Energy and Exergy (2E) Analysis of an Optimized Solar Field of Linear Fresnel Reflectors for a Conceptual Direct Steam Generation Power Plant

Abstract

:1. Introduction

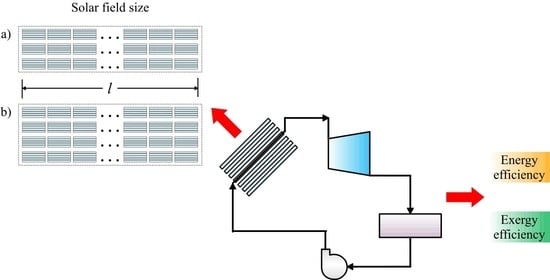

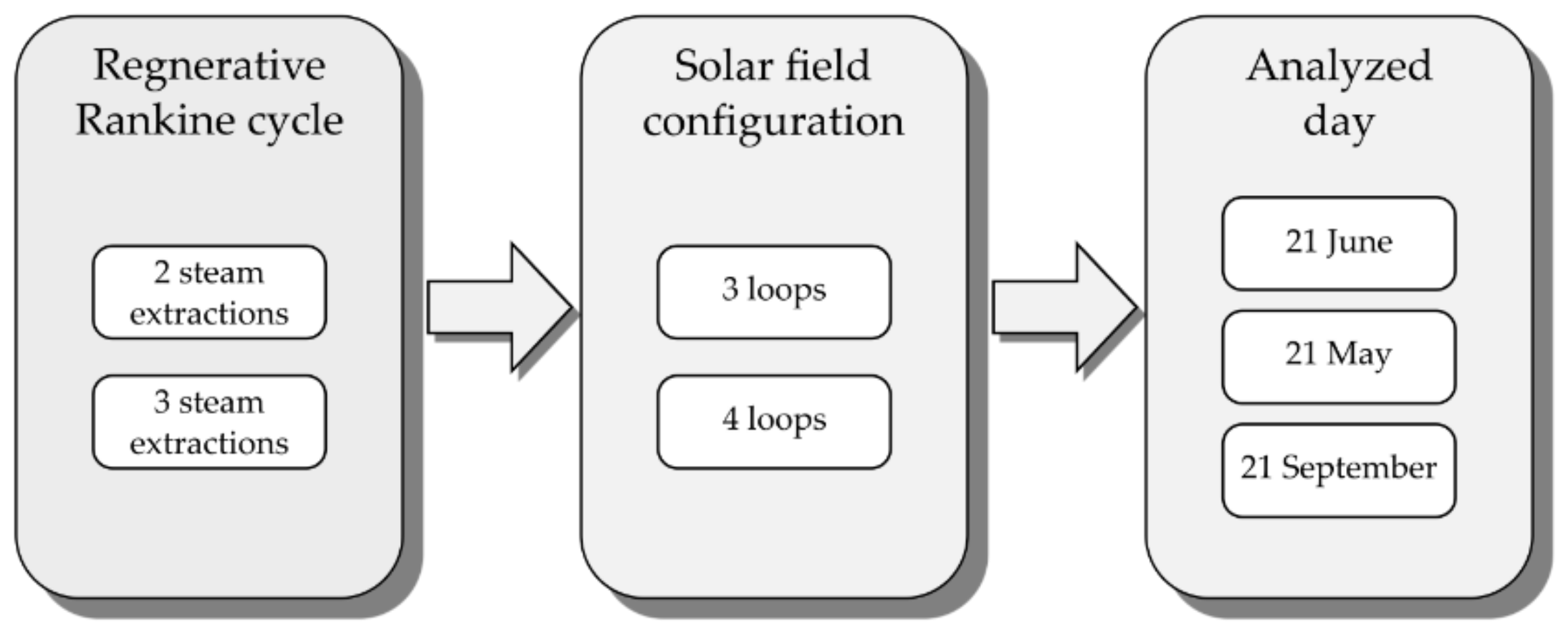

2. Characterization of Thermodynamic Cycles

2.1. Operating Parameters of the Regenerative Rankine Cycle

2.2. Analyzed Cycles

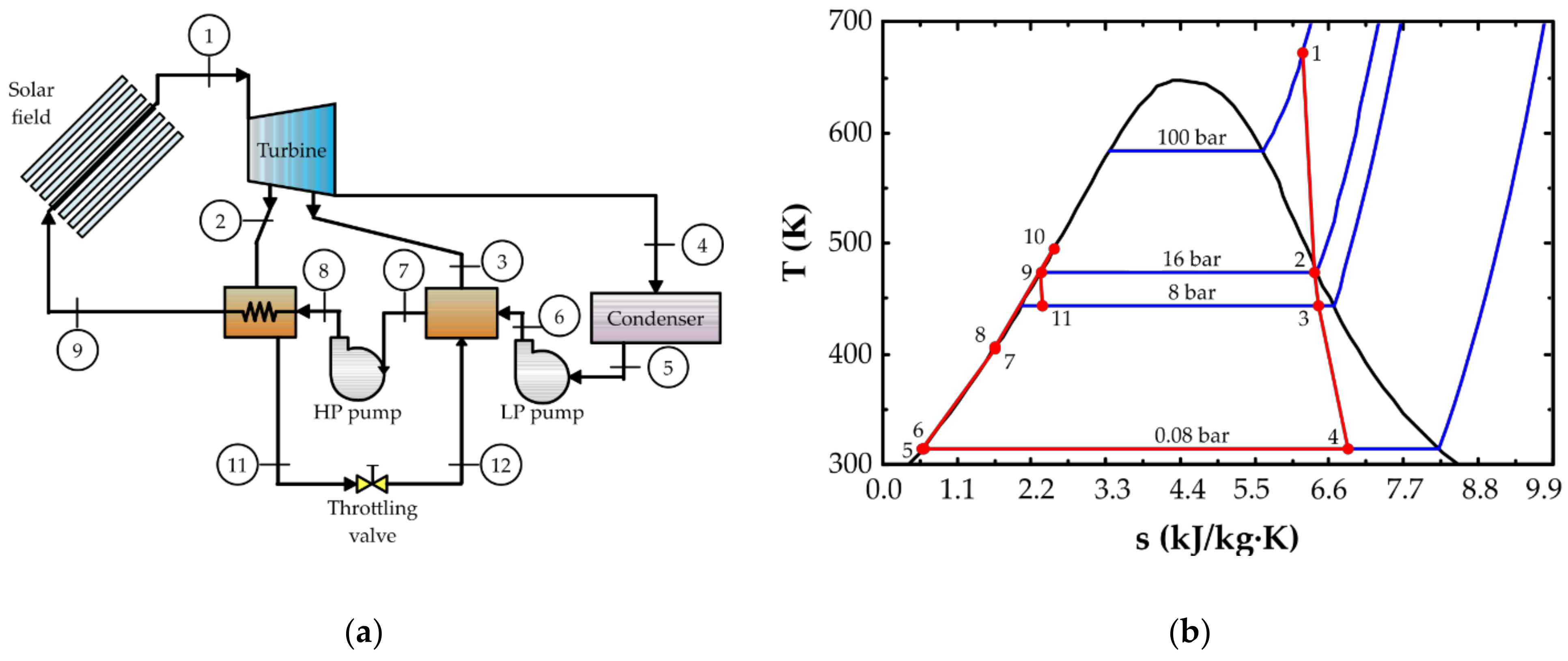

2.2.1. Regenerative Cycle with two Steam Extractions

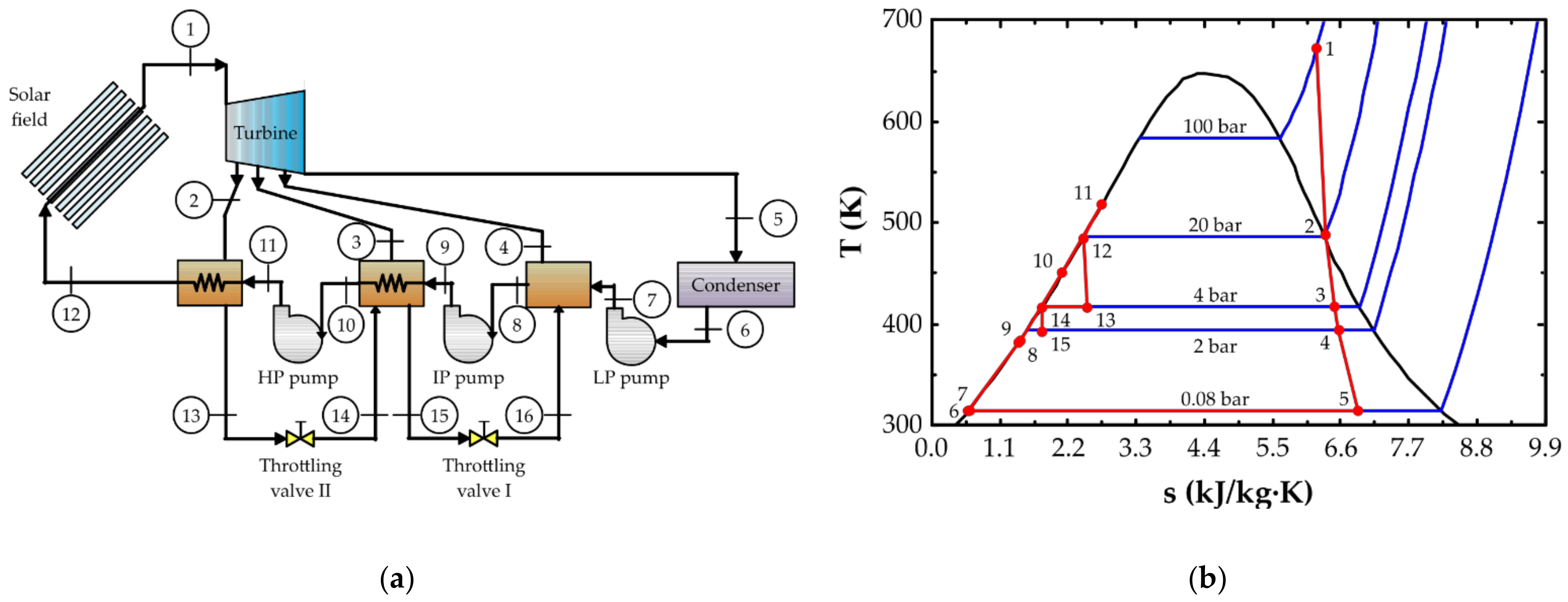

2.2.2. Regenerative Cycle with Three Steam Extractions

3. Solar Field: Linear Fresnel Reflector

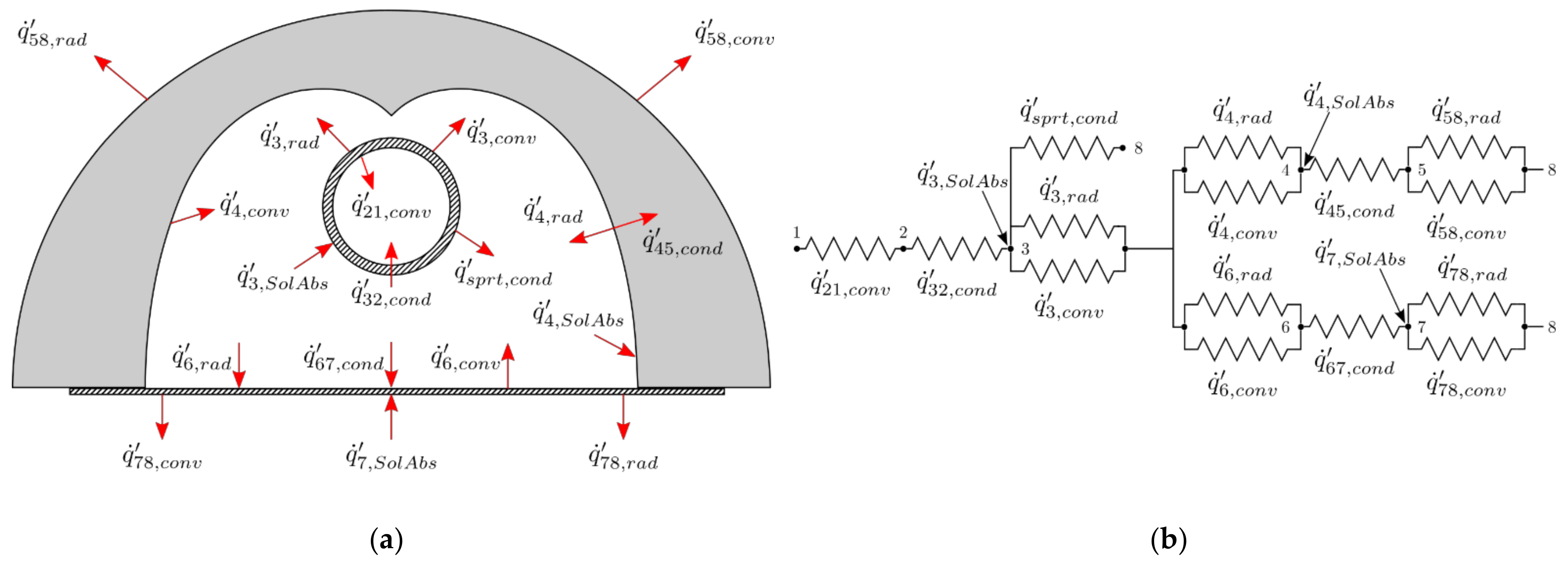

4. Thermo-Hydraulic Model Description and Validation

4.1. Solar Absorption

4.2. Convective Heat Fluxes

4.3. Radiation Heat Fluxex

4.4. Conduction Heat Fluxes

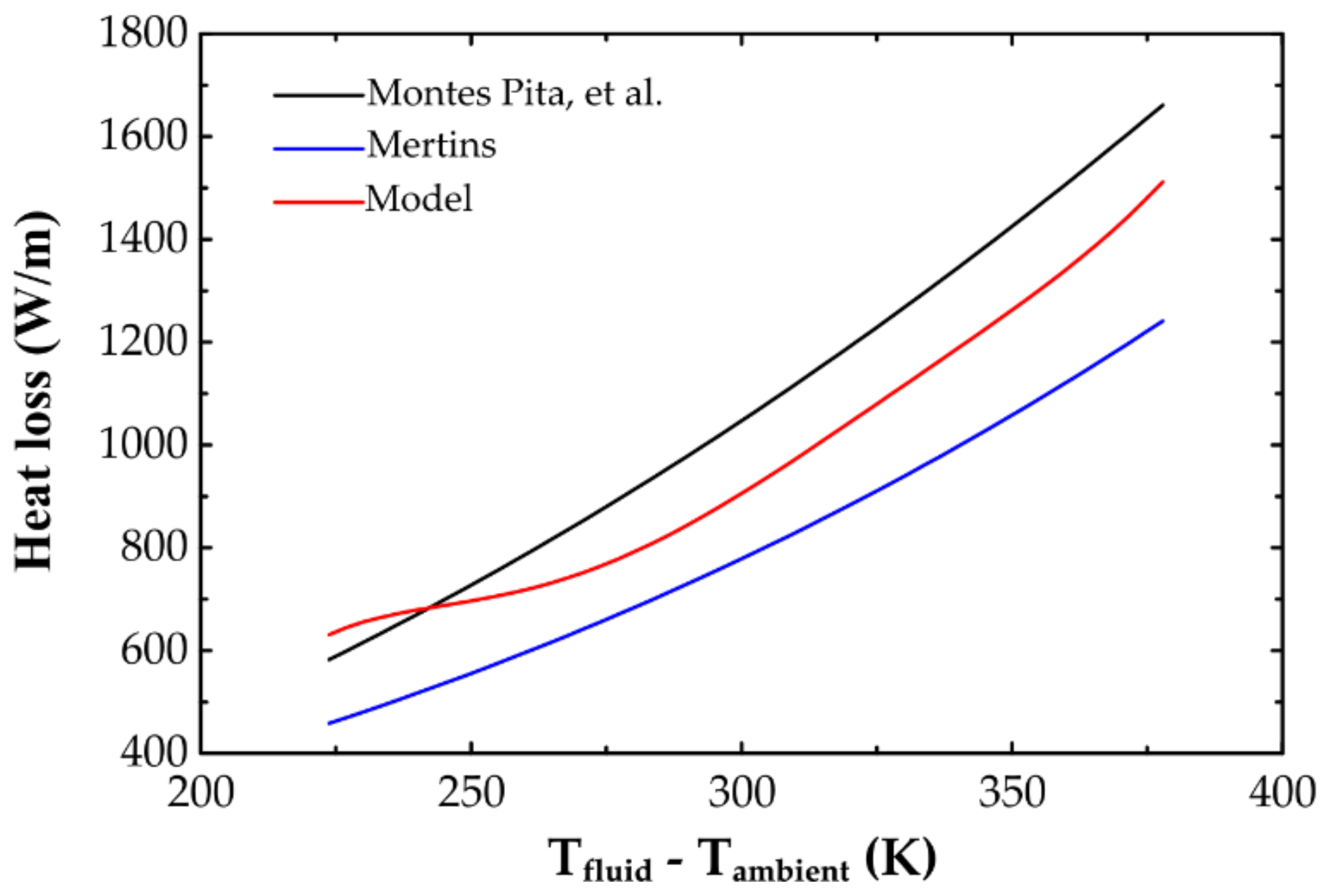

4.5. Thermal Model Validation

- Group 1: four solar absorption equations (, , , ).

- Group 2: four conduction equations (, , , ).

- Group 3: six convection equations (, , , , , ).

- Group 4: five radiation equations (, , , , ).

- Group 5: three radiosity equations.

- Group 6: seven balances (one per node).

- Group 7: fluid balance to calculate the enthalpy increase of the fluid.

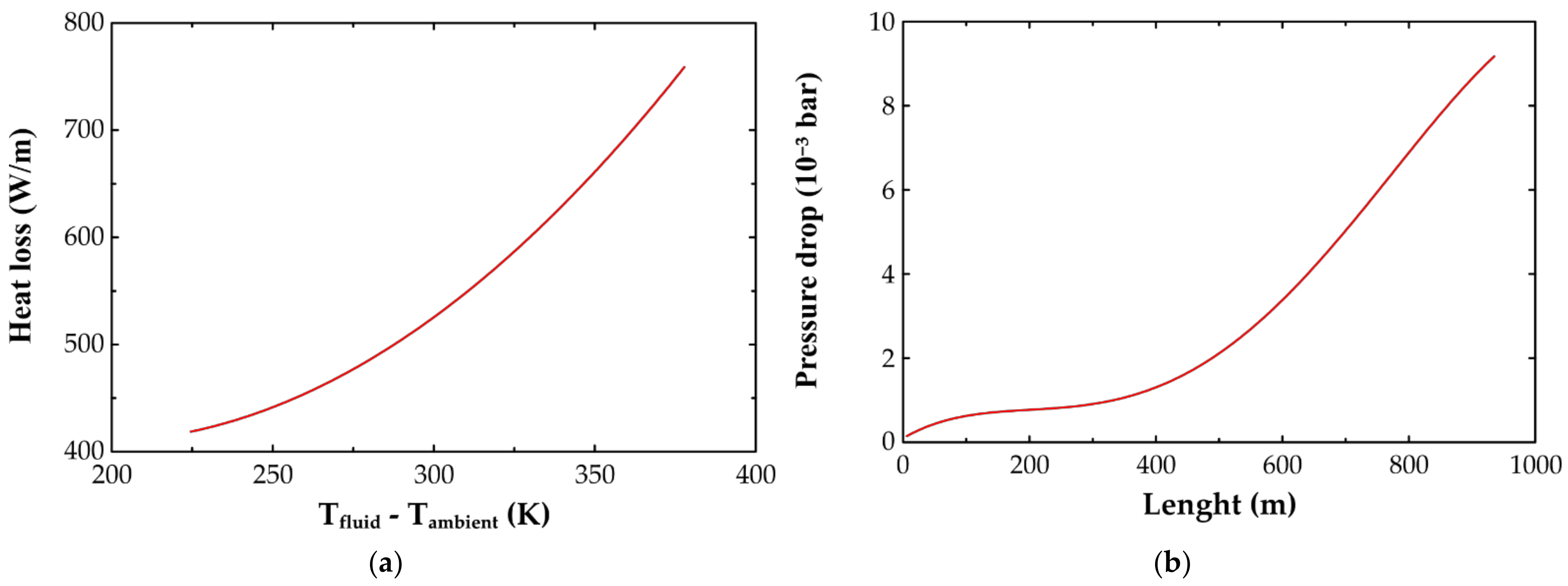

5. Thermo-Hydraulic Performance and Characterization of the System

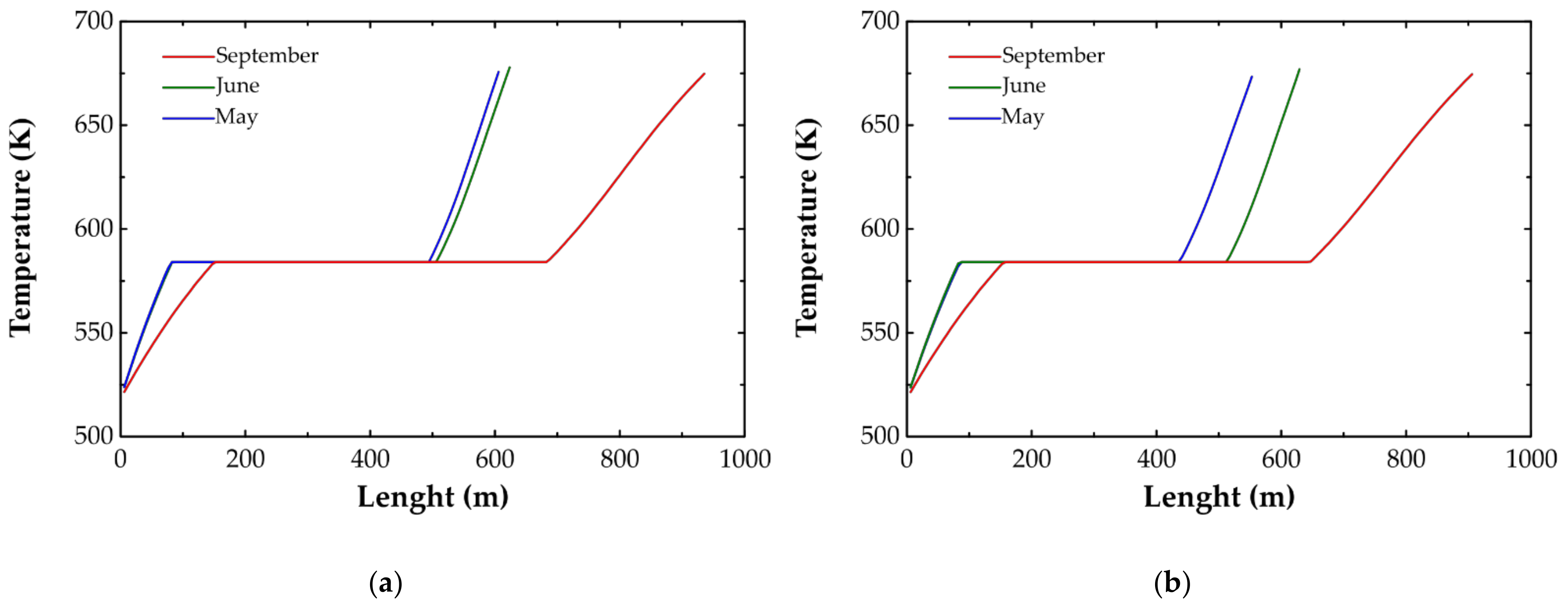

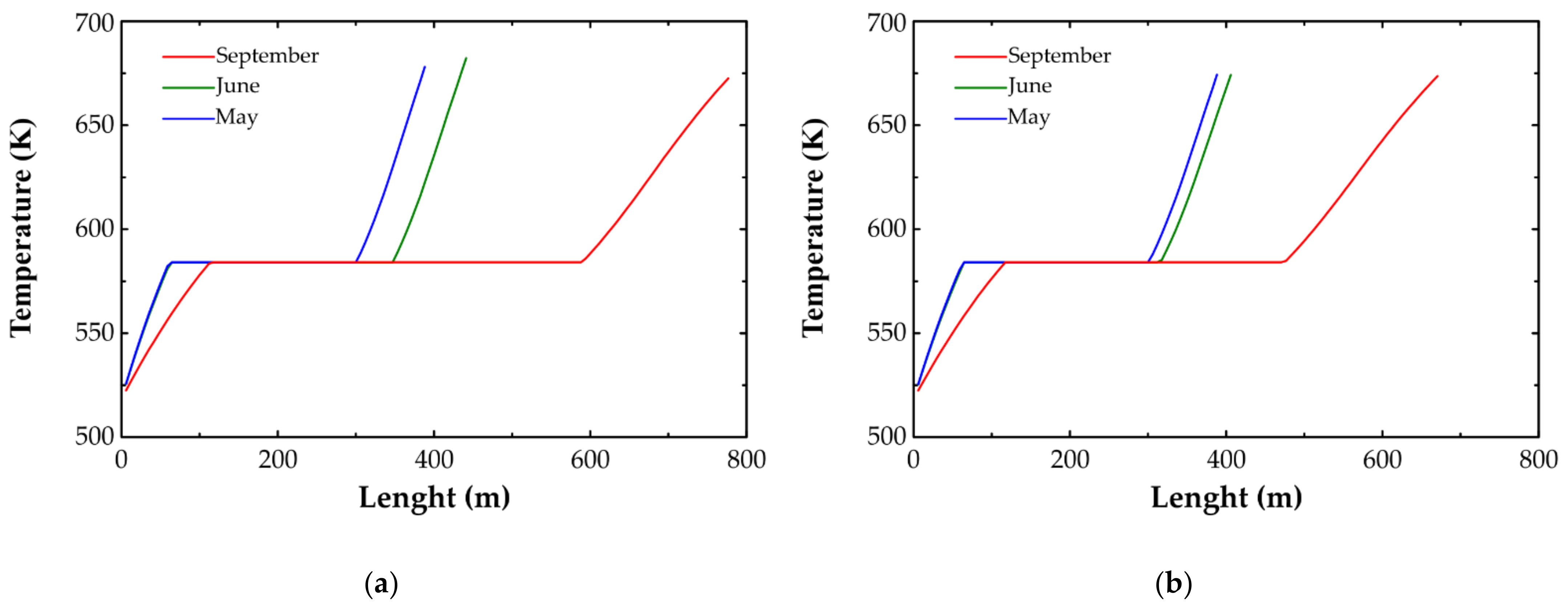

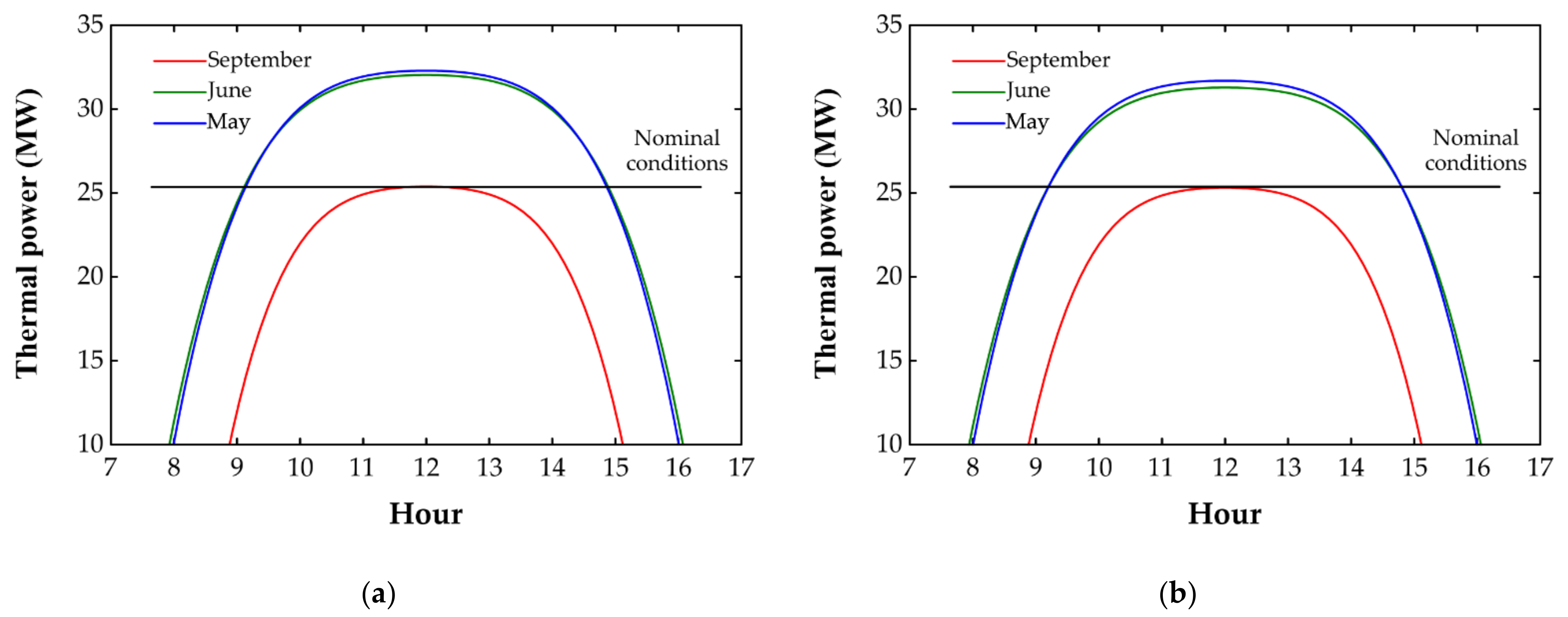

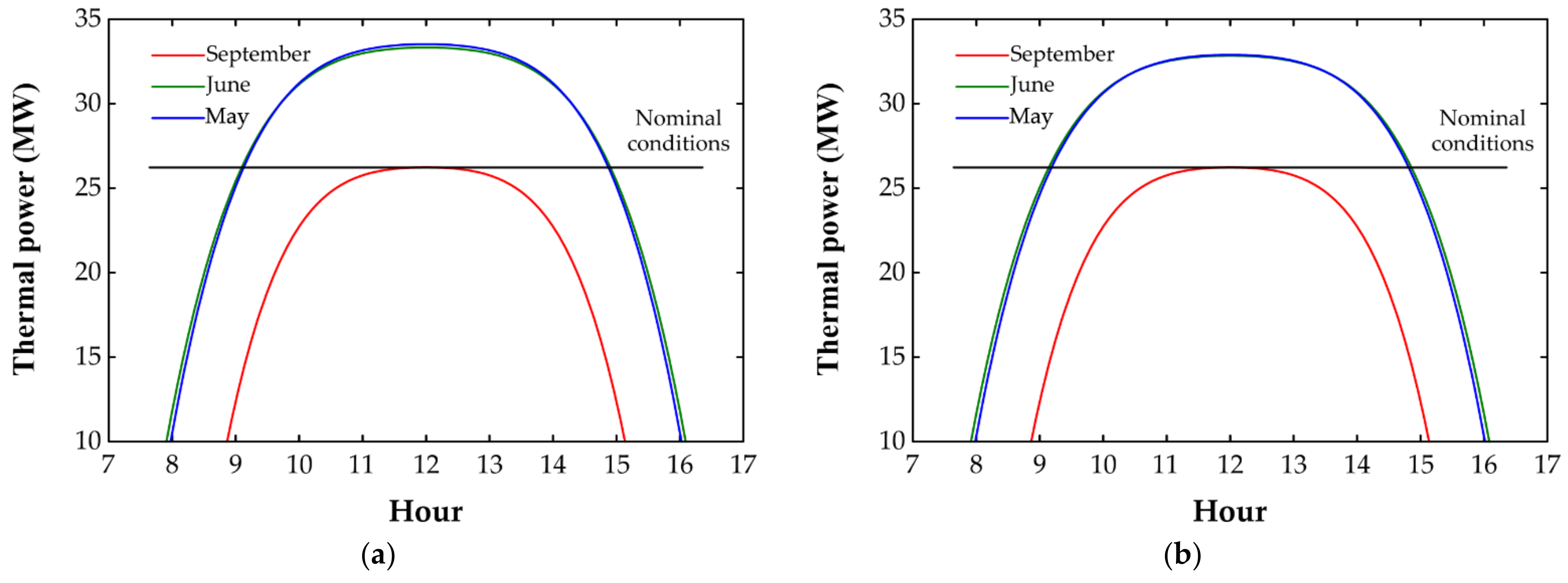

5.1. Three Loops Solar Fields

5.2. Four Loops Solar Fields

5.3. Dimensions of the Solar Field Loops

5.4. Solar Field for a Two-Steam Extraction Regenerative Rankine Cycle Power Block

5.5. Solar Field for a Three-Steam Extraction Regenerative Rankine Cycle Power Block

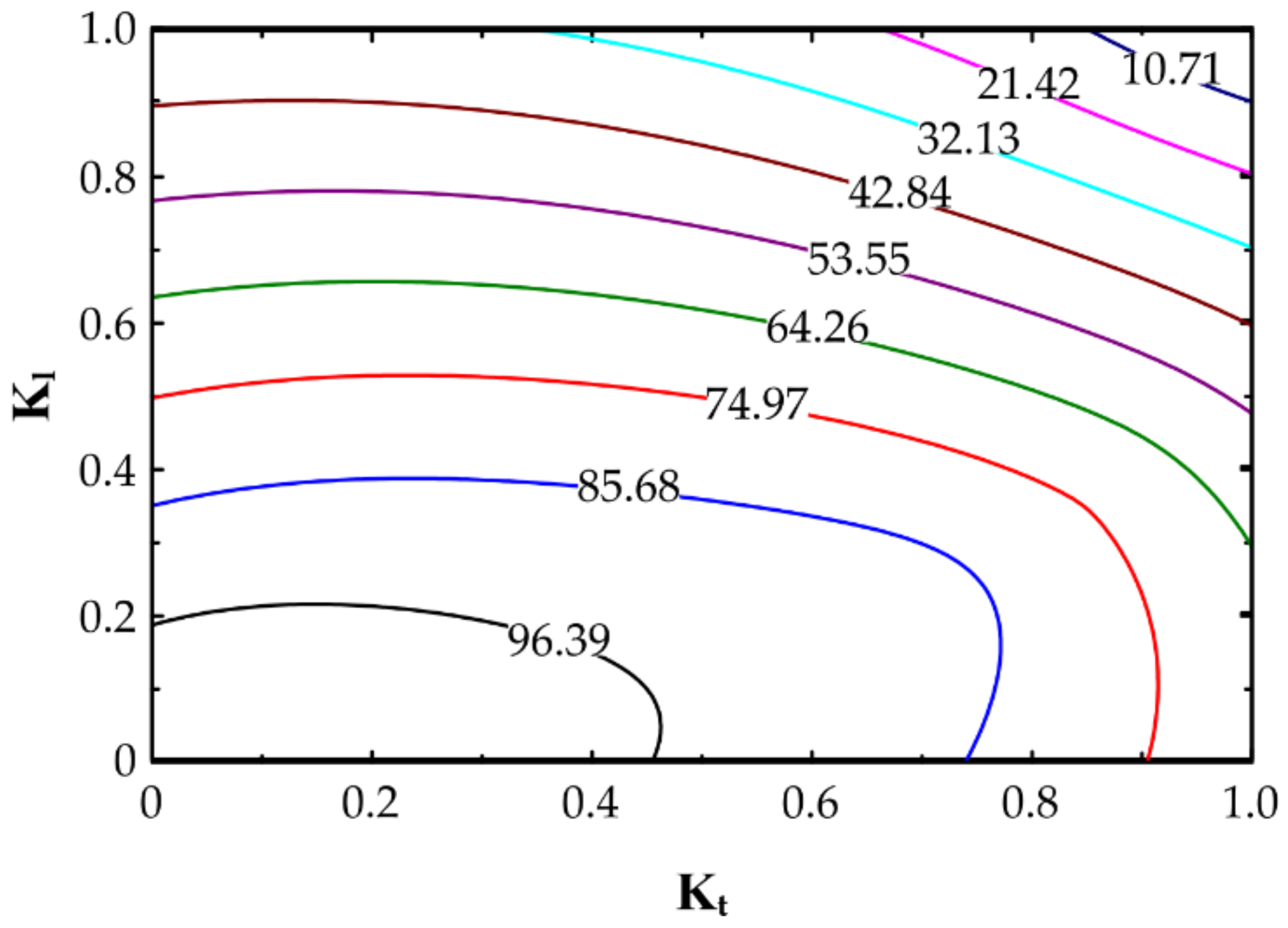

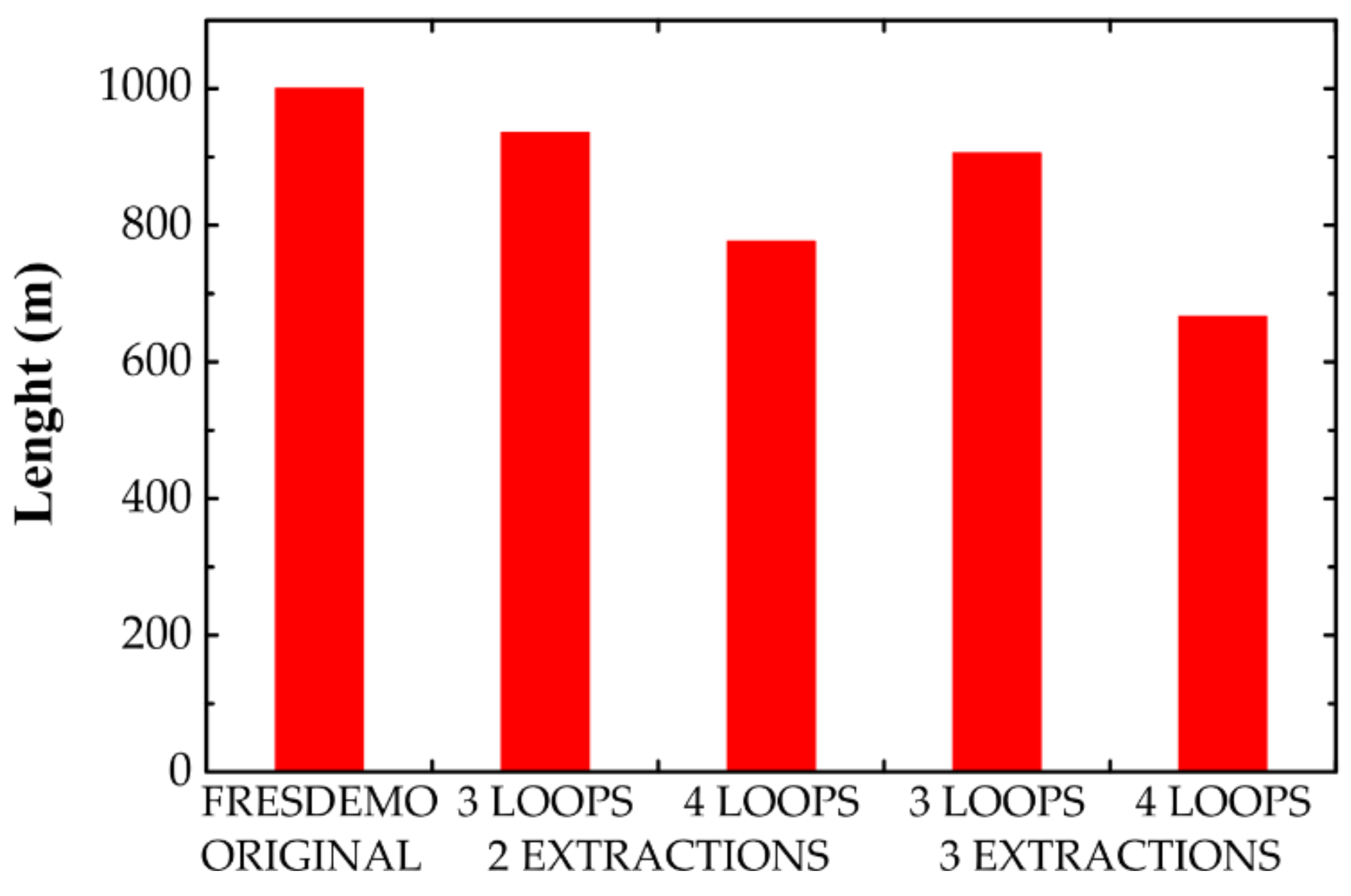

5.6. Solar Field Layout and Length

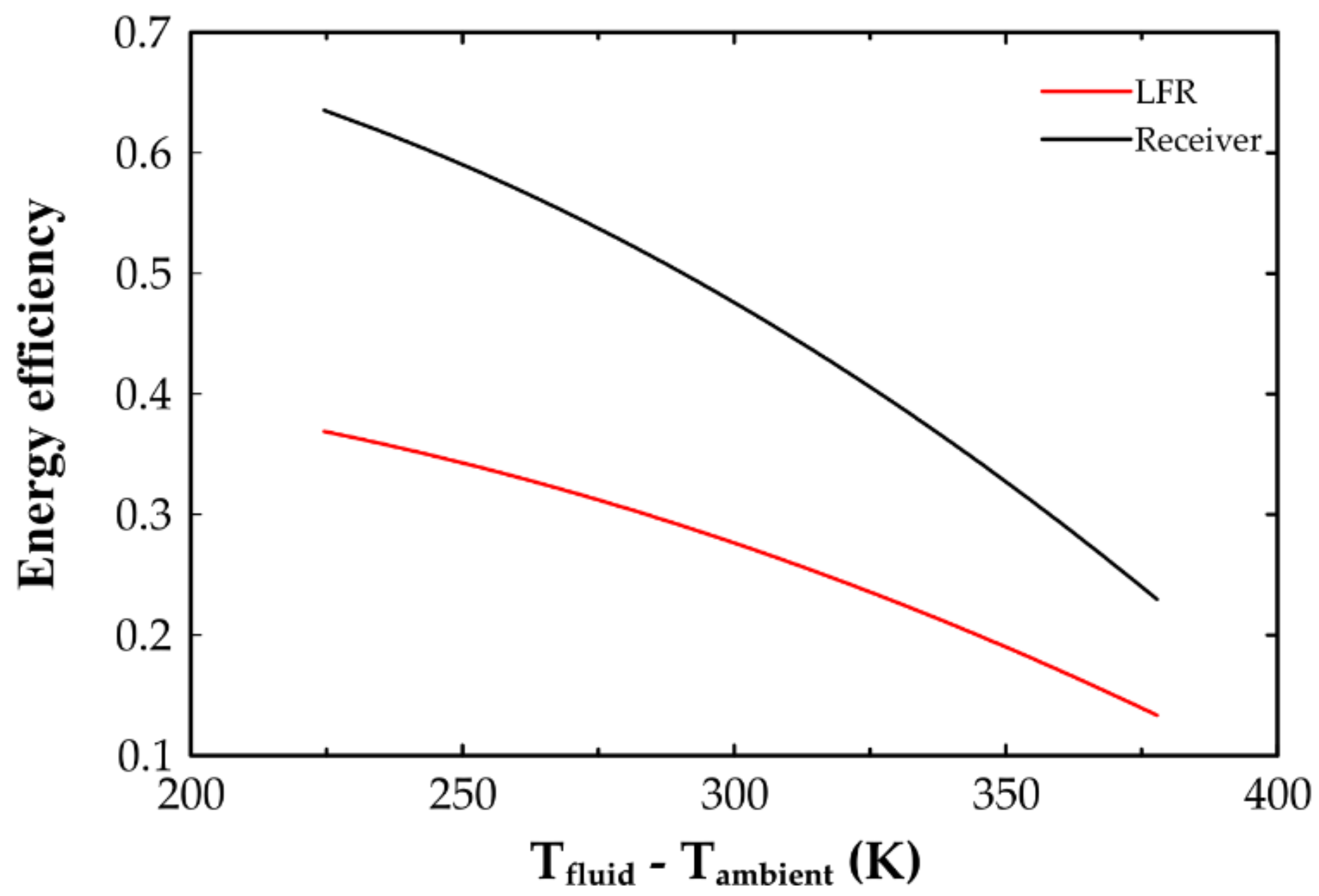

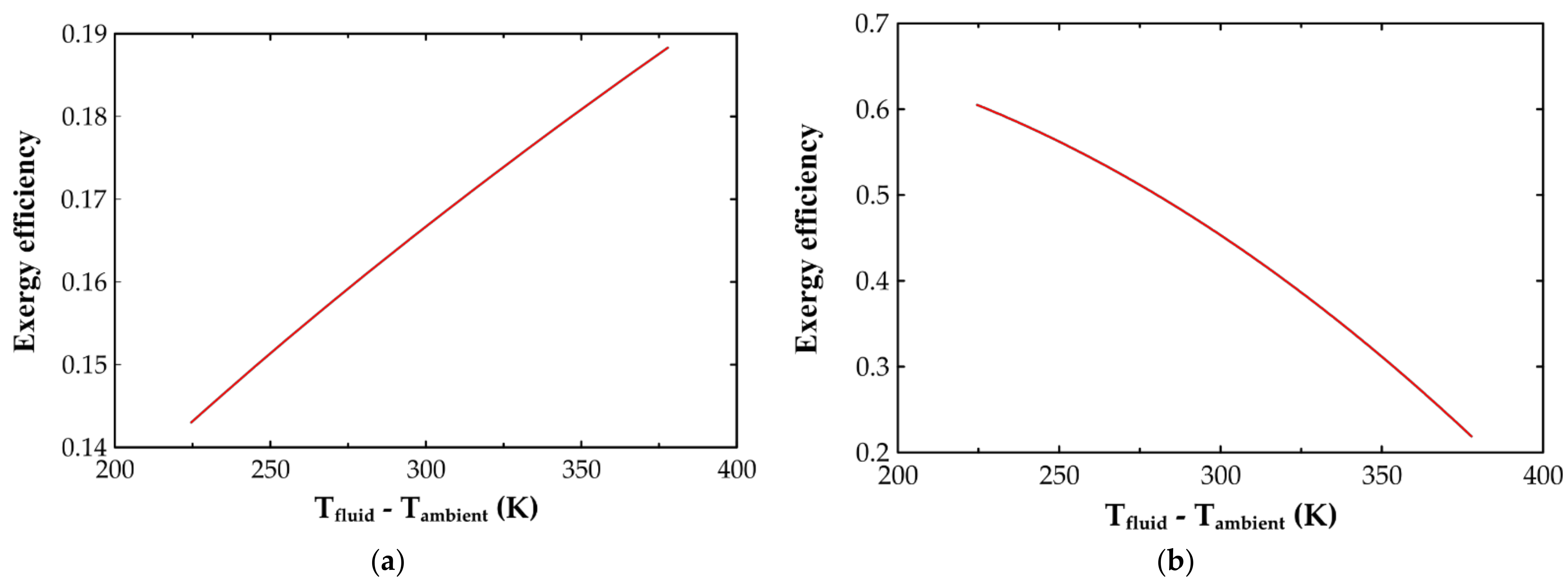

5.7. Energy and Exergy Efficiency

5.8. Comparison of the Optimized Field and FRESDEMO

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

References

- BP. Statistical Review of World Energy. 2018. Available online: https://www.bp.com/en/global/corporate/energy-economics/statistical-review-of-world-energy.html (accessed on 15 February 2019).

- Bernhard, R.; Laabs, H.-J.; de LaLaing, J.; Eickhoff, M. Linear Fresnel Collector Demonstration on the PSA, Part I—Design, Construction and Quality Control. In Proceedings of the International Symposium on Concentrated Solar Power and Chemical Energy Technologies, Casablanca, Morroco, 2–5 October 2008; Available online: https://www.researchgate.net/publication/225000351_Linear_Fresnel_Collector_Demonstration_on_the_PSA_Part_I_-_Design_Construction_and_Quality_Control (accessed on 10 July 2021).

- González-Mora, E.; Durán García, M.D. Methodology for an Opto-Geometric Optimization of a Linear Fresnel Reflector for Direct Steam Generation. Energies 2020, 13, 355. [Google Scholar] [CrossRef] [Green Version]

- Montes Pita, M.J. Análisis Y Propuestas De Sistemas Solares De Alta Exergía Que Emplean Agua Como Fluido Calorífero. Ph.D. Thesis, Universidad Politécnica de Madrid, Madrid, Spain, 2008. [Google Scholar]

- Almanza, R.; Lentz, A. Electricity production at low powers by direct steam generation with parabolic troughs. Sol. Energy 1998, 64, 115–120. [Google Scholar] [CrossRef]

- Almanza, R.; Lentz, A.; Jiménez, G. Receiver behavior in direct steam generation with parabolic troughs. Sol. Energy 1997, 61, 275–278. [Google Scholar] [CrossRef]

- Cui, W.; Li, H.; Li, L.; Liao, Q. Thermal stress analysis of DSG solar absorber tube in stratified two-phase regime. AIP Conf. Proc. 2013, 1558, 2217–2220. [Google Scholar]

- Eck, M.; Zarza, E.; Eickhoff, M.; Rheinländer, J.; Valenzuela, L. Applied research concerning the direct steam generation in parabolic troughs. Sol. Energy 2003, 74, 341–351. [Google Scholar] [CrossRef]

- Zarza Moya, E. Generación Directa de Vapor con Colectores Solares Cilindro Parabólicos. Proyecto DIrect Solar Steam (DISS). Ph.D. Thesis, Universidad de Sevilla, Sevilla, Spain, 2003. [Google Scholar]

- IEA. Technology Roadmap-Solar Thermal Electricity; IEA: Paris, France, 2014.

- NREL. Concentrating Solar Power Projects. Available online: https://solarpaces.nrel.gov/ (accessed on 20 March 2020).

- IRENA. Solar Energy. Available online: https://www.irena.org/solar (accessed on 27 February 2021).

- Elsafi, A.M. Exergy and exergoeconomic analysis of sustainable direct steam generation solar power plants. Energy Convers. Manag. 2015, 103, 338–347. [Google Scholar] [CrossRef]

- Schenk, H.; Hirsch, T.; Fabian Feldhoff, J.; Wittmann, M. Energetic comparison of linear Fresnel and parabolic trough collector systems. J. Sol. Energy Eng. 2014, 136, 041015. [Google Scholar] [CrossRef]

- Montes, M.J.; Barbero, R.; Abbas, R.; Rovira, A. Performance model and thermal comparison of different alternatives for the Fresnel single-tube receiver. Appl. Therm. Eng. 2016, 104, 162–175. [Google Scholar] [CrossRef]

- Hakkarainen, E.; Tähtinen, M.; Mikkonen, H. Dynamic model development of linear Fresnel solar field. In Proceedings of the ASME 2015 Power and Energy Conference, New York, NY, USA, 2–28 July 2015. [Google Scholar]

- Giostri, A.; Binotti, M.; Silva, P.; Macchi, E.; Manzolini, G. Comparison of two linear collectors in solar thermal plants: Parabolic trough versus Fresnel. J. Sol. Energy Eng. 2013, 135, 011001. [Google Scholar] [CrossRef]

- Hirsch, T.; Khenissi, A. A systematic comparison on power block efficiencies for CSP plants with direct steam generation. Energy Procedia 2013, 49, 1165–1176. [Google Scholar] [CrossRef] [Green Version]

- Sun, J.; Liu, Q.; Hong, H. Numerical study of parabolic-trough direct steam generation loop in recirculation mode: Characteristics, performance and general operation strategy. Energy Convers. Manag. 2015, 96, 287–302. [Google Scholar] [CrossRef]

- Hakkarainen, E.; Kannari, L. Dynamic Modelling of Concentrated Solar Field for Thermal Energy Storage Integration. In Proceedings of the 9th International Renewable Energy Storage Conference (IRES 2015), Düsseldorf, Germany, 9–11 March 2015. [Google Scholar]

- Adiutori, E. The New Engineering, 3rd ed.; Ventuno Press: Naples, FL, USA, 2017; ISBN 978-0-9626220-4-5. [Google Scholar]

- Bejan, A. Entropy Generation Minimization: The Method of Thermodynamic Optimization of Finite-Size Systems and Finite-Time Processes; Mechanical and Aerospace Engineering Series; Taylor & Francis: Boca Raton, FL, USA, 1995; ISBN 978-0-84939-651-9. [Google Scholar]

- Ying, Y.; Hu, E.J. Thermodynamic advantages of using solar energy in the regenerative Rankine power plant. Appl. Therm. Eng. 1999, 19, 1173–1180. [Google Scholar] [CrossRef]

- Moran, M.J.; Shapiro, H.N.; Boettner, D.D.; Bailey, M.B. Fundamentals of Engineering Thermodynamics, 8th ed.; Wiley: Hobooken, NJ, USA, 2014; ISBN 978-1-118-41293-0. [Google Scholar]

- Balmer, R.T. Modern Engineering Thermodynamics, 1st ed.; Academic Press: Cambridge, MA, USA, 2011; ISBN 008-096-1738. [Google Scholar]

- Siemens. Efficiency Turns Less into More; Siemens: Munich, Germany, 2017. [Google Scholar]

- Coco-Enríquez, L.; Muñoz-Antón, J.; Martínez-Val, J.M. Innovations on direct steam generation in linear Fresnel collectors. In Proceedings of the SolarPACES2013, Las Vegas, NV, USA, 17–20 September 2013; p. 45721. [Google Scholar]

- Bejan, A. Advanced Engineering Thermodynamics, 1st ed.; Wiley: Hoboken, NJ, USA, 2016; ISBN 978-0-47090-037-6. [Google Scholar]

- Bartlett, R.L. Steam Turbine Performance and Economics, 1st ed.; McGraw-Hill: New York, NY, USA, 1958. [Google Scholar]

- Tabatabaian, M.; Post, S.; Rajput, R.K. Advanced Thermodynamics; Mercury Learning Series; Mercury Learning & Information: Herndon, VA, USA, 2017; ISBN 978-1-93642-027-8. [Google Scholar]

- Boito, P.; Grena, R. Optimization of the geometry of Fresnel linear collectors. Sol. Energy 2016, 135, 479–486. [Google Scholar] [CrossRef]

- Veynandt, F. Cogénération Héliothermodynamique avec Concentrateur Linéaire de Fresnel: Modélisation de L’ensemble du Procédé. Ph.D. Thesis, Université de Toulouse, Toulouse, France, 2011. [Google Scholar]

- González-Mora, E.; Durán García, M.D. Energy and Exergy (2E) Analysis of an Optimized Linear Fresnel Reflector for a Conceptual Direct Steam Generation Power Plant. In Proceedings of the ISES Solar World Congress 2019, Santiago, Chile, 4–7 November 2019; International Solar Energy Society: Freiburg, Germany, 2019; pp. 907–918. [Google Scholar]

- Özışık, M.N. Radiative Transfer and Interactions with Conduction and Convection, 1st ed.; Wiley: Hoboken, NJ, USA, 1973; ISBN 978-0-47165-722-4. [Google Scholar]

- Howell, J.R.; Menguc, M.P.; Siegel, R. Thermal Radiation Heat Transfer, 6th ed.; CRC Press: Boca Raton, FL, USA, 2015; Volume 92, ISBN 978-1-49875-774-4. [Google Scholar]

- Rabl, A. Active Solar Collectors and Their Applications; Oxford University Press: Oxford, UK, 1985; ISBN 978-0-19536-521-4. [Google Scholar]

- Raithby, G.D.; Hollands, K.G.T. A General Method of Obtaining Approximate Solutions to Laminar and Turbulent Free Convection Problems. Adv. Heat Transf. 1975, 11, 265–315. [Google Scholar]

- Churchill, S.W.; Chu, H.H.S. Correlating equations for laminar and turbulent free convection from a horizontal cylinder. Int. J. Heat Mass Transf. 1975, 18, 1049–1053. [Google Scholar] [CrossRef]

- Churchill, S.W.; Bernstein, M. A Correlating Equation for Forced Convection From Gases and Liquids to a Circular Cylinder in Crossflow. J. Heat Transf. 1977, 99, 300–306. [Google Scholar] [CrossRef]

- Žukauskas, A. Heat Transfer from Tubes in Crossflow. Adv. Heat Transf. 1972, 8, 93–160. [Google Scholar]

- Pohlhausen, E. Der Wärmeaustausch zwischen festen Körpern und Flüssigkeiten mit kleiner reibung und kleiner Wärmeleitung. ZAMM J. Appl. Math. Mech. Z. Angew. Math. Mech. 1921, 1, 115–121. [Google Scholar] [CrossRef] [Green Version]

- Bergman, T.L.; Lavine, A.S.; Incropera, F.P.; Dewitt, D.P. Fundamentals of Heat and Mass Transfer, 7th ed.; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2011; ISBN 978-0-47050-197-9. [Google Scholar]

- Gungor, K.E.; Winterton, R.H.S. A general correlation for flow boiling in tubes and annuli. Int. J. Heat Mass Transf. 1986, 29, 351–358. [Google Scholar] [CrossRef]

- Forristall, R. Heat Transfer Analysis and Modeling of a Parabolic Trough Solar Receiver Implemented in Engineering Equation Solver; National Renewable Energy Lab.: Golden, CO, USA, 2003. [Google Scholar]

- Adiutori, E.F. A Critical Examination of Correlation Methodology Widely Used in Heat Transfer and Fluid Flow. In Proceedings of the ASME 2004 Heat Transfer/Fluids Engineering Summer Conference ASMEDC, Charlotte, NC, USA, 11–15 July 2004; Volume 1, pp. 929–934. [Google Scholar]

- Adiutori, E.F. Why Conventional Engineering Science should be Abandoned, and the New Engineering Science that should Replace It. Am. J. Mech. Eng. 2020, 9, 1–6. [Google Scholar] [CrossRef]

- Mertins, M. Technische und Wirtschaftliche Analyse von Horizontalen Fresnel-Kollektoren. Ph.D. Thesis, Universität Karlsruhe, Baden-Württemberg, Gremany, 2009. [Google Scholar]

- Meteotest Meteonorm; Version 7.2; METEOTEST: Bern, Switzerland, 2018.

- Wang, Z. Design of Solar Thermal Power Plants; Elsevier Science: Amsterdam, The Netherlands, 2019; ISBN 978-0-12815-613-1. [Google Scholar]

- Lovegrove, K.; Stein, W. Chapter 1-Introduction to concentrating solar power technology. In Concentrating Solar Power Technology; Lovegrove, K., Stein, W.B.T.-C.S.P.T., Eds.; Woodhead Publishing Series in Energy; Woodhead Publishing: Cambridge, UK, 2021; pp. 3–17. ISBN 978-0-12-819970-1. [Google Scholar]

- Parrott, J.E. Theoretical upper limit to the conversion efficiency of solar energy. Sol. Energy 1978, 21, 227–229. [Google Scholar]

- Bejan, A. Entropy Generation through Heat and Fluid Flow; Wiley: Hoboken, NJ, USA, 1982; Volume 1, ISBN 0-471-09438-2. [Google Scholar]

- Paoletti, S.; Rispoli, F.; Sciubba, E. Calculation of exergetic losses in compact heat exchanger passages. In Proceedings of the ASME AES, San Francisco, CA, USA, 10–15 December 1989; Volume 10, pp. 21–29. [Google Scholar]

- Blanco, M.J.; Miller, S. 1-Introduction to concentrating solar thermal (CST) technologies. In Advances in Concentrating Solar Thermal Research and Technology; Elsevier: Amsterdam, The Netherlands, 2017; pp. 3–25. [Google Scholar]

| Name | Technology | Capacity (MW) | Storage/Back Up | Status |

|---|---|---|---|---|

| Greenway CSP Mersin (Turkey) | Power tower | 1 | Molten salt tank | Non-operational |

| Puerto Errado 1 (Spain) | LFR | 1.4 | Single thermocline tank | Operational |

| Sundrop (Australia) | Power tower | 1.5 | No storage | Operational |

| Lake Cargelligo (Australia) | Power tower | 3 | Graphite thermal storage | Non-operational |

| Liddell Power Station (Australia) | LFR | 3 | No storage | Non-operational |

| Thai solar one (Thailand) | PTC | 5 | No storage | Operational |

| Kimberlina (USA) | LFR | 5 | No storage | Non-operational |

| Sierra SunTower (USA) | Power tower | 5 | No storage | Non-operational |

| eLLO (France) | LFR | 9 | Steam drum | Operational |

| PS10 (Spain) | Power tower | 11 | Heat storage | Operational |

| Dadri ISCC Plant (India) | LFR | 14 | Not specified | Under construction |

| PS20 (Spain) | Power tower | 20 | Heat storage | Operational |

| Puerto Errado (Spain) | LFR | 30 | Single thermocline tank | Operational |

| Khi Solar One (Spain) | Power Tower | 50 | Steam drum | Operational |

| Shangyi Tower (China) | Power Tower | 50 | 2 molten salt tanks | Under development |

| Zhangbei (China) | LFR | 50 | Solid-state formulated concrete | Non-operational |

| Zhangjiakou (China) | LFR | 50 | Solid-state formulated concrete | Under development |

| Huanghe Qinghai Delingha (China) | Power Tower | 135 | 2 molten salt tanks | Non-operational |

| Ivanpah (USA) | Power Tower | 392 | No storage | Operational |

| State | Ti(K) | Pi(bar) | hi(kJ/kg) | si(kJ/kg K) | bi(kJ/kg) | xi |

|---|---|---|---|---|---|---|

| 1 | 673.2 | 100 | 3097.4580 | 6.2141 | 1249.2832 | superheatedsteam |

| 2 | 474.5 | 16 | 2775.6092 | 6.3837 | 876.8784 | 0.9911 |

| 3 | 443.6 | 8 | 2672.1738 | 6.4449 | 755.1900 | 0.9530 |

| 4 | 314.7 | 0.08 | 2153.1660 | 6.8829 | 105.5952 | 0.8239 |

| 5 | 314.7 | 0.08 | 173.8396 | 0.5925 | 1.7490 | 0 |

| 6 | 314.7 | 8 | 174.9044 | 0.5933 | 2.5616 | liquid |

| 7 | 404.6 | 8 | 552.4712 | 1.6497 | 65.1769 | 0 |

| 8 | 406.3 | 100 | 566.3182 | 1.6582 | 76.4810 | liquid |

| 9 | 496.1 | 100 | 959.3855 | 2.5312 | 209.2742 | liquid |

| 10 | 474.5 | 16 | 858.4440 | 2.3435 | 164.3041 | 0 |

| 11 | 443.6 | 8 | 858.4440 | 2.3858 | 160.6143 | 0.0672 |

| State | Ti(K) | Pi(bar) | hi(kJ/kg) | si(kJ/kg K) | bi(kJ/kg) | xi |

|---|---|---|---|---|---|---|

| 1 | 673.2 | 100 | 3097.4580 | 6.2141 | 1249.2832 | superheated steam |

| 2 | 489.1 | 20 | 2809.6092 | 6.3622 | 917.2702 | superheated steam |

| 3 | 416.8 | 4 | 2576.3714 | 6.5075 | 640.7096 | 0.9242 |

| 4 | 393.4 | 2 | 2486.6878 | 6.5688 | 532.7680 | 0.9003 |

| 5 | 314.7 | 0.08 | 2147.8559 | 6.8660 | 105.3166 | 0.8217 |

| 6 | 314.7 | 0.08 | 173.8396 | 0.5925 | 1.7490 | 0 |

| 7 | 314.7 | 2 | 174.0977 | 0.5927 | 1.9460 | liquid |

| 8 | 382.1 | 2 | 456.7724 | 1.4067 | 41.9233 | 0 |

| 9 | 383.6 | 100 | 470.5577 | 1.4157 | 53.0272 | liquid |

| 10 | 451 | 100 | 758.2368 | 2.1063 | 134.8163 | liquid |

| 11 | 518.4 | 100 | 1062.9448 | 2.7353 | 251.9609 | liquid |

| 12 | 485.5 | 20 | 908.4743 | 2.4467 | 183.5490 | 0 |

| 13 | 416.8 | 4 | 908.4743 | 2.5055 | 166.0308 | 0.1424 |

| 14 | 416.8 | 4 | 604.6573 | 1.7765 | 79.5653 | 0 |

| 15 | 393.4 | 2 | 604.6573 | 1.7843 | 77.2359 | 0.0454 |

| Parameter | Value |

|---|---|

| Number of primary mirrors | 25 |

| Solar field width (m) | 21 |

| Total length of the primary mirrors (m) | 100 |

| Width of the primary mirrors (m) | 0.6 |

| Filling factor | 0.7143 |

| Receiver height (m) | 15 |

| Receiver width (m) | 0.5 |

| Absorber tube outer diameter (m) | 0.14 |

| Absorber tube inner diameter (m) | 0.125 |

| Semi-angle acceptance of the CPC (°) | 66.30 |

| Intercept factor | 0.7231 |

| Geometric concentration of the CPC | 1.1368 |

| Geometric concentration of the entire field | 34.105 |

| Number of supports per module | 17 |

| Heat Flux (W/m) | Heat Transfer Mode | Heat Transfer Path | |

|---|---|---|---|

| from | to | ||

| Convection | Inner absorber tube | Heat transfer fluid | |

| Conduction | Outer absorber tube | Inner absorber tube | |

| Conduction | Outer absorber tube | HCE supports | |

| Absorption of solar radiation | Incident solar radiation | Outer absorber tube | |

| Radiation | Outer absorber tube | Cavity | |

| Convection | Outer absorber tube | Cavity | |

| Radiation | CPC surface | Cavity | |

| Convection | CPC surface | Cavity | |

| Absorption of solar radiation | Incident solar radiation | CPC surface | |

| Conduction | CPC surface | Insulation | |

| Radiation | Insulation | Environment | |

| Convection | Insulation | Environment | |

| Radiation | Inner Pyrex surface | Cavity | |

| Convection | Inner Pyrex surface | Cavity | |

| Conduction | Inner Pyrex surface | Outer Pyrex surface | |

| Absorption of solar radiation | Incident solar radiation | Outer Pyrex surface | |

| Radiation | Outer Pyrex surface | Environment | |

| Convection | Outer Pyrex surface | Environment | |

| Parameter | 21 June | 21 May | 21 September |

|---|---|---|---|

| Condition | Design day | Greatest insolation | Lowest insolation |

| Day of the year | 172 | 141 | 264 |

| Atmospheric pressure(bar) | 0.886 | 0.884 | 0.885 |

| Ambient temperature (K) | 300.05 | 295.95 | 296.95 |

| Effective sky temperature (K) | 271.95 | 265.75 | 277.75 |

| DNI (W/m2) | 856.4815 | 889.6396 | 628.8580 |

| Wind speed (m/d) | 4 | 4.1 | 3.2 |

| Section | Two Steam Extractions | Three Steam Extractions | ||||

|---|---|---|---|---|---|---|

| June | May | September | June | May | September | |

| Pre-heating (m) | 88.6 | 86.6 | 161.4 | 91.5 | 89.4 | 156.1 |

| Evaporation (m) | 423.9 | 408.1 | 479.8 | 456.6 | 425.7 | 533.4 |

| Superheating (m) | 111 | 105.6 | 264.7 | 119.5 | 111 | 245.9 |

| Length per loop (m) | 623.5 | 600.2 | 905.9 | 667.6 | 626.1 | 935.5 |

| Total length 1 (km) | 1.87 | 1.8 | 2.7 | 2 | 1.9 | 2.8 |

| Section | Two Steam Extractions | Three Steam Extractions | ||||

|---|---|---|---|---|---|---|

| June | May | September | June | May | September | |

| Pre-heating (m) | 68.4 | 66.8 | 119.3 | 70.5 | 68.9 | 123.3 |

| Evaporation (m) | 274.8 | 239.6 | 476 | 247 | 233.8 | 353.1 |

| Superheating (m) | 93.8 | 81.8 | 181.1 | 83.9 | 81.2 | 190.3 |

| Length per loop (m) | 437 | 1.6 | 776.5 | 401.4 | 383.9 | 667.7 |

| Total length 1 (km) | 1.7 | 1.6 | 3.1 | 1.6 | 1.5 | 2.7 |

| Case | Two Steam Extractions | Three Steam Extractions | ||||

|---|---|---|---|---|---|---|

| June | May | September | June | May | September | |

| Three loops | 1.262 | 1.272 | 1 | 1.235 | 1.251 | 1 |

| Four loops | 1.269 | 1.277 | 1 | 1.251 | 1.253 | 1 |

| Parameter | FRESDEMO | Optimized Field |

|---|---|---|

| Energy efficiency | 67% | 64% |

| Exergy efficiency | 63% | 60% |

| Bejan number | 0.9901 1 | 0.9975 |

| Maximum length (m) | 1000 | 935 |

| Maximum SM | − | 1.27 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

González-Mora, E.; Durán-García, M.D. Energy and Exergy (2E) Analysis of an Optimized Solar Field of Linear Fresnel Reflectors for a Conceptual Direct Steam Generation Power Plant. Energies 2021, 14, 4234. https://doi.org/10.3390/en14144234

González-Mora E, Durán-García MD. Energy and Exergy (2E) Analysis of an Optimized Solar Field of Linear Fresnel Reflectors for a Conceptual Direct Steam Generation Power Plant. Energies. 2021; 14(14):4234. https://doi.org/10.3390/en14144234

Chicago/Turabian StyleGonzález-Mora, Eduardo, and Ma. Dolores Durán-García. 2021. "Energy and Exergy (2E) Analysis of an Optimized Solar Field of Linear Fresnel Reflectors for a Conceptual Direct Steam Generation Power Plant" Energies 14, no. 14: 4234. https://doi.org/10.3390/en14144234

APA StyleGonzález-Mora, E., & Durán-García, M. D. (2021). Energy and Exergy (2E) Analysis of an Optimized Solar Field of Linear Fresnel Reflectors for a Conceptual Direct Steam Generation Power Plant. Energies, 14(14), 4234. https://doi.org/10.3390/en14144234