Model-Free Control of UCG Based on Continual Optimization of Operating Variables: An Experimental Study

Abstract

:1. Introduction

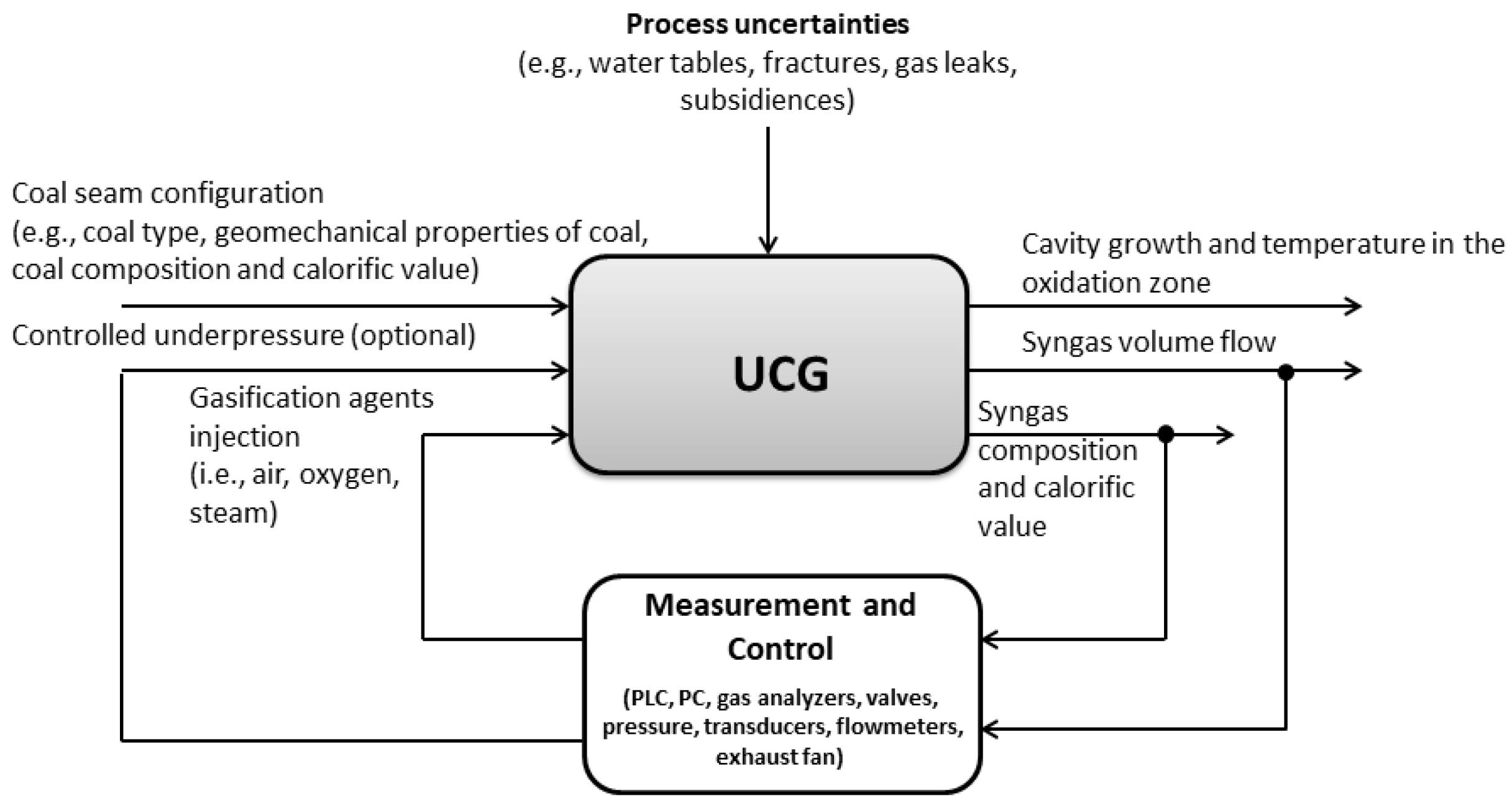

1.1. UCG Control

1.2. Model-Free Control

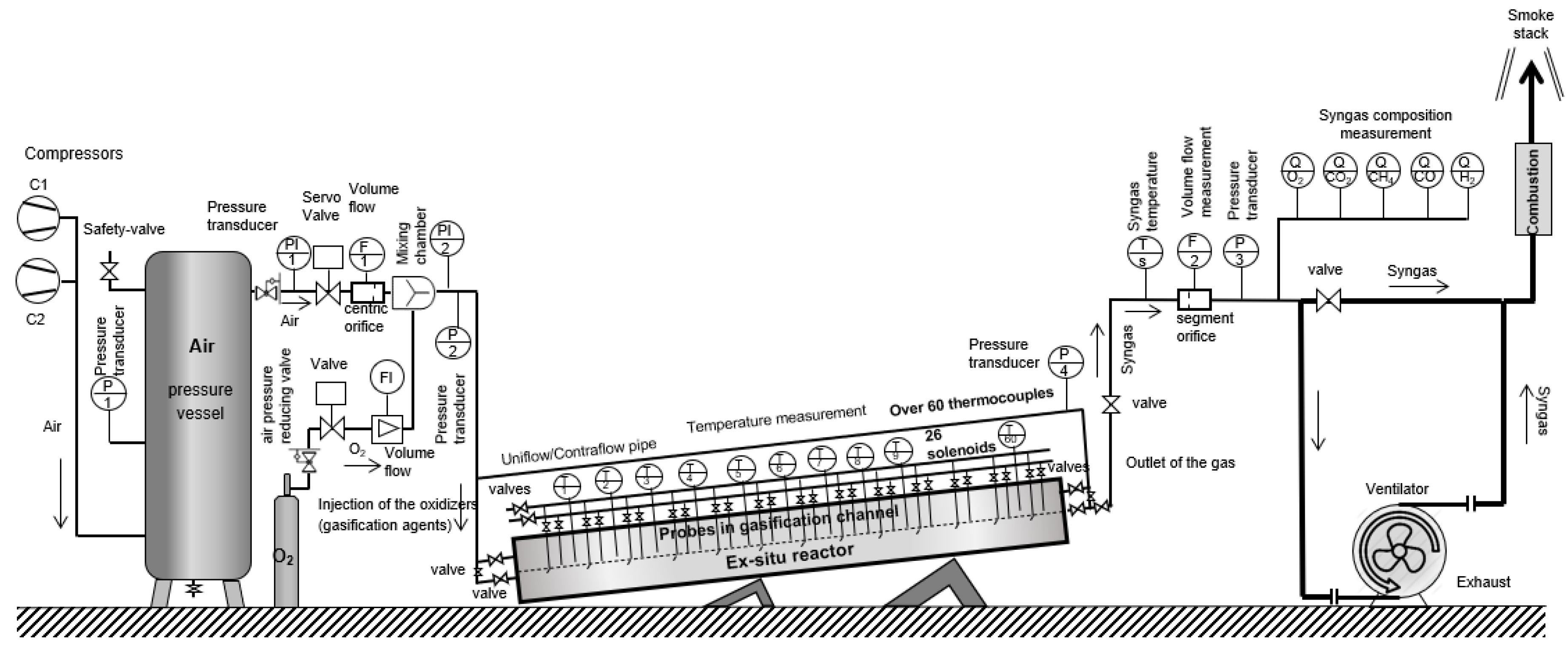

2. Experimental UCG in Ex Situ Reactor

- control of air pressure by two compressors;

- stabilization of airflow through servo valve;

- stabilization of temperature in the oxidizing zone;

- stabilization of the O2 concentration in syngas.

3. UCG Optimal Control Based on Dynamic Optimization

- Optimization with the mathematical model of the process;

- Optimization without the mathematical model of the process (i.e., the system is considered as the “black-box”).

- Optimal control systems with feedback;

- Optimal control systems with feed-forward;

- Combined optimal control systems.

3.1. Optimized Vector

3.2. Optimimality Criterion

3.3. Constraints

- For the control variables, the constraints are defined as the following:where , is the maximum and minimum of allowable servo valve opening (%, pulses) or airflow (m3/h), respectively, , is the maximum and minimum of allowable oxygen flow (m3/h), respectively, and , represent the maximum and minimum of allowable exhaust fan power frequency (Hz), or boundaries for controlled under pressure (Pa) on the outlet from the ex situ reactor, respectively;

- If the concentration of oxygen in the syngas is too high, it means that input is set up to a high flow of oxygen or a higher amount of oxidant is blown. High oxygen concentration at the outlet leads to a surplus of oxygen in the gasification process. It is reflected in a reduced calorific value. An ideal situation occurs when the oxygen concentration on the outlet is maintained at 0%. Given the above remarks, we can define a limit on the concentration of oxygen in the following form:where is the maximal permitted concentration of O2 in syngas (%), and is the minimal permitted concentration of O2 in syngas (%).

3.4. Optimization Method

4. Results

5. Discussion

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| UCG | Underground coal gasification |

| PI | Proportional integral |

| MPC | Model-predictive control |

| AMPC | Adaptive model-predictive control |

| ARX | Auto-regressive with eXogenous input |

| MARS | Multivariate adaptive regression splines |

| ADP | Adaptive dynamic programming |

| SMC | Sliding mode control |

| 1-D | One dimensional |

| 3-D | Three dimensional |

| PLC | Programmable logic controller |

| SCADA | Supervisory control and data acquisition |

| FIFO | First in, first out |

Nomenclature

| The state of the controlled system | |

| The manipulation variable | |

| The syngas calorific value (MJ/m3) | |

| The volume fraction of CO in syngas (%) | |

| The volume fraction of H2 in syngas (%) | |

| The volume fraction of CH4 in syngas (%) | |

| The initial vector of optimized manipulation variables | |

| The vector of optimized manipulation variables | |

| ℝ | Real numbers |

| The objective function | |

| The change of the servo valve position in pulses or airflow (m3/h) | |

| The volume flow of oxygen added to the oxidation mixture (m3/h) | |

| The exhaust fan motor power frequency (Hz) or controlled under pressure (Pa) | |

| The -th manipulation variable ( = 1, 2, 3) | |

| Minimum of the -th manipulation variable | |

| Maximum of the -th manipulation variable | |

| , | Boundaries of servo valve opening (%, pulses) or airflow (m3/h) |

| , | Boundaries of oxygen flow (m3/h) |

| , | Boundaries of exhaust fan power frequency (Hz) or under pressure (Pa) |

| The volume fraction of O2 in syngas (%) | |

| The minimal permitted concentration of O2 in syngas (%) | |

| The maximal permitted concentration of O2 in syngas (%) | |

| Time (s) | |

| , | Time of beginning and end of the analyzed section (s) |

| The coefficient of permeability (m2) | |

| The index of the control period of the optimal control algorithm | |

| The value of the objective function in the step (MJ/m3) | |

| The average calorific value (MJ/m3) of the syngas in the step | |

| The –th calorific value in the buffer (MJ/m3) | |

| The number of the samples in the FIFO buffer | |

| The value of in the –th step of the sampling | |

| The optimal control sampling period (s) | |

| The sampling period on the stabilization level (s) | |

| The vector of optimized control variables in the step | |

| The vector of the optimized variables in the step | |

| The common iterative constant | |

| The vector of iterative constants for each manipulation variable | |

| The gradient of the objective function | |

| Increments of manipulation variables ( = 1, 2, 3) | |

| The maximum allowable deviation from the arithmetic average (%) | |

| The maximum allowable value of the standard deviation |

References

- Perkins, G. Mathematical Modelling of Underground Coal Gasification, Academic Dissertation; University of New South Wales, Faculty of Science and Engineering: Sydney, NSW, Australia, 2005. [Google Scholar]

- Kačur, J.; Durdán, M.; Laciak, M.; Flegner, P. Impact analysis of the oxidant in the process of underground coal gasification. Measurement 2014, 51, 147–155. [Google Scholar] [CrossRef]

- Chandellea, V.; Lia, T.K.; Ledenta, P.; Patignya, J.; Henqueta, H.; Kowola, K.; Massona, G.; Mostadea, M. Belgo-German Experiment on Underground Gasification Demonstration Project; Technical Report; Commission of the European Communities: Brussels, Belgium, 1989; ISBN 92-825-9673-7. [Google Scholar]

- Creedy, D.P.; Garner, K.; Holloway, S.; Jones, N.; Ren, T.X. Review of Underground Coal Gasification Technological Advancements; Technical Report COAL R11 DTI/Pub URN 01/1041; Department of Trade and Industry: London, UK, 2001. [Google Scholar]

- Anon. Underground Coal Gasification Program; Report ERDA 77-51/4 on Contract No. EX-76-C-01-2343, Technical Report; Booz, Allen & Hamilton, Inc.: Washington, DC, USA; US Energy Research and Development Administration: McLean, VA, USA, 1977. [Google Scholar]

- Dobbs, R.L.; Krantz, W.B. Combustion front Propagation in Underground Coal Gasification, Final Report, Work Performed under Grant No. DE-FG22-86PC90512; Technical Report; Boulder Department of Chemical Engineering, University of Colorado: Boulder, CO, USA, 1990. [Google Scholar]

- Cena, R.J.; Thorsness, C.B. Underground Coal Gasification Database; Technical Report UCID-19169; Lawrence Livermore National Laboratory, University of California: Berkeley, CA, USA, 1981. [Google Scholar]

- Gibb, A. The Underground Gasification of Coal; Sir Isaac Pitman & Sons Ltd.: London, UK, 1964. [Google Scholar]

- Gregg, D.W.; Hill, R.W.; Olness, D.U. An Overview of the Soviet Effort in Underground Coal Gasification; Technical Report UCRL-52004; Lawrence Livermore Laboratory, University of California: Berkeley, CA, USA, 1976. [Google Scholar]

- Olness, D.U. The Angrenskaya Undergroud Coal Gasification Station; Technical Report UCRL-53300; Lawrence Livermore National Laboratory, University of California: Berkeley, CA, USA, 1982. [Google Scholar]

- Anon. Underground Coal Gasification—First Trial in the Framework of a Community Collaboration: Final Summary Report; Technical Report; Underground Gasification Europe (UGE): Alcorisa, Spain, 1999. [Google Scholar]

- Boysen, J.E.; Canfield, M.T.; Covell, J.R.; Schmit, C.R. Detailed Evaluation of Process and Environmental Data from the Rocky Mountain I Underground Coal Gasification Field Test; Technical Report No. GRI-97/0331; Gas Research Institute: Chicago, IL, USA, 1998. [Google Scholar]

- Robert, G.M.M.; Oliver, L.; Spackman, L.K. Field and laboratory results from the TONO 1 (CRIP) UCG Cavity Excavation Project. WIDCO Mine Site, Centralia, Washington. Fuel Sci. Technol. Int. 1989, 7, 1059–1120. [Google Scholar]

- Walker, L.K.; Blinderman, M.S.; Brun, K. An IGCC Project at Chinchilla, Australia Based on Underground Coal Gasification UCG. In Proceedings of the 2001 Gasification Technologies Conference, San Francisco, CA, USA, 8–10 October 2001; pp. 1–6. [Google Scholar]

- Koenen, M.; Bergen, F.; David, P. Isotope Measurements as a Proxy for Optimizing Future Hydrogen Production in Underground Coal Gasification, News in Depth. 2015. Available online: https://www.tno.nl/media/2624/information20-nid1.pdf (accessed on 26 May 2021).

- Brasseur, A.; Antenucci, D.; Bouquegneau, J.-M.; Coëme, A.; Dauby, P.; Létolle, R.; Mostade, M.; Pirlot, P.; Pirard, J.-P. Carbon stable isotope analysis as a tool for tracing temperature during the El Tremedal underground coal gasification at great depth. Fuel 2002, 81, 109–117. [Google Scholar] [CrossRef]

- Wu, J.M. Radon Distribution Under the Mine and the Application of Radon Measuring in the Monitoring of the Natural Fire Zone. Ph.D. Thesis, Shanxi Institute of Mining and Technology, Taiyuan, China, 1994. [Google Scholar]

- Wu, H.S. The Measuring Methods of Radon and Its Application; Nuclear Energy Press: Beijing, China, 1995. [Google Scholar]

- Wu, H.S.; Bai, Y.S.; Lin, Y.F.; Chang, G.L. The Action of Relay Transmission of Radon Migration. Chin. J. Geophys. 1997, 40, 136–142. [Google Scholar]

- Kačur, J.; Durdán, M.; Laciak, M.; Flegner, P. A Comparative Study of Data-Driven Modeling Methods for Soft-Sensing in Underground Coal Gasification. Acta Polytech. 2019, 59, 322–351. [Google Scholar] [CrossRef] [Green Version]

- Ge, Z.; Sun, Q.; Zhang, N. Changes in surface roughness of sandstone after heating and cooling cycles. Arab. J. Geosci. 2020, 13. [Google Scholar] [CrossRef]

- Schrauf, T.W.; Evans, D.D. Laboratory studies of gas flow through a single natural fracture. Water Resour. Res. 1986, 22, 1038–1050. [Google Scholar] [CrossRef]

- Chen, Z.; Narayan, S.P.; Yang, Z.; Rahman, S.S. An experimental investigation of hydraulic behavior of fractures and joints in granitic rock. Int. J. Rock Mech. Min. Sci. 2000, 37, 1061–1071. [Google Scholar] [CrossRef]

- Ge, Y.; Kulatilake, P.H.S.W.; Tang, H.; Xiong, C. Investigation of natural rock joint roughness. Comput. Geotech. 2014, 55, 290–305. [Google Scholar] [CrossRef]

- Kačur, J.; Kostúr, K. Approaches to the Gas Control in UCG. Acta Polytech. 2017, 57, 182–200. [Google Scholar] [CrossRef] [Green Version]

- Kačur, J.; Flegner, P.; Durdán, M.; Laciak, M. Model Predictive Control of UCG: An Experiment and Simulation Study. Inf. Technol. Control 2019, 48, 557–578. [Google Scholar] [CrossRef]

- Hou, Z.; Liu, S.; Yin, C. Local Learning-based Model-Free Adaptive Predictive Control for Adjustment of Oxygen Concentration in Syngas Manufacturing Industry. IET Control Theory Appl. 2016, 10, 1384–1394. [Google Scholar] [CrossRef]

- Kačur, J.; Laciak, M.; Durdán, M.; Flegner, P. Application of multivariate adaptive regression in soft-sensing and control of UCG. Int. J. Model. Identif. Control 2019, 33, 246–260. [Google Scholar] [CrossRef]

- Laciak, M.; Ráškayová, D. The using of thermodynamic model for the optimal setting of input parameters in the UCG process. In Proceedings of the ICCC 2016 17th International Carpathian Control Conference, High Tatras, Slovakia, 29 May–1 June 2016; pp. 418–423. [Google Scholar] [CrossRef]

- Laciak, M.; Kostúr, K.; Durdán, M.; Kačur, J.; Flegner, P. The analysis of the underground coal gasification in experimental equipment. Energy 2016, 114, 332–343. [Google Scholar] [CrossRef] [Green Version]

- Laciak, M.; Kačur, J.; Kostúr, K. The verification of thermodynamic model for UCG process. In Proceedings of the ICCC 2016 17th International Carpathian Control Conference, High Tatras, Slovakia, 29 May–1 June 2016; pp. 424–428. [Google Scholar] [CrossRef]

- Wei, Q.; Liu, D. Adaptive dynamic programming for optimal tracking control of unknown nonlinear systems with application to coal gasification. Trans. Autom. Sci. Eng. IEEE 2014, 11, 1020–1036. [Google Scholar] [CrossRef]

- Uppal, A.A.; Bhatti, A.I.; Aamir, E.; Samar, R.; Khan, S.A. Control oriented modeling and optimization of one dimensional packed bed model of underground coal gasification. J. Process Control 2014, 24, 269–277. [Google Scholar] [CrossRef]

- Arshad, A.; Bhatti, A.I.; Samar, R.; Ahmed, Q.; Aamir, E. Model Development of UCG and Calorific Value Maintenance via Sliding Mode Control. In Proceedings of the 2012 International Conference on Emerging Technologies, Islamabad, Pakistan, 8–9 October 2012; pp. 1–6. [Google Scholar] [CrossRef]

- Uppal, A.A.; Bhatti, A.; Aamir, E.; Samar, R.; Khan, S. Optimization and control of one dimensional packed bed model of underground coal gasification. J. Process Control 2015, 35, 11–20. [Google Scholar] [CrossRef]

- Uppal, A.A.; Alsmadi, Y.M.; Utkin, V.I.; Bhatti, A.I.; Khan, S.A. Sliding mode control of underground coal gasification energy conversion process. IEEE Trans. Control Syst. Technol. 2018, 26, 587–598. [Google Scholar] [CrossRef]

- Uppal, A.A.; Butt, S.S.; Bhatti, A.I.; Aschemann, H. Integral sliding mode control and gain-scheduled modified Utkin observer for an underground coal gasification energy conversion process. In Proceedings of the 23rd International Conference on Methods and Models in Automation and Robotics, Miedzyzdroje, Poland, 27–30 August 2018; pp. 357–362. [Google Scholar] [CrossRef]

- Uppal, A.A.; Butt, S.S.; Khan, Q.; Aschemann, H. Robust tracking of the heating value in an underground coal gasification process using dynamic integral sliding mode control and a gain-scheduled modified Utkin observer. J. Process Control 2019, 73, 113–122. [Google Scholar] [CrossRef]

- Sira Ramirez, H.; Luviano-Juárez, A.; Ramírez-Neria, M.; Zurita-Bustamante, E.W. Active Disturbance Rejection Control of Dynamic Systems; Butterworth-Heinemann an Imprint of Elsevier: Oxford, UK, 2017. [Google Scholar]

- Zhang, C.; Ordóñez, R. Extremum-Seeking Control and Applications: A Numerical Optimization-Based Approach; Springer: New York, NY, USA, 2012. [Google Scholar] [CrossRef]

- Ariyur, K.B.; Krstić, M. Real-Time Optimization by Extremum-Seeking Control; John Wiley & Sons, Inc.: New York, NY, USA, 2003. [Google Scholar] [CrossRef]

- Kostúr, K.; Kačur, J. Extremum Seeking Control of Carbon Monoxide Concentration in Underground Coal Gasification. IFAC PapersOnLine 2017, 50, 13772–13777. [Google Scholar] [CrossRef]

- Leblanc, M. Sur lélectrification des chemins de fer au moyen de courants alternatifs de fréquence élevée. Rev. Générale Lelectricité 1922, 12, 275–277. [Google Scholar]

- Krstić, M.; Wang, H.H. Stability of extremum seeking feedback for general nonlinear dynamic systems. Automatica 2000, 36, 595–601. [Google Scholar] [CrossRef]

- Tan, Y.; Nesic, D.; Mareels, I. On the dither choice in extremum seeking control. Automatica 2008, 44, 1446–1450. [Google Scholar] [CrossRef]

- Rotea, M.A. Analysis of multivariable extremum seeking algorithms. In Proceedings of the 2000 American Control Conference ACC (IEEE Cat. No.00CH36334), Chicago, IL, USA, 28–30 June 2000; pp. 433–437. [Google Scholar] [CrossRef]

- Busoniu, L.; Babuska, R.; De Schutter, B. A Comprehensive Survey of Multiagent Reinforcement Learning. IEEE Trans. Syst. Man Cybern. Part C 2008, 38, 156–172. [Google Scholar] [CrossRef] [Green Version]

- Rao, R.P.N. Reinforcement Learning: An Introduction; Sutton, R.S., Barto, A.G., Eds.; MIT Press: Cambridge, MA, USA, 1998; 380p, ISBN 0-262-19398-1. [Google Scholar]

- Bertsekas, D.; Tsitsiklis, J. Neuro-dynamic programming: An overview. In Proceedings of the 34th IEEE Conference on Decision and Control, New Orleans, LA, USA, 13–15 December 1995; Volume 1, pp. 560–564. [Google Scholar] [CrossRef] [Green Version]

- Szepesvári, C. Algorithms for Reinforcement Learning. Synth. Lect. Artif. Intell. Mach. Learn. 2010, 4, 1–103. [Google Scholar] [CrossRef] [Green Version]

- Busoniu, L.; Babuska, R.; De Schutter, B.; Ernst, D. Reinforcement Learning and Dynamic Programming Using Function Approximators; CRC Press: Boca Raton, FL, USA, 2010. [Google Scholar] [CrossRef] [Green Version]

- Farahmand, A. Regularization in Reinforcement Learning. Ph.D. Thesis, University of Alberta, Edmonton, AB, Canada, 2011. [Google Scholar]

- Kormushev, P.; Calinon, S.; Caldwell, D.G. Robot motor skill coordination with EM-based Reinforcement Learning. In Proceedings of the 2010 IEEE/RSJ International Conference on Intelligent Robots and Systems, Taipei, Taiwan, 18–22 October 2010; pp. 3232–3237. [Google Scholar] [CrossRef] [Green Version]

- Benosman, M. Adaptive Control: An Overview. In Learning-Based Adaptive Control; Elsevier: New York, NY, USA, 2016; pp. 1–35. [Google Scholar] [CrossRef]

- Kostúr, K.; Laciak, M.; Durdán, M.; Kačur, J.; Flegner, P. Low-calorific gasification of underground coal with a higher humidity. Measurement 2015, 63, 69–80. [Google Scholar] [CrossRef]

- Wiatowski, M.; Kapusta, K.; Stańczyk, K. Efficiency assessment of underground gasification of ortho-and meta-lignite: Highpressure ex-situ experimental simulations. Fuel 2019, 236, 221–227. [Google Scholar] [CrossRef]

- Stańczyk, K.; Kapusta, K.; Wiatowski, M.; Swiadrowski, J.; Smolinski, A.; Rogut, J. Experimental simulation of hard coal underground gasification for hydrogen production. Fuel 2012, 91, 40–50. [Google Scholar] [CrossRef]

- Kapusta, K.; Wiatowski, M.; Stańczyk, K. An experimental ex-situ study of the suitability of a high moisture ortho-lignite for underground coal gasification (UCG) process. Fuel 2016, 179, 150–155. [Google Scholar] [CrossRef]

- Kačur, J.; Kostúr, K. Research Report of the Project “Underground Gasification by Thermal Decomposition No. APVV-0582-06 for Year 2008”; Technical Report; Technical University of Košice, Faculty BERG and HBP a.s. Prievidza: Košice, Slovakia, 2008. [Google Scholar]

- Hrubina, K. Optimálne Riadenie I a II; Edičné stredisko VŠT v Košiciach: Košice, Slovakia, 1987. [Google Scholar]

- Hrubina, K. Riešenie Problémov Optimálneho Riadenia, Metódami Numerickej Analýzy, Záverečná Správa o Fakultnej Výskumnej Úlohe; Technical Report; E-Fak 9 VŠT Košiciach: Košice, Slovakia, 1975. [Google Scholar]

- Stengel, R.F. Optimal Control and Estimation; Dover, Inc.: New York, NY, USA, 1994. [Google Scholar]

- Hanuš, B.; Modrlák, O.; Olehla, M. Číslicová Regulace Technologických Procesů. Algoritmy, Matematicko-Fyzikálni analýza, Identifikace, Adaptace, 1. Vydání; Vysoké Učení Technické v Brňe, VUTIUM: Brno, Czech Republic, 2000. [Google Scholar]

- Kostúr, K. Optimalizácia Procesov; Edičné stredisko TU v Košiciach: Košice, Slovakia, 1991. [Google Scholar]

| Parameter | Value |

|---|---|

| Total Moisture (%) | 22.25 |

| Ash (%) | 26.33 |

| Volatiles (%) | 60.39 |

| Carbon (%) | 64.79 |

| Hydrogen (%) | 5.59 |

| Nitrogen (%) | 1.04 |

| Calorific value (MJ/kg) | 24.94 |

| Calorific value (MJ/kg) | 18.37 |

| Calorific value (MJ/kg) | 13.74 |

| Ash (%) | 20.47 |

| Carbon (%) | 37.11 |

| Hydrogen (%) | 3.20 |

| Nitrogen (%) | 0.59 |

| CaO (%) | 1.12 |

| MgO (%) | 0.62 |

| SiO2 (%) | 12.10 |

| Al2O3 (%) | 5.26 |

| Fe2O3 (%) | 2.89 |

| Na2O (%) | 0.14 |

| P2O5 (%) | 0.02 |

| TiO2 (%) | 0.17 |

| K2O | 0.55 |

| Volatiles (%) | 34.59 |

| Analytical Moisture (%) | 9.56 |

| Total Sulphur (%) | 1.93 |

| Sulphate Sulphur (%) | 0.01 |

| Pyritic Sulphur (%) | 1.35 |

| Organic Sulphur (%) | 0.57 |

| Oxygen (%) | 26.34 |

| Oxygen (%) | 19.4 |

| Test | Duration (min) | Optimized Variables | Optimization Steps | Maximum Temperature (°C) | Average Temperature (°C) | Initial Calorific Value (MJ/m3) | Average Calorific Value (MJ/m3) | Maximum Calorific Value (MJ/m3) | Final Calorific Value (MJ/m3) |

|---|---|---|---|---|---|---|---|---|---|

| #1 | 1100 | 4 | 1050 | 878 | 2.17 | 4.3 | 8.1 | 7.4 | |

| #2 | 1150 | 5 | 956 | 815 | 0.95 | 2.1 | 5.5 | 2.1 | |

| #3 | 650 | 5 | 1194 | 938 | 4.4 | 4.8 | 14.2 | 9.7 | |

| #4 | 650 | 6 | 1182 | 1054 | 4.4 | 5.1 | 8.5 | 8.0 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kačur, J.; Laciak, M.; Durdán, M.; Flegner, P. Model-Free Control of UCG Based on Continual Optimization of Operating Variables: An Experimental Study. Energies 2021, 14, 4323. https://doi.org/10.3390/en14144323

Kačur J, Laciak M, Durdán M, Flegner P. Model-Free Control of UCG Based on Continual Optimization of Operating Variables: An Experimental Study. Energies. 2021; 14(14):4323. https://doi.org/10.3390/en14144323

Chicago/Turabian StyleKačur, Ján, Marek Laciak, Milan Durdán, and Patrik Flegner. 2021. "Model-Free Control of UCG Based on Continual Optimization of Operating Variables: An Experimental Study" Energies 14, no. 14: 4323. https://doi.org/10.3390/en14144323

APA StyleKačur, J., Laciak, M., Durdán, M., & Flegner, P. (2021). Model-Free Control of UCG Based on Continual Optimization of Operating Variables: An Experimental Study. Energies, 14(14), 4323. https://doi.org/10.3390/en14144323