The Potential of the Reed as a Regenerative Building Material—Characterisation of Its Durability, Physical, and Thermal Performances

Abstract

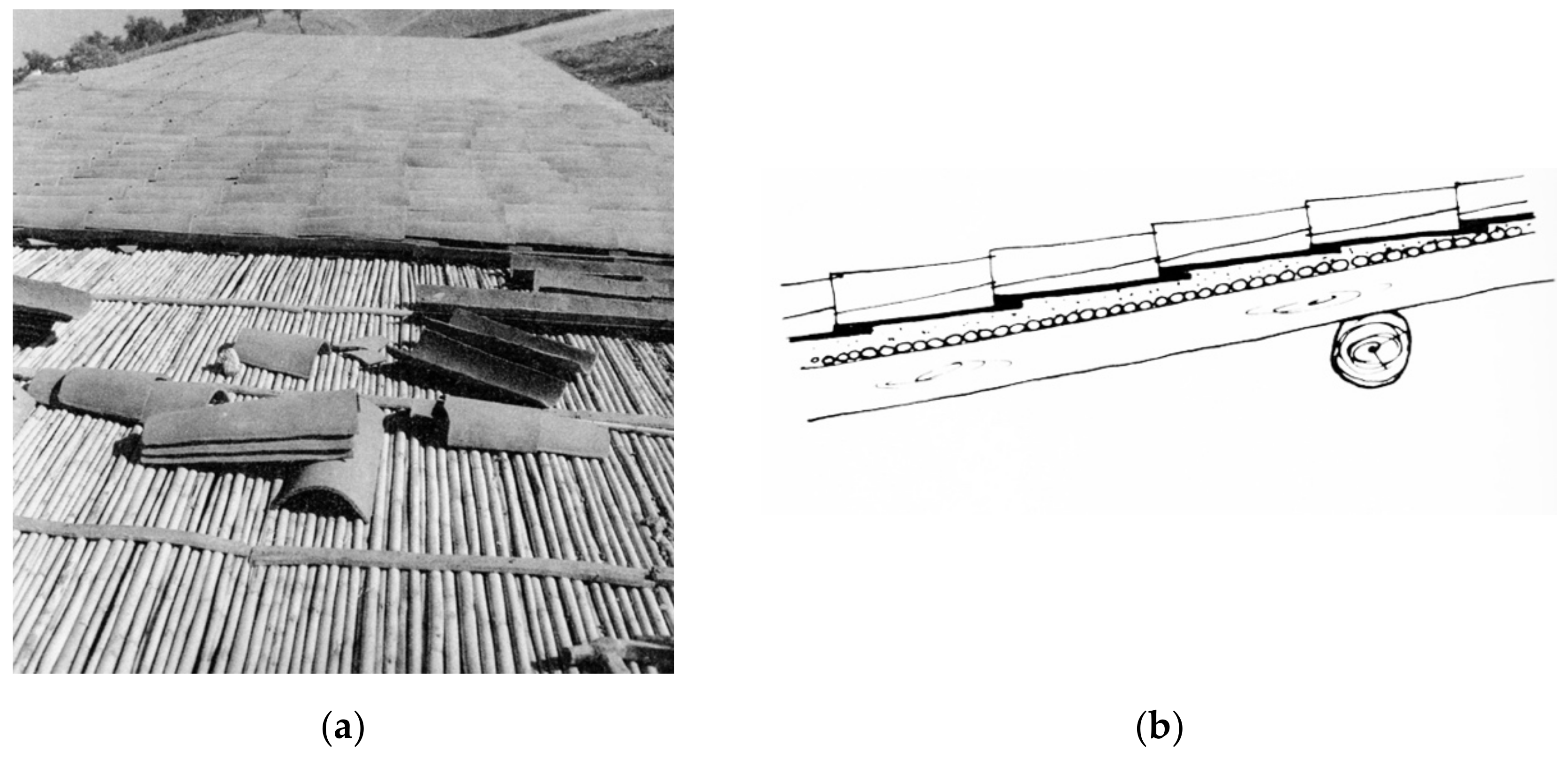

:1. Introduction

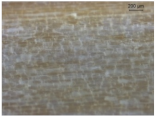

2. Materials and Methods

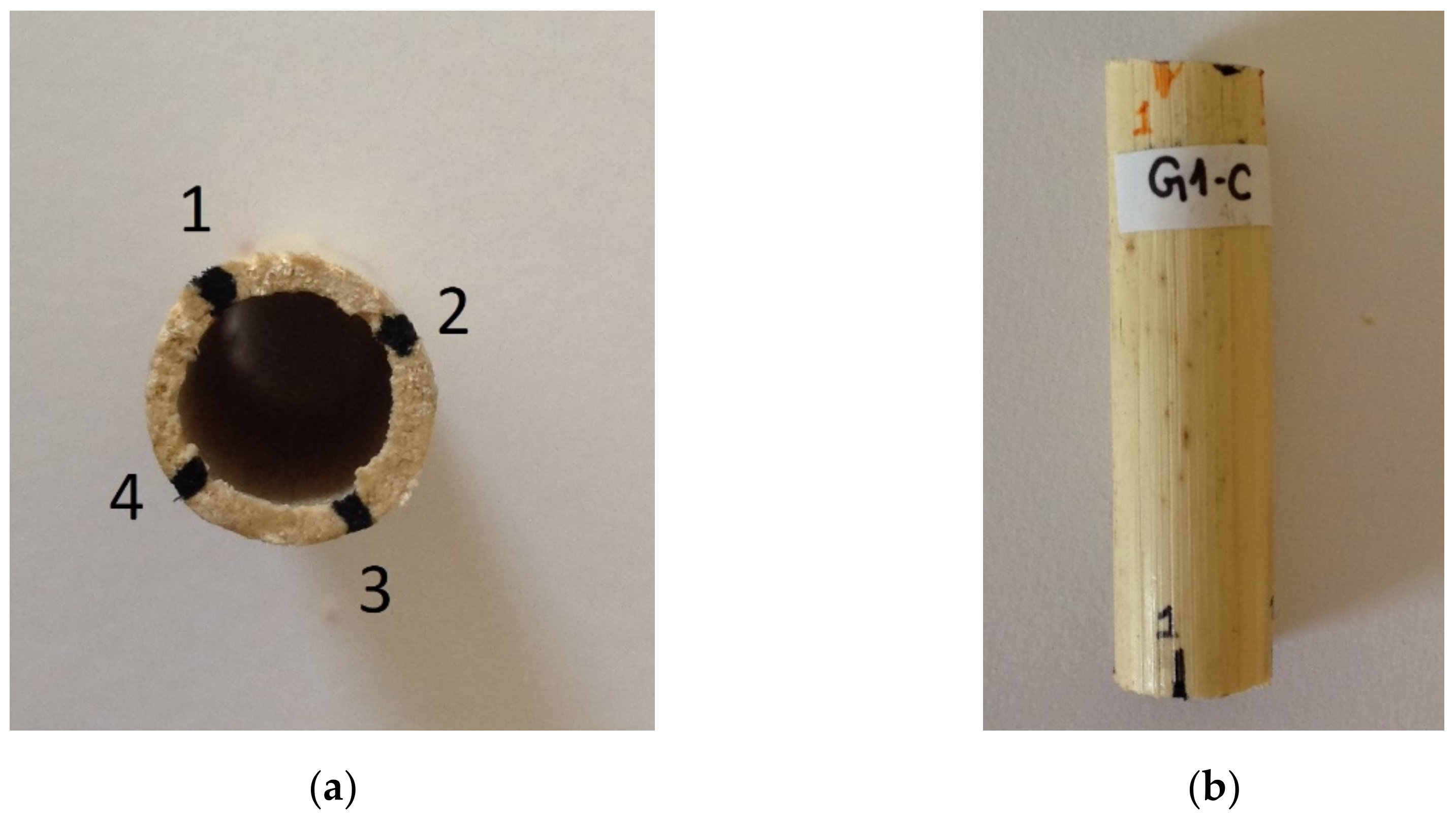

2.1. Specimens

2.2. Physical Properties

2.2.1. Moisture Content

2.2.2. Apparent Density

2.2.3. Dimensional Stability—Retraction

2.2.4. Capillary Water Absorption

2.3. Thermal Properties

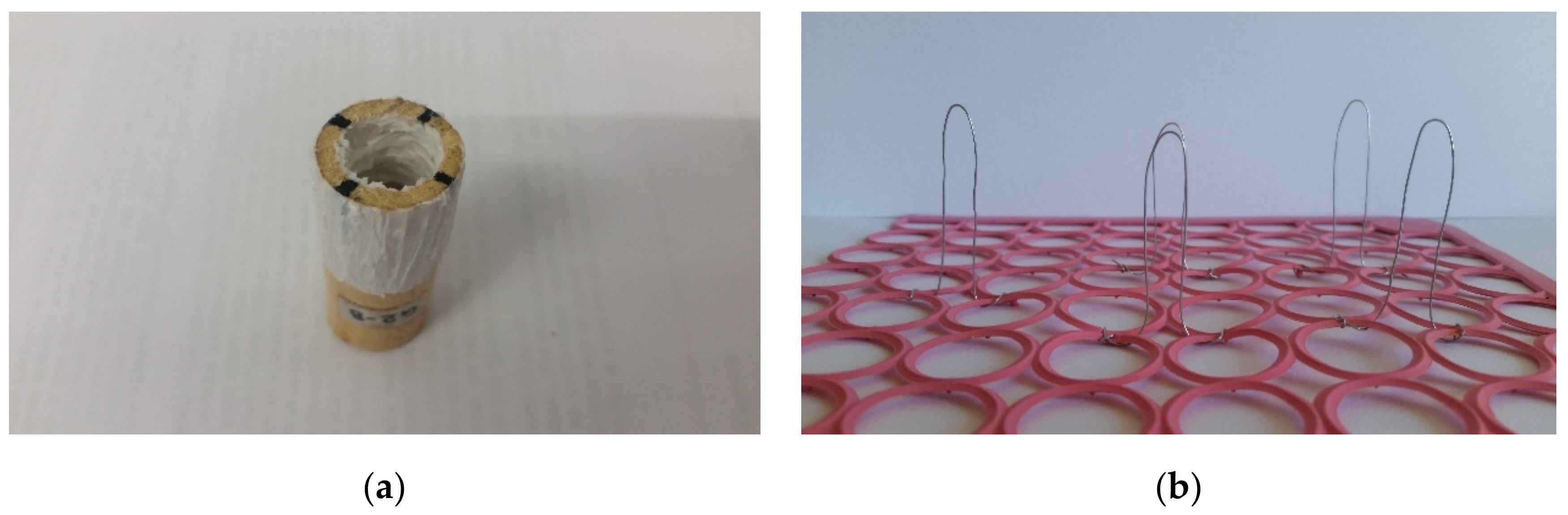

2.3.1. Reed Panels

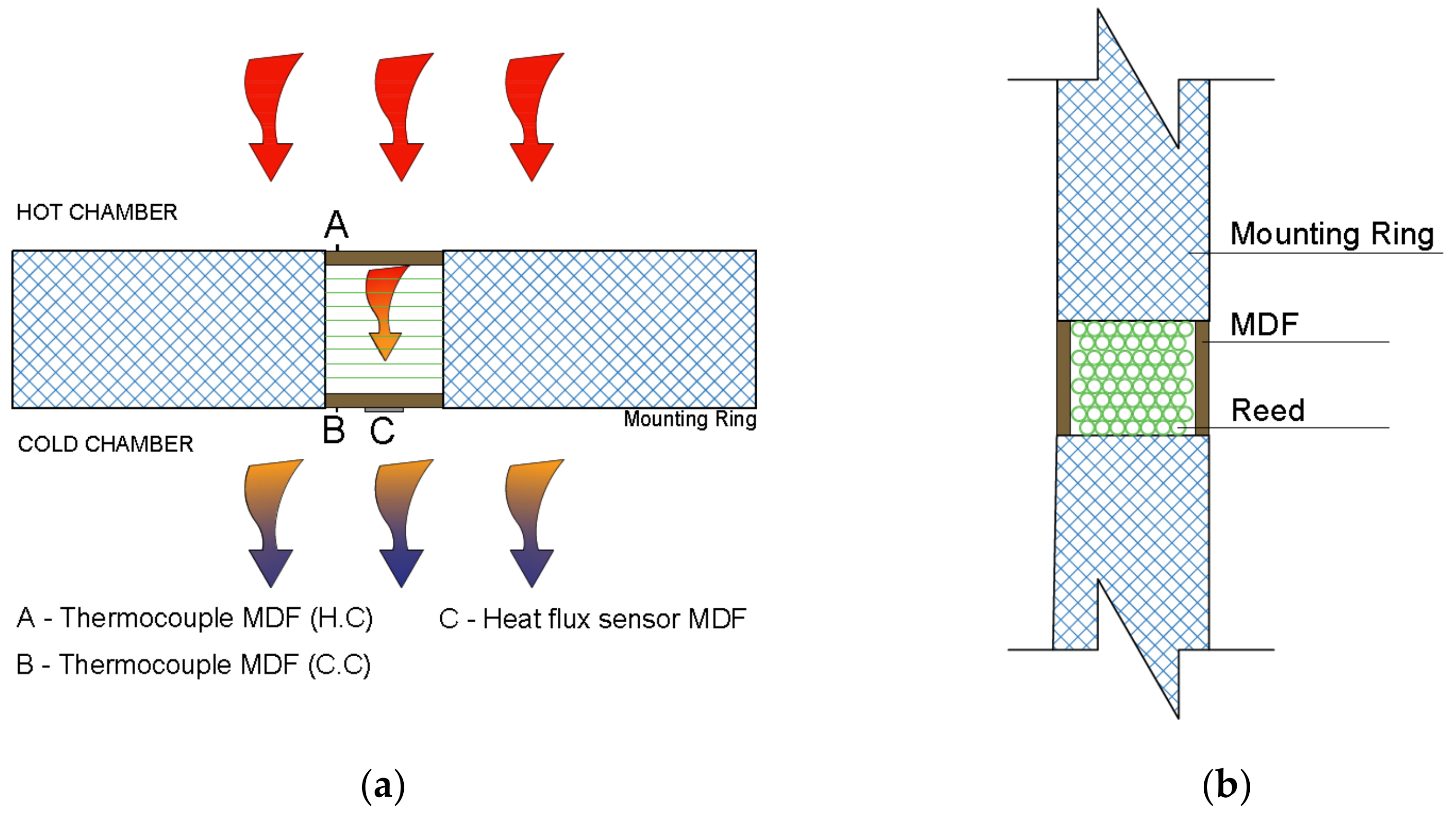

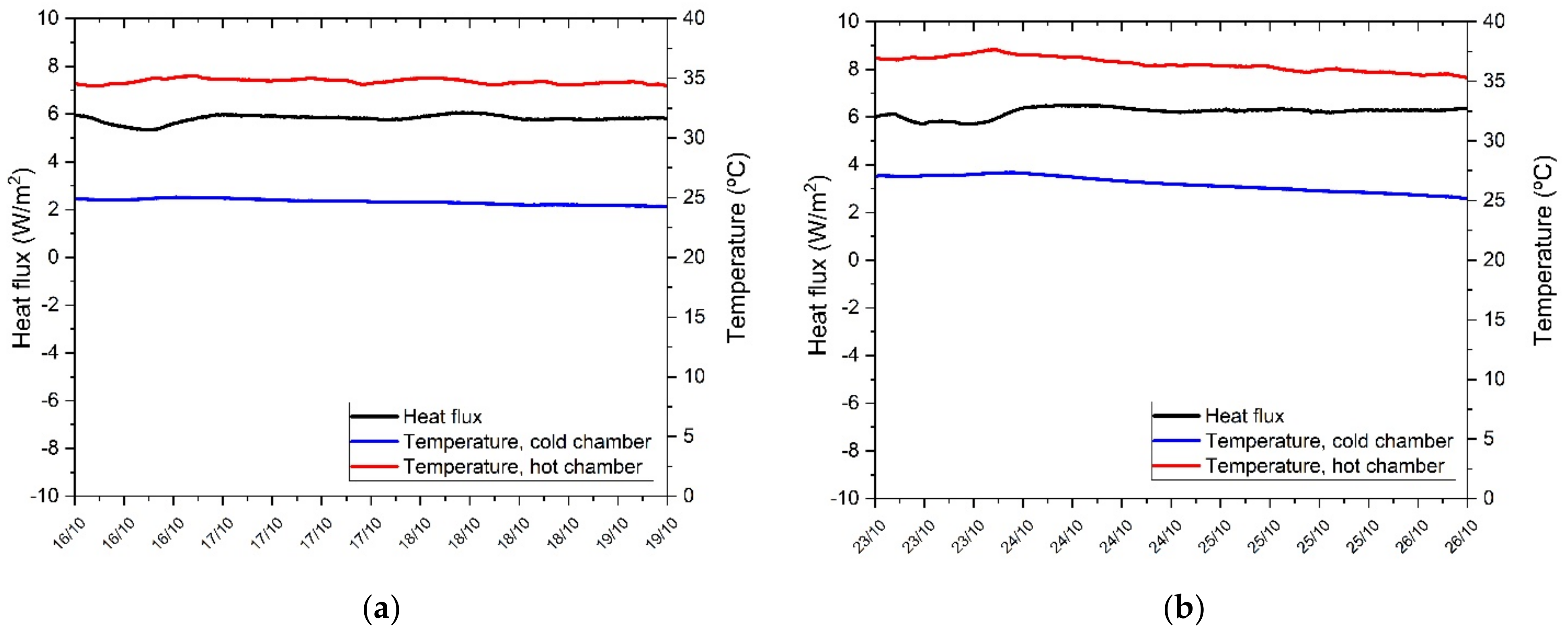

2.3.2. Hotbox Test

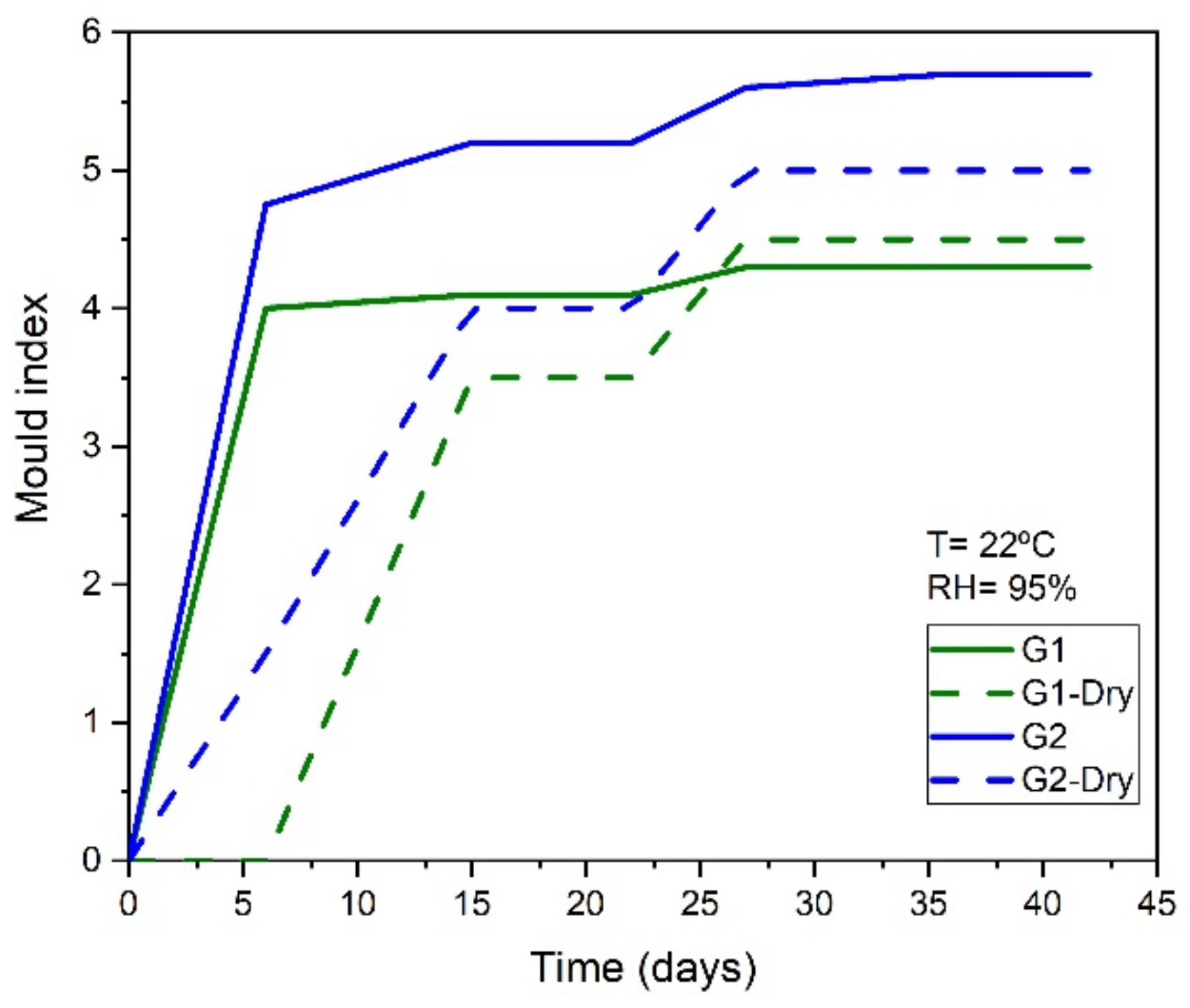

2.4. Durability—The Mould Development Test

3. Results and Discussion

3.1. Physical Properties

3.1.1. Moisture Content

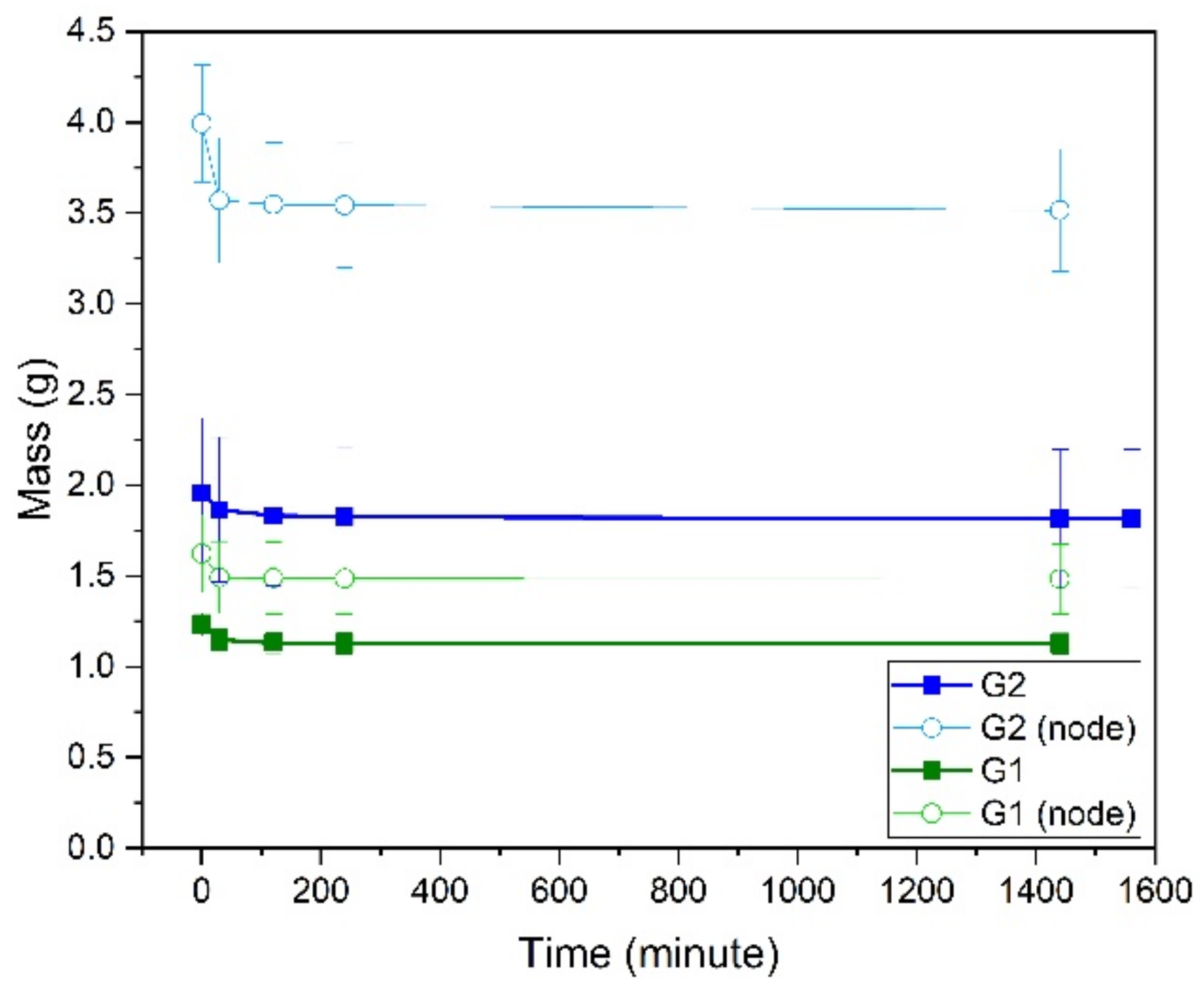

3.1.2. Apparent Density

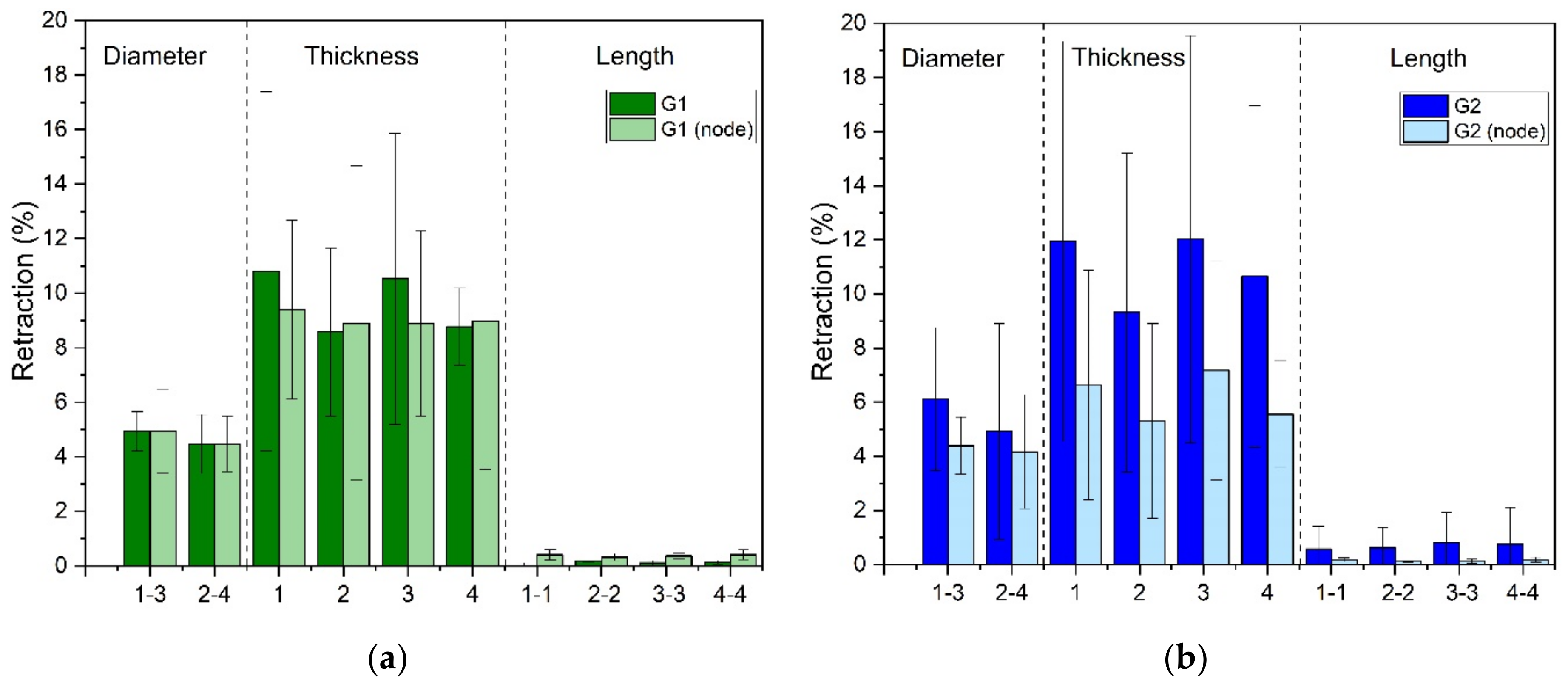

3.1.3. Dimensional Stability—Retraction

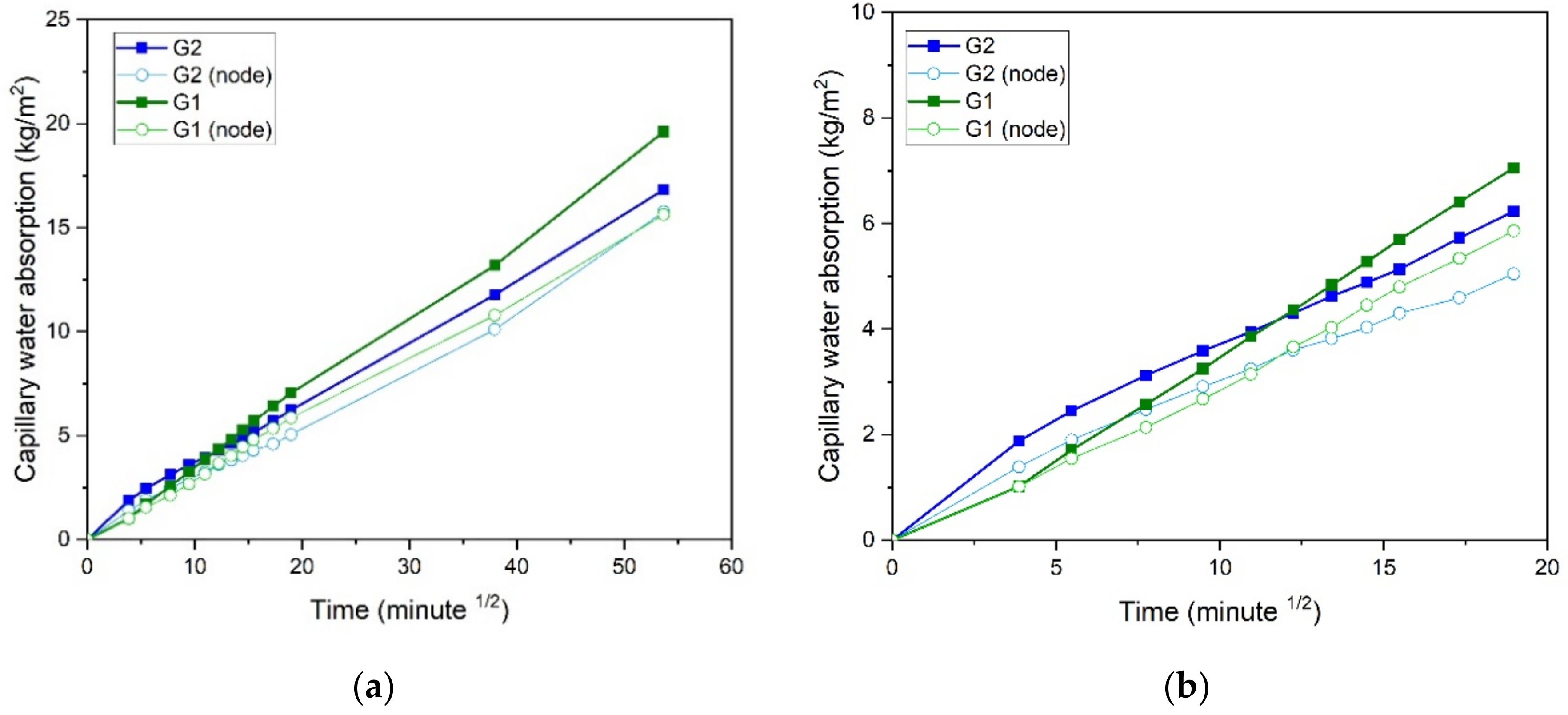

3.1.4. Capillary Water Absorption

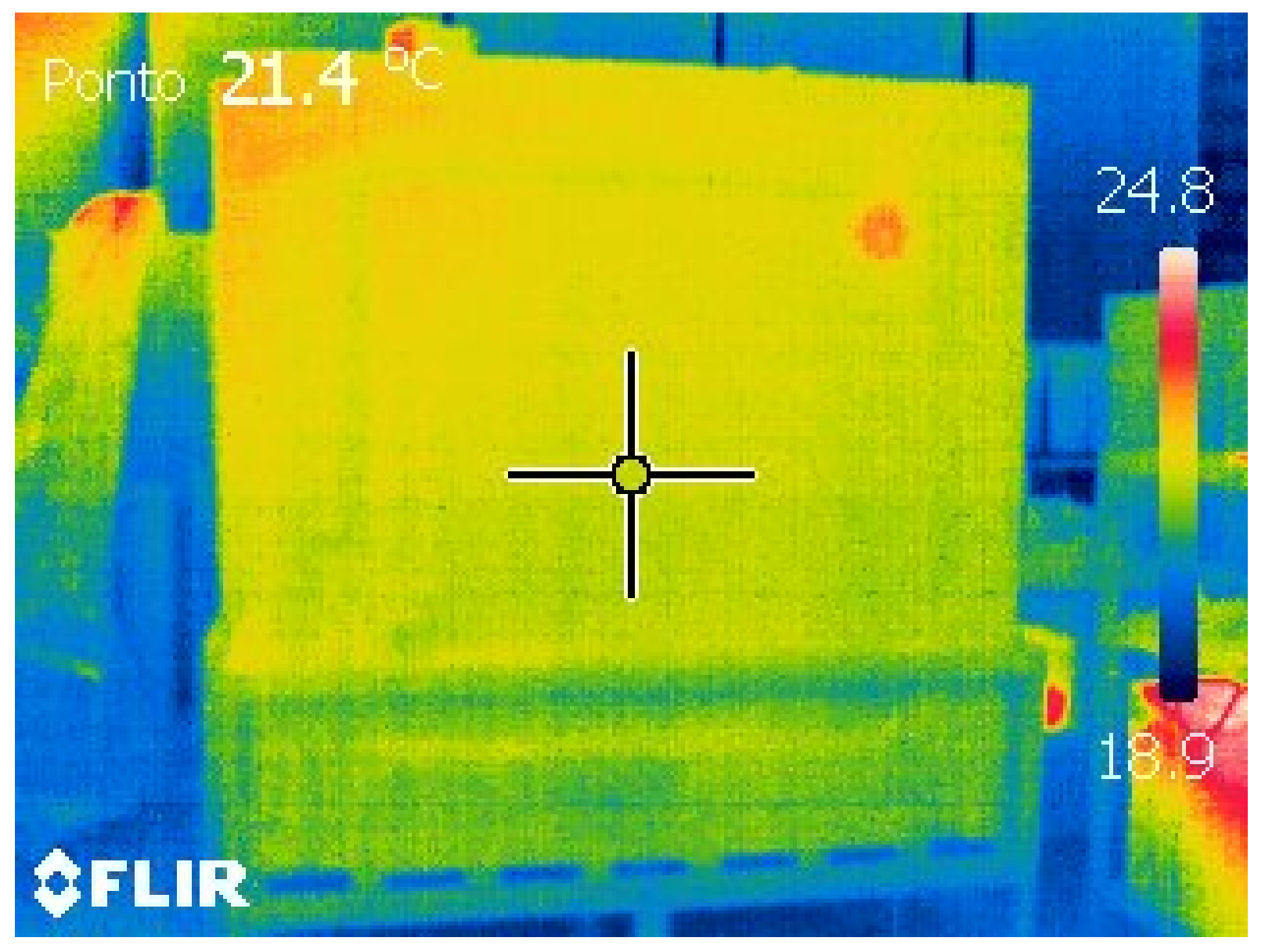

3.2. Thermal Properties

3.3. Durability—The Mould Growth Test

4. Conclusions

- (1)

- Based on the studied thermal parameters (thermal resistance, thermal transmittance, and thermal conductivity), it is possible to conclude that reed from Portugal, under the studied conditions, has an adequate thermal performance. Furthermore, its thermal resistance (1.8 m2·°C/W) and thermal conductivity (0.06 W/m·°C) were found to be in accordance with the requirements defined by Portuguese law for thermal insulation materials. The thermal resistance of reed is almost 60% of the insulation materials used in Portugal (e.g., rock wool, XPS, and cork). The geometric characteristics (diameter) and node presence were found to have no influence on the studied thermal properties.

- (2)

- The physical characteristics of reed from Portugal are compatible with its use as a construction material. The reed’s density and water content were found to be similar to the organic materials conventionally used in the construction sector. The reed has satisfactory dimensional stability, making it compatible with rigid connection accessories. However, attention should be paid to aspects such as retraction in its thickness. The hygroscopic nature of reed could be related to the high water absorption reached in the tests.

- (3)

- There is a trend for mould growth under favourable conditions (22 ± 2 °C and 90 ± 5% HR). Nevertheless, these specific temperature and humidity conditions are uncommon in Portuguese climatic conditions. Therefore, the durability of this material will not hinder its use as a building material.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Acknowledgments

Conflicts of Interest

References

- Allirand, J.-M.; Gosse, G. An above-ground biomass production model for a common reed (Phragmites communis Trin.) stand. Biomass Bioenergy 1995, 9, 441–448. [Google Scholar] [CrossRef]

- Köbbing, J.F.; Thevs, N.; Zerbe, S. The utilisation of reed (Phragmites australis): A review. Int. Mire Conserv. Group Int. Peat Soc. 2013, 13, 1–14. [Google Scholar]

- Barreca, F. Use of giant reed Arundo Donax L. in rural constructions. Agric. Eng. Int. CIGR J. 2012, 14, 46–52. [Google Scholar]

- Zámolyi, F.; Herbig, U. Reed as building material-renaissance of vernacular techniques. In International Symposium on Advanced Methods of Monitoring Reed Habitats; Csaplovics, E., Schmidt, J., Eds.; Rhombos Verlag Berlin: Berlin, Germany, 2011; p. 83. [Google Scholar]

- Speck, O.; Spatz, H.-C. Damped oscillations of the giant reed Arundo donax (Poaceae). Am. J. Bot. 2004, 91, 789–796. [Google Scholar] [CrossRef]

- Barreca, F.; Martinez, A.; Flores, J.A.; Pastor, J.J. Innovative use of giant reed and cork residues for panels of buildings in Mediterranean area. Resour. Conserv. Recycl. 2019, 140, 259–266. [Google Scholar] [CrossRef]

- Arundo donax Flora-On. Available online: https://flora-on.pt/#/1Arundo+donax (accessed on 11 March 2021).

- AAVV. Arquitectura Popular em Portugal; Associação dos Arquitetos Portugueses: Lisboa, Portugal, 1988. [Google Scholar]

- Mestre, V. Arquitetura Popular da Madeira; Argumentum: Lisboa, Portugal, 2002. [Google Scholar]

- Fernandes, J.; Malheiro, R.; Castro, M.D.F.; Gervásio, H.; Silva, S.M.; Mateus, R. Thermal Performance and Comfort Condition Analysis in a Vernacular Building with a Glazed Balcony. Energies 2020, 13, 624. [Google Scholar] [CrossRef] [Green Version]

- Fernandes, J. O Contributo da Arquitectura Vernacular Portuguesa para a Sustentabilidade dos Edifícios. Ph.D. Thesis, University of Minho, Guimarães, Portugal, 2012. [Google Scholar]

- Cravinho, A. Pedra & Cal n.24; Rua Pedro Nunes: Lisboa, Portugal, 2004; pp. 12–13. [Google Scholar]

- Fernandes, J.; Mateus, R.; Gervásio, H.; Silva, S.; Branco, J.; Almeida, M. Thermal Performance and Comfort Conditions Analysis of a Vernacular Palafitic Timber Building in Portuguese Coastline Context. Sustainability 2020, 12, 10484. [Google Scholar] [CrossRef]

- Ferreira, D.M.; Araújo, A.; Fonseca, E.M.; Piloto, P.; Pinto, J. Behaviour of non-loadbearing tabique wall subjected to fire—Experimental and numerical analysis. J. Build. Eng. 2017, 9, 164–176. [Google Scholar] [CrossRef] [Green Version]

- Sá, A.B.; Pereira, S.; Soares, N.; Pinto, J.; Lanzinha, J.C.; Paiva, A.; Cunha, S.P.D.S. An approach on the thermal behaviour assessment of tabique walls coated with schist tiles: Experimental analysis. Energy Build. 2016, 117, 11–19. [Google Scholar] [CrossRef]

- Fonseca, I.F.P. Permanência e Transformação: Contributos para a Utilização de Materiais Modernos na Conservação do Património Arquitetónico. Os Produtos Técnicos de Madeira; University of Évora: Évora, Portugal, 2014. [Google Scholar]

- Barroso, C.E.; Oliveira, D.V.; Ramos, L.F. Physical and mechanical characterization of vernacular dry stone heritage materials: Schist and granite from Northwest Portugal. Constr. Build. Mater. 2020, 259, 119705. [Google Scholar] [CrossRef]

- Ribeiro, V. (Ed.) Materiais, Sistemas e Técnicas de Construção Tradicional-Contributo para o Estudo d Arquitetura Vernácula da Região Oriental da Serra do Caldeirão; Edições Afrontamento e CCDR Algarve: Faro, Portugal, 2008. [Google Scholar]

- Arundo donax vs. Phragmites australis. Available online: http://desertfishes.org/cuatroc/organisms/arundo-vs-phragmites.html (accessed on 24 March 2021).

- Speck, O.; Spatz, H.-C. Mechanical Properties of the Rhizome of Arundo donax L. Plant Biol. 2003, 5, 661–669. [Google Scholar] [CrossRef]

- Miljan, M.; Miljan, M.-J.; Miljan, J.; Akermann, K.; Karja, K. Thermal transmittance of reed-insulated walls in a purpose-built test house. Mires Peat 2014, 13, 1–12. [Google Scholar]

- Asdrubali, F.; Bianchi, F.; Cotana, F.; D’Alessandro, F.; Pertosa, M.; Pisello, A.L.; Schiavoni, S. Experimental thermo-acoustic characterization of innovative common reed bio-based panels for building envelope. Build. Environ. 2016, 102, 217–229. [Google Scholar] [CrossRef]

- Barreca, F.; Fichera, C.R. Wall panels of Arundo donax L. for environmentally sustainable agriculture buildings: Thermal performance evaluation. J. Food Agric. Environ. 2013, 11, 1353–1357. [Google Scholar]

- Asdrubali, F.; D’Alessandro, F.; Schiavoni, S. A review of unconventional sustainable building insulation materials. Sustain. Mater. Technol. 2015, 4, 1–17. [Google Scholar] [CrossRef]

- Carneiro, P.; Jerónimo, A.; Faria, P. Reed-Cob: Tecnologia Inovadora de Baixo Carbono para Construção de Pequeno Porte. In II Encontro Nacional Sobre Reabilitação Urbana e Sustentabilidade; iiSBE Portugal & Universidade do Minho: Lisboa, Portugal, 2017. [Google Scholar]

- Molari, L.; Coppolino, F.S.; García, J.J. Arundo donax: A widespread plant with great potential as sustainable structural material. Constr. Build. Mater. 2021, 268, 121143. [Google Scholar] [CrossRef]

- Conte, P.; Fiore, V.; Valenza, A. Structural and Mechanical Modification Induced by Water Content in Giant Wild Reed (A. donax L.). ACS Omega 2018, 3, 18510–18517. [Google Scholar] [CrossRef] [Green Version]

- Soliman, M. Arundo donax L. and Its Use in the Thermal Insulation in Architecture to Decrease the Environmntal Pollution; Ain Shams University: Cairo, Egypt, 2009. [Google Scholar]

- García-Ortuño, T. Caracterización de la Caña Común (Arundo donax L.) para su Uso Como Material de Construcción; Universidad Miguel Hernández: Alicante, Spain, 2003. [Google Scholar]

- Volf, M.; Diviš, J.; Havlík, F. Thermal, Moisture and Biological Behaviour of Natural Insulating Materials. Energy Procedia 2015, 78, 1599–1604. [Google Scholar] [CrossRef] [Green Version]

- IPQ NP-614. Wood-Determination of Water Content (in Portuguese); IPQ NP-614: Lisboa, Portugal, 1973; p. 2. [Google Scholar]

- IPQ NP-616. Wood-Determination of Density (in Portuguese); IPQ NP-616: Lisboa, Portugal, 1973; p. 2. [Google Scholar]

- IPQ NP-615. Wood-Determination of Retraction (in Portuguese); IPQ NP-615: Lissboa, Portugal, 1973. [Google Scholar]

- Teixeira, E.R.; Machado, G.; De Adilson, P.; Guarnier, C.; Fernandes, J.; Silva, S.M.; Mateus, R. Mechanical and thermal performance characterisation of compressed earth blocks. Energies 2020, 13, 2978. [Google Scholar] [CrossRef]

- ASTM International. ASTM C1363—11 Standard Test Method for Thermal Performance of Building Materials and Envelope Assemblies by Means of a Hot Box Apparatus 1. Am. Soc. Test. Mater. 2014, 90, 1–44. [Google Scholar]

- ISO-9869. Thermal Insulation-Building Elements-In-Situ Measurement Thermal Resistance and Thermal Transmittance; International Organization for Standardization: Geneva, Switzerland, 1994; Volume 994, p. 24. [Google Scholar]

- Lautkankare, R. The mold test. In Guidebook of Reed Business; Ülo, K., Ed.; Tallinn University of Technology: Tallinn, Estonia, 2013; pp. 42–45. ISBN 978-9949-484-91-1. [Google Scholar]

- Bergholm, J. Susceptibility to Microbial Growth of Common Reed and Other Construction Materials; Turku University of Applied Sciences: Turku, Finland, 2012. [Google Scholar]

- Hukka, A.; Viitanen, H.A. A mathematical model of mould growth on wooden material. Wood Sci. Technol. 1999, 33, 475–485. [Google Scholar] [CrossRef]

- Liese, W. The Anatomy of Bamboo Culms; International Network for Bamboo and Rattan: Beijing, China, 1998; ISBN 8186247262. [Google Scholar]

- Couvreur, L.; Alejandro Buzo, R. Construir con Caña-Estudio del uso de la Caña en la Arquitectura Tradicional y de su Recuperación para la Construcción Contemporánea; Catálogo de publicaciones del Ministerio: Madrid, Spain, 2019. Available online: www.culturaydeporte.gob.es (accessed on 13 June 2021).

- Dias, J.R. Caracterization of the Stone Pine Timber (in Portuguese); University of Coimbra: Coimbra, Portugal, 2019. [Google Scholar]

- Freitas, M.P. Análise Prática das Propriedades Físicas e Mecânicas do Bambu Phyllostachys edulis, Cultivado em Portugal; University of Minho: Guimarães, Portugal, 2019. [Google Scholar]

- Rusch, F.; Éverton, H.; Ceolin, G.B. Anatomia de hastes adultas de bambu: Uma revisão. Pesqui. Florest. Bras. 2018, 38, 38. [Google Scholar] [CrossRef]

| ID | Quantity of Reed Stems | Reed Stems with Nodes (%) | Quantity of Nodes | Average Diameter (mm) | SD 1 | Average Thickness (mm) | SD | Steel Wire Mass (g) | Panel Mass: Reed and Wire (g) | Density (kg/m3) |

|---|---|---|---|---|---|---|---|---|---|---|

| Type 1 | 84 | 92.31% | 103 | 13.25 | 0.93 | 1.70 | 0.29 | 19.50 | 489.70 | 208.98 |

| Type 2 | 56 | 100% | 65 | 16.83 | 1.57 | 2.29 | 0.52 | 19.50 | 479.34 | 204.37 |

| Mould Index | Coverage | Description of Classification |

|---|---|---|

| 0 | 0 | No growth |

| 1 | 0 | Some growth detected only with microscopy |

| 2 | >10% | Moderated growth detected with microscopy |

| 3 | 0–10% | Some growth detected visually |

| 4 | 10–50% | Visually detected |

| 5 | 50–80% | Visually detected |

| 6 | 80–100% | Visually detected |

| Identification | Moisture Content (%) | SD 1 |

|---|---|---|

| G1 | 9.463 | 0.195 |

| G1—node | 9.432 | 0.056 |

| G2 | 9.495 | 0.242 |

| G2—node | 10.28 | 0.150 |

| Panel | Superficial Temperature (°C) | Heat Flux (W/m2) | Reset (m2·°C/W) | ReMDF (m2·°C/W) | Rereed (m2·°C/W) | λreed (W/m·°C) | |

|---|---|---|---|---|---|---|---|

| Hot Chamber | Cold Chamber | ||||||

| Type 1 | 34.66 | 24.66 | 5.61 | 1.834 | 0.147 | 1.540 | 0.064 |

| Type 2 | 36.37 | 26.37 | 5.88 | 1.886 | 0.147 | 1.592 | 0.063 |

| Test Period | Mould Index | Bare Eyes | Microscope (10×) |

|---|---|---|---|

|  | ||

| 14 days | 3.5 |  |  |

| 28 days | 4.5 |  |  |

| 42 days | 4.5 |  |  |

| Test Period | Mould Index | Bare Eyes | Microscope (10×) |

|---|---|---|---|

| 0 day | 0 |  |  |

| 14 days | 5 |  |  |

| 28 days | 5.5 |  |  |

| 42 days | 6 |  |  |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Malheiro, R.; Ansolin, A.; Guarnier, C.; Fernandes, J.; Amorim, M.T.; Silva, S.M.; Mateus, R. The Potential of the Reed as a Regenerative Building Material—Characterisation of Its Durability, Physical, and Thermal Performances. Energies 2021, 14, 4276. https://doi.org/10.3390/en14144276

Malheiro R, Ansolin A, Guarnier C, Fernandes J, Amorim MT, Silva SM, Mateus R. The Potential of the Reed as a Regenerative Building Material—Characterisation of Its Durability, Physical, and Thermal Performances. Energies. 2021; 14(14):4276. https://doi.org/10.3390/en14144276

Chicago/Turabian StyleMalheiro, Raphaele, Adriana Ansolin, Christiane Guarnier, Jorge Fernandes, Maria Teresa Amorim, Sandra Monteiro Silva, and Ricardo Mateus. 2021. "The Potential of the Reed as a Regenerative Building Material—Characterisation of Its Durability, Physical, and Thermal Performances" Energies 14, no. 14: 4276. https://doi.org/10.3390/en14144276

APA StyleMalheiro, R., Ansolin, A., Guarnier, C., Fernandes, J., Amorim, M. T., Silva, S. M., & Mateus, R. (2021). The Potential of the Reed as a Regenerative Building Material—Characterisation of Its Durability, Physical, and Thermal Performances. Energies, 14(14), 4276. https://doi.org/10.3390/en14144276