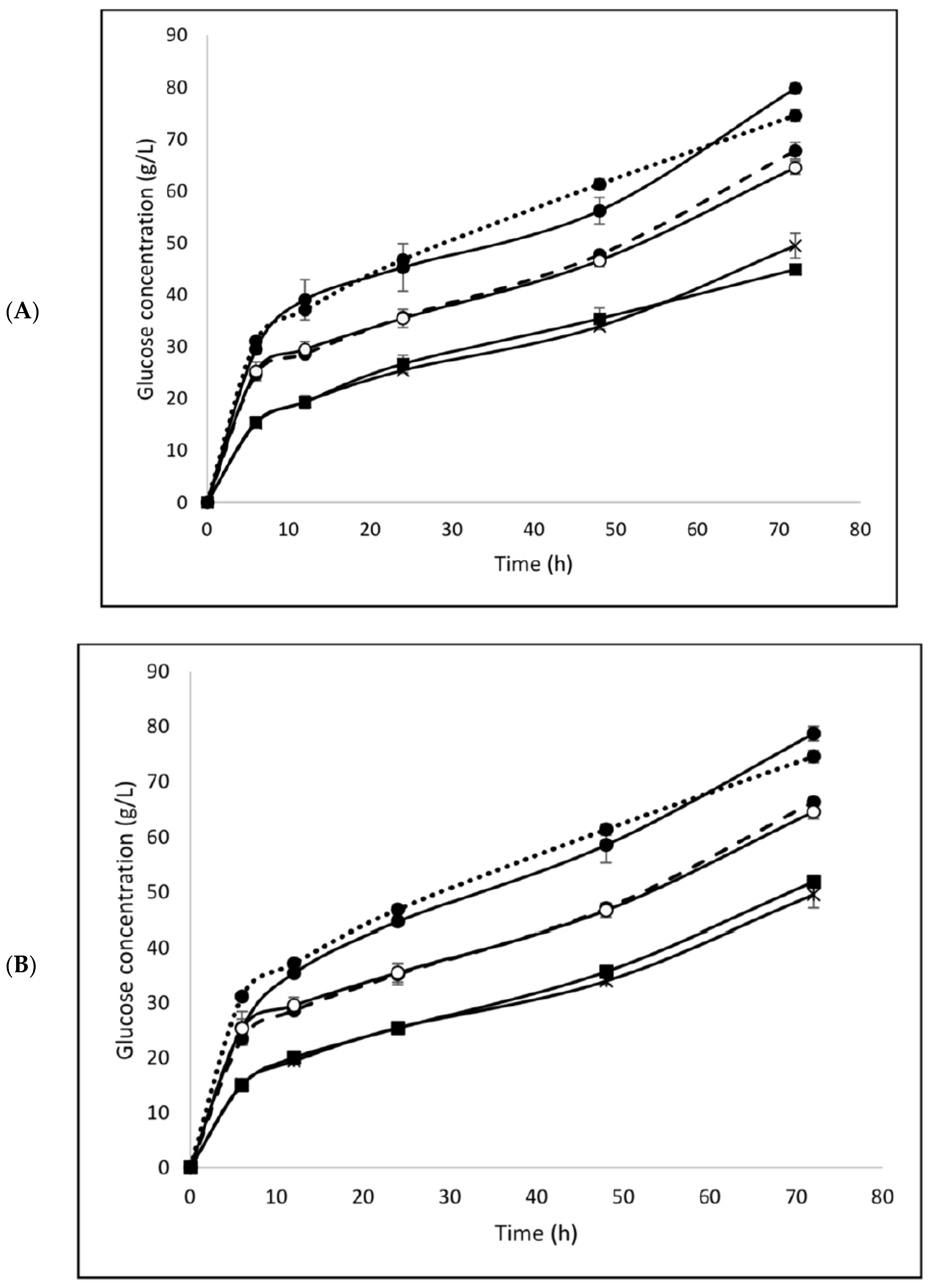

3.2. Enzyme Loading Evaluation

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Park, J.W.; Takahata, Y.; Kajiuchi, T.; Akehata, T.; Source, E. Effects of nonionic surfactant on enzymatic hydrolysis of used newspaper. Biotechnol. Bioeng. 1992, 5, 117–120. [Google Scholar] [CrossRef]

- Carrillo-Nieves, D.; Rostro, M.J.A.; Cruz, R.Q.; Ruiz, H.A.; Iqbal, H.M.N.; Parra-Saldívar, R.P. Current status and future trends of bioethanol production from agro-industrial wastes in Mexico. Renew. Sustain. Energy Rev. 2019, 102, 63–74. [Google Scholar] [CrossRef]

- Zhou, Y.; Chen, H.; Qi, F.; Zhao, X.; Liu, D. Non-ionic surfactants do not consistently improve the enzymatic hydrolysis of pure cellulose. Bioresour. Technol. 2015, 182, 136–143. [Google Scholar] [CrossRef] [PubMed]

- Singh, A.; Rodríguez-Jasso, R.M.; Gonzalez-Gloria, K.D.; Rosales, M.; Cerda, R.B.; Aguilar, C.N.; Singhania, R.R.; Ruiz, H.A. The enzyme biorefinery platform for advanced biofuels production. Bioresour. Technol. Rep. 2019, 7, 100257. [Google Scholar] [CrossRef]

- Olguin-Maciel, E.; Singh, A.; Chable-Villacis, R.; Tapia-Tussell, R.; Ruiz, H.A. Consolidated bioprocessing, an innovative strategy towards sustainable for biofuels production from crop residues: An overview. Agronomy 2020, 10, 1834. [Google Scholar] [CrossRef]

- Lou, H.; Zeng, M.; Hu, Q.; Cai, C.; Lin, X.; Qiu, X.; Yang, D.; Pang, Y. Nonionic surfactants enhanced enzymatic hydrolysis of cellulose by reducing cellulase deactivation caused by shear force and air-liquid interface. Bioresour. Technol. 2018, 249, 1–8. [Google Scholar] [CrossRef]

- Börjesson, J.; Peterson, R.; Tjerneld, F. Enhanced enzymatic conversion of softwood lignocellulose by poly(ethylene glycol) addition. Enzym. Microb. Technol. 2007, 40, 754–762. [Google Scholar] [CrossRef]

- Pino, M.; Rodríguez-Jasso, R.M.; Michelin, M.; Flores-Gallegos, A.C.; Morales-Rodríguez, R.; Teixeira, J.A.; Ruiz, H.A. Bioreactor design for enzymatic hydrolysis of biomass under the biorefinery concept. Chem. Eng. J. 2018, 347, 119–136. [Google Scholar] [CrossRef]

- Ruiz, H.A.; Vicente, A.A.; Teixeira, J.A. Kinetic modeling of enzymatic saccharification using wheat straw pretreated under autohydrolysis and organosolv process. Ind. Crops Prod. 2012, 36, 100–107. [Google Scholar] [CrossRef][Green Version]

- Saini, J.K.; Patel, A.K.; Adsul, M.; Singhania, R.R. Cellulase adsorption on lignin: A roadblock for economic hydrolysis of biomass. Renew. Energy 2016, 98, 29–42. [Google Scholar] [CrossRef]

- Rahikainen, J.; Mikander, S.; Marjamaa, K.; Tamminen, T.; Lappas, A.; Viikari, L.; Kruus, K. Inhibition of enzymatic hydrolysis by residual lignins from softwood-study of enzyme binding and inactivation on lignin-rich surface. Biotechnol. Bioeng. 2011, 108, 2823–2834. [Google Scholar] [CrossRef] [PubMed]

- Lu, X.; Zheng, X.; Li, X.; Zhao, J. Adsorption and mechanism of cellulase enzymes onto lignin isolated from corn stover pretreated with liquid hot water. Biotechnol. Biofuels 2016, 9, 118. [Google Scholar] [CrossRef]

- Li, Y.; Sun, Z.; Ge, X.; Zhang, J. Effects of lignin and surfactant on adsorption and hydrolysis of cellulases on cellulose. Biotechnol. Biofuels 2016, 9, 20. [Google Scholar] [CrossRef] [PubMed]

- Agrawal, R.; Satlewal, A.; Manali, K.; Sujit, M.; Biswajit, B. Investigating the enzyme-lignin binding with surfactants for improved saccharification of pilot scale pretreated wheat straw. Bioresour. Technol. 2017, 224, 411–418. [Google Scholar] [CrossRef]

- Yang, M.; Zhang, A.; Liu, B.; Li, W.; Xing, J. Improvement of cellulose conversion caused by the protection of Tween-80 on the adsorbed cellulase. Biochem. Eng. J. 2011, 56, 125–129. [Google Scholar] [CrossRef]

- Eriksson, T.; Börjesson, J.; Tjerneld, F. Mechanism of surfactant effect in enzymatic hydrolysis of lignocellulose. Enzym. Microb. Technol. 2002, 31, 353–364. [Google Scholar] [CrossRef]

- Ooshima, H.; Sakata, M.; Harano, Y. Enhancement of enzymatic hydrolysis of cellulose by surfactant. Biotechnol. Bioeng. 1986, 28, 1727–1734. [Google Scholar] [CrossRef] [PubMed]

- Pino, M.S.; Rodríguez-Jasso, R.M.; Michelin, M.; Ruiz, H.A. Enhancement and modeling of enzymatic hydrolysis on cellulose from agave bagasse hydrothermally pretreated in a horizontal bioreactor. Carbohydr. Polym. 2019, 211, 349–359. [Google Scholar] [CrossRef] [PubMed]

- Aguilar, D.L.; Rodríguez-Jasso, R.M.; Zanuso, E.; de Rodríguez, D.J.; Amaya-Delgado, L.; Sanchez, A.; Ruiz, H.A. Scale-up and evaluation of hydrothermal pretreatment in isothermal and non-isothermal regimen for bioethanol production using agave bagasse. Bioresour. Technol. 2018, 263, 112–119. [Google Scholar] [CrossRef] [PubMed]

- Singh, A.; Rodríguez-Jasso, R.M.; Saxena, R.; Belmares, R.C.; Singhania, R.R.; Ruiz, H.A. Subcritical water pretreatment for agave bagasse fractionation from tequila production and enzymatic susceptibility. Bioresour. Technol. 2021, 338, 125536. [Google Scholar] [CrossRef]

- Duran-Cruz, V.; Hernández, S.; Ortíz, I. Evaluation of steam explosion pretreatment and enzymatic hydrolysis conditions for agave bagasse in biomethane production. BioEnergy Res. 2021. [Google Scholar] [CrossRef]

- Aguirre-Fierro, A.; Ruiz, H.A.; Cerqueira, M.A.; Ramos-González, R.R.; Rodríguez-Jasso, R.M.; Marques, S.; Lukasik, R.M. Sustainable approach of high-pressure agave bagasse pretreatment for ethanol production. Renew. Energy 2020, 155, 1347–1354. [Google Scholar] [CrossRef]

- Ruiz, H.A.; Martínez, A.; Vermerris, W. Bioenergy potential, energy crops and biofuel production in Mexico. BioEnergy Res. 2016, 9, 981–984. [Google Scholar] [CrossRef]

- López-Sandin, I.; Zavala-García, F.; Levin, L.; Ruiz, H.A.; Hernández-Luna, C.E.; Gutiérres-Soto, G. Evaluation of bioethanol production from sweet sorghum variety roger under different tillage and fertilizer treatments. BioEnergy Res. 2021. [Google Scholar] [CrossRef]

- Ruiz, H.A.; Rodríguez-Jasso, R.M.; Fernandes, B.D.; Vicente, A.A.; Teixeira, J.A. Hydrothermal processing, as an alternative for upgrading agriculture residues and marine biomass according to the biorefinery concept. A review. Renew. Sustain. Energy Rev. 2013, 21, 35–51. [Google Scholar] [CrossRef]

- Ruiz, H.A.; Thomsen, M.H.; Trajano, H.L. Hydothermal Processing in Biorefineries, 1st ed.; Springer: Cham, Switzerland, 2017; pp. v–viii. [Google Scholar]

- Ruiz, H.A.; Conrad, M.; Sun, S.N.; Sanchez, A.; Rocha, G.J.M.; Romaní, A.; Castro, E.; Torres, A.; Rodríguez-Jasso, R.M.; Andrade, L.P.; et al. Engineering aspects of hydrothermal pretreatment: From batch to continuous operation, scale-up and pilot reactor under biorefinery concept. Bioresour. Technol. 2020, 299, 122685. [Google Scholar] [CrossRef]

- Aparicio, E.; Rodríguez-Jasso, R.M.; Pinales-Márquez, C.D.; Loredo-Treviño, A.; Robledo-Olivo, A.; Aguilar, C.N.; Kostas, E.; Ruiz, H.A. High-pressure technology for Sargassum spp biomass pretreatment and fractionation in the third generation of bioethanol production. Bioresour. Technol. 2021, 329, 124935. [Google Scholar] [CrossRef] [PubMed]

- Pinales-Márquez, C.D.; Rodríguez-Jasso, R.M.; Araújo, R.G.; Loredo-Treviño, A.; Nabarlatz, D.; Gullón, B.; Ruiz, H.A. Circular bioeconomy and integrated biorefinery in the production of xylooligosaccharides from lignocellulosic biomass. A review. Ind. Crops Prod. 2021, 162, 113274. [Google Scholar] [CrossRef]

- Ruiz, H.A.; Ruzene, D.S.; Silva, D.P.; Quintas, M.A.C.; Vicente, A.A.; Teixeira, J.A. Development and characterization of an environmentally friendly process sequence (autohydrolysis and organosolv) for wheat straw delignification. Appl. Biochem. Biotechnol. 2011, 164, 629–641. [Google Scholar] [CrossRef] [PubMed]

- Ruiz, H.A.; Cerqueira, M.C.; Silva, H.D.; Rodríguez-Jasso, R.M.; Vicente, A.A.; Teixeira, J.A. Biorefinery valorization of autohydrolysis wheat straw hemicellulose to be applied in a polymer-blend film. Carbohyd. Polym. 2013, 92, 2154–2162. [Google Scholar] [CrossRef]

- Aguilar-Reynosa, A.; Romaní, A.; Rodríguez-Jasso, R.M.; Aguilar, C.N.; Garrote, G.; Ruiz, H.A. Comparison of microwave and conduction-convection heating autohydrolysis pretreatment for bioethanol production. Bioresour. Technol. 2017, 243, 273–283. [Google Scholar] [CrossRef]

- UNC Eshelman School of Pharmacy, Emulsions: Preparation and Stabilization. Available online: https://pharmlabs.unc.edu/labs/emulsions/hlb.htm (accessed on 4 June 2018).

- Castanon, M.; Wilke, C.R. Effects of the surfactant tween 80 on enzymatic hydrolysis of newspaper. Biotechnol. Bioeng. 1981, 23, 1365–1372. [Google Scholar] [CrossRef]

- Bardant, T.B.; Sudiyarmanto, S.; Abimanyu, H.; Hanum, A.K. Effect of non ionic surfactant addition to cellulase performance in high-substrate-loading-hydrolysis of palm oil EFB and water-hyacinth. Indones. J. Chem. 2013, 13, 53–58. [Google Scholar] [CrossRef][Green Version]

- Flick, E.W.; William, A. Industrial Surfactants: An Industrial Guide; Elsevier, Noyes Publications: Park Ridge, NJ, USA, 2012. [Google Scholar]

- Ko, J.K.; Ximenes, E.; Kim, Y.; Ladisch, M.R. Adsorption of enzyme onto lignins of liquid hot water pretreated hardwoods. Biotechnol. Bioeng. 2015, 112, 447–456. [Google Scholar] [CrossRef] [PubMed]

- Oliva-Taravilla, A.; Carrasco, C.; Jonsson, L.F.; Martín, C. Effects of biosurfactants on enzymatic saccharification and fermentation of pretreated softwood. Molecules 2020, 25, 3559. [Google Scholar] [CrossRef]

- Alencar, B.R.A.; Dutra, E.D.; Sampaio, E.V.B.; Menezes, R.S.C.; Morais, M.A. Enzymatic hydrolysis of cactus pear varieties with high solids loading for bioethanol production. Bioresour. Technol. 2018, 250, 273–280. [Google Scholar] [CrossRef] [PubMed]

- Ouyang, J.; Dong, Z.; Song, X.; Lee, X.; Chen, M.; Yong, Q. Improved enzymatic hydrolysis of microcrystalline cellulose (Avicel PH101) by polyethylene glycol addition. Bioresour. Technol. 2010, 101, 6685–6691. [Google Scholar] [CrossRef]

- Perez-Pimienta, J.A.; Flores-Gómez, C.A.; Ruiz, H.A.; Sathitsuksanoh, N.; Balan, V.; Sousa, L.C.; Dale, B.E.; Singh, S.; Simmons, B.A. Evaluation of agave bagasse recalcitrance using AFEXTM, autohydrolysis, and ionic liquid pretreatments. Bioresour. Technol. 2016, 211, 216–223. [Google Scholar] [CrossRef]

- Nogueira, C.C.; Padilha, C.E.A.; Santos, E.S. Enzymatic hydrolysis and simultaneous saccharification andfermentation of green coconutfiber under high concentrations ofethylene oxide-based polymers. Renew. Energy 2021, 163, 1536–1547. [Google Scholar] [CrossRef]

- Li, H.; Wang, C.; Xiao, W.; Yang, Y.; Hu, P.; Dai, Y.; Jiang, Z. Dissecting the effect of polyethylene glycol on the enzymatic hydrolysis of diverse lignocellulose. Int. J. Biol. Macromol. 2019, 131, 676–681. [Google Scholar] [CrossRef]

- Agrawal, R.; Bhadana, B.; Mathur, A.S.; Kumar, R.; Gupta, R.P.; Satlewal, A. Improved enzymatic hydrolysis of pilot scale pretreated rice straw at high total solids loading. Front. Energy Res. 2018, 6, 115. [Google Scholar] [CrossRef]

- Vignesh, N.; Chandraraj, K. Improved high solids loading enzymatic hydrolysis and fermentation of cotton microdust by surfactant addition and optimization of pretreatment. Process Biochem. 2021, 106, 60–69. [Google Scholar] [CrossRef]

- Parnthong, J.; Kungsaant, S.; Chavadej, S. The influence of nonionic surfactant adsorption on enzymatic hydrolysis of oil palm fruit bunch. Appl. Biochem. Biotechnol. 2018, 186, 895–908. [Google Scholar] [CrossRef] [PubMed]

- Mo, W.; Li, B.; Li, Y.; Wu, S. Overcoming the drying-induced pore closure of APMP poplar fibers in old newsprint by surfactant treatment to promote enzymatic hydrolysis of the cellulose. Cellulose 2019, 26, 5529–5541. [Google Scholar] [CrossRef]

| Surfactant Type | Hydrophile–Lipophile Balance (HLB) |

|---|---|

| Tween 20 | 16.7 |

| Tween 80 | 15 |

| PEG 400 | 11.6 |

| Span 80 | 4.3 |

| Component | Composition (%) |

|---|---|

| Cellulose | 53.65 ± 0.51 |

| Hemicellulose | 2.89 ± 0.16 |

| Lignin | 35.39 ± 0.57 |

| DF | SS | MS | F | p-Value | |

|---|---|---|---|---|---|

| Treatments | 7 | 197.489 | 28.213 | 6.02 | 0.011000 |

| Error | 8 | 37.493 | 4.687 | ||

| Total | 15 | 234.983 |

| Treatment | Glucose Concentration (g/L) | 0.05 | |

|---|---|---|---|

| Surfactant Type | Surfactant Concentration (g/g Substrate) | ||

| PEG 400 | 0.1 | 79.760 | a |

| Tween 80 | 0.1 | 78.675 | a |

| Tween 20 | 0.02 | 78.055 | ab |

| Tween 80 | 0.02 | 77.570 | abc |

| Tween 20 | 0.1 | 76.800 | abc |

| Span 80 | 0.02 | 73.415 | bcd |

| PEG 400 | 0.02 | 72.585 | cd |

| Span 80 | 0.1 | 68.755 | d |

| DF | SS | MS | F | p-Value | |

|---|---|---|---|---|---|

| Surfactant type | 1 | 0.18 | 0.18 | 0.04 | 0.842733 |

| Enzyme loading | 2 | 1738.39 | 869.19 | 203.50 | 0.000003 |

| Interaction | 2 | 71.56 | 35.78 | 8.38 | 0.018335 |

| Error | 6 | 25.63 | 4.27 |

| Raw Material | Pretreatment | Enzymatic Hydrolysis | Surfactant Type | Glucose Production (g/L) | References |

|---|---|---|---|---|---|

| Agave bagasse | Hot compressed water | Solid loading of 10% (w/v) and 15 FPU/g substrate | PEG 400 | 79.76 | Present study |

| Cotton microdust | Two-stage alkali-acid pretreatment | Solid loading of 35% (w/v) and enzyme loading 22 FPU/g glucan | Polyethylene glycol (PEG) | 134 | [45] |

| Oil palm fruit bunch | Sodium hydroxide | Solid loading of 2% (w/v) and enzyme loading 10 FPU/g solid fiber | Tween 80 | 10.75 | [46] |

| Rice straw | Pilot scale—dilute sulfuric acid | Fed batch mode, solid loading of 20% (w/v) and 3 FPU/g total solids | Ecosurf E6 (Alcohol Ethoxylate) | 132 | [44] |

| Green coconut fiber | Steam explosion | Solid loading of 5% (w/v) and 20 FPU/g substrate | PEG 4000 | 9.9 | [42] |

| Poplar fibers | Vacuum drying | Solid loading of 2% (w/v) and 25 FPU/g substrate | PEG 8000 | 7.15 | [47] |

| Rice straw | Nitric acid | Solid loading of 2.5% (w/v) | PEG 4000 | 2.345 | [43] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pino, M.S.; Michelin, M.; Rodríguez-Jasso, R.M.; Oliva-Taravilla, A.; Teixeira, J.A.; Ruiz, H.A. Hot Compressed Water Pretreatment and Surfactant Effect on Enzymatic Hydrolysis Using Agave Bagasse. Energies 2021, 14, 4746. https://doi.org/10.3390/en14164746

Pino MS, Michelin M, Rodríguez-Jasso RM, Oliva-Taravilla A, Teixeira JA, Ruiz HA. Hot Compressed Water Pretreatment and Surfactant Effect on Enzymatic Hydrolysis Using Agave Bagasse. Energies. 2021; 14(16):4746. https://doi.org/10.3390/en14164746

Chicago/Turabian StylePino, Marcela Sofia, Michele Michelin, Rosa M. Rodríguez-Jasso, Alfredo Oliva-Taravilla, José A. Teixeira, and Héctor A. Ruiz. 2021. "Hot Compressed Water Pretreatment and Surfactant Effect on Enzymatic Hydrolysis Using Agave Bagasse" Energies 14, no. 16: 4746. https://doi.org/10.3390/en14164746

APA StylePino, M. S., Michelin, M., Rodríguez-Jasso, R. M., Oliva-Taravilla, A., Teixeira, J. A., & Ruiz, H. A. (2021). Hot Compressed Water Pretreatment and Surfactant Effect on Enzymatic Hydrolysis Using Agave Bagasse. Energies, 14(16), 4746. https://doi.org/10.3390/en14164746