Thermodynamic Performance Investigation of a Small-Scale Solar Compression-Assisted Multi-Ejector Indoor Air Conditioning System for Hot Climate Conditions

Abstract

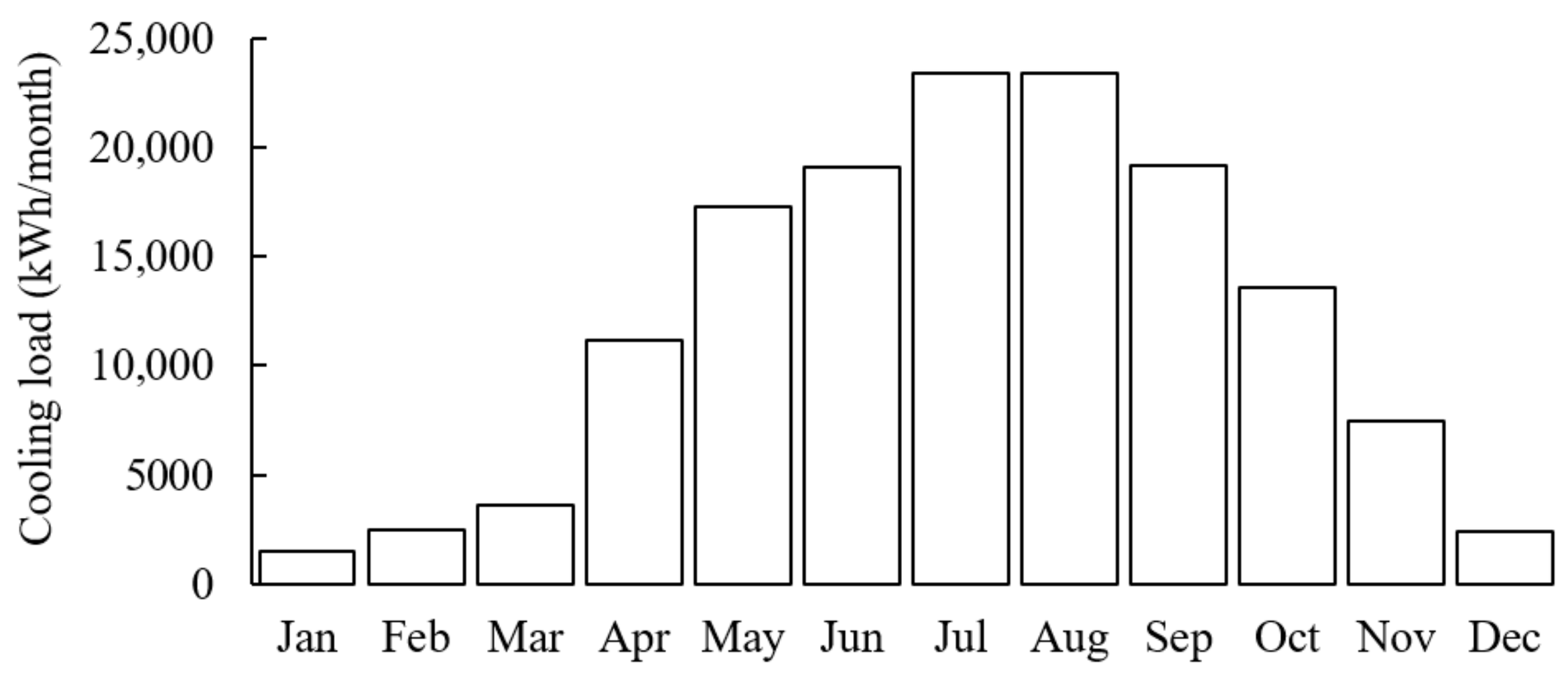

:1. Introduction

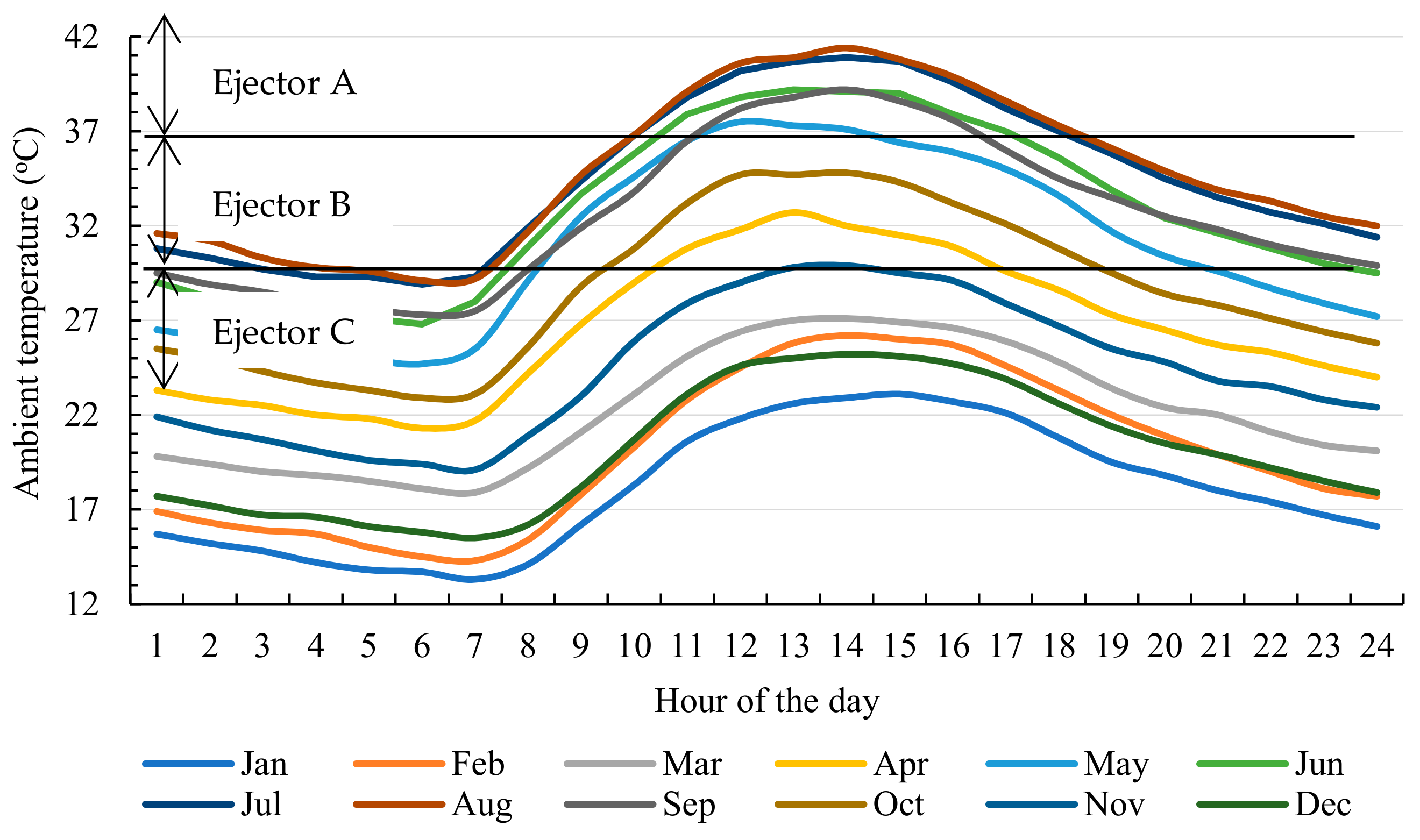

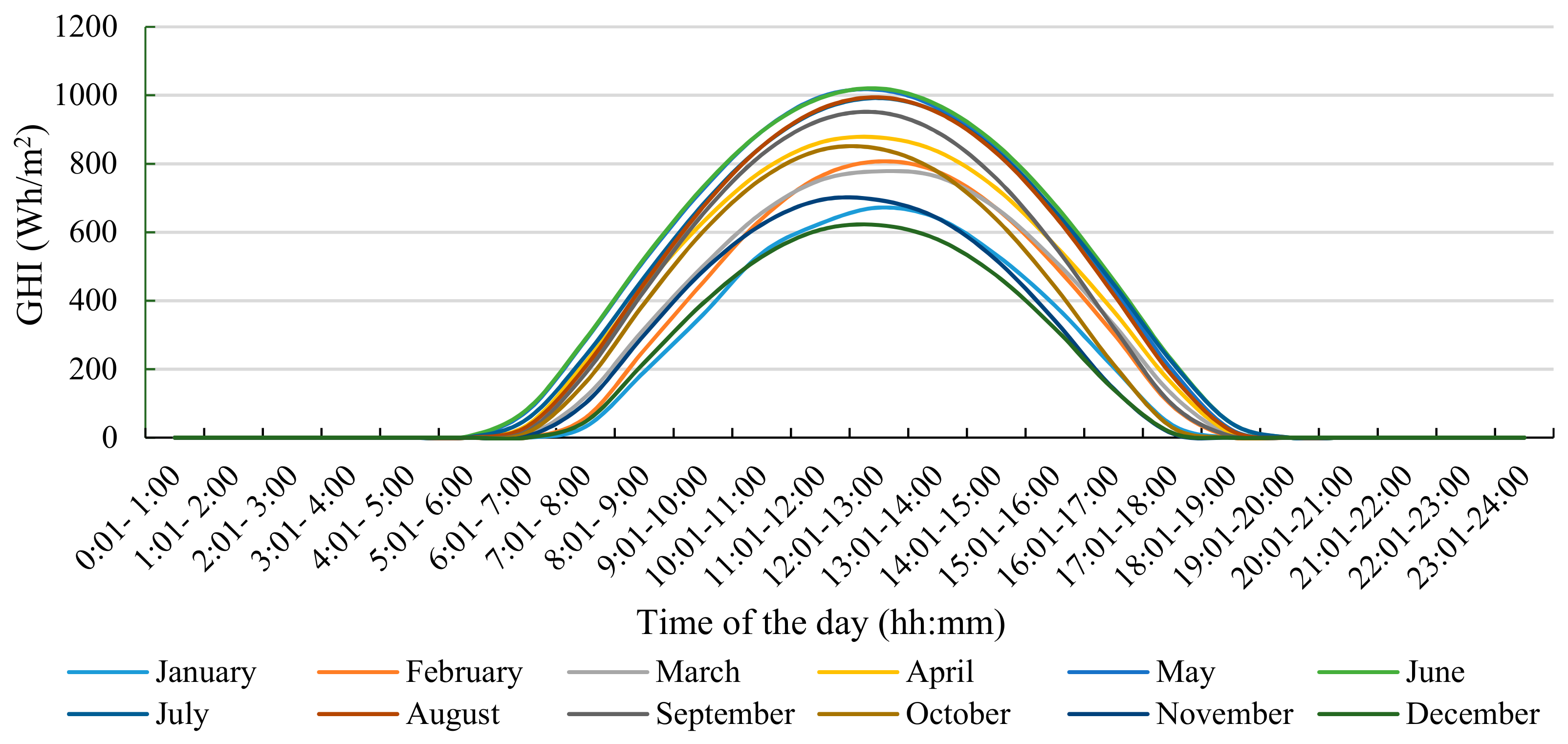

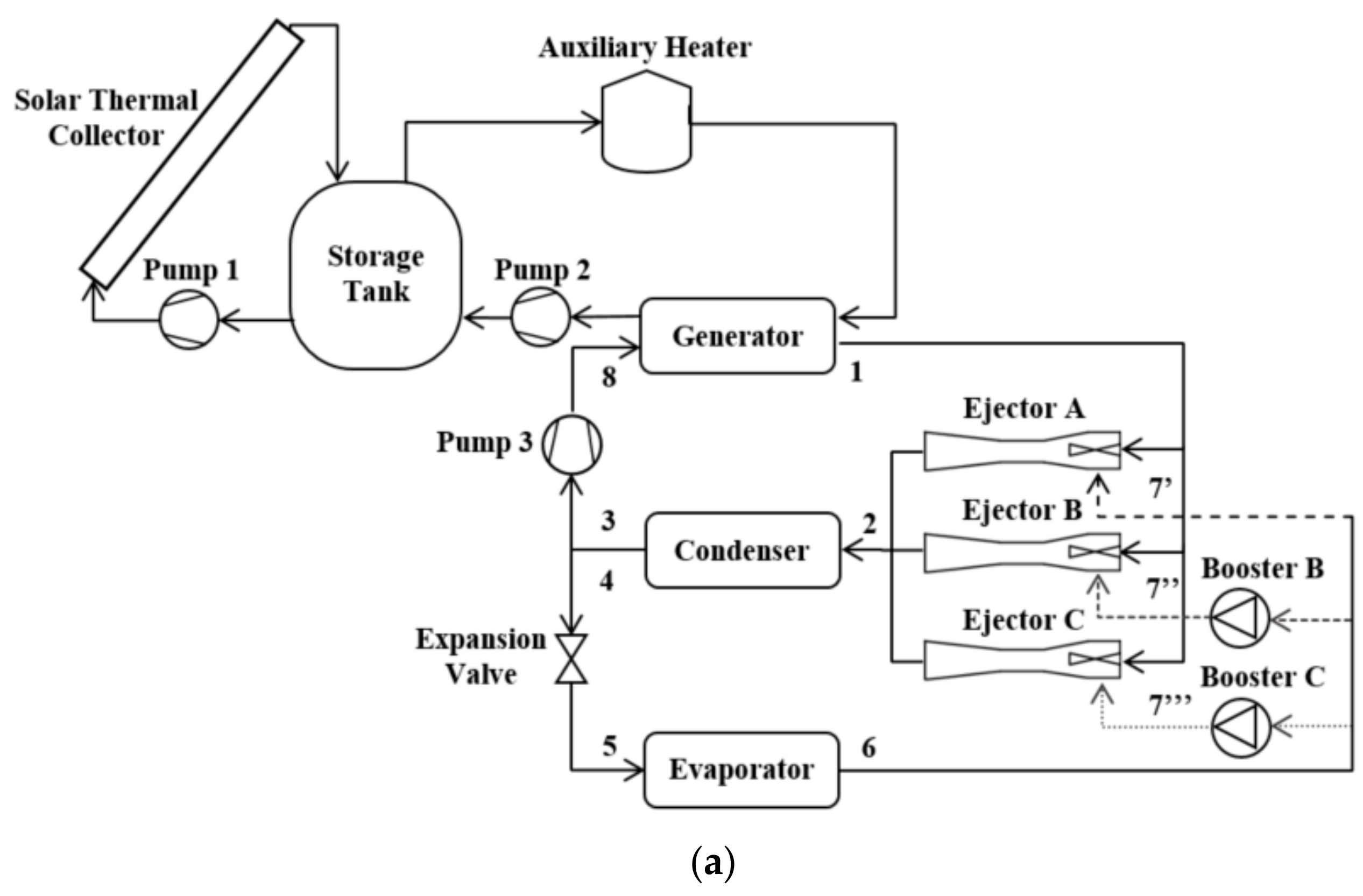

2. Solar-Assisted Ejector Space Cooling System

3. Mathematical Modeling

- Isenthalpic expansion in the throttling valve [19]

- One-dimensional steady flow [20]

3.1. First Law Analysis

3.2. Exergy Analysis

3.3. Performance Indices

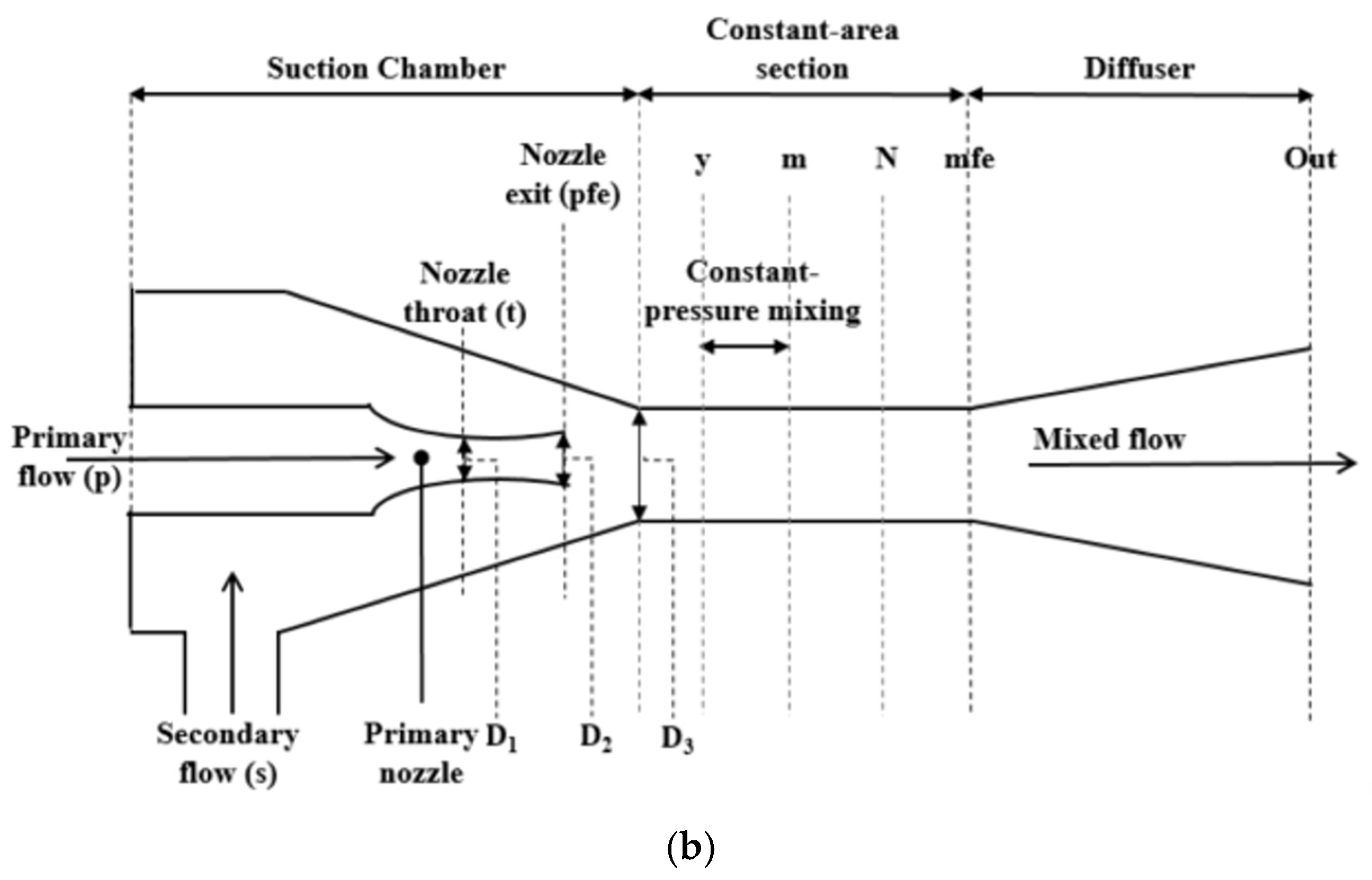

3.4. Ejector Model

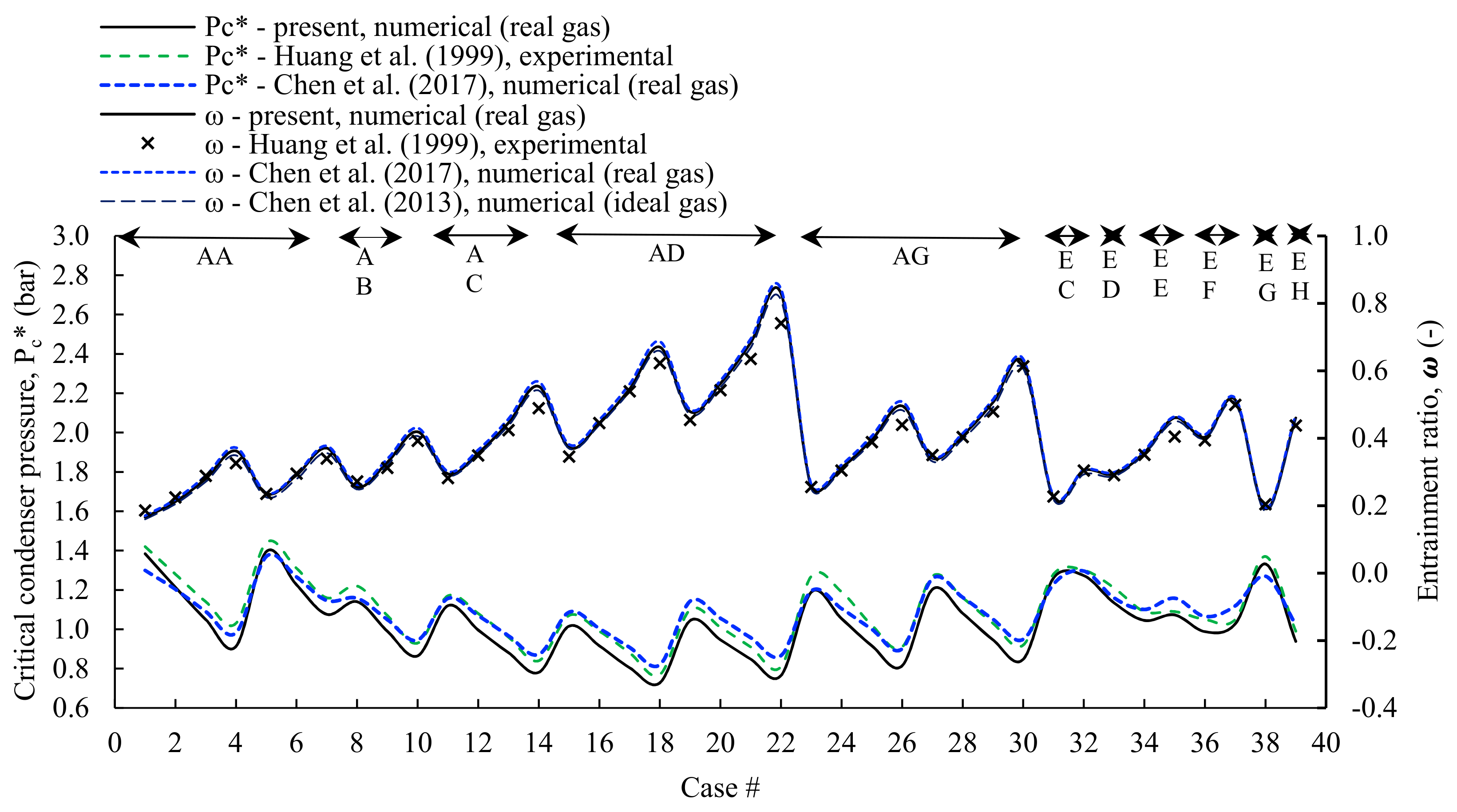

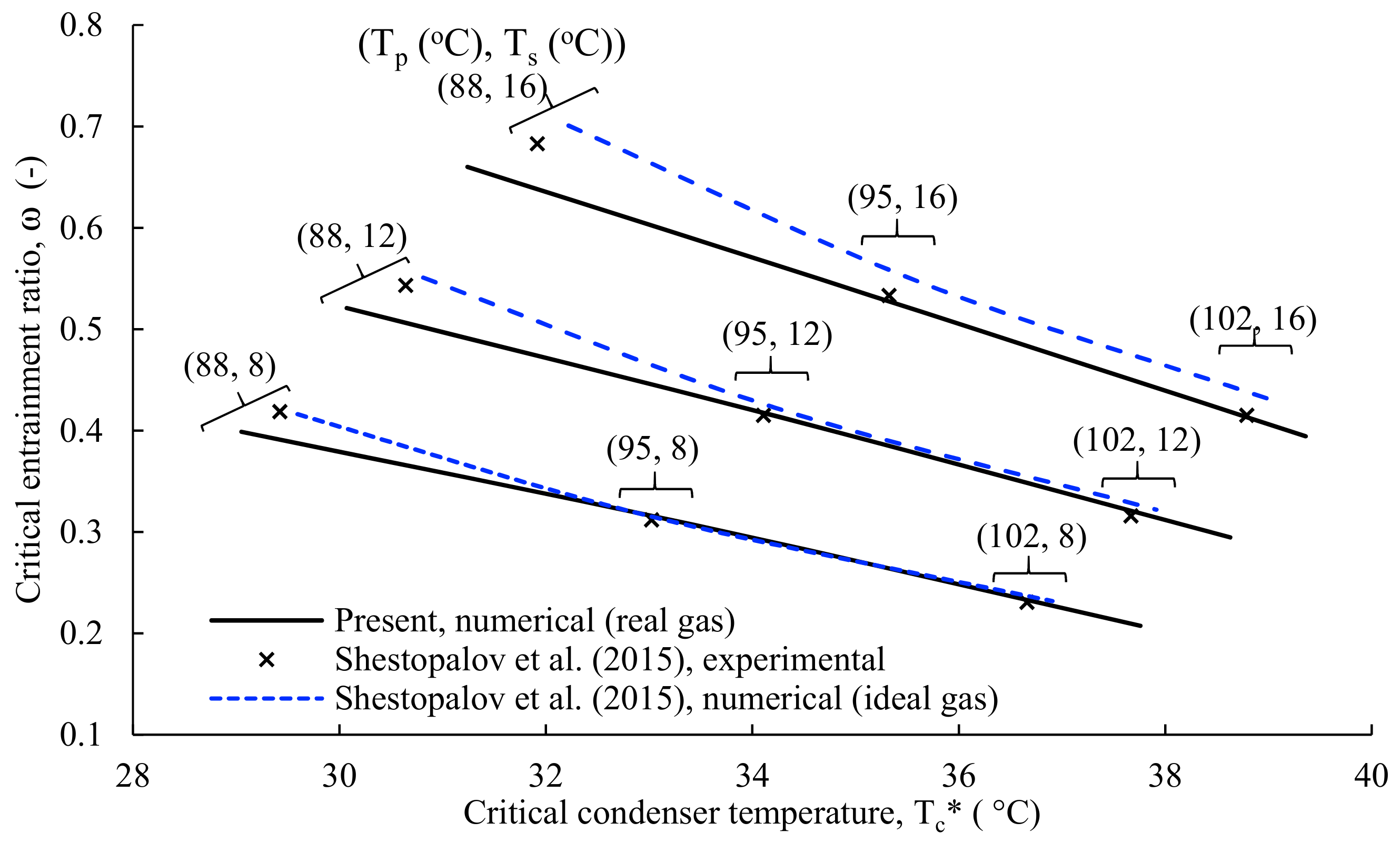

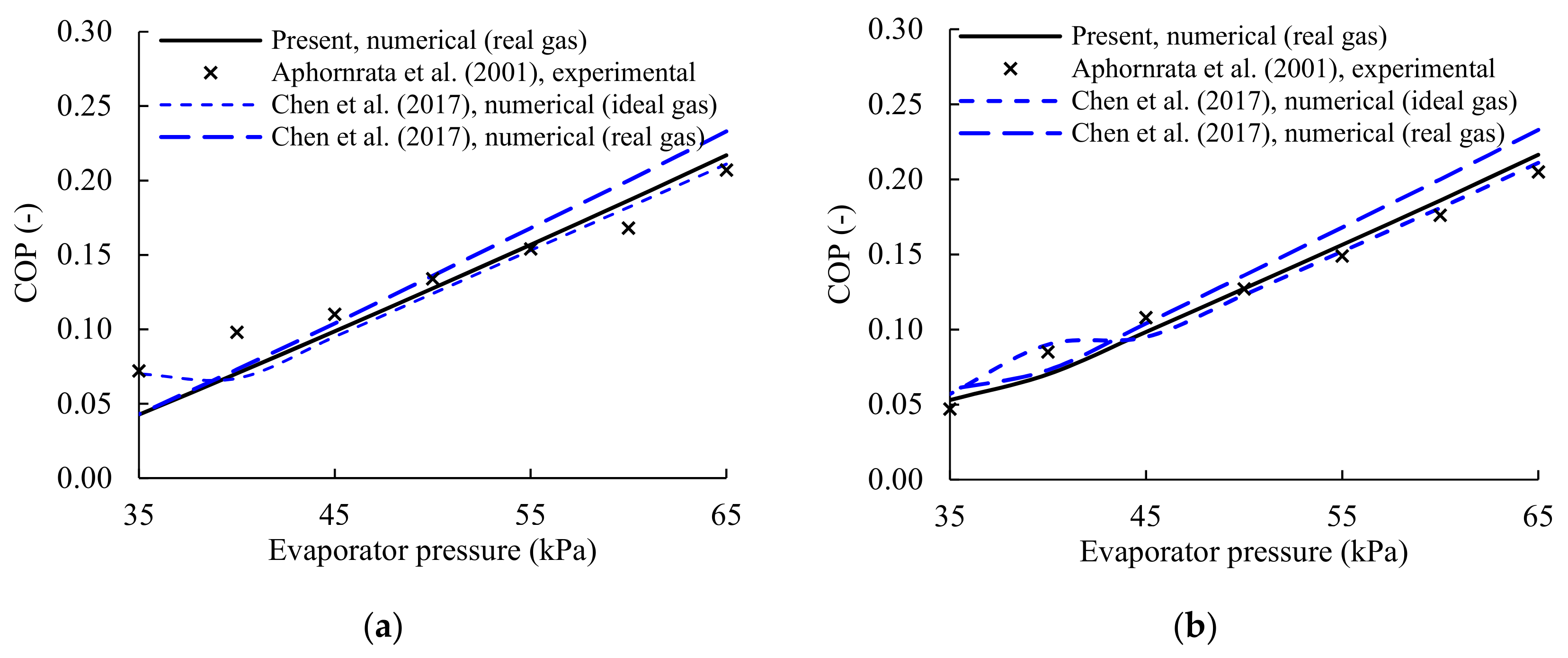

3.5. Refrigeration Sub-System Model Validation

4. Results and Discussion

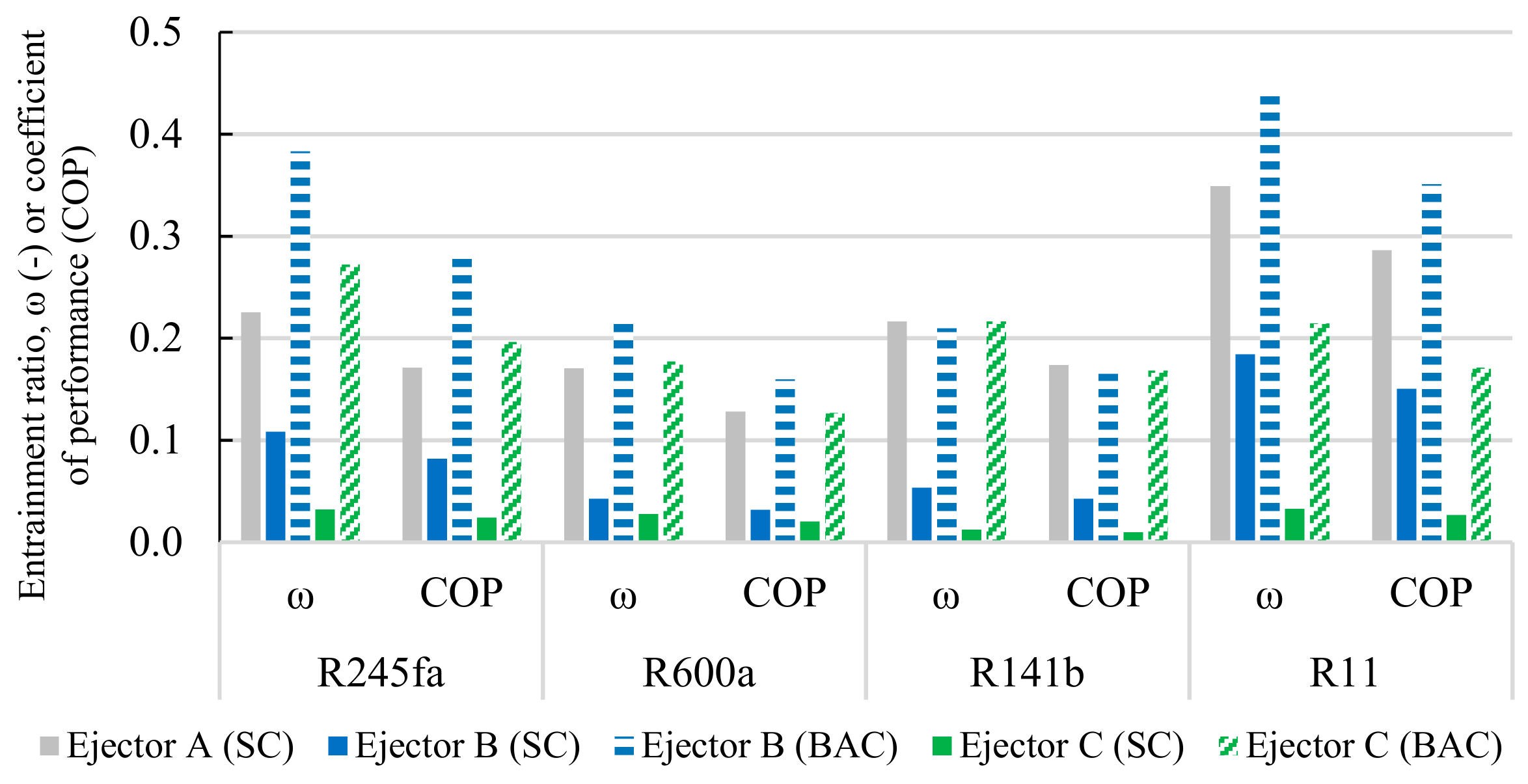

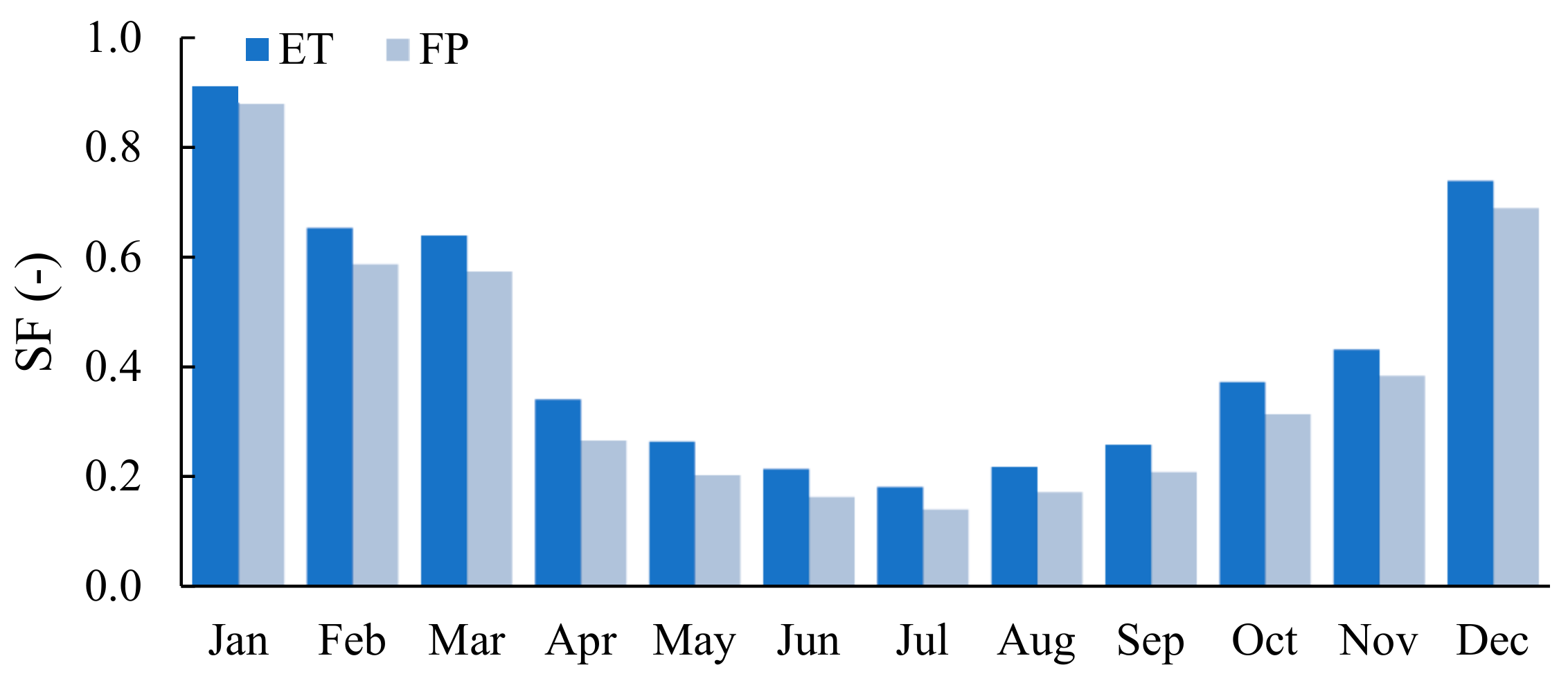

4.1. Refrigeration Sub-System Performance at Typical Operating Conditions

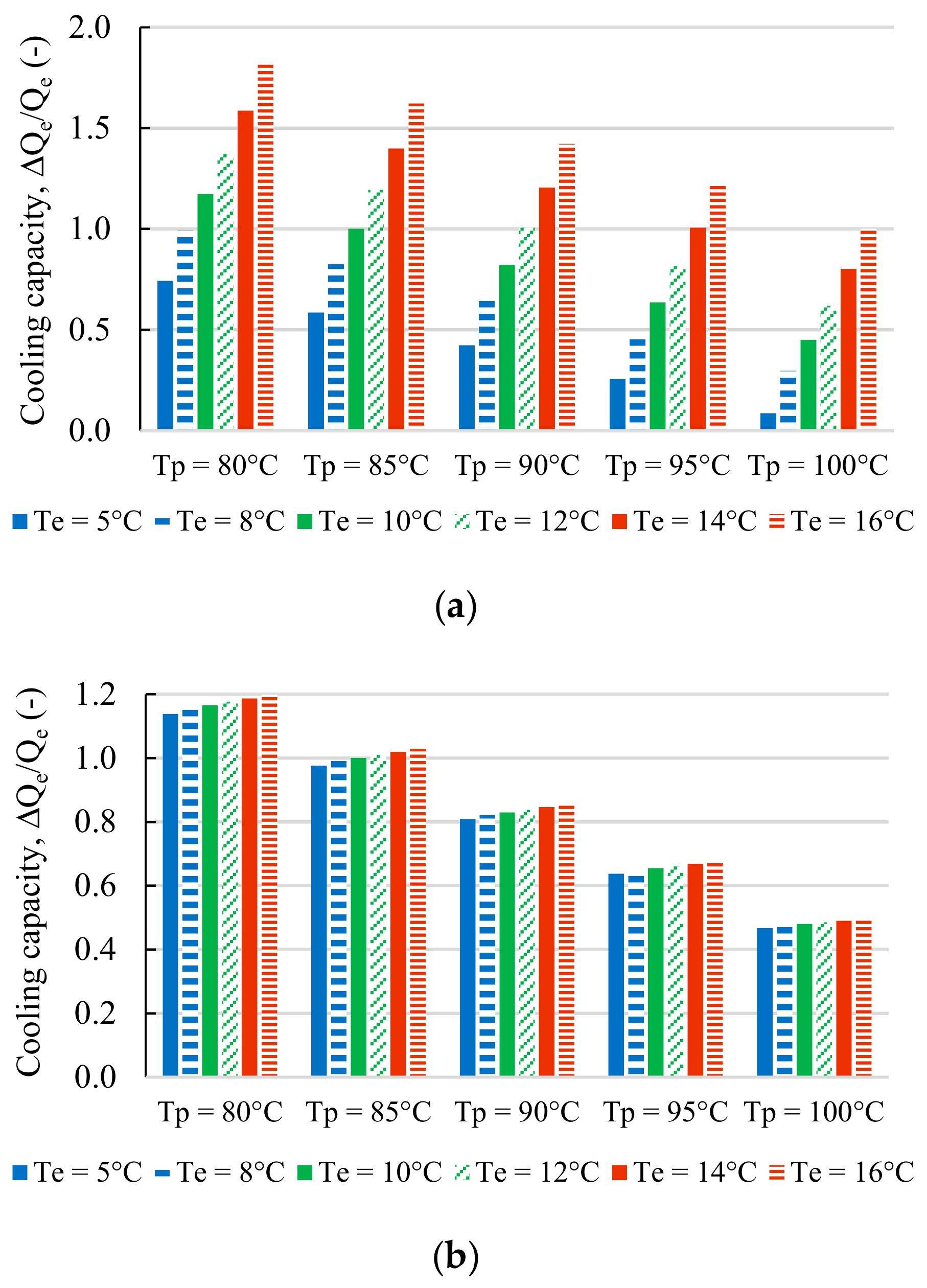

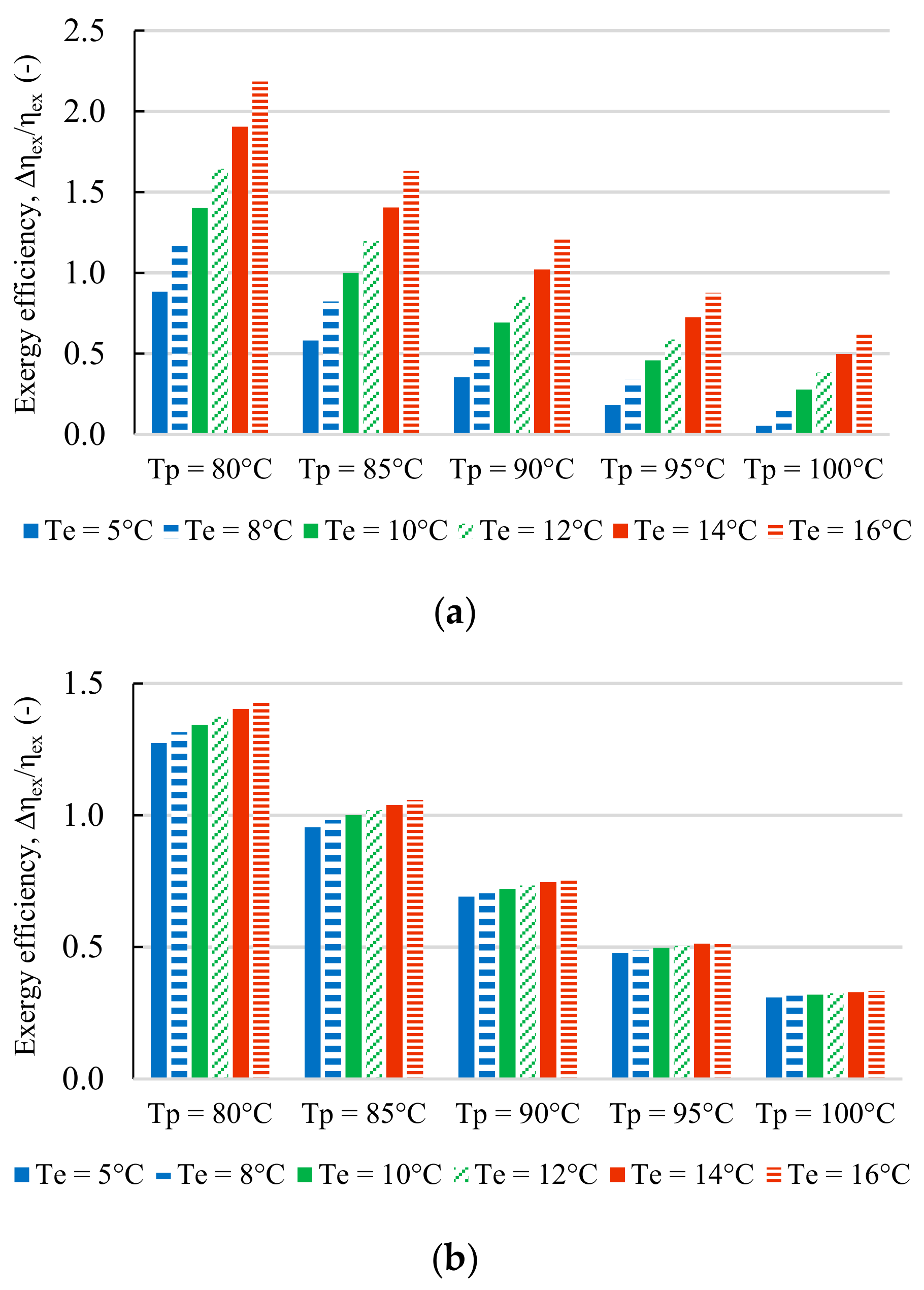

4.2. Refrigeration System Performance at Off-Design Conditions

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

Abbreviations

| BAC | booster-assisted cycle |

| CFC | chlorofluorocarbon |

| ET | evacuated tube |

| FP | flat plate |

| GHG | greenhouse gas |

| GWP | global warming potential |

| HC | hydrocarbon |

| HCFC | hydrochlorofluorocarbon |

| HFC | hydrofluorocarbon |

| N | normal shock |

| ODP | ozone depletion potential |

| SC | simple cycle |

| VCC | vapor compression cycle |

| Main Notations | |

| a | sonic velocity (m/s) or solar collector performance constant (-) |

| A | area (m2) |

| AL | atmospheric life (year) |

| COP | coefficient of performance (-) |

| Cp | specific heat capacity (kJ/kg-K) |

| D | diameter (m) |

| It | incident solar radiation (kW/m2) |

| GHI | global horizontal irradiance (Wh/m2) |

| h | specific enthalpy (kJ/kg) |

| M | mass (kg) or molecular weight (k/mol) |

| Ma | Mach number (-) |

| mass flow rate (kg/s) | |

| P | pressure (kPa) |

| heat transfer rate (kW) | |

| s | specific entropy (kJ/kg-K) |

| T | temperature (°C) |

| U | overall heat transfer coefficient (kW/m2-K) |

| specific volume (m3/kg) | |

| V | velocity (m/s) |

| y | exergy destruction ratio (-) |

| electrical or mechanical power (kW) | |

| SF | solar fraction (-) |

| Greek | |

| α | storage tank control function (-) |

| β | storage tank control function (-) |

| Δ | difference |

| ε | component exergy efficiency (-) |

| ϕ | frictional loss coefficient (-) |

| γ | variable speed pump control function (-) |

| ∑ | summation |

| ω | ejector entrainment ratio (-) |

| η | device isentropic efficiency or system thermodynamic efficiency (-) |

| mixing loss coefficient (-) | |

| Superscript | |

| * | ejector critical mode operation |

| Subscript | |

| amb | ambient |

| aux | auxiliary heater |

| b | booster compressor |

| booster | booster compressor |

| c | condenser, critical, or ejector back |

| ch | chemical |

| D | destruction or destroyed |

| e | evaporator |

| ex | exergy |

| f | solar collector source-side fluid |

| F | fuel |

| g | generator |

| h | heat source |

| H | high temperature reservoir |

| heater | heater |

| hs | heat source |

| i | storage tank segment or stream |

| is | isentropic |

| in | inlet |

| k | component |

| L | load or low temperature reservoir or loss |

| m | mixing |

| max | maximum |

| mech | mechanical |

| mfe | mixed flow exit |

| out | outlet |

| overall | overall |

| p | ejector primary flow or product |

| ph | physical |

| pfe | primary flow exit |

| pump1 | source-side single-speed water Pump 1 |

| pump2 | load-side variable speed water Pump 2 |

| pump3 | refrigeration sub-system Pump 3 |

| s | ejector secondary inlet |

| sat | saturation |

| sc | solar collector |

| sys | system |

| t | ejector primary nozzle throat |

| u | useful energy |

| w | water |

| y | ejector hypothetical throat |

| 0 | reference state |

| 1 | generator outlet or ejector primary nozzle throat |

| 2 | condenser inlet or ejector primary nozzle exit |

| 3 | Pump 3 inlet or ejector constant-area section exit |

| 4 | expansion valve inlet |

| 5 | evaporator inlet |

| 6 | evaporator outlet |

| 7′ | Ejector A secondary inlet |

| 7″ | Ejector B secondary inlet |

| 7‴ | Ejector C secondary inlet |

| 8 | generator inlet |

Appendix A. Global Horizontal Irradiation

Appendix B. Ejector Model

Appendix B.1. Primary Flow in the Convergent and Divergent Nozzle

Appendix B.2. Primary Flow Core from Primary Flow Nozzle Exit (pfe) to Hypothetical Throat (y)

Appendix B.3. Entrained Flow from Secondary Flow Inlet (s) to Hypothetical Throat (y)

Appendix B.4. Mixed Flow at Section m, Upstream of the Normal Shock at Section (N)

Appendix B.5. Mixed Flow across the Shock from Section (m) to (mfe)

Appendix B.6. Mixed Flow through Diffuser from Section (mfe) to the Diffuser Outlet at Section (Out)

References

- Cao, X.; Dai, X.; Liu, J. Building enersolgy consumption status worldwide and the state-of-the-art technologies for zero-energy buildings during the past decade. Energy Build. 2016, 128, 198–213. [Google Scholar] [CrossRef]

- Eveloy, V.; Ayou, D.S. Sustainable District Cooling Systems: Status, Challenges, and Future Opportunities, with Emphasis on Cooling-Dominated Regions. Energies 2019, 12, 235. [Google Scholar] [CrossRef] [Green Version]

- Ministry of Energy. The UAE State of Energy Report; Ministry of Energy: Dubai, United Arab Emirates, 2015.

- BP. BP Energy Outlook. 2020 Edition. 2020. Available online: https://www.bp.com (accessed on 7 May 2021).

- Ayou, D.S.; Eveloy, V. Integration of Municipal Air-Conditioning, Power, and Gas Supplies Using an LNG Cold Exergy-Assisted Kalina Cycle System. Energies 2020, 13, 4599. [Google Scholar] [CrossRef]

- Allouhi, A.; Kousksou, T.; Jamil, A.; Bruel, P.; Mourad, Y.; Zeraouli, Y. Solar driven cooling systems: An updated review. Renew. Sustain. Energy Rev. 2015, 44, 159–181. [Google Scholar] [CrossRef]

- Braimakis, K. Solar ejector cooling systems: A review. Renew. Energy 2021, 164, 566–602. [Google Scholar] [CrossRef]

- Zeyghami, M.; Goswami, D.Y.; Stefanakos, E. A review of solar thermo-mechanical refrigeration and cooling methods. Renew. Sustain. Energy Rev. 2015, 51, 1428–1445. [Google Scholar] [CrossRef]

- Pollerberg, C.; Ali, A.H.H.; Dotsch, C. Experimental study on the performance of a solar driven steam jet ejector chiller. Energy Convers. Manag. 2008, 49, 3318–3325. [Google Scholar] [CrossRef]

- Chen, J.; Jarall, S.; Havtun, H.; Palm, B. A review on versatile ejector applications in refrigeration systems. Renew. Sustain. Energy Rev. 2015, 49, 67–90. [Google Scholar] [CrossRef]

- Sokolov, M.; Hershgal, D. Optimal coupling and feasibility of a solar-powered year-round ejector air conditioner. Sol. Energy 1993, 50, 507–516. [Google Scholar] [CrossRef]

- Arbel, A.; Sokolov, M. Revisiting solar-powered ejector air conditioner—The greener the better. Sol. Energy 2004, 77, 57–66. [Google Scholar] [CrossRef]

- Besagni, G.; Mereu, R.; Inzoli, F. Ejector refrigeration: A comprehensive review. Renew. Sustain. Energy Rev. 2016, 53, 373–407. [Google Scholar] [CrossRef] [Green Version]

- Mansour, R.B.; Ouzzane, M.; Aidoun, Z. Numerical evaluation of ejector-assisted mechanical compression systems for refrigeration applications. Int. J. Refrig. 2014, 43, 36–49. [Google Scholar] [CrossRef]

- Takleh, H.R.; Zare, V. Performance improvement of ejector expansion refrigeration cycles employing a booster compressor using different refrigerants: Thermodynamic analysis and optimization. Int. J. Refrig. 2019, 101, 56–70. [Google Scholar]

- Wang, Y.; Chen, T.; Liang, Y.; Sun, H.; Zhu, Y. A novel cooling and power cycle based on the absorption power cycle and booster-assisted ejector refrigeration cycle driven by a low-grade heat source: Energy, exergy and exergoeconomic analysis. Energy Convers. Manag. 2020, 204, 112321. [Google Scholar] [CrossRef]

- Takleh, H.R.; Zare, V. Employing thermoelectric generator and booster compressor for performance improvement of a geothermal driven combined power and ejector-refrigeration cycle. Energy Convers. Manag. 2019, 186, 120–130. [Google Scholar] [CrossRef]

- Tashtoush, B.; Alshare, A.; Al-Rifai, S. Hourly dynamic simulation of solar ejector cooling system using TRNSYS for Jordanian climate. Energy Convers. Manag. 2015, 100, 288–299. [Google Scholar] [CrossRef]

- Allouche, Y.; Varga, S.; Bouden, C.; Oliveira, A.C. Dynamic simulation of an integrated solar-driven ejector based air conditioning system with PCM cold storage. Appl. Energy 2017, 190, 600–611. [Google Scholar] [CrossRef]

- Chen, W.; Shi, C.; Zhang, S.; Chen, H.; Chong, D.; Yan, J. Theoretical analysis of ejector refrigeration system performance under overall modes. Appl. Energy 2017, 185, 2074–2084. [Google Scholar] [CrossRef]

- Huang, B.J.; Chang, J.M.; Wang, C.P.; Petrenko, V.A. 1-D analysis of ejector performance. Int. J. Refrig. 1999, 22, 354–364. [Google Scholar] [CrossRef]

- Wang, F.; Yang, Y.N.; Ding, W.W.; Yin, S.P. Performance analysis of ejector at off-design condition with an unconstant-pressure mixing model. Int. J. Refrig. 2019, 99, 204–212. [Google Scholar] [CrossRef]

- National Renewable Energy Laboratory (NREL). User’s Manual for TMY2s (Typical Meteorological Years), NREL/SP-463-7668, and TMY2s, Typical Meteorological Years Derived from the 1961–1990 National Solar Radiation Data Base, June 1995, CD-ROM. Golden: NREL. Available online: http://sel.me.wisc.edu/trnsys/weather/tmy2data.htm (accessed on 1 May 2018).

- Ali, M.T.; Mokhtar, M.; Chiesa, M.; Armstrong, P. A cooling change-point model of community-aggregate electrical load. Energy Build. 2011, 43, 28–37. [Google Scholar] [CrossRef]

- Eldakamawy, M.H.; Sorin, M.V.; Brouillette, M. Energy and exergy investigation of ejector refrigeration systems using retrograde refrigerants. Int. J. Refrig. 2017, 78, 176–192. [Google Scholar] [CrossRef]

- Marugán-Cruz, C.; Sánchez-Delgado, S.; Rodríguez-Sánchez, M.R.; Venegas, M.; Santana, D. District cooling network connected to a solar power tower. Appl. Therm. Eng. 2015, 79, 174–183. [Google Scholar] [CrossRef]

- Atalla, N.; Hunt, L.C. Modelling residential electricity demand in the GCC countries. Energy Econ. 2016, 59, 149–158. [Google Scholar] [CrossRef] [Green Version]

- Bayram, S.; Al-Qahtani, M.; Saffouri, F.; Koç, M. Estimating the cost of summer cooling in Bahrain. In Proceedings of the 9th IEEE-GCC Conference and Exhibition 2017 (GCCCE), Manama, Bahrain, 8–11 May 2017. [Google Scholar] [CrossRef]

- Salameh, T.; Assad, M.E.H.; Tawalbeh, M.; Ghenai, C.; Merabet, A.; Öztop, H.F. Analysis of cooling load on commercial building in UAE climate using building integrated photovoltaic façade system. Sol. Energy 2020, 199, 617–629. [Google Scholar] [CrossRef]

- Chen, J.; Havtun, H.; Palm, B. Screening of working fluids for the ejector refrigeration system. Int. J. Refrig. 2014, 47, 1–14. [Google Scholar] [CrossRef]

- Lillo, G.; Mastrullo, R.; Mauro, A.W.; Trinchieri, R.; Viscito, L. Thermo-economic analysis of a hybrid ejector refrigerating system based on a low grade heat source. Energies 2020, 13, 562. [Google Scholar] [CrossRef] [Green Version]

- Sadeghi, M.; Mahmoudi, S.M.S.; Saray, R.K. Exergoeconomic analysis and multi-objective optimization of an ejector refrigeration cycle powered by an internal combustion (HCCI) engine. Energy Convers. Manag. 2015, 96, 403–417. [Google Scholar] [CrossRef]

- Aphornratana, S.; Chungpaibulpatana, S.; Srikhirin, P. Experimental investigation of an ejector refrigerator: Effect of mixing chamber geometry on system performance. Int. J. Energy Res. 2001, 25, 397–411. [Google Scholar] [CrossRef]

- Abas, N.; Kalair, A.R.; Khan, N.; Haider, A.; Saleem, Z.; Saleem, M.S. Natural and synthetic refrigerants, global warming: A review. Renew. Sustain. Energy Rev. 2018, 90, 557–569. [Google Scholar] [CrossRef]

- Shestopalov, K.; Huang, B.; Petrenko, V.; Volovyk, O. Investigation of an experimental ejector refrigeration machine operating with refrigerant R245fa at design and off-design working conditions. Part 2. Theoretical and experimental results. Int. J. Refrig. 2015, 55, 212–223. [Google Scholar] [CrossRef]

- Yu, W.; Xu, Y.; Wang, H.; Ge, Z.; Wang, J.; Zhu, D.; Xia, Y. Thermodynamic and thermoeconomic performance analyses and optimization of a novel power and cooling cogeneration system fueled by low-grade waste heat. Appl. Therm. Eng. 2020, 179, 115667. [Google Scholar] [CrossRef]

- UNEP. Montreal Protocol on Substances That Deplete the Ozone Layer; United Nations Environment Program: New York, NY, USA, 1987. [Google Scholar]

- GECR. Kyoto Protocol to the United Nations Framework Conservation on Climate Change; Global Environmental Change Report: New York, NY, USA, 1997. [Google Scholar]

- United Nations Environment Programme (UNEP), Ozone Secretariat. The Montreal Protocol on Substances That Deplete the Ozone Layer. Article 5: Special Situation of Developing Countries. Available online: https://ozone.unep.org/treaties/montreal-protocol/articles/article-5-special-situation-developing-countries (accessed on 22 May 2021).

- Multimedia.3m.com. United Nations Environment Programme (UNEP) Factsheet. The Kigali Amendment to the Montreal Protocol: HFC Phase-Down. Available online: https://multimedia.3m.com/mws/media/1365924O/unep-fact-sheet-kigali-amendment-to-mp.pdf (accessed on 30 June 2021).

- Booten, C.; Nicholson, S.; Mann, M.; Abdelaziz, O. Refrigerants: Market Trends and Supply Chain Assessment. Technical Report NREL/TP-5500-70207. February, 2020. Available online: https://www.nrel.gov/docs/fy20osti/70207.pdf (accessed on 30 June 2021).

- Roy, Z.; Halder, G. Replacement of halogenated refrigerants towards sustainable cooling system: A review. Chem. Eng. J. Adv. 2020, 3, 100027. [Google Scholar] [CrossRef]

- Nair, V. HFO refrigerants: A review of present status and future prospects. Int. J. Refrig. 2021, 122, 156–170. [Google Scholar] [CrossRef]

- American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE). ANSI/ASHRAE Standard 34-2019. Designation and Safety Classification of Refrigerants. Available online: https://www.ashrae.org (accessed on 5 May 2021).

- EES. Engineering Equation Solver. F-Chart Software, 1992–2016. Available online: www.fchart.com (accessed on 5 May 2021).

- Klein, S.A.; Beckman, W.A.; Mitchell, J.W.; Duffie, J.A.; Duffie, N.A.; Freeman, T.L.; Mitchell, J.C.; Braun, J.E.; Evans, B.L.; Kummer, J.P.; et al. TRNSYS 18, a TRaNsient SYstem Simulation Program; Mathematical Reference; Solar Energy Laboratory, University of Wisconsin-Madison: Madison, WI, USA, 2017. [Google Scholar]

- Mansuriya, K.; Patel, V.K.; Desai, N.B.; Vora, N.M. Performance evaluation of the ejector refrigeration system based on thermo-economic criteria through multi-objective approach. Clean Technol. Environ. Policy 2012, 23, 1087–1103. [Google Scholar] [CrossRef]

- Sarbu, I.; Sebarchievici, C. Review of solar refrigeration and cooling systems. Energy Build. 2013, 67, 286–297. [Google Scholar] [CrossRef]

- Zhao, H.; Zhang, K.; Wang, L.; Han, J. Thermodynamic investigation of a booster-assisted ejector refrigeration system. Appl. Therm. Eng. 2016, 104, 274–281. [Google Scholar] [CrossRef]

- Pridasawas, W.; Lundqvist, P. A year-round dynamic simulation of a solar-driven ejector refrigeration system with iso-butane as a refrigerant. Int. J. Refrig. 2007, 30, 840–850. [Google Scholar] [CrossRef]

- Moran, M.J.; Shapiro, H.N. Fundamentals of Engineering Thermodynamics, 6th ed.; Wiley: Hoboken, NJ, USA, 2007; ISBN 9780471787358. [Google Scholar]

- Duffie, J.A.; Beckman, W.A. Solar Engineering of Thermal Processes; Wiley-Interscience: New York, NY, USA, 1980. [Google Scholar]

- Sarbu, I.; Sebarchievici, C. Solar Collectors. In Solar Heating and Cooling Systems. Fundamentals, Experiments and Applications; Academic Press: Cambridge, MA, USA, 2017; Chapter 3; pp. 29–97. ISBN 9780128116623. [Google Scholar]

- Vidal, H.; Colle, S. Modeling and hourly simulation of a solar ejector cooling system. Appl. Therm. Eng. 2006, 26, 663–672. [Google Scholar] [CrossRef]

- Bejan, A.; Tsatsaronis, G.; Moran, M.J. Thermal Design and Optimization; John Wiley & Sons, Inc.: New York, NY, USA, 1996. [Google Scholar]

- Pektezel, O.; Acar, H.I. Energy and Exergy Analysis of Combined Organic Rankine Cycle-Single and Dual Evaporator Vapor Compression Refrigeration Cycle. Appl. Sci. 2019, 9, 5028. [Google Scholar] [CrossRef] [Green Version]

- Chen, W.; Liu, M.; Chong, D.; Yan, J.; Little, A.B.; Bartosiewicz, Y. A 1D model to predict ejector performance at critical and sub-critical operational regimes. Int. J. Refrig. 2013, 36, 1750–1761. [Google Scholar] [CrossRef]

- Shestopalov, K.O.; Huang, B.J.; Petrenko, V.O.; Volovyk, O.S. Investigation of an experimental ejector refrigeration machine operating with refrigerant R245fa at design and off-design working conditions. Part 1. Theoretical analysis. Int. J. Refrig. 2015, 55, 201–211. [Google Scholar] [CrossRef]

- International Renewable Energy Agency (IRENA). Renewable Energy Markey Analysis: GCC, 2019. Available online: https://www.irena.org/-/media/Files/IRENA/Agency/Publication/2019/Jan/IRENA_Market_Analysis_GCC_2019.pdf (accessed on 5 May 2021).

- Treyer, K.; Bauer, C. The environmental footprint of UAE’s electricity sector: Combining life cycle assessment and scenario modeling. Renew. Sustain. Energy Rev. 2016, 55, 1234–1247. [Google Scholar] [CrossRef]

| Working Fluid | Molecular Structure | M (g/mol) | TC (°C) | Pc (MPa) | Tsat at 1 atm (°C) | Safety | AL (year) | ODP (-) | GWP (-) |

|---|---|---|---|---|---|---|---|---|---|

| R11 | CCL3F | 137.37 | 198 | 4.41 | 23.7 | A1 | 45 | 1 | 4600 |

| R141b | CH3CCL2F | 116.95 | 204.2 | 4.25 | 32 | - | 9.3 | 0.086 | 700 |

| R245fA | CHF2CH2CF3 | 134.05 | 154.1 | 4.43 | 15.1 | B1 | 7.2 | 0 | 950 |

| R600a | CH(CH3)2-CH3 | 58.12 | 134.7 | 3.64 | −11.7 | A3 | - | 0 | ∼20 |

| Parameter and Unit | Value |

|---|---|

| Refrigeration sub-system | |

| Generator refrigerant outlet temperature, Tg (°C) | 85 (range of variation: 80−100) [18,20,21,35,48] |

| Evaporator refrigerant outlet temperature, Te (°C) | 10 (range of variation: 5−16) [18,20,21,25,35,48] |

| Minimum temperature difference (°C) | |

| Generator | 10 [25,36] |

| Condenser | 3 [32] |

| Ejector | |

| Primary nozzle exit to throat effective area diameter ratio, D2/D1 (-) 1 | 1.7 [20,21] |

| Isentropic efficiency coefficient for primary nozzle, (-) | 0.95 [25,35,47] |

| Isentropic efficiency coefficient from nozzle exit to section y, (-) | 0.88 (this study, based on [20,35]) |

| Isentropic efficiency coefficient for secondary, flow (-) | 0.85 [20,47] |

| Frictional loss coefficient in mixing section, (-) | 0.86 (this study, based on [17,20,25]) |

| Booster compressor pressure ratio (-) 2 | 1.7 (bB), 2.3 (bC) (this study, based on [12,15]) |

| Booster compressor isentropic efficiency, (-) | 0.65 [49] |

| Pump 3 isentropic efficiency, (-) | 0.50 [50] |

| Solar collector sub-system | |

| Surface area (m2) | 300 |

| Source-side mass flow rate, (kg/hr) | 2000 |

| Storage tank volume (m3) | 5 |

| Auxiliary heater efficiency (-) | 0.9 |

| Component | Energy Relation | Mass Relation |

|---|---|---|

| Generator | ||

| Evaporator | ||

| Condenser | ||

| Ejector | Section 3.1 | |

| Booster compressor B | ||

| Booster compressor C | ||

| Pump 3 | ||

| Expansion valve |

| Component | |||

|---|---|---|---|

| Generator | |||

| Evaporator | |||

| Condenser | = | ||

| Ejector | |||

| Booster compressor B | |||

| Booster compressor C | |||

| Pump 3 | |||

| Expansion valve |

| Working Fluid | Simple Cycle | Compression-Assisted Cycle | ||

|---|---|---|---|---|

| and Ejector | A2 (m2) | A3 (m2) | A2 (m2) | A3 (m2) |

| R245fa | ||||

| A | 0.000215 | 0.000453 | --- | --- |

| B | 0.001455 | 0.002426 | 0.000425 | 0.000709 |

| C | 0.006790 | 0.009370 | 0.000836 | 0.000935 |

| R600a | ||||

| A | 0.000121 | 0.000154 | --- | --- |

| B | 0.001971 | 0.001923 | 0.000389 | 0.000380 |

| C | 0.004042 | 0.003795 | 0.000676 | 0.000514 |

| R141b | ||||

| A | 0.000288 | 0.000532 | --- | --- |

| B | 0.002062 | 0.002569 | 0.001320 | 0.001644 |

| C | 0.029104 | 0.031827 | 0.001698 | 0.001693 |

| R11 | ||||

| A | 0.000158 | 0.000337 | --- | --- |

| B | 0.001037 | 0.001547 | 0.000565 | 0.000842 |

| C | 0.010424 | 0.009376 | 0.001604 | 0.001442 |

| Unit | εex,k (%) | ||||

|---|---|---|---|---|---|

| Ejector A (SC) | |||||

| Generator | 9.578 | 7.357 | 2.221 | 22.8 | 76.8 |

| Ejector | 8.840 | 3.565 | 5.275 | 54.2 | 40.3 |

| Condenser | 1.658 | 0 | 1.658 | 17.0 | 0 |

| Evaporator | 0.477 | 0.088 | 0.389 | 4.0 | 18.5 |

| Pump | 0.248 | 0.114 | 0.135 | 1.4 | 45.8 |

| Expansion valve | 0.35 | 0.29 | 0.061 | 0.6 | 82.7 |

| Overall cycle | 9.827 | 0.088 | 9.739 | 100.0 | 0.9 |

| Ejector B (BAC) | |||||

| Generator | 18.202 | 14.391 | 3.811 | 18.9 | 79.1 |

| Ejector | 18.828 | 10.158 | 8.670 | 42.9 | 54.0 |

| Condenser | 5.623 | 0 | 5.623 | 27.8 | 0 |

| Evaporator | 1.682 | 0.281 | 1.401 | 6.9 | 16.7 |

| Pump | 0.447 | 0.180 | 0.266 | 1.3 | 40.4 |

| Expansion valve | 1.256 | 0.889 | 0.357 | 1.8 | 71.6 |

| Booster compressor | 1.838 | 1.7613 | 0.077 | 0.4 | 95.8 |

| Overall cycle | 20.487 | 0.281 | 20.206 | 100.0 | 1.4 |

| Ejector C (BAC) | |||||

| Generator | 34.015 | 27.885 | 6.13 | 16.0 | 82.0 |

| Ejector | 37.632 | 23.726 | 13.906 | 36.2 | 63.1 |

| Condenser | 14.896 | 0 | 14.896 | 38. 8 | 0 |

| Evaporator | 2.414 | 0.367 | 2.048 | 5.3 | 15.2 |

| Pump | 0.79 | 0.267 | 0.523 | 1.4 | 33.7 |

| Expansion valve | 1.890 | 1.106 | 0.784 | 2.0 | 58.5 |

| Booster compressor | 3.971 | 3.8479 | 0.123 | 0.3 | 96.9 |

| Overall cycle | 38.776 | 0.367 | 38.410 | 100.0 | 1.0 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Eveloy, V.; Alkendi, Y. Thermodynamic Performance Investigation of a Small-Scale Solar Compression-Assisted Multi-Ejector Indoor Air Conditioning System for Hot Climate Conditions. Energies 2021, 14, 4325. https://doi.org/10.3390/en14144325

Eveloy V, Alkendi Y. Thermodynamic Performance Investigation of a Small-Scale Solar Compression-Assisted Multi-Ejector Indoor Air Conditioning System for Hot Climate Conditions. Energies. 2021; 14(14):4325. https://doi.org/10.3390/en14144325

Chicago/Turabian StyleEveloy, Valerie, and Yusra Alkendi. 2021. "Thermodynamic Performance Investigation of a Small-Scale Solar Compression-Assisted Multi-Ejector Indoor Air Conditioning System for Hot Climate Conditions" Energies 14, no. 14: 4325. https://doi.org/10.3390/en14144325

APA StyleEveloy, V., & Alkendi, Y. (2021). Thermodynamic Performance Investigation of a Small-Scale Solar Compression-Assisted Multi-Ejector Indoor Air Conditioning System for Hot Climate Conditions. Energies, 14(14), 4325. https://doi.org/10.3390/en14144325